#EPDM Rubber Prices

Explore tagged Tumblr posts

Text

Ethylene Propylene Diene Monomer (EPDM) Rubber Prices, News

North America

The EPDM Rubber market in the US has experienced a marginal 0.87% price increase in the fourth quarter of 2024, driven by stable supply and gradual demand recovery. The increase reflects a balance between supply constraints, including moderate raw material availability, and steady demand from the automotive sector, which saw continued growth in vehicle sales.

While feedstock prices for Ethylene and Propylene showed mixed trends, the market remained stable due to adequate supply and efficient sourcing strategies by manufacturers. The automotive sector provided significant support, with strong sales growth reported in November and December, while the construction sector remained subdued. Ongoing logistical challenges, including port congestion and labor shortages, extended delivery times, but did not disrupt supply enough to cause price spikes.

Despite a weakened manufacturing sector, cautious buying behavior, and moderate demand from the construction sector, EPDM Rubber prices showed resilience, reflecting a balanced market outlook. With expectations for gradual improvement in 2025, this trend of modest price increases is likely to continue.

0 notes

Text

Malaysian EPDM Rubber Sheet Prices That Are Reasonably Low | duratuf products pvt. ltd

Seeking the most affordable epdm rubber sheet prices in Malaysia? Premium-grade EPDM rubber sheets are available from duratuf at affordable prices. Because of their exceptional resilience to weather and durability, EPDM sheets are ideal for use in commercial and industrial settings. To find out the most recent costs and availability, please contact us. See our website for additional information!

0 notes

Text

EPDM Rubber Prices, Price, Trend, Supply & Demand and Forecast | ChemAnalyst

EPDM Rubber Prices, a versatile synthetic rubber known for its excellent weather resistance, durability, and thermal stability, has become a cornerstone material in various industries, including automotive, construction, and manufacturing. As with any commodity, its pricing dynamics are subject to a multitude of factors, influencing its market value and availability. Understanding these factors is crucial for businesses relying on EPDM rubber to navigate market fluctuations effectively.

One of the primary determinants of EPDM rubber prices is the cost of raw materials. EPDM is produced from ethylene, propylene, and a small amount of diene monomer. Thus, any fluctuations in the prices of these feedstocks significantly impact the overall production cost of EPDM. For instance, changes in crude oil prices, as ethylene and propylene are derived from petroleum, directly influence the cost of EPDM production. Additionally, factors such as supply chain disruptions, geopolitical tensions, and natural disasters can disrupt the availability of raw materials, further impacting prices.

Market demand and supply dynamics play a pivotal role in shaping EPDM rubber prices. As industries like automotive, construction, and electrical continue to grow, the demand for EPDM rubber escalates. Conversely, during economic downturns or periods of reduced industrial activity, demand may decrease, leading to a surplus in supply and subsequent price drops. Moreover, shifts in consumer preferences towards sustainable and eco-friendly products have prompted manufacturers to invest in EPDM rubber as a viable alternative, potentially driving prices higher due to increased demand.

Get Real Time Prices of EPDM Rubber: https://www.chemanalyst.com/Pricing-data/epdm-rubber-1110

Global economic conditions and currency fluctuations exert significant influence on EPDM rubber pricing. EPDM is a globally traded commodity, and its pricing is susceptible to macroeconomic factors such as inflation rates, exchange rates, and interest rates. For example, a stronger US dollar can make EPDM imports cheaper for countries with weaker currencies, boosting demand and prices in those markets. Conversely, a weaker dollar may lead to higher import costs, impacting pricing dynamics differently across regions.

Technological advancements and innovations in EPDM production processes also impact pricing. Manufacturers constantly strive to enhance production efficiency, reduce energy consumption, and minimize environmental impact. Investments in research and development (R&D) aimed at developing novel production techniques or improving product quality can affect production costs and, consequently, prices. Moreover, breakthroughs in recycling technologies enable the reuse of EPDM scrap and waste, mitigating supply constraints and potentially stabilizing prices.

Regulatory policies and environmental standards significantly influence the EPDM market. Stringent regulations aimed at reducing carbon emissions and promoting sustainable practices drive the demand for eco-friendly materials like EPDM rubber. Compliance with regulatory requirements often entails additional production costs, which may translate to higher prices for end consumers. Conversely, lax regulations or non-compliance penalties in certain regions can create price differentials, affecting global trade dynamics and price competitiveness.

Geopolitical factors, including trade agreements, tariffs, and sanctions, can disrupt EPDM rubber supply chains and pricing structures. Trade tensions between major EPDM-producing countries may lead to tariffs or trade barriers, affecting import/export volumes and prices. Political instability or conflicts in key EPDM-producing regions can disrupt production and transportation, leading to supply shortages and price volatility. Therefore, geopolitical risks are essential considerations for businesses reliant on EPDM rubber to assess market uncertainties and develop robust risk mitigation strategies.

In conclusion, EPDM rubber prices are influenced by a myriad of interconnected factors, ranging from raw material costs and market demand to technological innovations and regulatory policies. Businesses operating in industries dependent on EPDM rubber must closely monitor these factors and adapt their strategies accordingly to navigate market fluctuations effectively. By understanding the underlying dynamics shaping EPDM rubber prices, businesses can make informed decisions to optimize procurement, manage costs, and maintain competitiveness in the global marketplace.

Get Real Time Prices of EPDM Rubber: https://www.chemanalyst.com/Pricing-data/epdm-rubber-1110

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Aohong NBR Sealing Rubber Gaskets: The Cost-Effective Workhorse for Demanding Applications

Let's face it—when that hydraulic system starts leaking after just six months and you're knee-deep in oil-soaked components, you realize not all rubber gaskets are created equal. NBR Sealing Rubber Gaskets from Aohong solve what generic elastomers can't: delivering reliable sealing performance without breaking the bank. Here's why our nitrile rubber solution outperforms the competition where it matters most.

The Science Behind Superior Sealing

That 34% acrylonitrile content in Aohong's formulation isn't just a random number—it's the sweet spot for balancing oil resistance and flexibility. While cheaper NBR compounds cut corners with 28% content (and pay the price in swelling), we've optimized our material to deliver:

70±5 Shore A hardness (ASTM D2240 verified)

<10% oil swell after 1,000 hours in ASTM #3 oil

-40°C to 120°C service range—no brittle fractures in cold climates

85% compression set resistance at 100°C (beats EPDM in hot oil)

Pro Tip: That matte black finish isn't for looks—it's our proprietary carbon black reinforcement that adds 30% more tear strength versus standard NBR.

