#EPDM Rubber Price Trend

Explore tagged Tumblr posts

Text

Ethylene Propylene Diene Monomer (EPDM) Rubber Prices, News

North America

The EPDM Rubber market in the US has experienced a marginal 0.87% price increase in the fourth quarter of 2024, driven by stable supply and gradual demand recovery. The increase reflects a balance between supply constraints, including moderate raw material availability, and steady demand from the automotive sector, which saw continued growth in vehicle sales.

While feedstock prices for Ethylene and Propylene showed mixed trends, the market remained stable due to adequate supply and efficient sourcing strategies by manufacturers. The automotive sector provided significant support, with strong sales growth reported in November and December, while the construction sector remained subdued. Ongoing logistical challenges, including port congestion and labor shortages, extended delivery times, but did not disrupt supply enough to cause price spikes.

Despite a weakened manufacturing sector, cautious buying behavior, and moderate demand from the construction sector, EPDM Rubber prices showed resilience, reflecting a balanced market outlook. With expectations for gradual improvement in 2025, this trend of modest price increases is likely to continue.

0 notes

Text

Butyl Rubber Market Growth Accelerates as Demand Increases Across Automotive and Healthcare Sectors

The butyl rubber market plays a crucial role in the global synthetic elastomer industry, driven by its unique properties such as excellent gas impermeability, chemical resistance, and durability. These attributes make butyl rubber indispensable across several sectors including automotive, pharmaceuticals, construction, and industrial manufacturing. Conducting a thorough market analysis is vital to understanding how various factors influence its growth, pricing, and competitive landscape.

This blog provides an in-depth butyl rubber market analysis, focusing on key market drivers, challenges, segmentation, regional insights, and future prospects.

Market Overview

Butyl rubber is primarily synthesized from isobutylene and a small amount of isoprene, forming a highly elastic and airtight material. It comes in two main forms: conventional butyl rubber (IIR) and halogenated butyl rubber (BIIR and CIIR), with the latter offering enhanced curing speed and compatibility with other rubbers.

Due to its superior impermeability to gases, butyl rubber is widely used in tire inner liners, pharmaceutical closures, and sealing applications, which underscores its steady demand globally.

Key Market Drivers

Automotive Industry Growth

The automotive sector remains the dominant consumer of butyl rubber, primarily for tire inner liners and tubeless tires. The global rise in vehicle production, especially in developing economies such as China, India, and Southeast Asia, has led to increased consumption of butyl rubber.

The emergence of electric vehicles (EVs) is a significant trend impacting demand. EV tires require superior airtightness to improve battery efficiency and range, prompting tire manufacturers to invest in advanced butyl rubber formulations tailored for these vehicles.

Healthcare and Pharmaceutical Applications

Pharmaceutical packaging represents a rapidly growing segment within the butyl rubber market. Butyl rubber is preferred for vial stoppers, syringe seals, and closures due to its chemical inertness and ability to maintain sterility.

Heightened global healthcare awareness, coupled with increased vaccine production and distribution, particularly in response to recent health crises, has spurred higher demand for pharmaceutical-grade butyl rubber.

Construction and Infrastructure Development

The construction sector utilizes butyl rubber in waterproofing membranes, sealants, and adhesives due to its resistance to moisture, chemicals, and weathering. Urbanization, infrastructure investments, and government initiatives globally support consistent growth in this segment.

Market Challenges

Raw Material Price Volatility

Butyl rubber production depends heavily on petroleum-derived feedstocks like isobutylene. Fluctuations in crude oil prices directly impact raw material costs, resulting in price volatility for butyl rubber. This unpredictability poses challenges for manufacturers and end-users in budgeting and contract negotiations.

Environmental and Regulatory Pressures

Stringent environmental regulations aimed at reducing emissions, improving waste management, and promoting sustainability impact production methods. The synthetic nature of butyl rubber and difficulties in recycling have raised concerns, pushing manufacturers to adopt greener technologies and explore bio-based alternatives.

Competition from Alternative Elastomers

Butyl rubber faces competition from other synthetic rubbers such as EPDM, nitrile rubber, and thermoplastic elastomers. These materials sometimes offer advantages in cost, recyclability, or specific performance attributes, necessitating continuous innovation and differentiation by butyl rubber producers.

Market Segmentation

By Type

Conventional Butyl Rubber (IIR): Used in tires, adhesives, and sealants.

Halogenated Butyl Rubber (BIIR and CIIR): Preferred for pharmaceuticals, specialty tires, and high-performance industrial applications.

By Application

Automotive Tires: Inner liners and tubeless tires.

Pharmaceutical Packaging: Vial stoppers, syringe seals.

Construction: Waterproofing membranes, sealants.

Industrial Products: Hoses, belts, gaskets, adhesives.

By Region

Asia-Pacific: The largest and fastest-growing market, driven by expanding automotive production, infrastructure development, and pharmaceutical industry growth.

North America: Focused on specialty grades and sustainability initiatives.

Europe: Mature market with emphasis on advanced applications and environmental regulations.

Rest of the World: Emerging markets in Latin America, Middle East, and Africa showing steady growth potential.

Competitive Landscape

The butyl rubber market is moderately consolidated, dominated by major players with global production capabilities and strong R&D investments. Leading companies focus on expanding capacity, developing specialty products, and adopting sustainable practices to enhance competitiveness.

Strategic partnerships, mergers, and acquisitions are common as firms seek to strengthen their market position and access emerging markets.

Future Outlook and Trends

The butyl rubber market is expected to witness steady growth through the next decade. Key factors supporting this outlook include:

Technological Innovation: Advances in halogenated butyl rubber formulations and processing technologies will open new applications and improve performance.

Sustainability Focus: Increasing investment in eco-friendly production methods and bio-based materials will address environmental concerns and regulatory demands.

Electrification of Vehicles: Growth in EV production will continue to drive demand for specialized butyl rubber products.

Healthcare Expansion: Ongoing needs for pharmaceutical packaging solutions will sustain growth in this sector.

Emerging Markets: Rapid urbanization and industrialization in Asia, Latin America, and Africa present significant opportunities.

Conclusion

A comprehensive market analysis reveals that the butyl rubber industry is characterized by steady demand growth, driven by automotive, pharmaceutical, and construction sectors, tempered by raw material volatility and environmental challenges. Companies that prioritize innovation, sustainability, and strategic market expansion will be best positioned to capitalize on future opportunities.

0 notes

Text

Polyneoprene Rubber Market Size, Demand & Supply, Regional and Competitive Analysis (2025–2032)

Definition

Polyneoprene Rubber, commonly referred to as chloroprene rubber (CR), is a synthetic rubber known for its excellent weather resistance, durability, and flexibility. It is produced through the polymerization of chloroprene and is widely used in industrial applications such as automotive components, construction materials, adhesives, gaskets, seals, and protective clothing.

Its superior resistance to oil, heat, ozone, and chemicals makes Polyneoprene Rubber a highly versatile material. With increasing demand from end-use industries such as automotive, construction, and electronics, the global Polyneoprene Rubber market is witnessing steady growth.

This report offers a comprehensive insight into the Polyneoprene Rubber market’s size, growth trajectory, drivers, challenges, and regional dynamics over the forecast period 2025–2032.

Market Size

📥 Download Sample Report PDF Click here to download

The global Polyneoprene Rubber market was valued at USD 1,659.7 million in 2024 and is projected to reach USD 2,376.1 million by 2032, growing at a CAGR of 4.55% over the forecast period. This growth is driven by increasing industrial applications, particularly in automotive and construction sectors, along with advances in product formulations enhancing performance and sustainability.

Growth Projections and Market Trends

Polyneoprene Rubber has gained significant market traction due to its adaptability and performance characteristics. Key growth factors include:

Increasing demand for durable, oil-resistant materials in automotive and industrial machinery

Rising construction and infrastructure activities in developing countries

Growing adoption of neoprene-based adhesives in electronics and aerospace

Market trends indicate a shift toward eco-friendly neoprene alternatives, fueled by environmental regulations and the push for sustainable manufacturing. Additionally, innovations in synthetic rubber blends are expanding the application scope of Polyneoprene Rubber.

