#Construction equipment

Text

Construction Equipment, Portland, OR

© Robert Pallesen

#Construction Equipment#Street Scene#New Development#PDX#Portland#Urban Landscape#Black and White Photography#Robert Pallesen

79 notes

·

View notes

Text

46 notes

·

View notes

Text

I had the distinct pleasure of seeing a full grown forklift a few days ago. I worked in a building that served as a nursery, but we only ever saw the baby pallet jack stages. Seeing the big boys all grown up is always a treat. This one was having a nap right up by the fencing, but I got a couple pics and a little pat before I had to be on my way.

109 notes

·

View notes

Text

Bezdan, Serbia (2) (3) by Kenneth Seech

Via Flickr:

Visited my grandmother's birthplace, a little village.

(3) Halászle (fisherman's soup), Carda Sebesfok.

4 notes

·

View notes

Text

A dusting of snow covers the newly completed Sarcophagus of Chernobyl Reactor 4.

I am unsure of the exact date of this photograph, but it is likely winter 1986-87.

One of the cranes used to complete the Sarcophagus can be seen on the left of the image. The three cranes used to construct the Sarcophagus remained in place until 1991. I cannot find anything regarding their ultimate fate, but they were probably dismantled and buried due to high radiation levels.

[Image description: the Sarcophagus, an angular construction of black metal, sits completed over the gaping maw of the hole left by the explosion. It has three sides; a northern and western wall, as well as a roof. The Cascade Wall, the southern wall, is a series of four terraces. It covers a pile of debris blown out of the reactor as well as the collapsed northern wall of the reactor hall. The western wall is a reinforcing structure for the reactor hall walls, with ten buttresses running up its face. The roof is slightly sloped and covers the hole left in the roof by the explosion and prevents the emission of more radionuclides from the remains of the reactor. The entire site is covered in a light dusting of snow, giving an oddly peaceful feel to the once frantic and chaotic construction area. The power distribution poles of the plant can be seen in the distance, with steam rising from the cooling pond. The yellow boom of a crane peeks in on the left side of the image, its hook hanging dormant midair.]

#chernobyl#nuclear#nuclear power#disaster#history#autism#accidents and disasters#radiation#heavy machinery#construction equipment#construction#chernobyl hbo#reactor#chernobyl disaster#sarcophagus#soviet union#soviet#ussr (former soviet union)

29 notes

·

View notes

Text

Dear Gus & Magnus,

While trying to get this photo of our project manager on a job site, Bryan hit me with this pose. The whole time we were there, I watched the construction equipment and wished Magnus could have seen them. Magnus is big into his construction books right now -- "Goodnight, Goodnight, Construction Site," "Road Crew Coming Through," and "Digger, Dozer, Dumper" would still be in rotation, but he tore the cover off and it's awaiting repair.

Dad.

Coalgate, Oklahoma. 4.24.2024 - 11.34am.

3 notes

·

View notes

Photo

Wheels Or Tracks?: Excavators That Can Switch Between Wheels And Tracks

Do you know?

Follow us for more Tech Culture and Lifestyle Stuff.

5 notes

·

View notes

Text

Preparing for a bit of subterranean carpet laying on the beach at Cleveleys.

8 notes

·

View notes

Text

Steam Shovel

Charles Malam

The dinosaurs are not all dead.

I saw one raise its iron head

To watch me walking down the road

Beyond our house today.

Its jaws were dripping with a load

Of earth and grass that it had cropped.

It must have heard me where I stopped,

Snorted white steam my way,

And stretched its long neck out to see,

And chewed, and grinned quite amiably.

"Reflections on a Gift of Watermelon Pickle... And Other Modern Verse" - compiled by Stephen Dunning, Edward Lueders, and Hugh Smith

#book quotes#poetry#reflections on a gift of watermelon pickle#stephen dunning#edward lueders#hugh smith#steam shovel#charles malam#construction equipment#dinosaurs#iron#down the road#jaws#earth#soil#grass#steam#white steam#long neck#chewed#grinned#amiable

3 notes

·

View notes

Text

CONSTRUCTION SAFETY COMPLIANCE

Easiest Admin Safety Document Management Software Ever:

Monitoring everything from staff qualifications & training to the expiration of driver’s licenses and insurances. Implementing updates to company policies, confirming employee recognition of alterations and updates via a completely automated, simple to handle follow-up and compliance processes.