Real-World Proof: Hydraulic Cylinder Case Study

Take this OEM mining equipment application we solved last quarter:

Problem: Competitor's gaskets swelled 25% after 3 months

Conditions: 1,500 psi hydraulic fluid + 80°C continuous operation

Solution: Aohong's NBR gasket with enhanced oil swell resistance

After 18 months of brutal service: ✓ Zero leaks (pressure tested monthly) ✓ Only 8% thickness variation ✓ Saved $14,000 in downtime costs

Their maintenance supervisor called it "the only gasket that lasts through our service interval."

Installation: Do It Right the First Time

Surface Prep

32-64 RA surface finish (too smooth causes slippage)

Clean with isopropyl alcohol—never WD-40 (leaves silicone residue)

Torque Sequence

30% less torque than FKM gaskets

Criss-cross pattern for even compression

Break-In Period

Allow 24 hours for full compression set

Retorque after first thermal cycle

❌ $8,000 Mistake Using petroleum grease as lubricant—it degrades NBR over time. Silicone-based only.

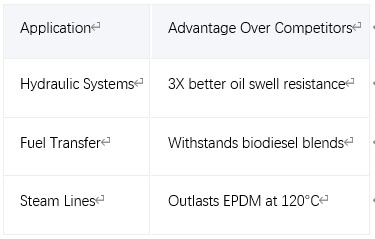

Where Aohong's NBR Excels

Safety Note: Never use with ketones or esters—they'll dissolve the material in weeks.

The Bottom Line

When your application needs oil resistance without fluoropolymer prices—whether it's a construction equipment hydraulic system or a biodiesel transfer line—Aohong's NBR Sealing Rubber Gasket delivers proven performance where generic rubber fails.

Why gamble with inferior materials? Contact Aohong's engineering team today for application-specific solutions—because in industrial sealing, "good enough" usually fails at the worst possible moment.

3 notes

·

View notes

Text

Choosing the Right Roofing Material for Orlando's Climate Conditions

Introduction

When it relates to selecting the appropriate roofing product, particularly in a sun-soaked and also humid locale like Orlando, recognizing the distinct temperature circumstances is actually paramount. Orlando's climate designs-- characterized by rigorous summer warm, in season tornados, and also high humidity-- participate in a vital part in finding out which roofing components will stand up the test of your time.

In this complete manual, we'll explore several roofing alternatives tailored particularly for Orlando's weather. Our team'll talk about variables including toughness, electricity productivity, maintenance requirements, as roofing company orlando fl well as cost-effectiveness to help you create a notified decision. Thus allow's dive into the details!

Choosing the Right Roofing Component for Orlando's Weather Conditions

When selecting a roofing component for your business or house in Orlando, take into consideration several aspects that affect both efficiency and longevity. The secret is actually to find a balance between appearances as well as functions while making certain that your roofing can stand up to Fla's unique weather challenges.

What are actually the best Popular Forms Of Business Roofing Materials?

When checking out commercial roofing choices in Orlando, you'll run into many well-known styles:

TPO (Thermoplastic Olefin): Understood for its energy effectiveness and also affordability. EPDM (Ethylene Propylene Diene Monomer): A long lasting rubber roofing that's excellent for standard roofs. Metal Roofing: Deals exceptional sturdiness and solar reflectivity. Built-Up Roofing (BUR): Consists of various levels for included protection. Modified Bitumen: A pliable alternative along with really good basement waterproofing properties.

Each of these products possesses its personal set of perks and drawbacks depending upon your certain needs.

youtube

How Lengthy Do Business Roofing Systems Commonly Last?

The life-span of business roofing systems varies widely based upon the material used:

TPO: 15-30 years EPDM: 20-30 years Metal: 40-70 years Built-Up Roofing: 20-30 years Modified Bitumen: 10-20 years

Understanding these timetables allows home owner to consider ahead for upkeep or replacement.

What Factors Affect the Cost of Putting Up a Business Roof?

Several factors bring about the total installation price of an office roof covering:

youtube

Material Choice: Costs materials commonly come with a much higher price. Roof Size: Larger roof coverings need even more components and also labor. Labor Costs: Neighborhood work fees can dramatically impact costs. Building Accessibility: Difficult-to-reach places may acquire added charges. Existing Roof covering Condition: If an old roof covering requires extraction or repair prior to installment, count on incorporated expenses. How Usually Ought to an Office Rooftop be Inspected?

Regular evaluations ar

2 notes

·

View notes

Text

#EPDM#EPDMRubber#EPDMRubberprices#EPDMRubbermarket#EPDMRubberpricetrend#EPDMRubberpriceforecast#EPDMRubberdemand

2 notes

·

View notes

Text

Tensile Fabric Structure Suppliers in Hyderabad

Tensile Fabric Structure in Hyderabad is fast becoming the top choice for architects and builders looking for innovative and durable solutions for modern construction. At PolyProjects, we take pride in being among the top Tensile Fabric Structure Manufacturers in Hyderabad, offering high-quality, customizable solutions that combine style, strength, and sustainability.

Our expertise in Tensile Fabric Structure extends beyond just design—we are also known as leading Self Drill Screws suppliers in Hyderabad, making us a one-stop destination for quality construction and roofing materials. Our wide product range includes Silicone Sealant, Polycarbonate Roofing Sheets, Galvanized Iron Color Coated Sheet, UPVC Sheets / Windows, Skylight Duct Covering, Self Drill Screws, Puff Sheets, Car Parking Sheds, CANOPY, Swimming Pool Covering, and EPDM Rubber Gasket.

Why Choose PolyProjects for Tensile Fabric Structures?

As one of the best Tensile Fabric Structure Manufacturers in Hyderabad, we focus on innovation, quality, and functionality. Our Tensile Fabric Structures are engineered with precision, offering a blend of strength and aesthetics that’s ideal for commercial, residential, and recreational spaces.