Market Dynamics

Drivers

Automotive Industry Growth: Neoprene is used in belts, hoses, and vibration mounts due to its resilience. Rising vehicle production fuels its demand.

Infrastructure Expansion: The construction industry utilizes neoprene in bridge bearings, seals, and waterproofing materials.

Chemical Resistance: Industries dealing with oils, greases, and chemicals prefer neoprene due to its superior resistance profile.

Restraints

Volatility in Raw Material Prices: Neoprene production depends on petroleum-based feedstocks, making it vulnerable to crude oil price fluctuations.

Environmental Concerns: The traditional manufacturing process involves toxic intermediates, prompting scrutiny from environmental agencies.

Opportunities

Bio-based Alternatives: Development of renewable neoprene options opens avenues for green market penetration.

Emerging Economies: Asia-Pacific and Latin America present high-growth potential due to industrialization and rising urban infrastructure projects.

Challenges

Intense Competition: With the entry of alternative elastomers such as EPDM and TPEs, manufacturers face stiff competition.

Stringent Environmental Regulations: Meeting global compliance standards increases R&D and operational costs.

Regional Analysis

North America

A mature market supported by high consumption in automotive and aerospace sectors. The U.S. remains the leading contributor with a strong manufacturing base.

Europe

Demand is driven by regulations mandating high-performance, non-toxic materials. Countries like Germany and France are major consumers in industrial applications.

Asia-Pacific

The fastest-growing region led by China, India, and Japan. The region benefits from rising vehicle production, construction activities, and growing electronics demand.

Latin America

Brazil and Mexico are expanding their industrial bases, creating demand for rubber products, especially in the transportation and energy sectors.

Middle East & Africa

Ongoing investments in infrastructure and oil-based industries are boosting neoprene consumption in countries like UAE and Saudi Arabia.

Competitive Landscape

Key Players in the Polyneoprene Rubber Market:

Denka Company Limited A leading producer globally, Denka offers various grades of CR for industrial and automotive applications.

Tosoh Corporation Specializes in advanced chloroprene rubber materials with high weather and oil resistance.

Chongqing Changshou Chemical Co., Ltd. A significant player in the Chinese market with increasing global exports.

Lanxess AG Renowned for its synthetic rubber innovations, Lanxess offers eco-friendly alternatives to conventional CR.

These companies focus on R&D, mergers, and geographic expansion to maintain a competitive edge.

Market Segmentation

By Type:

Solvent-Based Neoprene

Water-Based Neoprene

Latex-Based Neoprene

By Application:

Automotive

Construction

Electronics

Textile

Adhesives & Sealants

Industrial Machinery

FAQs

1. What is the projected market size of the Polyneoprene Rubber Market by 2032? The global Polyneoprene Rubber market is expected to reach USD 2,376.1 million by 2032.

2. Who are the major players in the Polyneoprene Rubber industry? Denka, Tosoh Corporation, Lanxess AG, and Chongqing Changshou Chemical are among the leading global manufacturers.

3. What factors are driving the demand for Polyneoprene Rubber? Key drivers include increasing automotive production, rising construction activities, and superior resistance properties of neoprene.

4. Which region is witnessing the fastest growth? Asia-Pacific is projected to grow the fastest due to rapid industrialization and infrastructure development.

5. What are the challenges facing the Polyneoprene Rubber market? Challenges include raw material price volatility, environmental concerns, and competition from alternative synthetic rubbers.

📘 Get The Complete Report & TOC Access Full Report

Contact Us:

24Chemical Research 203A, City Vista, Fountain Road, Kharadi, Pune, India - 411014 International: +1(332) 2424 294 Asia: +91 9169162030

Follow us on LinkedIn: 24ChemicalResearch

0 notes

Text

EPDM Rubber Prices in 2025: What’s Going On and What to Expect Next

In 2025, the EPDM rubber price trend has become a hot topic for many businesses and industries that rely on synthetic rubber materials. EPDM, or Ethylene Propylene Diene Monomer rubber, is used in a wide range of applications such as automotive seals, roofing membranes, electrical insulation, and industrial hoses. Because of its excellent resistance to weather, heat, and ozone, it’s a preferred choice in both construction and automotive sectors. As we step into 2025, prices have shown some mixed signals partly steady, partly fluctuating depending on demand, raw material supply, and global market shifts.

👉 👉 👉 Please Submit Your Query for EPDM Rubber price trend, forecast and market analysis: https://www.price-watch.ai/contact/

How the EPDM Rubber Market is Performing in 2025

The EPDM rubber market in 2025 is in a phase of gradual growth, but not without its ups and downs. In early 2025, prices remained somewhat stable compared to the volatile nature seen in the last couple of years, especially during the post-pandemic recovery. This stability is largely due to improved supply chains and consistent raw material availability. However, energy prices especially for natural gas and crude oil are still playing a big role in shaping production costs. This year, the demand for EPDM rubber has seen steady growth, particularly from the automotive and construction sectors, which are bouncing back with new projects and increased production. Automakers are increasing their focus on EVs (electric vehicles), and EPDM plays a key role in weather sealing and under-the-hood components in these vehicles. This trend is pushing EPDM consumption higher and keeping the market active.

What’s Driving the Market Size and Growth in 2025

The global EPDM rubber market size in 2025 is expanding at a slow but steady pace. Analysts estimate a moderate compound annual growth rate (CAGR) of around 4% to 5% through the next few years. Several factors are behind this growth. First, the world is becoming more urbanized, with construction projects booming in parts of Asia and the Middle East. EPDM is widely used in roofing, window seals, and waterproofing systems, so any growth in housing or commercial construction means more demand. Second, automotive manufacturing is picking up, not just in North America and Europe, but also in emerging markets. And third, EPDM is now being used in more specialized industrial applications, such as high-voltage insulation and solar panel framing. As the world turns to clean energy and advanced infrastructure, the need for long-lasting, weather-resistant materials like EPDM continues to rise.

Market Opportunities and Challenges This Year

2025 presents both opportunities and challenges for EPDM rubber producers and buyers. On the opportunity side, there's a growing demand in developing economies, especially in countries like India, Indonesia, and Brazil. These regions are seeing major investments in construction, infrastructure, and automobile assembly lines. At the same time, opportunities are arising in green building materials, where EPDM's durability and recyclability make it an attractive option. However, on the challenge side, environmental regulations are becoming stricter. Some countries are tightening rules on emissions from synthetic rubber production, which may lead to higher production costs. There's also competition from alternative elastomers and rubber materials, some of which are being marketed as more eco-friendly. For producers, balancing cost, compliance, and customer needs is becoming more complex, and smart players are investing in R&D and sustainable practices to stay competitive.

Who Are the Major Players in the Market

Several global companies are leading the EPDM rubber market in 2025. These include names like Dow, ExxonMobil, Arlanxeo, Lion Elastomers, Mitsui Chemicals, and Kumho Petrochemical. These companies are not only large in scale but also investing heavily in new technologies, production expansion, and sustainability efforts. For example, some producers are exploring bio-based EPDM alternatives, which could reduce the environmental impact of manufacturing. These big players often set the tone for pricing and supply in the global market, and their performance has a ripple effect across regions. Smaller players and regional manufacturers also exist, especially in Asia, where local demand is high, and customization is more common. The competition between global giants and regional suppliers keeps prices in check and encourages innovation in product offerings.

Market Segmentation in 2025

The EPDM rubber market in 2025 can be understood more clearly when we look at how it’s segmented. The most common way to break down the market is by application. Automotive is still the largest segment, using EPDM in weatherstrips, door seals, hoses, and other under-the-hood parts. Then there’s the building and construction segment, which includes roofing, seals, gaskets, and waterproofing systems. Industrial machinery and electrical insulation make up smaller but important segments. Region-wise, Asia Pacific continues to be the largest market, especially with countries like China, India, and Japan driving growth. North America and Europe follow, with steady but slower demand. Meanwhile, the Middle East and Africa are showing early signs of future growth, thanks to new construction and industrial development projects.