Go Digital With All of Your Forms:

Import your own company forms, or Build custom forms that are simple to fill-out and sign with follow-up actions, worker certifications, GPS locations, and offline support.

Accountability Through Visibility:

Easily create or add your existing forms and internal documents and distribute documents and then track completion by worker, location or document name, in real-time.

Contractor Management:

The program makes it easier than ever for Primes and General Contractors to ensure participation and safety compliance from every contractor and subcontractor in site.

Scheduled Forms:

Easily create and distribute documents and then track completion by worker, location or document name, in real-time.

Discover Insights:

Unlock the Power of Data Driven Safety. Analyse your safety program to identify trends and monitor KPIs using the most user friendly and advanced reporting engine on the planet!

Remember, a Safety Management System is not just about having safety measures in place; it’s about making safety a core value in your organization. So, start implementing SMS today and make your workplace a safer place for everyone.

2 notes

·

View notes

Text

Complete Manual on Hanging Scaffold Systems or Suspended Rope Platforms for plastering

In the realm of construction and maintenance tasks, there’s a stalwart ally that stands tall, quite literally. The Suspended Rope Platform (SRP), often recognized as a gondola or working platform, has become an indispensable tool for a spectrum of vertical endeavors. Specifically, in India, these platforms have etched their place firmly in various industries, revolutionizing the way projects are undertaken.

Evolution of Rope Suspended Platforms

Initially embraced primarily by major facade contractors, the trajectory of SRPs has undergone a significant shift. Over the past three years, a seismic shift has been witnessed, with the paint industry, spanning from manufacturers to applicators, showing an avid interest. This surge in demand has propelled manufacturers of these platforms to the forefront, dominating the market for close to a decade.

The utilization of Suspended Rope Platform isn’t confined to a singular purpose. From external wall plastering, painting high-rise structures, installing glass facades to the maintenance of expansive external surfaces, the applications are diverse and extensive. Even in scenarios necessitating alterations or demolition of buildings, these platforms emerge as indispensable temporary structures.

The Rise of Rope Suspended Platforms

What sets SRPs apart is their ascendance as the preferred mode of access across construction sites. Traditionally, scaffolding held sway, but the inherent advantages of SRPs, including efficiency and versatility, have prompted their ubiquitous presence in the construction landscape.

Quality and Innovation

Platforms like the hanging rope platform hoists from Jaypee India epitomize excellence, constructed meticulously using premium materials such as stainless steel and aluminum. The emphasis on stringent quality control ensures adherence to specified durability and reliability standards, ensuring that only the finest products reach customers.

Moreover, manufacturers of SRPs have undertaken a trajectory of innovation. Varied versions of these platforms cater to diverse job site specifications. Engineers have meticulously designed these platforms, integrating multiple safety measures to mitigate the inherent risks associated with erecting and maintaining tall structures.

Safety Features and Engineering Excellence

Safety stands paramount in the realm of suspended platforms. Manufacturers have embedded an array of safety features into their products to ensure secure operations:

Rope Failure Prevention: Incorporating locks to prevent tilting due to rope failure.

Advanced Technology: Integration of sophisticated mechanical and control electronics.

Quality Wire Ropes: Utilization of high-grade steel wire ropes to guarantee robustness.

Optional Overload Sensing: Offering the option for sensing overload, further enhancing safety.

Cable Locking Angle: Ensuring a secure cable locking angle of 3–8 degrees.

Superior Suspension Systems: Technologically superior suspension systems enhancing stability.

Durability: A testament to longevity, these platforms are engineered to withstand prolonged usage without succumbing to wear and tear.

Sturdy Construction: With a solid construction, these platforms exude reliability and stability.

Energy Efficiency: Notably, the energy requirements for operating these platforms are considerably lower compared to alternative access systems.

Proficient Management and Operations

One defining aspect of the Suspended Rope Platform (SRP),landscape in India is the involvement of extensively trained professionals overseeing the operation and maintenance of these platforms. Amidst a competitive market, manufacturers differentiate themselves by providing top-tier suspended platform services. These adept specialists, well-versed in every facet of access equipment, ensure superior maintenance and repair services right on the job site. From initial setup to operationalizing the platform, these professionals handle it all with finesse and expertise.

