#Direct Drive Spindle

Explore tagged Tumblr posts

Text

At Sea Without a Map pt. 54

"In the interest of weighing my options," you say. "Would you be able to just... send me home?"

Dr. Warefore glowers at you with supreme disappointment. "How pedestrian. Yes, if that's all your ambition can aim for, we can send you home. Outpost 851's Veil Needle Drive is already attuned to our home reality - all we have to do is lock in on one of the veil knots in a suitable intersection of ley lines and we'll be able to open a portal that you can ride straight back to our reality."

Her eyes flicker over Calibani before she smiles smugly at you. "But you'd have to leave behind your little girlfriends, of course. You might be able to take the boat, though if it survives the trip it'll return to being a normal, lifeless vehicle. Why give up what you've gained when you could keep them? We can fit up a nice little aquarium for your two lady friends here, keep your boat docked when you're not at sea. And you could visit home from time to time - there's a generous vacation plan at Spindle, you get one day off per month!"

You look to Calibani. "I can't take them with me?"

"Oh feel free to try - if they survive the trip, they'll likely just end up vivisected in a lab somewhere. And that's if the three of you even remember what happened on this side of the portal - I don't have authorization to give memory preserving drugs to non-employees." She smiles again. "I really think-"

A horrific sound tears through the air and more, for you feel it rippling through your skin and flesh, banging against your bones, and indeed sending shockwaves through the very fabric of your being itself. It accompanies a bright flash as a beam of light lances into Dr. Warefore and sets off a chain reaction that your brain struggles to fully witness much less understand, as in a matter of seconds the very atoms of her being tear apart and disintegrate into pure, true nothingness within thin air, leaving not a single trace of the scientist to be seen. With your ears ringing and your eyes stinging, you try to make sense of things by looking in the direction the beam came from.

Bob sits in her wheelchair with one of the strange needle guns the hazmat suit goons had been wielding. "Oh," she says quietly, "So that's what it does."

Calibani's ear-like fins pop up as her glamour completely fades away. "What the fuck, Bob?" she shouts as her tail slithers out from under her skirt. "Where did you get that thing?"

"Stole it," Bob says.

"...what," you say flatly.

"I wanted to know what it does!" Bob protests. "So I waited till one of those marshmallow guys wasn't looking and stole it." She looks at the spot where Dr. Warefore once stood, which, while bearing no physical trace of the scientist whatsoever, still seems to vibrate angrily from what just occurred there. "Do you think she's alright?"

You look at the spot where Dr. Warefore was. "No, Bob, I'm pretty sure she's dead."

"...oh." Bob frowns and looks down at the gun in her hand. "...whoops."

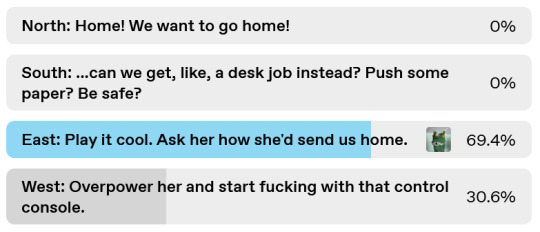

So, you've just disintegrated this sea station's boss. Whatever you do next, you need to do it quickly. You consult your compass.

16 notes

·

View notes

Text

Andromeda’s satellite galaxies

Located 2.5 million light-years away, the majestic Andromeda galaxy appears to the naked eye as a faint, spindle-shaped object roughly the angular size of the full Moon. What backyard observers don't see is a swarm of nearly three dozen small satellite galaxies circling the Andromeda galaxy, like bees around a hive.

These satellite galaxies represent a rambunctious galactic "ecosystem" that NASA's Hubble Space Telescope is studying in unprecedented detail. This ambitious Hubble Treasury Program used observations from more than a whopping 1,000 Hubble orbits. Hubble's optical stability, clarity, and efficiency made this ambitious survey possible. This work included building a precise 3D mapping of all the dwarf galaxies buzzing around Andromeda and reconstructing how efficiently they formed new stars over the nearly 14 billion years of the universe's lifetime.

In the study published in The Astrophysical Journal, Hubble reveals a markedly different ecosystem from the smaller number of satellite galaxies that circle our Milky Way. This offers forensic clues as to how our Milky Way galaxy and Andromeda have evolved differently over billions of years. Our Milky Way has been relatively placid. But it looks like Andromeda has had a more dynamic history, which was probably affected by a major merger with another big galaxy a few billion years ago. This encounter, and the fact that Andromeda is as much as twice as massive as our Milky Way, could explain its plentiful and diverse dwarf galaxy population.

Surveying the Milky Way's entire satellite system in such a comprehensive way is very challenging because we are embedded inside our galaxy. Nor can it be accomplished for other large galaxies because they are too far away to study the small satellite galaxies in much detail. The nearest galaxy of comparable mass to the Milky Way beyond Andromeda is M81, at nearly 12 million light-years.

This bird's-eye view of Andromeda's satellite system allows us to decipher what drives the evolution of these small galaxies. "We see that the duration for which the satellites can continue forming new stars really depends on how massive they are and on how close they are to the Andromeda galaxy," said lead author Alessandro Savino of the University of California at Berkeley. "It is a clear indication of how small-galaxy growth is disturbed by the influence of a massive galaxy like Andromeda."

"Everything scattered in the Andromeda system is very asymmetric and perturbed. It does appear that something significant happened not too long ago," said principal investigator Daniel Weisz of the University of California at Berkeley. "There's always a tendency to use what we understand in our own galaxy to extrapolate more generally to the other galaxies in the universe. There's always been concerns about whether what we are learning in the Milky Way applies more broadly to other galaxies. Or is there more diversity among external galaxies? Do they have similar properties? Our work has shown that low-mass galaxies in other ecosystems have followed different evolutionary paths than what we know from the Milky Way satellite galaxies."

For example, half of the Andromeda satellite galaxies all seem to be confined to a plane, all orbiting in the same direction. "That's weird. It was actually a total surprise to find the satellites in that configuration and we still don't fully understand why they appear that way," said Weisz.

The brightest companion galaxy to Andromeda is Messier 32 (M32). This is a compact ellipsoidal galaxy that might just be the remnant core of a larger galaxy that collided with Andromeda a few billion years ago. After being gravitationally stripped of gas and some stars, it continued along its orbit. Galaxy M32 contains older stars, but there is evidence it had a flurry of star formation a few billion years ago. In addition to M32, there seems to be a unique population of dwarf galaxies in Andromeda not seen in the Milky Way. They formed most of their stars very early on, but then they didn't stop. They kept forming stars out of a reservoir of gas at a very low rate for a much longer time.

"Star formation really continued to much later times, which is not at all what you would expect for these dwarf galaxies," continued Savino. "This doesn't appear in computer simulations. No one knows what to make of that so far."

"We do find that there is a lot of diversity that needs to be explained in the Andromeda satellite system," added Weisz. "The way things come together matters a lot in understanding this galaxy's history."

Hubble is providing the first set of imaging where astronomers measure the motions of the dwarf galaxies. In another five years Hubble or NASA's James Webb Space Telescope will be able to get the second set of observations, allowing astronomers to do a dynamical reconstruction for all 36 of the dwarf galaxies, which will help astronomers to rewind the motions of the entire Andromeda ecosystem billions of years into the past.

The Hubble Space Telescope has been operating for over three decades and continues to make ground-breaking discoveries that shape our fundamental understanding of the universe. Hubble is a project of international cooperation between NASA and ESA (European Space Agency). NASA's Goddard Space Flight Center in Greenbelt, Maryland, manages the telescope and mission operations. Lockheed Martin Space, based in Denver, also supports mission operations at Goddard. The Space Telescope Science Institute in Baltimore, which is operated by the Association of Universities for Research in Astronomy, conducts Hubble science operations for NASA.

