#Coriolis Guide

Explore tagged Tumblr posts

Text

Coriolis: The Third Horizon - Coriolis Station

Our latest video unravels the mysteries of Coriolis station in the epic tabletop RPG Coriolis: The Third Horizon by Free League Publishing. Unlock secrets, factions, and jaw-dropping lore! 🚀🎲 Watch now! #CoriolisRPG #TabletopGaming #FreeLeaguePublishing

Coriolis: The Third Horizon [PDF]Dive into Coriolis station in the tabletop RPG Coriolis: The Third Horizon! Explore its lore, factions, and political intrigue. Don’t miss out! Welcome to another mind-blowing episode where we dive into the enigmatic Coriolis station in the captivating universe of Coriolis: The Third Horizon by Free League Publishing! Unearth the mysteries and political intrigue…

View On WordPress

#Coriolis Adventure#Coriolis Factions#Coriolis Gameplay#Coriolis Guide#Coriolis Review#coriolis rpg#Coriolis Rulebook#Coriolis Setting#Coriolis station#Coriolis Storytelling#coriolis the third horizon#Coriolis Tips#free league publishing#legion of myth#role-playing game#RPG Mechanics#science fiction rpg#Space Station Lore#tabletop gaming#tabletop RPG#Third Horizon

0 notes

Text

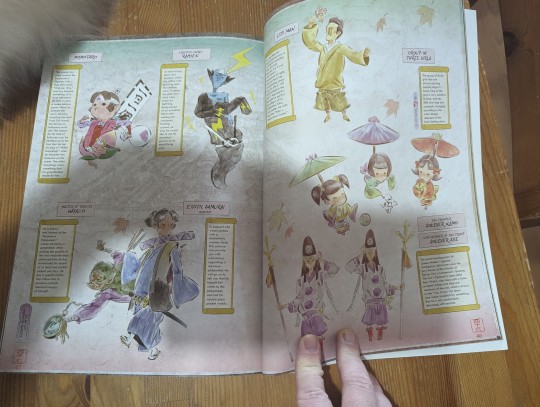

Professional Soldiers 2

(Left to Right)

Emerald Legion Pickkart - Perhaps the most famous archers in the Solar System, Pickkarts of the Galilean Royal Sentries are trained on advanced smart-bolts and experts on coriolis ballistics. They serve as guards for the Royal Family and their constituents. In addition to bowcraft, they typically employ light blades and sidearms to administer their duties.

Heart of Iron, (Brevtoli) - Sometimes called a huscarl. These are theocratic enforcers of the Third of Irons and cultural icons of Mirasuta. Each of these troopers chooses a Saint with which to guide their training and career. This huscarl embodies Brevtoli, Saint of Patience. A light-vacuum suit is traditional, best suited for spacecraft interiors and un-spun habitats. Typically, proudhearts deploy with shortblades, ballistic shields and medium firearms

Bysphere Vipretta Holstari - The lethal knights of the Bysphere are known for bright colors and vicious speed and precision. While normally in ceremonial garb, they are known to act in clandestine roles, often blending into the populace. Holstari carry blades and spine spitters and use them with exquisite lethality.

Kuiper Alliance Intelligence Agency (KAIA) Forward Agent (Pluchar Division) - KAIA agents come in a variety of roles, but Forward Agents are what most people think of when they imagine armed personnel of the Agency. Sealant suits made of interlaced photofiber and smartwave can do wonders to break up the silhouette in the face of cybernetic eyes. Combine that with agency provided cybernetic suites, lethal and non-lethal pin munitions and some of the most impressive training in the outer solar system, KAIA agents are revered for their expertise.

Sentinel of Bright - The True Light of Sol, a humanist-diasporic, transnational entity, does not maintain a military. However, the need for defensible missionaries who could provide for the local security of True Light bastions resulted in the sentinels. Champions of chivalry and community, Sentinels usually work with disciples and monks of the faith to establish chapters and interface with the public. Sentinels wear carbonweave armor, though styles vary wildly. Armament usually includes weapons that befit their station.

Charon Union Vactrooper - Vactroopers of the Charon Union were famously deployed in the Grapevine Insurrection of 2357. Over the course of the 19 month conflict, the Union used these soldiers to disable Scaldia Consortium drones as they landed.

34 notes

·

View notes

Text

It's been a wild few months here at theInstaGrahame HQ, but what never fails to make me happy is the rad games I get from the mail. I'm getting over a cold, so I'mma work on this instead of anything productive I could be doing!

Here's my month of RPG mail calls, and why I'm hyped!

Coriolis: The Last Cyclade: I've been curious about Coriolis' Middle Eastern-themed sci-fi vibes for a while, so I put this on a Secret Santa wishlist; and this is what I got! Excited to dive in.

Curios: Albrecht Manor and Jasper Park: Good Luck Press is one of those game design teams I'll try anything from, and the pitch for this is really unique. It's not an RPG per se, as much as a collection of books, papers, maps, and other materials that point toward a mystery you get to figure out. Playing it is just... looking through stuff.

Salvage Union: I am a big fan of post-apocalyptic media, and a fan of the mecha genre. So, yeah, this was an easy sell. It's built on the Quest system, which I've been meaning to get more into anyway, and it looks like a mech repair manual!

The Zone (which I apparently thought people would just recognize): This game is available for free online, but the box set is gorgeous, and features some designers I love. Trying to set up an online session soon, but I do really want to play it in person.

Deimos Academy: Honestly, I picked it up because of the creative team, but also the pitch is great. I skipped my high school reunion, but if there was a chance to go back and face a monster? I might've thought about going.

Brindlewood Bay + Nephews in Peril: I was originally just going to get the super popular Elderly Detectives Solve Eldritch Crimes RPG, but the title of the expansion/mystery book was just too perfect.

Rebels f the Outlaw Wastes: I've already mentioned I like post-apocalyptica? Well, this took a neat approach to achievements/leveling that I was super intrigued by, and I just dig the fun vibe. The reason I like post-apocalyptic media is that it's hopeful, and this feels moreso than a lot of other stuff.

Skyrealms Almanac and Creatures and Folks: I've been into setting guides this past year. And like, this one is also a coloring book? Hell yeah.

Stoneburner: I've been following the creator on Twitter and elsewhere for a while, so I was curious about this title. But definitely sold when they talked about some of the inspiration being the original Starcraft games.

Forgery: Again, picked it up because I really like Banana Chan's work, but this is a paint-by-numbers solo RPG about forging a demonic painting. So like, yeah. That's rad.

Vast Grimm: Space Cruisers: Vast Grimm is Mork Borg in Space, but I'm also a big fan of ship catalogs, so I really wanted to check this one out.

.Dungeon: Everything Snow makes is beautiful, queer, and nostalgic, so when they mentioned a re-release of .Dungeon was coming, I really wanted to check it out. I have a lot of nostalgia for the

Cloud Empress (everything, including a patch!): I mean, you say Nausicaa and I'm listening. This has some roots in that world, but also does some really interesting things with the Mothership game engine. I'm especially intrigued by the notion of replacing racial traits with age traits, and having a series of pretty mundane jobs as the classes.