What the Outlook Looks Like Moving Forward

The outlook for EPDM rubber in 2025 and beyond remains mostly positive, though not without a few bumps on the road. Analysts expect demand to continue rising, thanks to industrial expansion, automotive innovation, and increased urban development. However, pricing may remain sensitive to energy fluctuations, raw material costs, and environmental pressures. If oil prices spike or production is disrupted in key regions, it could cause short-term price hikes. Still, with more producers working on efficiency and sustainability, the long-term prospects are encouraging. Innovations in green chemistry and the shift toward more durable and recyclable rubber products will likely benefit the EPDM market. It’s also expected that government support for infrastructure development—especially in Asia and Africa—will continue to boost demand.

Industry Analysis and Forecast to 2030

Looking ahead, industry experts forecast a stable growth path for EPDM rubber through 2030. The CAGR is expected to hover between 4% and 6%, depending on regional factors and energy prices. EPDM will remain in high demand because of its reliability, versatility, and resistance to environmental conditions. The automotive sector will keep driving growth, especially as electric vehicles become more common and require specialized sealing solutions. At the same time, public and private investment in building infrastructure will open more opportunities in the roofing and waterproofing segment. Technological innovation, such as better formulations and eco-friendly versions of EPDM, will further help the market expand. Companies that adapt to sustainability trends and regional needs are expected to lead the market forward. Overall, EPDM rubber is set for steady growth, and 2025 is proving to be a foundational year in setting that path.

0 notes

Text

EPDM Rubber Price Index: Market Analysis, Trend, News, Graph and Demand

EPDM Rubber ENB (4.1–5.5) prices in the U.S. posted a marginal quarter-on-quarter decline of 1.66%, shaped by ongoing shifts in supply and demand conditions. Prices remained relatively stable on a month-to-month basis, but broader quarterly data pointed to slight downward movement, largely influenced by easing feedstock costs and improved availability. Ethylene prices fell sharply by 13.8% in March, while Propylene prices decreased by 6.2%, collectively supporting better production economics and reducing input cost pressures for EPDM manufacturers.

On the supply side, early-quarter logistical challenges such as port congestion and shipping delays that impacted January and February saw gradual resolution by March. This improved the flow of imports and helped stabilize regional availability. Demand signals were mixed over the quarter, with a slow start in automotive sales followed by a strong rebound in March. The construction sector, particularly residential development, provided steady support, though its growth was not sufficient to significantly boost overall market momentum. Broader macroeconomic concerns such as persistent inflation, evolving tariff structures, and cautious consumer behavior continued to influence downstream purchasing patterns and restrained any aggressive buying.

Manufacturing data remained relatively strong, signaling a steady industrial base, but the pace of growth was held in check by uncertainties surrounding trade regulations and rising logistics expenses. Suppliers adapted to moderate demand and shifting cost structures, maintaining a stable market balance. As a result, the EPDM rubber market experienced a slight correction in prices over the quarter without encountering sharp volatility, reflecting a market in measured equilibrium.

Get Real time Prices for EPDM Rubber: https://www.chemanalyst.com/Pricing-data/epdm-rubber-1110

The EPDM Rubber market in Japan recorded a mild quarter-on-quarter decline of 0.93% during Q1 2025, as the market adjusted to a combination of steady supply and softening demand. Feedstock availability, particularly Ethylene and Propylene, remained relatively balanced, although logistical recalibrations and lower Ethylene production rates added complexity to the supply chain. Japanese producers, including major players like Mitsui Chemicals, attempted to optimize operations and announced price adjustments for some elastomer products, though the direct impact on EPDM pricing was limited due to broader market pressures.

Demand was constrained by subdued global economic activity, with weaker-than-expected orders from major international markets such as the U.S., Europe, and China. While the domestic automotive sector maintained reasonable output levels and vehicle sales inched upward, the construction industry faced headwinds from elevated labor costs and a slowdown in project completions. These factors collectively muted EPDM consumption growth and created a cautious market atmosphere. Some positive domestic trends, such as a modest rebound in the housing sector, supported price stability to a degree, but they were not strong enough to counteract broader economic unease.

Manufacturing sentiment remained cautious, shaped by global trade uncertainty and sluggish export activity. As a result, the Japanese EPDM market experienced a subdued pace of price movement, reflecting the delicate balance between steady supply and weak external demand. The slight quarterly dip in pricing underscored a conservative outlook as market participants awaited clearer economic signals.

The European EPDM Rubber market saw a modest decline of 0.88% from the previous quarter, reflecting a period of relative price stability amid mixed economic and sectoral dynamics. Regional supply remained consistent, driven by uninterrupted domestic production and steady import volumes. Despite ongoing logistical complications at key European ports like Hamburg and Rotterdam, the impact on the EPDM supply chain was mitigated by healthy inventory levels and easing freight costs, which supported overall market availability.

On the demand front, conditions were uneven. The automotive sector showed a drop in vehicle registrations across several key countries during January and February, suggesting a cautious consumer environment. The construction industry also faced headwinds, with activity remaining subdued across residential, commercial, and public infrastructure projects. However, government-backed infrastructure initiatives, especially in civil engineering, hinted at potential recovery in the medium term. These sector-specific fluctuations were accompanied by broader economic developments, including rate cuts from the European Central Bank aimed at stimulating investment and consumption.

Despite these monetary policy efforts, lingering concerns about global trade conditions and inflationary pressures continued to cast a shadow over demand confidence. Market participants adopted a cautious stance, limiting stockpiling and procurement activity. Nonetheless, the European EPDM market demonstrated underlying resilience, with suppliers maintaining stable operations and adapting to evolving conditions. The slight downward shift in prices reflected a market navigating short-term challenges while holding an optimistic view for gradual recovery in the latter half of the year.

Get Real time Prices for EPDM Rubber: https://www.chemanalyst.com/Pricing-data/epdm-rubber-1110

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#EPDM Rubber Price Monitor#Ethylene Propylene Diene Monomer Rubber Price#India#United kingdom#United states#Germany#Business#Research#Chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

EPDM Cable Market Trends and Long-Term Outlook 2024 - 2032

The EPDM (Ethylene Propylene Diene Monomer) cable market is an essential segment of the electrical and telecommunications industry, driven by the growing demand for durable and reliable cable solutions across various applications. EPDM cables are known for their excellent weather resistance, flexibility, and insulation properties, making them suitable for use in harsh environments. This article provides an in-depth analysis of the EPDM cable market, discussing key trends, drivers, challenges, and future outlook.

Overview of EPDM Cables

The EPDM cable market is well-positioned for growth as industries increasingly prioritize durability, flexibility, and reliability in electrical solutions.

What Are EPDM Cables?

EPDM cables are electrical cables insulated with EPDM rubber, a synthetic material known for its exceptional resistance to heat, ozone, and weathering. These cables are commonly used in applications where durability and flexibility are critical, such as in outdoor and industrial settings.

Key Features of EPDM Cables

Weather Resistance: EPDM cables can withstand extreme temperatures, UV exposure, and moisture, making them ideal for outdoor applications.

Chemical Resistance: These cables exhibit resistance to various chemicals, oils, and solvents, ensuring longevity in industrial environments.

Flexibility: EPDM cables remain flexible even at low temperatures, facilitating easier installation and maneuverability.

Market Dynamics

Current Market Trends

The EPDM cable market is shaped by several significant trends:

Growing Demand for Renewable Energy: The rise in renewable energy projects, such as solar and wind power, is increasing the need for reliable and durable cable solutions.

Technological Advancements: Innovations in cable manufacturing processes are enhancing the performance characteristics of EPDM cables, driving their adoption in various applications.

Increasing Infrastructure Development: Ongoing investments in infrastructure, particularly in emerging economies, are fueling the demand for high-quality electrical cables.

Market Segmentation

The EPDM cable market can be segmented based on:

Type: Low-voltage cables, medium-voltage cables, high-voltage cables.

