#Ethernet transformer module

Explore tagged Tumblr posts

Text

iNRCORE 100B-2002 10/100 Base-TX dual-port Ethernet transformer module

0 notes

Text

Maximizing Efficiency with Autoclass in IEEE 802.3bt PoE: Why It Matters

Power over Ethernet (PoE) has transformed the way modern networks are designed — offering the dual benefits of data and power transmission over a single cable. This dramatically reduces installation costs and simplifies network planning by removing the need for separate electrical outlets near devices. But as networked devices continue to demand more power, optimizing how that power is allocated becomes critical. This is where Autoclass (AUC), a feature of the IEEE 802.3bt PoE standard, plays a game-changing role.

Why IEEE 802.3bt Is a Big Leap Forward

Introduced in September 2018, the IEEE 802.3bt standard was developed to meet the increasing power needs of modern devices such as CCTV cameras, Wi-Fi access points, thin clients, 5G equipment, and more. It builds on earlier standards — IEEE 802.3af (Type 1) and IEEE 802.3at (Type 2) — by delivering much higher power using all four wire pairs in an Ethernet cable. This enables power levels up to 90W at the Power Sourcing Equipment (PSE) and 71.3W at the Powered Device (PD).

The Role of Autoclass in Optimizing Power Use

In older PoE standards, the PSE allocated power based on preset classifications, often overestimating the actual need of the PD. This approach was inefficient, particularly when using shorter cables or higher-quality Ethernet like Cat6, where actual power loss is minimal.

Autoclass, a key feature in IEEE 802.3bt, solves this by allowing PDs to report their true maximum power requirement. During the classification phase, a PD signals its intent to use Autoclass by briefly adjusting the classification current. Once the device powers up, it draws its maximum required power, enabling the PSE to allocate just enough — no more, no less.

The result? More available power across the switch, reduced energy waste, and a more scalable, cost-effective PoE deployment.

Real-World Examples: Power Savings with Autoclass

Let’s consider two scenarios that highlight Autoclass optimization:

1. Using High-Quality Copper Cable

A PD requires 65W. Without Autoclass, the PSE defaults to allocating 90W (Class 8). With Autoclass, the PSE correctly adjusts to supply just 68.82W, saving over 21W per port. In an 8-port setup, that’s a saving of more than 160W.

2. Using Lower-Cost Copper-Aluminum Cable

With a 70W PD, Autoclass reduces unnecessary allocation from 90W to 73.78W, saving nearly 17W per port. Across 8 ports, that’s a total of 134W in power savings.

PoweredEthernet™ Products with Autoclass Support

Infomart’s PoweredEthernet™ IEEE 802.3bt modules — including the PEM9300BT (Class 8), PEM6300BT (Class 6), and PEB9300BT all-in-one PD boards — feature optional Autoclass support. This empowers system designers to maximize efficiency and lower costs while ensuring robust and reliable performance.

Additionally, these products offer Maintain Power Signature (MPS), another IEEE 802.3bt feature that allows ultra-low standby power consumption without disconnection risk — plus built-in wall adapter redundancy, all with minimal external components.

Conclusion: Autoclass is the Smart Choice for Smart Networks

Autoclass is more than a technical upgrade — it’s a critical enabler for modern, power-efficient networks. Whether you’re deploying a high-density PoE switch or designing next-gen connected devices, leveraging IEEE 802.3bt with Autoclass ensures optimal performance, significant cost savings, and a future-ready infrastructure.

0 notes

Text

Mobile Machine Control Systems: Revolutionizing Off-Highway Machinery

In the rapidly evolving field of automation and smart machinery, Mobile Machine Control Systems (MMCS) are playing a transformative role in improving efficiency, safety, and productivity. These systems, primarily used in construction, agriculture, mining, and other heavy-duty applications, integrate advanced electronics, sensors, actuators, and software to offer precise control and monitoring of mobile machines. As industries strive for increased automation and remote operability, MMCS stands at the forefront of modern machinery technology.

What is a Mobile Machine Control System?

A Mobile Machine Control System is an integrated system that enables real-time control, automation, and monitoring of mobile equipment such as excavators, harvesters, dozers, and forklifts. These systems combine hardware components like controllers, sensors, GPS/GNSS units, and communication modules with sophisticated software for data processing and visualization. The result is a machine that can operate with enhanced accuracy, lower operator input, and greater safety and productivity.

Key Components of MMCS

Electronic Control Units (ECUs): These are embedded systems that act as the brain of the mobile machinery. ECUs receive input from sensors, process the data, and send output signals to control actuators.

Sensors: A wide range of sensors including pressure, temperature, position, and accelerometers are used to monitor the operational status of machines. Sensor data is critical for real-time decision-making.

Actuators: These execute commands from the ECU to carry out physical tasks like lifting, steering, braking, and more.

User Interface (HMI): Operators use Human-Machine Interfaces to interact with the system. Touchscreens, control panels, and even remote controls can serve as the user interface.

Communication Modules: These modules enable the machine to communicate with other systems or control centers using CAN bus, Ethernet, wireless, or cellular networks.

Software Platform: The control software is where the magic happens. It integrates logic, machine learning algorithms, and diagnostic tools to automate and optimize machine operation.

Benefits of Mobile Machine Control Systems

1. Improved Accuracy

MMCS enables highly accurate operation, especially in tasks like digging, lifting, and planting. GPS-guided systems can position machinery within centimeters of the intended location, reducing rework and material waste.

2. Enhanced Productivity

By automating repetitive tasks and optimizing machine performance, MMCS allows operators to complete jobs faster and with less fatigue. Machines can work longer hours with consistent output, increasing overall productivity.

3. Greater Safety

Advanced safety features such as obstacle detection, auto shut-off, and real-time operator alerts help minimize accidents and machine wear. Remote operation capabilities further enhance safety in hazardous environments.

4. Lower Operating Costs

Efficient fuel usage, reduced manual labor, and lower maintenance needs contribute to significant cost savings over time. Diagnostic tools also help predict and prevent costly breakdowns.

5. Data-Driven Decisions

With onboard analytics and cloud integration, MMCS provides actionable insights into machine usage, operator behavior, and job site conditions. This data aids in maintenance planning and operational improvements.

