#Failure Analysis Testing Of Composite

Text

Failure Analysis Lab Mumbai, Pune, Nashik,Chennai,Hyderabad,India

#Failure AnalysisTesting Lab#Failure Analysis Testing Of Composite#Plastic#Metal#Alloy#Corrosion#Building Material#Fabric#Weld#Metallurgical#Wood#Oils & Lubricant#Biomedical#Polymer

0 notes

Text

Imperial Research Division Technical Report: Advancements in Phrik Alloy Metallurgy

Author: Dr. Jaina Dallows

Abstract: This technical report presents the findings of my research into metallurgy and the subsequent improvements made to Phrik and its alloys, a highly sought-after material renowned for its exceptional durability and lightsaber resistance. Through a comprehensive analysis of existing metallurgical techniques, combined with innovative experimentation and synthesis processes, I have successfully enhanced the structural properties and applicability of Phrik and its alloys, paving the way for enhanced military armaments and defensive systems in the Imperial arsenal.

Introduction: Phrik Alloy has long been revered for its unique properties, most notably its capability to withstand the energy blades of lightsabers. However, its insusceptibility to tooling, brittleness, and limited supply has hindered its widespread use. This research aimed to revolutionize phrik metallurgy by developing novel techniques that enhance its qualities, increase yield, and reduce the production costs associated with its synthesis.

2.1 Material Selection: A range of base metals, including beskar, corundum, vanadium, and tunqstoid, were meticulously examined to determine their suitability for alloying with Phrik. Through a series of trial compositions and evaluations, a combination of corundum and vanadium emerged as the optimal choice, offering improved hardness, thermal stability, and corrosion resistance.

2.2 Synthesis Process: The standard production process for phrik alloys was enhanced by introducing advanced metallurgical methodologies. A proprietary smelting technique involving controlled fusion in an plasma arc furnace was employed to ensure a homogeneous distribution of the constituent elements and minimize impurities. Furthermore, a novel quenching and tempering process was developed to enhance the material's hardness and resilience.

2.3 Nanostructural Modification: To further enhance the material's inherent properties, nanoscale structural modifications were introduced to the Phrik Alloy. Through controlled heat treatment, the alloy's grain boundaries were refined, resulting in increased mechanical strength and improved fracture toughness. This technique also mitigated the risk of crack propagation, rendering the alloy more resistant to catastrophic failure.

Characterization and Analysis: Comprehensive characterization of the improved Phrik Alloy was performed to validate its enhanced properties. Key tests included microstructural analysis using a hyperlight beam emission topographer, Erso hardness measurements, and tensile strength evaluations. The alloy exhibited an increase of 25% in hardness, surpassing its predecessors, while maintaining excellent ductility and resilience. Notably, the modified alloy demonstrated a 30% increase in resistance to ablative shock compared to previous iterations.

Industrial Implementation: The successful advancements in Phrik Alloy metallurgy have profound implications for the Empire's military capabilities. The improved alloy can be seamlessly integrated into various applications, including armored plating, melee weapons, and critical ship components. The increased availability and reduced production costs will allow for wider deployment within the Imperial forces, ensuring superior protection against lightsaber-wielding adversaries.

Conclusion: This research report presents a significant milestone in the development of Phrik Alloy metallurgy. By incorporating advanced techniques and nanostructural modifications, we have successfully improved the material's hardness, resilience, and theoretical lightsaber resistance. The enhanced Phrik Alloy offers the Empire a distinct advantage in combat scenarios, with the potential to revolutionize the defense industry. Further research is underway to explore additional applications and potential synergies with other advanced materials.

Acknowledgments: The author expresses sincere gratitude to the Imperial Research Division for providing the necessary resources and support for this study. Special thanks are extended to the team of researchers involved in the experimental work, and Commodore Fordo, without whom this breakthrough would not have been possible.

Disclaimer: The research findings contained in this report are classified and intended solely for internal distribution within the Imperial Research Division. Unauthorized reproduction or dissemination is strictly prohibited.

