#EPDM Market

Explore tagged Tumblr posts

Text

Ethylene Propylene Diene Monomer (EPDM) Market Overview

Introduction

Ethylene Propylene Diene Monomer Market is a type of synthetic rubber known for its excellent resistance to heat, oxidation, ozone, and weathering. EPDM rubber is used in a wide range of applications, including automotive weatherstripping and seals, roofing membranes, and industrial and construction products. The market for EPDM is growing steadily due to its superior properties and the increasing demand from various end-use industries.

Market Drivers

1. Automotive Industry Growth: The automotive sector is one of the largest consumers of EPDM, utilizing it in hoses, seals, and weatherstripping. The continuous growth in vehicle production and the shift towards electric vehicles, which require durable and heat-resistant materials, drive the demand for EPDM.

2. Construction Industry Demand: In the construction industry, EPDM is used in roofing membranes and other applications due to its durability and weather resistance. With increasing infrastructure projects and renovation activities, the demand for EPDM in the construction sector is rising.

3. Rising Industrial Applications: EPDM's properties make it suitable for various industrial applications, such as conveyor belts, gaskets, and hoses. The expansion of the manufacturing sector and the need for reliable and durable materials in industrial processes contribute to the market growth.

Market Challenges

1. Raw Material Price Volatility: The prices of raw materials used in the production of EPDM, such as ethylene and propylene, are subject to fluctuations. This volatility can affect the overall cost of production and impact profit margins for manufacturers.

2. Environmental Regulations: The production and disposal of synthetic rubber are subject to environmental regulations. Compliance with these regulations can increase production costs and pose challenges for manufacturers.

For a comprehensive analysis of the market drivers:- https://univdatos.com/report/ethylene-propylene-diene-monomer-market/

Regional Insights

1. North America: The North American EPDM market is driven by the robust automotive and construction sectors. The region's focus on sustainable and energy-efficient buildings further supports the demand for EPDM in roofing applications.

2. Europe: Europe is a significant market for EPDM due to its strong automotive industry and stringent environmental regulations that promote the use of durable and recyclable materials. The construction sector also contributes to the market growth in this region.

3. Asia-Pacific: The Asia-Pacific region is witnessing rapid growth in the EPDM market, fueled by the booming automotive industry in countries like China and India. Additionally, the expanding construction industry and increasing industrialization are driving the demand for EPDM in this region.

4. Latin America and Middle East & Africa: These regions are experiencing moderate growth in the EPDM market. The increasing automotive production and construction activities are key factors contributing to the market expansion in these regions.

Market Trends

1. Sustainability and Recycling: There is a growing emphasis on sustainability and recycling in the EPDM market. Manufacturers are focusing on developing eco-friendly production processes and recyclable EPDM products to meet the rising demand for sustainable solutions.

2. Technological Advancements: Innovations in production technologies and the development of advanced EPDM formulations are enhancing the performance and applications of EPDM. These advancements are expected to open new opportunities in various end-use industries.

3. Increased Use in Electric Vehicles: The shift towards electric vehicles (EVs) is driving the demand for high-performance materials like EPDM. EVs require materials that can withstand higher temperatures and provide better insulation, making EPDM an ideal choice.

For a sample report, visit:- https://univdatos.com/get-a-free-sample-form-php/?product_id=31683

Competitive Landscape

The EPDM market is highly competitive, with several key players operating globally. Companies are focusing on strategic initiatives such as mergers and acquisitions, collaborations, and new product developments to strengthen their market position. Some of the prominent players in the EPDM market include:

Conclusion

The Ethylene Propylene Diene Monomer (EPDM) market is poised for significant growth in the coming years, driven by the increasing demand from the automotive, construction, and industrial sectors. While challenges such as raw material price volatility and environmental regulations exist, advancements in technology and a focus on sustainability are expected to propel the market forward. The competitive landscape will continue to evolve as companies innovate and adapt to meet the changing demands of the market.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

Exploring Growth: A Guide to EPDM Market Trends and Key Insights

In the ever-evolving landscape of the global market, industries are continually influenced by emerging trends and technologies. Among the noteworthy players in this dynamic environment is the Ethylene Propylene Diene Monomer (EPDM) market. This versatile synthetic rubber has found its applications across various sectors, contributing to its growing significance in the global marketplace.

Decoding EPDM: What Does it Mean?