Applications of Mobile Machine Control Systems

Construction

In the construction industry, MMCS is revolutionizing how earthmoving and grading are done. With 3D machine control, graders and dozers achieve perfect surface levels with minimal manual input. This technology reduces the dependency on surveyors and manual stakes.

Agriculture

Precision farming relies heavily on MMCS. Tractors, seeders, and sprayers equipped with control systems can plant seeds with uniform spacing, apply fertilizers accurately, and harvest crops efficiently—all with minimal human intervention.

Mining

Autonomous haul trucks and drilling equipment in mines are examples of MMCS in action. These systems ensure safety in harsh and dangerous environments while maximizing output.

Material Handling

Forklifts and automated guided vehicles (AGVs) in warehouses utilize MMCS to enhance navigation, load handling, and inventory management, boosting efficiency and reducing labor costs.

Challenges in Implementing MMCS

Despite the benefits, adopting MMCS is not without its challenges:

High Initial Investment: The cost of implementing advanced control systems can be significant, particularly for small and mid-sized enterprises.

Complexity: Integrating multiple hardware and software components requires skilled personnel and careful planning.

Interoperability: Ensuring compatibility among various sensors, actuators, and communication protocols can be challenging.

Cybersecurity: As machines become more connected, the risk of cyber threats also increases, necessitating robust security measures.

The Future of Mobile Machine Control Systems

The future of MMCS is intertwined with emerging technologies such as artificial intelligence (AI), machine learning, and the Internet of Things (IoT). Future systems will be even smarter, capable of learning from past operations to improve efficiency automatically.

Remote diagnostics and over-the-air updates will become commonplace, ensuring machines are always running the latest software. Additionally, cloud-based platforms will allow operators and managers to monitor and control equipment from anywhere in the world.

The push toward sustainability will also drive the integration of electric drives and hybrid systems with MMCS, reducing the environmental footprint of mobile machinery.

Conclusion

Mobile Machine Control Systems by Servotechinc are fundamentally changing how industries like construction, agriculture, and mining operate. By combining advanced hardware with intelligent software, MMCS delivers greater precision, safety, and efficiency. While challenges such as cost and complexity exist, the long-term benefits far outweigh them.

As technology continues to evolve, these systems will become more accessible and capable, leading to smarter machines and more productive job sites. For companies seeking to stay competitive in a digital world, investing in Mobile Machine Control Systems is not just an option—it’s a necessity.

0 notes

Text

Automotive Ethernet Market Insights: Disruptions, Challenges, and Recovery Paths

The automotive industry is undergoing a significant transformation, with Ethernet technology playing a pivotal role in enabling the next generation of connected, autonomous, and software-defined vehicles. Automotive Ethernet provides high-speed, reliable communication networks essential for Advanced Driver Assistance Systems (ADAS), infotainment systems, and vehicle-to-everything (V2X) connectivity.

Key Drivers:

Adoption of Autonomous Vehicles: The increasing deployment of ADAS and autonomous driving technologies necessitates high-speed data transfer capabilities, driving the demand for automotive Ethernet.

Growth of Connected Vehicles: The proliferation of connected vehicle services, including real-time diagnostics, over-the-air updates, and V2X communication, requires robust networking solutions.

Transition to Zonal Architectures: OEMs are shifting towards zonal vehicle architectures, consolidating ECUs and reducing wiring complexity, which Ethernet facilitates effectively.

Download a Free Sample Report: - https://tinyurl.com/5febk3er

Technology & Application Insights

Bandwidth Segments:

100 Mbps (100BASE-T1): Dominated the market in 2023, suitable for basic control functions and less demanding data transmission needs.

1 Gbps (1000BASE-T1): Projected to witness significant growth, supporting high-speed communication required by ADAS, high-definition cameras, and real-time data processing modules.

Component Segments:

Hardware: Comprises Ethernet switches, connectors, cables, and ICs, and was the largest revenue-generating component in 2023.

Software & Services: Include network management, security protocols, and testing solutions, supporting the integration and maintenance of Ethernet networks.

Application Segments:

ADAS: Led the market in 2023, with Ethernet enabling high-speed data transfer for sensors and cameras essential for safety features.

Infotainment: Expected to witness significant growth, driven by the demand for advanced in-car entertainment and connectivity features.

Commercial Vehicles: Increasing adoption for fleet management, telematics, and operational efficiency.

🌍 Regional Insights

Asia Pacific:

Market Size: Generated USD XXX million in 2023, accounting for XX% of the global market share.

Growth Rate: Projected to grow at a CAGR of XX% from 2024 to 2030.

Key Drivers: Increasing sales of passenger cars with intelligent connectivity and safety features.

Europe:

Market Size: Expected to reach USD XXX billion by 2030, becoming the fastest-growing regional market.

Key Drivers: Stringent safety standards and a strong emphasis on technology innovation in the automobile sector.

North America:

Market Size: Projected to reach USD XXX billion by 2028, growing at a CAGR of XX% during the forecast period.

Key Drivers: Rising demand in premium cars with connected car features and a strong push from OEMs for transition towards zonal architecture in automotive networking.

Challenges

High Installation Costs: The initial cost of automotive Ethernet solutions, encompassing hardware, software development, testing, security implementation, and retrofits for older vehicles, poses a significant challenge to widespread adoption.

Network Complexity: Managing increasingly complex automotive networks with numerous ECUs and data flow requires expertise in high-speed networking protocols, network security, and mitigating electromagnetic interference.

Integration with Legacy Systems: Integrating Ethernet into existing vehicle architectures can require significant modifications and upgrades, posing a financial hurdle for manufacturers.

Future Outlook

The automotive Ethernet market is poised for significant growth, driven by advancements in vehicle technology and the increasing demand for connected and autonomous vehicles. Key trends shaping the future include:

Adoption of Zonal Architectures: OEMs are consolidating ECUs and reducing wiring complexity, with Ethernet facilitating effective communication within these architectures.

Integration with 5G and V2X: The convergence of automotive Ethernet with 5G networks and V2X communication will enable real-time data exchange, enhancing vehicle-to-vehicle and vehicle-to-infrastructure interactions.