Layers of Unreality: The first of this month's Zine Club deliveries! I keep hearing about Liminal Horror, and this particular module I've heard nothing but incredible things about. So I'm really hyped to check out what happens in these backrooms.

Fear the Taste of Blood: My second Zine Club book this month! Kayla Dice is one of those really rad creators who I think deserves more attention than she gets, so I'm really hyped to dive into this take on classic movie monsters.

I also got this from my partner's family's Secret Santa.

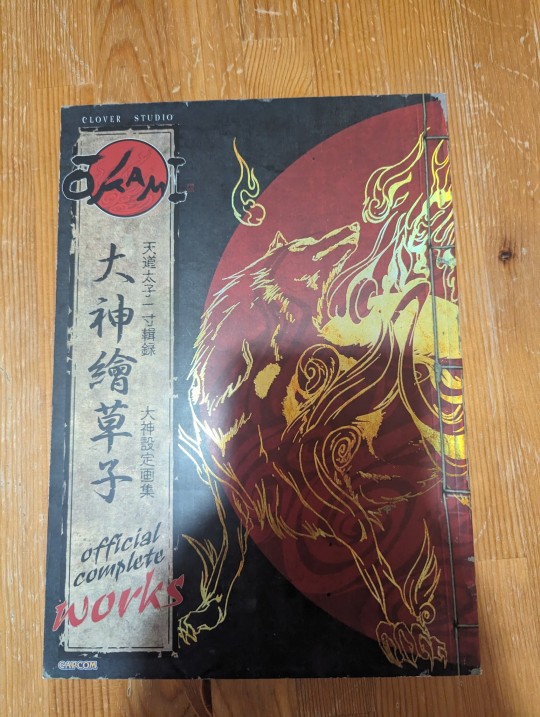

Okami is one of those games that sticks with me, and has ever since I first saw images from it, and played it. It's a genuinely beautiful experience, and while it's maybe not a game everyone will like, it's one that I really enjoy, and the art is a big part of that.

It stands out as an example of what you can do with a video game that's nearly impossible with most other art forms, and also a reason that I don't think the Arms Race for More Photorealistic Graphics in video game consoles is worth the effort.

43 notes

·

View notes

Text

She surprises me / by saying: grief’s no more than a postcard in lieu of a letter, a plus where a garden should be, // a disappointment you pull from the root.

A.D. Lauren-Abunassar, "Field Guide as Sonnet" from Coriolis

3 notes

·

View notes

Text

Complete Guide to Base Building in Dune: Awakening Using Blueprints

youtube

Understanding Blueprints in Dune: Awakening

In Dune: Awakening, blueprints are the foundation of everything when it comes to building structures, coordinating with guildmates, and surviving the harsh environments of the deep desert. Whether you're constructing a forward operating base or crafting an ornithopter, blueprints streamline the process and allow for full team participation.

When a player places a blueprint, they lay down a holographic version of the structure. These appear as green outlines—each square representing a building component. Anyone with permissions can jump in and begin filling in those parts, piece by piece, using materials from their inventory or local storage chests.

Live Blueprint Building in Action

During one of the game’s live stream events, viewers got a close look at how blueprint placement plays out. A guild was shown constructing a base on the shield wall in the deep desert. As the player flew overhead in a 2K resolution stream, you could see multiple members actively contributing to the build. It was a real-time collaboration, where green areas lit up as each component got installed.

Some players handled stairs and railings. Others worked on the upper sections. The moment a blueprint is dropped, anyone with build access and enough materials can contribute. The best part? It’s fast—assuming your guild is organized and you’ve prepped the resources.

How the Blueprint System Works

Creating and Placing Blueprints After creating a blueprint, it’s stored in a usable item. Players deploy this item on the terrain, adjusting it up or down to ensure a proper fit. Once positioned, the green layout becomes visible to builders.

Shared Access and Contribution Permissions matter. Only players with the right access can help fill in a blueprint. Each part of the structure pulls resources either from a player’s inventory or from nearby storage.

Storage Chest Mechanics If storage chests are inside your land claim, they automatically feed materials into the building process. This allows contributors to build without having to carry every resource individually.

Guild Coordination Is Key

Dune Awakening guilds need strong coordination to thrive. Weekly resets mean every team starts from scratch, and that’s by design. No matter how fast you reach the endgame, your structures and bases in the deep desert are wiped clean once the weekly cycle ends due to environmental resets like the Coriolis storm.

Here’s what a successful guild needs to do each week:

Reach the deep desert’s PvE zone

Deploy a forward operating base using a blueprint

Fill the blueprint with materials

Set up resource storage and recharge stations

Begin scouting operations

Weekly Reset Strategy in the Deep Desert

The Dune Awakening weekly reset forces every guild to re-establish their presence. Players have just one week to:

Build their base

Scout and locate POIs (Points of Interest)

Complete objectives

Defend control points if engaging in PvP

Survey beacons help unlock the fog of war, revealing new POIs. Players must create map copies and share them in guild chests so others can participate efficiently.

Crafting and Building Objectives Every Week

A major part of the weekly loop in Dune: Awakening is crafting. The game tracks over 400 rotating objectives that update with each reset. Only a few are PvP-related. Most focus on:

Building ornithopters

Crafting sand buggies

Delivering resources

Harvesting materials

Guilds often split roles:

Builders focus on blueprint construction

Harvesters gather crafting materials

Scouts identify POIs

Defenders secure key locations like control points

Crafters fulfill weekly objectives

Why Blueprints Save Time and Effort

Trying to rebuild complex structures manually every week would be a nightmare. Blueprints solve that. They:

Save layout templates

Allow team collaboration

Use shared storage for faster builds

Speed up the process to just minutes (with prep)

Even complex vehicles like ornithopters and sand buggies can be built from blueprints. One player creates it; the rest of the guild helps fill in the components.

PvP Isn’t the Focus—Guild Structure Is

Many players worry about being constantly ganked in the deep desert, but most guilds aren't focused on PvP. Instead, they’re:

Gathering resources

Completing time-sensitive objectives

Building and crafting

Defending control points only when necessary

So, unless you’re intentionally picking fights, your primary focus will be working with your guildmates to hit the week’s goals—not engaging in random PvP encounters.

Best Practices for Blueprint Efficiency

To make the most of the blueprint system in Dune Awakening, follow these tips:

Pre-stock storage chests with all essential materials

Use multiple contributors to speed up builds

Organize roles within your guild for crafting, scouting, and defending

Deploy and adjust blueprints early in the weekly cycle

Replicate and distribute map data to save scouting time

Key Takeaways

Blueprints allow fast, collaborative construction.

Weekly resets make organization crucial.

Guilds must coordinate roles to complete objectives.

PvP exists, but it’s not the game’s main focus.

Most gameplay revolves around crafting, building, and harvesting.