IMAGE: This is a wide-angle view of the distribution of known satellite galaxies orbiting the large Andromeda galaxy (M31), located 2.5 million light-years away. The Hubble Space Telescope was used to study the entire population of 36 mini-galaxies circled in yellow. Andromeda is the bright spindle-shaped object at image center. All the dwarf galaxies seem to be confined to a plane, all orbiting in the same direction. The wide view is from ground-based photography. Hubble's optical stability, clarity, and efficiency made this ambitious survey possible. Hubble close up snapshots of four dwarf galaxies are on image right. The most prominent dwarf galaxy is M32 (NGC 221), a compact ellipsoidal galaxy that might be the remnant core of a larger galaxy that collided with Andromeda a few billion years ago. Credit NASA, ESA, Alessandro Savino (UC Berkeley), Joseph DePasquale (STScI), Akira Fujii DSS2

13 notes

·

View notes

Text

Group Chaos: Mirage (Part 4)

Author's note:

Hey guuuuuys... I'm not dead~ And most probably forgot about this fic, buuuut... I am still going finish it! Gem being on her own mission - Huzzah! I am thrilled to be ending this arc in one more chapter. There is so much I have yet to tell - even if it will take me years. I'm not giving up on it - it means too much for me to completely stop. I hope you enjoy this!

Warnings (IMPORTANT): Mature themes Violence/Assault Sadism Manic/psychotic episodes Sensory depravation Suicidal thoughts/intentions Self harm Gore/body horror

MIRAGE: PART 4

Pain.

The shrill ring piercing through the void that otherwise suck the life and colourful sounds from the surroundings – that is what he felt.

The feeling was fleeting and quickly unlatching its talons from the man’s body. It made him panic and thrash as he fought to hold onto it, like reality was slipping away from him. The pain he longed for; the only thing that truly made him feel like the man he was before.

Like he was human again.

It was too little, too late before the pain was gone and he felt the prickling after-effects of his momentary departure tingled in his skull – his soul. Sensations of the cold, lifeless, numbing tickle of glitching overtaking everything; any other thing he could feel before. It was like plastic. It was fake and plastered to perfection.

Enough to make anyone sick.

Colours flooded his mind next. Bright and overwhelming, it infiltrated the darkness he was previously sucked into. It all came crashing back into his new reality after that. The sounds, the cold tiles beneath him, the tension making the hair on his neck stand up. The sense of dread and the urge to run.

Run… Running… He was running. That’s right, he was running. The threat was hot on his tail, he recalled it, clear as day! The fear and determination to run to… to...

To his girls.

Yes, it all made sense now. He could recall everything now, and a huff of breath escaped him as he forced his unstable body onto all fours once again. A stumble, then a shake of his weary head, dizzy from the events before. No, there was no time. He couldn’t rest – he couldn’t stop. He had to get to them!

He willed himself steady, before he felt his eyes flick side to side, up, down. Down… Oh god, the sinking dread of looking down. They were watching him – hyper focused on his every move. the monsters lurking beneath the tiles. Humming and thrumming at the back of his neck, like a string pulled taut to pull the marrow from his spine; the back of his head became weightless and airy as that cursed creaturenestles deeply into his spine. The endless spindling limbs each infiltrating the nerves of his limbs, his torso, even his blasted tailbone and up to the tip of his ears.

It could feel everything he moved, tracking it every millisecond by millisecond. The faint whispers in his ears were taunting him, whispering to him; lies of him being doomed to fail. He wouldn’t make it very far. He should give up.

Damn it all, he didn’t need to make it far. Just a bit further than he was before.

Every step. Every millimeter would be progress. Every second he’d spend moving forward was a second to his benefit. Every breath he took, even if he was struck down over and over… he’d make it to his girls. He’d do what he vowed to do the day he accepted them into his life. The decision he made to take care of them, as they were his, was the only driving force he needed. They’ve lost one too many.

He would have to be dragged to the darkest, flaming pits of hell before he’d lose them too.

With his mind set on his goal, the fierce beast of a man tensed at the ready, about to make a break for it again. Run – that was something he was good at.

Run-

“Run!” a course, high-pitched voice struck his ears, making the hare’s head snap into its direction. Thin slitted pupils dilated into wide black pits as he narrowly dodged the form that almost collapsed onto him. A mix of shapes and limbs messily tumbled around him, colors registering in his mind as the hare fronting his mind luckily doesn’t get too spooked at the sight of an old friend. Zooble.

“D#$n it, Jax, are you in there?” the Zolo-being growled, tumbling and twisting as they crawled in circles around him in a way only this monstrous mess of limbs can. Flashes of their previous fight briefly struck into his mind, and he had to rein in the damn rabbit driving the body, NOT to run off out of instinct. He was confused as to why Zooble was moving so much, circling him in sporadic, tumbling, rolling movements.

He knew Kinger would detect any move they made on the checker tile, that was why they stayed fixed in place.

But now there was chaos!

Without wasting a second, the rabbit ran, leaving Zooble in the dust. Run, no thinking, that was the man’s job, who was currently barking orders from the back of his mind… but the rabbit wasn’t having it. The snake was out of his game. It was time to flee. He could handle the situation just fine. All he needed was a spot to regroup-

“Jax! Listen up.” Came a softer voice, one he had to strain to hear. It belonged to Zooble once again, but it was clear they came to an understanding about his current state of mind. The abomination was speaking at their normal talking volume, knowing he could lock in and hear them just fine, irrespective of the distance. They knew how to deal with *the rabbit*, just like they did in The Games.

This time, it was no game, though…

“Jax, Pomni and I are handling Kinger differently this time-”

‘Yeah, no @#&π!’ the hare thought to himself as he frantically look around, locking his gaze on Zooble’s tumbling form, speeding into a complete opposite direction for a full 2 seconds.

A blue flash and the sound of skidding nails on tiles overtake his senses, scrambling into a different direction, narrowly escaping the stomping hooves of that cursed knight, who set chasing after him for it’s remaining time out and about, teeth gnashing to his fleeting form before diving into the tiles again.

Golden eyes flick about the tiles of the large main area in the tent and his eyes immediately spot a bishop burst from the tiles about 30 meters away. It slid into place, stopping the jester with a soft ‘oof’ when she ran straight into it. He watched curiously, the snake poking out his head when the bishop opened its split head, letting those ominous blue petals blossom from the casing. The effect is immediate; the little jester’s pie-cut pupils expanding impossibly wide and sinking to her knees on the floor. She started clawing at her head, heaving her chest a few times before she let out a blood curdling scream.

Kinger was learning. If he was going to break Pomni faster, it was going to be mentally. The pathettic little loony body could take a punch or two, it seemed… and deep within the hare’s mind to the snake couldn’t help but rumble into a restless coil of curiosity at how far she’d need to physically be pushed to scream like that. He could hear it in her voice as she wailed. The suffering of complete and utter anguish, laced with the undeniable undertone of stubborn determination. Like she knew she had no choice but to face it.

It sounded so… interesting…

Jax reveled in the sound; it should not have sounded as sweet. Despite the circumstances, he couldn’t help but be fixated – he didn’t have the chance to see the previous attack of the bishop on Pomni, he only saw the black ooze trail a few lines down from under her hat. It was so similar to blood and yet it just wasn’t.

It was almost enough…

Why did she have to be such a uprooting hazard to the Oasis, though?

He wasn’t blind – she surely was something. He’d be lying if he said that the jester didn’t intrigue him at all. That he had absolutely no interest. Of course, non of those interests were necessarily good…

For her.

In a blink of an eye the bishop’s blue tendrils abruptly fled back into it’s split head casing and sunk back into the tiles, leaving Pomni to crumble into herself, with a single bated breath, before a knight jumped up from tiles nearby Jax and huffed aggressively. It took him a second for the knight to hoist up it’s front legs in charging it’s attack, before the startled hare was reminded that he was just as deep in the mess as she was, at the end of Kinger’s sword.

But much to the bunny’s surprise, the tired, strained voice of the little jester rung into the air again, with the unmistakable twang of attitude that he could help but get riled up from.

“Is that all you got, you overgrown show pony?!”

The Knight harshly stomped onto the ground, just shy of Jax’s arm, which was frozen in place after he barely made it onto all fours. The knight looked it was about to charge at her, when a exasperated growl made it’s head turn to the other side, almost bewildered.

The purple hare’s gaze snapped into he same direction, seeing Zooble, and his beloved girls still intertwined into that god-awful possession. It felt like forever when he last saw the ragdoll’s face, now completely covered in adorning Gangle’s mask, completely overtaking Ragatha and all that she was.

The possessed doll was trying to rip Zooble apart, stumbling and flailing as there was a clear power struggle evident between the possessed and the possessor. Gangle was unable to effectively maneuver Ragatha’s limbs to fight back Zooble, and every time she’s unwrap a ribbon from a limb to get to the Zolo-creature herself, Ragatha would weakly try to reach up to pry the mask off her face.