Focus on Cybersecurity: As vehicles become more connected, ensuring robust cybersecurity measures in Ethernet networks will be paramount to protect against potential threats.

Industry News

BMW and Analog Devices Collaboration: In May 2024, BMW Group announced the adoption of Analog Devices' E²B™ technology, utilizing 10BASE-T1S Ethernet to facilitate edge bus connectivity in automotive applications.

SMK Corporation's Ethernet Connector: In April 2023, SMK Corporation developed the SE-R1, the industry's smallest Ethernet connector for automotive applications, supporting both 100BASE-T1 and 1000BASE-T1 standards.

Read Full Report: - https://www.uniprismmarketresearch.com/verticals/automotive-transportation/automotive-ethernet

0 notes

Text

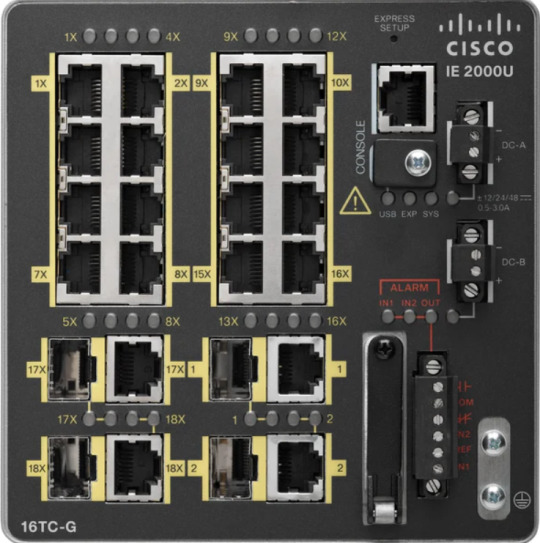

How Advanced Components Like the 1769-L24ER-QBFC1B and Industrial Ethernet Switches Are Shaping Smarter Automation

Industrial automation continues to evolve, with modern facilities prioritizing real-time communication, precise control, and seamless device integration. From intelligent controllers to advanced networking gear, the foundation of smart manufacturing relies heavily on dependable hardware. Among the standout tools enabling this transformation are the 1769-L24ER-QBFC1B, the compact yet powerful Allen Bradley controller series, versatile Industrial Ethernet Switches, and legacy-supporting adapters like the 1784-U2DHP.

Why Controllers Like the 1769-L24ER-QBFC1B Matter

Tight control over machine processes starts with the right logic controller. The 1769-L24ER-QBFC1B, part of Allen Bradley's CompactLogix line, is built for integrated motion and control applications. Offering embedded digital, analog, and high-speed counter I/O, this controller is particularly effective in systems where space is limited, but versatility cannot be compromised.

Its dual Ethernet ports support device-level ring topologies, adding fault tolerance and reducing downtime—a critical factor in high-output environments.

The Role of a Modern Allen Bradley Controller in Scalable Systems

Modern automation isn’t just about basic on/off control; it's about data-driven decisions, predictive maintenance, and remote diagnostics. The Allen Bradley controller family—such as the 5069-L320ERMS3—brings high-speed processing, built-in safety, and seamless integration with Studio 5000 software, supporting everything from packaging lines to advanced robotics. These controllers enable synchronized motion, streamlined programming, and scalable deployment.

Reliable Communication Starts with Industrial Ethernet Switches

Data flow across industrial networks must be both fast and secure. That’s where an Industrial Ethernet Switch like the Cisco IE-2000-16TC-G-E comes into play. Engineered for harsh environments, this switch features robust build quality and supports advanced switching protocols like QoS and VLANs—ensuring smooth traffic management even in network-heavy setups.

In automation systems where devices like HMIs, PLCs, and I/O modules constantly communicate, an industrial-grade switch ensures that data isn’t just fast—it’s also reliable and isolated from disruptions.

Bridging the Gap with 1784-U2DHP

While modern systems lean on Ethernet-based protocols, many plants still operate legacy systems that use older communication methods like Data Highway Plus (DH+). The 1784-U2DHP adapter serves as a bridge, allowing USB-equipped laptops to interface with DH+ networks. It provides essential diagnostic and programming access to older equipment, extending the lifecycle of valuable assets and supporting a phased modernization strategy.

Final Thoughts

Industrial control systems today demand more than just speed—they need resilience, flexibility, and smart connectivity. From an intuitive Allen Bradley controller like the 1769-L24ER-QBFC1B to rugged Industrial Ethernet Switches and legacy support tools like the 1784-U2DHP, these technologies together form the backbone of intelligent automation systems.

0 notes

Text

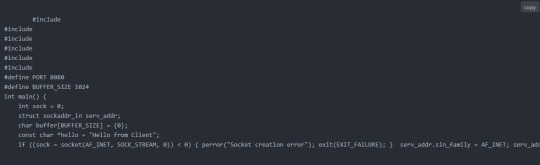

E5908 module RJ45 interface communication

How to achieve communication with the E5908 module RJ45, a brief introduction to help you take the next step

Introduction to the module and interface E5908 is an Ethernet communication module with a built-in TCP/IP protocol stack. It supports direct communication with an Ethernet switch or router through the RJ45 interface. The main control MCU can interact with the module through UART (AT command) or SPI/SDIO (depending on the module description).

Hardware connection (RJ45 interface) RJ45 interface (with magnetic transformer): The module's onboard RJ45 interface has an integrated magnetic transformer and can be plugged into a standard network cable without an external transformer. Power and ground: VCC (3.3V/5V) -> module VCC, GND -> module GND. UART connection: MCU_TX -> module UART_RX, MCU_RX -> module UART_TX Reset pin: connected to the MCU GPIO for module hardware reset. Decoupling capacitors: Add 10µF and 0.1µF decoupling capacitors to the module power pins to ensure stable power supply.

Network configuration:

DHCP: AT+NETMODE=DHCP returns +IP:...; Static IP: AT+NETMODE=STATIC,<IP>,<Mask>,<Gateway>. Establish socket: TCP client: AT+TCPSTART="<IP>",<Port>; TCP server: AT+TCPLISTEN=<Port>; UDP: AT+UDPSTART="<IP>",<Port>.

