#Compact Concrete batching plants

Explore tagged Tumblr posts

Text

Everything You Need to Know About Concrete Batching Plants

Introduction Concrete batching plants are integral to the construction industry, providing the essential solution for producing high-quality concrete efficiently and consistently. Whether you’re building skyscrapers, roads, or bridges, a concrete batching plant ensures that every batch meets your project’s specifications. In this blog, we’ll explore what concrete batching plant are, how they work, factors affecting their price, and the importance of choosing a reliable manufacturer.

What Is a Concrete Batching Plant?

A concrete batching plant is a facility where raw materials like cement, aggregates, water, and additives are mixed to produce concrete. The process is precise, automated, and customizable, ensuring uniform quality for different types of construction projects.

Key Components of a Concrete Batching Plant:

Mixing Unit: Combines raw materials to produce concrete.

Aggregate Storage and Conveying: Stores and transports aggregates (sand, gravel, etc.).

Cement Silo: Holds and dispenses cement.

Control System: Ensures accurate batching and mixing through automation.

Water Tank and Dispensers: Adds water to the mix in precise quantities.

How Do Concrete Batching Plants Work?

The process begins with weighing and feeding the raw materials into the mixer. The control system ensures each ingredient is added in the correct ratio to produce concrete with consistent strength and quality. The mixed concrete is then discharged for transportation to the construction site, either in transit mixers or directly as required.

Types of Concrete Batching Plants

Stationary Concrete Batching Plants:

Designed for long-term use at a fixed location.

Ideal for large infrastructure projects.

Mobile Concrete Batching Plants:

Portable and easy to set up.

Suitable for small to medium-scale projects that require flexibility.

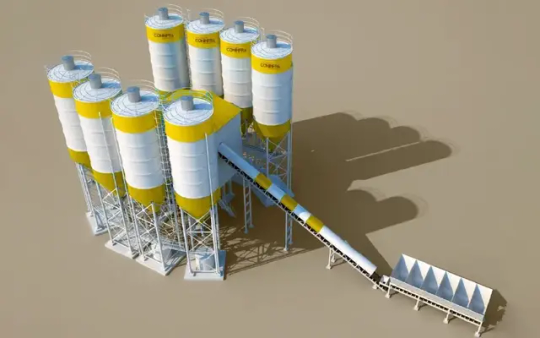

Compact Concrete Batching Plants:

A space-saving option that combines portability with high performance.

Ready-Mix Concrete Batching Plants:

Tailored for producing ready-mix concrete for urban and commercial construction.

Factors Affecting Concrete Batching Plant Price

The price of a concrete batching plant varies depending on several factors:

Capacity: Plants with higher production capacities cost more.

Type: Stationary plants are generally more expensive than mobile or compact plants.

Automation Level: Advanced control systems and automation increase the price.

Brand: Reputed manufacturers may charge a premium for quality and after-sales support.

Customization: Additional features or modifications impact the overall cost.

When considering the price, it’s important to evaluate the plant’s long-term value, durability, and efficiency.

Choosing the Right Concrete Batching Plant Manufacturer

Partnering with a reputable concrete batching plant manufacturer is crucial for a successful investment. Look for manufacturers that offer:

High-Quality Components: Ensure the plant is built with durable and reliable materials.

Customization Options: The ability to adapt the plant to your specific needs is vital.

After-Sales Support: Timely maintenance, spare parts, and technical support enhance operational efficiency.

Competitive Pricing: Balance cost with quality to get the best value for your money.

Companies like Nilkanth Engineering Works are industry leaders, offering innovative batching plant solutions tailored to diverse requirements. Whether you’re looking for budget-friendly options or premium models, working with a trusted manufacturer ensures peace of mind.

Why Invest in a Concrete Batching Plant?

Improved Construction Quality: Produces consistent concrete with precise mixes.

Cost-Efficiency: Reduces reliance on third-party suppliers and cuts transportation costs.

Time-Saving: Ensures on-demand availability of concrete, speeding up construction timelines.

Flexibility: Tailored mixes for specific project requirements.

Conclusion A concrete batching plant is a cornerstone of any construction project, offering unmatched efficiency, quality, and convenience. Understanding the types of plants, factors influencing their price, and the importance of a reliable manufacturer helps you make an informed decision. Whether you’re exploring options for high-capacity plants or portable solutions, the right batching plant enhances productivity and profitability.

If you’re considering investing in a batching plant, check out industry leaders like Nilkanth Engineering Works for cutting-edge solutions. Their expertise and commitment to quality make them a trusted choice for projects worldwide.

#cement silo#compact concrete batching plant#compact concrete batching plants#concrete batching plant#Concrete Batching Plant Manufacturer#concrete batching plant Price#concrete batching plants#mobile concrete batching plants#stationary Concrete batching plants

0 notes

Text

#concrete batching plant#mobile concrete batching plants#compact concrete batching plants#automatic concrete plants#automatic concrete batching plants

0 notes

Text

Reversible Compact Concrete Batching Plant in India | Nilkanth Machine Tools

One such innovation that has gained popularity across infrastructure projects, real estate developments, and public works is the Reversible Compact Concrete Batching Plant. These technologically advanced batching systems are designed to provide efficient, accurate, and fast concrete mixing without occupying much space—making them an ideal choice for urban and rural construction sites alike.

At Nilkanth Machine Tools, we are proud to be one of the leading manufacturers and suppliers of Reversible Compact Concrete Batching Plants in India. With a strong commitment to quality, innovation, and customer satisfaction, our machines have been engineered to meet the dynamic needs of the construction sector.

Understanding Reversible Compact Concrete Batching Plants

The Reversible Compact Concrete Batching Plant is a revolutionary piece of construction machinery. Unlike conventional batching plants, these models combine the advantages of compact design with the efficiency of reversible mixing technology.

The core mechanism involves a reversible drum mixer, which rotates in both clockwise and counterclockwise directions. This unique feature allows the mixing and discharging of concrete within the same unit, minimizing mechanical wear and ensuring better homogenization of concrete ingredients. These plants are especially beneficial in small to medium-scale construction projects where space, mobility, and budget are key considerations.

Features of Reversible Compact Concrete Batching Plant

Compact Design: One of the primary advantages of a Reversible Compact Concrete Batching Plant is its space-efficient layout. These plants require minimal installation area, making them highly suitable for projects with space constraints. Despite their compact design, they deliver high productivity and consistent concrete quality.

Reversible Drum Mixing Technology: The heart of the plant lies in its reversible drum mixer. This technology enables mixing and discharge within the same unit, thereby reducing operational time and maintenance. The reversible action ensures thorough mixing, resulting in high-grade concrete for various applications.