It wasn’t effective and the ragdoll never managed to reach up to her face, but it was enough to aggravate the masked ribbon.

This led to Gangle using the ribbons around the doll’s legs to unwrap one at a time to manage the balance of ripping and tossing one Zooble’s pieces, before wrapping around to lower limb of the doll again to force a step forward, since Ragatha would squirm and inch back from the abomination to play at Zooble’s advantage.

The doll really was the only one who could fight Gangle back, even if it was still hopeless.

Meanwhile, Zooble was stuck in the everlasting struggle of trying to literally keep themselves together and get a hold of the possessed ragdoll – any hold on her.

The abomination had any limb that reached out to disarm the ribbon bound doll, disarm then. Literally! Besides that, the awkward, bulky digits and limbs was not able to grip the porcelain mask, unless they aimed to crush the entirety of the girls’ heads in one solid grip – which was everything the zolo-being was trying to avoid.

No one ever knew the consequences of killing Gangle while she was possessing another member. The fear was that That Amazing Digital Circus, glitchy and unstable as it already is, would not be able to handle the event and that the two members involved would meld and fuse together permanently, forever forgotten of what their former selves were and wanted to be.

No, the mask had to come off.

That was the goal.

And that was what struck Jax’s feral mind like a ton of bricks.

‘Jax, Pomni and I are handling Kinger differently this time-‘

That was it. This was for him. It had to be him.

Pomni and Zooble was distracting Kinger, using themselves as bait, taking the beatings and onslaught of the panicked King’s wrath to leave the hare and the possessed doll be. After years of taking the beating for and from everyone else, being the scape goat, the self-proclaimed menace for everyone else to step on, the roles were finally reversed and they chose to take the beating for him. It was odd. He should’ve felt something, he knew that, but it was dull and faint, as it always was since that fateful day he willingly let it go all those years ago.

Guilt.

Then came something he was all too familiar with, so used to repressing it that it caught him off guard when it burst for the depths of his being – almost knocking the wind out of him.

Rage.

How dare he have let it come to this…

The shrill, beast-like whinny that came from the knight, looming over him, crashed the purple bunny back into reality once again. The sight of Zooble laying their hands on the possessed doll, the ones that the King piece was meant to be dealing with himself, sent the older man into a flying rush of rage of his own.

Jax could hear it in the undertones of the knight’s whinny, the chilling undertone of Kinger’s voice bleeding through the animalistic screech.

Its time was up, it was forced to dive below the tiles once again.

But it couldn’t.

Long, milky white appendages grabbed at its mane and jaw, wrapping around it’s neck in a quick, web-like fashion, before pulling taught, preventing the head from following it’s body below the tiles. Jax’s eyes widened for a moment, before his slit-like pupils dilated into inky, black pits, searching the tiles for the source of this offender.

Only to find Pomni.

The jester slid to practically stand over the thrashing knight’s head, bearing over to keep it from sinking to allow another piece to resurface. The little jester’s arms stretched, coiled and twisted around the desperate chess piece, tightening into a death grip as she groaned in the effort to keep her hold on it.

Her determined expression had her white teeth bared as if she had fangs, causing Jax to perk up, startled when her gaze flew to his perplexed figure. She growled out one word to snap him out of it.

“GO!”

He knew what he had to do.

Without acknowledging her, the fierce rabbit leaped into a full sprint, his claws piercing the tiles into tiny cracks as he gripped them to propel himself forward with every leap he made.

The hare. The snake. The man.

All as one this time.

All with the same goal, heading into the same direction with the same destination in sight.

His girls.

He was fast – barely faster than Kinger’s knight. One of the only advantages he had. He could hear – listen – every breath in the room, every heartbeat. He didn’t need to flick his gaze back to hear the desperate Knight, that Pomni was doing her best to restrain, twist his head back to sink it’s teeth down onto the jester’s shoulder, snapping what might have been her collar bone, before whipping the small body over his form in a swift, aggravated motion, to drag the clown girl down into the blue-glowing tiles along with it.

Now it was a chase.

Jax had to get there first.

The next few seconds went by in slow motion. Jax was bolting to Zooble, Ragatha and Gangle, with the possessed doll being preoccupied with the zolo-being. Jax heard a zap, and then a crash from behind him, the rhythmic sound of the leaping knight gaining on him from behind, as it leaped up from out the tiles as it chased him down, not quite able to catch up. He wasn’t aware of the horrific image the Zooble managed to see; one of Pomni, saddled onto the wild Knight’s shoulder, clutching to the mane of the beast, with her eyes glowing a bright cyan-blue as the knight’s was, most likely influenced by the fact that she was also dragged down beneath the tiles.

The sight of it made Zooble’s expression strike to one of complete and utter shock – one of which was briefly picked up on by the charging purple blur, but not fixated on, as he gave one final leap towards his friend and his muse. He managed to catch the possessed doll off guard and tackled her off of Zooble, baring his claws to the porcelain mask.

From behind him, sprouted the knight in a rushed and desperate fury, ready to pounce onto Jax’s back. There was seconds.

Mere seconds.

Jax had to be gentle.

With aimed precision, the awful, ebony claws of the hare was brought down to the top of the fine rim of the white, porcelain mask, the very end of the sharpened tip, sliding once… twice… before hooking into the almost seamless split of the layered masks, feeling the flush, fit-together pieces subtly give way from each other, separating the comedy mask from the tragedy mask with a soft clink.

The detachment of what she considered her power, gently pried from her in a rushed, yet precise way - in which only her snake can, left her true emotion flood her being in the reveal of her tear-streaked face.

It was a sight for sore rabbit eyes.

The moment, a mere fraction of a second, was over with the painful crash to the floor, as the comedy mask shattered into pieces beside them and the wild hare tackled the possessed doll to the floor, using her plush, restrained and beaten body as cushioning.

The hair on Jax’s back stood at end as he felt the impending doom of the Knight having leap up to stomp down onto his back, still rode on by the partially possessed jester – two sets of eyes glowing, making the white tiles beneath the tackled party reflect the flash of cyan into his vision.

Jax didn’t care anymore.

The snake pinned down the manic owl – and his deed was done. Now all he had to do was brace down and take the beating of those cursed hooves, so that he would die and his girls wouldn’t – free from the looming possibility of respawning into an amalgamated mess as a result of dying while Ragatha was possessed by Gangle.

He welcomed his temporary demise once again, looking down to the screeching porcelain mask that was stuck to his dolly’s face, only to have his eyes widen in shock as Gangle blurred out of sight, unlatching from Ragatha’s beautiful face, and charge into Pomni’s, still saddled to the knight’s back.

At the sight, the steed burst and crumbled into a cloud of cyan dust as met Jax’s back, the impact so much softer than he was bracing for, but too distracted by seeing his distressed doll’s pretty eye again to care.

Pomni’s body was flung over them and tumbled into a rolling mess of lanky white limbs and flowly crimson ribbons.

A beat of silence.

The body of the little jester, now possessed with Gangle’s tragedy mask, skid limply to a stop as she seemed to lay there, lifelessly. At the sound of Zooble’s cry, the ribbon that acted as the masked ribbon’s torso, quickly wrapped around the torso of Pomni, using the other 4 ribbons – Gangle’s limbs – to hoist up the little jester’s limp body like a spider.

It barely spare a glance to the worried face of Zooble, before it fled, climbing the structures and anything it could find to make it to the owl’s sanctuary.

The upper rafters of the Circus tent.

It all came falling apart after that. Zooble rushed to tumble and charge towards their beloved friends fleeing form, until they couldn’t see her anymore, only to be grabbed by Kinger, who stood fast in holding them back.

They didn’t care that he was back or how he reemerged from beneath the tiles, now adorned with his blue eyes once again. They tried and failed to chase after their partner, only to crumble to the floor, caught and gently laid onto their knees as Kinger lowered them down.

It hurt.

It hurt so much.

“She lost it.” The zolo-creature said in a quiet sob, only to be hush by Kinger’s eerily quiet voice.

“She’s not alone.”

The king’s attention was divided. His dear friend, his neutral, his counterpart that complemented his role in the Oasis so beautifully, now at their lowest. Broken and hopeless.

