#Winding Rewinding Machine With Slitting System

Explore tagged Tumblr posts

Text

High-Performance Printing & Converting Machines | Advanced Solutions

In the modern world, the printing and packaging industry has started to completely rely on precision, effectiveness, and novelty. Advanced technology such as slitting rewinding machines, label die cutting machines, paper core cutting machines, hot foil stamping machines, and UV curing systems is among the most significant tools rendering final mba product quality.

Machine manufacturers and converters rely heavily on high-level technological tools to speed up the process of production, increase accuracy, and aid versatility of their machines. The description of the machines' importance in various industrial applications has been outlined in a set of present practice method, showing machines' necessity in printing and packaging industries today.

Slitting Rewinding Machine

A slitting rewinding machine is a vital component in industries dealing with flexible packaging, paper, films, and foil materials. It enables the precise slitting and rewinding of large master rolls into smaller rolls with accurate tension control.

Key Features of a Slitting Rewinding Machine:

High-Speed Performance: Ensures rapid slitting and rewinding without compromising quality.

Precision Cutting: Adjustable slitting blades provide clean and accurate cuts.

Tension Control Mechanism: Maintains optimal tension for smooth rewinding.

User-Friendly Interface: Automated controls for easy operation and reduced downtime.

Versatile Applications: Suitable for plastic films, aluminum foils, paper rolls, and adhesive tapes.

Applications of Slitting Rewinding Machines:

Flexible Packaging Industry: For slitting plastic films and foils.

Label Production: Converts large rolls into label-sized formats.

Printing Industry: For handling coated and laminated materials.

Label Die Cutting Machine

A label die cutting machine is essential for the precise cutting of labels, stickers, and adhesive sheets. It ensures clean edges, intricate shapes, and high-speed production for industries requiring mass labeling.

Key Features of a Label Die Cutting Machine:

Rotary & Flatbed Cutting: Supports various die-cutting methods for different label types.

Automatic Waste Removal: Ensures a cleaner output with no excess material.

High Cutting Accuracy: Ideal for custom shapes and intricate label designs.

Multi-Layer Processing: Allows multiple layers for enhanced durability.

User-Friendly Control Panel: Simplifies operation and reduces labor requirements.

Applications of Label Die Cutting Machines:

Food & Beverage Labeling: Used for bottle and container labeling.

Pharmaceutical Industry: For precision-cut medical labels.

Cosmetic & Personal Care Products: Ensures premium quality label cutting.

Paper Core Cutting Machine

A paper core cutting machine is used to cut paper tubes and cores to the desired length, ensuring smooth edges and accurate dimensions for various industrial applications.

Key Features of a Paper Core Cutting Machine:

High Cutting Precision: Produces accurate and smooth cuts for uniform core sizes.

Adjustable Cutting Lengths: Allows customization for different applications.

Heavy-Duty Construction: Ensures durability and longevity.

Automatic & Manual Operation: Supports both automatic and manual cutting modes.

Dust-Free Operation: Minimizes waste and enhances cleanliness.

Applications of Paper Core Cutting Machines:

Packaging Industry: For manufacturing paper cores for packaging rolls.

Printing Sector: Used for paper roll cores and film winding.

Textile Industry: For fabric and yarn core cutting.

Hot Foil Stamping Machine

A hot foil stamping machine enhances the visual appeal of printed products by adding metallic and holographic foil designs. It is widely used in luxury packaging, book covers, greeting cards, and promotional materials.

Key Features of a Hot Foil Stamping Machine:

Advanced Foil Transfer Technology: Ensures sharp and clean imprints.

Temperature & Pressure Control: Allows precise adjustments for different materials.

Multi-Purpose Applications: Works on paper, plastic, leather, and fabric.

Automatic Foil Feeding System: Ensures smooth and continuous foil application.

Energy-Efficient Design: Reduces operational costs and improves efficiency.

Applications of Hot Foil Stamping Machines:

Luxury Packaging: Enhances premium product packaging.

Branding & Promotions: Used for high-end business cards and brochures.

Security Printing: Adds holographic elements for anti-counterfeiting.

UV Curing Systems

A UV curing system is an advanced technology used for instant drying and curing of inks, coatings, and adhesives using ultraviolet light. This method ensures high-quality finishes, durability, and eco-friendly operations.

Key Features of a UV Curing System:

Instant Drying & Curing: Reduces production time significantly.

Energy Efficiency: Consumes less power compared to traditional drying methods.