Conclusion: Base Building in Dune Awakening Starts with Blueprints

Mastering blueprints is essential for success in Dune: Awakening. Every week resets your guild’s progress in the deep desert, making fast and efficient base building a top priority. By coordinating roles, prepping resources early, and making use of the blueprint system, you and your team can hit the ground running each cycle. Whether you're crafting forward bases, ornithopters, or defense points, blueprints give you the tools to build smarter—not harder.

With teamwork and planning, base building doesn't have to be stressful or time-consuming. Instead, it becomes one of the most rewarding systems in the game.

Frequently Asked Questions (FAQ)

Q1: What are blueprints used for in Dune: Awakening? Blueprints let players pre-design buildings and vehicles, which can then be placed in the game world and completed using materials. They're essential for efficient base building and teamwork.

Q2: Can multiple players contribute to the same blueprint? Yes. Once placed, any guild member with the right permissions and required materials can help complete the blueprint.

Q3: How often are bases wiped in Dune Awakening? All structures in the deep desert are reset weekly. This encourages regular rebuilding and keeps gameplay balanced.

Q4: Do you need to carry all materials yourself? No. As long as storage chests are inside your land claim, they’ll automatically supply nearby builds with materials.

Q5: Is PvP required in the deep desert? Not necessarily. Most guilds focus on crafting, harvesting, and completing objectives. PvP only occurs when going after control points or if you encounter hostile players.

Q6: What’s the benefit of using blueprints for vehicles like ornithopters? It speeds up construction and allows your entire team to contribute to large builds instead of relying on one player.

Q7: What’s the best way to get ready for weekly resets? Prepare blueprints in advance, organize resources, assign guild roles, and establish a solid building and scouting plan.

🎮 Meet Haplo Gaming Chef 🍳

Level 99 Kitchen Warrior here! I'm on a quest to transform your gaming sessions into epic culinary adventures. When I'm not farming rare ingredients in MMOs, I'm crafting real-world recipes inspired by your favorite video games.

Specializing in: • Game-inspired recipe creation • Cooking quest guides • Power-up snacks for gaming sessions • Achievement-worthy meal prep

Join my party as we explore the delicious intersection of pixels and plates. Whether you're a casual foodie or a hardcore gamer, there's always room at my crafting table! #Gaming #GamingGuides #GamingChef #HaploGamingChef For More Visit: https://haplogamingchef.blogspot.com/

#dune awakening#dune awakening base building guide 2025#dune awakening blueprints guide#dune awakening complete base building#how to use blueprints dune awakening#dune awakening blueprint system#dune awakening base construction#dune awakening building tutorial#dune awakening blueprint mechanics#dune awakening base design#dune awakening building guide#dune awakening blueprint tips#dune awakening base optimization#dune awakening construction blueprints#dune awakening building strategies#dune awakening blueprint walkthrough#dune awakening base planning#dune awakening building materials#dune awakening shelter blueprints#dune awakening advanced building#Youtube

0 notes

Text

Gyro Sensor: Everything You Need to Know About This Advanced Motion-Sensing Technology

Gyro sensors, also known as gyroscopic sensors or angular rate sensors, play a critical role in a wide range of modern technologies—from smartphones and gaming consoles to autonomous vehicles and industrial machinery. These sensors measure angular velocity, which allows systems to detect orientation, maintain balance, and track motion with remarkable precision. In this detailed guide, we delve deep into the workings, applications, and benefits of gyro sensors to provide you with a comprehensive understanding of their importance in today’s digital and mechanical world.

What Is a Gyro Sensor?

A gyro sensor is an electronic device that detects the rate of rotation around a particular axis. It helps systems determine orientation and rotational motion by using the principles of angular momentum. Unlike accelerometers that measure linear motion, gyro sensors are essential for sensing rotational dynamics.

There are several types of gyro sensors, including:

MEMS gyroscopes (Micro-Electro-Mechanical Systems)

Fiber optic gyroscopes

Ring laser gyroscopes

Vibrating structure gyroscopes

Each type has unique characteristics suitable for different applications, ranging from compact consumer electronics to high-precision aerospace systems.

How Do Gyro Sensors Work?

At the core of most modern gyro sensors, especially MEMS gyroscopes, is the principle of Coriolis Effect. When an object rotates, the Coriolis force is exerted on a vibrating structure inside the sensor. This force causes a change in the vibration direction, which the sensor interprets to calculate the angular velocity.

The steps involved in gyro sensor operation include:

A tiny mass inside the sensor vibrates at a consistent frequency.

When rotation occurs, the Coriolis force alters the path of the vibration.

This deviation is detected by capacitive or piezoelectric elements.

The sensor processes this data to determine angular speed.

Key Features of a Gyro Sensor

When choosing or designing a system with a gyro sensor, understanding its critical features is essential. The most notable features include:

High sensitivity to angular velocity changes

Low noise and drift for stable performance

Compact size and low power consumption, especially in MEMS versions

Wide operating temperature range

3-axis sensing capability for comprehensive motion tracking

These attributes make gyro sensors ideal for embedded systems and portable electronics, where both performance and space-saving designs are vital.

Applications of Gyro Sensors in Modern Technology

1. Smartphones and Tablets

Modern smartphones rely heavily on gyro sensors for functions such as:

Auto-rotation of the screen

Gesture-based control

Augmented reality (AR) and virtual reality (VR) features

Enhanced camera stabilization

Combined with accelerometers and magnetometers, gyroscopes form the foundation of Inertial Measurement Units (IMUs) used in mobile devices.

2. Automotive Industry

In vehicles, gyro sensors are pivotal for:

Electronic Stability Control (ESC)

Anti-lock Braking Systems (ABS)

Inertial navigation systems

Autonomous driving and Advanced Driver Assistance Systems (ADAS)

They ensure safety, enhance vehicle dynamics, and provide real-time feedback for intelligent driving systems.

3. Aerospace and Aviation

Precision and reliability are paramount in aerospace applications. Gyro sensors are used for:

Attitude and heading reference systems (AHRS)

Flight control and stabilization

Satellite orientation and navigation

Here, ring laser gyroscopes and fiber optic gyroscopes offer high precision with minimal drift over time.

4. Gaming and Virtual Reality

Gyro sensors have revolutionized the gaming industry by enabling:

Motion-sensing controllers

Head tracking in VR headsets

Realistic 3D movement simulations

This immersive experience is made possible through accurate real-time orientation detection.

5. Robotics and Drones

Autonomous robots and drones depend on gyroscopic feedback to:

Maintain balance

Navigate accurately in 3D space

Compensate for external disturbances like wind

Gyro sensors are integral to IMU-based navigation systems in UAVs and mobile robots.

Advantages of Using Gyro Sensors

Gyro sensors offer several advantages, making them indispensable across multiple sectors:

Real-time precision: Immediate detection of orientation changes

Compact and cost-effective: Especially true for MEMS gyroscopes

Reliable over time: High-end models maintain calibration and reduce drift

Integration-ready: Easily embedded in modern electronics

Their ability to work in conjunction with other sensors like accelerometers and magnetometers enhances the accuracy of orientation and positioning systems.