Easy Installation and Relocation: These batching plants are engineered for portability and ease of installation. They can be assembled or dismantled in a short period, making them a preferred choice for contractors who operate at multiple project locations.

Advanced Control Panel: Modern Reversible Compact Concrete Batching Plants are equipped with fully automatic control panels that ensure precision in batching and mixing operations. The control system allows operators to monitor and adjust operations with ease, ensuring efficiency and minimal wastage.

High-Quality Components: At Nilkanth Machine Tools, our machines are built using premium-grade materials and components sourced from trusted suppliers. From the mixer drum to load cells and control systems, every element is crafted for durability and performance.

Applications of Reversible Compact Concrete Batching Plants

The versatility of Reversible Compact Concrete Batching Plants makes them suitable for a wide range of applications, including:

Residential and Commercial Buildings: Ideal for projects requiring regular concrete supply with limited space availability.

Road Construction: Portable and efficient, these plants are perfect for infrastructure projects such as highways and bridges.

Rural Development Projects: Easy to transport and set up in remote areas with minimal infrastructure.

Precast Concrete Production: The uniform mixing capability ensures consistent quality of precast elements.

Advantages of Using a Reversible Compact Concrete Batching Plant

Efficient Concrete Production: The reversible mixing system provides uniform blending of cement, sand, aggregates, and water, resulting in high-quality concrete. The quick cycle times ensure that large volumes can be produced within shorter durations.

Reduced Operational Costs: With fewer mechanical parts and simplified design, these batching plants are low on maintenance. Their energy-efficient operation also contributes to lower operational expenses over time.

Mobility: Being compact and easy to transport, these batching plants can be relocated effortlessly, making them ideal for contractors involved in multiple projects.

Environmental Compliance: The enclosed mixing system and efficient control of raw material usage help minimize dust and noise, making the plant environmentally friendly.

Time-Saving: Automated control systems and the reversible drum ensure a seamless and fast operation, reducing project timelines and labor efforts.

Why Choose Nilkanth Machine Tools?

As a trusted name in the concrete machinery manufacturing industry, Nilkanth Machine Tools stands out for its innovation, reliability, and customer-centric approach. Here’s what makes us a top choice for Reversible Compact Concrete Batching Plants in India:

Proven Expertise: With years of experience in the industry, we understand the challenges of modern construction and provide solutions tailored to client requirements.

Custom Configurations: We offer various capacity options and configurations to suit different project scales.

Quality Assurance: Every plant is tested for performance, safety, and durability before dispatch.

After-Sales Support: Our service team ensures prompt assistance and spare part availability for uninterrupted operations.

Competitive Pricing: Get top-tier machinery at cost-effective rates, ensuring value for money.

Reversible Compact Concrete Batching Plant in India – A Growing Trend

India’s booming infrastructure sector demands construction equipment that is not only efficient but also adaptable to diverse project environments. The Reversible Compact Concrete Batching Plant in India has become a favored choice for developers and contractors aiming to improve productivity while managing space and cost constraints.

With initiatives like Smart Cities Mission, Affordable Housing, and National Highway Development, the demand for reliable and portable concrete batching solutions is on the rise. At Nilkanth Machine Tools, we are committed to empowering this growth with our innovative and robust machinery solutions.

Maintenance and Best Practices

To ensure optimal performance and longevity of your Reversible Compact Concrete Batching Plant, follow these best practices:

Regular Lubrication: Ensure that all moving parts, especially the mixer drum, are properly lubricated to prevent wear.

Periodic Inspection: Regular checks on electrical systems, sensors, and load cells help identify issues early.

Cleaning: Clean the drum and hopper after each batch to avoid material buildup and contamination.

Calibration: Calibrate the weighing system periodically for precise batching.

Training: Provide adequate training to operators to enhance efficiency and safety.

A Reversible Compact Concrete Batching Plant is more than just a machine—it’s a cornerstone for modern construction efficiency. Combining compactness, advanced technology, and high performance, these plants offer unmatched benefits for contractors and developers alike. Whether you’re working on a small residential project or a large-scale infrastructure venture, investing in a Reversible Compact Concrete Batching Plant from Nilkanth Machine Tools ensures quality, speed, and reliability.

Ready to Upgrade Your Construction Site?

Contact Nilkanth Machine Tools today and experience the future of concrete batching. Our experts are here to guide you through the best model for your needs and ensure smooth deployment at your site. Enhance your productivity and efficiency with the most trusted Reversible Compact Concrete Batching Plant in India.

📞 Call Us Now or 📩 Drop Your Inquiry Today!

Visit: https://nilmac.com/

Contact: 9724452725

Email id: [email protected]

Location: Near, 5503/1,GIDC, Cross Road, Trikampura Patiya, Vatva Vatva, Ahmedabad, Gujarat 382445

#Reversible Compact Concrete#Reversible Compact Concrete Batching Plant#Concrete Batching Plant#Reversible Compact Concrete Batching Plant in India

0 notes

Text

AASPA is the single-source supplier of turnkey concrete botching and mixing plant solutions. With decades of experience in the industry. We have numerous installations of various capacities to our credit. We are renowned for offering you everything that is needed to run the very heart of your business. In order to produce the highest quality concrete required as well as an on-site Compact Concrete Batching Plant for the construction of large civil projects such as roads, bridges, ports, dams, runaways, buildings, tunnels, etc., AASPA solutions are designed to confer maximum flexibility by giving your plant the ideal combination of engineered and proven components.

0 notes

Text

Mini Mobile Concrete Batching Plant

Printout &USB system. Automatic water control. Options of single, two, three & four Bins. Smart hopper design to reduce spillage & wastage. Compact design for easy transport and shifting by towing also.

#Mini batching plant#Mobile concrete plant#Compact concrete batching#Portable batching plant#Construction equipment#Small-scale construction

0 notes

Text

Ready-Mix Concrete Market Growth Driven By Urban Infrastructure Expansion

The Ready-Mix Concrete Market is experiencing accelerated growth, largely fueled by the rapid expansion of urban infrastructure across the globe. As metropolitan areas evolve to accommodate population booms and economic progress, demand for construction materials that deliver speed, strength, and scalability—like ready-mix concrete (RMC)—has intensified significantly.

Urbanization Sparks Strong Demand

With global urban populations growing at unprecedented rates, cities face pressure to enhance housing, mobility, and essential utilities. Ready-mix concrete, known for its quality consistency and efficiency, is increasingly favored in the construction of roads, metro systems, tunnels, bridges, and large residential and commercial projects.

