#Disperse Dyes manufacturer

Text

RK Industries |Disperse Dye Manufacturers for Various Needs

RK Industries is a manufacturer of Disperse Dyes for their high quality, innovative solutions for various industrial applications, ensuring quality & reliability

#Disperse Dyes manufacturer#Disperse Dyes supplier#Disperse Dyes supplier in vadodara#Best Disperse Dyes#top Disperse Dye#Disperse Dyes manufacturer in India#Vietnam#Brazil

0 notes

Text

How Disperse Dyes Manufacturers are Shaping the Textile Industry in 2024?

In 2024, the textile industry is undergoing a profound transformation, propelled by innovations in dyeing technology. Disperse dye manufacturers play a pivotal role in this evolution, shaping the way fabrics are colored and enhancing the efficiency and sustainability of textile production processes.

The Rise of Disperse Dyes

Disperse dyes have gained significant traction in the textile industry due to their ability to color synthetic fibers effectively. Unlike traditional dyes that are designed for natural fibers like cotton or wool, disperse dyes are formulated specifically for polyester, nylon, and other synthetic materials. This specialization has fueled their adoption in a wide range of applications, from apparel and home textiles to automotive upholstery and technical fabrics.

Key Advantages of Disperse Dyes

Vibrant Colors: Disperse dyes offer a vibrant and long-lasting color palette, allowing textile manufacturers to create eye-catching designs and patterns that resonate with consumers.

Durability: These dyes are known for their excellent color fastness, ensuring that fabrics maintain their appearance even after repeated washings or exposure to sunlight.

Versatility: Disperse dyes can be applied using various dyeing techniques, including exhaust, pad, and printing methods, making them versatile for different production processes.

Environmental Sustainability: Manufacturers are increasingly focusing on eco-friendly dyeing solutions, and disperse dyes are playing a crucial role in reducing water consumption, energy usage, and chemical waste in textile manufacturing.

Technological Innovations

The landscape of disperse dyes manufacturing has evolved significantly in recent years, driven by advancements in chemical engineering and process optimization. Key innovations include:

Nano-dispersion Technology: This cutting-edge approach enables the creation of ultra-fine dye particles, resulting in improved color penetration and uniformity on synthetic fibers.

Low-Temperature Dyeing: Manufacturers are developing dyes that can be applied at lower temperatures, reducing energy consumption and environmental impact during the dyeing process.

Digital Printing: Disperse dyes are compatible with digital printing technologies, allowing for precise and customizable color application, even on complex fabric designs.

Market Impact

The demand for disperse dyes is on the rise, driven by factors such as:

Fashion Trends: Consumers are increasingly drawn to vibrant, color-rich textiles, driving the need for advanced dyeing solutions that can meet evolving design preferences.

Technical Textiles: Industries like automotive, aerospace, and healthcare rely on technical textiles that require specialized dyeing techniques, where disperse dyes excel.

Sustainability Initiatives: Textile manufacturers are aligning with sustainability goals, opting for dyes that minimize environmental impact without compromising on color quality.

Future Outlook

As we look ahead, the role of disperse dyes manufacturers will continue to be pivotal in shaping the textile industry. Anticipated developments include:

Bio-based Dyes: Research is underway to develop bio-based disperse dyes derived from renewable sources, further enhancing the sustainability profile of textile dyeing processes.

Smart Dyeing Solutions: Integration of smart technologies like IoT sensors and data analytics in dyeing equipment to optimize dye usage, reduce waste, and enhance color consistency.

Regulatory Compliance: Manufacturers are proactively addressing regulatory requirements related to chemical usage, ensuring that disperse dyes remain compliant with global standards.

Conclusion

In conclusion, disperse dyes manufacturers are at the forefront of innovation in the textile industry, driving advancements in color technology, sustainability, and performance. Their contributions are instrumental in meeting the demands of a dynamic market landscape while paving the way for a more sustainable and vibrant future for textiles.

0 notes

Text

SOLVENT DYE- CHEMWORLD INTERNATIONAL

Solvent dye is soluble in an organic solvent, mainly used to impart color to different products, including solvents, waxes, and plastics. Hydrocarbon fuels and lubricants are some other leading applications of solvent dyes.

In addition, there are solvent dyes explicitly meant for use in fuels. These dyes are insoluble in water. These solvent-soluble dyes are widely used across the coating and ink industry. Chemicals that can easily dissolve in other chemicals and form a solution are called solvents. They cannot, however, be dissolved in water. These dyes are completely soluble in organic solvents, which means they will not form a separate layer or residue. The ability of the dye to completely dissolve is important to achieve a consistent color.

https://www.chemworldintl.com/

In addition, there are solvent dyes explicitly meant for use in fuels. These dyes are insoluble in water. These solvent-soluble dyes are widely used across the coating and ink industry. Chemicals that can easily dissolve in other chemicals and form a solution are called solvents. They cannot, however, be dissolved in water. These dyes are completely soluble in organic solvents, which means they will not form a separate layer or residue. The ability of the dye to completely dissolve is important to achieve a consistent color.

#acid dyes manufacturers usa#reactive dyes suppliers#solvent dyes manufacturers#basic dyes manufacturer#dye manufacturers usa#direct dyes manufacturers#disperse dyes suppliers#plastic dye manufacturers in USA

0 notes

Text

Dye, doll, dye

I did a dyeing thing - a white Resinsoul centaur (Dawn) and different vinyl shell parts of an Obitsu 50 cm body (whitey and super whitey).