Data sending and receiving: Sending: AT+TCPSEND=<Len> → module prompts > → sending data; Receiving: module serial port pushes +TCP:RECV,..., followed by data.

Typical C code example:

#define UARThuart1 bool at_send(const char *cmd, const char *exp, uint32_t to) {...} void net_init(void) { //reset HAL_GPIO_WritePin(RESET_GPIO_Port, RESET_Pin, GPIO_PIN_RESET); HAL_Delay(50); HAL_GPIO_WritePin(RESET_GPIO_Port, RESET_Pin, GPIO_PIN_SET); HAL_Delay(200); at_send("AT+NETMODE=DHCP", "OK", 2000); } void tcp_client(void) { at_send("AT+TCPSTART=\"192.168.1.50\",8000", "CONNECT", 5000); at_send("AT+TCPSEND=5", ">", 2000); HAL_UART_Transmit(&UART, (uint8_t*)"hello", 5, 100); at_send("", "SENDOK", 2000); at_send("AT+TCPSTOP", "CLOSED", 3000); }

If you want to know more detailed solutions, please read this article: E5908 module Ethernet communication implementation solution

1 note

·

View note

Text

ARMxy RK3568B2 Industrial IoT Gateway OPC UA for Unified Data Interoperability

The ARMxy BL410 series is a versatile industrial ARM controller designed for flexible I/O configuration. It is based on the Rockchip RK3568J/RK3568B2 processor, featuring aquad-core ARM Cortex-A55 architecture with clock speed up to 1.8GHz/2.0GHz. The device is equipped with 8/16/32GB eMMC storage and various combinations of 1/2/4GB LPDDR4X RAM. Additionally, it includes a built-in 1TOPS computing power Neural Processing Unit (NPU) for supporting deep learning tasks.

The BL410 series ARM embedded computer offers a rich array of interfaces including

3 x 10/100M Ethernet ports, 2 x USB 2.0 ports, 1 x optional HDMI 2.0a port, 1 x optional X series IO board, 2 x optional Y series IO boards. These interfaces support various functions such as communication, PWM output, pulse counting, and data acquisition and control. The BL410 also supports hardware decoding of 1080P@60fps videos.

Additionally, it features a built-in Mini PCIe interface to support communication modules such as Bluetooth, WiFi, and 4G modules.

The BL410 series ARM embedded computers support Linux-4.19.232, Linux-RT-4.19.232 kernels, Debian-10.13, Android 13, Docker containers, Node-RED, and Qt-5.15.2 for graphical interface development tools. In addition, BL410 is compatible with BLIoTLink industrial protocol conversion software for data collection and transformation, and can seamlessintegration with various mainstream IoT cloud platforms and industrial SCADA software. Users can leverage the BLRAT for remote access and maintenance of the BL410 embedded computer. Additionally, with support for Node-Red, users can rapidly develop IoT applications on the BL410.

The BL410 series ARM embedded computer has undergone rigorous electrical performance design and high-low temperature testing to ensure stability and reliability. It is designed for DIN35 rail mounting, making it suitable for various industrial application environments.

This embedded computer is widely used in industrial IoT, photovoltaic power generation and energy storage systems, automation control, and transportation and rail applications.

0 notes

Text

Network Monitoring Technology Market Overview: Scope, Challenges, and Growth 2032

The Network Monitoring Technology Market Size was esteemed at USD 2.35 billion in 2023 and is supposed to arrive at USD 4.29 billion by 2032 and develop at a CAGR of 6.93% over the forecast period 2024-2032.

Network Monitoring Technology is evolving rapidly, driven by the increasing complexity of IT infrastructure and the growing need for real-time data analysis. Businesses are adopting advanced monitoring solutions to enhance security, optimize performance, and prevent downtime. The demand for cloud-based and AI-driven network monitoring tools is fueling market expansion.

Network Monitoring Technology Market continues to gain traction as enterprises shift towards digital transformation and cloud computing. With rising cyber threats, organizations are prioritizing proactive monitoring solutions to detect vulnerabilities and ensure seamless operations. Companies are integrating AI, automation, and predictive analytics into their monitoring systems to stay ahead of potential network issues.

Get Sample Copy of This Report: https://www.snsinsider.com/sample-request/3788

Market Keyplayers:

Viavi Solutions Inc. (Observer Platform, GigaStor)

Juniper Networks, Inc. (Junos Telemetry, Mist AI)

Datadog (Network Performance Monitoring (NPM) Module)

Broadcom Inc. (DX NetOps, AppNeta)

Kentik (Kentik NPM Analytics)

Gigamon (GigaVUE Visibility Platform)

Apcon (INTELLAPATCH Series, TitanXR)

Cisco Systems, Inc. (Cisco ThousandEyes, Meraki Insight)

Garland Technology (Packet Broker, TAP Solutions)

NETSCOUT Systems, Inc. (nGeniusONE, Arbor Sightline)

SolarWinds Corporation (Network Performance Monitor)

Riverbed Technology (SteelCentral NPM Solutions)

LogicMonitor, Inc. (LM Envision)

Paessler AG (PRTG Network Monitor)

Nagios Enterprises, LLC (Nagios XI, Nagios Core)

ManageEngine (Zoho Corporation) (OpManager)

Dynatrace (Network Path Monitoring)

Ixia (Keysight Technologies) (IxChariot, CloudLens)

Micro Focus International Plc (Network Node Manager i)

SevOne (Network Data Platform, SevOne NPM)

Market Trends Driving Growth

1. Adoption of AI-Powered Monitoring

Artificial Intelligence and Machine Learning are transforming network monitoring by enabling automated anomaly detection, predictive analytics, and intelligent troubleshooting.

2. Rising Demand for Cloud-Based Solutions

With organizations migrating to cloud environments, cloud-native network monitoring tools are becoming essential for managing hybrid and multi-cloud infrastructures.

3. Increased Focus on Cybersecurity

As cyber threats grow, businesses are investing in real-time network visibility and security monitoring solutions to detect and mitigate threats before they cause damage.