Our structures are widely used in:

Sports complexes

Outdoor canopies

Parking lots

Walkway coverings

Event halls

Shopping malls

These structures are lightweight, easy to install, and offer superior durability in extreme weather conditions.

Leading Suppliers of Self Drill Screws in Hyderabad

In addition to being Tensile Fabric Structure Manufacturers in Hyderabad, we are also prominent Self Drill Screws suppliers in Hyderabad. Our Self Drill Screws are known for their superior holding power and corrosion resistance, making them perfect for roofing, metal sheet installation, and structural applications. These fasteners are critical for high-performance installations and ensure long-term durability in all weather conditions.

Explore Our Diverse Product Line

At PolyProjects, we’re more than just a Tensile Fabric Structure company. Our clients also count on us for:

Polycarbonate Roofing Sheets: Lightweight, UV-resistant, and perfect for skylights or greenhouse applications.

Galvanized Iron Color Coated Sheets: Durable and rust-resistant, ideal for roofing and cladding.

UPVC Sheets / Windows: Energy-efficient and maintenance-free for modern construction.

Silicone Sealant and Silicon Sealant: Excellent bonding and waterproofing materials.

EPDM Rubber Gasket: Offers excellent weather and temperature resistance.

Car Parking Sheds and CANOPY solutions: Stylish and durable options for residential and commercial spaces.

Swimming Pool Covering: Protects your pool while enhancing aesthetic appeal.

Puff Sheets: Lightweight insulation material perfect for energy-efficient construction.

Why We Stand Out

As a company trusted for delivering top Tensile Fabric Structure and accessories, we are known for:

High-quality materials

Competitive pricing

Customization options

Timely delivery

Professional installation support

We understand that every project is unique, and that’s why our team works closely with clients to deliver tailored solutions that meet their exact needs.

Conclusion

Choosing the best Tensile Fabric Structure Manufacturers in Hyderabad is crucial for any successful building project, and PolyProjects stands out with its blend of quality, reliability, and customer satisfaction. As trusted Self Drill Screws suppliers in Hyderabad and providers of roofing and construction solutions, we are committed to delivering excellence in every product.

For the top Tensile Fabric Structure services and comprehensive construction solutions in Hyderabad, get in touch with PolyProjects today at 92909 12888 or visit our website: https://www.polyprojects.in

#TensileFabricStructureManufacturersInHyderabad#TensileFabricStructure#SelfDrillScrewSuppliersInHyderabad#TopTensileFabricStructure#BestTensileFabricStructure#SiliconeSealant#PolycarbonateRoofingSheets#CarParkingSheds#CanopyDesigns#PuffSheets#EPDMRubberGasket#SkylightDuctCovering#UPVCSheetsWindows#SwimmingPoolCovering

0 notes

Text

DIY vs Professional Roofer: When to Call in the Experts

Introduction

When it comes to roofing, whether you're dealing with a leaky roof or considering a complete roof replacement, you might find yourself at a crossroads. Should you tackle the issue yourself with a DIY approach, or is it time to call in the experts? The decision can be daunting and often hinges on several factors, including your skill level, the scope of the project, and potential risks involved. In this comprehensive guide, we will explore the nuances of DIY versus hiring a professional roofer and help you determine when it’s best to take matters into your own hands versus when to enlist experienced roofing contractors.

DIY vs Professional Roofer: When to Call in the Experts

Making decisions regarding your roof involves understanding its structure and materials. Whether you're considering asphalt shingles, metal roofs, or TPO roofing, knowing when to call a professional can save you time and money.

Understanding Roof Types 1. Common Roofing Materials

Roofing materials come in various types, each suited for different climates and aesthetics. Here are some common materials:

Asphalt Shingles: Affordable and versatile. Metal Roofing: Durable with excellent longevity. Tile Roofs: Elegant and energy-efficient. EPDM Roofing: Best for flat roofs due to its waterproof nature. Slate Shingles: A premium choice known for its beauty. 2. Specialty Roofing Options

Depending on your needs, specialty options like rubber roofing or built-up roofs may also be worth considering.

DIY Roof Repair: Pros and Cons 3. Advantages of DIY Roofing Cost Savings: Avoid labor costs associated with hiring professionals. Personal Satisfaction: Completing a project can be fulfilling. Flexibility: Work at your own pace without scheduling conflicts. 4. Disadvantages of DIY Roofing Safety Risks: Climbing ladders can pose hazards if not done properly. Quality Concerns: Lack of expertise may lead to poor workmanship. Time Consumption: What seems like an easy task can quickly become complex. When Is DIY Appropriate? 5. Minor Repairs

Small issues like replacing a few missing shingles or patching leaks may be manageable for those with basic skills.

6. Routine Maintenance

Cleaning gutters or removing debris from the roof surface is often safe for homeowners who are careful.

Professional Roofer Services Overview 7. Expertise in Complex Issues

Professional roofers bring years of experience that can be invaluable in resolving complex roofing problems effectively.

8. Access to Quality Materials

Roofing companies often have access to high-quality materials at better prices than individual https://www.google.com/search?kgmid=/g/11nn200nbb&sei=JjNHaIqFDPCWwbkPqMOI4Q4#lpc=lpc&prid=8599937398375946310 consumers.

When Should You Hire a Professional? 9. Major Repairs

Significant issues such as structur

1 note

·

View note

Text

Buying Rubber Hoses in UAE: Common Mistakes and How to Avoid Them

The application of rubber hoses involved in industries in the UAE cuts across all industries; construction, oil and gas, agriculture, and marine industries. Nevertheless, making the wrong selection of the hose or selecting the wrong provider of rubber hoses in UAE may lead to equipment breakage, safety violations, and costly lost work. The mistakes made by buyers have been described in this article and the way to avert these is through collaboration with reputable rubber hose suppliers in UAE.

Learn About Your Application First Before You Purchase

The first mistake commonly made by most purchasers is to buy a rubber hose without knowing how it has to be used. A case in point is the transfer of chemicals that require a different structure and material requirements than the hose used in water pumping or fuel suction.

By conveying your application properly, you will be able to create the necessary safety and performance in the UAE. The professional suppliers will advise you on the type of hose, the material of the hose, and the reinforcement depending on the needs of your industry.