In regions such as Southeast Asia, Sub-Saharan Africa, and parts of Latin America, new city zones and urban extensions are being built from the ground up. These megaprojects rely on high-volume, precise delivery—features that RMC suppliers are uniquely equipped to provide.

Public Infrastructure Projects Drive Consumption

Governments around the world are scaling up infrastructure budgets, seeing public works as economic catalysts. In India, the Smart Cities Mission has driven large-scale RMC usage in rapid transit, stormwater systems, and energy-efficient buildings. In the U.S., the Infrastructure Investment and Jobs Act is earmarking over $1 trillion for highways, ports, and broadband, all requiring concrete in massive quantities.

Emerging economies are likewise directing funds into roads, water systems, and urban housing. Ready-mix concrete, with its time-saving batch mixing process and regulated quality control, is vital in these cost-conscious yet high-speed initiatives.

Superior Efficiency and Quality Assurance

Urban construction projects face several challenges: limited space, tight timelines, and labor shortages. RMC addresses these pain points by offering:

Factory-controlled quality: Batching plants monitor mix ratios to deliver consistent results.

Reduced on-site labor: Fewer workers are needed for mixing, lowering costs and safety risks.

Faster completion: Concrete is delivered ready to pour, minimizing construction delays.

Additionally, batching plants are often strategically located near high-demand zones, reducing delivery times and ensuring uninterrupted project flow.

Technological Enhancements Aid Urban Construction

Urban developers are also leveraging new technologies in concrete mix design. Today’s RMC includes self-compacting, fiber-reinforced, and temperature-controlled variants. These innovations improve workability in constrained sites and enhance load-bearing capacity for large-scale structures.

Digital integration is another growth catalyst. Contractors use real-time delivery tracking, sensor-based slump measurement, and automated plant controls to ensure consistency. These features are particularly critical in urban environments where construction timelines are often non-negotiable.

Regulatory Pressures and Environmental Goals

As cities adopt sustainability frameworks, the construction sector is under increasing scrutiny for its environmental footprint. RMC producers are responding by adopting:

Low-carbon cement blends

Recycled water use

Waste management systems at batching plants

Urban building codes now often require LEED or BREEAM-certified construction. RMC plays a central role in meeting such criteria by offering pre-tested, specification-compliant mixes that reduce overall site emissions.

Urban Resilience and Climate Readiness

Climate-resilient infrastructure is a growing priority for urban planners. RMC is vital in constructing flood-resistant buildings, sea walls, and drainage systems. In coastal cities, special formulations of ready-mix concrete are being used for salinity resistance and long-term durability.

As extreme weather events increase, RMC’s flexibility in composition enables builders to tailor solutions that stand the test of time while still meeting fast-paced project schedules.

Future Outlook: Expansion with Strategy

The ready-mix concrete industry is responding to urban growth by investing in regional batching capacity, fleet upgrades, and process digitization. Leading players are forming partnerships with public agencies, real estate developers, and transit authorities to secure long-term supply contracts.

Markets like China, Indonesia, Brazil, and Egypt are forecast to experience double-digit RMC growth in the next five years as megacities emerge and peri-urban zones expand.

Conclusion

Urban infrastructure expansion is transforming the landscape of the Ready-Mix Concrete Market. With high-performance requirements, sustainable building standards, and rising urban density, RMC is emerging not just as a preferred material but as an urban construction essential. As infrastructure evolves, so will the role of RMC—cementing its position in building the cities of tomorrow.

#urbaninfrastructure#readymixconcrete#constructiontrends#cementindustry#smartcities#sustainablebuilding#civilengineering#concreteinnovation#infrastructuredevelopment#urbanplanning

0 notes

Text

What Makes a High-Quality Brick or Concrete Block

Walk past any construction site, and you’ll see bricks and blocks quietly doing their job—forming the backbone of homes, offices, and everything in between. But behind every sturdy wall is a story of precision, consistency, and a whole lot of quality control.

For brick and block manufacturers, ensuring product quality isn't just about meeting a checklist—it's about building trust, structure by structure. So how do they make sure that every single unit lives up to the mark? Let’s dig in.

Why Quality Is More Than Just a Buzzword

When a builder chooses bricks or blocks, they’re not just picking a material—they’re investing in safety, longevity, and peace of mind. Poor-quality bricks can lead to cracks, water damage, or even structural failure down the line. That’s a big deal.

So for manufacturers, quality isn't optional. It’s the foundation of everything they do—literally and figuratively.

It All Starts With the Right Ingredients

Choosing Raw Materials Wisely Just like a good dish starts with good ingredients, quality bricks and blocks begin with top-notch raw materials. For clay bricks, that means clean, plastic clay with the right mineral balance. For concrete blocks, it’s about using high-quality cement, sand, fly ash, and aggregates.

Testing, Testing, Testing

Before these materials even make it into production, manufacturers run several tests:

Moisture content checks (too much water = weak bricks)

Sieve analysis for aggregates (ensures the right size distribution)

Chemical composition of additives (especially fly ash and lime)

All of this helps eliminate surprises later in the process.

Precision in Every Step of Production

Mixing It Just Right

Getting the proportions right is absolutely crucial. Whether it's the cement-to-sand ratio in concrete or the clay-sand mix for traditional bricks, everything has to be consistent. Many manufacturers now rely on automatic batching systems that remove the guesswork entirely.

Molding: Where Form Meets Function After mixing, the material is shaped into bricks or blocks. This could happen through extrusion, hydraulic pressing, or mold casting. The pressure and technique used here impact the final strength and density of the product.

Automatic machines are the norm for most serious manufacturers—they guarantee uniform size, clean edges, and consistent compaction.

Curing: The Secret Ingredient This is where strength is developed. For clay bricks, it means high-temperature kiln firing—up to 1100°C. For concrete blocks, it's usually a 14–28 day curing process with controlled humidity and temperature.

Skipping or rushing this step? That’s a recipe for brittle products.

Quality Checks: Before, During, and After In-Process Monitoring Throughout production, technicians perform ongoing checks. This includes measuring moisture levels, checking machine calibration, and random sampling of the output.

If anything looks off—even slightly—the batch is rechecked or held back. No compromises.

Post-Production Testing Once the bricks or blocks are ready, several tests ensure they’re fit for the real world:

Compressive Strength: Can it handle the load?

Water Absorption: Will it stand up to rain or moisture?

Efflorescence: Any risk of white stains from salts?

Size & Shape Consistency: Uniformity matters in construction

If a unit doesn’t pass, it doesn’t ship. Simple as that.

Technology Is Raising the Bar

Smart Manufacturing Tools

Modern manufacturers are leaning into tech to do things better and faster. Sensors, real-time analytics, and even AI are helping catch inconsistencies early—sometimes before they’re visible to the naked eye.