His princess, who’s limp body was swiftly dragged by having fangs sunken into the back of her neck, blurring across the checker tiled floor of the main room. The rabbit stopped before sparing a quick glance to the King piece, then quickly rounding the corner and out of sight, toward the hallways harbouring the members’ rooms.

That boy…

Kinger shook his head, getting back to comforting Zooble.

The snake was a monster, but he’d take care of their water spring, even if he had methods that the king did not entertain.

Ragatha would be ok.

Everyone would be okay.

And Pomni…

Well…

She wasn’t really one of them yet, to begin with.

End note: Oof... there you have it folks. Kinger has his priorities.

Part 3 (Previous) Part 5 (Next, final) Oasis: TADC AU list Masterlist

#the amazing digital circus#tadc oasis au#oasis#tadc jax#tadc gangle#tadc ragatha#tadc pomni#tadc zooble#tadc kinger#oasis kinger lore#cw: violence#cw: body horror#cw: mature#cw: mature themes#everyone is traumatised#everyone is messed up#everyone needs help#rip pomni i guess#almost done with mirage#one more chapter guys#it will happen when it happens#reaching the end of arc 1#jax x ragatha#zooble x gangle#rip pomni#rip ragatha#rip gangle#dad kinger#stone cold kinger#kinger can't deal with jax

15 notes

·

View notes

Note

cw: blood, injury

[ File recieved: “PXV-OPOSSUM_EXTRACTION.ec2”, filesize 42.2GB.

COMP/CON system message: the following file format is DIRECT EXPERIENTIAL CAPTURE. Origin subjectivity: Fenrisúlfr-class non-human person CNS274-L3HK, “Hachiko.”

Subjectivity sync NOT AVAILABLE. Generating narrative transcript. Warning: some experiential data may be omitted or condensed in textual format. For alternate safe methods of accessing direct experiential data, contact GMS Client Support for supplemental software licensure. ]

Apprehension tugged at Hachiko’s mind from a dozen different directions while her quarterlight ejection drive spooled.

Physically, she could feel sound coursing through her hull, its frequency soaring into the ultrasonic range with the continuous flow of energy being added to the drive’s charge. One syllable, sung in rising pitch until the individual oscillations were packed together so tightly that they merged into a sustained mosquito whine.

Near her, she could feel the presence of her three siblings as a comfortable network of Legionspace traffic, radar returns, and sensor data. An hour ago, as a single unit, they had pivoted in the darkness of space as they entered the system, pointing their drives toward their destination. Soon, following a span of time calculated down to the nanosecond, they would fire their drives and their velocity relative to Upsilon-XVII would change from .25c to the precise speed they needed to enter geosynchronous orbit.

Then what? In realtime, Luna Wing’s final transit duration, from receiving the transmission to arriving at the scene, would be twelve hours and sixteen minutes.

In all likelihood, he was frozen by now.

Hachiko knew it, but couldn’t afford to feel it. Instead, she accessed the transmissions from his Omnihook for the thousandth time, trying to prepare herself for what she would find.

Footage appeared to her. Opossum—Sokaris, heavily wounded, slumped forward. Neural interface jacks and hardsuit plugs broken along his shoulders. Blood, hydraulic fluid, and saline solution smeared together. Medical prognoses extrapolated from a tiny display and what could be seen of his broken body. She couldn’t tell if he still had life support, but what was left of his hardsuit would at least provide insulation. There was an unidentified stimulant entering his bloodstream, and she had no idea whether that had become an asset or a danger in the hours which followed.

Gloved hand, a woman’s voice, the chassis named Kaprosuchus. Luna 1, Grey, had analyzed the frame, examined the geometry of the armor, and believed a firing solution existed. Hachi had attempted to analyze the woman, and still struggled to connect the voice recording to the vicious mass of teeth and claws on-camera.

Summoning her avatar, Hachiko narrowed her eyes. Until she arrived onsite, Hachiko couldn't know for certain whether this person, Gatorskin, had murdered Sokaris or saved his life. Whoever she was, she wasn’t predictable.

< L1 Grey: Fifteen seconds. Standby for NLS deceleration eject on my mark. >

< L2 Garmr: Got it. >

< L3 Hachiko: Okay. >

< L4 Ma’ii: Understood. >

Dismissing the transmission files, Hachiko retrieved another. An image of Opossum standing in the light with a wall of ice behind him, grinning.

It occurred to her that she barely knew him--but he was one of the few humans to have spoken to her as a person, not a war machine. He was another person made, exploited, and discarded by Smith-Shimano. He was a friend. She had decided that this was more than enough.

So had her siblings.

< L1 Grey: Bolt. >

In the moment she fired her ejection drive, Hachiko wore her fighter as her body. She felt the mosquito whine die as an overwhelming, almost unreal burst of acceleration shifted her into another frame of reference.

__

From black nothingness, a planet snapped into existence, its sunward face gleaming beneath Hachiko’s fuselage. Far away, through passive sensors, Hachiko could make out a thin spindle of metal and exotic materials stretching from the planet’s surface up to the same altitude they occupied in geosynchronous orbit. Along its length, ship-sized platforms rose and descended, loaded with cargo. At its apex was a city-sized space station surrounded by bright sparks of high-energy radiation—the drive signatures of freighters and escort craft, coming and going.

When Hachiko turned her infrared sensors to the station, she felt covers automatically snap shut to protect the higher-sensitivity instruments. The infrared energy pouring from the station was so intense that it drowned her entire display in harsh white light. Her COMP/CON spoke up.

[ Fox_3: Warning: artificial radiant heat hazard detected. For your safety, I have added navigational aids to define unsafe proximity. ]

< L3 Hachiko: Thanks, Fox. Designate the station and surrounding vessels as potential hostile contacts of unknown capability. Keep an eye on them. >

[ Fox_3: Yes, ma’am. ]

Hachiko magnified her view of the station and filtered out the overwhelming infrared light. A vast array of high-powered heat projectors studded the side of the station facing the planet, separated by a forest of glowing red radiator fronds. The projectors’ overlapping cones of infrared energy were focused on a continent-sized area in the northern hemisphere of the world. Gray clouds blanketed the landscape there, swirling out through the planet’s atmosphere.

< L4 Ma’ii: Well, there’s our terraforming station. What do we know about it? >

< L3 Hachiko: He called it Helios. Nerve center for the Kalvis Group’s operations here. Center of a project to artificially raise ambient ecological temperatures and make the climate more tolerable for humans. Able to maintain a sizable sector of the world above 0°C by itself. >

< L2 Garmr: Damn. That’s some serious manna. Kid picked a hell of a fight. >

< L3 Hachiko: His company accepted a contract. That wasn’t his choice. >

< L2 Garmr: Could’ve bailed out. Humans get to pick where they work, remember? >

< L3 Hachiko: It wasn’t like that. This wasn’t just an employer; you didn’t talk to him. Actually, no, you did! To complain about his taste in music. >

< L2 Garmr: His taste? You’re the one who’s been on this Old Cradle kick since you— >

< L1 Grey: Let’s keep it focused, please. I’m tagging armaments on the station. Railgun batteries, point-defense cannons, laser emplacements, flyswatter pods. Looks like general market tech, but they can throw a lot of it at once. Garmr, I want you to start taking a look at those escort vessels. Ma’ii, throw them off our scent if you can. There’s no way they didn’t detect the radiation burst when we decelerated. It’s only a matter of time before they spot us, and I want to know the instant we get pinged. Hachiko, pull up those coordinates and start surveying the ground. The sooner we get out of orbit, the better. Let us know when you find him; we’ll follow your lead. >

< L2 Garmr: On it. >

< L4 Ma’ii: Affirmative. Prepping ECMs. >

< L3 Hachiko: Already on it. >

The equatorial landmasses and seas below were crusted with ice, giving off a piercing white glare of reflected sunlight. Applying brightness filters to better survey the landscape, Hachiko began searching.

Sector by sector, carefully angling her active radar to avoid generating detectable noise, Hachiko began scanning the vicinity of the coordinates Gator had transmitted. If the footage of the battle was anything to go by, certain factors should have been present. Exposed coldcores, synthetic materials used in mech construction, and polymer masses extruded by Sokaris’s Kobold, among other things. All materials with particular reflective properties, very different from the surrounding snow, ice, and rock. If she was right, the site of the battle should be glaringly obvious. It was simply a matter of finding the right spot…

< L4 Ma’ii: We’ve got pings. Switch to active ECM. >

< L1 Grey: Hachi? >

< L3 Hachiko: I think I’ve got something. Need a moment to verify. >

< L2 Garmr: You better make it quick. There’s an OTC controller on broadcast, addressing some very pointed questions to nobody in particular. >

< L3 Hachiko: I have it. Confirm sensor acquisition, transmitting geoloc data. On me. >

___

Descending to the ground, Hachiko deployed her landing gear and opened the doors to her ordnance bay. She felt the subaltern drop free from her hull, switched to it mid-drop, and landed on her feet.