Challenges and Limitations of Gyro Sensors

While gyro sensors are versatile, they do come with limitations:

Sensor drift: Over time, small errors can accumulate, affecting long-term accuracy.

Temperature sensitivity: Extreme temperature changes can impact sensor performance.

Complex calibration: To maintain precision, especially in dynamic environments.

However, combining gyroscopes with other sensors in sensor fusion algorithms (e.g., Kalman filters) helps overcome these issues effectively.

Future Trends in Gyro Sensor Technology

The evolution of gyro sensors continues to push boundaries. Key trends include:

Miniaturization and integration: Smaller, more energy-efficient sensors are being developed for wearables and IoT devices.

Improved AI algorithms: Machine learning is enhancing sensor calibration and data interpretation.

Advanced fusion systems: Combining gyro data with GPS, cameras, and LiDAR for improved situational awareness in autonomous systems.

Quantum gyroscopes: A cutting-edge innovation that uses quantum mechanics to achieve ultra-high accuracy without external references.

These advancements ensure that gyro sensors will remain a cornerstone of technological progress in motion tracking and spatial awareness.

Choosing the Right Gyro Sensor for Your Application

Selecting the appropriate gyro sensor depends on your specific application needs. Consider the following criteria:

Precision required (e.g., consumer-grade vs. aerospace)

Cost constraints

Size and power requirements

Environmental conditions (e.g., shock, temperature, vibration)

Axis configuration (single-axis or tri-axis)

Understanding these factors ensures optimal performance and longevity of the motion detection system in your product.

Conclusion

Gyro sensor is a transformative components in today's motion-sensitive world. From enhancing user experience in smartphones to ensuring safety and precision in autonomous vehicles and aerospace, their role cannot be overstated. As innovation continues, the capabilities and applications of gyro sensors will expand, opening new doors in automation, robotics, and immersive digital experiences.

0 notes

Text

How to Select the Perfect Measurement Solution for Your Fluid Processing System

In today's industrial landscape, selecting the right fluid measurement solution can make or break your processing system's efficiency, accuracy, and overall operational costs. With countless options available in the market, finding the perfect fit for your specific application requires careful consideration of numerous factors. This comprehensive guide will walk you through the essential steps to ensure you make an informed decision when choosing measurement tools for your fluid processing needs.

Understanding Your Process Requirements First

Before diving into the various measurement technologies available, you must thoroughly understand what you're measuring and why. A successful fluid system measurement strategy begins with clearly defining your process parameters:

Process Media Characteristics

Viscosity (Is your fluid thick like honey or thin like water?)

Corrosiveness (Will your fluid potentially damage measurement equipment?)

Temperature and pressure ranges

Presence of solids or bubbles

Conductivity properties

Performance Requirements

Required measurement accuracy (±0.2%, ±0.5%, or ±1%)

Flow rate range (minimum and maximum expected rates)

Pressure drop limitations

Repeatability needs

Response time

Installation Environment

Available space constraints

Straight pipe run availability

Ambient conditions (temperature, humidity, vibration)

Hazardous area classifications

Taking the time to document these requirements will significantly narrow your options and prevent costly mistakes down the road.

Exploring Common Fluid Measurement Technologies

Each measurement technology has its unique strengths and limitations. Let's explore the most common options and when they shine:

Electromagnetic Flow Meters

Electromagnetic flowmeters excel when measuring conductive fluids. By generating a magnetic field across the pipe and measuring the voltage produced as the conductive fluid passes through, these meters deliver exceptional accuracy.

Best suited for:

Water-based solutions

Slurries and wastewater

Chemical processing

Food and beverage applications

Key advantages:

No moving parts means minimal maintenance

No pressure drop

Unaffected by fluid density, viscosity, or temperature

Available in sanitary designs for hygienic applications

However, electromagnetic flow sensors cannot measure non-conductive fluids like oils or gases, so they're not universal solutions.

Ultrasonic Flow Meters

Ultrasonic flow meters use sound waves to determine flow rates, either through transit-time or Doppler methods. The transit-time approach measures how long it takes for sound waves to travel between transducers, while Doppler systems measure frequency shifts caused by reflections off particles in the fluid.

Best applications:

Clean liquids (transit-time)

Dirty liquids with suspended particles (Doppler)

Large diameter pipes

Non-invasive measurement needs

Strengths:

Clamp-on options available (no pipe cutting required)

No pressure drop or flow obstructions

Suitable for corrosive applications

Bidirectional measurement capabilities

Ultrasonic flow meter accuracy can be affected by fluid consistency and pipe condition, so proper installation is crucial.

Coriolis Flow Meters

When ultimate accuracy is non-negotiable, coriolis flow meters often provide the solution. Using the Coriolis effect, these meters measure mass flow directly rather than volumetric flow, eliminating concerns about temperature and pressure effects on density.

Ideal for:

Custody transfer applications

High-value products

Multi-phase fluids

Applications requiring density or concentration measurement

Benefits:

Exceptional accuracy (typically ±0.1% to ±0.5%)

Direct mass flow measurement

Independent of flow profile and fluid properties

Can measure multiple parameters simultaneously (flow, density, temperature)

The primary drawbacks include higher initial cost and larger installation footprints, especially for larger pipe sizes.

Rotameter Flowmeters

For applications where simplicity, reliability, and visual indication are priorities, rotameter flowmeters remain popular choices. These variable area meters use a float in a tapered tube to indicate flow rate.

Commonly used for:

Low-flow applications

Local flow indication without power

Simple proportional control

Purge and blanketing systems

Advantages:

No power required for basic models

Visual indication without instruments

Simple operation and maintenance

Cost-effective for smaller applications

Accuracy tends to be lower than other technologies (typically ±2-5%), making rotameters less suitable when precision is paramount.

Critical Selection Factors Beyond Technology Type

While understanding the different measurement technologies is important, several other factors should influence your final decision:

Total Cost of Ownership

Initial purchase price is just one component of the total cost. Consider:

Installation complexity and costs

Power requirements

Calibration frequency and expense

Spare parts availability and cost

Expected service life

Maintenance requirements

A higher upfront investment in a premium flow meter might deliver substantial savings over its operational lifetime through reduced maintenance and higher accuracy.

Integration with Existing Systems

Your measurement solution should seamlessly integrate with your current control and monitoring systems:

Compatible output signals (4-20mA, HART, Fieldbus, etc.)

Communication protocol support

Software compatibility

Power supply requirements

Ensuring proper integration prevents costly rework and communication issues after installation.

Regulatory and Compliance Requirements

Many industries face strict regulatory oversight regarding fluid measurement:

Industry-specific certifications (FDA, 3A, EHEDG for food and pharma)

Hazardous area approvals (ATEX, IECEx, FM)

Custody transfer approvals (OIML, NTEP, MID)

Environmental compliance documentation

Non-compliance can result in production shutdowns, fines, or rejected products, making this a critical consideration.