Some plants use IoT sensors to monitor kiln temperature or curing chamber humidity 24/7. Others use image recognition to flag shape defects in blocks before they leave the conveyor belt.

Full Traceability

Many manufacturers now tag batches with production dates, raw material sources, and machine settings. That means if a problem ever comes up later, they can trace it back in seconds and figure out exactly what went wrong.

Sustainability Meets Quality

Interestingly, many of today’s top-quality bricks and blocks are also eco-friendly. By incorporating materials like fly ash (a by-product of coal power plants), manufacturers not only reduce their carbon footprint but often end up with stronger, more durable blocks.

Recycling cracked or damaged products back into production is also becoming more common. It’s smart, efficient, and good for the planet.

Wrapping It Up: Why It All Matters

Behind every high-quality brick or block is a series of choices, tests, and processes that most people never see. For brick and block manufacturers, it’s not just about production—it’s about responsibility. Responsibility to builders, homeowners, and entire communities.

When you buy from a manufacturer who takes quality seriously, you’re not just getting better materials. You’re getting peace of mind.

FAQ: Common Questions About Brick and Block Quality

What’s the biggest factor that affects brick or block quality? It’s hard to pick just one, but curing is often where quality is made or broken. Without proper curing, even the best materials can underperform.

Do all manufacturers follow the same standards? No. The best ones follow national or international standards like IS, ASTM, or ISO. Always check for certifications—it’s a great sign of consistency.

Can eco-friendly blocks be as strong as regular ones? Absolutely. Fly ash and recycled aggregates can actually improve performance when used correctly.

How can builders spot a high-quality brick or block? Look for uniformity in size, a solid sound when tapped, and no visible cracks. Ask the supplier for test reports—good manufacturers won’t hesitate to share them.

Are handmade bricks still a thing? In some regions, yes. But for most modern construction, machine-made bricks and blocks offer better consistency and performance.

#arecaleafplatesmakingmachine#automaticflyashbrickmakingmachine#automaticinterlockingblockmakingmachine#automaticpaverblockmakingmachine#brickandblockmanufacturers#automaticsolidblockmakingmachine#fullyautomaticflyashbrickmakingmachine#hydraulicshearingmachinemanufacturers#interlockingblockmakingmachine#concretepanmixermachine

0 notes

Text

Which Concrete Solution Fits UAE Projects Better: Self Loading Mixer or Mobile Concrete Plant?

The UAE's construction landscape presents unique challenges that demand innovative concrete solutions. With projects ranging from towering skyscrapers to sprawling infrastructure developments, contractors face critical decisions about their concrete production methods. Two technologies have emerged as frontrunners in this demanding environment: self loading mixer and mobile concrete plants. Each offers distinct advantages tailored to different project requirements, but choosing the right one can make or break a project's efficiency and profitability.

Understanding which solution fits better requires examining several factors unique to the UAE context. The region's extreme temperatures, dust conditions, and ambitious construction timelines create special considerations for concrete production. Additionally, labor availability, transportation logistics, and project scales vary dramatically across different emirates. This analysis will help you navigate these complexities to select the optimal concrete solution for your specific needs in this dynamic market.

Operational Flexibility in UAE's Diverse Project Sites

Mobility and Space Constraints

Self-loading mixers shine in confined urban job sites common in Dubai and Abu Dhabi. Their compact footprint allows operation in spaces as tight as 6-meter wide lots, perfect for high-rise construction in dense city centers. The ability to load, mix, and pour concrete from a single machine eliminates the need for separate batching plants and transit mixers.

Temperature Adaptability

UAE's scorching climate demands special considerations. Modern self-loading concrete mixers in UAE incorporate thermal management systems that maintain optimal mixing temperatures even in 50°C heat. Their enclosed mixing drums protect materials from direct sunlight and dust contamination, crucial for maintaining concrete quality in desert conditions.

Production Capacity and Project Scale Considerations

Meeting High-Volume Demands

Mobile concrete plants dominate when large-scale production is required. For mega-projects like Expo City developments or major highway constructions, their 60-120 m³/hour output capacity proves indispensable. These systems can be scaled up with additional mixing units to match project growth, a critical feature for the UAE's rapidly evolving construction timelines.

Material Consistency Across Batches

Centralized batching in mobile batching plants ensures uniform quality control across thousands of cubic meters. This becomes particularly important for specialized concrete mixes used in UAE's iconic architectural projects, where precise strength and finish requirements must be maintained consistently.

Economic and Logistical Factors

Labor Optimization Strategies

Self-loading mixers require just 1-2 operators, a significant advantage in the UAE's tight labor market. Their automated systems reduce dependency on skilled workers while maintaining production quality. This operational simplicity translates to lower training costs and reduced visa-related overheads.

Transportation and Setup Economics

Mobile concrete plants offer better economies of scale for long-duration projects. While requiring more initial setup time, their per-unit production costs drop dramatically at higher volumes. For remote projects in emirates like Ras Al Khaimah, they eliminate the need for lengthy concrete hauls from centralized batching plants.

The choice between these technologies ultimately depends on your specific project parameters in the UAE context. Self-loading mixers offer unparalleled flexibility for urban projects with space constraints and variable daily requirements. Mobile concrete plants deliver superior efficiency for large-scale, long-duration projects where consistent high-volume output is critical. Smart contractors often employ both, using self-loaders for finishing work while relying on mobile plants for structural elements, creating an optimized hybrid approach tailored to the UAE's unique construction challenges.