4. Growth in IoT and Edge Computing

The expansion of IoT devices and edge computing has increased the need for real-time network monitoring to ensure seamless connectivity and prevent potential failures.

Enquiry of This Report: https://www.snsinsider.com/enquiry/3788

Market Segmentation:

By Offering

Equipment

Network TAPs

Data Monitoring Switches

Software & Services

By Bandwidth

1 To 10 Gbps

40 Gbps

100 Gbps

By Technology

Ethernet

Fiber Optic

InfiniBand

By End User

Enterprises

Telecommunications Industry

Government Organizations

Cloud Service Providers

Market Analysis and Current Landscape

Key drivers contributing to this growth include:

Growing IT Infrastructure Complexity: Enterprises are managing large-scale networks that require continuous monitoring for performance optimization.

Regulatory Compliance Requirements: Organizations must adhere to strict data security regulations, driving demand for compliance-focused monitoring solutions.

Advancements in Network Analytics: AI-driven analytics are providing deeper insights into network traffic and performance, improving decision-making.

Rising Demand from SMEs: Small and medium-sized enterprises are increasingly adopting affordable, scalable monitoring tools to enhance network reliability.

Despite strong growth, challenges such as high implementation costs, integration issues, and data privacy concerns persist. However, innovations in AI, cloud, and automation are addressing these barriers, making network monitoring more efficient and accessible.

Future Prospects: Innovations and Industry Outlook

1. Expansion of AI-Driven Predictive Monitoring

AI and predictive analytics will further enhance real-time network monitoring, allowing businesses to prevent outages before they occur.

2. Integration with 5G and Edge Computing

As 5G networks expand, network monitoring solutions will be critical in managing latency, bandwidth, and connectivity in real-time applications.

3. Growth of Zero-Trust Security Frameworks

Enterprises will integrate network monitoring tools into Zero-Trust security architectures, ensuring continuous verification and protection against cyber threats.

4. Rise of Automated Incident Response

AI-powered automation will streamline network troubleshooting and incident response, reducing downtime and improving operational efficiency.

Access Complete Report:https://www.snsinsider.com/reports/network-monitoring-technology-market-3788

Conclusion

The Network Monitoring Technology Market is set for substantial growth, driven by AI advancements, cybersecurity needs, and the expansion of cloud and IoT networks. As businesses prioritize real-time insights and proactive monitoring, the demand for intelligent network monitoring solutions will continue to rise. Organizations that invest in cutting-edge monitoring tools will gain a competitive edge in ensuring network security, efficiency, and seamless connectivity.

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Jagney Dave - Vice President of Client Engagement

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Network Monitoring Technology Market#Network Monitoring Technology Market Scope#Network Monitoring Technology Market Growth#Network Monitoring Technology Market Trends

0 notes

Text

Recent Trends in MEP Engineering Services for Green Buildings

The demand for green buildings is rising at a rapid rate as the world moves toward sustainable and energy-efficient structures. MEP Engineering Services are the essence of achieving this sustainability through integrating cutting-edge technology in building designs. With their keen eye set on carbon footprint reduction and maximization of energy efficiency, MEP Consultants in Gurgaon are working towards outside-the-box approaches to create not only functional buildings but also environmentally-friendly ones.

Let us know the latest trends in MEP Services in Gurgaon which are transforming the landscape of green building construction.

1. Energy-Efficient Smart HVAC Systems

HVAC systems are amongst the highest single users of any building's energy. The current trend within MEP Engineering Services has been embracing the use of intelligent HVAC systems integrated with AI, IoT, and automation. The systems constantly respond by modulating temperature and air flow with varying occupancy levels, weather, and actual real-time energy use, resulting in meaningful energy reductions.

Besides, most MEP Consultants in Gurgaon are increasingly incorporating geothermal HVAC systems that realize indoor temperature control via heat exchange in the ground. This reduces reliance on conventional sources of energy and maximizes overall sustainability.

2. Water-Saving Plumbing Solutions

Water saving is a critical element of sustainable building design. MEP Services today include advanced plumbing solutions such as:

Greywater recycling systems that treat wastewater for recycling in landscaping and flushing.

Rainwater collection systems to reduce dependence on other water supplies.

Low-flow taps and sensor faucets to control wastage of water.

Such solutions make it possible for the buildings to utilize less water without compromising their functions in any aspect. MEP Consultants in Gurgaon also highlight leak detection systems, which contain sensors in order to recognize and repair leaks before they evolve into extensive issues.

3. Incorporation of Renewable Energy Solutions

One of the largest jumps in MEP Engineering Services has been the incorporation of solar panels, windmills, and other renewable power sources into building systems. Current buildings can generate their own power, reducing fossil fuel consumption.

Building-integrated photovoltaics (BIPV) are being widely accepted, in which solar panels are incorporated in the building itself, i.e., the roofs and the facade. Furthermore, MEP Consultants in Gurgaon are also devising hybrid power systems using solar power with grid electricity for providing power supply around the clock.

4. Smart Lighting and Electrical Systems

Lighting consumes a considerable amount of a building's energy, and latest MEP Services in Gurgaon are making lighting systems more efficient than ever before. Some of the latest trends are:

Semi-automatic LED lights with dimmable amounts of brightness depending on the level of occupancy and natural light available.

Daylight harvesting systems featuring sensors to regulate artificial lighting and thereby utilize maximum daylight.

Smart grid power that provides maximum distribution of energy without wastage.

Additionally, MEP Consultants are increasingly incorporating power-over-Ethernet (PoE) technology, where devices like lights, security cameras, and sensors are powered and receive data through a single cable, facilitating easy installation and energy saving.

5. High-Tech Building Management Systems (BMS)

Use of technology in MEP Engineering Services has advanced leaps and bounds with the entry of Building Management Systems (BMS). BMS systems integrate HVAC, lighting, security, and other mechanical systems on one control panel that can monitor in real time and make changes.

A few important features of innovative BMS are:

AI-powered analytics for preventive maintenance, keeping equipment downtime at the lowest levels.

IoT sensors that monitor indoor air quality, energy consumption, and temperature changes.

Remote access and automation, allowing facility managers to control systems remotely.

With MEP Consultants in Gurgaon services, businesses can integrate BMS to achieve optimal building performance and sustainability.