What I used:

A big shiny pot. Life pro tip - if you have an induction cooktop, check your crappy pot that you ordered from Amazon right away. Amazon sellers are liars.

Lots of towels (water everywhere). Dye (RIT DyeMore is what I used, because it's specifically for synthetics), isopropyl (rubbing) alcohol and a melamine sponge (Magic Eraser) for oopsies, and weed whacker trimmer string for the parts. Plus coffee.

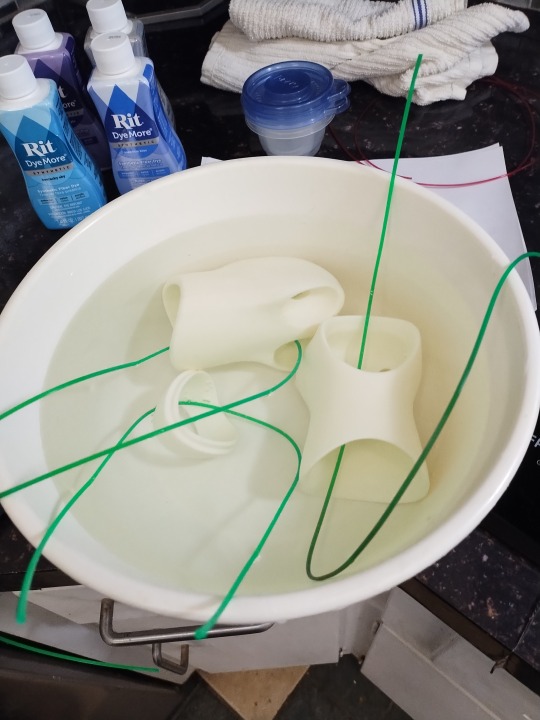

Strung doll parts. NOTE: before I dye resin or vinyl, I soak it in cold water for 10-15 minutes. Resin is porous. Water will help open the pores for a slightly more even dye distribution.

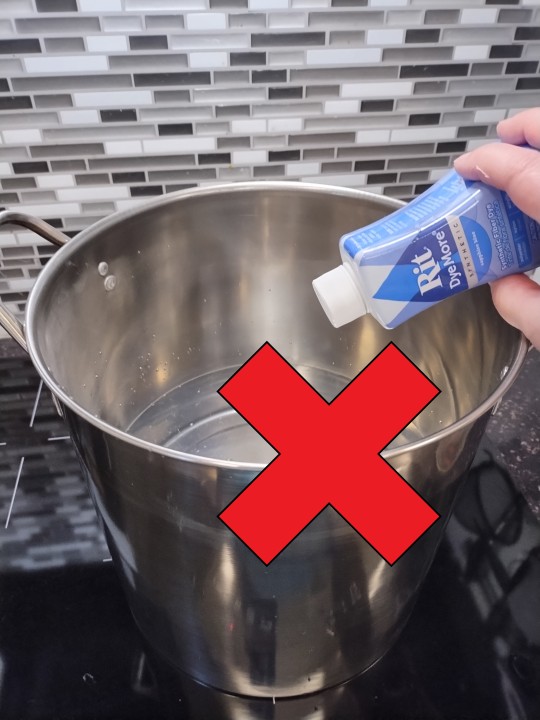

So one thing I see over and over that drives me CRAZY is people dumping the whole bottle of dye directly into the water.

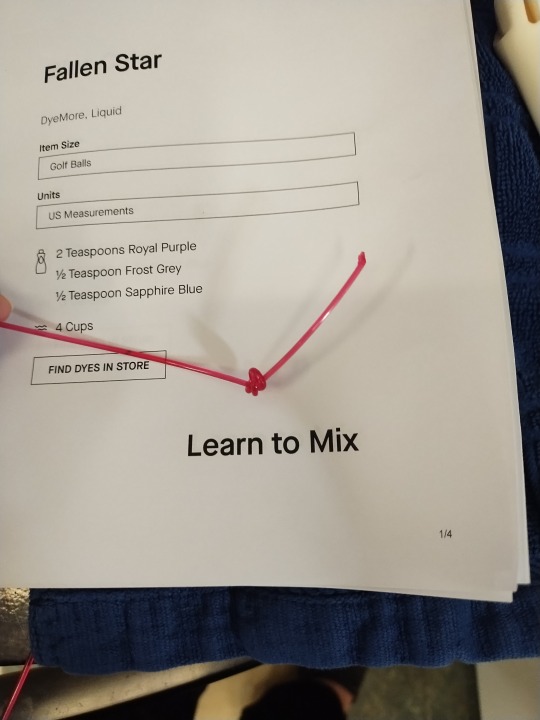

RIT has recipes. Here's the recipe for Fallen Star using "small" items:

It doesn't matter which small item you pick - the recipe is the same. For a more intense color, increase the amount of dye (Fallen Star is 2 teaspoons of Royal Purple, 1/2 teaspoon Frost Grey, 1/2 teaspoon Sapphire Blue per 4 cups of water). If you dump in the whole bottle, 1) you're wasting dye, and 2) you're not going to get the color that the dye is supposed to produce.

Dye measured - and then I measure one more batch in a separate cup. As stuff goes in the water, dye is absorbed and removed from the water - so you gotta add a little back. Like, an eyedropper at a time, a little.