Supplier Expertise and Support

The right measurement partner offers more than just hardware:

Application engineering support

Commissioning assistance

Training programs

Responsive technical support

Calibration services

Global presence for multinational operations

Working with experienced measurement solution providers like XINSIER TECHNOLOGY ensures you benefit from 15+ years of industry knowledge and support across 53 countries worldwide.

Decision-Making Framework: A Practical Approach

To systematize your selection process, consider implementing this step-by-step framework:

Document process requirements (fluid properties, accuracy needs, environmental conditions)

Screen technologies based on compatibility with your application

Evaluate qualified options using weighted criteria important to your operation

Request detailed specifications from shortlisted suppliers

Perform cost-benefit analysis including total cost of ownership

Check references from similar applications

Conduct site assessment to verify installation feasibility

This structured approach narrows options progressively while ensuring all critical factors receive proper attention.

Real-World Considerations From Industry Experience

After working with thousands of fluid processing systems across diverse industries, we've observed several practical considerations often overlooked during selection:

Future-proofing: Select measurement solutions that can accommodate potential process changes or expansions

Standardization benefits: Using consistent meter types across your facility simplifies maintenance and reduces spare parts inventory

Redundancy needs: Critical measurements might warrant backup measurement systems

Local support availability: Even the best technology fails without proper support infrastructure

Environmental impact: Consider energy consumption and end-of-life disposal impacts

Conclusion: Making Your Final Decision

Selecting the perfect measurement solution for your fluid processing system requires balancing technical requirements, financial considerations, and practical implementation factors. By thoroughly understanding your process needs, evaluating the strengths and limitations of different technologies, and considering the total cost of ownership, you'll be well-positioned to make an informed decision.

Remember that the cheapest option rarely delivers the lowest long-term cost, and the most expensive isn't automatically the best fit for your application. Instead, focus on finding the right match for your specific requirements while ensuring proper installation and maintenance.

With over 15 years of experience providing scientific and cost-effective measuring solutions, XINSIER TECHNOLOGY has helped thousands of facilities optimize their fluid measurement systems. Our team of specialists can guide you through the selection process to ensure you achieve the precision, reliability, and performance your operation demands.

Whether you need electromagnetic flowmeters for water treatment, ultrasonic flow meters for large pipelines, or coriolis flow meters for high-accuracy custody transfer applications, partnering with experienced measurement professionals ensures you'll get the perfect solution for your unique requirements.

0 notes

Text

How to Choose the Right Flow Meter for Your Industry

Selecting the right flow meter is essential for ensuring accurate measurement, process efficiency, and cost optimization across various industries. With different types of flow meters available, understanding their working principles and choosing the best one for your application can be challenging.

Whether you are in water treatment, oil & gas, pharmaceuticals, food processing, or chemical manufacturing, this guide will help you make an informed decision. Plus, we’ll highlight some of the top flow meter manufacturers in India to help you find the best supplier.

What is a Flow Meter?

Factors to Consider When Choosing a Flow Meter

1. Type of Fluid Being Measured

Before selecting a flow meter, consider whether you are measuring liquid, gas, or steam. The characteristics of the fluid, such as viscosity, conductivity, and cleanliness, will impact the type of flow meter needed.

Water & Wastewater ��� Electromagnetic or ultrasonic flow meters

Oil & Gas — Coriolis or thermal mass flow meters

Steam & Air — Vortex flow meters

2. Accuracy Requirements

Industries such as pharmaceuticals and chemical processing require high-precision flow meters, while applications like water distribution may allow for slight variations.

High Accuracy Needs — Coriolis or ultrasonic flow meters

General Industrial Use — Electromagnetic or turbine flow meters

3. Installation Environment

Consider the pipeline size, temperature, and pressure conditions where the flow meter will be installed. Some flow meters require direct contact with the fluid, while others work non-invasively.

High Temperature & Pressure — Vortex or differential pressure flow meters

Non-Contact Measurement — Ultrasonic flow meters

4. Maintenance and Durability

Some flow meters have moving parts that require regular maintenance, while others are designed for low-maintenance operation. If your application requires a long-lasting, durable solution, opt for a non-mechanical flow meter.

Low Maintenance — Ultrasonic or electromagnetic flow meters

Regular Calibration Required — Turbine or positive displacement flow meters

5. Cost and Budget Considerations

The cost of a flow meter varies depending on technology, accuracy, and durability. Investing in the right flow meter can save costs in the long run by reducing errors, minimizing waste, and improving operational efficiency.

Cost-Effective Solutions — Electromagnetic or turbine flow meters

Premium Accuracy & Performance — Coriolis or ultrasonic flow meters

Top Flow Meter Manufacturers in India

Choosing a reliable flow meter manufacturer in India is just as important as selecting the right type of flow meter. Atlantech is one of the leading manufacturers, offering high-quality electromagnetic, ultrasonic, Coriolis, and thermal mass flow meters designed for industrial applications.

Why Choose Atlantech?

Wide Range of Flow Meters — Suitable for various industries

High Accuracy & Durability — Ensures long-term performance

Advanced Technology — Designed for precise measurement

Strong After-Sales Support — Maintenance, calibration, and technical assistance

If you are looking for trusted flow meter manufacturers in India, Atlantech provides cutting-edge solutions to meet your industry’s specific needs.

Conclusion

Choosing the right flow meter depends on several factors, including fluid type, accuracy, installation environment, and maintenance needs. Investing in a high-quality flow meter ensures better efficiency, cost savings, and regulatory compliance for your industry.

For the most reliable and advanced flow meters, trust Atlantech, one of the leading flow meter manufacturers in India. Contact Atlantech today to find the best flow measurement solutions tailored to your business!

#flow meters#digital flow meters#Digital Water Flow Meter India#Magnetic flow meter#Electromagnetic Flow Meters#digital water flow meter#Electromagnetic water meter#Digital Water Flow Meter manufacturer in India#Flow meter manufacturer#Electromagnetic Flow meter manufacturers in India#flow meter suppliers in india#flow meter manufacturers in india#electromagnetic flow meter suppliers in india#digital water meter#water flow meter

0 notes

Text

You may have noticed that the Revopoint POP 3, among other things, is packing an inertial measurement unit, commonly shortened to IMU, inside it. So, IMUs aren’t exactly new technology, having been around since the 1940s and even used in the Apollo missions to help guide the rockets. But, like many technologies, they have shrunk to small chip sizes over time, which has helped them spread across a whole gamut of devices, from drones to your phone to even Nintendo Wii controllers. So let’s look at what’s an IMU and how it helps POP 3 scan better.

What Do IMUs Do?

In a nutshell, IMUs are used to track position, orientation, and velocity. And devices with an IMU typically use this data for navigation as it helps a device know where it is. Or if you’ve ever checked your step count on your phone, this data was likely obtained from the device’s IMU, which recorded the phone’s motion as you walked.

How Does It Work?