6. Use of Eco-Friendly and Sustainable Materials

Selection of materials is a second important feature of sustainable building design. MEP Services in Gurgaon are becoming more and more inclined to use materials with lower environmental impact, such as:

Sustainable and recycled insulation materials that enhance energy efficiency.

Lead-free plumbing systems for safe water quality.

Non-toxic refrigerants in HVAC systems to reduce environmental contamination.

These materials not only increase sustainability but also ensure healthier indoor environments.

7. Prefabrication and Modular MEP Systems

Another emerging trend in MEP Engineering Services is the use of prefabricated and modular MEP components. They are produced off-site and later installed on-site, which reduces construction time, waste, and labor costs.

Some of the benefits of prefabrication in MEP are:

Quick installation through pre-engineered modules.

Less wastage of material, which means less carbon emission.

Improved quality control, as the components are manufactured in a controlled environment.

MEP Consultants in Gurgaon are increasingly adopting this approach, which streamlines the construction process and makes it more sustainable.

Conclusion

Sustainable architecture is no longer a choice but the need of the time, and MEP Engineering Services are leading the charge to make it a reality. With their assistance, developers and entrepreneurs can implement these solutions in a bid to conserve energy, reduce expenses, and construct eco-friendly future-proof buildings.

Source URL: Blogspot.com

0 notes

Text

How the SIMATIC S7-200 Smart Can Transform Your Automation Projects

Siemens has long known how to create fit-for-purpose innovations in industrial automation for present-day industries. In their family of products, the SIMATIC S7-200 Smart stands out with advanced features for reliability and economy. This programmable logic controller is engineered for small to medium applications and can be implemented by industries in a transformative way.

This article gives a thorough account of what the SIMATIC S7-200 Smart is all about, including its features, functions, and advantages, with references made to the variations, S7200 Smart, and S7200 Smart PLC.

What is the SIMATIC S7-200 Smart?

The SIMATIC S7-200 Smart is a PLC, small and powerful, which will help to meet the increased demand of the automation industry. It represents the SIMATIC series by making everything flexible, scalable, and including high-end technology in a compact design.

This PLC ideally suits applications requiring fast processing, reliable communication and easy incorporation. Because of its suitability and robustness, S7200 Smart PLC has become popularly adopted in manufacturing, textile, and packaging industries.

Key Features of SIMATIC S7-200 Smart

The SIMATIC S7-200 Smart offers advanced features and is a flexible automation solution:

High-Processing Speed: The S7200 Smart PLC guarantees rapid data processing capacity, thus taking off the constraints on a time-to-market schedule for most applications.

Scalability: This PLC is designed in a way that it grows with the need. It has modular expansions and allows the addition of more I/O modules as the system evolves, beyond what is standard.

Integrated communication: The S7-200 Smart perfectly bridges the gap between connected devices and systems within a plant by offering Ethernet and MODBUS RTU connectivity.

Compact Design: The S7200 Smart is one of the smallest, most powerful products available for applications that do not have a great deal of space.

Convenience of Programming: Programming of the PLC is done with STEP 7 Micro/WIN SMART software from Siemens, which has a user-friendly interface as well as more advanced programming tools. Hence, fewer efforts and time are expended on development.

SIMATIC S7-200 Smart Applications

The S7200 Smart PLC is a solution that can be deployed across a palette of applications such as:

Manufacturing Automation: Help enhance assembly lines in manufacturing with sharp control and real-time monitoring.

Packaging Machines: Give up the pace and bring accuracy in speed processing of packaging machines.

Textile Industry: More control over and monitoring of production processes of extensive textile machinery yields better productivity and quality of the product.

Energy Management: Enhancing the performance in reading and monitoring energy consumption reduces operational expenses.

Building Automation: Improves the efficiency of HVAC systems, lighting, and other building automation processes.

Advantages of SIMATIC S7-200 Smart

SIMATIC S7-200 Smart PLC include the advantages of this choice for industrial automation:

Affordable Solutions: Cost-effective functionality at the higher end for this S7200 Smart PLC makes it an affordable option even for small businesses.

Reliable Operations: Built for rigorous environments, this PLC guarantees steady performance, saving on downtime and maintenance costs.

Easy-to-Use: The easy-to-use diagnostic tools and the intuitive programming interface make this S7200 Smart PLC a top favorite among engineers.

Energy Efficiency: More effective monitoring and control of processes reduces energy consumption, providing businesses with valuable input towards sustainability.

Remote Monitoring and Control: Enhanced convenience and operational efficiency are a result of having this PLC capable of monitoring and controlling systems remotely, thanks to Ethernet support.

Why choose SIMATIC S7-200 Smart?

The SIMATIC S7-200 Smart is a complete solution to all aspects of the PLC world with respect to the individual problems of industrial automation. The robust solutions, further enhanced with high-speed processing and reliable communication, make it an enabler for companies looking to optimize their operations.

S7200 Smart ensures that upgrading an existing system or implementing a new one is done seamlessly while performing at its best. Its ability to tackle complex scenarios yet remain simple operation-wise has made it one of the most favorite PLCs ever.

Wrapping it up

The SIMATIC S7-200 Smart is nothing but confirmation that Siemens has made a dedicated automation solution with strong belief in it delivering high-quality efficiency. This micro-programmable controller is very affordable and compact but also with advanced functionalities and as such, it ranks as one of the most-preferred controller systems for small to medium-size industries.

S7200 Smart PLC by Naksh Technology Solutions LLP is an innovative process optimization, reduced cost, and increased competitiveness tool in manufacturing, packaging, or energy management that simply eradicates costs and brings everything up to the present in its fast pace of change.

Invest in the SIMATIC S7-200 Smart, simply invest in smarter, more efficient automation solutions that create success. Let this PLC take a whole new direction in which industrial automation is approached!

0 notes

Text

The Role of LoRaWAN Gateways in IoT: Connecting Devices Seamlessly

A LoRaWAN Gateway is a device that facilitates long-range wireless communication between IoT devices and centralized servers. It receives data from LoRaWAN devices using LoRa modulation and forwards it to network servers via a backhaul connection, typically using Ethernet, Wi-Fi, or cellular networks. Lansitec Outdoor LoRaWAN Gateway is an ideal product for IoT commercial deployment. Its modularity and customization options allow for flexibility when deploying a solution.