I set the water to be just under a boil - no bubbling, but still painful when you accidentally stick a finger in there. It's soapy because RIT recommends adding a tiny bit of dish soap and a little salt to the dye bath to help disperse the color evenly.

Dunk:

The resin parts got 3 minutes each. The vinyl parts got 6 minutes.

Horse butt magnet came unglued, and there's something on the butt that prevented it from absorbing dye. I don't know what it is. I'll have to color correct with pastels. Also: the horse body was cast in two parts that were glued together, and the seams sanded. This became immediately apparent post-dye.

The floating blobs top left are vinyl thigh parts after 3 minutes in the dye bath. The darker blue human parts of vinyl parts after a six minute bath.

A few more things: whatever that butt glue was, it liquified in the pot and stuck to stuff. I am not happy about this.

Because parts are thinner in some places and thicker in others, when I pulled a part out of the bath, I would run it under cool water. Then I grabbed my melamine sponge and scrubbed areas where the dye was darker or absorbed funny. Isopropyl alcohol can also help remove some of the dye.

The dye continued to process, even after I rinsed all the parts. When I woke up the next morning, everything was an even more intense blue - especially the vinyl.

My self-imposed max time for resin in a hot water dye bath is 3 minutes. 2-part epoxy resin reacts quickly and hardens to equilibrium - NOT completion. When resin parts are put into almost-boiling hot water, the reaction is reactivated. The resin parts will shrink. I read on a resin manufacturer's website that after 20 minutes, the resin will become extremely brittle and fragile. From past experience, I know that 3 minutes in hot water is enough to make a resin part shrink.

Since the resin parts were dyed for 3 minutes each, this means I will NOT be attempting a gradation with dye. I'll use pastels instead.

But vinyl, however - vinyl can take some heat. Heh heh heh.

Next up: purple!

60 notes

·

View notes

Text

New polymerization approach could transform the manufacturing of specialty plastics

Researchers in Carnegie Mellon University's Department of Chemistry have improved a popular technology used to generate a range of industrial plastics for applications ranging from paints and coatings to adhesives and sealants.

Using environmentally-friendly reaction conditions, including running the reaction in water with light and a water-soluble dye, the novel method offers a promising approach for creating polymers in a greener and more practical way during the emulsion polymerization process.

In a commercial setting, emulsion polymerization is one of the least expensive ways of making a range of useful polymers. The process is limited, however, because scientists cannot precisely control the molecular weight and dispersity of the resulting polymers. And controlling the polymer structure is key to making specialty polymers that have very specific features.

Read more.

#Materials Science#Science#Polymerization#Polymers#Materials processing#Plastics#Carnegie Mellon#Infrared

13 notes

·

View notes

Text

What Products can the Vacuum Homogeneous Emulsifier Produce?

The vacuum homogeneous emulsifier is a kind of cosmetic equipment, but due to the development of science, the production technology has been continuously innovated. The vacuum homogeneous emulsifier is not only used in the cosmetics industry, but also in many industrial production fields. Let’s follow the editor of YeKeey, a professional emulsifying machine manufacturer to see what products can be produced by the vacuum homogeneous emulsifier.

Vacuum Homogeneous Emulsifier Application

From the scope of application, the emulsifier can be used in a wide range of liquid products. For products with low viscosity, the emulsifier can handle them easily, and you don’t even need to turn on the homogenization function. You only need to mix, and even two-way mixing is sometimes a bit wasteful. To be precise, it is a bit overkill, and the price of the emulsifier is not cheap, and there is no need to use such a piece of good equipment. Ordinary stainless steel mixing tanks can be used for products such as lotion. But for products with a certain viscosity, it can only be produced by a vacuum homogeneous emulsifier.

The emulsifying machine

widely used in producing food sauces

Food sauces, such as salad dressing, mayonnaise, custard sauce, etc. The function of the emulsification tank of vacuum emulsification equipment is to dissolve one or more food materials in another liquid phase and make the combination into a relatively stable emulsion. Therefore, it is widely used in the emulsification and mixing of edible oils, powders, sugars, and other raw and auxiliary materials.

The emulsifier in the chemical industry

In the chemical industry, some ink coatings, paint emulsification, and dispersion also use vacuum emulsification tanks, especially suitable for mixing and emulsifying some insoluble colloidal additives CMC and other raw materials. The emulsifier is ideal for producing cosmetics, medicine, food, chemical dyeing, printing, ink, and other industrial products. It is more effective, especially for the emulsification of materials with high matrix viscosity and relatively high powder content.

High-shear vacuum homogenizing emulsifiers are widely used in the field of cosmetics

In the field of cosmetics, high-shear vacuum homogenizing emulsifiers are widely used in cosmetic creams, shampoos, shower gels, sunscreens, and other cream products. The emulsifier performs high-speed shearing, dispersion, and impact on the material through the high-speed rotation of the homogenizing head connected to the engine. In this way, the material will become more delicate and promote the fusion of oil and water. The material will be mixed with air during the production process, which will cause the product to become air-bubbled, bacterially polluted, easily oxidized and the appearance is not smooth. This situation will not occur when using a vacuum emulsifying machine.

It will disperse and emulsify evenly in a vacuum state, and air bubbles are no longer mixed in the process of production and mixing, so it can ensure the cream is delicate and stable.

Yekeey

YeKeey vacuum homogeneous emulsifier is easy to operate, has stable performance, good homogeneity, and high production efficiency. Moreover, this equipment also has the characteristics of convenient cleaning, reasonable structure, and a high degree of automation. YeKeey can also provide customers with the service of sending materials to the factory for test machines. If you have a demand for a vacuum homogeneous emulsifier, please consult YeKeey.