Before delving into market specifics, it's crucial to understand the essence of EPDM. Ethylene Propylene Diene Monomer, abbreviated as EPDM, is a synthetic rubber known for its exceptional durability and resistance properties. This elastomer is widely used in manufacturing products ranging from automotive parts to roofing materials. Our exploration goes beyond the acronym, unraveling the unique qualities that make EPDM a sought-after material in various industries.

EPDM Market Trends: A Glimpse into the Future

Understanding market trends is crucial for businesses looking to stay ahead in today's competitive landscape. The EPDM market is witnessing a notable uptrend, driven by its exceptional properties and diverse applications. As a key player in the elastomer industry, EPDM is gaining traction due to its resistance to heat, ozone, and weathering, making it a preferred choice in automotive, construction, and electrical industries.

Ethylene Propylene Diene Monomer (EPDM) Rubber Market Size was valued at USD 3.6 billion in 2022 and is projected to reach USD 4.8 billion by 2027, growing at a cagr 5.9% from 2022 to 2027.

Leaders in Production: Unveiling the Largest EPDM Producers

In the vast tapestry of EPDM production, certain industry giants stand out as leaders. These producers play a pivotal role in shaping the market dynamics. From formulation to distribution, understanding the key players is essential for businesses navigating the EPDM landscape. In our exploration, we'll uncover the identities and contributions of the largest EPDM producers, shedding light on their market influence.

Download PDF Brochure:

EPDM in Pharmaceuticals: An Unexpected Player

While EPDM is commonly associated with industries like automotive and construction, its presence in the pharmaceutical sector may come as a surprise. The pharmaceutical industry relies on EPDM for specific applications, leveraging its properties for specialized purposes. In this segment, we'll uncover the role of EPDM in pharmaceuticals, providing insights into its applications and benefits in this unexpected but crucial arena.

INQUIRY BEFORE BUYING :

The EPDM market is not only a reflection of technological advancements but also a testament to the adaptability of industries worldwide. As we navigate the trends, explore the key producers, and unravel the diverse applications of EPDM, it becomes evident that this synthetic rubber is set to play an increasingly influential role in shaping the future of multiple sectors.

0 notes

Text

EPDM Rubber Price Index: Market Analysis, Trend, News, Graph and Demand

EPDM Rubber ENB (4.1–5.5) prices in the U.S. posted a marginal quarter-on-quarter decline of 1.66%, shaped by ongoing shifts in supply and demand conditions. Prices remained relatively stable on a month-to-month basis, but broader quarterly data pointed to slight downward movement, largely influenced by easing feedstock costs and improved availability. Ethylene prices fell sharply by 13.8% in March, while Propylene prices decreased by 6.2%, collectively supporting better production economics and reducing input cost pressures for EPDM manufacturers.

On the supply side, early-quarter logistical challenges such as port congestion and shipping delays that impacted January and February saw gradual resolution by March. This improved the flow of imports and helped stabilize regional availability. Demand signals were mixed over the quarter, with a slow start in automotive sales followed by a strong rebound in March. The construction sector, particularly residential development, provided steady support, though its growth was not sufficient to significantly boost overall market momentum. Broader macroeconomic concerns such as persistent inflation, evolving tariff structures, and cautious consumer behavior continued to influence downstream purchasing patterns and restrained any aggressive buying.

Manufacturing data remained relatively strong, signaling a steady industrial base, but the pace of growth was held in check by uncertainties surrounding trade regulations and rising logistics expenses. Suppliers adapted to moderate demand and shifting cost structures, maintaining a stable market balance. As a result, the EPDM rubber market experienced a slight correction in prices over the quarter without encountering sharp volatility, reflecting a market in measured equilibrium.

Get Real time Prices for EPDM Rubber: https://www.chemanalyst.com/Pricing-data/epdm-rubber-1110

The EPDM Rubber market in Japan recorded a mild quarter-on-quarter decline of 0.93% during Q1 2025, as the market adjusted to a combination of steady supply and softening demand. Feedstock availability, particularly Ethylene and Propylene, remained relatively balanced, although logistical recalibrations and lower Ethylene production rates added complexity to the supply chain. Japanese producers, including major players like Mitsui Chemicals, attempted to optimize operations and announced price adjustments for some elastomer products, though the direct impact on EPDM pricing was limited due to broader market pressures.