Application: Power generation, telecommunications, automotive, industrial equipment, and others.

Region: North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

Key Drivers of Market Growth

Rising Energy Demand

The growing global energy demand, coupled with the expansion of power generation infrastructure, is driving the need for durable electrical cables like EPDM.

Increasing Adoption of Electric Vehicles

The rise of electric vehicles (EVs) is boosting the demand for EPDM cables, which are used in charging stations and EV components due to their flexibility and durability.

Stringent Safety Standards

Regulatory requirements for safety and environmental standards are encouraging manufacturers to use high-quality materials like EPDM in cable production, driving market growth.

Challenges Facing the Market

Price Volatility of Raw Materials

Fluctuations in the prices of raw materials used in the production of EPDM cables can impact manufacturing costs and pricing strategies.

Competition from Alternative Materials

The availability of alternative insulation materials, such as PVC and silicone, may limit the growth of the EPDM cable market, as some users may prefer these alternatives for specific applications.

Technical Challenges

The manufacturing of EPDM cables requires advanced technology and expertise, which may pose challenges for smaller manufacturers looking to enter the market.

Future Outlook

Market Projections

The EPDM cable market is expected to witness steady growth over the next several years, driven by increasing demand in various sectors, including renewable energy and electric vehicles.

Innovations on the Horizon

Future developments may include enhanced formulations of EPDM for improved performance, such as better thermal stability and higher conductivity, as well as the integration of smart technologies for monitoring and control.

Strategic Collaborations

Collaborations between manufacturers, end-users, and research institutions will be essential for driving innovation and expanding the market reach of EPDM cables.

Conclusion

While challenges such as raw material price volatility and competition from alternative materials exist, the ongoing demand for high-quality cables in renewable energy, electric vehicles, and infrastructure development will drive market adoption. As technological advancements continue to emerge, EPDM cables will play a vital role in enhancing the performance and safety of electrical systems across various applications, contributing to a more sustainable and efficient energy future.

0 notes

Text

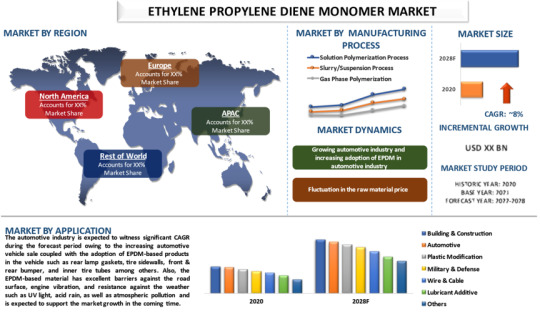

Ethylene Propylene Diene Monomer (EPDM) Market Overview

Introduction

Ethylene Propylene Diene Monomer Market is a type of synthetic rubber known for its excellent resistance to heat, oxidation, ozone, and weathering. EPDM rubber is used in a wide range of applications, including automotive weatherstripping and seals, roofing membranes, and industrial and construction products. The market for EPDM is growing steadily due to its superior properties and the increasing demand from various end-use industries.

Market Drivers

1. Automotive Industry Growth: The automotive sector is one of the largest consumers of EPDM, utilizing it in hoses, seals, and weatherstripping. The continuous growth in vehicle production and the shift towards electric vehicles, which require durable and heat-resistant materials, drive the demand for EPDM.

2. Construction Industry Demand: In the construction industry, EPDM is used in roofing membranes and other applications due to its durability and weather resistance. With increasing infrastructure projects and renovation activities, the demand for EPDM in the construction sector is rising.

3. Rising Industrial Applications: EPDM's properties make it suitable for various industrial applications, such as conveyor belts, gaskets, and hoses. The expansion of the manufacturing sector and the need for reliable and durable materials in industrial processes contribute to the market growth.

Market Challenges

1. Raw Material Price Volatility: The prices of raw materials used in the production of EPDM, such as ethylene and propylene, are subject to fluctuations. This volatility can affect the overall cost of production and impact profit margins for manufacturers.

2. Environmental Regulations: The production and disposal of synthetic rubber are subject to environmental regulations. Compliance with these regulations can increase production costs and pose challenges for manufacturers.

For a comprehensive analysis of the market drivers:- https://univdatos.com/report/ethylene-propylene-diene-monomer-market/

Regional Insights

1. North America: The North American EPDM market is driven by the robust automotive and construction sectors. The region's focus on sustainable and energy-efficient buildings further supports the demand for EPDM in roofing applications.

2. Europe: Europe is a significant market for EPDM due to its strong automotive industry and stringent environmental regulations that promote the use of durable and recyclable materials. The construction sector also contributes to the market growth in this region.

3. Asia-Pacific: The Asia-Pacific region is witnessing rapid growth in the EPDM market, fueled by the booming automotive industry in countries like China and India. Additionally, the expanding construction industry and increasing industrialization are driving the demand for EPDM in this region.

4. Latin America and Middle East & Africa: These regions are experiencing moderate growth in the EPDM market. The increasing automotive production and construction activities are key factors contributing to the market expansion in these regions.

Market Trends

1. Sustainability and Recycling: There is a growing emphasis on sustainability and recycling in the EPDM market. Manufacturers are focusing on developing eco-friendly production processes and recyclable EPDM products to meet the rising demand for sustainable solutions.

2. Technological Advancements: Innovations in production technologies and the development of advanced EPDM formulations are enhancing the performance and applications of EPDM. These advancements are expected to open new opportunities in various end-use industries.

3. Increased Use in Electric Vehicles: The shift towards electric vehicles (EVs) is driving the demand for high-performance materials like EPDM. EVs require materials that can withstand higher temperatures and provide better insulation, making EPDM an ideal choice.

For a sample report, visit:- https://univdatos.com/get-a-free-sample-form-php/?product_id=31683

Competitive Landscape

The EPDM market is highly competitive, with several key players operating globally. Companies are focusing on strategic initiatives such as mergers and acquisitions, collaborations, and new product developments to strengthen their market position. Some of the prominent players in the EPDM market include:

Conclusion

The Ethylene Propylene Diene Monomer (EPDM) market is poised for significant growth in the coming years, driven by the increasing demand from the automotive, construction, and industrial sectors. While challenges such as raw material price volatility and environmental regulations exist, advancements in technology and a focus on sustainability are expected to propel the market forward. The competitive landscape will continue to evolve as companies innovate and adapt to meet the changing demands of the market.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

The Complete Guide to Flat Roofing Materials

Flat roofing refers to a kind of roofing system that has a minimum slope, usually less than 10 ranges, and is normally used in commercial and business homes. It differs from sloped roofs, which have a steeper incline and are extra commonly discovered in residential homes. Some of the most famous flat roofing substances include EPDM, TPO, and PVC, which can be durable and long-lasting.

Most Common Types of Flat Roofing Materials

The maximum not unusual varieties of flat roofing substances are:

EPDM (Ethylene Propylene Diene Monomer) :

It's a synthetic rubber membrane that is regarded for its sturdiness and versatility. EPDM is immune to UV rays, ozone, and extreme temperatures, making it a wonderful alternative for flat roofs.

TPO (Thermoplastic Olefin) :

A unmarried-ply roofing membrane made from thermoplastic polyolefin. It's a famous choice for flat roofs due to its strength efficiency and potential to mirror UV rays.

PVC (Polyvinyl Chloride) :

It's a thermoplastic fabric that is recognised for its durability and resistance to chemical compounds, fire, and excessive temperatures. PVC is likewise power green and UV resistant.

Built-up Roofing (BUR) :

It's a traditional roofing machine made from a couple of layers of felt or fiberglass, which are lined with tar or asphalt to create a waterproof barrier.

Modified Bitumen:

It's a type of asphalt-based totally roofing this is bolstered with either a polyester or fiberglass mat. It provides properly sturdiness and resistance to punctures and tears.

It's well worth noting that every kind of flat roof material has its personal precise set of benefits and drawbacks. The nice desire in your building will rely upon elements which include region, weather, and finances.