2 notes

·

View notes

Text

Black Masterbatches: Importance and Benefits for the Plastic Industry

In this industrial blog, we will emphasize a plastic industry-centric important product, black Masterbatch, and the role of black masterbatch manufacturer in Ahmedabad.

Before we move forward, it makes sense to learn about a few relevant things, including masterbatches and additives. This move will help you understand the product better. At the same time, general readers will get to know the product in simple language.

Understanding masterbatches

Right from morning till we go to bed, we come across a wide range of plastic-made items and objects, including pipes, water bottles, dust bins, lunch boxes, chairs, CDs, and many more. It isn't the glorification if we say life can’t be imagined without plastic. Containers come in numerous attractive colours. How does that happen? Here comes the role of a masterbatch. Masterbatch is an additive that imparts colour to products and a host of other properties. Black masterbatch manufacturer in Ahmedabad are using the latest technology to manufacture a variety of black masterbatches.

A mixture comprising pigments and additives is heated together. This mixture acts as a carrier polymer. Afterward, this raisin is left to cool and cut into small pieces called granules. These granules are responsible to impart different types of colours and a host of significant properties.

From basics, let’s now move towards the main subject, Black Masterbatches.

Learning about the Black Masterbatches

These types of masterbatches are typically high concentrations of carbon black, ranging between 15-50%. It is dispersed in thermoplastic resins. The thermoplastic resin is acting as a carrier or binder. There are a few other commonly used pigments, including nigrosine dye and bone black.

This product is manufactured with up to 50% of carbon black content in its composition. Therefore, it becomes eligible for use as black pigment in many plastic applications. In this regard, you can connect with a leading black masterbatch supplier.

Salient features

The product is famous for numerous salient features and properties, including:

High Jets

UV Stability

Uniform Dispersion

High-Temperature Resistance

No Issues of bleed or bloom

Ease of processibility

For further details, you can get in touch with the masterbatch supplier in Ahmedabad.

Applications of the product

The business-centric product has found many applications in plastic-based industries. These include Pipes and Film Extrusion, Rotomolded Tank Molding, HDPE Pipes and extrusion, Geo Membranes, Non-Woven Bags, Drip Irrigation, For High Jet, Gloss film, UV sensitive, Geo Textiles, Laterals, Mulch Film, Tarpaulin, Laminations, Thin Film, Molding, Economical glade for injection molding and thick film, PP fiber grade for Multifilament and Mono-Filament, Furthermore, the industry-centric product is useful in a host of other industries, including, electronics, wire, and cable, etc.

Industries

Coming to the industries wherein the brilliant business-centric product is used, it is used namely in:

Building & construction

Agriculture

Automotive

Packaging

In addition to the above major industries, the product is used in many other industries. You are advised to get in touch with a prominent black masterbatch manufacturer in Ahmedabad

Customization

The black masterbatch is available in more than 100 shades to choose from. In addition, a few famous and established masterbatch manufacturers and suppliers in India offer customized solutions. In case, you are looking for customized solutions, connect with Sumiran Masterbatches.

Connect with Sumiran Masterbatches

Are you into the plastic industry? Are you looking for a leading masterbatch manufacturer in Ahmedabad? If your answer to these two questions is yes, then join Hands with Sumiran Masterbatches. The professionally managed company is a leading manufacturer and supplier of a wide range of masterbatches, including White Masterbatch, Black Masterbatch, Colour Masterbatch, and Additive Masterbatches among others.

#black masterbatch manufacturer in ahmedabad#black masterbatch supplier#.Masterbatch supplier#Masterbatch supplier

2 notes

·

View notes

Text

Discover Premium Pigments for Paints

Welcome to Aron Universal, your trusted partner in providing top-quality pigments for industrial and specialty paints. Our pigments are the cornerstone of vibrant, long-lasting, and visually stunning finishes, catering to both professional painters and artists alike. Whether you're working on a large industrial project or a creative masterpiece, Aron Universal has the perfect pigments to meet your needs.

Why Choose Aron Universal Pigments?

At Aron Universal, we pride ourselves on delivering pigments that offer brilliant colors and ensure consistent performance. Our pigments are carefully formulated to disperse evenly in paints, providing a smooth and uniform finish every time. With our pigments, you can trust that your work will stand out, boasting rich colors and superior quality.

The Magic of Fluorescent Pigments

One of the standout features of Aron Universal pigments is our range of fluorescent pigments. These unique colorants add a vibrant glow to your projects, making them truly eye-catching. Whether you're looking to create striking artwork or want to add a pop of color to your interiors, our fluorescent pigments are the perfect solution. They bring an extra dimension of brilliance and luminosity, ensuring your work leaves a lasting impression.

Customized Pigment Solutions for Unique Projects

Every project is unique, and at Aron Universal, we understand the importance of finding the right pigment for your specific needs. That’s why we offer customized solutions tailored to your project requirements. Our expert team is always ready to assist you in selecting the ideal pigments and provide technical support to ensure you achieve the best results.

Understanding the Difference Between Pigments and Dyes

When choosing colorants for your projects, it’s essential to understand the difference between pigments and dyes. Pigments are fine particles, either natural or synthetic, that are insoluble in the medium they are mixed with. They provide color and opacity to paints and coatings, creating distinct hues and effects. Unlike dyes, which are soluble and typically provide translucent colors, pigments offer greater coverage and durability, making them ideal for paint applications.