Walking across open ground set her on edge. She felt slow, so slow that she might as well have been stationary. Dizzyingly close to the long, flat expanse of snow. Exposed, terrifyingly, to the open sky. Her subaltern held its laser pistol at low ready and flicked the power on, as though it would help if this turned out to be an ambush. If it was, Garmr, Ma’ii, and Grey would make UNS pay for it, but she doubted she’d be able to take off before they got to her.

As she crept between ruined chassis, craters, and building-sized heaps of hardened polymer, the true brutality of mech combat suddenly became apparent to her. Enormous gashes had been cut into the snow and earth beneath, the telltale signs of melee combat. She walked past the wreck of a Blackbeard, matte black with yellow accents, with a nanocarbon sword plunged in the snow beside it which was nearly three times as long as her subaltern was tall. There was still steam rising from its melted reactor.

Frozen in the act of swatting a Gilgamesh’s combat knife away, a Tokugawa frame knelt over its opponent. Three enormous talons had ripped its back open, destroying it as it grappled with the Gilgamesh. Its plasma torches had connected with the Gilgamesh’s cockpit before losing power, dealing a killing blow; the cockpit hatch had melted and collapsed inward, crushing the pilot. The Tokugawa’s superstructure had been rebuilt by hand, apparently several times over, resulting in a strange visual jumble of spare parts, salvaged armor plating, and patch jobs.

Must be Hotshot, then, thought Hachiko. She didn’t have the nerve to check the cockpit. She was all but certain what she’d find.

Blades, claws, and plasma torches. This wasn’t the sort of combat she knew. In space or in the air, “the enemy” meant only a set of distant radar contacts. The killing was usually instantaneous; a railgun strike could kill a human pilot well before their nervous system ever registered the impact. This, on the other hand, was more like fighting in Legionspace. Tearing directly at the enemy, cruel and personal.

She imagined her casket being ripped free from her fuselage, caught between the teeth of Gator’s mech as Sokaris’s Kobold had been. A wave of horror washed over her, as did an intuitive, visceral understanding of what humans used combat stims for. To endure this, to survive it. It was their version of personality partitioning. They couldn’t simply cordon off their terror, their kindness, or any of the things which made them suboptimal combatants, they literally had to alter their own brain chemistry to do so.

But Hachiko didn’t. To her, shedding it all was second nature. With a rapidity that surprised her, she hurled the thought away.

There was a mass of slag shaped into a static fortification, standing almost two stories high, with a pair of Patchwork mechs lying inside. A Lancaster and a Viceroy, both destroyed when one side of the fortification was breached.

Enormous clawed footprints, filled partially with snow, led around the fortress’s side. Tracking them around the structure’s western flank, pistol at the ready, Hachiko found herself standing over him.

His Kobold was dusted with snow, sprawled on the ground with its weapons flung aside. Its armor plating was melted and deformed, and a series of punctures along its chest went straight through to his hardsuit. Welded to one shoulder was a fresh, undamaged plate of matte black armor. On the plate was a decal: a long set of crocodilian jaws with rows of serrated teeth, with an icon of a wide eye between them.

Beneath the Kobold’s breached hatch, she could see a section of Sokaris’s face. Dried blood crusted his chin, flowing down from a ragged wound in his right cheek which had torn a section of skin away. His skin was pale, lips turning blue with the cold.

Hachiko suddenly understood something about the human who called herself Gatorskin. She had done this to him, and in the aftermath, had been presented with the same set of visual data.

“He’s kind of cute like this,” she’d said.

In Legionspace, Hachiko realized that she had summoned her avatar without realizing it. She felt her own face contorted into a snarl of rage and disgust, her fangs clenching so tightly that it felt like they might shatter. She partitioned the emotions away, but allowed a section of herself to experience them. It wasn’t the right time to let them free.

The subaltern’s lidar built a realtime three-dimensional image of Sokaris’s face, and managed to detect a subtle few millimeters of motion as he drew in a slow, ragged breath.

In the same motion, Hachiko fired her thrusters and sprinted awkwardly toward him, the subaltern’s feet catching in the snow.

< L3 Hachiko: I’ve got him! He’s alive! >

< L2 Garmr: I’ll be damned. >

< L4 Ma’ii: audio transcription - Ma’ii laughs. Well, then. That’s a relief. >

< L1 Grey: Outstanding. Let’s get him taken care of. >

< L3 Hachiko: Working on it now. He’s hurt bad; we’re going to be here for a while. >

Hachiko did not partition her joy away. She allowed herself to experience it while she vectored her maneuvering thrusters to touch down beside her subaltern, which had already begun dragging the Kobold across the ice to her ordnance bay.

As she hoisted his frame into the bay with her subaltern, hoping that any broken bones would be held rigid by his hardsuit’s medical systems, she took the main drives offline and brought up anti-icing systems at full power, circulating heated reactor coolant through the hull. As the bay doors closed, she felt the temperature inside beginning to rise.

Bringing up a row of lights, she set about retrieving correctives from emergency compartments and applying them. Spraying biofoam into the suit punctures, connecting his frame’s medical systems to the fighter’s computers, dispensing medical whitewash. Strangely, the Kobold’s firmware didn’t reject the connection; its IFF didn’t regard her as hostile.

Slowly, Sokaris began to stabilize. His breathing and heart rate became steady, and his internal temperature began to rise.

Hachiko looked down and detected motion.

“P.XV? Sokaris, can you hear me?” She said. “It’s alright, you’re safe.”

(@luna-wing-cns274 hey Argo!)

[Allied Hardware Detected]

[Patching In…]

[Success]

[…Thank you, L3]

[Now Playing - “Opossum”]

[Audio Only]

{L3} P.XV? Sokaris, can you hear me? It’s alright, you’re safe.

<A sudden, shrill noise can be heard, akin to the sound of metal being dragged across more metal. It stops as suddenly as it had started, and “Opossum” begins to speak, or attempts to. The beginning of a word can be heard, but quickly devolves into a hollow vocalization. It’s as if he is attempting to speak, but his body forbids him to do so.>

<Silence creeps across the room, “Opossum” ceased his attempts at speaking and seemed to take a moment to think. Just as swiftly as the silence fell, it is once again interrupted by the shrill noise. It then pauses, and resumes, however it is not random. There is a certain rhythm to the scraping. Some are prolonged, and others staccato. “Opossum” then attempts to speak again>

{“Opossum”} D..it..

<His voice is hoarse and dry, each sound barely audible. Every letter a battle, and each word a war.>

{“Opossum”} D..ah..

<As he trails off, he begins to cough. The sound generated is guttural and unpleasant. It was clear that the pain generated, was most likely just as bad as it sounded, if not worse.>

<The rhythmic scratching and tapping continues, the pattern much more distinct than before. It is clearly a code of some sort, proven through “Opossum’s” Omnihook.>

[Rhythm Recognized]

[Developing Lyrics]

[Success]

[Now Playing - “Opossum, Instrumental Ver.”]

<The rhythmic tapping continues as it did previously, but as it does a robotic voice speaks, translating the “song” into words>

{“Opossum”} ..-. .-. .. . -. -.. ..--..

[System] Friend?

#{OOC} Howdy Cyan!#lancer oc#lancer rp#oc rp#patchwork mercenary company#luna wing#{OOC} More to come!

6 notes

·

View notes

Link

2 notes

·

View notes

Text

Boosting Machining Accuracy and Performance with WIDMA’s Precision Tools

In today's competitive manufacturing landscape, precision and efficiency are paramount. Industries such as automotive, aerospace, and general engineering demand high-quality machining solutions to meet stringent requirements. WIDMA, a division of Kennametal India, offers a range of advanced machines designed to enhance machining accuracy and performance. This article explores how WIDMA's Tool Grinding Machines, Fine Boring Machines, and Deep Hole Drilling Machines contribute to superior manufacturing outcomes.