Eco-Friendly Operation: Eliminates the need for solvents and harmful chemicals.

High Durability: Ensures scratch-resistant and long-lasting prints.

Wide Compatibility: Suitable for offset, flexographic, and screen printing.

Applications of UV Curing Systems:

Printing Industry: For UV-cured inks and coatings.

Electronics & PCB Manufacturing: Ensures durable protective coatings.

Medical Devices: Used for adhesive bonding in healthcare applications.

Why Invest in High-Performance Printing & Converting Machines?

Enhanced Production Efficiency – Reduces downtime and increases output.

Precision & Quality – Ensures accurate cutting, stamping, and curing.

Cost-Effective Solutions – Optimizes material usage and reduces waste.

Versatile Applications – Suitable for various industries, from packaging to textiles.

Advanced Automation – Minimizes manual labor and improves operational accuracy.

By integrating the latest slitting rewinding machine, label die cutting machines, paper core cutting machines, hot foil stamping machines, and UV curing systems, manufacturers can achieve superior productivity and quality.

Project Name: UV Graphic Technologies Pvt. Ltd

Address: Plot 15, Sector 140A, Noida UP 201305

Contact No: 919810114365

Email ID: [email protected]

Our Website: https://gtigti.com/

Linkedin ID: https://www.linkedin.com/company/uv-graphic-technologies-pvt-ltd/

You tube: https://www.youtube.com/watch?v=EleXfuBanIk&ab_channel=AbhayDatta

0 notes

Link

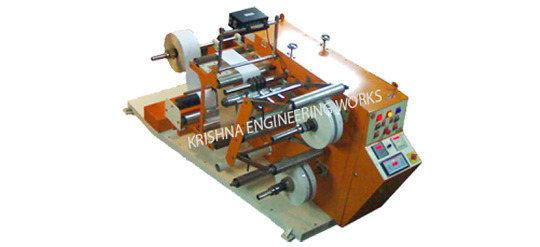

We are Winding Rewinding Machine With Slitting System, Winding Rewinding Machine on custom application and client's requirement. All type of slitter Rewinder machines is special quality machines, designed and created for special applications. We are Manufacturer of Winding Rewinding Machine, Unwinder Rewinder System, Slitter Rewinder Machine on custom application and client’s requirement. Manufacturer of widely used Winding rewinding with Slitting System with variable speed drive and salvage rewinding, corrosion resistant system in flexible packaging and converting industry. Cantilever design-balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner). Mechanical 1.5 / 2.5 Kg. Optional Magnetic powder brake with tension controller & Torque control potentiometer. Provision for incorporating Inkjet Printing System with Hot air ink drying.

#Slitter Rewinder Machine#Slitting System#Winding Rewinding#Winding Rewinding Machine#Winder Rewinder#Slitting Rewinding Machine#Slitting Rewinding#Slitter Machine#Slitters#Winding Rewinding Manufacturer#Slitter Rewinder Machine Manufacturer#Slitter Rewinder Machine Supplier#Inkjet Printer#Doctor Rewinder Machine#Doctoring Rewinding#Industrial Inkjet Printer#Batch Coding Machine#Winding Rewinding Machine with Slitting System

0 notes

Link

Winding Rewinding Machine with Slitting System Manufacturer India. Manufacturer of widely used form of Winding rewinding with slitting system with variable speed drive and salvage rewinding, corrosion resistant system. Cantilever design-balancing body for easy loading and unloading of parent / rewound reel. The Model is specially designed for correcting badly wounded reels for inspection & doctoring operation. It is great substitute to online coding / batching operation. Winding Rewinding Machine With Inkjet Printer.

#Winding Rewinding Machine with Slitting System#Winding Rewinding Machine#Winding Rewinding Machines#Winding Rewinding#Slitting Machine#Winder Rewinding#Winder Rewinding Machine#Winder Rewinder Machine#Winder Rewinder Machines#Winder Rewinder#Winder Rewinders#Winder Rewinders Machine

1 note

·

View note

Link

We have been manufacturing various types of Doctoring Rewinding Machine for separate industries and for different request per client’s requirement. Custom and proper Application for Doctoring Rewinding Machine, 28 separate type of Doctoring Rewinding Machine Manufacturer, exporter, supplier. Doctoring Rewinding Machine with Slitting System like, Standard Doctoring Rewinding Machine, High Speed Doctoring Rewinding, Heavy Duty Doctoring Rewinding, Doctoring Rewinding with Slitting System, Table Top Doctoring Rewinding etc.