2 notes

·

View notes

Text

Exploring The Depths: How Geotechnology Soil Boring And Drilling Services Benefit Nyc Construction Projects

Geotechnology Soil Boring and Drilling Services involve the use of specialized equipment and techniques to extract soil and rock samples from a construction site. These samples are then analyzed to determine the soil and rock composition, as well as their strength and stability. The information obtained from this analysis is used by architects and engineers to design and build structures that can withstand the soil and rock conditions at the construction site. The services are an essential part of any construction project, as they help to ensure that the structures are safe, stable, and able to withstand the test of time.

At NYCER Design, we believe that geotechnology services play a crucial role in the success of any construction project in New York City. Our Geotechnology Soil Boring and Drilling Services provide critical information about the soil and rock formations beneath the surface of a construction site, which helps architects and engineers design and build strong, stable, and safe structures. In this blog post, we will explore the benefits of our Geotechnology Soil Boring and Drilling Services and how they help to ensure that construction projects in NYC are built to the highest standards.

What are NYCER Design’s Geotechnology Soil Boring and Drilling Services?

Our Geotechnology Soil Boring and Drilling Services involve drilling a series of holes into the ground to obtain samples of the soil and rock formations beneath the surface. These samples are then analyzed in a laboratory to determine their composition and other characteristics, such as the presence of groundwater, soil density, and shear strength. The results are used to create geotechnical reports that help architects and engineers design and build strong, stable, and safe structures.

Benefits of NYCER Design’s Geotechnology Soil Boring and Drilling Services

Ensure Strong and Stable Foundations –

One of the main benefits of our Geotechnology Soil Boring and Drilling Services is that they help to ensure that construction projects are built on a solid foundation that can withstand the stresses and strains of the surrounding environment. Soil and rock formations vary significantly across different parts of New York City, and even across different areas within the same construction site. Our soil boring and drilling services help engineers to identify these variations and design the foundations accordingly.

Reduce Risk of Foundation Failure and Structural Issues –

Our geotechnology services can also help reduce the risk of foundation failure and other structural issues that can lead to costly repairs and safety hazards. These issues can be caused by factors such as poor soil conditions, excessive groundwater, and sinkholes. By conducting soil boring and drilling services, our engineers can identify these potential issues and design solutions to mitigate or eliminate them.

Design Efficient Structures –

Our Geotechnology Soil Boring Services NYC and Drilling Services can also help to reduce construction costs by ensuring that structures are designed and built as efficiently as possible. By understanding the characteristics of the soil and rock formations at a construction site, engineers can design foundations and structures that require less material, time, and labor to construct.

Conclusion

In conclusion, at NYCER Design, we are committed to providing Geotechnology Soil Boring and Drilling Services that are essential for the success of construction projects in New York City. Our services provide critical information about the soil and rock formations beneath the surface, which helps architects and engineers design and build strong, stable, and safe structures. With our geotechnology services, construction projects can be built to the highest standards, ensuring that they are safe, efficient, and long-lasting.

2 notes

·

View notes

Text

A discussion of the newly released Electric Clojure by Hyperfiddle. What is Electric? "Electric Clojure, a reactive Clojure/Script dialect for web UI with compiler-managed client/server data sync." What does that mean? You write a single piece of code, e.g. a UI component function, and hint which parts need to run on the server vs. the client. "The Electric compiler performs deep graph analysis of your unified frontend/backend program to automatically determine the optimal network cut, and then compile it into separate client and server target programs that cooperate and anticipate each other's needs." Thus you program as if there was no hard client-server divide (no 2 separate files with REST calls in between) and Electric handles splitting it up and managing the communication between them on your behalf. It is groundbreaking and fascinating, with potential to significantly simplify web apps. Go read more about it.

Highlights from the discussion (many comments by the founder):

[..] we're seeing 10x LOC reduction (18k to 2k) in rebuilding Electric's sister project, Hyperfiddle (a spreadsheet like tool for robust UI development), as well as massive gains in performance.

NOTE: Til now focus was on correct program semantics, now started work on DX etc.

Our DOM module is only 300 LOC - it's bare metal DOM point writes + Electric (reactive language) + macros for JSX-y syntax. When the programming language itself is reactive, DOM rendering falls out for free.

Mechanically, Electric is comparable to Solid.js except the reactive engine (missionary) is general purpose, not coupled to DOM rendering, which is a special case of incremental view maintenance.

