#DOUBLE DIAPHRAGM

Text

BLAGDON AIR-OPERATED DOUBLE DIAPHRAGM (AODD) PUMPS

Blagdon AODD Pumps provide high performing, reliable solutions for your pumping needs. We specialize in extreme condition environments and applications, keeping your process moving both, above and below ground.

0 notes

Text

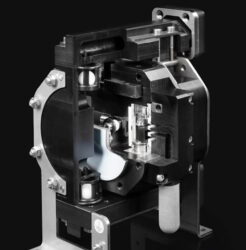

Double Diaphragm Pump Working

A Double Diaphragm Pump uses two diaphragms to move liquids. As one diaphragm pulls fluid in, the other pushes it out. This pump design works well with thick or gritty fluids and can even self-prime, making it versatile and reliable for many industrial tasks. Its simple, efficient operation helps keep things moving smoothly.

0 notes

Text

0 notes

Text

Exploring the Latest Technological Advancements in Electrically Operated Double Diaphragm Pumps

The fluid handling industry is undergoing a transformation with the emergence of Electrically Operated Double Diaphragm pumps. These cutting-edge pumps provide a versatile and reliable solution, presenting an alternative to traditional pneumatic diaphragm pumps.

#pump and valves#eodd pumps#idexcognito#cognitotm eodd#diaphragm pump#eodd pump#diaphragm pump electric driven#double diaphragm pump#Electrically Operated Double Diaphragm pumps

0 notes

Text

Double Diaphragm Pumps (DDP) Market Worldwide Industry Analysis, Future Demand and Forecast till 2032

Double Diaphragm Pumps (DDP) Market Size Was Valued at USD 6.04 Billion in 2023 and is Projected to Reach USD 11.29 Billion by 2032, Growing at a CAGR of 7.2% From 2024-2032.

Double diaphragm pumps are characterized by two flexible diaphragms that reciprocate back and forth, creating a temporary chamber, which draws in and then expels fluid through the pump. This design allows the pump to handle a wide range of fluids, from clean, light viscosity to corrosive, abrasive, medium viscosity fluids, and even fluids containing solid particles.

These pumps are used in various industries due to their adaptability and efficiency. Key industries include chemical processing, water and wastewater management, pharmaceuticals, food and beverage, and oil and gas. They are particularly valued in applications where the fluid being pumped is complex, like high viscosity, or contains fragile solids or abrasive particles.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/9889

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Leading players involved in the Double Diaphragm Pumps (DDP) Market include:

Dover Corporation (USA), Flowserve (USA), Idex Corporation (USA), Graco Inc. (USA), Xylem Inc. (USA), Pump Solutions Group (USA), SPX Flow, Inc. (USA), DAYTON (USA), WHITE KNIGHT (USA), EDSON (USA), SOTERA (USA), VERSA-MATIC (USA), SANDPIPER (USA), WARREN-RUPP (USA), STANDARD PUMP (USA), ARO (USA)

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

If You Have Any Query Double Diaphragm Pumps (DDP) Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/9889

Segmentation of Double Diaphragm Pumps (DDP) Market:

By Operation Type

Single Acting

Double Acting Agent

By Mechanism Type

Air Operated Pumps

Electrically Operated Pumps

By End User Industry

Oil & Gas

Food & Beverages

Water & Waste Water

Chemicals & Petrochemicals

Pharmaceuticals

An in-depth study of the Double Diaphragm Pumps (DDP) industry for the years 2024–2032 is provided in the latest research. North America, Europe, Asia-Pacific, South America, the Middle East, and Africa are only some of the regions included in the report's segmented and regional analyses. The research also includes key insights including market trends and potential opportunities based on these major insights. All these quantitative data, such as market size and revenue forecasts, and qualitative data, such as customers' values, needs, and buying inclinations, are integral parts of any thorough market analysis.