Demand was constrained by subdued global economic activity, with weaker-than-expected orders from major international markets such as the U.S., Europe, and China. While the domestic automotive sector maintained reasonable output levels and vehicle sales inched upward, the construction industry faced headwinds from elevated labor costs and a slowdown in project completions. These factors collectively muted EPDM consumption growth and created a cautious market atmosphere. Some positive domestic trends, such as a modest rebound in the housing sector, supported price stability to a degree, but they were not strong enough to counteract broader economic unease.

Manufacturing sentiment remained cautious, shaped by global trade uncertainty and sluggish export activity. As a result, the Japanese EPDM market experienced a subdued pace of price movement, reflecting the delicate balance between steady supply and weak external demand. The slight quarterly dip in pricing underscored a conservative outlook as market participants awaited clearer economic signals.

The European EPDM Rubber market saw a modest decline of 0.88% from the previous quarter, reflecting a period of relative price stability amid mixed economic and sectoral dynamics. Regional supply remained consistent, driven by uninterrupted domestic production and steady import volumes. Despite ongoing logistical complications at key European ports like Hamburg and Rotterdam, the impact on the EPDM supply chain was mitigated by healthy inventory levels and easing freight costs, which supported overall market availability.

On the demand front, conditions were uneven. The automotive sector showed a drop in vehicle registrations across several key countries during January and February, suggesting a cautious consumer environment. The construction industry also faced headwinds, with activity remaining subdued across residential, commercial, and public infrastructure projects. However, government-backed infrastructure initiatives, especially in civil engineering, hinted at potential recovery in the medium term. These sector-specific fluctuations were accompanied by broader economic developments, including rate cuts from the European Central Bank aimed at stimulating investment and consumption.

Despite these monetary policy efforts, lingering concerns about global trade conditions and inflationary pressures continued to cast a shadow over demand confidence. Market participants adopted a cautious stance, limiting stockpiling and procurement activity. Nonetheless, the European EPDM market demonstrated underlying resilience, with suppliers maintaining stable operations and adapting to evolving conditions. The slight downward shift in prices reflected a market navigating short-term challenges while holding an optimistic view for gradual recovery in the latter half of the year.

Get Real time Prices for EPDM Rubber: https://www.chemanalyst.com/Pricing-data/epdm-rubber-1110

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#EPDM Rubber Price Monitor#Ethylene Propylene Diene Monomer Rubber Price#India#United kingdom#United states#Germany#Business#Research#Chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Ethylene Propylene Diene Monomer (EPDM) Rubber Prices, News

North America

The EPDM Rubber market in the US has experienced a marginal 0.87% price increase in the fourth quarter of 2024, driven by stable supply and gradual demand recovery. The increase reflects a balance between supply constraints, including moderate raw material availability, and steady demand from the automotive sector, which saw continued growth in vehicle sales.

While feedstock prices for Ethylene and Propylene showed mixed trends, the market remained stable due to adequate supply and efficient sourcing strategies by manufacturers. The automotive sector provided significant support, with strong sales growth reported in November and December, while the construction sector remained subdued. Ongoing logistical challenges, including port congestion and labor shortages, extended delivery times, but did not disrupt supply enough to cause price spikes.

Despite a weakened manufacturing sector, cautious buying behavior, and moderate demand from the construction sector, EPDM Rubber prices showed resilience, reflecting a balanced market outlook. With expectations for gradual improvement in 2025, this trend of modest price increases is likely to continue.

0 notes

Text

Epdm Foam Rubber Market Forecast 2025-2033: Technology and Demand

Epdm Foam Rubber Market Research Report

Market Strides has recently added a new report to its vast depository titled Global Epdm Foam Rubber Market. The report studies vital factors about the Global Epdm Foam Rubber Market that are essential to be understood by existing as well as new market players. The report highlights the essential elements such as market share, profitability, production, sales, manufacturing, advertising, technological advancements, key market players, regional segmentation, and many more crucial aspects related to the Epdm Foam Rubber Market.

Get Free Sample Report PDF @ https://marketstrides.com/request-sample/epdm-foam-rubber-market

Epdm Foam Rubber Market Share by Key Players

Armacell

Fostek Corporation

Roop koepp

L’isolante K-Flex

Kaimann GmbH

Huamei Energy-Saving

Aeroflex

NMC

Epdm Foam Rubber Market Segmentation

The report on Global Epdm Foam Rubber Market provides detailed toc by type, applications, and regions. Each segment provides information about the production and manufacturing during the forecast period of 2025-2033 . The application segment highlights the applications and operational processes of the industry. Understanding these segments will help identify the importance of the various factors aiding to the market growth.