Inside the IMU are tiny gyroscopes, accelerometers, and sometimes magnetometers to measure angular attitude, acceleration, and magnetic field, respectively. In POP 3’s case, there are 9 sensors, one of each for each axis, to detect the pitch, roll, and yaw as you move POP 3. Then an algorithm analyzes this data to determine the scanners’ speed and direction.

Gyroscopes

Measures the angular attitude of POP 3. The tiny gyroscopes in an IMU work through small masses vibrating with an equal amount in opposite directions. Then the Coriolis forces acting on the masses determine the angular attitude.

Accelerometer

As the name suggests, this measures the acceleration of a device as you move it. It does it by using something called the Piezoelectric effect, which uses microscopic crystal structures to generate a voltage when they vibrate. And the level of voltage generated indicates the acceleration occurring to the device.

Magnetometer

Otherwise known as an electronic compass, it measures the strength and directions of the Earth’s magnetic field. And are in IMUs to provide a point of reference that the gyroscope and accelerometer use to compare their results against. This helps to prevent the IMU positioning from drifting too much. However, even with the help of a magnetometer, IMUs still sometimes need to be recalibrated to maintain accuracy.

How Does an IMU Help a 3D Scanner?

POP 3’s IMU helps you scan in a few ways. Firstly, it helps to smooth the frame stitching as you scan because now the scanner knows its precise position for each capture frame, making it easier to stitch the frames together accurately by checking their positional data.

Secondly, POP 3 is better at dealing with shaking and being moved too quickly when scanning by hand because it can use the IMU data to work out if it’s in an unexpected position caused by either of these and then delete the faulty frames caused by it.

1 note

·

View note

Text

Coriolis: The Third Horizon - People of the Third Horizon

Ready to meet the people who make Coriolis: The Third Horizon more than just stars and spaceships? 🌌 Our latest video dives into the cultures, conflicts, and stories of the Third Horizon! 🎲✨ #CoriolisRPG #FreeLeaguePublishing #TabletopGaming

Coriolis: The Third Horizon [PDF]Meet the people of the Third Horizon in Coriolis: The Third Horizon! Explore unique cultures and conflicts in this must-see tabletop RPG video. Hey there, space adventurers! In today’s video, we’re zooming in on the diverse people of the Third Horizon in Coriolis: The Third Horizon by Free League Publishing! Discover the unique cultures, riveting conflicts, and…

View On WordPress

#Coriolis Characters#Coriolis Guide#Coriolis Lore#Coriolis NPCs#Coriolis Review#coriolis rpg#Coriolis Rulebook#Coriolis Societal Structure#Coriolis Storytelling#coriolis the third horizon#Coriolis Worldbuilding#free league publishing#legion of myth#People of the Third Horizon#role-playing game#RPG Social Dynamics#science fiction rpg#tabletop gaming#tabletop RPG#Third Horizon Cultures#Third Horizon Society

0 notes

Text

A Guide to Natural Gas Flow Meters

As you reviewed the selection guide, you have likely narrowed your search to a few meters that might be suitable for your project. Now you should weigh the advantages and disadvantages of each so that you can make an educated decision.

Thermo mass flow meters rely on the principle that heat transfer is proportional to the mass flow of gas. They contain a heated element and one or more temperature sensors. In order to determine the flow rate, the temperature difference between the heated element and the gas is measured. For large natural gas pipelines, the flow meter price can be very low for insertion type natural gas flow meters and inline type natural gas flow meters. It has SCFM, kg/h, grams per second, grams per minute, mmscfd, Sm3/h, Nm3/h.

These meters utilize the Coriolis effect, which is the deflection of fluid due to the rotation of the Earth. The gas flows through a vibrating tube in a Coriolis flow meter. The gas motion causes the tube to twist, and the degree of twisting is proportional to the mass flow rate. The Coriolis flow meter is the best natural gas flow meter. It can measure natural gas mass flow directly, and it is the most accurate meter for measuring natural gas flow. Additionally, it can measure natural gas flow rates at high pressures.

A turbine rotor is placed in the gas stream to measure the flow rate. The rate of rotation is proportional to the flow rate as the gas flows through the meter. In order to calculate the flow rate, this rotational motion is converted into an electrical signal.

The Vortex Shedding Flow Meter is based on the principle that vortices or swirling patterns are shed alternately on each side of an obstacle when gas flows past it (such as a bluff body). Flow rate is determined by the frequency of vortex shedding. These vortices are detected and counted.

An orifice plate is a thin plate with a hole (or orifice) in the center. With each flow of gas through the orifice, there is a pressure drop that correlates to the flow rate. Pressure sensors are used to measure this pressure drop before and after the orifice plate.

Technical specifications for natural gas flow meters

A wide range of natural gas flow sensors is available: 3/4", 1/2", 1", 2", 3", 4", NB 100mm, 6", 8", 10", 12" and max 6000mm.

Process connections include wafers or flanges, threads, inline natural gas turbine flow meters, and insertion natural gas flow meters.

A low pressure rating, such as 10 PSI, can be used to detect natural gas leaks and measure low flow rates. It also comes in high pressure ratings, such as 150LB, 300LB, 600LB ,900 class high pressure natural gas flow meters.

Natural gas turbine flow meter with 4-20mA, pulse or relay outputs, real-time data transmission, RS485 or HART interface

Price of natural gas flow meters in the industry

Industrial natural gas flow meters are priced based on a number of factors. Our natural gas flow meter price starts at $500. Customers can choose the right meter for their field application and budget. Contact us at [email protected] to get your price cost for an industrial natural gas flow meter.

Generally, the larger the gas sensor size, the higher the price. For example, a 4" natural gas flowmeter costs more than a 1" flowmeter.

The different measurement principle for natural gas flowmeters results in different prices. In addition to DP flow meters (differential pressure flow meters), we can also provide orifice flow meters for natural gas, Coriolis mass flow meters, thermal gas flow meters for measuring natural gas, and turbine flow meters for measuring natural gas volumetric flow. Unfortunately, SILVER does not offer portable natural gas flow meters or ultrasonic natural gas flow meters.

Our natural gas flowmeters are rated at 232 PSI (normal condition), but if customers require 600LB or 300 Class flowmeters, ANSI or ASME pressure, the price will be higher. To detect leaks from NG pipes, you can purchase our low flow natural gas flow meter for NG gas with typical low flow.

There are several functions of a natural gas flowmeter: electronic natural gas flow meter, totalizer calculation, HART communication, RS 485, lithium battery power supply, and EVC (temperature and pressure correction). These functions affect the price of a natural gas flowmeter. Get more info about compressed air insertion flow meter.

Natural gas flowmeter brand: The natural gas flowmeter of well-known brands is not cheap, such as EMERSON, ROSEMOUNT, ENDRESS, FOXTHERMAL, SIERRA. In contrast, SILVER offers many cheap alternatives, you can buy economical natural gas flow meters from China factories.

What is the best natural gas flow meter?

In order to save money on natural gas flow meters, we all hope to buy the best models. The best natural gas lies in the working conditions and applications that the industrial natural gas flowmeter you choose to meet, the budget to be met, the prompt delivery date, and the timely after-sales service. Choosing the right manufacturer is the best solution for your industrial natural gas flow meter needs.