#Doctoring Rewinding Machine#Doctoring Machine#Doctoring Rewinding Machine with Slitting System#Doctoring Rewinding Machine Manufacturers#Inspection Machine#Doctoring Rewinding Machine Price#Heavy Duty Doctoring Rewinding Machine#Film Winder Rewinder Machine#Winding Rewinding Machine#Slitting Rewinding Machines

7 notes

·

View notes

Link

We are Winding Rewinding Machine with Slitting System, Winding Rewinding Machine on custom application and client’s requirement. All type of slitter Rewinder machines is special quality machines, Slitting Rewinding System, Winding Unwinding Machine designed and created for special applications. We are Manufacturer of Winding Rewinding Machine, Unwinder Rewinder System, Slitter Rewinder Machine on custom application and client’s requirement. Slitting System with variable speed drive and salvage rewinding, corrosion resistant system in flexible packaging and converting industry.

#Winding Rewinding Machine With Slitting System#Winding Rewinding Machine#Winding Rewinding Machine Manufacturer#Winding Rewinding#Rewinding Machine#Slitter Rewinder#Slitting Rewinding Machine Manufacturers#Doctoring Rewinding Machine#Slitter Rewinder Machine#Paper Slitting Machine Supplier

0 notes

Link

Krishna Engineering Works Manufacturers, exports & supplies Table Top Doctoring Rewinding. Our Table Top Doctoring Rewinding Machine is used for all types of Laminates like, Foil, Paper, LDPE, HDPE, PVC, etc. Our Table Top Doctoring Rewinding Machine is manufactured with us most precision which ensure zero maintenance up to 10 years. We have been manufacturing various types of Doctoring Rewinding Machine for different industries and for different applications per client’s requirement. For more information contact our sales team: [email protected]

#Doctoring Rewinding Machine#Standard Doctoring Rewinding Machine#Table Top Doctoring Rewinding#High Speed Doctoring Rewinding#Heavy Duty Doctoring Rewinding#Doctoring Rewinding With Slitting System#Doctoring Slitting Rewinding#Doctoring Rewinding Winding Unwinding#Doctoring Rewinding Winding Rewinding For Batch Printing#Doctoring Winding Rewinding With Inkjet Printer#Industrial Inkjet Printer with Winder Rewinder Machine#Inspection Doctoring Rewinding Machine

4 notes

·

View notes

Link

Krishna Engineering Works is a leading manufacturer, exporter and supplier of Rewinding Machine, Roll-to-Roll Processing Machines for a variety of processes such as Rewinding Machine, Slitting, Docking Rewinding, Winding Rewinding, Rewinding Unwinding, Jumbo Roll to Small Roll Folding, etc. Different types of Winding Rewinding Machine with high quality and heavy duty equipment. Winding rewinding machine with 25 different types per client's application and industry specific requirements. Also a manufacturer of doctoring rewinding machine, Rotogravure printing machine.

#Winding Rewinding Machine for Inkjet Printer#Winding Rewinding Machine#Film Winder Rewinder Machine#Rewinder for Inkjet Printer#Industrial Inkjet Printer with Winder Rewinder Machine#Heavy Duty Doctoring Rewinding Machine#Doctoring Rewinding Machines#Doctoring Machine#Doctoring Re-Reeling Machine#Doctoring Inspection Machine with Slitting System

6 notes

·

View notes

Link

We CON-PAP-TEX are been successfully Manufacturing, Exporting & Supplying all types of Heavy Duty Doctoring Rewinding Machine and Winding Rewinding Machine for Inkjet Printer & Batch Printing, Slitter Rewinder Machine at best price. Doctoring Rewinding Machine industrialist to make doctoring process for your flexible Packaging Roll with high-quality equipment. It is actually designed and built for the heavy-duty procedure of doctoring rewinding.

#Doctoring Rewinding Machine#Doctoring Machine#Heavy Duty Doctoring Rewinding Machine#Inspection Rewinding Machine#Rewinding Machine#Rewinding Machine Price#Automatic Rewinding Machine#Heavy Duty Winding Rewinding Machine#Doctoring Inspection Machine with Slitting System#Winding Rewinding Machine#Doctoring Rewinding#Winder Rewinder#Slitter Winder

1 note

·

View note

Link

We are Specialised manufacturer, exporter & supplier of heavy duty Winding Rewinding Machines, high quality equipment Winder Rewinder Machine Manufacturer. Winding Rewinding Machines Like, Film Winding Rewinding For Batch Coding, Winding Rewinding For Batch Printing, Winding Rewinding With Inkjet Printer and with Multihead Inkjet Printer, Winding Rewinding With Thermal Transfer Over printer, Doctoring Film Strip Winding Rewinding, Winding Rewinding With and Without Slitting System, Coil Winding, Winding Unwinding, Inspection Doctoring Slitting, Inspection Rewinding for Inkjet and Batch Printing, Industrial Inkjet Printer with Winder Rewinder, also Thermal Transfer Printer and (TTO) With Winding Rewinding, Unwinder Rewinder System Manufacturer, Doctoring Rewinding Machines, Inspection Rewinding, Inspection Rewinding Unwinding Machine.