The report is segmented as follows:

By Type

Closed Cell Rubber

Semi-closed Cell Rubber

By Application

HVAC

Automotive

Electrical & Electronics

Construction

Others

Get Detailed @ https://marketstrides.com/report/epdm-foam-rubber-market

Epdm Foam Rubber Market Frequently Asked Question

1) What are Epdm Foam Rubber Market and why are they important?

2) What is the future outlook for the Epdm Foam Rubber Market?

3) What are the Segments Covered in the Market?

4) Who are the prominent key players in the Market?

Key Highlights

It provides valuable insights into the Epdm Foam Rubber Market.

Provides information for the years 2025-2033. Important factors related to the market are mentioned.

Technological advancements, government regulations, and recent developments are highlighted.

This report will study advertising and marketing strategies, market trends, and analysis.

Growth analysis and predictions until the year 2032.

Statistical analysis of the key players in the market is highlighted.

Extensively researched market overview.

Buy Epdm Foam Rubber Market Research Report @ https://marketstrides.com/buyNow/epdm-foam-rubber-market

Contact Us:

Email : [email protected]

#Epdm Foam Rubber Market Size#Epdm Foam Rubber Market Share#Epdm Foam Rubber Market Growth#Epdm Foam Rubber Market Trends#Epdm Foam Rubber Market Players

0 notes

Text

EPDM Cable Market Trends and Long-Term Outlook 2024 - 2032

The EPDM (Ethylene Propylene Diene Monomer) cable market is an essential segment of the electrical and telecommunications industry, driven by the growing demand for durable and reliable cable solutions across various applications. EPDM cables are known for their excellent weather resistance, flexibility, and insulation properties, making them suitable for use in harsh environments. This article provides an in-depth analysis of the EPDM cable market, discussing key trends, drivers, challenges, and future outlook.

Overview of EPDM Cables

The EPDM cable market is well-positioned for growth as industries increasingly prioritize durability, flexibility, and reliability in electrical solutions.

What Are EPDM Cables?

EPDM cables are electrical cables insulated with EPDM rubber, a synthetic material known for its exceptional resistance to heat, ozone, and weathering. These cables are commonly used in applications where durability and flexibility are critical, such as in outdoor and industrial settings.

Key Features of EPDM Cables

Weather Resistance: EPDM cables can withstand extreme temperatures, UV exposure, and moisture, making them ideal for outdoor applications.

Chemical Resistance: These cables exhibit resistance to various chemicals, oils, and solvents, ensuring longevity in industrial environments.

Flexibility: EPDM cables remain flexible even at low temperatures, facilitating easier installation and maneuverability.

Market Dynamics

Current Market Trends

The EPDM cable market is shaped by several significant trends:

Growing Demand for Renewable Energy: The rise in renewable energy projects, such as solar and wind power, is increasing the need for reliable and durable cable solutions.

Technological Advancements: Innovations in cable manufacturing processes are enhancing the performance characteristics of EPDM cables, driving their adoption in various applications.

Increasing Infrastructure Development: Ongoing investments in infrastructure, particularly in emerging economies, are fueling the demand for high-quality electrical cables.

Market Segmentation

The EPDM cable market can be segmented based on:

Type: Low-voltage cables, medium-voltage cables, high-voltage cables.

Application: Power generation, telecommunications, automotive, industrial equipment, and others.

Region: North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

Key Drivers of Market Growth

Rising Energy Demand

The growing global energy demand, coupled with the expansion of power generation infrastructure, is driving the need for durable electrical cables like EPDM.

Increasing Adoption of Electric Vehicles

The rise of electric vehicles (EVs) is boosting the demand for EPDM cables, which are used in charging stations and EV components due to their flexibility and durability.

Stringent Safety Standards

Regulatory requirements for safety and environmental standards are encouraging manufacturers to use high-quality materials like EPDM in cable production, driving market growth.

Challenges Facing the Market

Price Volatility of Raw Materials

Fluctuations in the prices of raw materials used in the production of EPDM cables can impact manufacturing costs and pricing strategies.