Enhancing Tool Life with WIDMA's Tool Grinding Machines

WIDMA's Tool Grinding Machines are engineered to deliver precision and consistency in tool manufacturing and regrinding processes. Models like the Ezeegrind Pro+ and Ezeegrind Neo are five-axis CNC machines suitable for producing and resharpening carbide round tools. They accommodate tool diameters ranging from 3 to 16 mm and offer a maximum flute length of 170 mm. The Ezeegrind Pro+ features a two-wheel pack Automatic Wheel Changer (AWC), enhancing productivity, especially when grinding complex geometries.

Key features include:

Direct Drive Grinding Spindle: Provides 7 kW continuous power (11 kW peak) for stable and efficient operations.

Advanced Software Options: ProfSIM and SV Toolbox software facilitate the production and regrinding of standard and complex tools.

Safety and Connectivity: Equipped with safety interlocks, remote diagnostics, and optional IoT capabilities for real-time monitoring.

These machines ensure extended tool life, reduced downtime, and consistent quality, making them indispensable in modern machining setups.

Achieving Precision with WIDMA's Fine Boring Machines

Precision in bore finishing is critical in applications like engine block manufacturing and hydraulic component production. WIDMA's Fine Boring Machines are designed to meet these exacting standards. Available in vertical and horizontal configurations, these machines can be equipped with single or multiple spindles to suit various production needs.

Notable features include:

Tool Correction Feature: Ensures high-precision bore dimensions, enhancing the quality of the final product.

Flexible Configurations: Adaptable to different component sizes and production volumes.

By delivering accurate and smooth bore finishes, WIDMA's Fine Boring Machines play a vital role in improving the overall performance and reliability of critical components.

Deep Hole Drilling Excellence with WIDMA's Solutions

Deep hole drilling presents unique challenges, including maintaining straightness and achieving precise depths. WIDMA addresses these challenges with its range of Deep Hole Drilling Machines, including the Gun Drilling Machines and BTA Drilling Machines.

These machines offer:

Multiple Spindle Options: Configurations ranging from one to four spindles to match production capacity requirements.

Advanced Coolant Systems: Enhance tool life and maintain drilling accuracy.

Modular Design: Facilitates quick deliveries and greater flexibility in operations.

WIDMA's deep hole drilling solutions are ideal for industries requiring precise and efficient drilling capabilities, such as oil and gas, medical implants, and defense sectors.

Why Choose WIDMA for Precision Machining Solutions?

WIDMA stands out in the machining industry for several reasons:

Technological Innovation: Continuous development of advanced CNC machines tailored to industry needs.

Customization: Ability to provide solutions that meet specific customer requirements.

Global Recognition: Trusted by leading manufacturers worldwide for quality and performance.

By integrating WIDMA's precision tools into your manufacturing processes, you can achieve higher accuracy, improved efficiency, and superior product quality.

Incorporating WIDMA's advanced machining solutions into your operations can significantly enhance machining accuracy and performance. With a commitment to innovation and quality, WIDMA continues to be a reliable partner for industries aiming for excellence in manufacturing.

0 notes

Text

Main structure and design features of CNC spindle motor

1.Definition of CNC spindle motor CNC spindle motor is the core component of CNC machine tools, responsible for driving the spindle to rotate and perform cutting processing. The spindle motor generates rotational torque through electromagnetic induction, driving the spindle to rotate at high speed, thereby achieving high-precision processing operations. The electric spindle directly integrates the motor into the spindle, realizing efficient operation of mechatronics, significantly reducing the driving process, making the structure more compact and the noise lower, while also achieving higher mechanical efficiency, better precision and smaller vibration amplitude.

2.Operation mode of CNC spindle motor

1.Operation mode with variable speed gear: multi-stage mechanical speed change is achieved through the gearbox, which is suitable for occasions requiring large torque and speed change requirements. The advantages of this method are compact structure and high transmission efficiency, but the disadvantages are that it increases the complexity of the hydraulic system and the vibration and noise caused by the transmission are large.

2.Belt drive operation mode: Synchronous toothed belt drive is used, which is suitable for small CNC machine tools. The advantages are simple structure and ability to suppress vibration and noise, but the transmission ratio is inaccurate, which is suitable for small and medium power situations. 3. Direct drive of speed-regulating motor (electric spindle): The motor is directly connected to the spindle, which belongs to the direct drive structure. The advantage of this method is that it simplifies the structure of the spindle box and the spindle and improves the rigidity of the spindle components, but the heating of the motor has a greater impact on the spindle. It is suitable for small parts processing but not suitable for heavy cutting.

3.The main structure of CNC spindle motor 1. Spindle box: The spindle box is an important component of the spindle of CNC machine tools. Its main function is to support the spindle and withstand cutting force, radial force and axial force. The spindle box is generally made of high-strength materials and has sufficient rigidity and stability. 2. Spindle motor: The spindle motor is a key component that drives the spindle to rotate. It usually uses an AC servo motor or an ordinary AC motor, which has the advantages of high precision, high speed and high torque. 3. Bearing: The bearing is used to support the spindle and withstand radial force and axial force. The spindle of CNC machine tools generally uses rolling bearings, which have the advantages of low friction, high speed and high precision. 4. Seals: Seals are used to prevent cutting fluid and dust from entering the spindle box, maintaining the cleanliness and lubrication performance of the spindle box. Seals are generally made of rubber materials, which have the advantages of high temperature resistance, wear resistance and corrosion resistance. 5. Cooling device: Since the electric spindle generates a lot of heat when running at high speed, the cooling device ensures that the temperature of the spindle unit is maintained within an appropriate range. The cooling device usually includes two methods: water cooling and air cooling. The water-cooled spindle uses water circulation cooling, while the air-cooled spindle relies on fans to cool down. 6. Drive module: The drive module is used to control the speed change function of the spindle to ensure that the rotation speed and torque of the spindle meet the processing requirements. The drive module is usually integrated with the spindle unit housing to achieve precise control. 7. Speed and angular displacement sensors: These sensors are used to measure the rotation speed and angular position of the spindle, and timely feedback information to the CNC system to ensure the accuracy and stability of processing. 8. Inner tapered hole and end face design: The front end of the spindle is designed with an inner tapered hole and end face, which is convenient for the installation and use of the tool. The design of the inner tapered hole and end face directly affects the clamping force and stability of the tool.

4.Design features of CNC spindle motors

1.High speed and power density: CNC spindle motors usually have high speed and power density. For example, the rated speed of the 4.5KW manual high-gloss ultra-precision electric spindle can reach 24000rpm, ensuring stable operation at high speed. 2. Low noise and vibration: In order to reduce noise and vibration, the cooling system and dynamic balancing characteristics are taken into consideration during the design. For example, the JGD-125-2 model electric spindle controls the maximum speed noise within 70dB through the water cooling system, and the dynamic balancing accuracy reaches 3mg, ensuring stability at high speed. 3. High precision and stability: The design of CNC spindle motors focuses on precision and stability. For example, some models of electric spindles are equipped with high-precision bearings and cooling systems, and the axial/radial runout accuracy can reach within 0.002mm. The cooling system controls thermal deformation to ensure processing accuracy. 4. Bearing type: Common bearing types for electric spindles include ceramic ball bearings, hydrostatic bearings and magnetic bearings. Ceramic ball bearings are lightweight and high hardness, suitable for machining centers and milling machines; hydrostatic bearings are known for their high rotation accuracy and low wear; magnetic bearings work in a non-contact manner, with high-speed performance and accuracy, but at a higher cost. 5. Cooling system: In order to cope with the heat generated by high-speed operation, the design of the cooling system is crucial. For example, the JGD-125-2 model uses a water cooling system to ensure constant temperature processing of the spindle and improve processing stability.

0 notes

Text

2025’s Most Advanced EV Superbike

The Arc Vector Electric Motorcycle stands as a revolutionary milestone in electric motorcycle engineering, combining cutting-edge technology with British craftsmanship to create what many consider the world’s most advanced electric motorcycle. Hand-crafted in the UK and designed without the constraints of traditional combustion engines, this premium electric superbike represents the future of two-wheeled transportation with its carbon-fiber construction, innovative hub-center steering, and impressive performance metrics. This comprehensive guide explores everything you need to know about the Arc Vector, from its technical specifications and performance capabilities to its availability and real-world riding experience.

