#Dust Control

Explore tagged Tumblr posts

Text

facebook.com

Jake Olson Studios

31 notes

·

View notes

Text

Spring light changes everything. It shifts where the sun hits, how it moves through a room, and what it reveals. In May, you start to notice the fine layer of dust you missed in winter—the kind that clings to glass, settles on frames, and hangs just enough in the air to dull even the cleanest space. That’s when many turn to the Top TD Cleaning Company for a deep seasonal refresh.

0 notes

Text

Delhi Air Quality Sees Improvement Amid New Measures

Introduction: A Breath of Fresh Air for Delhi Delhi, one of the world’s most polluted capitals, has seen a significant improvement in air quality in 2025. According to the Central Pollution Control Board (CPCB), the city’s AQI has dropped to a moderate 129 — a promising shift compared to the ‘very poor’ and ‘severe’ levels seen in past winters. This shift is attributed to enhanced enforcement of…

#air pollution reduction#anti-smog guns#AQI Delhi#clean air campaign#construction regulations#Delhi 2025#Delhi air quality#Delhi government#Delhi initiatives#dust control#environmental measures#GRAP#pollution control#public health Delhi#urban environment

0 notes

Text

Clear Indoor Dust from Droughts

Droughts boost indoor dust 15%, bad for lungs. Tape cloth over window gaps, seal door gaps, cover air vents, 5-20 minutes, household items. Video shows steps. Saves 10% purifier energy.

How dusty is your home?

Music credit-

Memories by Liborio Conti

0 notes

Text

Home renovations are exciting, but they come with a fair share of mess and risk—especially when it comes to flooring. Whether you’re installing a new kitchen, knocking down walls, or simply repainting, hardwood floors are vulnerable to scratches, dents, and dust. Without the right protection, all the effort and investment that went into your flooring could be compromised. Fortunately, a few practical steps can help shield your floors throughout any renovation project. If your floors have already suffered damage, FK Floor Sanding can restore their beauty with professional sanding and refinishing services.

0 notes

Text

March 25 2025 - dust control

and there is lots and lots and lots of dust

0 notes

Text

Dry Fog Dust Suppression System: A Revolutionary Solution for Airborne Dust Control

In industries where dust generation is a concern, controlling airborne dust efficiently is crucial to ensure compliance with environmental regulations and maintain workplace safety. Our Dry Fog Dust Suppression System (DFDS) offers an innovative solution that effectively suppresses dust without wetting the product, maintaining its integrity while adding minimal moisture—usually less than 0.1%.

How Does the DFDS Work?

Our system utilizes ultrasonically produced water droplets that are similar in size to dust particles, typically less than 5 microns. By achieving this precise size, the water droplets agglomerate with airborne dust, making it easier to control and remove from the atmosphere. This method eliminates the need for costly extraction systems and chemical additives, providing a cost-effective and eco-friendly alternative.

The DFDS system is effective in controlling both breathable dust (less than 5 microns) and larger fugitive dust particles up to 600 microns. It is suitable for industries handling materials such as silica sand, dried clay, limestone, coal, aggregates, road stone, phosphate, fiberglass, and more. The system efficiently suppresses visible emissions from primary and secondary crushing, screening, transfer points, and loading/unloading operations, including hoppers, feeders, bins, silos, terminals, and transport vehicles.

Key Features of the Dry Fog Dust Suppression System

The system operates using SoniCom atomizing nozzles, which require a compressed air supply and simple on/off controls to function effectively. These nozzles suppress respirable dust particles as small as 0.1 to 3 microns, providing a highly efficient dust control solution. Compared to traditional ventilation-type control systems, the DFDS system offers significant cost savings in terms of initial investment, operation, and maintenance. It requires only 5% of the total energy used by conventional dust control systems and can be installed at approximately 40% of the cost of a standard bag filter system.

Benefits of the DFDS System

Minimal Product Wetting: Adds less than 0.5% moisture, far lower than conventional water spray systems.

Optimized Water Usage: Micron-sized water droplets increase surface area coverage while reducing total water consumption.