#Winder Rewinder#Rewinder Unwinder#Unwinder Rewinder System Manufacturer#Winding Rewinding Machines#Doctoring Rewinding Machines#Doctoring Slitter Machine#slitting machine price#fabric slitting machine#paper roll slitting machine#Slitter Rewinder Machines

1 note

·

View note

Link

Web Guiding System Manufacturer, Rewinding Unwinding is a process to rewind - unwind your material available in roll form like, flexible packaging, film, paper, foil, etc. Rewinding Unwinding is a repetitive process with high accuracy to wind or rewind your material in roll form. Unwinding or Rewinding Machine designed and suitable for all types of machines like Roto Gravure Printing Machine, Lamination, Coating Machine, Slitting Rewinding Machine, Extruder Machine, Textile Machine, Tyre Machine, etc. Web Guiding System Manufacturer, Rewinding Unwinding, Web Guiding System, Slitting Rewinding Machine, Doctoring Salvage Rewinder, Salvage Rewinders, Slitter Rewinder Machine , Winding Rewinding, Web Guiding Salvage Rewinding, Web Guiding System Manufacturer

#Web Guiding System Manufacturer#Rewinding Unwinding#Web Guiding System#Slitting Rewinding Machine#Doctoring Salvage Rewinder#Salvage Rewinders#Slitter Rewinder Machine#Winding Rewinding#Web Guiding Salvage Rewinding

1 note

·

View note

Link

KEW ENGG. & MFG. PVT. LTD. have been manufacturing, exporting and supplying various types of Winding Rewinding Machine. Different types of Winding Rewinding Machine with high quality and heavy duty equipment. Winding Rewinding Machines Like, Film Winding Rewinding For Batch Coding, Winding Rewinding For Batch Printing, Winding Rewinding With Inkjet Printer and with Multihead Inkjet Printer, Winding Rewinding With Thermal Transfer Overprinter, Doctoring Film Strip Winding Rewinding, Winding Rewinding With and Without Slitting System, Coil Winding etc.

#Film Winding Rewinding Machine For Batch Coding#Rewinding Machine#Film Winding Rewinding For Batch Coding#Winding Rewinding For Batch Printing#Winding Rewinding With Inkjet Printer#Winding Rewinding With Thermal Transfer Overprinter#Doctoring Film Strip Winding Rewinding#Winding Rewinding With and Without Slitting System#Doctoring Rewinding Machines#Heavy Duty Doctoring Rewinding Machine#Film Winding Rewinding Machine#Doctoring Rewinding Machine#Winding Unwinding Machine#Roll to Roll Rewinding Machine#Automatic Roll Rewinder Machine#Inspection Winding Rewinding Machine

1 note

·

View note

Link

Equipments Tyre Cord Dipping Plant, Two Stage Let off Station, Automatic Tension Control, Let-Off Accumulator, Centre Guiding System, Stretch Heat Zone, etc. Krishna Engineering Works is a leading manufacturer and exporter of Equipments Tyre Cord Dipping Plant, Tyre Cord and Technical Textile Fabric Dipping Plant/Machine and equipment with meeting the highest performance, safety, environment and cost criteria. It is designed for excellent quality of tire cord fabric for all categories of tyres.