[..] over-abstracting is a primary risk and has been top of mind for us since project conception in ~2012. [..] Electric is an attempt to find exactly the right level of abstraction. The goal is to remove and flatten layers, not add them, thus decreasing abstraction weight in the end if we succeed. Maybe we fail, but first let me share some details about how we think about this:

I've personally failed to build this project several times, Electric Clojure is something like the 7th attempt.

strong composition model as a starting point, based on category theory generalization of "function" -> "async function" -> "reactive function" -> "stream function" -> "distributed function". [..] (This rigor is in response to the past failures.)

Functional effect system (monad stuff) at the bottom, which provides strong semantics guarantees about glitch-free reactive propagation, process supervision (like Erlang) (transparent propagation of cancellation and failure), strong resource cleanup guarantees (DOM nodes can never be left hanging, event handlers can never fail to be detached and disposed). Already this results in tighter operational semantics than we have ever achieved with manual resource management (and, again, we tried, see past failures).

Electric affords the programmer trapdoors to the underlying FRP/concurrency primitives. Electric is essentially a Clojure-to-FRP compiler, so if you code raw concurrency and effect management, that actually typechecks with what Electric generates, allowing seamless transition in and out of the abstraction.

3k LOC + 3k test LOC is the size of Electric today (includes a rewrite of the Clojure analyzer). Spring Framework is, let me go check, 59k just for spring-core/src/main/java, and there are like 20 other modules I excluded. Indeed it is not a fair comparison but certainly we have complexity budget to spare.

About Missionary: "Missionary is a reactive dataflow programming toolkit providing referentially transparent operators for lazy continuous signals, eager discrete streams, and IO actions. Missionary aims to improve over state-of-the-art reactive systems, it can be used as a general-purpose asynchronous programming toolkit but also as a basis for event streaming and incremental computations." Electric uses it for functional effects and as its reactive engine.

1 note

·

View note

Text

How Soil Testing Labs in the UAE Help Mitigate the Risks of Building on Desert Land | +971 554747210

Building on desert land poses unique challenges due to the nature of the soil and environmental conditions. The arid climate, sandy terrain, and high salinity in the UAE create several risks for construction projects. Understanding the soil's properties is crucial for mitigating these risks and ensuring the structural integrity and safety of buildings. This is where soil testing labs play a vital role.

Soil testing labs in the UAE provide critical data that helps developers, engineers, and architects make informed decisions about how to approach construction on desert land. These labs analyze the soil’s composition, strength, moisture content, and other factors that influence the stability and longevity of structures.

In this blog, we’ll explore how soil testing lab help mitigate the risks associated with building on desert land in the UAE and why their role is essential for successful construction projects.

Challenges of Building on Desert Land in the UAE

The desert environment in the UAE presents several unique challenges for construction, including:

1. Loose, Sandy Soil

Desert soil is predominantly sandy, which means it lacks cohesion and stability. Sandy soils can shift easily under load, leading to settlement issues or even foundation failure if not properly managed.

2. High Salinity Levels

The high salinity in UAE desert soil can corrode building materials, especially concrete and steel, over time. If not addressed, this can significantly reduce the lifespan of buildings and infrastructure.

3. Limited Moisture Retention

Desert soil typically has low moisture retention, which can lead to issues with water infiltration and drainage. Poor moisture management can result in soil movement, affecting the foundation's stability.

4. Temperature Extremes

The desert environment in the UAE experiences extreme temperature variations between day and night. These fluctuations can cause soil expansion and contraction, affecting the foundation’s performance.

Given these challenges, conducting a thorough soil analysis before any construction project is critical to prevent structural issues and delays.

The Role of Soil Testing Labs in Mitigating Construction Risks

Soil testing labs in the UAE play a key role in mitigating the risks of building on desert land by providing accurate and reliable data on soil properties. Below are the key ways these labs help reduce the risks of construction in such environments.

1. Assessing Soil Stability

One of the primary concerns when building on desert land is the stability of the soil. Loose, sandy soils can lack the necessary load-bearing capacity to support structures, leading to foundation failure or settlement issues. Soil testing labs perform a variety of tests to assess soil stability, including:

Soil Compaction Testing: This test determines the density of the soil and whether it can be compacted to support heavy loads. By understanding how compactable the soil is, engineers can decide whether additional stabilization measures, such as soil improvement or the use of geosynthetic materials, are necessary.