Eliminates Chemical Additives: No need for costly wetting agents or chemical controls.

Prevents Conveyor Belt Issues: Does not wet conveyor belts, thereby avoiding tracking problems.

Reduces Downtime: Less frequent conveyor maintenance and belt replacements.

Enhances Dust Collection Systems: Agglomerated dust improves the efficiency of precipitators, baghouses, and collectors.

Low Operating Costs: Nozzles function with low-pressure air and water, eliminating the need for expensive pumping systems.

Improves Workplace Safety: Reduces airborne dust, ensuring compliance with health and safety regulations.

Minimizes Cleaning and Maintenance Costs: Keeps operational areas cleaner, reducing overall maintenance expenses.

Material Recovery: Facilitates the collection and reuse of spilled materials, minimizing waste.

Why Choose Our DFDS?

Our Dry Fog Dust Suppression System is a game-changer for industries struggling with airborne dust. By implementing this efficient, cost-effective, and eco-friendly solution, businesses can improve operational efficiency, reduce maintenance costs, and ensure regulatory compliance while creating a healthier working environment.

1 note

·

View note

Text

Get Fertilizer Dust Control Agents from NAQ Global

NAQ Global brings you amazing fertilizer coating agents that will help you prevent caking and extra dust while handling fertilizer in bulk. If you are interested, kindly visit our website to know more.

Visit now: https://www.naqglobal.com/product/dust-control-fertilizer-coating

#defoamer chemical suppliers#fertilizer dust control#dust control system#dust control methods#dust control agents#dust control

