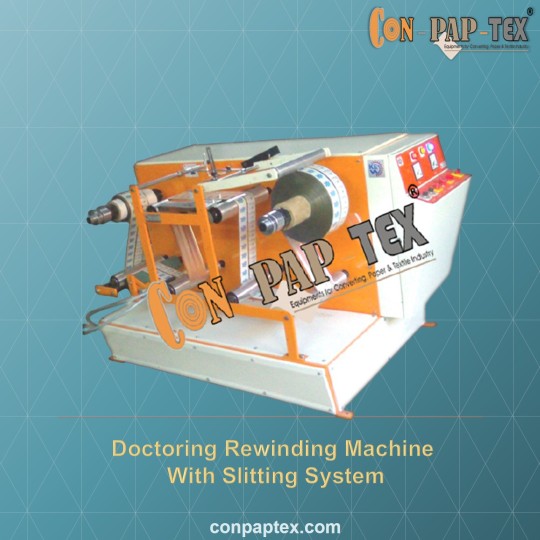

#Doctoring Rewinding with Slitter System

Explore tagged Tumblr posts

Link

We CON PAP TEX are been successfully Manufacturing, Exporting & Supplying all types of Doctoring Rewinding Machine with Slitting System and Winding Rewinding Machine for Inkjet Printer & Batch Printing, Expandable Shaft. Doctoring Rewinding Machines for different industries and for different applications per client’s requirement. Doctoring Rewinding Machines like, Standard Doctoring Rewinding Machine, Doctoring Rewinding Machine with Slitting System, High Speed Doctoring Rewinding, Heavy Duty Doctoring Rewinding etc.

#Doctoring Rewinding Machine with Slitting System#Winding Rewinding Machine for Inkjet Printer#Standard Doctoring Rewinding Machine#Table Top Doctoring Rewinding#High Speed Doctoring Rewinding#Heavy Duty Doctoring Rewinding#Doctoring Rewinding with Slitter System#Doctoring Rewinding#Doctoring Slitting Rewinding#Film Winding Rewinding for Batch Coding#Winding Rewinding for Batch Printing#Winding Rewinding with Thermal Transfer Overprinter#Inspection Doctoring Slitting

1 note

·

View note

Link

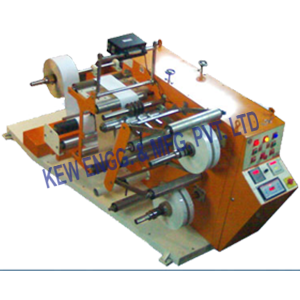

We are Specialised manufacturer, exporter & supplier of heavy duty Winding Rewinding Machines, high quality equipment Winder Rewinder Machine Manufacturer. Winding Rewinding Machines Like, Film Winding Rewinding For Batch Coding, Winding Rewinding For Batch Printing, Winding Rewinding With Inkjet Printer and with Multihead Inkjet Printer, Winding Rewinding With Thermal Transfer Over printer, Doctoring Film Strip Winding Rewinding, Winding Rewinding With and Without Slitting System, Coil Winding, Winding Unwinding, Inspection Doctoring Slitting, Inspection Rewinding for Inkjet and Batch Printing, Industrial Inkjet Printer with Winder Rewinder, also Thermal Transfer Printer and (TTO) With Winding Rewinding, Unwinder Rewinder System Manufacturer, Doctoring Rewinding Machines, Inspection Rewinding, Inspection Rewinding Unwinding Machine.