Selecting the Right Pigments for Paints

Choosing the right pigment for your paint formulation can be challenging, given the wide variety of options available. Here’s how to select the perfect pigment:

1. Explore Pigment Families: Understand the different types of pigments available, including organic, inorganic, and hybrid pigments. Each offers unique properties, influencing color, opacity, and stability.

2. Consider Key Properties: Ensure the pigments provide the desired hue and opacity for your paint. Check their compatibility with other components like binders and solvents and assess their stability against environmental factors.

3. Select the Ideal Product: Match the pigments with your formulation needs, considering factors like color strength, durability, and application ease. Always consult technical data and expert advice to make informed decisions.

Why Aron Universal?

Quality is at the heart of our manufacturing process. We adhere to strict quality control standards, ensuring that our pigments deliver dependable, high-quality results for all your coating needs. With Aron Universal, you can elevate your projects with pigments that not only enhance visual appeal but also ensure long-lasting performance.

Get in Touch with Aron Universal Today

Enhance your paint and coating projects with Aron Universal's exceptional pigments. Whether you’re seeking the vibrant glow of fluorescent pigments or the reliable performance of our standard pigments, we have the solutions you need. Contact us today t

0 notes

Text

Nail Polish: A Colorful Evolution The History and Science Behind Modern Nail enamel

Early Origins and Nail Polish

While nail enamel in its modern form was a 20th century development, the practice of decorating fingernails and toenails dates back thousands of years. Some of the earliest nail treatments and colorings were discovered in ancient Egypt, where both men and women regularly stained or painted their nails as a symbol of social status. Wealthy Egyptians would use kohl or henna to darken their nails, while poorer citizens were restricted from the practice. These early polishes were crude, often consisting of plant-based dyes mixed with oils or waxes to adhere to the nail plate.

In Medieval Europe, red nail enamel made from crushed insects and fish scales became a popular aristocratic trend. However, the invention of synthetic dyes and new formulations revolutionized nail treatments in the late 1800s. In the late Victorian era, long, pointed, almond-shaped nails known as "spoon nails" became fashionable, and colorings grew more complex. By the early 20th century, specialized nail enamel was commercially produced and marketed directly to consumers as a beauty product. This marked a turning point where nail paint became widely available to the general public rather than a rare, conspicuous luxury.

Formulation Nail Polish

Early commercial nail enameles were oil-based formulas that stained the Nail Polish but lacked staying power. They had strong, unpleasant odors and caused damage when removed. A major advancement came in the 1930s with the invention of modern synthetic organic polymers that gave nail enamel its characteristic glossy shine and long-lasting application. The development of cellulose-based formulas allowed for thinner, drying polishes that adhered better without cracking or smudging. Polymers also enabled new tones and color effects that expanded options beyond traditional reds and light pinks.

By the mid-20th century, advancements continued with the introduction of formaldehyde resin formulas. These provided better wear and facilitated easy removal without damage. Formulations also grew more refined, incorporating moisturizing and strengthening ingredients to improve nail health. The emergence of creative packaging and brush designs made application easier and more precise. The 1950s mark the modern nail enamel era, with a wide range of saturated hues and finishes available to the masses at affordable prices. Technology progressed further in later decades, giving rise to chip-resistant, long-wear varieties suitable for modern lifestyles.

Modern Components and Manufacturing

Today's nail enameles are emulsion-based liquid suspensions containing insoluble polymer pigments dispersed in a film-forming solution. Key components include:

- Film formers (cellulose derivatives, formaldehyde resins) that dry to a flexible, durable coating protecting the nail.

- plasticizers and moisturizers like glycols that keep the polish flexible and prevent chipping.

- Solvents like water, ethanol or acetone to dissolve polymer formulas and adjust viscosity.

- Pigments like iron oxides, chromium oxides or calcium aluminum borosilicate spheres that provide rich, long-lasting colors.

- Preservatives like formaldehyde or formaldehyde releasers to prevent microbial growth.

manufacturing involves meticulously blending proprietary polymer formulations with precisely controlled pigment dispersions and solutions. State-of-the-art milling techniques ensure homogenous mixtures down to nano scales for maximum luster, opacity and uniformity. Automated filling lines quickly and hygienically transfer finished polishes into bottles or convenient pen-style applicators for the global market. Quality control labs rigorously monitor each batch to maintain consistent performance and aesthetics.

Get more insights on Nail Polish

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#Nail Polish#Manicure#Nail Care#Nail Lacquer#Nail Art#Nail Colors#Gel Polish#Nail Varnish#Nail Trends#Beauty Products#Nail Enamel

0 notes

Text

C.O. Citric Acid: Understanding Organic Citric Acid

Organic citric acid, often abbreviated as C.O. citric acid, is a versatile and widely used natural compound known for its acidic properties and various applications in food, beverages, cosmetics, and household products. This guide explores the origins, uses, benefits, and considerations of organic citric acid, emphasizing its role as a natural alternative in modern lifestyles.

What is Organic Citric Acid?

Definition and Properties

Citric acid is a weak organic acid found naturally in citrus fruits such as lemons, limes, oranges, and grapefruits. It is widely used as a flavoring agent, preservative, and acidulant in food and beverage industry due to its tart flavor and pH-regulating properties. Organic citric acid is produced through fermentation of organic sources, ensuring it meets organic standards and avoids synthetic additives or genetically modified organisms (GMOs).