0 notes

Text

Concrete Plants

Concrete Plants: The Backbone of Modern Construction Concrete plants play a vital role in the infrastructure and development of modern cities, highways, and industrial projects. As construction demands continue to evolve, the functionality and importance of these facilities have become increasingly evident. From skyscrapers to sidewalks, concrete plants are at the heart of producing the most widely used construction material in the world. Understanding how they work, what types exist, and how they impact project efficiency is essential for anyone involved in construction or urban planning. What Are Concrete Plants? Concrete plants, also known as concrete batching plants, are facilities where various ingredients like cement, water, sand, gravel, and additives are combined to produce concrete. These plants are designed to provide precise mixtures according to project specifications, ensuring consistent quality and performance. Unlike manual mixing, which can lead to inconsistencies, concrete plants streamline the process, making it more reliable and scalable. At the core of a concrete plant is a batching system that measures and blends the components into a homogenous mixture. Depending on the scale and type of the project, concrete can be produced in large volumes and either transported to a job site via mixer trucks or used on-site in real time. Types of Concrete Plants There are several types of concrete plants, each designed to meet specific construction needs and environmental considerations. These include dry mix, wet mix, stationary, and mobile plants. Each type has its own set of benefits and ideal use cases. Dry Mix Concrete Plants Dry mix plants prepare all dry ingredients (cement, aggregates, and additives) and load them into a concrete mixer truck. Water is added to the mix once the truck is en route or at the job site. These plants are ideal for long-distance transportation or when water availability is a concern at the plant site. They also allow more control for on-site adjustments but require skilled drivers and consistent mixing during transit. Wet Mix Concrete Plants Wet mix plants combine all ingredients, including water, at the batching facility. The resulting mixture is then poured into a mixer truck for delivery. This method ensures a more uniform and higher-quality product, making it suitable for critical structural elements and architectural finishes. Wet mix plants also reduce dust and airborne emissions, contributing to a cleaner working environment. Stationary Concrete Plants Stationary concrete plants are fixed installations used for large-scale or long-term construction projects. These plants offer high production capacity, advanced automation systems, and storage facilities for raw materials. Because of their size and complexity, stationary plants are often used in infrastructure projects such as bridges, highways, airports, and commercial developments. Mobile Concrete Plants Mobile concrete plants are designed for flexibility and convenience. These compact units can be easily transported and installed at remote or temporary job sites. They are commonly used in road construction, rural infrastructure, and small-scale residential projects. While they offer lower production volumes than stationary plants, their mobility and ease of setup make them indispensable in fast-paced environments. Key Components of Concrete Plants Concrete plants consist of several integrated systems that work together to ensure the production of high-quality concrete. Each component plays a crucial role in achieving precision, consistency, and efficiency.

Aggregate Bins These storage bins hold coarse and fine aggregates like sand and gravel. Bins are often separated by size and type to ensure accurate batching. They are usually equipped with weigh hoppers that measure the exact amount required for each mix.

Cement Silos Cement silos store bulk cement, protecting it from moisture and contamination. Pneumatic systems are used to convey cement from delivery trucks into the silo. The material is then discharged into the mixer through a screw conveyor or air slide system.

Water Tanks Water is a key ingredient in concrete, affecting its workability, strength, and curing time. Concrete plants include water storage and measurement systems to ensure the correct amount is used in each batch. Some systems also include heaters or chillers to regulate water temperature for optimal mix performance.

Mixing Units Mixers are the heart of the batching system. Depending on the plant type, they can be pan mixers, twin-shaft mixers, or drum mixers. These units blend all components into a consistent, workable mixture. Mixing duration and speed are carefully controlled to avoid under- or over-mixing, both of which can compromise concrete quality.

Control Systems Modern concrete plants use advanced digital control systems to automate and monitor the production process. These systems manage batching sequences, ingredient ratios, mixing times, and loading procedures. Real-time data collection ensures traceability, quality control, and compliance with industry standards. Benefits of Using Concrete Plants The use of concrete plants brings a range of benefits to construction projects, enhancing productivity, sustainability, and overall performance. Consistency and Quality Concrete plants offer unmatched control over mix proportions and production processes, resulting in consistent quality across batches. This is particularly important for projects requiring high-strength or specialty concrete formulations. Time and Cost Efficiency By automating the batching process and reducing manual labor, concrete plants speed up project timelines and reduce labor costs. Ready access to large volumes of concrete minimizes downtime and supports continuous construction flow. Environmental Responsibility Many modern concrete plants incorporate eco-friendly technologies such as dust collection systems, water recycling, and energy-efficient equipment. These practices help reduce environmental impact and support green building initiatives. Customization and Versatility Concrete plants can be tailored to produce a wide range of mix designs, from standard concrete to fiber-reinforced, high-performance, and self-consolidating concrete. This versatility allows contractors to meet unique project requirements without compromising structural integrity. Safety and Compliance Automated systems reduce human error and minimize safety risks associated with manual handling of raw materials. Additionally, concrete plants are designed to meet local and international safety and environmental regulations, supporting responsible construction practices. Challenges and Considerations While concrete plants offer numerous advantages, they also come with operational challenges that must be managed effectively. Space Requirements Stationary plants require substantial space for equipment, storage, and truck access. Site selection must account for zoning laws, noise control, and traffic management to avoid community disruption. Initial Investment Setting up a concrete plant involves a significant capital investment in equipment, land, and infrastructure. Return on investment depends on production volume, project duration, and ongoing maintenance costs. Skilled Labor Operating a concrete plant requires trained personnel to manage batching systems, perform quality checks, and maintain equipment. Ongoing training and certification ensure consistent performance and regulatory compliance. Future of Concrete Plants As construction methods evolve, so too do concrete plants. Innovations in automation, sustainable materials, and real-time monitoring are reshaping the industry. The integration of IoT (Internet of Things), AI-driven quality control, and mobile app-based plant management systems are pushing concrete production into a new era of efficiency and adaptability. Advancements in alternative binders and carbon-reducing additives also point to a greener future. With the construction industry under pressure to reduce its environmental footprint, concrete plants are poised to play a pivotal role in achieving carbon neutrality goals. Conclusion Concrete plants are indispensable to the construction landscape, supporting everything from residential developments to massive infrastructure undertakings. Their ability to deliver high-quality, consistent, and customizable concrete solutions makes them a foundational element of modern building practices. As technology continues to advance and sustainability becomes a central focus, concrete plants will remain at the forefront of innovation, shaping the skylines and roadways of tomorrow. Understanding their capabilities, challenges, and future potential is essential for anyone involved in building the world we live in.

concreteplanters #concrete #concreteplanter #concretepots #concretedesign #plants #concreteart #interiordesign #planters #cement #concretedecor #parkercolorado #denver #castlerockcolorado #denvercolorado #littletoncolorado #lonetreecolorado #colorado #highlandsranchcolorado

1 note

·

View note

Text

Concrete Batching Plants in Kenya: Enhancing Quality and Efficiency in Construction

Kenya’s construction industry is booming, driven by large-scale infrastructure projects, urban development, and the increasing demand for residential and commercial properties. As the sector expands, so does the need for high-quality concrete. To meet this demand, concrete batching plants are becoming an integral part of the construction landscape in Kenya, offering a solution that improves both quality and efficiency.

What is a Concrete Batching Plant?

A concrete batching plant is a facility where various materials like sand, cement, aggregates, and water are combined in specific proportions to produce concrete. These plants come in different sizes and capacities, catering to a wide range of construction needs. They can either be stationary or mobile, making them versatile for various project requirements.

Batching plants ensure that the concrete produced is consistent in quality, which is critical for construction projects that demand high strength and durability. The plants also speed up the production process, making them indispensable for large construction projects such as highways, bridges, and skyscrapers.