Wrong Material of Hose Pipe

Rubber hoses are not all the same. The hose material should provide proper resistance depending on whether the material is going to be used to transport fuel, air, chemicals, or high-pressure fluids. There are specific uses for each of the following rubbers- nitrile, EPDM neoprene, and others.

The providers of rubber hoses that are reputable in UAE will give hose material compatibility data and also suggest the most appropriate hose material that best fits an operating environment and media.

Wrong Size and Pressure Ratings

The diameter of the hoses and pressure rating should be that which is required in your system. A hose that is too small is apt to lose some pressure, and a low-rating one to rupture in pressure: is dangerous to those around.

To avoid such problems, please ensure you contact experienced suppliers of rubber hoses in UAE who could advise on the proper selection of the inner diameter (ID), the wall thickness, and the pressure rating to comply with the performance.

The application of rubber hoses involved in industries in the UAE cuts across all industries; construction, oil and gas, agriculture, and marine industries. Nevertheless, making the wrong selection of the hose or selecting the wrong provider of rubber hoses in UAE may lead to equipment breakage, safety violations, and costly lost work. The mistakes made by buyers have been described in this article and the way to avert these is through collaboration with reputable rubber hose suppliers in UAE.

Purchasing on Price Only

The price is a factor that should not be disregarded, yet the more narrow-minded the concentration is on the low end of the price spectrum, the less durable the products are and the more often they have to be substituted. The consequence of this error could end up being expensive for your business.

Select the rubber hose vendors in the UAE that sell quality, certifications, and lifetime of the product even when it is slightly expensive at first. Good hoses minimize the chances of risk and enhance the efficiency of operation.

Negligence of Hose Fittings and Assemblies

The best hose cannot work without the best fitting. Fitting each hose and hose fittings to the other requires individual purchases or purchases made with different sellers and may hence result in mismatched hoses and hose fittings and may hence cause leaks.

The most prominent rubber hose suppliers in UAE provide end-to-end hoses with fittings, couplings, and even pressure testing services on all their assemblies; compatibility, and safety on the first day.

Ignorance in Stock and Delivery Time

Cases have been reported where many projects are delayed because planners badly planned their inventory or the supplier is slow. When time is of the essence or a situation is being handled on a large scale, a delay in delivery may alter productivity by several weeks.

As you work with known rubber hose suppliers in UAE, it will result in reducing the time of delivery, stock on hand, and support on the spot. Seek suppliers who have distribution centers in big cities such as Dubai, Sharjah, and Abu Dhabi.

Failure to Check Certifications

Employing non-certified rubber hoses has the potential to result in loss of equipment and even bring about legal responsibility in a regulated industry, oil, and gas, and even marine.

The rubber-hose suppliers trusted in UAE ensure that their products are ISO, SAE, and API-certified, and this will ensure that you are free of any of the worries in terms of quality, safety, and compliance.

Select the Proper Rubber hoses supplier in the UAE

The right purchase of rubber hose is essential in ensuring safety, performance, as well as efficiency in all your work done in the industry. Let's say that by knowing about your particular needs and knowing which mistakes are attributed to each you can make better buying decisions thus saving yourself time and money in the long run.To achieve avenues of trusted service, good quality products that are certified, and professional support, AFC is a name that many suppliers in the UAE would consider reliable. AFC has all the rubber hose solutions of high quality since its wide inventory and experience in the field of industry has offered high-quality rubber hose solutions considering your application to guarantee durability, compliance, and value in the long run.

0 notes

Text

Exploring Rubber Sheet Manufacturing and Advanced Additives in India

India has become a key player in the global rubber industry, largely due to its expanding network of high-quality rubber sheet manufacturers. These manufacturers produce a wide range of rubber sheets tailored for applications in automotive, construction, electronics, pharmaceuticals, and general engineering sectors.

Rubber sheet production involves precise blending of rubber materials and additives to meet performance criteria like resistance to heat, oil, abrasion, and chemicals. Among the many variants produced, silicone rubber compound remains a top choice for demanding environments due to its superior thermal and chemical stability.

The Role of Rubber Sheet Manufacturers

Rubber sheet manufacturers in India operate advanced facilities capable of producing both standardized and custom-designed rubber sheets. These include natural rubber sheets, EPDM sheets, nitrile sheets, neoprene sheets, and silicone rubber sheets. The sheets are used for gaskets, flooring, insulation, anti-vibration pads, and sealing applications.

With a focus on precision, durability, and compliance with global standards, Indian manufacturers serve both domestic markets and international clients across Europe, the Middle East, and Southeast Asia.

Silicone Rubber Compound: A Versatile Material

One of the standout materials in the rubber industry is silicone rubber compound. It is known for maintaining elasticity and functionality in extreme temperatures, high UV exposure, and chemical-prone environments. Silicone rubber compound is used in applications where hygiene, flexibility, and reliability are non-negotiable—such as food processing, pharmaceuticals, and electronics.

Many rubber sheet manufacturers in India offer silicone-based rubber sheets in both solid and sponge forms, catering to niche markets that demand precision and high performance.

Rubber Masterbatches: Enhancing Manufacturing Efficiency

A key innovation that has revolutionized rubber production is the use of rubber masterbatches. These are pre-mixed blends of rubber-compatible additives, offering consistent quality and improved dispersion during sheet production. With rubber masterbatches, manufacturers achieve better process control, reduced production time, and minimal material loss.

Indian rubber manufacturers use custom rubber masterbatches to meet the specific needs of clients in sectors like railways, defense, healthcare, and oil & gas.

Why India Leads in Rubber Sheet Manufacturing

India’s advantage in rubber manufacturing is driven by several strengths:

Advanced technology and R&D

Skilled labor and material expertise

Global quality standards (ISO, RoHS, FDA-compliance)

Strong export capabilities

Growing demand for sustainable and recyclable rubber products

With these factors, Indian rubber sheet manufacturers are meeting the rising global demand for high-quality rubber solutions at competitive pricing.

Conclusion

From high-performance silicone rubber compounds to efficient production through rubber masterbatches, India’s rubber sheet manufacturers are helping global industries operate more safely, reliably, and efficiently. Their ability to combine traditional expertise with modern innovation is positioning India as a global hub for advanced rubber solutions.