Production Process

Organic citric acid is typically produced by fermenting sugars from organic sources such as cane sugar or molasses with the use of a specific mold, Aspergillus niger. This fermentation process yields citric acid in its pure form, which is then purified and crystallized for various industrial and commercial applications.

Applications of Organic Citric Acid

Food and Beverage Industry

Flavor Enhancer

Organic citric acid is commonly used as a flavor enhancer and acidulant in food and beverages, providing a tart and refreshing taste. It is used in carbonated drinks, fruit juices, candies, jams, sauces, and preserves to balance sweetness and acidity.

Preservative

Due to its antimicrobial properties, organic citric acid acts as a natural preservative in food products, extending shelf life and preventing spoilage. It inhibits the growth of bacteria and molds, enhancing food safety and maintaining freshness.

Cosmetic and Personal Care Products

pH Adjuster

In cosmetics and personal care products, organic citric acid is used as a pH adjuster to maintain the acidity or alkalinity of formulations. It helps stabilize the pH level of skincare products such as creams, lotions, exfoliants, and masks, ensuring optimal efficacy and compatibility with skin.

Chelating Agent

Organic citric acid also functions as a chelating agent, binding to minerals and metals in water-based formulations to improve stability and prevent oxidation. It enhances the effectiveness of preservatives and antioxidants, prolonging the shelf life of cosmetic products.

Household Cleaners

Cleaning Agent

In household cleaners and detergents, organic citric acid acts as a cleaning agent and water softener, effectively removing stains, limescale, and soap scum. It is used in dishwashing liquids, surface cleaners, toilet bowl cleaners, and laundry detergents for its non-toxic and biodegradable properties.

Pharmaceutical and Industrial Applications

Medical Uses

Organic citric acid is utilized in pharmaceutical preparations and medical products as an excipient or buffering agent. It is used in tablets, syrups, and effervescent formulations to improve taste, enhance solubility, and regulate pH levels.

Industrial Uses

In industrial applications, organic citric acid serves as a dispersing agent, binder, and emulsifier in manufacturing processes. It is employed in textile dyeing, metal cleaning, and industrial fermentation to facilitate chemical reactions and enhance product quality.

Health Benefits of Organic Citric Acid

Antioxidant Properties

Citric acid exhibits antioxidant properties, scavenging free radicals and reducing oxidative stress in the body. Antioxidants help protect cells from damage, support immune function, and promote overall health and well-being.

Digestive Aid

Consuming organic citric acid in moderate amounts can stimulate digestive enzymes and gastric acid production, aiding in digestion and nutrient absorption. It may alleviate symptoms of indigestion, bloating, and discomfort after meals.

Alkalizing Effect

Despite its acidic nature, organic citric acid has an alkalizing effect on the body when metabolized. It helps balance pH levels and maintain alkalinity, which is essential for cellular function and metabolic processes.

Considerations for Choosing Organic Citric Acid

Organic Certification

Ensure that organic citric acid products are certified by reputable organic certifying bodies such as USDA Organic or equivalent standards in your region. Certification guarantees that the product has been produced according to organic farming practices and meets stringent quality and purity criteria.

Non-GMO and Allergen-Free

Verify that organic citric acid is derived from non-GMO sources and free from allergens such as gluten, soy, and dairy. This ensures product safety and compatibility with dietary preferences and restrictions.

Sustainability and Environmental Impact

Organic citric acid production supports sustainable agriculture practices that prioritize soil health, biodiversity, and resource conservation. Choosing organic options promotes eco-friendly alternatives to conventional chemical processes.

Practical Tips for Using Organic Citric Acid

Culinary Uses

Add a pinch of organic citric acid powder to recipes as a natural flavor enhancer for soups, sauces, marinades, and beverages. It provides a tangy flavor similar to fresh citrus juice without adding liquid volume.

Cleaning Solutions

Create eco-friendly cleaning solutions by mixing organic citric acid with water and essential oils. Use the solution to clean kitchen countertops, sinks, glass surfaces, and appliances for a streak-free shine.

Skincare Applications

Incorporate organic citric acid into homemade skincare formulations such as facial toners, exfoliating scrubs, and bath soaks. Dilute it with water or floral hydrosols to adjust pH and enhance skin clarity and brightness.

Conclusion

Organic citric acid, derived from natural fermentation processes, offers a versatile and sustainable alternative for various applications in food, beverages, cosmetics, household products, pharmaceuticals, and industrial processes. Its acidic properties, antioxidant benefits, and non-toxic nature make it a preferred choice for enhancing flavor, extending shelf life, regulating pH, and promoting health and wellness. By understanding the origins, uses, benefits, and considerations of organic citric acid, consumers can make informed choices that support organic farming practices, environmental sustainability, and healthier lifestyles. Embrace organic citric acid as a valuable ingredient in culinary creations, personal care routines, household cleaning regimens, and industrial applications to experience its multifaceted benefits and contribute to a greener, healthier world.