The Role of Concrete Batching Plants in Kenya’s Construction Boom

Kenya is currently experiencing rapid growth in infrastructure, with numerous road, rail, and housing projects underway. For these projects to be completed on time and meet stringent quality standards, concrete batching plants are essential. Here’s how these plants contribute to the construction industry in Kenya:

Consistency in Concrete Quality Concrete batching plants ensure that every batch of concrete meets the required standards for strength, workability, and durability. With automated systems that accurately measure each ingredient, there is little room for error. This is particularly important for projects requiring strict compliance with Kenyan and international construction regulations.

Enhanced Efficiency and Productivity Batching plants significantly reduce the time it takes to mix concrete compared to traditional methods. This not only speeds up construction projects but also reduces labor costs. Contractors can rely on the plant’s efficiency to deliver large volumes of concrete in a short period, which is crucial for projects on tight schedules.

Cost-Effective Solution While the initial investment in a concrete batching plant can be significant, the long-term savings are undeniable. Contractors in Kenya can benefit from lower labor costs, reduced material wastage, and a faster project turnaround. Furthermore, producing concrete on-site eliminates the costs associated with transportation and potential delays.

Compliance with Construction Standards Kenya has stringent standards when it comes to concrete quality and safety, especially for large-scale infrastructure projects. The Kenya Bureau of Standards (KEBS) has put in place regulations that govern the quality of materials used in construction, including concrete. Concrete batching plants are designed to meet these standards, providing a level of assurance that traditional mixing methods cannot guarantee.

Types of Concrete Batching Plants Popular in Kenya

There are several types of batching plants used in Kenya, depending on the project requirements. Here are the most common types:

Stationary Concrete Batching Plants: These are ideal for long-term projects that require high volumes of concrete, such as highways and dams. Once set up, these plants can continuously produce concrete for months or even years.

Mobile Concrete Batching Plants: Perfect for smaller or temporary projects, mobile batching plants can be easily transported and set up on-site. This flexibility is particularly useful in rural areas or projects where transportation infrastructure is limited.

Compact Concrete Batching Plants: These plants are smaller in size but still offer high output and efficiency. They are commonly used in urban construction projects where space is limited.

Key Players in Kenya’s Concrete Batching Industry

Several local and international companies have established a presence in Kenya, offering a range of concrete batching solutions. Some key players include:

Nilkanth Engineering Works: A globally recognized manufacturer of concrete batching plants, Nilkanth offers a range of plants suitable for Kenyan construction needs. Their batching plants are known for reliability, efficiency, and compliance with quality standards.

Local Manufacturers and Suppliers: Kenya is home to a growing number of companies that supply both mobile and stationary batching plants, catering to the unique needs of the local market.

Challenges Facing the Concrete Batching Plant Sector in Kenya

Despite the many benefits, there are challenges that the concrete batching plant industry faces in Kenya. Some of these include:

High Initial Costs: Setting up a batching plant can be expensive, which may deter smaller contractors from investing in their own plant. However, many construction companies opt for leasing or purchasing second-hand plants to mitigate these costs.

Lack of Skilled Labor: Operating a concrete batching plant requires skilled personnel to ensure the equipment is functioning correctly and that the concrete produced meets quality standards. The shortage of such expertise in Kenya poses a challenge, but this is gradually being addressed through training programs.

Environmental Concerns: Concrete production is known to have environmental impacts, particularly with the emission of dust and the use of water. As Kenya moves toward more sustainable practices, batching plants are being upgraded to reduce their environmental footprint, with features like dust collection systems and water recycling.

The Future of Concrete Batching Plants in Kenya

As Kenya continues to invest in infrastructure and construction, the demand for high-quality concrete will only increase. This will drive the adoption of more advanced and efficient batching plants across the country. In addition, the growing emphasis on sustainable construction practices will push manufacturers to innovate, offering eco-friendly solutions.

Concrete batching plants will play a pivotal role in ensuring that Kenya’s construction projects are completed on time, within budget, and to the highest quality standards. For contractors, investing in the right batching plant can be the key to staying competitive in this fast-growing industry.

Conclusion

Concrete batching plant in Kenya are transforming construction landscape by enhancing the quality and efficiency of concrete production. As the country continues to develop, the use of these plants will only become more widespread, helping to meet the growing demands of Kenya’s infrastructure projects. Whether for large-scale infrastructure or smaller urban developments, concrete batching plants provide the reliability and consistency needed to build Kenya’s future.

#compact concrete batching plant#compact concrete batching plants#concrete batching plant#concrete batching plant in Kenya#mobile concrete batching plants#stationary Concrete batching plants

0 notes

Text

Compact Bin Concrete Batching Plants is used to produce concrete at sites where space is a constraint for installation of Inline Feeder Plants. Generally Compact Concrete plants are installed where space is limited for both installation of plant & execution of construction projects. Compact Concrete plants are designed & fabricated having material storage bins, belt conveyor arrangement & Mixer unit on a single frame. This design reduce the overall size of inline concrete plants to a compact concrete plant. Compact Concrete plants are also Automatic in operations just like inline concrete plants. Though it has reduced bin, storage capacity is lesser as compared to inline bin concrete plants but there are more benefits of installing a compact concrete batching plant at construction sites mentioned below:

A) Requirement of Lesser space for Installation : Compact Concrete batching plants requires 10 meter & 2.5 meter space for installation.

B) Availablity with All types of Mixer units : Compact concrete batching plants are having versatility with all types of mixer like reversible drum, pan mixer or Twin Shaft mixer.

C) Wide Range of Capacity : Coompact concrete batching plants are available in wide range of capacity having 20M³/Hr , 30M³/Hr , 45M³/Hr & 60M³/H.

D) Power Consumption : Compact Concrete batching plants consume lesser power. Electric Power Consumption required for a Compact batching plant is 82KVA.

Navya Engineers & Equipments is a leading & prominent manufacturing company of Automatic Concrete Batching Plants, Tractor Transit Mixers & Silos for Cement & Fly Ash. For more Product details Visit www.navyaindia.in or Call us at +919855597851.

#concrete batching plant#tractor transit mixer manufacturers#automatic concrete plants#compact concrete batching plants#manufacturers of tractor transit mixers#tractor transit mixer#automatic concrete batching plants#mini concrete transit mixer#stationary concrete batching plant#cement silo manufacturers

0 notes

Text

Reversible Compact Concrete Batching Plant in India | Nilkanth Machine Tools

Nilkanth Machine Tools offers a highly efficient Reversible Compact Concrete Batching Plant in India, designed for consistent performance and easy mobility. Ideal for small to medium construction projects, it features a user-friendly control panel, low maintenance, and fast mixing capability. With robust construction and advanced technology, this batching plant ensures reliable concrete production while saving time and labor costs, making it a preferred choice for contractors across the country.