Competition from Alternative Materials

The availability of alternative insulation materials, such as PVC and silicone, may limit the growth of the EPDM cable market, as some users may prefer these alternatives for specific applications.

Technical Challenges

The manufacturing of EPDM cables requires advanced technology and expertise, which may pose challenges for smaller manufacturers looking to enter the market.

Future Outlook

Market Projections

The EPDM cable market is expected to witness steady growth over the next several years, driven by increasing demand in various sectors, including renewable energy and electric vehicles.

Innovations on the Horizon

Future developments may include enhanced formulations of EPDM for improved performance, such as better thermal stability and higher conductivity, as well as the integration of smart technologies for monitoring and control.

Strategic Collaborations

Collaborations between manufacturers, end-users, and research institutions will be essential for driving innovation and expanding the market reach of EPDM cables.

Conclusion

While challenges such as raw material price volatility and competition from alternative materials exist, the ongoing demand for high-quality cables in renewable energy, electric vehicles, and infrastructure development will drive market adoption. As technological advancements continue to emerge, EPDM cables will play a vital role in enhancing the performance and safety of electrical systems across various applications, contributing to a more sustainable and efficient energy future.

0 notes

Text

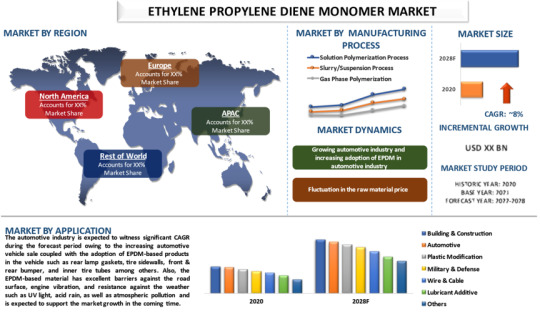

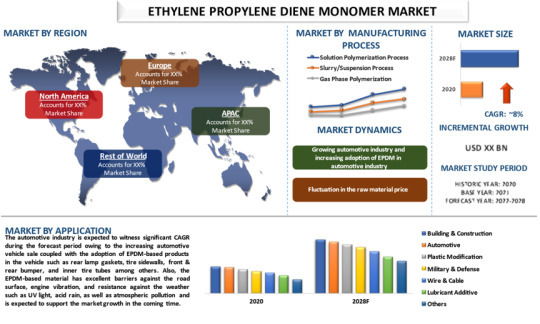

Global Ethylene Propylene Diene Monomer Market is expected to grow at a significant rate of around 8% during the forecast period.

0 notes

Text

#At 5.9% CAGR#EPDM Rubber Market Size to hit USD 4.86 Billion by 2031#says Intellectual Market Insights Research#intellectualmarketinsights

0 notes

Text

#EPDM Roofing Market COVID-19 Analysis Report#EPDM Roofing Market Demand Outlook#EPDM Roofing Market Primary Research#EPDM Roofing Market Size and Growth#EPDM Roofing Market Trends#EPDM Roofing Market#global EPDM Roofing market by Application#global EPDM Roofing Market by rising trends#EPDM Roofing Market Development#EPDM Roofing market Future#EPDM Roofing Market Growth#EPDM Roofing market in Key Countries#EPDM Roofing Market Latest Report#EPDM Roofing market SWOT analysis#EPDM Roofing market Top Manufacturers#EPDM Roofing Sales market#EPDM Roofing Market COVID-19 Impact Analysis Report#EPDM Roofing Market Primary and Secondary Research#EPDM Roofing Market Size#EPDM Roofing Market Share#EPDM Roofing Market Research Analysis#EPDM Roofing Market Trends and Outlook#EPDM Roofing Industry Analysis

0 notes

Text

Ethylene Propylene Diene Monomer (EPDM) Market: Current Analysis and Forecast (2022-2028)

According to a new report published by UnivDatos Markets Insights, the Ethylene Propylene Diene Monomer (EPDM) Market is expected to grow at a CAGR of around 8% from 2022-2028. The analysis has been segmented into Manufacturing Process (Solution Polymerization Process, Slurry/Suspension Process, and Gas Phase Polymerization); Application (Building & Construction, Automotive, Plastic Modification, Military & Defense, Wire & Cable, Lubricant Additive, and Others); Region/Country.