Advantages and Disadvantages of Flat Roofing

Advantages of flat roofing:

Cost-powerful:

Flat roofs are normally much less high priced to install and maintain than sloped roofs. This is because they require much less substances and hard work to construct.

Easy Access:

Flat roofs are easy to get entry to, which makes it handy for protection and maintenance. This can shop money and time in the end.

Space:

Flat roofs may be used as an extra out of doors space, along with for creating a rooftop lawn or terrace.

Energy efficient:

TPO and PVC have reflective properties that can assist to lessen the amount of heat absorbed with the aid of the building, that can lead to lower cooling fees.

Disadvantages of flat roofing:

Drainage:

Flat roofs will have drainage problems: if now not nicely designed and maintained. This can result in water ponding, leaks, and different harm.

Weather Damage:

Flat roofs are extra at risk of harm from heavy rain and snow, in addition to excessive winds.

Not suitable for all climates: Flat roofs are not suitable for areas with heavy snow or frequent heavy rains, because of the threat of water ponding.

Reduced lifespan:

Without right protection, flat roofs generally tend to have a shorter lifespan than sloped roofs.

It's worth noting that with proper design, installation, and upkeep, flat roofs may be a viable alternative for many buildings. It's crucial to seek advice from a professional roofing contractor to determine if a flat roof is the right preference in your precise constructing and vicinity.

Also Read :

Why Are Flat Roofs Used?

WHY SOLID ROOF CONSERVATORIES ARE A GROWING TREND

0 notes

Text

Synthetic rubber Market Revolution: A Market Overview

The global synthetic rubber market size is expected to reach USD 36.15 billion by 2032, according to a new study by Polaris Market Research. The report “Synthetic Rubber Market Share, Size, Trends, Industry Analysis Report, By Product Type (SBR, IIR, EPDM, IR, NBR, & Others), By Application, By Industry Vertical, By Regions, Segments & Forecast, 2019 – 2032” gives a detailed insight into current market dynamics and provides analysis on future market growth.

Synthetic Rubber Market is expected to grow at a quickest rate over the forecast period owing to wider applications of Synthetic rubbers in tire and non-tire segments of automobile industry. Adoption of synthetic rubber from industry such as industrial goods, fmcg and medical sector in various applications coupled with rising prices of natural rubber are some of other factors behind the growth of the market in the coming years.

Synthetic rubbers are artificially produced materials that mimic natural rubber's desirable properties. Petrochemical feedstocks are the primary raw materials for manufacturing of synthetic rubber. The major development of synthetic rubber can be attributed to one factor during the World War II period when the United States was cut off from all of its sources of natural rubber. To meet the country's needs, the government built synthetic rubber plants and sold the plants to industries in the post-war period, which gave a kick-start to commercializing synthetic rubber.

The synthetic rubber are widely adopted in a variety of applications for some of its beneficial characteristics such as better abrasion resistance, superior elasticity, heat and aging resistance, flame retardant, and flexibility at low temperatures. Some of the most common varieties of synthetic rubber used by end-use industry butyl rubber (IIR), polybutadiene rubber, styrene-butadiene (SBR) rubber, chloroprene rubber, Ethylene propylene diene monomer rubber (EPDM) rubber, nitrile rubber.

For instance, as per the European Automobile Manufacturer's Association (ACEA), world vehicle production has increased by 1.3% from 2020 to 2021, with a value of 79.1 million motor vehicles. Moreover, global car and commercial vehicle production grew by 0.03% and 4% from 2020 to 2021. In addition, the aggregate value for cars and commercial vehicles production in 2021 was 80.14 million, which was 3% higher than the 2020 production number of 77.71 million per the International Organization of Motor Vehicle Manufacturers.

Various inhibiting factor for the Synthetic Rubber market can be attributed to the price fluctuation of Petrochemical feedstock (Crude Oil) raw materials in the last few years. Since crude oil prices largely depend on various factors, such as demand-supply and other geo-political relations between trading countries, it greatly affects the price structure and profit margins of synthetic rubber producers. In addition, the high manufacturing and rising transportation costs also impact the end-price of synthetic rubber products, further decreasing the demand from buyers end to some extent.

Have Questions? Request a sample or make an Inquiry before buying this report by clicking the link below: https://www.polarismarketresearch.com/industry-analysis/synthetic-rubber-market/request-for-sample

The COVID-19 pandemic has negatively impacted the Synthetic Rubber market across all regions. Various countries' governments have imposed certain measures to control the virus to further spread among the people. The temporary shutdown of multiple shops and production units had led to the decrease in demand and supply of products constituting synthetic rubber. In the pandemic period, the consumer demand was remained insignificant as consumers preferred spending money on their health and essential goods. The declining demand for various end-use industries has lowered the synthetic rubber market during pandemic period.

Synthetic Rubber Market Report Highlights:

The Styrene Butadiene Rubber (SBR) is anticipated to dominate the synthetic rubber market owing to its properties including high abrasion resistance, high tensile strength, and good aging stability, favor styrene butadiene rubber.

While, Nitrile Butadiene Rubber (NBR) has been anticipated to witness the fastest growth rate in the forecast period. The major factors for segment growth can be ascribed to its benefits, such as fuel and oil resistance, abrasion resistance, and good temperature properties.

The Tire segment is anticipated to account for a major share of the Synthetic Rubber market. The major factors can be attributed to various advantages such as better aging and heat resistance, abrasion resistant, excellent electrical insulation material, and others. For instance, as per the USA Tire Manufacturers Association, both passenger and truck tires use 24% and 11% synthetic polymers for their contribution to the life of a tire.

Asia-Pacific Region is accounted for the largest market share in 2022 due to presence of major tire producing countries in the region such as India, China, Japan, South Korea, Thailand, and Indonesia. For instance, as per European Automobile Manufacturer's Association (ACEA), Greater China accounted for around 33% of world car production in 2021 and 31% of commercial vehicle production in the same period.

Polaris Market Research has segmented the Synthetic Rubber Computing Market report based on product type, application, industry vertical, and region:

Synthetic Rubber Computing Market, Product Type Outlook (Revenue - USD Billion, 2019 - 2032)

Styrene-butadiene Rubber (SBR)

Butyl Rubber (IIR)

Ethylene-propylene-diene Rubber (EPDM)

Isoprene Rubber (IR)

Acrylonitrile-butadiene Rubber (NBR)

Others

Synthetic Rubber Computing Market, Application Outlook (Revenue - USD Billion, 2019 - 2032)

Tire

Non-Tire Automobile Applications

Footwear

Industrial Goods

Sporting Goods

Other Applications

Synthetic Rubber Computing Market, Industry Vertical Outlook (Revenue - USD Billion, 2019- 2032)

Automotive

Industrial Goods

Chemical Industry

Medical Industry

Paper & Pulp

Others

Synthetic Rubber Computing Market, Regional Outlook (Revenue - USD Billion, 2019 - 2032)

North America

U.S.

Canada

Europe

Germany

UK

France

Italy

Spain

Russia

Netherlands

Asia Pacific

China

India

Japan

South Korea

Indonesia

Malaysia

Latin America

Argentina

Brazil

Mexico

Middle East & Africa

UAE

Saudi Arabia

Israel

South Africa

Purchase the Report for Key Insights:@ https://www.polarismarketresearch.com/industry-analysis/synthetic-rubber-market

Bottom of FormAbout Us:

Polaris Market Research is a worldwide market research and consulting organization. We give unmatched nature of offering to our customers present all around the globe across industry verticals. Polaris Market Research has expertise in giving deep-dive market insight along with market intelligence to our customers spread crosswise over various undertakings. We at Polaris are obliged to serve our different client base present over the enterprises of medicinal services, healthcare, innovation, next-gen technologies, semi-conductors, chemicals, automotive, and aerospace & defense, among different ventures, present globally.