0 notes

Text

India's Rising Rubber Manufacturing Power

In today's fast-paced industrial environment, components that ensure safety, efficiency, and reliability are more critical than ever. Among these essential components are rubber seals, gaskets, and custom-moulded products—key to preventing leaks, managing pressure, and improving machine performance. India, with its growing manufacturing expertise, is now home to leading global suppliers in this space. Companies like GB Rubber Product and other custom rubber moulded products manufacturers are setting high standards in quality, innovation, and customization.

The Importance of Seals and Gaskets in Industrial Applications

Whether it's an automotive engine, hydraulic system, chemical plant, or food processing equipment, seals and gaskets are indispensable. They prevent the leakage of liquids and gases, withstand high pressures and temperatures, and extend the service life of machinery. That’s why choosing the right seals and gaskets suppliers is essential for industries across sectors.

Top seals and gaskets suppliers in India now offer a broad range of solutions—including rubber, silicone, PTFE, and graphite gaskets—that are resistant to oil, chemicals, and temperature fluctuations. They serve key sectors such as automotive, railways, aerospace, defense, oil & gas, and pharmaceuticals, delivering components that meet global standards.

GB Rubber Product: A Name Synonymous with Quality

One of the most trusted names in the Indian rubber industry is GB Rubber Product. Known for its commitment to quality and customer satisfaction, the company specializes in manufacturing rubber components that are used across diverse industries.

GB Rubber Product offers a comprehensive range of solutions including anti-vibration mounts, rubber-to-metal bonded parts, gaskets, seals, bellows, and custom-engineered rubber parts. With a strong focus on R&D and product testing, the company ensures all products meet stringent performance requirements and international certifications.

Thanks to its investment in modern infrastructure and highly skilled workforce, GB Rubber Product is not only serving the domestic market but is also exporting to clients across Europe, the Middle East, and North America. Their products are engineered to perform in the most demanding environments, offering reliability and long service life.

Custom Rubber Moulded Products Manufacturer: Tailored to Industry Needs

The industrial world is rapidly shifting toward customization, and that's where a Custom Rubber Moulded Products Manufacturer becomes crucial. These manufacturers specialize in designing and producing tailor-made rubber components to suit specific operational needs.

A custom rubber moulded products manufacturer can develop products in various shapes, hardness levels, and material types—whether it’s Nitrile, EPDM, Silicone, Neoprene, or Viton. These custom components are widely used in sealing, vibration isolation, damping, and load-bearing applications across industries.

By working closely with clients during the design and prototyping stages, these manufacturers ensure that the final product offers a perfect fit and optimal performance. From rubber grommets and bushings to engine mounts and diaphragms, the focus is always on delivering value through innovation and precision.

Conclusion

India's rubber manufacturing sector is evolving rapidly, offering both standard and customized components for industries across the globe. Reputed seals and gaskets suppliers, industry leaders like GB Rubber Product, and skilled custom rubber moulded products manufacturers are driving this change with their technical expertise, material knowledge, and commitment to quality.

As global demand grows for reliable and performance-focused rubber components, Indian manufacturers are perfectly positioned to deliver—backed by scalable production, competitive pricing, and strong engineering capabilities.

0 notes

Text

Find Low-Cost epdm rubber sheeting prices in the United Arab Emirates- duratuf products

In search of reliable epdm rubber sheeting prices in the United Arab Emirates? Because of its exceptional resistance to weathering, UV radiation, and extreme temperatures, EPDM rubber is highly recommended for use in industrial applications, roofing, and insulation. Duratuf Products provides premium EPDM sheets that are customized to your project's specifications at affordable costs.

0 notes

Text

EPDM Rubber Price Index: Market Analysis, Trend, News, Graph and Demand

EPDM Rubber ENB (4.1–5.5) prices in the U.S. posted a marginal quarter-on-quarter decline of 1.66%, shaped by ongoing shifts in supply and demand conditions. Prices remained relatively stable on a month-to-month basis, but broader quarterly data pointed to slight downward movement, largely influenced by easing feedstock costs and improved availability. Ethylene prices fell sharply by 13.8% in March, while Propylene prices decreased by 6.2%, collectively supporting better production economics and reducing input cost pressures for EPDM manufacturers.

On the supply side, early-quarter logistical challenges such as port congestion and shipping delays that impacted January and February saw gradual resolution by March. This improved the flow of imports and helped stabilize regional availability. Demand signals were mixed over the quarter, with a slow start in automotive sales followed by a strong rebound in March. The construction sector, particularly residential development, provided steady support, though its growth was not sufficient to significantly boost overall market momentum. Broader macroeconomic concerns such as persistent inflation, evolving tariff structures, and cautious consumer behavior continued to influence downstream purchasing patterns and restrained any aggressive buying.

Manufacturing data remained relatively strong, signaling a steady industrial base, but the pace of growth was held in check by uncertainties surrounding trade regulations and rising logistics expenses. Suppliers adapted to moderate demand and shifting cost structures, maintaining a stable market balance. As a result, the EPDM rubber market experienced a slight correction in prices over the quarter without encountering sharp volatility, reflecting a market in measured equilibrium.

Get Real time Prices for EPDM Rubber: https://www.chemanalyst.com/Pricing-data/epdm-rubber-1110

The EPDM Rubber market in Japan recorded a mild quarter-on-quarter decline of 0.93% during Q1 2025, as the market adjusted to a combination of steady supply and softening demand. Feedstock availability, particularly Ethylene and Propylene, remained relatively balanced, although logistical recalibrations and lower Ethylene production rates added complexity to the supply chain. Japanese producers, including major players like Mitsui Chemicals, attempted to optimize operations and announced price adjustments for some elastomer products, though the direct impact on EPDM pricing was limited due to broader market pressures.

Demand was constrained by subdued global economic activity, with weaker-than-expected orders from major international markets such as the U.S., Europe, and China. While the domestic automotive sector maintained reasonable output levels and vehicle sales inched upward, the construction industry faced headwinds from elevated labor costs and a slowdown in project completions. These factors collectively muted EPDM consumption growth and created a cautious market atmosphere. Some positive domestic trends, such as a modest rebound in the housing sector, supported price stability to a degree, but they were not strong enough to counteract broader economic unease.