The Ethylene Propylene Diene Monomer (EPDM) market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the Ethylene Propylene Diene Monomer (EPDM) market. The Ethylene Propylene Diene Monomer (EPDM) market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the Ethylene Propylene Diene Monomer (EPDM) market at the global and regional levels.

Market Overview

Ethylene Propylene Diene Monomer (EPDM) is a synthetic material obtained from natural gas and thermal cracking petroleum products such as naphtha. EPDM is widely used in low-slope buildings, automotive applications, and construction applications due to their longer durability and superior resistance to environmental factors such as UV, ozone, and other weather condition. In recent times, the EPDM witnessed significant demand due to its increasing demand from the automotive industry, manufacturing & construction industry attributed to its lower cost, higher moldability, and longer durability. Also, the EPDM could be used as an alternative to silicon rubber and could also be incorporated in the hose, O-ring, accumulator bladder, diaphragms, and connectors for wire & cables among many other applications on the account of their higher resistance towards tearing, abrasive, solvent, and temperature.

Factors such as technological advancement coupled with the growing number of industries and manufacturing units along with the new product launches in the market are some of the prominent factors that are positively influencing the market growth globally.

Some of the major players operating in the market include DowDuPont Inc., Exxon Mobil Corporation, Lion Elastomers, Johns Manville, SK Global Chemical Co. Ltd, Lanxess AG, Mitsui Chemical Inc., PetroChina Company Limited, Kumho Polychem, and Versalis S.p.A.

COVID-19 Impact

The recent covid-19 pandemic has disrupted the world and has brought a state of shock to the global economy. The global pandemic has impacted the manufacturing industry along with supply chain disruption, regulatory and policy changes, labor reliance, working capital management, and liquidity & solvency management. The Ethylene Propylene Diene Monomer (EPDM) market has been significantly affected during these times owing to the gap between supply and demand.

The global Ethylene Propylene Diene Monomer (EPDM) market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

Based on application, the market is segmented into building & construction, automotive, plastic modification, military & defense, wire & cable, lubricant additive, and others. The automotive industry is expected to witness significant CAGR during the forecast period owing to the increasing automotive vehicle sale coupled with the adoption of EPDM-based products in the vehicle such as rear lamp gaskets, tire sidewalls, front & rear bumper, and inner tire tubes among others. Also, the EPDM-based material has excellent barriers against the road surface, engine vibration, and resistance against the weather such as UV light, acid rain, as well as atmospheric pollution and is expected to support the market growth in the coming time.

Based on the manufacturing process, the market is segmented into solution polymerization process, slurry/suspension process, and gas phase polymerization. The solution polymerization segment is expected to witness significant growth during the forecast period due to the higher concentration and lower required amount for the optimized performance. Additionally, solution polymerization is used to manufacture both crystalline and amorphous polymer grades and is expected to support market growth.

Ethylene Propylene Diene Monomer (EPDM) Market Geographical Segmentation Includes:

North America (United States, Canada, and Rest of North America)

Europe (Germany, United Kingdom, Spain, Italy, France, and the Rest of Europe)

Asia-Pacific (China, Japan, India, and the Rest of Asia-Pacific)

Rest of the World

Asia-Pacific is anticipated to grow at a substantial CAGR during the forecast period. This is mainly due to the rapid industrialization and growing automotive industries along with the electronic & electrical industry, consumer goods industry, and medical sector in the region. Also, the ongoing infrastructural projects and increasing disposable income of the individual are expected to support market growth in the coming time. Furthermore, EPDM has also been used as a substitute for thermoplastic olefins and thermoplastic vulcanizate in the manufacturing industry. Also, the lower cost of the raw material coupled with the lower cost of production associated with the lower labor cost propels the market for the EPDM. Moreover, the growing research & development activities, increasing investment, and technological investment are expected to derive the market in the coming time. For instance, in March 2022, Arlanxeo a Netherland-based firm announced to increase in its production capacity by 15% for its EPDM plant based in Changzhou, China.

The major players targeting the market include:

DowDuPont Inc.

Exxon Mobil Corporation

Lion Elastomers

Johns Manville

SK Global Chemical Co. Ltd

Lanxess AG

Mitsui Chemical Inc.

PetroChina Company Limited

Kumho Polychem

Versalis S.p.A.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=31683

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the Ethylene Propylene Diene Monomer (EPDM) market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the Ethylene Propylene Diene Monomer (EPDM) market?