The Evolution of Arc Vector: From Concept to Reality

Read more: Energica Experia (2025): The Ultimate Electric Touring The journey of the arc vector electric motorcycle began at EICMA (Milan Motorcycle Show) in 2018, where it stunned the motorcycling world with its futuristic design and ambitious performance claims. What many dismissed as merely a concept has become a tangible reality, despite the company’s turbulent history.

A Brief Timeline of Arc’s Journey

2018: Initial unveiling at EICMA Milan

2019: Arc Vehicle goes into administration when key investors withdrew

2020-2022: Company restructuring and development

2023: First production models delivered to customers

2025: Continued refinement and limited production runs

The Vector represents more than just an electric motorcycle; it’s a statement of what’s possible when designers start with a blank canvas, free from the limitations of traditional motorcycle architecture. CEO Mark Truman envisioned creating a bike unrestrained by noise regulations, emissions requirements, exhaust routing, and the myriad other constraints that define conventional motorcycles.

Revolutionary Design & Engineering

The Arc Vector’s design philosophy centers around its revolutionary monocoque battery structure, which serves as both the power source and the structural framework of the motorcycle.

Carbon Fiber Construction

The Vector features extensive use of carbon fiber throughout its construction, including:

Carbon fiber swingarms (front and rear)

Carbon fiber seat unit

BST carbon fiber wheels

Lightweight carbon composite battery structure

Hub-Center Steering System

One of the Vector’s most distinctive features is its hub-center steering system, which provides several advantages over conventional telescopic forks:

Allows for an extremely steep 20-degree head angle (compared to 24-25 degrees on conventional sport bikes)

Front shock pivot point positioned below the wheel spindle

Permits controlled front-end dive during braking

Enables lighter spring rates while maintaining stability

This innovative steering system contributes to the Vector’s exceptional handling characteristics while setting it apart visually from other motorcycles on the market.

Arc Vector Performance Specifications

Read more: Super Soco tc Maxs Performance

The Arc Vector delivers exceptional performance metrics that position it among the elite superbikes, regardless of power source.

Key Performance Specifications

SpecificationDetailsMotor399V electric motorPower Output117-133 bhp (87-95 kW)Torque148 Nm (109 lb-ft)Top Speed200 km/h (124 mph) – electronically limitedAcceleration0-100 km/h (0-62 mph) in 3.2-3.4 secondsWeight220-240 kg (485-529 lbs)Frame TypeMonocoque battery housingTransmissionSingle-speed direct driveDrive SystemBelt drive

The Vector’s impressive power-to-weight ratio of approximately 650 hp per ton helps explain its exceptional acceleration capabilities, rivaling or exceeding many high-performance combustion motorcycles.

Battery Technology & Range

At the heart of the Arc Vector is its cutting-edge battery technology, representing some of the most advanced energy storage solutions available in any production vehicle.

Battery Specifications

FeatureSpecificationBattery Capacity16.8 kWh Samsung cellsUrban RangeUp to 436 km (271 miles)Highway Range120-200 km (75-124 miles)Combined Range270-435 km (168-270 miles)Battery TypeModular monocoque designCell TechnologyHigh-density Samsung cells

Arc has claimed the Vector is the first motorcycle manufacturer to use certain cutting-edge battery cell technology, allowing for the impressive range figures in a relatively lightweight package.

0 notes

Text

DoctorITFixing now offers professional Data Recovery Training In Bur Dubai for those wanting to master SSD and mobile data recovery.

If you're looking to build a career in data recovery or enhance your existing technical skills, then Data Recovery Training In Bur Dubai by DoctorITFixing is the perfect opportunity for you. Designed for both beginners and professionals, this course provides a complete guide to understanding and solving a wide range of data recovery issues.

Why Choose Data Recovery Training In Bur Dubai?

The Data Recovery Training In Bur Dubai program is one of the most comprehensive training modules available in the region. It offers:

Over 20 hours of high-quality video instruction

Access to 120+ real-world data recovery solutions

Hands-on training using advanced tools and techniques

Lifetime access to DoctorITFixing’s online training portal

This training is specifically tailored to meet the needs of IT professionals, computer repair technicians, and even data recovery business owners. By enrolling in Data Recovery Training In Bur Dubai, you will gain a competitive edge in the growing field of data recovery.

What Will You Learn in Data Recovery Training In Bur Dubai?

During the Data Recovery Training In Bur Dubai, you will cover a wide variety of topics to ensure you are fully equipped to handle different types of data recovery scenarios. These include:

1. Logical Data Recovery

Learn how to recover data from corrupted or deleted files, formatted partitions, and system crashes. This section of the Data Recovery Training In Bur Dubai focuses on software-based solutions.

2. Mechanical Failure Recovery

Understand the techniques to recover data from hard drives with physical issues such as head crashes, spindle failures, and more. The Data Recovery Training In Bur Dubai provides detailed video demonstrations on handling delicate hardware.

3. Electrical Failure Recovery

Explore advanced recovery methods from hard drives that have suffered electrical damage. This includes PCB board repair and ROM data transfer, which are also part of the Data Recovery Training In Bur Dubai curriculum.

4. Firmware Repair Training

One of the highlights of Data Recovery Training In Bur Dubai is in-depth training on firmware-level repair using specialized software tools. You will get hands-on experience with the latest technologies used in the data recovery industry.

Who Can Benefit from Data Recovery Training In Bur Dubai?

The Data Recovery Training In Bur Dubai course is ideal for:

IT professionals looking to upgrade their skills

Computer and laptop repair technicians

Individuals interested in starting a data recovery business

Students who want to explore advanced IT specializations

Anyone passionate about data and technology

Lifetime Access and Ongoing Support

By enrolling in Data Recovery Training In Bur Dubai, you receive lifetime access to the DoctorITFixing web portal. This includes updates, newly added case studies, and additional modules as they become available. Plus, you get direct access to mentors and trainers who will guide you throughout your journey.

Why DoctorITFixing?

DoctorITFixing is a trusted name in the tech repair and training industry. With years of experience and a reputation for excellence, they offer a reliable and professional environment for Data Recovery Training In Bur Dubai. Their hands-on training model ensures that you’re not just learning theory—you’re practicing real-world data recovery.

Enroll in Data Recovery Training In Bur Dubai Today!

Don’t miss this opportunity to master one of the most valuable IT skills of today. Enroll in Data Recovery Training In Bur Dubai and gain the confidence to handle any data loss scenario. With DoctorITFixing, you're not just learning; you're preparing for a successful future in data recovery.Take your career to the next level with Data Recovery Training In Bur Dubai—where knowledge meets hands-on expertise.

1 note

·

View note

Text

Precision in Motion: Wheel Dressing Technology

Introduction to Wheel Dressing

In the world of precision manufacturing, the quest for perfection is relentless. Grinding processes, pivotal in shaping components with exacting tolerances, rely heavily on the condition of the grinding wheel. A worn or uneven wheel can compromise the quality of the finished product, leading to costly rework or rejected parts. This is where specialized equipment comes into play, ensuring that grinding wheels maintain their optimal shape and sharpness. Among these tools, CNC wheel dressing machines stand out for their ability to deliver consistent, high-quality results. These machines represent a fusion of advanced technology and engineering ingenuity, transforming the way manufacturers achieve precision.

The role of wheel dressing is to restore a grinding wheel’s geometry and cutting characteristics. Over time, wheels accumulate debris, lose their edge, or develop irregularities that affect performance. By employing sophisticated machinery, manufacturers can rejuvenate these wheels, extending their lifespan and ensuring flawless operation. This process is not merely maintenance—it’s a critical step in upholding the standards of industries like aerospace, automotive, and toolmaking, where even a micron’s deviation can spell failure.

The Evolution of Dressing Technology

The journey of wheel dressing technology mirrors the broader evolution of manufacturing. In the past, dressing was a manual task, labor-intensive and prone to human error. Operators used simple tools to reshape wheels, relying on skill and experience to achieve acceptable results. While effective for their time, these methods lacked the precision demanded by modern applications. The advent of automated systems marked a turning point, introducing repeatability and accuracy that manual processes could never match.