In conclusion, the evolution of suspended rope platforms for plastering and other vertical endeavors has heralded a paradigm shift in the construction and maintenance landscape. With an emphasis on safety, innovation, and efficiency, these platforms have become the linchpin in accessing vertical spaces, promising durability, reliability, and optimal performance. As the industry continues to evolve, these platforms are poised to remain at the vanguard, catering to the ever-expanding demands of vertical construction and maintenance tasks.

#Suspended rope platform for plastering#Suspended rope platform#Rope Suspended platform for plastering#Buy Suspended Rope Platform#Rope Suspended Platform (RSP)#Construction Equipment Manufacturer and Supplier in India#Construction Equipment#Facade cleaning system manufacturers in india#Gondola Suspended Rope Platform Manufacturer

3 notes

·

View notes

Text

Medieval Construction Cranes

Tossing this out there in case anyone wants (or needs) to see what a treadmill crane (aka drum winch) looks like and how it would have been used to build castles and cathedrals. This technology dates back to Roman times and was heavily in use in the 13th century.

youtube

#Research#Medieval Construction#Construction Equipment#Treadmill Crane#Drum Winch#Castles#Building castles#Tom Scott#YouTube#Video#Medieval Times

7 notes

·

View notes

Text

While I was pretty happy to leave my job, I was sad but I wouldn't be able to see my crane trio anymore. They're getting close to finishing their nest, and I'm sure it's going to be good for their little ones. I took the above photo on my last day, and they were all looking happy and healthy.

I had mentioned to my favorite manager that I would miss watching my cranes build their nest, and this morning he sent me an update photo.

He said he'd make sure to keep me updated!

138 notes

·

View notes

Text

LẮP CẨU THÁP LT6010- 10B ; TMAX= 10 TẤN, TMIN = 1.6 TẤN , BÁN KÍNH : 60M

CÔNG TRÌNH : RẠP XIẾC- PHÚ THỌ , QUẬN 10 , TP.HCM

----------------------------------------------------------------------

🏗 TAKITA ✈️

☎️[P]: 090 784 38 38

🌐[E]: [email protected]

🌐[W]: https://www.tankientao.com

🌐[W]: https://www.thietbinangvn.net

🌐[W]: https://www.phutungcauthapvanthang.vn

🌐[F]: https://www.facebook.com/Cauthap.vanthang.hcm

https://phutungca

https://phutungcauthapsg.wordpress.com/.../cau-thap-mini.../

2 notes

·

View notes

Text

INFRA ENGINEERS INDIA PVT LTD

We are proud to announce that Our company Infra Engineers India Pvt Ltd got recognized in the '20 Best Companies To Watch in 2023' in The CEO Magazine.

Glad to share the Magazine: https://www.theceo.in/industry/infra-engineers-india-pvt-ltd-iepl-creating-the-future

3 notes

·

View notes

Text

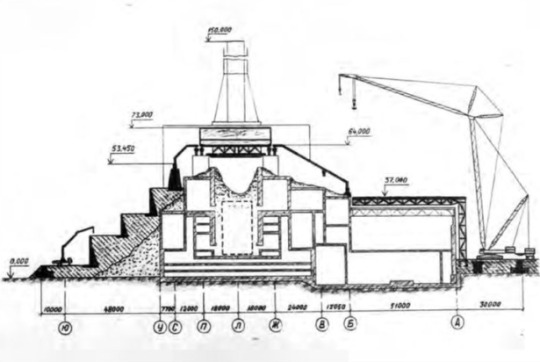

The collapsed northern wall of the reactor building of Chernobyl Reactor 4.

A cross section diagram of the final design of the Sarcophagus.

The Cascade Wall (seen on the left of the diagram above) was one of the most difficult sections of the Sarcophagus to build, but it was one of the most important. It covered the partially collapsed northern wall of the reactor building, as well as the pile of highly radioactive debris left by the explosion. The wall was composed of four stepped tiers, and topped out at 54 meters above the ground.

This was the first part of the Sarcophagus to begin construction. To begin, the men of Sredmesh Unit US-605 installed "Pioneer Walls" (I will make a post on these later) to lessen the gamma radiation at the site. They then filled the space between the Pioneer Walls and the reactor with concrete. On top of this base, they placed huge prefabricated metal wall sections, like the one seen below.

Demag 21 prepares to lift a section of the Cascade Wall into place.

The first tier of the Cascade Wall during installation.