0 notes

Text

Sewing Thread Lubricant Manufacturer India | 9041070303

Fabric strength is derived from its thread, and the strength of the thread hinges on the quality of its lubricant. Chemical Brothers is the preferred choice for thread lubricants, earning us the reputation as the best sewing thread lubricant manufacturers in India. We are premium suppliers of various chemicals related to the cosmetic and textile industries, including pre-treatment chemicals, printing auxiliaries, dyeing auxiliaries, and more. Our extensive range of sewing thread lubricants is widely distributed across India and internationally. Sewing Thread Lubricant Manufacturer India

Silicon-Based Thread Lubricant

Silicon-based thread lubricants offer exceptionally low friction for both spun cotton and polyester threads. They are cost-effective and durable compared to other lubricants. These lubricants enhance the surface slip and heat resistance of sewing threads, allowing them to be quickly wound into cones and wrapped without microbial activity. Consistent results in various textile industries have made silicone-based sewing thread lubricants a preferred choice. Chemical Brothers consistently ranks at the top of the list of sewing thread lubricant manufacturers in India.

Features of Silicon-Based Thread Lubricant:

Reduces the coefficient of friction on the thread.

Excellent heat stability.

Uniform pick-up over the thread surface.

Great abrasion resistance.

Ideal for high-speed sewing lines.

Suitable for use on colored items.

Reduces hairiness and improves gloss.

Requires minimal cleaning when applied with high-speed winders.

More cost-efficient and productive than other lubricants.

Industrial-Ready Sewing Thread Lubricants

Sewing thread lubricants are essential raw materials for thread manufacturers. Our lubricants are unmatched in quality, providing an ultra-smooth finished surface to fabrics. We are known for:

Timely delivery

Excellent customer support

Advanced manufacturing technologies

High color yield with minimal dye quantity

Smooth and adhesive auxiliaries

Superior dispersive quality

Quality-tested and approved products

Customizable volumes and bulk delivery

High-quality chemicals for various home and personal care industries

Beyond thread lubricants, we offer specialized synthetic chemicals, coloring assistants, and raw materials for cosmetics. We also provide a wide range of textile printing inks, coloring auxiliaries, and finishing agents. Our products enhance the appearance and durability of textiles and are suitable for all types of sewing threads. With extensive experience, we understand the needs of Indian textile manufacturers and tailor our products accordingly.

Why Choose Chemical Brothers?

As a trusted name in the industry, we are committed to providing quality thread lubricants and other chemical products at affordable prices. Our dedication to excellence and customer satisfaction has established us as esteemed sewing thread lubricant manufacturers in India. For any chemical requirements, feel free to contact us or visit our website to ensure you receive the best raw materials.

Experience the superior quality and reliability of Chemical Brothers for all your sewing thread lubricant needs.

#Sewing Thread Lubricant Manufacturer India#Sewing Thread Lubricant Manufacturers India#Sewing Thread Lubricant Manufacturer#Sewing Thread Lubricant

0 notes

Text

RK Industries |Disperse Dye Manufacturers for Various Needs

RK Industries is a manufacturer of Disperse Dyes for their high quality, innovative solutions for various industrial applications, ensuring quality & reliability

#Disperse Dyes manufacturer#Disperse Dyes supplier#Disperse Dyes supplier in vadodara#Best Disperse Dyes#top Disperse Dye#Disperse Dyes manufacturer in India#Vietnam#Brazil

0 notes

Text

Explore the future of disperse dye manufacturing and its emerging trends in this informative article. Discover how technological advancements, sustainability, and changing consumer demands are shaping the future of this industry.

1 note

·

View note

Text

We gladly offer market-focused raw materials for your varying color application requirements

We specialize in:

Full-range of organic dyestuffs

Dry powders and dispersions for the pigments market

Specialty and fine chemicals

https://www.chemworldintl.com/

#acid dyes manufacturers usa#reactive dyes suppliers#disperse dyes#plastic dye manufacturers in usa#basic dyes manufacturer#direct dyes manufacturers#disperse dyes suppliers#solvent dyes manufacturers

0 notes

Text

Different FD&C Dyes and Aluminum Lakes for Food Coloring

The term FD&C refers to Food, Drugs, and Cosmetics are those approved dyes and lakes that are most widely used to create versatile food colors to improve the appealing, palatable value, and overall look and feel of a food. FD&C food dyes and aluminum lakes are dyes and lakes certified and approved by the FDA for use on food coloring in various industrial applications. All FD&C food colors are derived from Synthetic Dyes and Aluminum Lakes, which are produced in a fine, powdery form.

However, businesses and industrialists need to use FD&C dyes and aluminum lakes from a reputed manufacturer and exporter of FD&C dyes and lakes that follow rigorous safety standards and measurements to produce superior quality products that offer 99.99 % purity and ensure 100% safety. Hridhan Chem Pvt. Ltd. is the largest manufacturer and exporter of chemical dyestuff, including but not limited to Food Colors, Pharmaceutical Colors, Cosmetic Colors, Personal & Home Care Colors, Coating Plastic dyes, and Inkjet & Printing Dyes.

All right! Here we will walk you through the use of FD&C dyes and aluminum lakes used for food coloring in different industrial applications.

So, let’s dive right in!

Understanding FD&C Dyes and Aluminum Lakes

Generally, food colors are mainly divided into two broad categories; artificial food colorants and natural food colorants. Artificial food colorants are also called certified colorants since these types of colors are carried out for rigorous testing by the FDA (Food and Drug Organization) during each phase of its manufacturing process.

Once the FDA has thoroughly evaluated, tested, and approved the sample, the dye is awarded as a certified color, signifying that it meets all the stringent standards and safety measurements for safe consumption. A certified colorant means that the color is specifically produced and suitable for food coloring.