Contact Us:

Polaris Market Research

Email: [email protected]

Phone: +1-929-297-9727

0 notes

Text

Revolutionizing the Rubber Realm: A Deep Dive into the Thriving EPDM Market Landscape

In the ever-evolving landscape of the global market, the Ethylene Propylene Diene Monomer (EPDM) industry is poised for significant growth. According to the latest report, the EPDM Market is estimated to be USD 3.6 billion in 2022 and is projected to reach USD 4.8 billion by 2027, reflecting a noteworthy Compound Annual Growth Rate (CAGR) of 5.9% during the forecast period from 2022 to 2027.

EPDM Market Overview

EPDM, a versatile synthetic rubber, finds its applications across diverse sectors, including Automotive, Building & Construction, Plastic Modification, Tires & Tubes, Wires & Cables, and Lubricant Additives. Automotive, in particular, emerges as the major driver of the EPDM market, contributing significantly to its growth. As the automotive sector experiences a robust recovery in the Asia-Pacific (APAC) region, the demand for EPDM is expected to surge.

Key Insights and Opportunities

The automotive application holds the largest share in the EPDM market, with China playing a pivotal role. The country's focus on developing new energy vehicles (NEVs), encompassing Fuel Cell Electric Vehicles (FCVs), Plug-in Hybrid Electric Vehicles (PHEVs), and Battery Electric Vehicles (BEVs), is a key catalyst for the increased usage of EPDM in the automotive industry. According to the China Association of Automobile Manufacturers (CAAM), the total production of cars in 2021 witnessed a 3% year-on-year increase.

Additionally, the growing demand for electric and hybrid vehicles presents new opportunities in the EPDM market. The development of eco-friendly technologies for EPDM production aligns with the global shift towards sustainable practices in the automotive sector.

Manufacturing Processes and Market Dynamics

EPDM can be manufactured through various processes, and the Solution Polymerization Process currently dominates the market. This process is highly versatile, allowing for the production of a wide range of polymers. Polymerization and catalyst technologies play a crucial role in tailoring EPDM to meet specific application and processing needs.

Regional Market Dynamics

The Asia-Pacific region emerged as the frontrunner in the global EPDM market in 2021, with China being a key player in both production and consumption. The region's dominance is attributed to the concentration of EPDM producers and the flourishing automotive and construction sectors. New construction projects and sustained growth in the automotive industry are propelling the EPDM market in Asia Pacific.

Industry Players and Strategies

Leading players in the EPDM market include ARLANXEO, DOW Inc., Exxon Mobil Corporation, JSR Corporation (Kumho Polychem Co. Ltd.), PetroChina Company Limited, Versalis S.p. A., SK Global Chemical Co., Ltd., Sumitomo Chemical Co., Ltd., and Mitsui Chemicals, Inc. These industry giants are actively shaping the market through strategic initiatives, ensuring competitiveness and sustainability.

Download PDF Report :

Navigating the Future

As the EPDM market continues to evolve, keeping an eye on ethylene propylene diene monomer prices, EPDM market trends, and the EPDM price trend for 2023 will be critical. Stakeholders should remain vigilant about the dynamic market forces, ensuring they are well-positioned to capitalize on emerging opportunities and navigate challenges.

The EPDM market's growth trajectory is marked by resilience and adaptability, making it a key player in the global rubber market. Stay tuned for more updates on the EPDM market, where innovation meets opportunity in this dynamic industry landscape.

0 notes

Text

Rubber Coated Fabric Market Share, Trends, Report 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the global rubber coated fabric market size at USD 6.14 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects the global rubber coated fabric market size to grow at a significant CAGR of 4.3% reaching a value of USD 8.25 billion by 2029. Major growth drivers for the global rubber coated fabric market include an increasing adoption of rubber-coated fabrics in the production of military and protective apparel. In the automotive sector, original equipment manufacturing (OEM), particularly in airbags, represents the primary application for these coated fabrics. Notably, they find uses in automotive interiors, headliners, convertible tops, pickup truck bed covers, heavy-duty truck covers, and various protective covers. The expansion of global rubber coated fabric market is also attributed to the growing utilization of these materials in industrial products like conveyor belts and PTFE tapes. Additionally, there's an expected boost from the rising acceptance of coated fabrics as cost-effective alternatives to leather in upholstery and trim applications. Market growth is further driven by fluctuating raw material prices, strict environmental regulations, and ongoing technological innovations aimed at cost reduction and production efficiency enhancement. However, availability of low cost substitute and release of pollutant during manufacturing process are anticipated to restrain the overall market growth during the period in analysis.

Global Rubber Coated Fabric Market – Overview

The global rubber coated fabric market refers to the worldwide industry involved in the production, distribution, and utilization of textile materials that have been coated or laminated with rubber or rubber-like compounds. These coated fabrics offer enhanced properties, such as durability, resistance to abrasion, weatherproofing, and flexibility, making them suitable for various applications in automotive, military, industrial, and other sectors. The market encompasses the manufacturing, supply chain, and demand for rubber-coated fabrics used in a wide range of products, including protective clothing, conveyor belts, PTFE tapes, automotive components, and various industrial applications.

Sample Request @ https://www.blueweaveconsulting.com/report/rubber-coated-fabric-market/report-sample

Impact of COVID-19 on Global Rubber Coated Fabric Market

COVID-19 pandemic adversely affected the global rubber coated fabric market. Various end-use industries, including aerospace, automotive, and marine, witnessed a negative influence on demand. Original equipment manufacturers (OEMs) faced operational challenges, operating at reduced or zero capacity, primarily due to disruptions in the supply chain. These disruptions encompassed delays or non-arrival of raw materials, disruptions in financial transactions, and an increase in absenteeism among production line personnel, consequently leading to diminished demand for rubber coated fabric products. Also, the automotive industry, a significant consumer of rubber coated fabrics, witnessed substantial repercussions as non-essential businesses were compelled to close during the pandemic outbreak. With a dwindling demand for automobiles, production came to an abrupt standstill. As reported by the International Organization of Motor Vehicle Manufacturers, global automotive production plummeted by 16% in 2020.

Global Rubber Coated Fabric Market – By Type

Based on type, the global rubber coated fabric market is bifurcated into Natural and Synthetic segments. The synthetic segment holds a higher share in the global rubber coated fabric market by type. Synthetic rubbers, such as polychloroprene, ethylene propylene diene monomer (EPDM), and butyl rubber, exhibit superior performance compared to natural rubbers in two significant aspects: thermal stability and resistance to oils and related substances. Synthetic rubber surpasses natural rubber in several key properties, including resistance to abrasion, chemicals, fluids, ozone, electrical heat, and the effects of aging. Also, many synthetic rubber variants, including polychloroprene, EPDM, and butyl rubber, possess flame-resistant qualities, rendering them suitable for insulation in electrical devices. Consequently, the combination of these advantageous properties in synthetic rubber makes it a highly effective choice for coated fabrics, thereby driving growth within the market.

Competitive Landscape

Major players operating in the global rubber coated fabric market include Trelleborg AB, GUMOTEX Coating, Continental (ContiTech), RAVASCO (Indus Belts), Zenith Rubber, Fairprene (Alpha Engineered Composites), Chemprene, White Cross Rubber Products, Arville, Kurwa Rubber & Valves, Bobet, Fabri Cote, Vikamshi, and Colmant Coated Fabrics. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

Global Synthetic rubber Market Research Report : Ken Research

Buy Now

Synthetic rubber is a flexible polymer made commonly from petroleum wastes. Synthetic rubber has a variability of qualities, involving flexibility, grease resistance, durability, and good water repellence, making it ideal for a variability of applications in construction, footwear, automotive & transportation, industrial, and several other fields. It's also utilized to make polymer concrete for waterproofing, as well as tires, hoses, conveyor belt coverings, gaskets, and tubes. Styrene-butadiene rubbers (SBR) are the most shared synthetic rubbers, produced from the copolymerization of styrene and 1,3-butadiene.