#Winder Rewinder#Rewinder Unwinder#Unwinder Rewinder System Manufacturer#Winding Rewinding Machines#Doctoring Rewinding Machines#Doctoring Slitter Machine#slitting machine price#fabric slitting machine#paper roll slitting machine#Slitter Rewinder Machines

1 note

·

View note

Link

Web Guiding System Manufacturer, Rewinding Unwinding is a process to rewind - unwind your material available in roll form like, flexible packaging, film, paper, foil, etc. Rewinding Unwinding is a repetitive process with high accuracy to wind or rewind your material in roll form. Unwinding or Rewinding Machine designed and suitable for all types of machines like Roto Gravure Printing Machine, Lamination, Coating Machine, Slitting Rewinding Machine, Extruder Machine, Textile Machine, Tyre Machine, etc. Web Guiding System Manufacturer, Rewinding Unwinding, Web Guiding System, Slitting Rewinding Machine, Doctoring Salvage Rewinder, Salvage Rewinders, Slitter Rewinder Machine , Winding Rewinding, Web Guiding Salvage Rewinding, Web Guiding System Manufacturer

#Web Guiding System Manufacturer#Rewinding Unwinding#Web Guiding System#Slitting Rewinding Machine#Doctoring Salvage Rewinder#Salvage Rewinders#Slitter Rewinder Machine#Winding Rewinding#Web Guiding Salvage Rewinding

1 note

·

View note

Link

Web Guiding System Manufacturer, Edge Guide System India, We have supplied 150 units of position control guiding systems per month, web guide system repairing from 0.25 to 3 HP. Hydro–Pneumatic Web Aligner are the Heart of Hydro Pneumatic web guiding system, to automatically guide all type of material of any width, at any speed, under any load. Completely self-contained with an integral air generator for the sensor. It is coupled with 3 phase AC motor and the Hydraulic pump is also attached to the same shaft which is fitted inside the oil tank filled with Hydraulic oil.

https://youtu.be/8Z1iLsTmVPk

#Web Guiding System#Edge Guide System#Web Guiding System Manufacture#Web Guiding System Supplier#Web Aligner System#Web Aligner#Doctoring Rewinding Machine#Winding Rewinding Machine#winding machine#doctoring machine#rewinding machine price#doctor machine#winding machine price#automatic winding machine#slitting machine#slitting and rewinding machine#slitter Rewinder manufacturers#Web Aligner System price

1 note

·

View note

Link

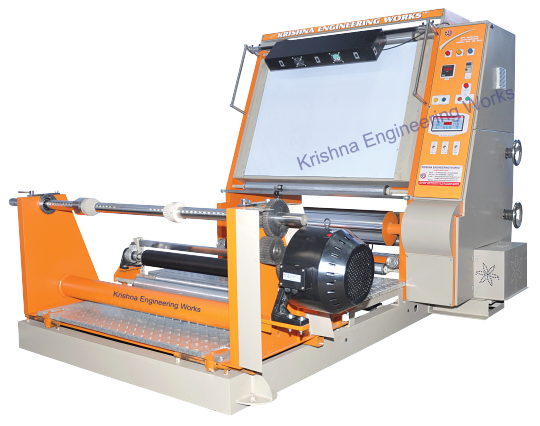

We are Winding Rewinding Machine With Slitting System, Winding Rewinding Machine on custom application and client's requirement. All type of slitter Rewinder machines is special quality machines, designed and created for special applications. We are Manufacturer of Winding Rewinding Machine, Unwinder Rewinder System, Slitter Rewinder Machine on custom application and client’s requirement. Manufacturer of widely used Winding rewinding with Slitting System with variable speed drive and salvage rewinding, corrosion resistant system in flexible packaging and converting industry. Cantilever design-balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner). Mechanical 1.5 / 2.5 Kg. Optional Magnetic powder brake with tension controller & Torque control potentiometer. Provision for incorporating Inkjet Printing System with Hot air ink drying.