Standard Penetration Test (SPT): The SPT measures the resistance of soil to penetration and provides valuable data on its strength and density. This information is crucial for determining the foundation type and depth required for the building.

By analyzing the stability of the desert soil, soil testing labs help engineers choose the appropriate foundation design, ensuring that the structure is stable and capable of withstanding the desert’s harsh conditions.

2. Analyzing Soil Moisture Content and Permeability

Soil moisture content and permeability are critical factors that influence the behavior of soil under load. Desert soil typically has low moisture retention, which can cause settlement or foundation instability. Soil testing labs in the UAE conduct tests such as:

Moisture Content Test: This test measures the amount of water present in the soil. It helps determine how the soil will behave in different environmental conditions and during the construction process.

Permeability Test: This test assesses how easily water can move through the soil. In desert areas, where rain is infrequent but can be intense, understanding permeability is crucial for managing drainage and preventing water accumulation around foundations.

By understanding the soil’s moisture content and permeability, construction teams can implement drainage solutions, water-proofing measures, and appropriate foundation designs to mitigate risks associated with water movement and soil settlement.

3. Determining Soil Salinity Levels

Salinity is a major concern when building on desert land in the UAE. High salt content in the soil can lead to the corrosion of building materials, particularly concrete and steel, which can compromise the structure’s integrity over time.

Soil testing labs conduct chemical analysis to determine the salinity levels in the soil. Based on these results, engineers can recommend protective measures such as:

Using corrosion-resistant materials: In cases where high salinity levels are detected, the use of corrosion-resistant materials, coatings, or sealants may be necessary to prevent long-term damage.

Soil Treatment: Labs may recommend treatments to neutralize the salinity of the soil or suggest alternative construction materials that are less susceptible to corrosion.

By identifying the salinity levels early, soil testing labs help developers implement preventative measures, extending the lifespan of the building and reducing the need for costly repairs.

4. Evaluating Soil Bearing Capacity

Soil bearing capacity refers to the ability of the soil to support the weight of a building or structure. In desert regions, the soil's bearing capacity can vary significantly due to its loose, sandy nature. Soil testing labs perform bearing capacity tests to determine how much load the soil can handle before it experiences failure or excessive settlement.

If the soil's bearing capacity is too low, labs may recommend:

Soil Stabilization: Techniques such as soil compaction, chemical stabilization, or the use of reinforcement materials can help improve the soil’s bearing capacity.

Deep Foundations: In cases where the soil cannot support shallow foundations, deep foundations like piles may be required to transfer the building’s load to deeper, more stable layers of soil.

By evaluating the soil’s bearing capacity, soil testing labs ensure that buildings are constructed on a stable foundation, reducing the risk of structural failure.

5. Identifying Soil Expansion and Shrinkage Potential

Desert soils in the UAE can exhibit expansion and shrinkage due to temperature fluctuations and moisture changes. Expansive soils can cause significant damage to foundations if not managed properly.

Soil testing labs perform tests such as the Atterberg Limits Test to determine the soil’s potential to expand or shrink. Based on these results, engineers can design foundations that are resistant to movement or recommend soil stabilization methods to mitigate the effects of expansion and contraction.

6. Providing Recommendations for Soil Improvement

In many cases, soil testing labs in the UAE identify issues with the soil that can be mitigated through soil improvement techniques. These may include:

Soil Stabilization: Adding chemicals like lime, cement, or fly ash can improve the strength and stability of the soil.

Compaction: Proper compaction techniques can enhance the load-bearing capacity of loose desert soils.

Drainage Systems: Implementing drainage solutions can prevent water accumulation around the foundation, reducing the risk of settlement.

By providing tailored recommendations for soil improvement, testing labs help ensure that construction projects are built on solid ground, reducing the likelihood of future problems.

Why Choosing the Right Soil Testing Lab Matters

Choosing a reputable and experienced soil testing lab in the UAE is crucial for mitigating the risks associated with building on desert land. Not all labs offer the same level of expertise or advanced testing methods, so it’s essential to select a lab that:

Is accredited and certified: Ensure that the lab follows international standards such as ISO 17025, which guarantees the accuracy and reliability of test results.

Has experience with desert soil: A lab that has experience working with the unique conditions of desert soil in the UAE will provide more accurate and relevant recommendations for your project.