For More:

#iot#lansitec#lora#lorawan#technology#IoT Devices#LoRaWAN Devices#LoRaWAN Gateway#Outdoor LoRaWAN Gateway#Lansitec#Lansitec Outdoor LoRaWAN Gateway#wireless#IoT Network#LoRaWAN Network

0 notes

Text

Take Smart Power to the Next Level with IEEE 802.3bt’s Autoclass Feature

Power over Ethernet (PoE) has revolutionized how we deploy networked devices — but with growing demands for power, efficiency is no longer optional. Enter Autoclass (AUC), a smart feature within the IEEE 802.3bt modules standard. Let’s dive into why Autoclass deserves a spot in your next PoE deployment.

Why PoE Is a Game-Changer

Lower installation costs: One Ethernet cable delivers both data and power, cutting down on labor and materials — no AC outlet required near every device.

Built for safety and ease: Safe under 60V DC, PoE avoids high-voltage complexities. It eliminates extra circuit protection and simplifies relocations.

Reliable power management: PoE systems include standardized protocols to negotiate and monitor power with built-in safety mechanisms.

What’s New with IEEE 802.3bt?

Formalized in September 2018, the IEEE 802.3bt standard aligns with the power needs of modern devices — CCTV cameras, Wi‑Fi 6/6E access points, thin/zero clients, 5G radios, and more.

Type 1 (802.3af): Up to 15.4W (PSE), 12.95W (PD) using two pairs.

Type 2 (802.3at): Up to 30W (PSE), 25.5W (PD) using two pairs.

Type 3/4 (802.3bt): Up to 90W (PSE), 71.3W (PD) using all four pairs.

This enables robust power delivery for high-demand scenarios — ideal for heavy-duty enterprise deployments.

⚙️ The Power Drawback in Traditional PoE

Earlier standards pre-assign power based on class — not actual need. So even if your device truly needs 65W, the system reserves the full 90W. That means wasted energy at the switch and fewer devices supported per port budget.

Autoclass to the Rescue

Autoclass transforms the game:

Smart handshake: During classification, a compliant PD signals Autoclass support to the PSE.

Power draw measurement: Once active, the PD draws its actual peak current.

Dynamic allocation: The PSE adjusts output to match real need — no more, no less.

Result: Up to 20W+ saved per port on a Class 8 setup — representing hundreds of watts saved across a switch.

Real-World Examples

Premium Cat5e cable: A 65W device pulls only ~68.8W instead of 90W — saving ~21W per port, or ~168W on an eight-port switch.

Copper-Aluminum cable: A 70W device uses ~73.8W, freeing ~16W per port — adding up to ~134W saved at scale.

PoweredEthernet™ PDs with Autoclass

Infomart’s PoweredEthernet™ IEEE 802.3bt PD modules — such as:

PEM9300BT (Class 8)

PEM6300BT (Class 6)

PEB9300BT (all-in-one PD board)

— support optional Autoclass. That empowers equipment designers to:

Accurately budget power based on real-world usage

Maximize port power capacity in high-density PoE networks

Minimize wastage and operating costs

Simplify device deployment with fewer external parts

These modules also include Maintain Power Signature (MPS) technology — supporting ultra-low standby power without losing PoE connection, plus built-in wall plug redundancy.

🎯 Why Autoclass Matters

Save energy — cut down on wasted watts, slash bills

Scale smarter — fit more devices under your switch’s power budget

Future-proof — ideal for next-gen devices and dense deployments

Boost ROI — lower infrastructure costs and maximize uptime

Ready to Power Smarter?

Autoclass in IEEE 802.3bt isn’t just a technical feat — it’s a strategic advantage. For any smart building, enterprise network, or IoT deployment, Autoclass is the difference between guesswork and precision. Want to explore specific use cases or product options? Let me know — I’d be happy to tailor the blog further!

0 notes

Text

A Guide to PLC Programming for Smart Manufacturing

Introduction

In today’s industrial landscape, automation is revolutionizing manufacturing processes, making them more efficient, reliable, and scalable. One of the key technologies driving this transformation is Programmable Logic Controller (PLC) programming. PLCs are essential components of smart manufacturing, enabling seamless automation, precise control, and real-time monitoring of industrial operations. This guide explores PLC programming, its importance, key components, and best practices for implementing it in smart manufacturing.

What is PLC Programming?

PLC programming is the process of creating, configuring, and optimizing software for Programmable Logic Controllers (PLCs). These are ruggedized digital computers designed to automate electromechanical processes in industries such as manufacturing, robotics, automotive, and energy. PLC programming allows these controllers to execute logical operations, manage data inputs and outputs, and communicate with other devices within a factory environment.

Importance of PLC Programming in Smart Manufacturing

With the advent of Industry 4.0, PLCs play a crucial role in enabling smart manufacturing. They provide:

Increased Efficiency: Automating processes reduces human intervention and enhances production speed.

Real-time Monitoring: PLCs allow continuous tracking of equipment performance and process status.

Improved Safety: Automation reduces the risk of human error and workplace accidents.

Seamless Integration: Modern PLCs connect with IoT, AI, and cloud-based systems for data-driven decision-making.

Cost Reduction: Minimizing downtime and optimizing resource utilization lead to significant savings.

Key Components of PLC Programming

PLC programming involves multiple components that work together to ensure efficient automation:

1. Hardware Components

Central Processing Unit (CPU): The brain of the PLC, responsible for executing program instructions.

Input Modules: Receive signals from sensors, switches, and other devices.

Output Modules: Control actuators, motors, and alarms.

Communication Modules: Enable connectivity with other devices via Ethernet, RS-232, or fieldbus protocols.

2. Software Components

Programming Languages: PLCs use specialized languages such as:

Ladder Logic (LD): Graphical representation resembling relay logic.

Structured Text (ST): Text-based high-level programming.

Function Block Diagram (FBD): Visual block-based programming.

Sequential Function Chart (SFC): Organizes complex processes into structured steps.