• Which factors are influencing the Ethylene Propylene Diene Monomer (EPDM) market over the forecast period?

• What are the global challenges, threats, and risks in the Ethylene Propylene Diene Monomer (EPDM) market?

• Which factors are propelling and restraining the Ethylene Propylene Diene Monomer (EPDM) market?

• What are the demanding global regions of the Ethylene Propylene Diene Monomer (EPDM) market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

Browse Related Newsletter from UnivDatos Market Insights

Titanium Dioxide Market - SWOT Analysis [2023-2028]

Recycled Carbon Fiber Market - SWOT Analysis [2023-2028]

About Us:

UnivDatos Market Insights: Your Partner in Data-Driven Market Strategies. Unlock growth opportunities and make smart decisions with our expert research and insights.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

Revolutionizing the Rubber Realm: A Deep Dive into the Thriving EPDM Market Landscape

In the ever-evolving landscape of the global market, the Ethylene Propylene Diene Monomer (EPDM) industry is poised for significant growth. According to the latest report, the EPDM Market is estimated to be USD 3.6 billion in 2022 and is projected to reach USD 4.8 billion by 2027, reflecting a noteworthy Compound Annual Growth Rate (CAGR) of 5.9% during the forecast period from 2022 to 2027.

EPDM Market Overview

EPDM, a versatile synthetic rubber, finds its applications across diverse sectors, including Automotive, Building & Construction, Plastic Modification, Tires & Tubes, Wires & Cables, and Lubricant Additives. Automotive, in particular, emerges as the major driver of the EPDM market, contributing significantly to its growth. As the automotive sector experiences a robust recovery in the Asia-Pacific (APAC) region, the demand for EPDM is expected to surge.

Key Insights and Opportunities

The automotive application holds the largest share in the EPDM market, with China playing a pivotal role. The country's focus on developing new energy vehicles (NEVs), encompassing Fuel Cell Electric Vehicles (FCVs), Plug-in Hybrid Electric Vehicles (PHEVs), and Battery Electric Vehicles (BEVs), is a key catalyst for the increased usage of EPDM in the automotive industry. According to the China Association of Automobile Manufacturers (CAAM), the total production of cars in 2021 witnessed a 3% year-on-year increase.

Additionally, the growing demand for electric and hybrid vehicles presents new opportunities in the EPDM market. The development of eco-friendly technologies for EPDM production aligns with the global shift towards sustainable practices in the automotive sector.

Manufacturing Processes and Market Dynamics

EPDM can be manufactured through various processes, and the Solution Polymerization Process currently dominates the market. This process is highly versatile, allowing for the production of a wide range of polymers. Polymerization and catalyst technologies play a crucial role in tailoring EPDM to meet specific application and processing needs.

Regional Market Dynamics

The Asia-Pacific region emerged as the frontrunner in the global EPDM market in 2021, with China being a key player in both production and consumption. The region's dominance is attributed to the concentration of EPDM producers and the flourishing automotive and construction sectors. New construction projects and sustained growth in the automotive industry are propelling the EPDM market in Asia Pacific.

Industry Players and Strategies

Leading players in the EPDM market include ARLANXEO, DOW Inc., Exxon Mobil Corporation, JSR Corporation (Kumho Polychem Co. Ltd.), PetroChina Company Limited, Versalis S.p. A., SK Global Chemical Co., Ltd., Sumitomo Chemical Co., Ltd., and Mitsui Chemicals, Inc. These industry giants are actively shaping the market through strategic initiatives, ensuring competitiveness and sustainability.

Download PDF Report :

Navigating the Future

As the EPDM market continues to evolve, keeping an eye on ethylene propylene diene monomer prices, EPDM market trends, and the EPDM price trend for 2023 will be critical. Stakeholders should remain vigilant about the dynamic market forces, ensuring they are well-positioned to capitalize on emerging opportunities and navigate challenges.

The EPDM market's growth trajectory is marked by resilience and adaptability, making it a key player in the global rubber market. Stay tuned for more updates on the EPDM market, where innovation meets opportunity in this dynamic industry landscape.

0 notes

Text

Isolator Gloves Market Size, Type, segmentation, growth and forecast 2023-2030

Isolator Gloves Market

The Isolator Gloves Market is expected to grow from USD 141.10 Million in 2022 to USD 228.10 Million by 2030, at a CAGR of 7.11% during the forecast period.