Offers comprehensive testing services: From geotechnical testing to chemical analysis, the lab should offer a wide range of tests to cover all aspects of soil evaluation.

Conclusion

Soil testing labs in the UAE play an essential role in mitigating the risks of building on desert land. Through a comprehensive evaluation of soil stability, moisture content, salinity, and bearing capacity, these labs provide valuable insights that help engineers and developers design safe, stable, and long-lasting structures. By choosing the right soil testing lab and addressing potential risks early, construction projects can succeed even in the challenging conditions of the UAE desert.

0 notes

Text

Understanding the Importance of a Material Testing Lab

In today's competitive market, ensuring the quality and reliability of materials is crucial for the success of any product. This is where a material testing lab becomes indispensable. These specialized facilities play a critical role in assessing the properties and performance of materials, ensuring they meet the required standards and specifications.

Material testing labs are equipped with advanced technologies and instruments designed to conduct a wide range of tests. These tests can include mechanical, thermal, chemical, and environmental assessments, among others. By examining materials under various conditions, these labs help in understanding their behavior, durability, and suitability for specific applications.

One of the primary functions of a material testing lab is to evaluate the mechanical properties of materials. This includes tests for tensile strength, hardness, impact resistance, and fatigue. Such evaluations are essential for determining how materials will perform under different stresses and loads, which is crucial for applications in construction, automotive, aerospace, and manufacturing industries.

In addition to mechanical testing, material testing labs also conduct thermal analysis to assess how materials respond to temperature changes. This includes tests for thermal conductivity, expansion, and thermal stability. Understanding these properties is vital for materials used in environments with extreme temperatures or thermal cycling.

Chemical analysis is another key area of focus. Material testing labs analyze the chemical composition and purity of materials to ensure they meet industry standards and regulatory requirements. This is especially important in industries such as pharmaceuticals, food and beverage, and electronics, where material contamination can have significant consequences.

Moreover, environmental testing evaluates how materials perform in various environmental conditions such as humidity, corrosion, and UV exposure. This helps in predicting the lifespan and reliability of materials when exposed to real-world conditions.

By providing accurate and reliable data, material testing labs help manufacturers and researchers make informed decisions, enhance product quality, and ensure compliance with safety standards. Investing in material testing not only improves product performance but also reduces the risk of failures and recalls.

In conclusion, material testing labs are an essential component of modern industry. Their expertise and advanced testing capabilities ensure that materials meet the necessary standards and perform reliably in their intended applications. Whether you're developing new products or evaluating existing ones, partnering with a reputable material testing lab is key to achieving success and maintaining quality.

1 note

·

View note

Text

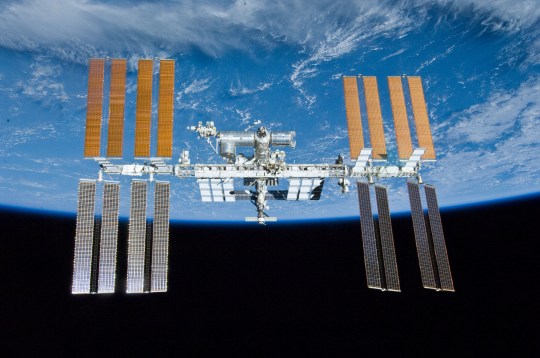

Keeping mold out of future space stations

Study models how dust, humidity create problems for astronauts

Mold can survive the harshest of environments, so to stop harmful spores from growing on future space stations, a new study suggests a novel way to prevent its spread.

Researchers created a predictive approach for modeling unintended microbial growth in critical spaces and applied it to life on the International Space Station.

An analysis of dust samples obtained from the space station found that repeated elevated humidity exposures for even a short time can lead to rapid microbial growth and composition changes in dust that make it easier for microbes, such as fungi, to thrive.

The study provides important insight into how healthy environments might be maintained during future missions, especially as the commercial space industry begins to prompt more people to live and work above Earth, said Karen Dannemiller, senior author of the study and an associate professor of civil, environmental and geodetic engineering and environmental health sciences at The Ohio State University.

“It’s really important to understand the exposures that happen in the space environment in part because we see immune system changes in astronauts,” she said. “People who are normally healthy individuals may be especially vulnerable to microbes in space, more so than on Earth.”