Manufacturing sentiment remained cautious, shaped by global trade uncertainty and sluggish export activity. As a result, the Japanese EPDM market experienced a subdued pace of price movement, reflecting the delicate balance between steady supply and weak external demand. The slight quarterly dip in pricing underscored a conservative outlook as market participants awaited clearer economic signals.

The European EPDM Rubber market saw a modest decline of 0.88% from the previous quarter, reflecting a period of relative price stability amid mixed economic and sectoral dynamics. Regional supply remained consistent, driven by uninterrupted domestic production and steady import volumes. Despite ongoing logistical complications at key European ports like Hamburg and Rotterdam, the impact on the EPDM supply chain was mitigated by healthy inventory levels and easing freight costs, which supported overall market availability.

On the demand front, conditions were uneven. The automotive sector showed a drop in vehicle registrations across several key countries during January and February, suggesting a cautious consumer environment. The construction industry also faced headwinds, with activity remaining subdued across residential, commercial, and public infrastructure projects. However, government-backed infrastructure initiatives, especially in civil engineering, hinted at potential recovery in the medium term. These sector-specific fluctuations were accompanied by broader economic developments, including rate cuts from the European Central Bank aimed at stimulating investment and consumption.

Despite these monetary policy efforts, lingering concerns about global trade conditions and inflationary pressures continued to cast a shadow over demand confidence. Market participants adopted a cautious stance, limiting stockpiling and procurement activity. Nonetheless, the European EPDM market demonstrated underlying resilience, with suppliers maintaining stable operations and adapting to evolving conditions. The slight downward shift in prices reflected a market navigating short-term challenges while holding an optimistic view for gradual recovery in the latter half of the year.

Get Real time Prices for EPDM Rubber: https://www.chemanalyst.com/Pricing-data/epdm-rubber-1110

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#EPDM Rubber Price Monitor#Ethylene Propylene Diene Monomer Rubber Price#India#United kingdom#United states#Germany#Business#Research#Chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Professional Roof Waterproofing Services to Stop Leaks Fast

Let’s be real—if your roof is leaking, it’s not just annoying. It’s a ticking time bomb. One good downpour, and suddenly you’re dealing with water stains, mould, damaged ceilings, or worse—a full-blown roof collapse. And here's the kicker: most of it could be avoided with proper roof waterproofing services.

In this guide, I’ll walk you through everything you need to know about keeping your roof sealed, safe, and leak-free. No fluff. No jargon. Just straight talk about protecting your home (or business) before it's too late.

Why Roof Waterproofing Services Matter

Think of your roof like your phone screen. Once there’s a crack, even a tiny one, the damage spreads fast. Similarly, a small leak in your roof doesn’t stay small for long. That’s where professional roof waterproofing services come in. These services don’t just patch leaks—they prevent them from happening in the first place.

Roof waterproofing is about creating a moisture-proof barrier. It blocks rain, humidity, and seepage from creeping in and turning your concrete, wood, or steel roof into a breeding ground for structural damage.

Signs You Need Roof Waterproofing (Now, Not Later)

You don’t need to be a contractor to spot the red flags. Here are signs your roof is screaming for waterproofing:

Water stains on ceilings or walls

Mould or mildew smells in your attic

Paint or plaster peeling near the roofline

Visible cracks or holes in roofing material

Leaks during or after rain

If you're seeing even one of these, it's time to bring in experts for roof waterproofing services—fast.

Types of Roof Waterproofing Techniques

Not all waterproofing methods are created equal. The right one depends on your roof type, climate, and budget. Here's a no-nonsense breakdown:

Bituminous Membrane Waterproofing

This method involves applying a thick, durable membrane (bitumen-based) over the roof. Ideal for flat or low-sloped roofs. It’s cost-effective, easy to apply, and lasts years.

Liquid Waterproofing

Think of it like painting on protection. This is a liquid sealant applied in layers that dries into a flexible waterproof layer. Great for irregular surfaces or tight corners.

Polyurethane Waterproofing

Extremely strong and flexible. Polyurethane membranes can cover small cracks and resist weather extremes. On the pricier side, but worth it for durability.

Cementitious Waterproofing

Common in Pakistan and other developing regions. It’s easy to apply and ideal for internal areas like bathrooms or kitchens—but not so great for roofs exposed to direct weather.

EPDM Rubber Roofing

A synthetic rubber sheet that’s rolled out and fixed onto the roof. Super resilient and used in commercial buildings.

Which one should you pick? That’s where a quality provider of roof waterproofing services steps in—they’ll assess and recommend the best fit.

Benefits of Professional Roof Waterproofing Services

Let’s get one thing straight. DIY fixes won’t cut it long-term. Here’s why going pro saves you time, money, and stress:

Stops Current Leaks Cold Professionals don’t guess. They detect the root cause and stop the leak where it starts.

Prevents Future Damage With high-grade materials and proper application, you’re not just fixing today’s issue—you’re blocking next season’s too.

Increases Roof Lifespan A well-waterproofed roof can last years longer than one left exposed to weather damage.

Boosts Property Value Thinking of selling your house? A waterproofed roof is a big tick for buyers.

Saves Money

Sure, it’s an upfront cost. But compare that to interior repairs, mould removal, and roof replacements… suddenly, waterproofing looks like a bargain.

How to Choose the Right Roof Waterproofing Services Provider

Not all contractors are created equal. Here’s how to pick someone legit:

Check reviews or ask for references

Ensure they offer warranty-backed work

Ask about the materials they use (cheap stuff doesn’t last)

Look for experience, not just low pricing

Make sure they inspect the full roof before quoting

Want a shortcut? Go with providers who specialise specifically in roof waterproofing services, not just generic “contractors.”

Common Mistakes to Avoid

Too many people wait until it's too late. Here are the most common mistakes we see:

Ignoring small leaks – They always grow.

Relying on temporary fixes – Silicone fillers and tape are not long-term solutions.

Hiring cheap labour – Bad application means you’ll be paying double in a yea

Skipping regular inspections – Prevention is always cheaper than repair.

Roof Waterproofing for Homes vs. Commercial Buildings

While the core idea is the same, the scale and materials differ.