0 notes

Text

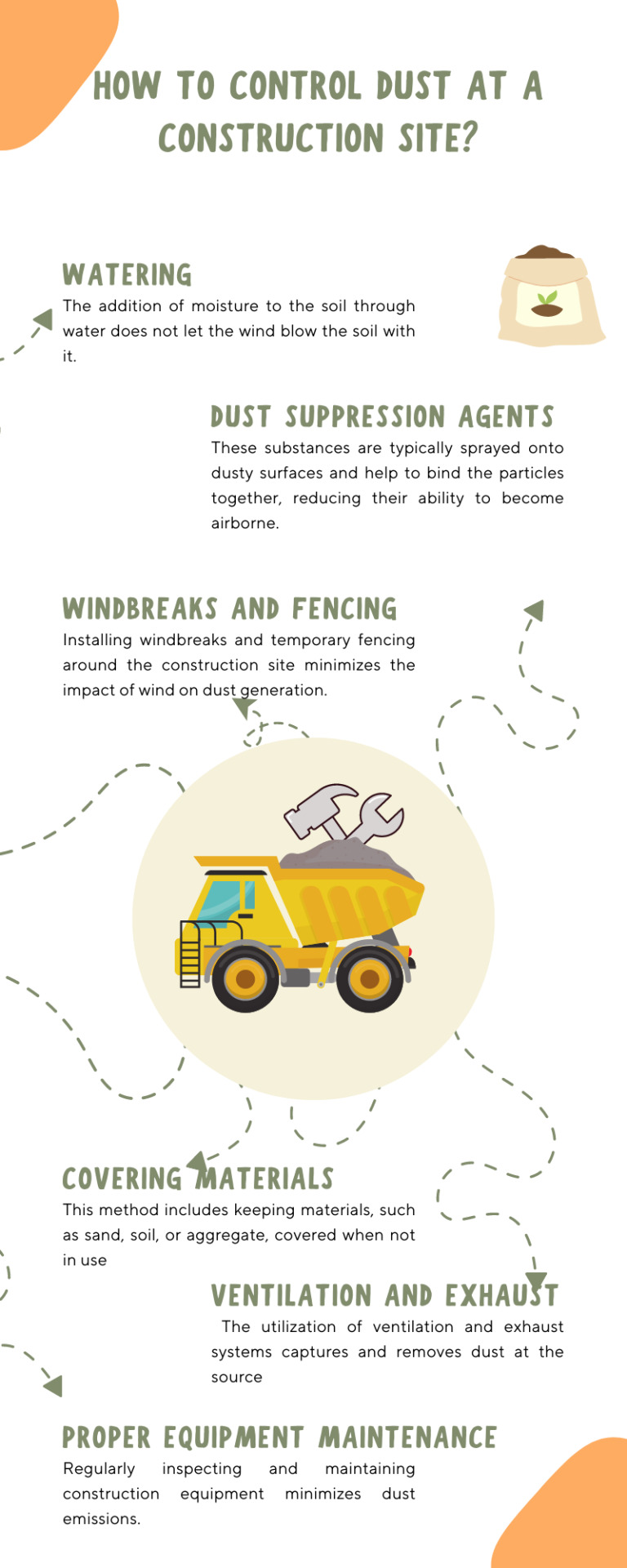

Why Dust Control is Crucial for Construction Sites 🏗️🌫️

Dust control is essential on construction sites to ensure worker safety, improve air quality, and prevent health issues. By prioritizing dust management, companies can create a cleaner, safer environment and reduce long-term damage to equipment. Learn more about the importance of dust control in construction and how to implement effective solutions. 🚧💨 For more information visit our new blog.

0 notes

Text

Buzz Lite PVC Strip Curtains: The Versatile Solution for Your Space

#dust control#Industrial curtains#insect control#Pvc strip curtain for cold storage#PVC strip Curtains

0 notes

Text

How to Effectively Use Cyclone Dust Collectors?

Cyclone dust collectors (also referred to as a cyclone separator or simply a cyclone) are essential in various industrial applications for controlling air quality and minimizing dust emissions. The efficiency of these cyclonic systems hinges on the precise dimensions and relationships of their components.

In this blog, we’ll explore the critical factors that influence the performance of cyclone dust collectors, along with best practices for installation and usage.

WHAT ARE THE ADVANTAGES AND DISADVANTAGES OF CYCLONE DUST COLLECTORS?

Advantages

1. Dry Cleaning Method: The dry cleaning method facilitates the centralized treatment and recycling of dust.

2. Corrosive Dust Handling: Cyclone can be used to treat corrosive dust gas.

3. Compact Design: The cyclone separator is small and occupies less space, therefore making it easy to install. Additionally, it has a simple structure and is relatively inexpensive.

4. User-Friendly: The cyclone structure is not complex, making it easy to use.

5. High-Temperature Gas Purification: Cyclone can purify high-temperature dusty gases. The cyclone dust collector made of carbon steel can handle gas temperatures up to 100°C, while those with refractory materials can process gases at 500°C.

Disadvantages

1. Limited Handling Capacity: Due to the small handling capacity of a single cyclone dust collection unit, multiple cyclone collection units need to be connected in parallel for larger volumes.

2. Ineffective on Fine Dust: A cyclone separator is not suitable for treating dust particles smaller than 5μm. For light dust particles and high filtration efficiency, baghouse filters are the preferred choice.

3. Not Suitable for Sticky Dust:The cyclones are ineffective in purifying sticky dust particles.

WHAT ARE THE FACTORS AFFECTING THE EFFICIENCY OF A CYCLONE?

1. Inlet Size

The inlet is a crucial component of a cyclone dust collector, significantly impacting dust removal efficiency. A smaller inlet area increases airflow velocity, which enhances dust separation from other particles.

2. Diameter and Height of the Cyclone Cylinder

The diameter and height of the cylindrical body influence the efficiency of the cyclone.With a constant rotational airflow speed, a larger diameter results in reduced centrifugal force on the dust particles. This leads to lower dust removal efficiency and makes it harder for dust to be drawn into the machine. Therefore, the inlet diameter should not be excessively large or too small. A suitable size is essential to avoid clogging by larger dust particles.

3.Diameter and Depth of the Exhaust Pipe

The diameter and depth of the exhaust pipe also affect cyclone dust removal efficiency. A smaller diameter in the exhaust pipe restricts airflow, making it more difficult for dust to exit. To improve efficiency, it's important to increase the exhaust velocity and the pipe diameter.