According to the report analysis, ‘Synthetic Rubber Market: Current Analysis and Forecast (2021-2027)’ states that the growth of synthetic rubber industry reliant on the performance of end user industries such as tire, automotive, footwear, consumer goods, and growing foray of synthetic rubber in natural rubber insights. The global augment in production of tire, footwear, and consumer goods products among others has augmented the company's reliance on synthetic rubber as it proposes the high performance at a lower cost compared to natural rubber. Further, growing end user production process demands the large quantity of raw materials and since production of natural rubber is restricted therefore augment in requirement resulted in supply-demand disruption thus growing the price of natural rubber. Further, increasing population and augmenting consumer disposable power has resulted in the rising demand of footwear, around the globe. In addition, speedy changing fashion trend and consumer implementation to those changes also resulted in the requirement of new footwears. These aspects are advancing the market of synthetic rubber. However, crude oil is the commonly raw material for the introduction of synthetic rubber. Hence, volatility in the crude oil cost affects the dynamics of synthetic rubber market.

Request For Sample Report-https://kenresearch.com/sample-report.php?Frmdetails=NTIyMjY5

Based on type, the market is classified into SBR, BR, SBC, EPDM, IIR, NBR, and several others. Among these, SBR controlled the prominent share in the global synthetic rubber market. SBR is broadly use in tire industry as it is better suited to encounter the progressively stringent specifications of great-performance tires. Furthermore, in automotive industry SBR founds application in belt, hoses, gasket. Hence, growth in tire industry and replacement of automotive components are some of the foremost factors for its significant position in the market.

Based on application, the market is classified into tire, automotive, footwear, industrial goods, consumer goods, textile, and several others. Among these, tire controlled the significant share in the market. This can be accredited to tire large and increasing demand of tire from automobile industry. Tire is utilized as an original equipment with a new vehicle as well as its large requirement during old tire replacement. Further, growing demand of high-performance tire resulting in the increasing demand of synthetic rubber in tire industry.

Asia-Pacific controlled the prominent position in the global synthetic rubber market due to its large tire manufacturing industry and greatest automobile production base around the globe. For instance, tire producers like Bridgestone, Yokohama, Kumho, Hankook, Triangle, Apollo, and MRF are among the greatest producer of tire, around the globe. Further, the regional is the greatest producer footwear across the world, with country like China, Vietnam, Indonesia, and India has significant market share.

For More Information, refer to below link:-

Global Synthetic rubber Market Research Report

Related Reports

Adhesives & Sealants Market: Current Analysis and Forecast (2021-2027)

Polyisoprene Market: Current Analysis and Forecast (2021-2027)

Follow Us

LinkedIn | Instagram | Facebook | Twitter | YouTube

Contact Us:-

Ken Research

Ankur Gupta, Head Marketing & Communications

+91-9015378249

0 notes

Text

Rubber Lining Pipe Market Outlook Development Factors, Latest Opportunities and Forecast 2028

“A New Market Study, Titled “Rubber Lining Pipe Market Upcoming Trends, Growth Drivers and Challenges” has been featured on fusionmarketresearch.

The Rubber Lining Pipe market’s sales volume, price, revenue, gross margin, trends, historical growth, and future growth estimates are all included in the research report. It includes complete information on all regional markets, as well as a thorough examination of all segments, categories, and regional and country segments investigated in the study. The study report can be used by businesses, investors, stakeholders, suppliers, service providers, and distributors to examine the Rubber Lining Pipe market. Global industry and marketing trends are analyzed to acquire a better grasp of the present market condition.

Get Free Sample Report @ https://www.fusionmarketresearch.com/sample_request/Global-Rubber-Lining-Pipe-Market/56373

This research covers COVID-19 impacts on the upstream, midstream and downstream industries. Moreover, this research provides an in-depth market evaluation by highlighting information on various aspects covering market dynamics like drivers, barriers, opportunities, threats, and industry news & trends. In the end, this report also provides in-depth analysis and professional advices on how to face the post COIVD-19 period.

Key Players Covered in Rubber Lining Pipe market report are:S. R. Polychem Imperial Pipe Iracore International Jemond Rubbers Industries Leak Prevention Goodwest Townley Abtrex Raymond Internationa ACR Rubbertex Associated Rubber & Mechanicals Li Sheng Technology Sichuan Yonton Machinery Jiangsu Kaiyuan Environmental Technology

Market split by Type, can be divided into: Natural Rubber Butyl Rubber Nitrile Rubber EPDM Others

Market split by Application, can be divided into: Chemical Plants Steel & Mining Oil & Gas Power Generation Paints & Pigments

Market split by Sales Channel, can be divided into: Direct Channel Distribution Channel

Market segment by Region/Country including: North America (United States, Canada and Mexico) Europe (Germany, UK, France, Italy, Russia and Spain etc.) Asia-Pacific (China, Japan, Korea, India, Australia and Southeast Asia etc.) South America (Brazil, Argentina and Colombia etc.) Middle East & Africa (South Africa, UAE and Saudi Arabia etc.)

Enquiry before buying Report @ https://www.fusionmarketresearch.com/enquiry.php/Global-Rubber-Lining-Pipe-Market/56373

Russia-Ukraine War Impact Analysis In the Rubber Lining Pipe market analysis, the impact of the Russia-Ukraine war on global and domestic markets is also explored. For firms and individuals interested in the industry, the report is a significant source of direction and information. It includes vital information as well as an assessment of the major manufacturers’ current state.

Competitive Scenario The complete analysis looks at the Rubber Lining Pipe market on a micro level. By understanding manufacturers’ global revenue, global price, and global output throughout the predicted period, the reader can determine their footprints. The main participants in the market are described in this section of the study. It helps the reader understand how companies compete in the market and how they collaborate.

Key Questions Answered in this Report

What was the global Rubber Lining Pipe market size in 2022? 2. What are the key factors driving the global Rubber Lining Pipe market? 3. What has been the impact of COVID-19 on the global Rubber Lining Pipe market? 4. What is the breakup of the global Rubber Lining Pipe market based on the type? 5. What is the breakup of the global Rubber Lining Pipe market based on the technology? 6. What is the breakup of the global Rubber Lining Pipe market based on the system? 7. What is the breakup of the global Rubber Lining Pipe market based on the end-use industry? 8. What are the key regions in the global Rubber Lining Pipe market? 9. Who are the key players/companies in the global Rubber Lining Pipe market?

Table of Content – Analysis of Key Points

Chapter 1. Executive Summary

Chapter 2. Global Market Definition and Scope

Chapter 3. Global Market Dynamics

Chapter 4. Global Market Industry Analysis

Chapter 5. Global Market, by Type

Chapter 6. Global Market, by Application

Chapter 7. Global Market, Regional Analysis

Chapter 8. Competitive Intelligence

Chapter 9. Research Process

Continued…

ABOUT US: Fusion Market Research is one of the largest collections of market research reports from numerous publishers. We have a team of industry specialists providing unbiased insights on reports to best meet the requirements of our clients. We offer a comprehensive collection of competitive market research reports from a number of global leaders across industry segments.

CONTACT US [email protected] Phone: + (210) 775-2636 (USA) + (91) 853 060 748

0 notes

Text

EPDM Rubber Compound Market Size, Trends, Forecast & Competitive Landscape (2025–2032)

Definition

EPDM (Ethylene Propylene Diene Monomer) rubber compound is a versatile synthetic rubber used extensively across industries due to its superior resistance to heat, weathering, ozone, and aging. It is widely applied in automotive weather-stripping and seals, roofing membranes, wires and cables, mechanical goods, and industrial rubber applications. With its excellent durability, flexibility, and resistance to environmental factors, EPDM is considered essential in performance-driven manufacturing sectors.

Market Size & Forecast

As of 2024, the global EPDM rubber compound market is valued at approximately USD 4,310 million, and it is projected to grow to USD 5,870 million by 2032, reflecting a CAGR of 3.90% over the forecast period (2025–2032).

This market growth is fueled by rising demand in the automotive, construction, and electrical sectors, where EPDM rubber is critical for weather-resistant, durable, and lightweight components.