Get the Sample Report: https://www.reportprime.com/enquiry/sample-report/11101

Isolator Gloves Market Size

Isolator Gloves are a type of protective gloves that are designed to provide a barrier between the wearer's hands and harmful substances such as chemicals, viruses, and bacteria. The Isolator Gloves market research report includes an analysis of the market segment based on type, application, and region. The types of Isolator Gloves include Nitrile, Hypalon, EPDM, Neoprene, Latex, and Butyl. The primary applications of Isolator Gloves are in Electronics, Pharmaceutical, Food, Chemical, and Laboratory industries. The report covers the market players such as Ansell, PIERCAN, Renco Corporation, Safetyware Group, Inert Corporation, Jung Gummitechnik, Terra Universal, Honeywell, Nichwell, and Hanaki Rubber. The report also covers regulatory and legal factors specific to market conditions. Isolator Gloves are subject to strict regulations due to their use in critical industries, and market players must ensure compliance with standards set by regulatory bodies. The report provides an in-depth analysis of the Isolator Gloves market, including its market size, growth rate, competitive landscape, and future prospects.

Isolator Gloves Market Key Player

Ansell

PIERCAN

Renco Corporation

Safetyware Group

Inert Corporation

Buy Now & Get Exclusive Discount on this https://www.reportprime.com/enquiry/request-discount/11101

Isolator Gloves Market Segment Analysis

The Isolator Gloves market caters to a niche customer base, which includes pharmaceutical manufacturers, biotechnology companies, healthcare institutions, and medical device manufacturers. These gloves are extensively used in cleanroom environments to maintain hygiene, prevent contamination and ensure aseptic handling of drug substances and medical devices.

The driving factors for revenue growth in the Isolator Gloves market are the increasing demand for sterile pharmaceutical products, the growing prevalence of chronic diseases, and the strict regulatory requirements for cleanroom environments. Furthermore, the Isolator Gloves market is experiencing growth due to the ongoing research and development activities and technological advancements in the field of medical devices.

The latest trends followed in the Isolator Gloves market include the adoption of non-latex gloves to reduce the risk of latex allergy, increasing demand for powder-free gloves to minimize the transfer of allergens, and the use of vibration-dampening gloves to reduce hand fatigue in workers. Moreover, manufacturers are focusing on developing gloves with improved tactile sensitivity and flexibility, which can provide better user comfort and dexterity.

The major challenges faced by the Isolator Gloves market include the high cost of raw materials and production, stringent regulations for cleanroom environments, and increasing competition from local players in the market. Additionally, the COVID-19 pandemic has disrupted the supply chain and logistics operations, resulting in the temporary closure of manufacturing facilities and delays in delivering products to customers.

The report's main findings suggest that the Isolator Gloves market is projected to grow at a significant rate over the forecast period due to the increasing demand for sterile pharmaceutical products and the stringent regulatory requirements for cleanroom environments. Furthermore, the report recommends that manufacturers focus on developing eco-friendly and biodegradable gloves, as the demand for sustainable products is increasing. Moreover, manufacturers should prioritize improving their supply chain management and logistics operations to meet the market demands and maintain a competitive edge.

In conclusion, the Isolator Gloves market caters to a niche customer base, and the major factors driving revenue growth are the increasing demand for sterile pharmaceutical products and the strict regulatory requirements for cleanroom environments. The Isolator Gloves market is experiencing growth due to technological advancements and ongoing research and development activities. The latest trends in the market encompass the adoption of non-latex gloves, powder-free gloves, and vibration-dampening gloves. However, the Isolator Gloves market is also facing challenges due to high production costs, stringent regulatory requirements, and increasing competition from local players. The report's main recommendations include focusing on sustainable products, improving supply chain management, and logistics operations.

This report covers impact on COVID-19 and Russia-Ukraine wars in detail.

Purchase This Report: https://www.reportprime.com/checkout?id=11101&price=3590

Market Segmentation (by Application):

Electronics

Pharmaceutical

Food

Chemical

Laboratory

Information is sourced from www.reportprime.com

2 notes

·

View notes

Text

#EPDM#EPDMRubber#EPDMRubberprices#EPDMRubbermarket#EPDMRubberpricetrend#EPDMRubberpriceforecast#EPDMRubberdemand

2 notes

·

View notes

Text

0 notes