The study was published today in the journal Microbiome.

Historically, many spacecraft have had issues with unintended microbial growth because, much like a typical home on Earth, they, too, are environments that tend to trap the moisture humans emit. On the ISS, dust is usually produced by people as they go about their daily activities, but left unchecked, these floating particles can cause a range of negative health issues for the crew, such as asthma or allergies, and degrade building materials and equipment.

To ensure that dust levels aboard the ISS are carefully controlled, every week astronauts must clean the protective screens that cover the filters of the space station’s air ventilation system. In this study, four separate vacuum bag samples of the dust collected from these housekeeping chores were sent down to Dannemiller’s team to be tested.

After incubating the samples for two weeks at different relative humidities to simulate a scenario where an unexpected event, such as a temporary air ventilation system failure, could cause bursts of moisture, analysis revealed that fungi and bacteria can grow in the same concentrated amounts as dust collected from residential homes on the ground.

“Spacecraft actually aren’t that different from what we see on Earth in terms of having a unique indoor microbiome,” said Nicholas Nastasi, lead author of the study and a postdoctoral researcher at Ohio State’s Indoor Environmental Quality Laboratory. “If you put people in a space, there will always be microbes there, so it’s important to prevent their spread because once it starts, it’s often not too easy to get rid of.”

Spacecraft are especially prone to microbial growth because they are enclosed environments where humans constantly exhale moisture. If that moisture builds up, mold can begin to grow, as seen in past space stations such as Mir. Although the ISS has much improved controls for moisture, unexpected situations can still easily occur, said Nastasi.

Additionally, while Earth and space environments are complex in their own unique ways, the two more often than not contain similar core microbial communities, Nastasi said. Moreover, staying knowledgeable about the evolution of these communities will make certain that vulnerable individuals both on- and off-world have the information needed to maintain a healthy indoor microbiome on the space station.

“In designing some of our current space station systems, we’ve already learned a lot of really important lessons in terms of how to keep moisture under control,” said Dannemiller. “Now we’re learning even more that we can use to advance these systems in the future.”

In general, the study also suggests that the team’s research could later aid the development of planetary protection protocols aimed at preventing contamination of Earth or any other celestial bodies humans may visit.

Next, the team will likely work to discover what effect other untested spaceflight variables, such as microgravity, radiation and elevated carbon dioxide levels, have on microbial growth in similar working space stations, like NASA’s lunar station Gateway or other imminent commercial projects. Many of their upcoming projects will also benefit from Ohio State’s terrestrial analog of the George Washington Carver Science Park, a replica of Starlab space station science park that will allow researchers to conduct parallel missions on the ground.

“There’s a lot of other unique spaceflight factors we can potentially add to these microbial models to make them more accurate and useful,” said Nastasi. “We’ll keep refining what we do to maintain those healthy space environments and having unprecedented access to a platform such as Starlab will help immensely.”

This study was supported by NASA. Other Ohio State co-authors were Ashleigh Bope, Marit E. Meyer and John M. Horack.

1 note

·

View note

Text

What Are the Key Services Provided by a Steel Testing Lab?

Steel plays a critical role in numerous industries, from construction to automotive manufacturing. Ensuring that steel used in these applications meets the necessary quality and safety standards is vital. But how do companies verify the quality of steel? This is where a Steel Testing Lab comes into play. But what exactly is tested, and why is it important?

Understanding the Role of a Steel Testing Lab

A Steel Testing Lab is a specialized facility where various types of tests are performed on steel materials to evaluate their properties, composition, and overall performance. The tests ensure that the steel meets industry standards and can withstand the required conditions in different applications. Whether it is testing for tensile strength or chemical composition, a Steel Testing Lab ensures that the steel will perform as needed in its intended use.

Types of Steel Tests

Steel testing involves a variety of tests, each designed to measure a different aspect of the material's quality. The most common types of steel tests include:

Tensile Strength Testing: This test measures the steel’s ability to resist breaking under tension. It is critical for ensuring that steel used in construction or manufacturing can withstand the forces applied to it.

Hardness Testing: Hardness tests are used to measure how resistant steel is to deformation or indentation. This is important for applications that require steel to be durable and long-lasting.