Once the wall sections were all in position, remote controlled concrete pump trucks (seen on the left of the above image) filled the space between the wall and the reactor building, in a similar manner to the area between the Pioneer Walls and the reactor building. This process was repeated until the Cascade Wall was completed.

Crews help to position a section of the third tier of the Cascade Wall before it is lifted into place by crane. These sections weighed more than 120 tons.

Note the white cabin on the crane. These were built similarly to the bathyscaphes used to survey the reactor building during construction of the sarcophagus, with air filters and thick lead sheeting.

The first and second halves of the fourth and final tier of the Cascade Wall, on the left and right respectively.

The men of Sredmash Unit US-605 Shift Four, who installed the fourth tier of the Cascade Wall.

I could not find their names, but I felt compelled to share this photo in their honor.

Without the Cascade Wall, radiation levels would have remained dangerously high and radioactive debris would have been left exposed to the atmosphere. Additionally, it shored up the collapsed northern wall of the reactor building, which had to support some of the weight of the roof section of the Sarcophagus. The men who participated in the project are some of the worst affected amongst the liquidators in terms of sickness.

Men of US-605 fourth shift celebrate the completion of the Cascade Wall with a ceremonial flag raising.

[Image descriptions:

First image: This black and white photo shows the partially destroyed northern wall of the reactor building. Twisted metal and piles of concrete rubble sit on various ledges within the collapsed wall. A network of pipes is visible about three fourths of the way up the wall. The main circulation pumps of the reactor sit partially covered by rubble at the bottom of the wall. Burns cover much of the concrete. An even gravel surface makes up the foreground of the photo, and a large crane is on the right. The striped circular stack of the plant rises in the top left of the image.

Second image: A cutaway diagram of the sarcophagus viewed from the west side of the reactor building. It shows the original structure of the power plant and the plans for the structure of the sarcophagus. From left to right it consists of the four steps of the Cascade Wall, then a slight incline up to the roof section over the reactor hall, then another more gradual slope down to the section covering the turbine hall.

Third image: A black and white photo showing a large crane on the right preparing to lift a large section of metal wall on the ground in front of it. The wall has a small section to help it stand on its own protruding at ninety degrees at its bottom, with angular pipes bracing it against the wall. The crane is lifting it via its hook, which is attached in the shape of an uppercase A. A large metal brace holds the two halves of the lifting section apart above the wall section.

Fourth image: A black and white photo showing the early construction of the cascade wall. The collapsed northern wall sits above the newly placed first section of the cascade wall. The wall is on a raised embankment, below which sit a concrete pump truck sticking its spindly white boom into the wall to add concrete and help build the structure.

Fifth image: The same large crane is lifting another section of the cascade wall just off of the ground. The first and second tiers of the wall can be seen in place in the background of the photo. Nine men, dwarfed by the section of wall they are working on, pull on ropes attached to the wall to angle it correctly for placement on top of the previous sections. The heavy protective cabin of the crane can be seen mounted on the crane chassis, a large white metal box with thick windows to protect the driver from radiation.

Sixth and seventh images: these twin images show the lifting of the two final sections of the cascade wall into place. These sections are both shown in the air on the way to their destination.

Eighth image: A group photo of about forty men in front of the destroyed reactor during the construction of the cascade wall. The wall is only partially finished, but the men are posing in two rows for a photo (crazy!). The men are dressed in dark khaki/deep blue clothes, and white sanitary caps that cover their hair and prevent contaminated. Some of them are also wearing masks or respirators.

Ninth image: this color image shows another gathering of liquidators around a blue concrete pump with a red banner attached to the end of its pump arm. The arm is fully extended about a hundered feet into the air. The group is a lot more informal. The cascade wall is seen fully completed behind the men, but several white and orange concrete pumps still work on other parts of the Sarcophagus. The large yellow crane used to lift the wall sections into place sits idle on the right of the image. Also in this image is the iconic red and white striped chimney of the plant.

#chernobyl#chernobyl hbo#nuclear#nuclear power#radiation#accidents and disasters#history#reactor#autism#disaster#concrete#remote control#concrete pump#construction equipment#construction#welding#heavy lifting#chernobyl disaster#collapse#explosion#cleanup#soviet#soviet union#ussr (former soviet union)#ussr#ussr history#reactor 4#sarcophagus#chnpp#nuclear disaster

8 notes

·

View notes