Visit: https://nilmac.com/product-page/reversible-compact-concrete-batching-plant/

#Reversible Compact Concrete#Reversible Compact Concrete Batching Plant#Concrete Batching Plant#Reversible Compact Concrete Batching Plant in India

0 notes

Text

Mobile Concrete Plant

Mobile Concrete Plant The construction industry is evolving rapidly, and with increasing demand for efficiency and flexibility, traditional stationary methods of producing concrete are being reimagined. At the forefront of this transformation is the mobile concrete plant. Designed to bring production directly to the job site, mobile concrete plants offer a game-changing solution for both small-scale operations and large infrastructure projects. These portable units are reshaping how contractors and builders approach time-sensitive construction challenges, providing agility without sacrificing quality. Understanding What a Mobile Concrete Plant Is A mobile concrete plant is a portable facility that enables on-site mixing and production of concrete. Unlike stationary plants that require a permanent setup and significant space, mobile plants are mounted on trailers or skids, allowing them to be easily transported from one location to another. They consist of all essential components including aggregate bins, cement silos, mixers, conveyors, and control systems, all housed within a compact and mobile design. This flexibility makes the mobile concrete plant a highly efficient option, especially for remote areas or projects that demand rapid setup and movement. Whether it's for road construction, residential builds, bridges, or infrastructure development, having the ability to mix concrete on-demand right where it's needed can significantly cut down on transportation time and material waste. Key Components and Features of a Mobile Concrete Plant Modern mobile concrete plants are engineered with efficiency, automation, and portability in mind. While configurations may vary, most units are composed of several core components:

Aggregate Bins – These bins store different types of aggregates (sand, gravel, crushed stone) used in the concrete mix. They're typically separated by compartments and equipped with weigh belts or batchers for precise measurement.

Cement Silo – A mobile concrete plant usually includes an onboard cement silo for storing powdered cement. This silo is integrated with feeding systems to automatically deliver cement into the mixer.

Mixing Unit – The heart of the plant, the mixer blends all ingredients into a uniform mixture. Mobile plants may use twin shaft, pan, or planetary mixers depending on the desired output and consistency.

Water System – Precise water control is critical to achieving the correct concrete slump. The system includes pumps, tanks, and meters for accurate dosing.

Control Panel – Fully automated systems enable operators to manage batching, mixing, and monitoring operations through a centralized control panel. Advanced models feature programmable logic controllers (PLC) and real-time data feedback.

Chassis and Wheels – Mounted on a strong chassis with road-legal wheels and axles, the entire system can be towed by truck or transported via flatbed. These features make the mobile concrete plant an all-in-one, ready-to-deploy solution ideal for a wide range of field conditions. Benefits of Using a Mobile Concrete Plant The advantages of using a mobile concrete plant extend far beyond just convenience. These plants deliver measurable gains in productivity, cost savings, and project timelines. Here’s how:

Enhanced Flexibility and Portability A mobile concrete plant can be moved to different job sites with minimal effort. This is especially useful for contractors managing multiple projects or working in areas without access to ready-mix suppliers. The ability to produce concrete exactly where it is needed eliminates the delays and costs associated with transporting wet concrete over long distances.

Faster Project Turnaround On-site production of concrete enables immediate pouring and reduces idle time. Crews don’t have to wait for scheduled deliveries or worry about concrete setting during transit. As a result, projects can move forward faster, which is critical for tight deadlines and weather-dependent jobs.

Improved Concrete Quality Because concrete is produced fresh on-site, its properties can be closely controlled. The mix can be adjusted instantly based on environmental conditions or project-specific requirements, improving strength, consistency, and durability. This level of quality control is hard to achieve when relying on third-party suppliers.

Reduced Material Waste A mobile concrete plant allows for precise batching based on actual demand, minimizing leftover material. This not only reduces waste and environmental impact but also cuts down on disposal costs. Additionally, leftover concrete from a pour can often be reused for smaller tasks on the same site.

Cost Savings Over Time Although the upfront investment in a mobile concrete plant may seem significant, the long-term savings are compelling. Contractors save on delivery fees, reduce reliance on suppliers, and mitigate the risk of delays caused by logistical issues. Over time, the plant pays for itself through improved efficiency and cost control.

Ideal for Remote or Rural Projects In areas where access to traditional batching plants is limited or nonexistent, mobile units offer a viable solution. Whether it’s building in mountainous terrain, agricultural zones, or disaster relief areas, the mobile concrete plant provides a reliable method for continuous concrete production. Challenges and Considerations Despite the many benefits, operating a mobile concrete plant does come with its own set of challenges. It’s important to recognize these limitations to ensure optimal performance and ROI.

Operator Training Operating a mobile plant requires skilled personnel who understand both the mechanical and software components of the system. Training is essential to ensure safety and to achieve consistent quality in the mix.

Maintenance Requirements Like any piece of heavy machinery, mobile plants require routine maintenance to keep them operating efficiently. Components such as mixers, conveyors, and pumps must be regularly inspected, cleaned, and serviced to prevent breakdowns.

Permitting and Compliance Even though mobile, these plants still need to comply with local zoning, environmental, and safety regulations. Depending on the jurisdiction, obtaining the necessary permits to operate a mobile concrete plant may take time and require documentation regarding emissions, dust control, and noise levels.

Initial Investment While cost-effective over the long term, acquiring a mobile concrete plant is a capital-intensive decision. Small or emerging contractors need to carefully assess their project pipeline and operational capacity before committing to the purchase.