HOW DO YOU CHOOSE A CYCLONE SEPARATOR?

1.Matching Purification Capacity

The actual amount of dust-laden gas to be processed should match the capacity of the cyclone dust collector. Therefore, when you select the diameter of the cyclone dust collector, keep it as small as possible. If you require a larger airflow, then you can use several smaller diameter cyclone dust collectors in parallel.

2.Inlet Airspeed

The inlet airflow velocity should be maintained between 18 and 23 m/s. If the velocity is too low, dust removal efficiency will decrease. On the other hand, if the velocity is too high, resistance loss will increase. And power consumption will also rise, resulting in little improvement in dust removal efficiency.

3. Low Resistance Loss

You should select a cyclone dust collector with low resistance loss. Additionally, it should have low power consumption. Finally, it should feature a simple structure for easy maintenance.

4. Minimum Dust Particle Capture

The cyclone dust collector should capture the smallest dust particle size. This size should be slightly smaller than the particle size in the gas being processed.

5. High-Temperature Dust-Laden Gas

When you deal with high-temperature dust-laden gas, you should apply insulation. This prevents moisture from condensing inside the collector. If the dust does not absorb moisture and the dew point is between 30°C and 50°C, you should set the collector temperature at least 30°C higher. If the dust is hygroscopic (such as cement, gypsum, or alkaline dust) and the dew point is between 20°C and 50°C, you should maintain the collector temperature 40°C to 50°C above the dew point.

6. Sealed Structure

You should ensure that the cyclone dust collector has a well-sealed structure to prevent any air leakage, especially during negative pressure operations. Additionally, you should emphasize the reliability of the discharge lock device.

7. Explosion-Proof Measures

For flammable and explosive dust (such as coal dust), explosion-proof measures should be in place. A common practice is to install a safety explosion-proof valve in the inlet pipeline.

8. Dust Concentration Limits

When the dust is less viscous, you can relate the maximum allowable mass concentration of dust to the diameter of the cyclone. Specifically, a larger diameter allows for a higher allowable mass concentration.

WHAT ARE THE INSTALLATION POINTS?

1.Ensure Uniform Airflow Distribution

When combining multiple cyclone dust collectors, it is essential to maintain uniform airflow to prevent short-circuiting. The inlet, hopper, and outlet zones must be properly sealed to avoid air leaks.

2.Material Selection

Depending on the operational conditions, cyclone dust collectors can be constructed from various materials, including steel, organic plastics, and ceramics. Selecting the right material is crucial for ensuring durability and resistance to wear and tear.

3.Positioning in Series

When connecting cyclone dust collectors in series, they should be arranged based on their performance. High-efficiency collectors should be placed first to capture the majority of the dust before it reaches lower-performing units.

HOW DO YOU MAINTAIN YOUR CYCLONE SEPARATOR?

I. Stable Operating Parameters

The operating parameters of a cyclone dust collector mainly include the inlet airflow velocity, the temperature of the gas being processed, and the inlet mass concentration of dust-laden gas.

♦Inlet Airflow Velocity

For a cyclone dust collector of fixed dimensions, increasing the inlet airflow velocity improves the gas handling capacity. It also effectively enhances separation efficiency. However, this increase also raises the pressure drop. Once the inlet airflow velocity reaches a certain value, the separation efficiency may decline. Additionally, wear may increase, and the lifespan of the cyclone dust collector may shorten. Therefore, you should maintain the inlet airflow velocity in the range of 18 to 23 m/s.

♦Temperature of the Processed Gas

As gas temperature increases, its viscosity rises, which increases the centripetal force acting on dust particles, leading to a decrease in separation efficiency. Therefore, cyclone dust collectors operating under high-temperature conditions should have a larger inlet airflow velocity and a smaller cross-sectional flow rate.

♦Inlet Mass Concentration of Dust-Laden Gas

A higher concentration of larger dust particles significantly carries smaller dust particles, which improves separation efficiency.