#Slitter Rewinder Machine#Slitting System#Winding Rewinding#Winding Rewinding Machine#Winder Rewinder#Slitting Rewinding Machine#Slitting Rewinding#Slitter Machine#Slitters#Winding Rewinding Manufacturer#Slitter Rewinder Machine Manufacturer#Slitter Rewinder Machine Supplier#Inkjet Printer#Doctor Rewinder Machine#Doctoring Rewinding#Industrial Inkjet Printer#Batch Coding Machine#Winding Rewinding Machine with Slitting System

0 notes

Link

Doctoring Inspection Machine with Slitting System manufacturer, similar application machines, winding rewinding, slitter rewinder machine with doctoring rewinder machine, Inspection Doctoring Slitting Machine, Inspection Winding Rewinding Machine, Winding Rewinding. Inspection facility of perfect slitting of rolls with consistent quality and constant line speed. Inspection with high quality and accurate slitting system, also slitter rewinder machine for all type of fmcg, paper and fabric materials.

#Doctoring Inspection Machine#Doctoring Inspection#Doctoring Inspection Machine with Slitting System#Doctoring Inspections#Slitting Machine#Slitting Rewinding Machine#Doctor Rewinder#Doctor Rewinder Machine#Doctoring Rewinding#Doctoring Rewinding Machine#Doctoring Rewindings#winding rewinding#winding rewinding Machine#slitter rewinder machine#slitter rewinder machine manufacturer#slitter rewinder

0 notes

Link

We CON-PAP-TEX are been successfully Manufacturing, Exporting & Supplying all types of Heavy Duty Doctoring Rewinding Machine and Winding Rewinding Machine for Inkjet Printer & Batch Printing, Slitter Rewinder Machine at best price. Doctoring Rewinding Machine industrialist to make doctoring process for your flexible Packaging Roll with high-quality equipment. It is actually designed and built for the heavy-duty procedure of doctoring rewinding.

#Doctoring Rewinding Machine#Doctoring Machine#Heavy Duty Doctoring Rewinding Machine#Inspection Rewinding Machine#Rewinding Machine#Rewinding Machine Price#Automatic Rewinding Machine#Heavy Duty Winding Rewinding Machine#Doctoring Inspection Machine with Slitting System#Winding Rewinding Machine#Doctoring Rewinding#Winder Rewinder#Slitter Winder

1 note

·

View note

Link

We are specialised manufacturer and supplier of Lidding High Performance Doctoring Rewinding Machines, high quality equipment Doctoring Slitter Machine. Doctoring Rewinding, Doctoring Rewinding Table Top, Table Top Doctoring Rewinding, High Speed Doctoring Rewinding, Heavy Duty Doctoring Rewinding, Doctoring Rewinding With Slitter System, Doctoring Slitting Rewinding, Label Stock Doctoring Rewinding, Special Application For Doctoring Rewinding, Film Winding Rewinding For Batch Coding, Winding Rewinding For Batch Printing. Winding Rewinding With Inkjet Printer, Winding Rewinding With Thermal Transfer Overprinted, Winding Rewinding With Multihead Inkjet Printer, Doctoring Film Strip Winding Rewinding, Winding Rewinding With Slitter System, Winding Rewinding Without Slitter System, Coil Winding, Winding Unwinding, Inspection Doctoring Slitting, Inspection Rewinding for Inkjet and Batch Printing, Doctoring Inspection, Doctoring Inspection with Slitter System, Doctor Re Reeling, Industrial Inkjet Printer, Industrial Inkjet Printer With Winder Rewinder, Industrial Thermal Transfer Printer.

#Doctoring Slitter Machine#Slitter Machine#Doctoring Rewinding Machines#Doctoring Rewinding#Rewinding Machines#Rewinder Machine#Slitting Machine#Winder Rewinder#Doctor Rewinding#Slitter System#Doctor Re Reeling#Industrial Inkjet Printer#slitter Rewinder manufacturers#foil slitting machine#aluminium foil slitting machine#aluminum slitting machine#paper slitting machine#slitting machine price#fabric slitting machine#paper roll slitting machine

0 notes

Link

We are Winding Rewinding Machine with Slitting System, Winding Rewinding Machine on custom application and client’s requirement. All type of slitter Rewinder machines is special quality machines, Slitting Rewinding System, Winding Unwinding Machine designed and created for special applications. We are Manufacturer of Winding Rewinding Machine, Unwinder Rewinder System, Slitter Rewinder Machine on custom application and client’s requirement. Slitting System with variable speed drive and salvage rewinding, corrosion resistant system in flexible packaging and converting industry.