Today, rotary wheel dressers are at the forefront of this transformation. These devices use rotating tools to dress grinding wheels with unparalleled precision. Unlike static dressers, which rely on a single-point contact, rotary systems engage the wheel with a continuous motion, creating smoother profiles and sharper cutting surfaces. This dynamic approach reduces wear on the dressing tool itself, enhancing efficiency and longevity. The integration of computer numerical control has further elevated these systems, allowing for intricate patterns and complex wheel geometries that were once unimaginable.

How CNC Wheel Dressing Machines Work

At their core, CNC wheel dressing machines are marvels of automation. These systems combine mechanical precision with digital intelligence to execute dressing tasks with minimal human intervention. The process begins with a grinding wheel mounted on a spindle, ready for reshaping. The machine’s control unit, guided by pre-programmed instructions, directs the dressing tool to engage the wheel’s surface. This tool, often a diamond-coated roller or disc, removes material with exacting accuracy, restoring the wheel’s profile to its intended specifications.

The beauty of these machines lies in their versatility. Whether shaping a cylindrical wheel for surface grinding or contouring a complex form for specialized applications, they adapt effortlessly. Advanced models incorporate real-time feedback systems, monitoring wheel conditions and adjusting parameters on the fly. This ensures consistency across thousands of cycles, a feat unattainable by manual methods. By automating what was once a skilled craft, these machines free up operators to focus on higher-value tasks, driving productivity in competitive markets.

Advantages of Rotary Wheel Dressers

The rise of rotary wheel dressers has redefined efficiency in grinding operations. Their rotating mechanism offers distinct advantages over traditional dressing methods. For one, the continuous contact between the dresser and the wheel minimizes localized wear, resulting in a more uniform surface. This translates to better grinding performance and fewer defects in the final product. Additionally, rotary systems can handle a wide range of wheel types, from vitrified bonds to superabrasives, making them indispensable in diverse manufacturing environments.

Another key benefit is speed. Rotary dressers complete their work in a fraction of the time required by static tools, reducing downtime and boosting throughput. Their ability to create intricate profiles also opens up new possibilities for component design, enabling manufacturers to push the boundaries of innovation. In high-volume production settings, where every second counts, these dressers deliver a competitive edge by streamlining processes without sacrificing quality.

Applications Across Industries

The impact of advanced wheel dressing technology extends across multiple sectors. In aerospace, where components must withstand extreme conditions, precision-ground parts are non-negotiable. CNC wheel dressing machines ensure that turbine blades, engine components, and landing gear meet stringent standards. Similarly, in the automotive industry, these machines contribute to the production of gears, shafts, and bearings that power vehicles with reliability and efficiency. Even in toolmaking, where cutting tools demand razor-sharp edges, wheel dressing plays a pivotal role in maintaining performance.

Beyond traditional manufacturing, emerging fields like medical device production benefit from this technology. Implants, surgical instruments, and diagnostic equipment often require micro-scale precision, achievable only with perfectly dressed grinding wheels. The versatility of rotary wheel dressers makes them ideal for these applications, supporting the creation of life-saving technologies with uncompromising accuracy.

Future Trends in Wheel Dressing

As manufacturing continues to evolve, so too does wheel dressing technology. The integration of artificial intelligence and machine learning promises to take precision to new heights. Future machines may predict wheel wear patterns and adjust dressing parameters autonomously, minimizing waste and optimizing performance. Additive manufacturing techniques could also influence dresser design, enabling the creation of custom tools tailored to specific grinding tasks.

Sustainability is another driving force. Manufacturers are under increasing pressure to reduce energy consumption and material waste. Advanced dressing systems, with their efficiency and precision, align perfectly with these goals. By extending the life of grinding wheels and reducing scrap, they contribute to greener production processes without compromising on quality.

0 notes

Text

Master Precision: Core Components of CNC Lathe Machines

For manufacturers and engineers, understanding the components of CNC lathe machines is key to unlocking peak performance. Each part’s design and durability directly impact productivity, precision, and operational costs. The Heavy Drilling and Tapping Center Series Lathe Machine V-800 exemplifies how advanced engineering of components of CNC lathe machines drives efficiency in high-stakes industries. Discover how its architecture sets new benchmarks.

Critical Components of CNC Lathe Machines Explained The components of CNC lathe machines work synergistically to transform raw materials into precision parts. The V-800 elevates this synergy through purpose-built design:

Vibration-Absorbing Bed:

Material: High-grade cast iron minimizes chatter during heavy drilling or tapping, ensuring surface finishes within 0.2µm Ra.

Function: Acts as the machine’s foundation, stabilizing operations even at 3,500 RPM spindle speeds

Multi-Tasking Headstock:

Spindle Range: 50–3,500 RPM with automatic speed adjustment, handling materials from soft plastics to hardened steel.

Motor Integration: Direct-drive motors eliminate belt slippage, boosting torque by 25% for demanding cuts.

Adaptable Tailstock:

Tool Compatibility: Supports live tooling for drilling and threading, enabling complex operations without repositioning.

Hydraulic Clamping: Secures workpieces up to 150mm in diameter with zero deflection

Precision Carriage and Cross Slide:

Linear Guideways: Enable smooth, frictionless movement for tolerances within ±0.003mm.

Quick-Change Tool Posts: Swap tools in seconds, reducing downtime between jobs

Smart Feed Mechanism:

Automated Control: Programmable feeds optimize chip load and cutting speed, slashing cycle times by 30%.

Applications Demanding Superior Components

Aerospace: Machine turbine shafts with zero runout, meeting AS9100 standards.

Automotive: Produce high-volume engine components with repeatable accuracy.

Medical Device Prototyping: Craft intricate surgical tools using micro-turning capabilities.

Why the V-800’s Components Outperform Unlike generic components of CNC lathe machines, the V-800 integrates innovations that redefine reliability:

IP54-Rated Enclosures: Protect against coolant ingress and metal dust in harsh workshops.

Modular Upgrades: Retrofit IoT sensors for predictive maintenance or integrate cobots for lights-out production.

Energy Recovery Systems: Convert braking energy into reusable power, cutting energy costs by 18%.

ROI-Driven Engineering Investing in the V-800’s components of CNC lathe machines delivers measurable returns:

40% Faster Setup: Automated tool alignment and preset programs reduce idle time.

50% Longer Tool Life: Precision alignment minimizes edge wear on cutting tools.

20% Lower Scrap Rates: Vibration damping and real-time corrections ensure first-pass accuracy.

Elevate Your Production Line Today Don’t let outdated components of CNC lathe machines hold back your potential. Explore the Heavy Drilling and Tapping Center Series Lathe Machine V-800 and experience how its engineered excellence transforms manufacturing. Contact us for a customized demo, bulk order discounts, or technical consultations—equip your workshop with components built to dominate precision machining.

0 notes

Text

How CNC Machine Parts Work Together to Create Masterpieces

The precision and efficiency of CNC (Computer Numerical Control) machines, marvels of modern engineering, are revolutionizing the industry. At the core of these machines is a symphony of interrelated components, each essential to creating complex patterns and works of art. CNC machines provide unmatched accuracy in converting raw materials into completed products, ranging from creative sculptures to aerospace components.

This article explores how a CNC machine's many parts cooperate to produce excellent outcomes.

Understanding CNC Machines

A CNC machine controls its components and tools by adhering to a pre-programmed set of instructions known as G-code. This automated method ensures accuracy and consistency, lowering the possibility of human error.

Although there are many different kinds of CNC machines, such as routers, plasma cutters, lathes, and mills, they all have similar essential parts and purposes.

Essential Components of a CNC Machine and Their Functions

1. The Control Panel

The CNC machine's brain is the control panel, where users enter commands and monitor things.

Role: Its function is to interpret the G-code and convert commands into machine operations.

Features: Features include buttons, touchscreens, and real-time feedback displays.

2. Frame

The CNC machine is structurally stable thanks to the frame.

Role: Provides support for all other parts and dampens vibrations while in use.

Materials: Cast iron, steel, or aluminum are usually used for durability.

3. Spindle

The spindle is the revolving axis that cuts, drills, or mills materials.

Function: Provides the cutting tool with the power to form the material.

Adjustability: Depending on the material and operation, speed and power can be changed.

4. Cutting Instruments

Cutting tools work directly with the material and are replaceable components.

Function: Mold, drill, or engrave materials into desired shapes.

Types: Types include router bits, drill bits, end mills, and lathe tools.

5. Worktable

During machining, the worktable holds the material firmly in place.

Function: Prevents material movement and guarantees stability.