0 notes

Text

The much taller, masked individual walked with her into the rain, lantern swinging. “No” they said promptly in their electronic voice, leading on.

The drunk melkine had either moved or been moved. A washed stain remained on the stones steps where they had vomited. Now there was hardly anyone out here. Even the dispersed voices were fewer and farther between. Many of the lights behind the screened walls were dimmer or out entirely.

“We are not to speak” said the neutral, buzzing voice. “Might contaminate your memories… thoughts.”

The figure guided her through a maze of similar streets. The city was dense, rustic and strangely beautiful in the dark rain. Clouds of lights and lanterns were strung between the structures overhead. Wind chimes made melodic sounds in the night. They happened upon a canal and bridge. Several people were perched upon the ornate, pedestrian structure and scores of floating lanterns bobbed in the water below. In this open space, the rain could be seen better. Sheets of droplets emerged from the sky in an arc, their path bending with Coriolis force as the world slowly rotated. Still, the night was quiet.

Her escort did not slow.

On the other side of the canal, tucked against another block of dense city structures, a reached a building with narrow entrance. The entrance opened on a corridor that descended into total blackness. The keeper raised its lantern and stuck it onto the hook at the end of its staff. It then offered a gloved hand with fingers that were too long to be baseline.

“Come”

Asova smiled at Noelle. “You like meeting new people, correct? A people person? I seem to recall that you are fantastic at talking to quirky customers!”

@songofsilentechoes

29 notes

·

View notes

Text

Title: Coriolis Author: A.D. Lauren-Abunassar Publication Year: 2023 Publisher: University of Arkansas Press Genre: poetry

A bit of a short rambling for this poetry collection, mainly because I’m not entirely sure how to describe it, other than that it’s worth picking up to explore the wonders of Lauren-Abunassar’s poems. There’s a clear flow and steady pulse that carries the reader from one poem to the next. I guess in a way, it makes sense that the title of this collection would borrow from the Coriolis effect, which (to my understanding) is the way moving objects and weather patterns are deflected relative to the earth’s rotating surface. There’s a way that these poems move and make patterns that I found riveting.

Some favorites: “Something I Wrote Down,” “Aphantasia,” “Field Guide as Sonnet,” “Where Have You Gone, Connie Converse,” “Courage the Cowardly Dog Goes Off on a Tangent,” “Anything with Skin,” and “Cryptid Poem // Victim Impact Statement”

Content Warning: death, grief, references to suicide

0 notes

Text

uhhhhh noah fence but I’d die for Boris Singleton

#larp stuff#coriolis#roman wouldnt DIE fir him but uhhhhh they respect him#roman vc: boris youre the only mf on this guide who can handle me

5 notes

·

View notes

Text

a brief guide to French elite universities (Grandes Ecoles); alternative title: Finally Telling You Where The Fuck I Have Been For The Past Two Years And Why I Complain About Orals Every Other Day

Sometime in the 18th century, the French state decided it wasn’t enough for its technical and military officers to just be rich and noble: they ought to be competent too. They created the original Grandes Ecoles, universities which were meant to provide a high quality higher education for the finest French youth, especially engineers and military personnel. Overtime, these schools evolved into three main categories: engineering, for people who are good at math; humanities, for people who are good at literature; and business, for people who either suck at both, or are just noncommittal (there’s also architecture & others but these are the main ones) what sets these universities apart is their extremely competitive entry exam, which is decomposed in written exams (april-may) and oral exams (july), SUPPOSEDLY (“”) to ensure the purest form of meritocracy.

fast forward to 2020, the world is in the throes of Covid, everyone is losing their mind and I just go, ���wouldn’t it be fun if I became an aeronautical engineer? no, like, wouldn’t it be FUN?” ….. and so I did. except designing things that go zoom in the sky certainly is fun, but the road to get there is anything but. the most esteemed way to do it is through one of the Grandes Ecoles; but much like you don’t send a soldier to the frontline before he’s held a rifle, you do not send a high school graduate to the entry exam if you value their safety at all. that is where preparatory schools (prépas) come in.

(i’m sure @softeninglooks will not blame me for a little bit of henri IV-library drooling, as an illustration)

a preparatory school is as much a two-year extension of high school as it is a pact with the devil. “hey, I’m eighteen years old and I think Planes are neat. is there a way I could get a degree in Planes?” “say no more, I got you, fam. all it will cost you is any and all social outings you may have planned for the next two years, any hobby that might bring you joy, any hope for a decent sleep schedule, and like, one mental breakdown a week, probably.” congratulations! you’re enrolled in a prépa! the entry exam is so difficult and competitive, there really is no other way but to Grind™, and Grind hard. imagine the Olympics 100m men’s final. in this scenario, classes and tests are Usain Bolt, you are me (a Below Average sprinter), and there’s also a horde of alligators on your tail. to sacrifice thirty minutes to catch up on sleep you lost on an assignment is to accept the two weeks you will have to spend studying to make up for lost time. every Saturday morning you take mock written tests, where your grade is Unimportant – only your ranking is, because the one thing you must remember is it does not matter to be good, all that matters it to be better than the guy next to you. every other day, you take mock oral tests, during which the professor gives you a problem and you must solve it in front of them: truly one of the most legendary aspects of prépa. (examples of real problems I & others have been asked to solve, live in front of the guy grading you, with no prior knowledge of it whatsoever: “here’s a force. discuss the influence of this random parameter on the trajectory of mercury.” “a balloon is punctured. how long until it deflates completely?” “an ice hockey player misses his shot. when confronted about it by his coach, he says it is because of the Coriolis acceleration. is it possible?” and my personal favorite, “[the guy clears the board] calculate the entropy variation due to my gesture.”) anyway, I cannot emphasize how draining it is, mentally and physically, and how absolutely fucking fed-up and berserk one gets in the terrible, terrible winter months… but also how, paradoxically, it’s the most valuable two years of my life. it’s an Experience, to be sure. do I regret doing it? not in the slightest. would I do it again? … bro this is the cause of all my existential crises lately.

ANYWAY, after being a martyr to mathematics and working 70h/week for two years straight, you eventually reach the written exams period! you get examined over the course of four weeks total, each week a different concours – and each concours represents a group of universities, of different standings. for engineering, the groups mostly go as follows:

“Polytechnique (nicknamed “X”)

“Centrale” & “Mines” (you’ll find people who’ll tell you this one or the other is harder; I don’t believe them. they’re different, but both a pain.)

“CCP” (absolutely nothing to do with soviet Russia I guarantee)

“e3a”

and then probably others I don’t know the names of??

X is the absolute crème de la crème of French engineering and I am equal parts admiring and terrified of them. they see the world in 5 dimensions or something. they’re sometimes a little weird and also Very Pedantic, but truly the only cool thing about them is they get a fucking Sword im literally so jealous!!!!!!!!!!!!!! and they’re smart. they probably know how long it takes for that balloon to deflate.