Site Preparation Even though the plant is mobile, it still needs a stable base to operate from. The site must be level, have access to water and power (or generators), and be configured to safely receive raw materials and dispatch the finished product. Applications of Mobile Concrete Plants The versatility of mobile concrete plants makes them suitable for a wide variety of projects. Some common applications include: • Highway and Road Construction – Eliminates the need for long hauls and provides fresh concrete for paving and repair. • Bridge and Infrastructure Projects – Produces customized mixes on-site for piers, beams, and foundations. • Residential and Commercial Development – Enables small batch pours for footings, slabs, and driveways without depending on external suppliers. • Remote Mining or Energy Operations – Supplies concrete in isolated locations where traditional logistics are impractical. • Emergency Relief and Disaster Response – Allows quick setup to restore infrastructure in crisis-affected regions. Conclusion A mobile concrete plant offers an intelligent, agile alternative to traditional batching facilities, empowering construction teams to produce high-quality concrete on demand, wherever it’s needed. Its combination of portability, precision, and productivity makes it a powerful tool in today’s competitive and fast-paced construction landscape. For contractors who value speed, control, and reliability, the mobile concrete plant stands out as a vital asset that can transform the way concrete is delivered and applied on-site.

concreteplanters #concrete #concreteplanter #concretepots #concretedesign #plants #concreteart #interiordesign #planters #cement #concretedecor #parkercolorado #denver #castlerockcolorado #denvercolorado #littletoncolorado #lonetreecolorado #colorado #highlandsranchcolorado

1 note

·

View note

Text

Compact Concrete Batching Plant Guide

AASPA is the single-source supplier of turnkey concrete botching and mixing plant solutions. With decades of experience in the industry. We have numerous installations of various capacities to our credit. We are renowned for offering you everything that is needed to run the very heart of your business. In order to produce the highest quality concrete required as well as an on-site Compact Concrete Batching Plant for the construction of large civil projects such as roads, bridges, ports, dams, runaways, buildings, tunnels, etc., AASPA solutions are designed to confer maximum flexibility by giving your plant the ideal combination of engineered and proven components.

+91 98983 41024 (For Domestic Inquiries)

+91 94283 25161 (For Export Inquiries)

0 notes

Text

How Many Types of Chillers Does Reynold India Manufacturer?

Compressor-Based Chiller Types

Screw Chillers

Air-Cooled Screw Chillers

Water-Cooled Screw Chillers

Industrial Screw Chillers Designed for high-capacity operations, these chillers are suitable for extreme tropical conditions and are known for their energy efficiency .

Scroll Chillers

Air-Cooled Scroll Chillers

Water-Cooled Scroll Chillers These are compact, energy-efficient units ideal for medium-capacity applications. They are designed to operate efficiently in tropical climates .

Reciprocating Chillers

Air-Cooled Reciprocating Chillers

Water-Cooled Reciprocating Chillers Known for their ruggedness, these chillers are suitable for various industrial processes .

Centrifugal Chillers These chillers are designed for large-scale cooling requirements and offer high efficiency .

Application-Specific Chillers

Medical Equipment Chillers Tailored for cooling sensitive medical devices like MRI and CT scanners

Rubber and Shoe Moulding Chillers Designed to maintain precise temperatures during the moulding processes in the rubber and footwear industries

Injection Moulding Chillers Optimized for cooling in plastic injection moulding applications

Blow Moulding Chillers Used extensively in the beverage industry for bottle manufacturing processes

Brine Chillers Suitable for applications requiring low-temperature cooling using brine solutions .

Oil Chillers Designed to cool hydraulic and lubricating oils in various machinery

Glycol Chillers Ideal for processes requiring coolant temperatures as low as -40°C

Gas Liquefaction Chillers Used in processes involving the liquefaction of gases

Batching Plant Chillers Employed in concrete batching plants to maintain the required mix temperatures .

Cascade Low Temperature Chillers Designed for ultra-low temperature applications .

Hazardous Area Chillers ATEX-certified chillers suitable for explosive or hazardous environments

Dual Temperature Chillers Capable of providing two different temperature outputs simultaneously

Variable Speed Chillers Equipped with technology to adjust cooling capacity based on demand, enhancing energy efficiency .

Cooling Method-Based Chillers

Air-Cooled Chillers These chillers dissipate heat using ambient air and are easier to install and maintain.

Water-Cooled Chillers Utilize water for heat dissipation, offering higher efficiency, especially in large-scale applications.

Reynold India's chillers are designed to cater to a wide range of industries, including pharmaceuticals, plastics, food processing, medical equipment, and more. Their products are known for durability, energy efficiency, and adaptability to various environmental conditions.

For more detailed information on their product range and specifications, you can visit their official website:

#reynold india#How Many Types of Chillers Does Reynold India Manufacturer#water chiller manufacturer company in india

0 notes

Text

Reducing Dust and Ensuring Material Integrity with Coninfra’s Cement/Fly Ash Silo

In any large-scale concrete or asphalt operation, loss of material and site pollution from airborne cement dust can create serious environmental, health and economic problems. Coninfra Machinery Pvt. Ltd.’s Cement/Fly Ash Silo is designed to address these challenges head-on, providing sealed storage, precise dosing and integrated dust-collection in a single modular system.

1. Why Sealed Silos Matter

Open storage of fine powders like cement and fly ash leads to significant material loss through wind dispersal, especially in windy, ancillary industrial area settings, or during bulk transfers. Coninfra’s silo features dust-tight hoppers, pneumatic conveyance and emergency-vent filters that keep your on-site footprint clean and your stock levels accurate. By minimizing fugitive emissions, you comply with local CPCB regulations and reduce the need for costly site cleanup.

2. Precise Dosing for Consistent Batches

Whether you’re feeding a Concrete Batching Plant or mixing bituminous asphalt concrete in a Wet Mix Macadam Plant, accurate cement and fly ash proportions are critical. Coninfra’s silo-mounted load cells and screw-conveyor feeders deliver material at ±1% accuracy. This precision reduces over-use of binder, limits expensive rework and ensures every batch—be it hot mix asphalt or ready-mix concrete—meets the specified mix design.

3. Seamless Integration with Construction Equipment

As a leading road construction equipment supplier, Coninfra recognizes that on-site logistics often involve multiple engineering tools & equipment, from transit mixers to paver machines. Their silo modules are skid-mounted for quick hook-up to your batching plant’s pneumatic lines or belt conveyors. In retrofit scenarios, existing baghouses or vacuum systems can be tied into the silo’s dust collector, giving you a turnkey solution without rip-and-replace of your material handling.

4. Health, Safety and Environmental Benefits

Fine cement and fly ash particles pose inhalation risks to workers and can settle on machinery, accelerating wear. Enclosed silos with integrated cartridge filters trap over 99% of particulates, keeping your site ISO-certified clean and your crew safer. In combination with proper road cleaning brushes and sweepers, you maintain a dust-free environment around your mobile or stationary plant.

5. Scalability and Maintenance

Coninfra’s silos come in capacities ranging from 50 to 200 tonnes, so you can right-size your storage to match project demands—whether you’re running a compact ready mix plant in an urban infill site or a high-capacity asphalt plant on a highway corridor. Wear-resistant liners and easy-access inspection hatches simplify routine checks, while local service teams ensure that any filter or gasket replacements arrive within 24 hours.

By incorporating Coninfra’s Cement/Fly Ash Silo into your material flow, you’ll significantly cut dust-related losses, improve batch consistency for both concrete and asphalt and uphold environmental and safety standards across every job site.

0 notes