For homes:

Aesthetic matters

Smaller surface area

Often sloped roofs

Cost-conscious solutions preferred

For commercial buildings:

Flat roofs more common

Large-scale waterproofing systems

Heavy-duty solutions like bituminous or rubber-based membranes

Professional roof waterproofing services can tailor the solution based on your space—whether it’s a small house or a multi-storey plaza.

Cost of Roof Waterproofing in Pakistan

Let’s talk numbers. In Pakistan, the cost of roof waterproofing services typically ranges from:

Rs. 30 – Rs. 100 per square foot depending on material

Labour charges may vary by city (Lahore, Karachi, Islamabad)

Additional costs for roof prep, crack repair, and cleaning

Always get a detailed quote upfront. Cheap rates often hide shortcuts or inferior materials.

Maintenance Tips After Waterproofing

Once your roof is sealed, your job isn't over. Here's how to keep it protected:

Schedule inspections before and after monsoon season

Clear leaves and debris from gutters and roof edges

Reapply waterproof coating every 4–5 years (based on material)

Watch for early signs of wear, especially after heavy storms

FAQs: Roof Waterproofing Services

Q: How long does roof waterproofing last?

A: Depends on the material—typically 5 to 15 years with proper maintenance.

Q: Can I waterproof the roof myself?

A: Not recommended. Without proper tools and experience, DIY solutions rarely last and often make the issue worse.

Q: When is the best time for waterproofing?

A: Dry season is ideal. Avoid applying during or right before monsoon.

Q: Will waterproofing fix existing damage?

A: It stops future leaks but won’t fix structural damage already caused. You’ll need repair + waterproofing in such cases.

Q: How do I know if my contractor did a good job?

A: Ask for before/after pictures, inspect the roof after rain, and make sure they give a warranty.

0 notes

Text

Butyl Rubber Market Growth Accelerates as Demand Increases Across Automotive and Healthcare Sectors

The butyl rubber market plays a crucial role in the global synthetic elastomer industry, driven by its unique properties such as excellent gas impermeability, chemical resistance, and durability. These attributes make butyl rubber indispensable across several sectors including automotive, pharmaceuticals, construction, and industrial manufacturing. Conducting a thorough market analysis is vital to understanding how various factors influence its growth, pricing, and competitive landscape.

This blog provides an in-depth butyl rubber market analysis, focusing on key market drivers, challenges, segmentation, regional insights, and future prospects.

Market Overview

Butyl rubber is primarily synthesized from isobutylene and a small amount of isoprene, forming a highly elastic and airtight material. It comes in two main forms: conventional butyl rubber (IIR) and halogenated butyl rubber (BIIR and CIIR), with the latter offering enhanced curing speed and compatibility with other rubbers.

Due to its superior impermeability to gases, butyl rubber is widely used in tire inner liners, pharmaceutical closures, and sealing applications, which underscores its steady demand globally.

Key Market Drivers

Automotive Industry Growth

The automotive sector remains the dominant consumer of butyl rubber, primarily for tire inner liners and tubeless tires. The global rise in vehicle production, especially in developing economies such as China, India, and Southeast Asia, has led to increased consumption of butyl rubber.

The emergence of electric vehicles (EVs) is a significant trend impacting demand. EV tires require superior airtightness to improve battery efficiency and range, prompting tire manufacturers to invest in advanced butyl rubber formulations tailored for these vehicles.

Healthcare and Pharmaceutical Applications

Pharmaceutical packaging represents a rapidly growing segment within the butyl rubber market. Butyl rubber is preferred for vial stoppers, syringe seals, and closures due to its chemical inertness and ability to maintain sterility.

Heightened global healthcare awareness, coupled with increased vaccine production and distribution, particularly in response to recent health crises, has spurred higher demand for pharmaceutical-grade butyl rubber.

Construction and Infrastructure Development

The construction sector utilizes butyl rubber in waterproofing membranes, sealants, and adhesives due to its resistance to moisture, chemicals, and weathering. Urbanization, infrastructure investments, and government initiatives globally support consistent growth in this segment.

Market Challenges

Raw Material Price Volatility

Butyl rubber production depends heavily on petroleum-derived feedstocks like isobutylene. Fluctuations in crude oil prices directly impact raw material costs, resulting in price volatility for butyl rubber. This unpredictability poses challenges for manufacturers and end-users in budgeting and contract negotiations.

Environmental and Regulatory Pressures

Stringent environmental regulations aimed at reducing emissions, improving waste management, and promoting sustainability impact production methods. The synthetic nature of butyl rubber and difficulties in recycling have raised concerns, pushing manufacturers to adopt greener technologies and explore bio-based alternatives.

Competition from Alternative Elastomers

Butyl rubber faces competition from other synthetic rubbers such as EPDM, nitrile rubber, and thermoplastic elastomers. These materials sometimes offer advantages in cost, recyclability, or specific performance attributes, necessitating continuous innovation and differentiation by butyl rubber producers.

Market Segmentation

By Type

Conventional Butyl Rubber (IIR): Used in tires, adhesives, and sealants.

Halogenated Butyl Rubber (BIIR and CIIR): Preferred for pharmaceuticals, specialty tires, and high-performance industrial applications.

By Application

Automotive Tires: Inner liners and tubeless tires.

Pharmaceutical Packaging: Vial stoppers, syringe seals.

Construction: Waterproofing membranes, sealants.

Industrial Products: Hoses, belts, gaskets, adhesives.

By Region

Asia-Pacific: The largest and fastest-growing market, driven by expanding automotive production, infrastructure development, and pharmaceutical industry growth.

North America: Focused on specialty grades and sustainability initiatives.

Europe: Mature market with emphasis on advanced applications and environmental regulations.

Rest of the World: Emerging markets in Latin America, Middle East, and Africa showing steady growth potential.

Competitive Landscape

The butyl rubber market is moderately consolidated, dominated by major players with global production capabilities and strong R&D investments. Leading companies focus on expanding capacity, developing specialty products, and adopting sustainable practices to enhance competitiveness.

Strategic partnerships, mergers, and acquisitions are common as firms seek to strengthen their market position and access emerging markets.

Future Outlook and Trends

The butyl rubber market is expected to witness steady growth through the next decade. Key factors supporting this outlook include:

Technological Innovation: Advances in halogenated butyl rubber formulations and processing technologies will open new applications and improve performance.