Market Segment by Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

Key Benefits of Double Diaphragm Pumps (DDP) Market Research:

Research Report covers the Industry drivers, restraints, opportunities and challenges

Competitive landscape & strategies of leading key players

Potential & niche segments and regional analysis exhibiting promising growth covered in the study

Recent industry trends and market developments

Research provides historical, current, and projected market size & share, in terms of value

Market intelligence to enable effective decision making

Growth opportunities and trend analysis

Covid-19 Impact analysis and analysis to Double Diaphragm Pumps (DDP) market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=9889

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assist our clients grow and have a successful impact on the market. Our team at IMR is ready to assist our clients flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, specialized in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyze extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1 773 382 1049

Email: [email protected]

#Double Diaphragm Pumps (DDP)#Double Diaphragm Pumps (DDP) Market#Double Diaphragm Pumps (DDP) Market Size#Double Diaphragm Pumps (DDP) Market Share#Double Diaphragm Pumps (DDP) Market Growth#Double Diaphragm Pumps (DDP) Market Trend#Double Diaphragm Pumps (DDP) Market segment#Double Diaphragm Pumps (DDP) Market Opportunity#Double Diaphragm Pumps (DDP) Market Analysis 2024

0 notes

Text

Double diaphragm pumps for greater reliability in chemical processes

Product Manager Stefan Anstöter knows the requirements of the chemical industry and knows what users value.

"From the material to the design and the accessibility for repairs: Chemical pumps must function flawlessly in practical application," says Stefan Anstöter, Product Manager at Timmer GmbH. "We know: Here there is no room for error. That's why we have optimised our pumps so that they meet – and even exceed – all industry requirements. This starts with deliberate use of suitable pump materials. For example, stainless steel, which has proven to be effective in other industries, is often not suitable for chemical applications because it is subject to attack by alkalis and acids. Instead, the pumps in the ‘Tim Chem’ product line are equipped with a plastic housing. The polytetrafluoroethylene (PTFE) that we use is compatible with the chemicals that are used.”

External influences such as significant temperature fluctuations change the shape of the material, and the housing then tends to leak at the connections. “We use a design for our pumps that connects the highly-resistant plastic components that are in contact with media, by means of tie rods. The force exerted by the tie rods is distributed by the large-area reinforcement plates – a measure that significantly minimises deformation of the plastic,” says Anstöter.

The Tim Chem series chemical pumps come factory-standard with a sensor that monitors the status of the pump and that can be integrated directly into the user's process control system.

To ensure maximum protection, stainless steel sheets encompass the pump and provide stability for the entire construction. Metal does not come into contact with the medium. Plastic, and plastic only, which has been tested for resistance, completely encloses the processed medium. The material is FDA-compliant and thus it is food-safe.

Optimal sealing of a pump is a major aspect of process reliability. It is a characteristic that plays a central role in product development at Timmer. In this regard, the design follows a simple rule: The fewer sealing surfaces, the fewer possibilities of a leak. Consequently, chemical pumps from Timmer have only four sealing points – and these pumps are Atex-compliant.

Easy access for repairs

A look inside the pump shows the sealing concept, which significantly minimises the risk of leaks. The design enables easy access for repairs and fast on-site service.

These double diaphragm pumps come factory-standard with an intelligent sensor for condition monitoring. The sensor can be integrated directly into the user's process control system. Integrated in a process control system the sensor shows the real-time status of the pump and by means of an additional system, immediately sounds an alarm should an error occur. The company decides how the pump should be integrated into the system and what data it should display. If an error message occurs and if repairs are required, service technicians benefit from the easy accessibility offered by the pumps. For example, valve balls and valve cages can be replaced without dismounting the side covers. Use of special tools is not necessary.

The heart of the pump, a special, extremely low-wear, ceramic latching valve, ensures smooth operation. All of the valve's friction pairs are made of ceramics in conjunction with precision-ground, high-performance plastics. The result is minimum wear in the valve itself. The reduced stroke path provides long-term protection of the diaphragm.

www.timmer.de

Read the full article

0 notes

Text

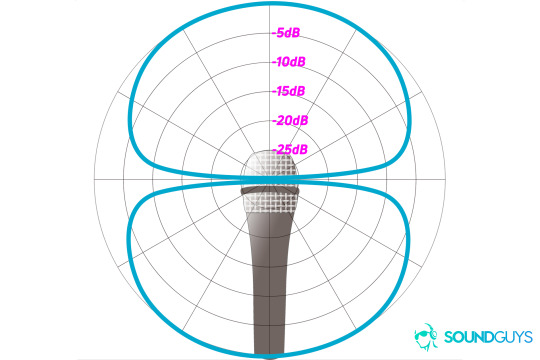

If you have seen Ted Lasso you may have noticed these unusual microphones used by the football commentators.

Despite being a microphone nerd, I had never seen anything like them before. So I decided to go into research mode and discovered these microphones are quite fascinating.

They are called "Lip-Ribbon" or "Commentator's" microphones.