HMI (Human-Machine Interface): Interfaces that allow operators to interact with the PLC system.

Common PLC Programming Languages

1. Ladder Logic (LD)

Ladder Logic is the most widely used PLC programming language due to its resemblance to electrical relay logic. It consists of rungs representing logical conditions that trigger specific actions.

2. Structured Text (ST)

Structured Text is a high-level language similar to Pascal or C, ideal for mathematical and algorithmic functions. It is used for complex calculations and data processing.

3. Function Block Diagram (FBD)

FBD uses interconnected blocks to represent logic functions, making it user-friendly for designing control processes without extensive coding.

4. Sequential Function Chart (SFC)

SFC organizes processes into steps and transitions, making it suitable for sequential operations like batch processing and robotic control.

Steps to Develop a PLC Program

1. Define the Requirements

Identify the system’s objectives, inputs, and outputs. Understand the process that needs to be automated.

2. Select the Right PLC Hardware

Choose a PLC based on processing power, memory, communication capabilities, and environmental conditions.

3. Develop the Logic Design

Create a flowchart or ladder diagram that defines the system’s operation.

4. Write the PLC Program

Using a suitable programming language, write and configure the control logic.

5. Test the Program in a Simulation Environment

Use PLC simulation software to test and debug the logic before deployment.

6. Deploy and Monitor the System

Upload the program to the PLC, conduct real-world testing, and continuously monitor system performance.

Best Practices for Efficient PLC Programming

Keep Code Organized: Use comments and labels for easy readability.

Modular Programming: Break down large programs into reusable modules.

Optimize Scan Time: Write efficient logic to minimize execution delays.

Implement Error Handling: Use fail-safe mechanisms and diagnostics.

Regularly Update Firmware: Ensure compatibility with the latest technologies.

Future of PLC Programming in Smart Manufacturing

With advancements in Industrial IoT (IIoT), Artificial Intelligence (AI), and cloud computing, PLC programming is evolving. Future trends include:

Edge Computing: Enhancing real-time data processing at the PLC level.

AI Integration: Implementing machine learning algorithms for predictive maintenance.

Wireless Connectivity: Using 5G for seamless device communication.

Cybersecurity Enhancements: Protecting industrial networks from cyber threats.

Conclusion

PLC programming is a fundamental aspect of smart manufacturing, enabling automation, efficiency, and connectivity. By leveraging advanced programming techniques and integrating with modern technologies, industries can optimize their manufacturing processes, reduce costs, and stay competitive in the evolving digital landscape. Understanding PLC programming is essential for engineers and automation specialists looking to build future-ready smart factories.

0 notes

Text

Revolutionizing Industrial Processes with Automation Components

Automation components are at the heart of modern industrial systems, enabling seamless, efficient, and reliable operations. Industries worldwide depend on these essential components to enhance productivity, optimize workflows, and achieve precision in their processes. At Ram Automations, we provide a comprehensive range of high-quality automation components from globally recognized brands, tailored to meet your industrial needs.

What Are Automation Components?

Automation components refer to the various parts and systems used to automate industrial processes. These components work together to improve operational efficiency, reduce downtime, and minimize human intervention in repetitive tasks. Key automation components include:

1. Sensors

Sensors detect environmental changes like temperature, pressure, or motion and send signals to other components for necessary adjustments.

Examples: Smart temperature sensors, pressure sensors, motion detectors.

2. Actuators

Actuators convert electrical signals into mechanical movements, enabling tasks like opening valves or moving robotic arms.

Examples: Pneumatic actuators, hydraulic actuators, and electric actuators.

3. Programmable Logic Controllers (PLCs)

PLCs act as the brain of automation systems, managing complex tasks and ensuring seamless operations.

Popular models: Allen-Bradley MicroLogix PLCs, Siemens SIMATIC PLCs.

4. Relays and Switches

These components regulate electrical currents, ensuring safe and controlled power distribution across devices.

Examples: Electromechanical relays, solid-state relays.

5. Communication Devices

Facilitate smooth interaction between various automation components. They ensure that systems work in harmony.

Examples: Industrial Ethernet, wireless communication modules.

Top Brands in Automation Components

At Ram Automations, we collaborate with globally renowned brands to bring you reliable automation solutions.

1. Allen-Bradley

Known for innovative automation systems.

Popular Products:

Programmable Logic Controllers (PLCs).

Human-Machine Interfaces (HMIs).

2. Siemens

Specializes in cutting-edge technology for industries like energy and manufacturing.

Popular Products:

SIMATIC PLCs, Drive Systems, Smart Sensors.

3. Schneider Electric

A leader in sustainable automation solutions.

Popular Products:

Modicon PLCs, Variable Frequency Drives (VFDs), Smart Sensors.

4. Honeywell

Recognized for its automation and control innovations.

Popular Products:

Flame Detectors, Pressure Transmitters, Control Systems.

5. Danfoss

Focused on energy-efficient and sustainable automation solutions.

Popular Products:

Pressure Transmitters, Pressure Controls.

Why Choose Automation Components?

Automation components are indispensable for industries looking to:

Enhance Productivity: Streamline operations and reduce downtime.

Improve Safety: Minimize manual interventions in hazardous processes.

Optimize Energy Usage: Achieve greater efficiency with smart technologies.

Ensure Accuracy: Eliminate human errors in repetitive tasks.

Your Partner in Automation – Ram Automations

Looking for reliable automation solutions? At Ram Automations, we pride ourselves on offering top-quality components and unmatched customer support. Whether you need PLCs, sensors, or any other industrial automation equipment, we have the expertise to guide you.

Why Choose Us?

Access to globally trusted brands.

Competitive pricing and swift delivery.

Expert support for installation and integration.

For more information, explore our wide range of automation components on Ram Automations today!

Final Thoughts

Investing in high-quality automation components can transform your industrial processes, enhancing efficiency and productivity. Choose Ram Automations for a seamless experience and solutions that fit your business needs. Contact us now to take your operations to the next level!

By incorporating automation components, your business can stay ahead of the curve and thrive in a competitive market. Make the smart choice with Ram Automations – your trusted partner in industrial automation!

0 notes