#Winding Rewinding Machine With Slitting System#Winding Rewinding Machine#Winding Rewinding Machine Manufacturer#Winding Rewinding#Rewinding Machine#Slitter Rewinder#Slitting Rewinding Machine Manufacturers#Doctoring Rewinding Machine#Slitter Rewinder Machine#Paper Slitting Machine Supplier

0 notes

Link

Slitting Rewinding Machine for Batch Printing Coding, Slitting Machines, Slitter Rewinder Machine for Industry specific Batch Printing, Batch Printing, Slitter Rewinder Machine, Doctoring Rewinding Machine, Batch Coding Machine, Packaging Machine, Printing Machine, Fabric Folding Machine, Cantilever design-balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner).Mechanical 1.5 / 2.5 Kg. Optional Magnetic powder brake with tension controller & Torque control potentiometer. Provision for incorporating Inkjet Printing System with Hot air ink drying. The Model is specially designed for correcting badly wounded reels for inspection & doctoring operation. It is great substitute to online coding / batching operation

http://www.windingrewindingmachine.com/slitting-rewinding-machine-for-batch-printing-coding.php

#batch coding machine#batch printing machine#slitter machine manufacturer#winder Rewinder machine#Winding Rewinding Machine Manufacturer#slitter Rewinder#slitting rewinding machine#motor winding machine price#date printing machine#manual batch coding machine#Bopp tape slitting machine#batch printing machine price#rewinding machine price#paper winding machine#digital batch coding machine

1 note

·

View note

Link

We are leading Manufacturer, Exporter of Flexible Packaging, Paper, Tire-Cord, Textile Machinery. We manufacture machines like, Rotogravure Printing, Lamination, Flexo Printing, Coating, Slitter Rewinder Machine, Inspection Rewinding Machine, Doctoring Rewinding Machine, Winder Rewinder Machine for Inkjet Printer, Hydro Pneumo Web Aligner System, Web Aligner System, Web Guiding System, Roll Stretch Wrapping, BOPP Tape Cutting, Core Cutting, Edge Guiding Systems. Textile Machinery with custom application for different industries specific requirements.

#Flexible Packaging#Flexible Packaging Machine#Slitter Rewinder Machine#Slitter Rewinder#Doctoring Rewinding Machine#Doctoring Rewinding#Winder Rewinder Machine#Winder Rewinder#Web Aligner#Web Aligner Unit#Web Aligners

2 notes

·

View notes

Link

We are dealing in high quality performance and long durability on Doctoring Rewinding Machine. Our Doctoring Rewinding is highly used for all types of Laminates like, Foil, Paper, LDPE, HDPE, PVC and many more. heavy duty doctoring rewinding machine, doctoring rewinding machine with slitting system, winding unwinding machine and doctoring cum slitting rewinding machine. We have been manufacturing various types of Doctoring Rewinding Machines for different industries and for different applications per client’s requirement.

#Winding Unwinding Machine Winding Unwinding Winding Rewinder Machine Winding Rewinder Winder Rewinder Machine Winder Rewinder Doctoring Rewi#Winding Unwinding Machine#Winding Unwinding#Winding Rewinder Machine#Winding Rewinder#Winder Rewinder Machine#Winder Rewinder#Doctoring Rewinding#Doctor Rewinder Machine#slitting rewinding machine#slitting system#Slitting Rewinding#Slitter Rewinder

0 notes

Link

Inspection Rewinding Machine Manufacturer India, for Non-Woven, Fabric, Film, Cloth Slitter Rewinder, Doctoring Rewinding Machine Manufacturer, Inspection Rewinder. Also, we make Film Inspection Rewinding with the Slitting system, Non-Woven Fabric Inspection Machine. Inspection Rewinding Machine used majorly for checking of badly printed materials on Rotogravure Printing, Flexo Printing Machine, Batch Printing and much more.