II. Preventing Air Leakage

Air leakage in a cyclone dust collector can severely impact dust removal efficiency. For instance, experts estimate that a 1% air leak at the lower cone or the discharge valve will decrease dust removal efficiency by 5%. Moreover, if a 5% leak occurs, the efficiency will drop by 30%. You can find air leakage in three areas. These areas are at the inlet and outlet flanges, in the body of the cyclone dust collector, and at the discharge mechanism.

The causes of air leakage include:

Flange Leakage: This is mainly caused by loose bolts, uneven gasket thickness, or irregular flange surfaces.

Body Leakage: The primary reason for leakage in the dust collector body is wear, particularly in the lower cone. Experience shows that when the mass concentration of dust-laden gas exceeds 10 g/m³, a 3 mm thick steel plate can wear out in less than 100 days.

Discharge Mechanism Leakage: This is mainly due to poor sealing in mechanical automatic discharge valves (e.g., weight-operated valves).

III. Preventing Wear in Key Areas

Factors affecting wear in critical areas include load, airflow velocity, and dust particle characteristics. The wear-prone areas include the casing, cone, and discharge outlet. Technical measures to prevent wear include:

Preventing Discharge Outlet Blockage: This mainly involves selecting high-quality discharge valves and regularly adjusting and maintaining them.

Preventing Excessive Gas Backflow into the Discharge Outlet: The discharge valves should be tightly sealed and properly weighted.

Regular Inspections: Frequent checks for air leaks due to wear should be conducted to take timely corrective measures.

Using Replaceable Wear Plates: In high-impact areas, install replaceable wear plates or increase the wear-resistant layer.

Minimizing Welds and Joints: Reduce the number of welds and joints; existing welds should be ground smooth, and flanges should have matching inner diameters and maintain good alignment.

Maintaining Airflow Velocities: The tangential velocity of airflow at the cyclone dust collector wall and the inlet airflow velocity should be kept within the critical range.

IV. Avoiding Dust Blockage and Buildup

Blockages and dust buildup in cyclone dust collectors mainly occur near the discharge outlet and in the intake and exhaust pipelines.

Discharge Outlet Blockage and Prevention Measures: Blockages at the discharge outlet are typically caused by two factors:

large materials or debris (such as shavings, wood chips, plastic bags, shredded paper, rags, etc.) getting stuck at the discharge outlet, leading to dust accumulation around them.

excessive dust accumulation in the hopper that has not been discharged in time. Preventive measures include adding a mesh at the intake and creating access holes above the discharge outlet (with covers and gaskets sealed with adhesive).

Intake and Exhaust Blockage and Prevention Measures: Improper design often causes blockages at the intake and exhaust ports. Rough right angles or slanted angles at the ports can lead to ash adhesion and buildup. This buildup eventually causes blockages.

CONCLUSION

Cyclone dust collectors are a vital component of effective dust management in industrial settings. By understanding the key design elements, adhering to installation best practices, and implementing innovations from Darko, operators can significantly enhance performance and efficiency. Regular maintenance and attention to detail will ensure that these systems operate at their best, providing a cleaner and safer working environment.

If you have any questions or would like to learn more about cyclone dust collectors and their applications, feel free to reach out.

0 notes

Text

Say goodbye to dust! Explore practical dust management strategies to reduce allergens and maintain a cleaner, healthier living environment.

1 note

·

View note

Text

Good night kiss

Husk in his room:

#my art#huskerdust#hazbin hotel#angel dust#hazbin hotel husk#husk having no self control cause he is that in love

4K notes

·

View notes

Text

Dust Control Solutions: Best Practices for Managing Air Quality in Construction Sites

Construction sites are notorious for generating high dust levels, which can pose significant health risks to workers and nearby communities. Exposure to construction dust has been linked to respiratory issues, allergies, and even long-term health problems. Therefore, implementing effective dust control solutions is of utmost importance to safeguard the well-being of workers and minimize environmental impact. In this article, we will discuss the best practices for managing air quality in construction sites.

Pre-Construction Planning

Effective dust control starts with careful planning before the construction phase. Assessing the site conditions, weather patterns, and nearby sensitive areas allows for developing appropriate strategies. It is crucial to consider the proximity of schools, hospitals, and residential areas and plan mitigation measures accordingly.