They were specially designed by the BBC in the 1950s for extremely noisy environments. Soccer Football stadiums have peaked at 130 decibels so they needed something that would not get overwhelmed in that circumstance.

They use several very clever techniques to make sure only the voice is picked up and everything else is rejected.

First, they use a bidirectional polar pattern.

That means it will accept sound from two directions, but reject any sound coming in from the sides. And since the diaphragm is only exposed on one side, that helps reject sound coming from the other direction.

Next, the microphone is not very sensitive so you literally have to hold it up to your lips (hence "lip-ribbon") in order for your voice to have enough sound energy to vibrate the diaphragm.

That top part rests directly on your lip and there is a little pop filter to keep your plosives in check.

There is a built-in high pass filter so it rejects any sound below the frequencies typically used by the human voice.

But my favorite trick... a labyrinthian internal baffle system.

(I found a diagram of this when researching but then I lost the tab and I cannot find it again. So you'll just have to accept this crude photoshop I did in 30 seconds to help you understand.)

Sound is energy. And that energy is diminished the farther it travels. The inverse square law for sound states that the intensity of sound decreases by approximately 6 dB for each doubling of distance from the sound source. Sound also diminishes when it reflects off a surface.

That is a very sciency way of saying... make sounds go through a tiny maze and only sounds with the most energy will prevail.

So if you have your lip pressed up against the front of the mic, your voice's energy will make it through the labyrinth of baffles without issue. But every other sound in the stadium will have a much harder time getting through.

These mics may even be vuvuzela-proof.

And even more amazing... this microphone was designed in the 1950s and they have yet to create anything better for incredibly noisy environments.

Isn't that neat?

I think it is neat.

26K notes

·

View notes

Text

#Electric Contact Pressure Gauge#Contact Pressure Gauge#Digital Pressure Gauge#Double Diaphragm Gauge#pressure gauges#Differential Pressure Gauge#absolute pressure gauge#barometer pressure gauge#Gas Filled Temperature Gauges#Mercury Filled Temperature Gauges#All SS Pressure Gauge

0 notes

Quote

Global Double Diaphragm Pumps (DDP) Market was valued at USD 5.90 Billion in 2022 and is expected to reach USD 8.75 Billion by the year 2028, at a CAGR of 5.80%.

Global Double Diaphragm Pumps Market Size, Share And Industry Analysis (2022- 2028) | IMR

0 notes

Text

6 Benefits of Using an Air Operated Double Diaphragm Pump

Transferring fluids in different industrial settings come with challenges that affect process effectiveness, safety, and overall productivity. Some of these obstacles are:

Transitioning Between Phases: The shift from vapour to liquid phases presents an obstacle in fluid transfer procedures within industrial settings. Having a grasp of these transition dynamics is crucial for enhancing efficiency and ensuring streamlined operations.

#air-operated double-diaphragm pump#AODD Pump#Pneumatic Air Pump#Sandpiper Diaphragm#IDEX India#Pump and Valves

0 notes

Text

0 notes

Text

1 note

·

View note

Text

Introducing Cognito™ EODD Pump: Smart Fluid Handling Solutions

Experience the cutting-edge Cognito™ EODD Pump, a smart, IoT-enabled Electrically Operated Double Diaphragm pump meticulously crafted through collaborative efforts with our customers. Leveraging over 30 years of design and engineering expertise, along with profound application knowledge in fluid technology, the Cognito™ EODD Pump is engineered to meet the diverse demands of modern industries. With a robust mechanism ensuring increased production efficiency and reduced total cost of ownership, this pump facilitates seamless handling of a wide range of fluids and slurries. Trust Cognito™ EODD for unparalleled fluid handling solutions.

#pump and valves#eodd pumps#idexcognito#cognitotm eodd#diaphragm pump#eodd pump#water and wastewater treatment#double diaphragm pump#diaphragm pump electric driven

0 notes

Text

Condition monitoring system for process and diaphragm metering pumps

The Lewa ‘Smart Monitoring’ is a monitoring system consisting of sensors, a programmable logic controller (PLC), an industrial PC (IPC) and data analysis for new and existing pumps. The system determines characteristic values and key performance indicators. It is suitable for the Lewa ecoflow process and triplex diaphragm metering pump series. The focus of the system are critical and permanent applications from chemical, pharma or beverage industries.

For more information: www.lewa.com/en/services/digital-services/lewa-smart-monitoring

Read the full article

0 notes