#Inspection Rewinding Machine#Inspection Machine Manufacturer#Doctoring Inspection Rewinding Machine#Inspection Slitting Machine#Inspection Rewinding Machine for Inkjet and Batch Printing

2 notes

·

View notes

Link

ConPapTex Equipment, Textile Machinery Spare Parts in South Africa, Flexible Packaging Machinery in South Africa, high-quality equipment of different industries like Converting, Paper. Manufacturer of Rubber Roller, Web Guiding System, Rubber Fillet, Bow Roll, Metal Roller, Air Shaft, etc., Equipment for converting, paper and textile industry, repair, and service. Also, dealing with Slitter Rewinder, Doctoring Rewinding Machine Manufacturer, Industrial Roller, Batch Coding, Printing Machine, and many more extraordinary machines.

#Rubber Fillet Manufacturer#Bow Roll Manufacturer#Metal Roller in South Africa#Air Shaft Manufacturer#Sitter Rewinder Manufacturer#Industrial Roller Manufacturer#Batch Coding Machine in South Africa#Printing Machine Manufacturer#Manufacturer of Rubber Roller#Web Guiding System

1 note

·

View note

Link

We have been successfully manufacturing, exporting and supplier Web Aligner System. Servicing and repairing of high quality and heavy duty equipment. High-quality parts included in Web Aligner System, Web Guiding System, Hydraulic Power Pack Unit, Web Aligner, Hydro-Pneumo Web Edge Aligner, Web Aligner unit, different types of Machines like Doctoring Rewinding Machine, Winding Rewinding and Slitter Rewinder Machine. Different from models are 0.25 HP to 3 HP. We have capacity to supply 100-150 units of web guiding system per month.

#Web Aligner System#Web Aligner Systems#Web Aligner#Web Guiding System#Web Guiding Systems#Web Guiding#Web Guiding System Manufacturer#Web Guide System#Web Guide Systems#Web Guide System Manufacturer

3 notes

·

View notes

Text

SP Ultraflex’s ROBOSLIT impresses Constantia Parikh

Vienna-based Constantia is one of the largest flexible packaging manufacturers globally. It now has several plants in India based on its acquisitions of Parikh Packaging and Creative Polypack. It also set up a Greenfield plant for its recyclable PE-based flexible packaging plant called Constantia Ecoflex in Ahmedabad, inaugurated in 2019. We are producing an edited version of an interview of Ahmedabad-based Pragnesh Shah, plant head of the Constantia Parikh Packaging sub-cluster below.

Please tell us a bit about the inception of Constantia Parikh Packaging and its area of focus within the flexible packaging segment.

Pragnesh Shah – Constantia Parikh Packaging was formed in 2013, when the Parikh family, promoters of Parikh Packaging, welcomed the Constantia Flexibles group as partners. Regular investments in infrastructure, systems, and plant and machinery enabled the company to grow 3x, and the monthly output now stands at 1800 MT. In 2017, we decided to venture into 100% recyclable laminates and set up our new state of art plant ‘Ecoflex’ in 2019. We launched ‘Ecolam,’ a 100% PE-based laminate to replace aluminum foil from the new unit. By 2025, we plan for 100% of all consumer and pharma packaging to be recyclable, reflecting our commitment to society for environmental friendliness.

Can you help us with an overview of the plant and machinery in your company?

Pragnesh Shah – We started with indigenous machines but were let down in terms of performance. As a result, we shifted to European and Korean technology. We are happy to share that after seeing improvements in Indian machines over the years, we have come full circle today. Most of the recent additions to our plant are from reputed Indian manufacturers.