📥 Download Sample Report PDF https://www.24chemicalresearch.com/download-sample/290165/global-epdm-rubber-compound-forecast-market-2025-2032-275

Market Trends & Growth Drivers

Automotive Industry Boom EPDM is extensively used in automotive weather seals, hoses, belts, and gaskets due to its resistance to ozone and heat. With the surge in global automotive production and rising electric vehicle (EV) adoption, the demand for EPDM is accelerating.

Expansion in the Construction Sector EPDM membranes are widely used in roofing and waterproofing applications. Increased investment in commercial and residential infrastructure across emerging economies is propelling demand.

Advances in Compound Formulations Innovations in EPDM compounding have enhanced the performance of EPDM in extreme conditions, broadening its usage in new applications such as solar panel encapsulation and high-voltage insulation.

Market Dynamics

Drivers

Growing automotive production in Asia-Pacific and Europe

Rising construction activities and infrastructure modernization

Increasing demand for sustainable and long-life materials

Favorable regulatory frameworks supporting non-toxic rubber alternatives

Restraints

Volatility in raw material prices, especially ethylene and propylene

Environmental concerns related to synthetic rubber waste disposal

Availability of alternative materials such as silicone and thermoplastic elastomers (TPEs)

Opportunities

Rising electric vehicle (EV) penetration creating new EPDM demand

Adoption in renewable energy infrastructure like solar panel gaskets

Technological advancements in bio-based EPDM compounds

Challenges

Competition from alternative high-performance elastomers

Pressure to innovate with sustainable manufacturing techniques

Regional Insights

North America: Stable market driven by mature automotive and construction sectors. Demand sustained by stringent energy-efficiency standards and quality regulations.

Europe: High adoption of EPDM in electric vehicles, roofing systems, and cable insulation due to environmental norms and green construction initiatives.

Asia-Pacific: The fastest-growing market with significant production and consumption in China, India, and Japan. Rapid urbanization and industrialization boost EPDM usage.

Latin America & Middle East & Africa: Emerging demand led by infrastructure development and growing vehicle ownership.

Competitive Landscape

Key players in the global EPDM rubber compound market include:

Lanxess AG

The Dow Chemical Company

ExxonMobil Chemical

JSR Corporation

Lion Elastomers

These companies focus on enhancing EPDM performance, reducing environmental impact, and expanding into untapped markets through strategic partnerships and R&D investments.

Market Segmentation

By Type

Injection Molding Compound

Extrusion Compound

Others

By Application

Automotive

Building & Construction

Wire & Cable

Mechanical Goods

Others

📄 Get the Complete Report & TOC https://www.24chemicalresearch.com/reports/290165/global-epdm-rubber-compound-forecast-market-2025-2032-275

Frequently Asked Questions (FAQ)

What is the market size of the EPDM Rubber Compound Market in 2024? The market is valued at USD 4,310 million in 2024 and is projected to reach USD 5,870 million by 2032.

Which industries drive the demand for EPDM rubber compounds? Key industries include automotive, construction, electrical & electronics, and mechanical goods manufacturing.

What are the major challenges in the EPDM market? Raw material volatility, environmental impact, and competition from alternative elastomers pose major challenges.

Which region is expected to lead the EPDM rubber market growth? Asia-Pacific is anticipated to exhibit the highest growth due to rapid industrial expansion and infrastructure development.

What are the emerging trends in the EPDM market? Trends include sustainable EPDM production, increased EV applications, and integration into green building technologies.

Contact Us 203A, City Vista, Fountain Road, Kharadi, Pune, India - 411014 📞 International: +1(332) 2424 294 📞 Asia: +91 9169162030 🔗 LinkedIn: https://www.linkedin.com/company/24chemicalresearch/

About 24Chemical Research Founded in 2015, 24Chemical Research is a trusted source of in-depth chemical industry analysis. Serving Fortune 500 clients, the company delivers data-driven insights and strategic intelligence across global markets.

0 notes

Text

Nanosilica Market Trends, 2020-2030

Nanosilica Market: Introduction

The global nanosilica market is expected to reach a value of ~US$ 55 Bn by 2030, expanding at a CAGR of ~7% during the forecast period. Increase in the demand for nanosilica for use in various applications is a key factor driving the global nanosilica market. Additionally, growth in the adoption of nanotechnology across the globe is expected to fuel the global market during the forecast period.

Key Drivers of Nanosilica Market

The global nanosilica market is primarily driven by increasing use of nanosilica in paints and coatings and construction applications. The demand for nanocoatings in aviation, automobile, and medical applications is estimated to increase in the near future. This, in turn, is projected to fuel the demand for nanosilica during the forecast period. The application of nanomaterials in concrete helps enhance the properties of concrete. Nanosilica, owing to its small particle size, can positively affect properties of concrete by changing its microstructure.

Request PDF Brochure –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=37574

Nanosilica: Market Segmentation

P-Type emerged as the leading product segment of the global nanosilica market in 2019. Increasing demand from the concrete industry led by growth of the construction sector, including residential and commercial buildings, is projected to propel the segment during the forecast period. The growing construction sector, particularly in Asia Pacific and North America, is projected to be a key factor driving the demand for P-type nanosilica during the forecast period.

Request for Covid-19 Impact Analysis :

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=37574

Due to its property of dispersion, S-type nanosilica can be used as a filler material in several applications including electronics, coatings, and varnishes. This makes S-type nanosilica useful for external additive materials, sintering materials, and fillers for liquid-type sealants. Rubber & plastic additives emerged as the leading application segment, in terms of both volume and revenue, in 2019. Nanosilica is used as an additive in various types of rubbers such as natural rubber, ethylene propylene diene monomer (EPDM), styrene–butadiene rubber (SBR), ethylene acrylic rubber, nitrile butadiene rubber (NBR), and silicone rubber. It is extensively utilized as a reinforcing agent to enhance the mechanical strength of vulcanized rubber.

More Trending Reports by Transparency Market Research –

https://www.prnewswire.com/news-releases/glycerol-market-to-advance-at-cagr-of-6-3-during-20212031--asserts-tmr-study-301500966.html

The paints & coatings segment followed the rubber and plastic additives segment in 2019. Nanosilica is widely utilized in super-hydrophobic coatings. Lower prices of nanosilica than its substitutes, such as carbon nanotubes, have boosted the demand for nanosilica in the paints & coatings industry.

Asia Pacific Holds a Prominent Share of Nanosilica Market

In terms of volume, Asia Pacific accounted for a leading share of the global nanosilica market in 2019, due to rise in investments by governments of China, India, and Thailand in the construction sector. Europe held a considerable share of the global nanosilica market in 2019.

Buy Our Premium Research Report@

https://www.transparencymarketresearch.com/checkout.php?rep_id=37574<ype=S

Europe also has a strong industry for rigid packaging. Several countries in the region are witnessing high per capita consumption of packaged products. In North America, increasing adoption of the next-generation technology, such as nanotechnology, may lead to increased production and use of nanosilica in various end-use industries. Growth of rubber & plastic additives, automotive, and construction industries in the region is boosting the demand for nanosilica in North America.

Key Players in Global Market

The global nanosilica market is moderately consolidated, with the presence of a few large-sized manufacturers. Companies operating in the global nanosilica market are investing significantly in research and development activities and advancements in technology. Major players operating in the global nanosilica market include Evonik Industries AG, Wacker Chemie AG, Normet, Nanosil (Asia Pacific) Sdn. Bhd, and US Research Nanomaterials, Inc.

About Us:

Transparency Market Research is a global market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather, and analyse information. Now avail flexible Research Subscriptions, and access Research multi-format through downloadable databooks, infographics, charts, interactive playbook for data visualization and full reports through MarketNgage, the unified market intelligence engine. Sign Up for a 7 day free trial!

Contact

Rohit Bhisey Transparency Market Research, 90 State Street, Suite 700, Albany, NY 12207 Tel: +1-518-618-1030 USA – Canada Toll Free: 866-552-3453 Email: [email protected] Website: https://www.transparencymarketresearch.com

0 notes

Text

Global C5 Petrochemicals Market Study Report 2014-2030

Analysis of the C5 PETROCHEMICALS MARKET