(for some reason they get to march in front of the president on national day as if they were actual soldiers in napoleonic times and not the biggest nerds I’ve ever met asdjfnsjbf look at them. they look so stupid. i am not jealous of their cool ass swords)

during the summer, the students who succeed in the written exams take a further set of exams, oral this time (remember the trajectory of mercury? yeah), for the concours they are still defending – their grades at these oral exams determine their national ranking and the university they eventually get admitted into.

so yes, I am going through this whole charade, and that is why I have disappeared for a while now, and not written anything in literal years, plural. we probably are in agreement that this is way too complicated and that I should already have had my degree in Planes, because oh my god that is literally all I ever wanted, not to find out how many people an ice skating ring can hold in the audience before it melts?? but unfortunately I must carry on with the orals I got. even if the school I really really wanted (the school that is the Authority™ on planes) is in the Mines concours… which I did not pass the written exams for. I may repeat the second year (that is commonplace, though less so in engineering than in hums) and attempt the exam one last time… but I don’t know if I can take an extra year of all of this. so that is where I’m at right now. unsure, and hungry, and in need of a FUCKING BREAK!!!!!!

#i have thousands of stories on this because this system exists as a microcosm in the french education system#it honestly exists outside of time i think#france#french culture#french shit really#clara en prépa

14 notes

·

View notes

Text

The Complete Guide to Industrial Flow Measurement Technology

In today's complex industrial environments, accurate flow measurement isn't just helpful—it's essential. Whether you're monitoring water treatment processes, managing chemical manufacturing, or overseeing oil and gas operations, understanding the fundamentals of flow measurement technology can make the difference between optimal efficiency and costly mistakes.

Understanding Industrial Flow Measurement Basics

Industrial flow measurement involves quantifying the movement of fluids—whether liquid, gas, or steam—through pipes, channels, or other containment structures. The accuracy of these measurements directly impacts production quality, operational efficiency, and regulatory compliance.

Most industrial processes rely on precise flow data to:

Maintain product quality and consistency

Optimize energy consumption

Ensure regulatory compliance

Prevent system failures

Reduce waste and operating costs

Key Flow Measurement Technologies in Modern Industry

Electromagnetic Flow Measurement

Electromagnetic flowmeters operate on Faraday's Law of Electromagnetic Induction. When conductive fluid passes through a magnetic field generated by the meter, it produces a voltage proportional to the flow velocity. This voltage is then measured by electrodes and converted into flow rate readings.

Electromagnetic flow sensors excel in applications involving:

Wastewater treatment

Pulp and paper processing

Mining slurries

Chemical manufacturing

Food and beverage production

The technology offers exceptional accuracy for conductive fluids, with minimal pressure drop and maintenance requirements. However, they cannot measure non-conductive fluids like hydrocarbons or purified water.

Ultrasonic Flow Meter Technology

Ultrasonic flow meters use sound waves to measure fluid velocity. These devices come in two primary varieties:

Transit-time ultrasonic meters measure the difference in time it takes for ultrasonic pulses to travel with and against the flow direction. This technology works exceptionally well with clean, homogeneous liquids.

Doppler ultrasonic meters measure the frequency shift of an ultrasonic signal reflected off particles or bubbles in the fluid. This makes them ideal for slurries, sludge, and other particle-laden flows.

Ultrasonic flow meter installations offer several advantages:

Non-invasive measurement (clamp-on types)

No moving parts to wear out

No pressure drop

Suitable for large pipe diameters

Ability to measure bi-directional flow

These meters have transformed industries like water distribution, HVAC, and energy management by providing reliable measurements without disrupting the flow process.

Coriolis Flow Meter Precision

Coriolis flow meters represent the gold standard for mass flow measurement accuracy. These meters measure the twist in oscillating tubes caused by the Coriolis effect as fluid moves through them. This technology directly measures mass flow rather than volumetric flow, eliminating the need for temperature and pressure compensation.

Industries that benefit most from coriolis flow meter technology include:

Pharmaceutical manufacturing

Food processing

Oil and gas custody transfer

Chemical batching

High-purity applications

While these meters typically command higher upfront costs, their exceptional accuracy (often ±0.1% or better) and ability to simultaneously measure density and temperature make them invaluable for critical applications.

Traditional Rotameter Flowmeter Applications

Despite advances in digital technology, variable area meters—commonly known as rotameter flowmeters—remain widely used in certain applications. These simple devices consist of a tapered tube containing a float that rises proportionally to flow rate.

Rotameter flowmeters are particularly valuable in:

Local flow indication without power

Low-flow applications

Simple process monitoring

Laboratory settings

Economical installations

While lacking the advanced features of electronic meters, rotameters offer reliability, simplicity, and visual indication at a fraction of the cost.

Selecting the Right Flow Measurement Technology

Choosing the appropriate flow meter requires careful consideration of several factors:

Fluid Properties: Viscosity, conductivity, corrosiveness, and presence of particles all influence meter selection.

Process Conditions: Temperature, pressure, flow range, and required accuracy determine which technologies are viable.

Installation Requirements: Available straight pipe runs, space constraints, and maintenance access affect installation options.

Budget Considerations: Initial purchase cost must be balanced against maintenance requirements, expected lifespan, and accuracy needs.

Industry Standards: Certain applications may require specific meter types to meet regulatory or custody transfer requirements.

Flow Monitoring Integration with Industrial Systems

Modern flow measurement extends beyond standalone meters to integrated monitoring systems. Today's flow meters often include:

Digital communication protocols (HART, Modbus, Foundation Fieldbus)

Built-in diagnostics and verification capabilities

Remote monitoring functionality

Data logging and analysis features

Mobile connectivity options

These advanced features enable predictive maintenance, reduce downtime, and provide valuable insights into process efficiency.

Future Trends in Flow Measurement Technology

The industrial flow measurement landscape continues to evolve with several emerging trends:

Increased Intelligence: Self-calibrating meters with advanced diagnostics

Multi-parameter Measurement: Single devices measuring flow, temperature, pressure, and fluid quality

IIoT Integration: Flow meters as critical nodes in Industrial Internet of Things networks

Enhanced Visualization: Augmented reality interfaces for maintenance and troubleshooting

Machine Learning Applications: AI-driven flow pattern analysis for predictive insights

Conclusion

Effective industrial flow measurement requires understanding available technologies and selecting the right solution for each specific application. Whether implementing electromagnetic flowmeters for conductive fluids, ultrasonic flow meters for non-invasive monitoring, coriolis flow meters for mass flow precision, or traditional rotameter flowmeters for visual indication, proper selection ensures accurate data for process control and optimization.

As industrial processes grow increasingly complex, reliable flow measurement becomes ever more critical. By understanding the strengths and limitations of each technology, industrial operators can make informed decisions that improve efficiency, reduce costs, and ensure consistent product quality.

For specialized applications or challenging environments, consulting with flow measurement experts can help identify the optimal solution among the diverse range of flowmeter technologies available today.

0 notes