Being one of the oldest and most reputed converters in the region, we would like to know how important the role of slitting rewinding machines in the overall process of converting is?

Pragnesh Shah – Slitting is usually the last process before the final product is delivered to our customer. Most of our customers are from the food industry and cannot afford stoppages in their packing lines due to slitting defects. In addition, slitting defects can undo all the efforts made in the printing and lamination processes. Therefore, we feel it is essential to invest in the best technology for slitter rewinders, mainly because their cost is a small fraction of the total investment.

Which performance parameters are critical and which features are ‘must haves’ on a good slitter rewinder?

Pragnesh Shah – First and foremost, the ITM (Intelligent tension management), is an absolute must to reduce dependency on operator expertise. Here, the PLC computes and maintains the tension levels suitable to the job. I see the next level of automation in the area of the job setup. The hygiene factor is also very important for food and pharma customers, and a close study of the layout from this perspective is most essential while finalizing the machine. Lastly, I would stress the static management system, which will soon be the need of the hour as more and more customers switch to high-speed packing machines that are most intolerant to residual static.

After installing multiple dual turret slitter machines worldwide, how has your experience with this technology been so far?

Pragnesh Shah – Slitter rewinders with dual turret rewinds are the order of the day in these competitive times where the focus is to increase efficiency. Unlike duplex slitters, these machines run virtually non-stop, offering higher productivity, improved efficiency of man and machine, and optimal use of floor space. Consistency in performance is also higher as compared to duplex machines. Opting for dual turret slitters would also reduce the total number of slitters required to support a given plant capacity over a period of time.

You installed a ROBOSLIT machine from SP Ultraflex a few months back. How was your experience?

Pragnesh Shah – The OHP version of the Roboslit was installed at our plant in February 2021, and we have found its performance to be at par with the best in the world. The team at SP Ultralflex puts in a lot of effort in learning, researching, and understanding the customer’s pain areas and channelizes their inputs to their design department, leading to continuous improvements and innovations. They are also very supportive, understanding the significance of our queries, and give clear and meaningful answers.

Pragnesh Shah, plant head of the Constantia Parikh Packaging sub-cluster[/caption]

In general, most converters prefer compact, rear-loading slitter rewinders. But you have purchased the overhead model of the Roboslit series, the Roboslit OHP. What made you go for that model?

Pragnesh Shah – The most admirable quality in the OHP version is the overhead web movement. Substrates running between idle rollers at high speed tend to develop static charge and attract dust. This is not acceptable, especially when it comes to food and pharma customers. The substrate is always at a good distance from the floor level in the OHP layout, leaving no scope for the dust to contaminate its surface. Other advantages of the overhead path include easy access to the cutting section and better visibility of the running substrate. Last but not least, this layout improves the safety quotient of the machine – something that is non-negotiable within the Constantia Flexibles group.

To what extent did SP Ultraflex meet the expectations of Constantia Flexibles in terms of output, quality, operator friendliness, and safety standards?

Pragnesh Shah – To start with, safety and user-friendliness are of utmost importance to Constantia Flexibles, and both these aspects are well taken care of in the machine. Coming to the output, I have already spoken about the increased productivity of this machine by virtue of its dual turret rewind. I want to share another important dimension, which affects productivity – the ratio of rework. We have seen a drastic reduction in the percentage of narrow width coils that need to be edge corrected on doctoring machines, thanks to the better quality of finished reels produced on this machine.

How, in your opinion, does the SP machine compare with the European make machines in your plant?

Pragnesh Shah – It is a good indigenous technology at par with global standards, with certain additional features and a good team.

What is the future focus for Constantia Parikh Packaging in terms of capital equipment technology? As mentioned earlier, we are looking for indigenous machines which will fulfill our requirements and expectations. We have a robust technical evaluation team that defines the ‘what’ and ‘why.’ If all such conditions and expectations are fulfilled, we would prefer Indian make machines, thereby supporting the Make in India movement.

0 notes