Additionally, it ensures that the manufactured color is different from colorants designed for use in pharmaceuticals, drugs, and cosmetics, which may have different FDA requirements and restrictions.

Different FD&C Dyes or Colorants Used for Food Coloring

The use of FDA-certified or synthetic dyes is growing with the increasing interest of consumers in buying colorful products. You can find a diverse range of FD&C food dyes and colorants that are most commonly used in various commercial industrial applications for coloring foods, items, or products. There are several groups interested in natural dyes, but artificial food colors are the most preferred colors used for coloring different food and confectionery products. Here is the list of the top 7 FDA-certified food dyes for food coloring:

FD&C Yellow 5 – Provides Yellow shade when dissolved in water.

FD&C Yellow 6 – produces an orange shade when dissolved in water.

FD&C Red 3 – Creates a pink shade when mixed with water.

FD&C Red 40 – Offers a red shade when mixed with water.

FD&C Blue 1 – Provides a sky blue shade when dissolved in water.

FD&C Blue 2 – Formulates blue shade when mixed with water.

FD&C Green 3 – Creates bluish green shade when dissolved in water.

Both dyes and aluminum lakes are used to formulate FD&C colors. Reputed manufacturers and exporters of artificial colors like Hridhan Chem Pvt. Ltd. use the purest form of dyes and lakes to build the highest quality FD&C colors for use in different industrial purposes.

FD&C Aluminum Lakes

Aluminum Lake Pigments refer to insoluble materials that often tint by dispersion. Lakes are oil dispersible but not oil soluble and are produced from FD&C Dyes. However, they are easier to mix with oils and fats. It is also easier to disperse these lakes in different carriers, including but not limited to glycerin, propylene glycol, and sucrose.

FD&C Aluminum Lakes produced from FD&C Dyes provide different concentrations, such as Low Dye, Medium Dye, and High Dye. Lakes are easy to mix in the shade as opposed to dyes. However, it’s worth noting that FD&C Red 3 Aluminum Lake is not approved or permitted for use in food. Here is the list of different FD&C aluminum lakes used for food coloring:

FD&C Blue 1 Aluminum Lake

FD&C Blue 2 Aluminum Lake

FD&C Red 40 Aluminum Lake

FD&C Yellow 5 Aluminum Lake

FD&C Yellow 6 Aluminum Lake

Are FD&C Dyes Are Safe Food Coloring?

Are you also wondering whether FD&C Dyes are safe food coloring or not? Well, the answer is Yes! FD&C color additives are 100% safe when they are strictly used in accordance with FDA regulations. It’s the FDA that monitors and regulates the use of food color additives, clearly determining the types of dyes that can be used and the maximum quantity to be permitted per serve. FDA follows stringent guidelines and safety standards for the approval of these FD&C dyes and aluminum lakes for the safe use of food coloring.

Difference between FD&C Dyes and Lakes

Dyes are best known for their distinct chemicals which produce coloring power when dissolved in water. Dyes are water-soluble, oil-insoluble, and comparatively less dusty, and can be bought easily in a powder format granular form.

On the other hand, aluminum lakes are insoluble materials that tint when being dispersed. Dyes are used to produce lakes and are often oil-dispersible. It is easier to mix lakes with oils and fats due to their oil-insoluble nature.

Conclusion

Both FD&C dyes and aluminum lakes are broadly used for food coloring in a variety of industrial applications, including foods & beverages, drugs, and cosmetics & personal care products. FD&C dyes are FDA-certified means that they are 100% safe and can be used for a variety of food coloring applications. However, it is advisable for businesses to buy FD&C food dyes or aluminum lakes from a trusted manufacturer and exporter of chemical dyestuff, including food colors, pharmaceutical colors, cosmetic colors, inkjet & printing dyes, and coating & plastic dyes.

We at Hridhan Chem Pvt. Ltd. manufacture premium-quality synthetic dyes, pigments, and aluminum lakes for food coloring. The company has proven years of experience, state-of-the-art manufacturing units, and in-house capabilities with advanced machinery to help you get high-quality, cost-effective, and 100% safe food coloring for your food products. Looking for the best and affordable synthetic dyes or pigments for food coloring, contact us today!

1 note

·

View note

Text

The Essence of Color Masterbatch in the Polymer Industry

Color Masterbatch is a pivotal component in the polymer industry, revolutionizing the way colors are incorporated into plastic products. With its versatility and efficiency, Color Masterbatch has become indispensable across various sectors, from packaging to automotive, textiles to electronics. Let's delve into the significance of Color Masterbatch and its multifaceted applications.

Color Masterbatch, a concentrated mixture of pigments or dyes encapsulated in a carrier resin, offers precise color matching and consistent dispersion, ensuring uniformity in the final product. Its formulation involves meticulous blending of pigments or dyes with additives to achieve desired hues and properties, such as UV resistance, heat stability, and opacity.

In the realm of packaging, Color Masterbatch plays a vital role in enhancing product aesthetics and brand identity. Whether it's vibrant hues for food packaging or subtle tones for luxury goods, manufacturers rely on Color Masterbatch to create visually appealing packaging solutions that captivate consumers' attention.

In the automotive sector, Color Masterbatch contributes to both aesthetics and functionality. From interior trims to exterior body parts, automotive manufacturers leverage Color Masterbatch to achieve custom colors and textures while ensuring durability and weather resistance, vital for withstanding harsh environmental conditions.

1 note

·

View note