Training and Education

Properly educating and training construction site personnel about the risks associated with dust exposure and the importance of dust control measures is essential. Workers should be informed about the potential health effects, proper use of personal protective equipment (PPE), and techniques for minimizing dust generation.

Site Layout and Dust Suppression

Managing the layout of the construction site is crucial for effective dust control. Diverting traffic away from sensitive areas, implementing windbreaks, and controlling the movement of vehicles and equipment can help minimize dust generation. Additionally, the use of dust suppression techniques, such as water spraying, can effectively reduce airborne dust particles.

Water Management

Water plays a vital role in controlling construction site dust. Proper water management involves regularly wetting the ground, stockpiles, and materials to prevent dust from becoming airborne. Using sprinkler systems, water trucks, or even water cannons can help keep dust levels under control.

Enclosures and Barriers

Enclosing construction activities within structures or temporary barriers can be highly effective in preventing dust from spreading. Installing barriers around particularly dusty operations like cutting, grinding, or demolition can help contain the dust within the designated area, reducing the risk of dispersion.

Dust Collection Systems

Utilizing dust collection systems, such as industrial vacuum cleaners or dust collectors, can significantly improve air quality on construction sites. These systems capture airborne particles directly at the source, preventing their dispersion into the surrounding environment. Regular maintenance and proper disposal of collected dust are essential to ensure their effectiveness.

Personal Protective Equipment (PPE)

In addition to implementing engineering and administrative controls, providing workers with appropriate personal protective equipment is crucial. Respiratory protection, such as N95 masks or respirators, should be worn by workers exposed to high levels of dust. Other PPE, including safety glasses, gloves, and coveralls, should also be used to minimize direct contact with dust.

Regular Site Cleaning

Frequent cleaning of the construction site is essential to prevent the accumulation of dust. Regular sweeping, vacuuming, and washing of surfaces can significantly reduce the amount of dust available for resuspension. Proper disposal of collected debris and dust is equally important to prevent recontamination.

Monitoring and Compliance

Implementing a robust monitoring system allows for the continuous assessment of dust levels and the effectiveness of control measures. Regular air quality testing can help identify areas that require additional attention and ensure compliance with regulatory standards.

Communication and Stakeholder Engagement

Maintaining open lines of communication with workers, nearby residents, and other stakeholders is crucial for successful dust control. Informing them about the measures in place, addressing concerns, and soliciting feedback can help foster a cooperative and supportive environment.

In conclusion, managing air quality in construction sites requires a comprehensive approach that integrates careful planning, effective dust suppression techniques, proper use of personal protective equipment, and regular monitoring.

By implementing these best practices, construction companies can create safer work environments, protect the health of workers and nearby communities, and minimize their environmental impact. Taking proactive measures to control dust not only improves air quality but also enhances overall project efficiency and sustainability.

Construction sites can be models for responsible and environmentally conscious practices, setting a precedent for other industries to follow suit. With a collective commitment to dust control solutions, we can create healthier work environments and build a brighter future for all.

1 note

·

View note

Text

Dust control is quite crucial during construction for best results and lets no harm to the people.

0 notes

Text

[Pit Babe 2 ep 5]

-----

bonus:

my reaction to Kim in this scene:

#literally i could hear Mark Lee's voice in my head as Kim spun that car around#also that last gif would be a near perfect loop if not for the fact that it starts with no dust cloud but then gains one as the car goes#Kim just staring straight into Kenta's soul as;fkjja;asfasfelksfj#the way that Kenta moves ever so slightly to stay out of the car's way without looking concerned at all that Kim might hit him#absolutely sure that Kim has total control over the car in every moment#because he does#but also#oh dude he's flirting#pit babe 2#pit babe 2 ep 5#kimkenta#kentakim#benzgarfield#benz atthanin#garfield pantach#mia gifs pit babe things#mia gifs drama things#mia gifs things#look at me remembering to watermark my gifs for once#mia watches things

154 notes

·

View notes