Sustainability Focus: Increasing investment in eco-friendly production methods and bio-based materials will address environmental concerns and regulatory demands.

Electrification of Vehicles: Growth in EV production will continue to drive demand for specialized butyl rubber products.

Healthcare Expansion: Ongoing needs for pharmaceutical packaging solutions will sustain growth in this sector.

Emerging Markets: Rapid urbanization and industrialization in Asia, Latin America, and Africa present significant opportunities.

Conclusion

A comprehensive market analysis reveals that the butyl rubber industry is characterized by steady demand growth, driven by automotive, pharmaceutical, and construction sectors, tempered by raw material volatility and environmental challenges. Companies that prioritize innovation, sustainability, and strategic market expansion will be best positioned to capitalize on future opportunities.

0 notes

Text

Polyneoprene Rubber Market Size, Demand & Supply, Regional and Competitive Analysis (2025–2032)

Definition

Polyneoprene Rubber, commonly referred to as chloroprene rubber (CR), is a synthetic rubber known for its excellent weather resistance, durability, and flexibility. It is produced through the polymerization of chloroprene and is widely used in industrial applications such as automotive components, construction materials, adhesives, gaskets, seals, and protective clothing.

Its superior resistance to oil, heat, ozone, and chemicals makes Polyneoprene Rubber a highly versatile material. With increasing demand from end-use industries such as automotive, construction, and electronics, the global Polyneoprene Rubber market is witnessing steady growth.

This report offers a comprehensive insight into the Polyneoprene Rubber market’s size, growth trajectory, drivers, challenges, and regional dynamics over the forecast period 2025–2032.

Market Size

📥 Download Sample Report PDF Click here to download

The global Polyneoprene Rubber market was valued at USD 1,659.7 million in 2024 and is projected to reach USD 2,376.1 million by 2032, growing at a CAGR of 4.55% over the forecast period. This growth is driven by increasing industrial applications, particularly in automotive and construction sectors, along with advances in product formulations enhancing performance and sustainability.

Growth Projections and Market Trends

Polyneoprene Rubber has gained significant market traction due to its adaptability and performance characteristics. Key growth factors include:

Increasing demand for durable, oil-resistant materials in automotive and industrial machinery

Rising construction and infrastructure activities in developing countries

Growing adoption of neoprene-based adhesives in electronics and aerospace

Market trends indicate a shift toward eco-friendly neoprene alternatives, fueled by environmental regulations and the push for sustainable manufacturing. Additionally, innovations in synthetic rubber blends are expanding the application scope of Polyneoprene Rubber.

Market Dynamics

Drivers

Automotive Industry Growth: Neoprene is used in belts, hoses, and vibration mounts due to its resilience. Rising vehicle production fuels its demand.

Infrastructure Expansion: The construction industry utilizes neoprene in bridge bearings, seals, and waterproofing materials.

Chemical Resistance: Industries dealing with oils, greases, and chemicals prefer neoprene due to its superior resistance profile.

Restraints

Volatility in Raw Material Prices: Neoprene production depends on petroleum-based feedstocks, making it vulnerable to crude oil price fluctuations.

Environmental Concerns: The traditional manufacturing process involves toxic intermediates, prompting scrutiny from environmental agencies.

Opportunities

Bio-based Alternatives: Development of renewable neoprene options opens avenues for green market penetration.

Emerging Economies: Asia-Pacific and Latin America present high-growth potential due to industrialization and rising urban infrastructure projects.

Challenges

Intense Competition: With the entry of alternative elastomers such as EPDM and TPEs, manufacturers face stiff competition.

Stringent Environmental Regulations: Meeting global compliance standards increases R&D and operational costs.

Regional Analysis

North America

A mature market supported by high consumption in automotive and aerospace sectors. The U.S. remains the leading contributor with a strong manufacturing base.

Europe

Demand is driven by regulations mandating high-performance, non-toxic materials. Countries like Germany and France are major consumers in industrial applications.

Asia-Pacific

The fastest-growing region led by China, India, and Japan. The region benefits from rising vehicle production, construction activities, and growing electronics demand.

Latin America

Brazil and Mexico are expanding their industrial bases, creating demand for rubber products, especially in the transportation and energy sectors.

Middle East & Africa

Ongoing investments in infrastructure and oil-based industries are boosting neoprene consumption in countries like UAE and Saudi Arabia.

Competitive Landscape

Key Players in the Polyneoprene Rubber Market:

Denka Company Limited A leading producer globally, Denka offers various grades of CR for industrial and automotive applications.

Tosoh Corporation Specializes in advanced chloroprene rubber materials with high weather and oil resistance.

Chongqing Changshou Chemical Co., Ltd. A significant player in the Chinese market with increasing global exports.

Lanxess AG Renowned for its synthetic rubber innovations, Lanxess offers eco-friendly alternatives to conventional CR.

These companies focus on R&D, mergers, and geographic expansion to maintain a competitive edge.

Market Segmentation

By Type:

Solvent-Based Neoprene

Water-Based Neoprene

Latex-Based Neoprene

By Application:

Automotive

Construction

Electronics

Textile

Adhesives & Sealants

Industrial Machinery

FAQs

1. What is the projected market size of the Polyneoprene Rubber Market by 2032? The global Polyneoprene Rubber market is expected to reach USD 2,376.1 million by 2032.

2. Who are the major players in the Polyneoprene Rubber industry? Denka, Tosoh Corporation, Lanxess AG, and Chongqing Changshou Chemical are among the leading global manufacturers.

3. What factors are driving the demand for Polyneoprene Rubber? Key drivers include increasing automotive production, rising construction activities, and superior resistance properties of neoprene.

4. Which region is witnessing the fastest growth? Asia-Pacific is projected to grow the fastest due to rapid industrialization and infrastructure development.

5. What are the challenges facing the Polyneoprene Rubber market? Challenges include raw material price volatility, environmental concerns, and competition from alternative synthetic rubbers.

📘 Get The Complete Report & TOC Access Full Report

Contact Us:

24Chemical Research 203A, City Vista, Fountain Road, Kharadi, Pune, India - 411014 International: +1(332) 2424 294 Asia: +91 9169162030

Follow us on LinkedIn: 24ChemicalResearch

0 notes