#Tire Cord Machinery#Tyre Cord Dipping Plant#Tire Cord Machine Manufacturer#Tyre Cord Dipping Plant price#Web Guiding System#Web Guiding Systems Manufacturer#Tire Cord Machine#Automatic Tension Control#Slitting Rewinding Machine price#Slitters#Slitter Machine#Winder Rewinder Machine#Winding Rewinding Machine#tire cord manufacturer#tyre cord#Tire Cord Exporter

0 notes

Link

Web Guiding System Manufacturer, Edge Guide System India, We have supplied 150 units of position control guiding systems per month, web guide system repairing from 0.25 to 3 HP. Hydro–Pneumatic Web Aligner are the Heart of Hydro Pneumatic web guiding system, to automatically guide all type of material of any width, at any speed, under any load. Completely self-contained with an integral air generator for the sensor. It is coupled with 3 phase AC motor and the Hydraulic pump is also attached to the same shaft which is fitted inside the oil tank filled with Hydraulic oil.

https://youtu.be/8Z1iLsTmVPk

#Web Guiding System#Edge Guide System#Web Guiding System Manufacture#Web Guiding System Supplier#Web Aligner System#Web Aligner#Doctoring Rewinding Machine#Winding Rewinding Machine#winding machine#doctoring machine#rewinding machine price#doctor machine#winding machine price#automatic winding machine#slitting machine#slitting and rewinding machine#slitter Rewinder manufacturers#Web Aligner System price

1 note

·

View note

Link

Conveyor For Inkjet Printer Manufacturer India, Conveyor for Batch Printing for bottom edge coding with full bottom coding system We have designed and built it with applications like, Variable Speed, Reversible Direction, Stainless Steel Or depending on production requirements. It is arranged horizontally to adopt non-metal wear-resistant material. Also, useful for most of all industries like, chemical industry, machinery, metallurgy, light industry, food, medicine and many more. Cantilever design-balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner).Mechanical 1.5 / 2.5 Kg. Slitter Rewinder, Slitting Rewinding Machine Manufacturer, Optional Magnetic powder brake with tension controller & Torque control potentiometer. Provision for incorporating Inkjet Printing System with Hot air ink drying.

#Batch Printing#Conveyor for Inkjet Printer#Hydraulic Web Aligner#Slitting Rewinding Machine Manufacturer#slitter rewinder machine#Slitting Rewinding#Conveyor for Batch Printing#Conveyor for Batch Printing price#Inkjet printer#Printer Manufacturer#Printer Price#Inkjet printer Supplier#Inkjet Printing System#Slitter Machine Manufacturer#Slitter Machine#Winder Rewinder Machine#Winding Rewinding Machine#Batch printer Machine

1 note

·

View note

Link

We are specialised manufacturer Repairing & Servicing of Winding Rewinding Machine is used for all types of Laminates like, Foil, Paper, LDPE, HDPE, and PVC. Our Repairing & Servicing of Winding Rewinding Machine is used for all types of Laminates like, Foil, Paper, LDPE, HDPE, PVC, etc. Our Repairing & Servicing of Winding Rewinding Machine is manufactured with us most precision which ensure zero maintenance up to 10 years. Winding Rewinding Machine and Winding Rewinding Machine for Inkjet Printer & Batch Printing. Cantilever design-balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner). Mechanical 1.5 / 2.5 Kg. Optional Magnetic powder brake with tension controller & Torque control potentiometer. Provision for incorporating Inkjet Printing System with Hot air ink drying. The Model is specially designed for correcting badly wounded reels for inspection & doctoring operation. It is great substitute to online coding / batching operation.

#Winding Rewinding Machine#Winder Rewinder#Inkjet Printing System#Hydraulic Web Aligner#Batch Printing Machine#Web Guiding Sysytem#Winder Rewinder Machine#Rewinder Unwinder#Slitting Machine#Slitting Rewinding Machine#Slitter Machine#Slitter Rewinder Machine Manufacturer#Winder Rewinder Price#Batch Coding Machine#Rewinding Machine

0 notes

Link

Krishna Engineering works leading Manufacturer of doctoring rewinding machine, winder rewinder machine with inkject printer, winder rewinder machine for inkject printer, winder rewinder machine for batch coding, inkjet printing roll rewinding machine and inkject printer rewinder machine. Doctoring Rewinding Machines Manufacturer to make doctoring process for your flexible Packaging Roll with high-quality equipment. We have been manufacturing various types of Doctoring Rewinding Machine for different industries and for different applications per client’s requirement.

#Doctoring Rewinding Machine#Doctoring Machine#Doctoring Rewinding Machine Manufacturer#Winder Rewinder for Inkjet Printer#Winder Rewinder Machine for Batch Coding#Heavy Duty Doctoring Rewinding Machine#Winding & Rewinding Machine#Inspection Doctoring Rewinding Machine#Doctoring Inspection Machine with Slitting System#Winding Rewinding Machine#Winder Rewinder for Inkjet Printer Thermal Printer#Industrial Inkjet Printer with Winder Rewinder Machine

5 notes

·

View notes