Impact Testing: Impact tests assess how steel behaves under a sudden force or shock. This is especially relevant for industries where the material is exposed to high-energy impacts.

Chemical Composition Analysis: This type of test determines the elemental makeup of steel, ensuring that the correct blend of elements is present for the intended use of the material.

Corrosion Resistance Testing: Steel used in environments exposed to moisture or corrosive chemicals must be resistant to corrosion. This test checks how well the steel can withstand such conditions.

Importance of Steel Testing

Testing steel in a Steel Testing Lab is crucial for a variety of reasons:

Safety: Poor-quality steel can lead to catastrophic failures in construction, transportation, and manufacturing industries. Testing ensures that the steel meets safety standards and can handle the required load and stress.

Compliance: Industries like construction and automotive manufacturing have strict regulations regarding the materials they use. A Steel Testing Lab helps companies meet these compliance requirements by certifying that their materials are up to code.

Cost Efficiency: Investing in high-quality steel may initially seem expensive, but it can save companies from costly repairs, replacements, or accidents in the long run. Testing ensures that the steel will last, providing value over time.

Performance Optimization: Understanding the properties of steel through lab testing allows engineers and manufacturers to select the best materials for specific applications. This optimizes the performance and durability of the final product.

How Steel Testing Labs Benefit Different Industries

Steel testing is not just about safety and compliance—it also enables industries to innovate and improve the performance of their products. Here’s how various sectors benefit from steel testing:

Construction Industry: Ensuring that steel structures, such as buildings and bridges, can withstand environmental stresses and loads is vital. Steel testing ensures that construction companies use materials that are both strong and durable.

Automotive Industry: Steel is widely used in vehicle manufacturing, especially in components that need to withstand impact or wear over time. Testing ensures the steel used in cars and trucks meets strict safety standards.

Oil and Gas Sector: Pipelines, rigs, and storage tanks in the oil and gas industry are often exposed to extreme conditions. Steel testing ensures that the materials used can withstand corrosion, high pressures, and harsh environments.

Manufacturing Industry: Manufacturers need to ensure that the steel they use is consistent in quality and performance, especially when producing high-precision components. Testing helps ensure uniformity across production runs.

Conclusion:

In a world where material quality directly impacts safety and efficiency, the role of a Steel Testing Lab cannot be overstated. From ensuring compliance with industry regulations to providing data that helps optimize performance, these labs play a critical role in modern industries. Regular testing helps companies avoid failures, save money, and produce high-quality products that stand the test of time. Whether you are involved in construction, automotive manufacturing, or any industry that relies on steel, working with a reputable Steel Testing Lab can ensure that your materials meet the highest standards of quality and safety.

If you need reliable and accurate steel testing services, don’t hesitate to contact us. Our state-of-the-art Steel Testing Lab offers a range of tests designed to ensure your materials meet industry standards. Contact us today for more information on how we can help you with your steel testing needs.

0 notes

Text

Reliable Positive Material Inspection in Pune | PMI Services & XRF PMI Technology

Positive Material Identification (PMI) is a crucial process in industries where the integrity and composition of materials are of utmost importance. At Integrated NDE Solutions, we specialize in providing comprehensive PMI services in Pune, ensuring that your materials meet the required specifications and standards.

What is Positive Material Identification (PMI)?

Positive Material Identification (PMI) is a non-destructive testing (NDT) technique used to verify the chemical composition of materials, particularly metals. PMI is essential in industries such as oil and gas, aerospace, manufacturing, and construction, where material mix-ups can lead to severe consequences, including safety risks and costly failures.

Our PMI Services in Pune

At Integrated NDE Solutions, we offer a range of PMI services to meet the diverse needs of our clients:

XRF PMI Equipment: We utilize advanced X-Ray Fluorescence (XRF) PMI equipment to provide accurate and reliable material identification. XRF PMI technology allows us to perform on-site inspections quickly, ensuring minimal disruption to your operations.

PMI Inspection: Our PMI inspections are conducted by experienced technicians who are trained to identify the composition of various materials, including alloys, stainless steel, and carbon steel. This is particularly important for industries where precise material identification is critical.

PMI Material Identification: Our PMI material identification services are designed to confirm the exact composition of materials used in your projects. This helps prevent material mix-ups and ensures compliance with industry standards.

Positive Material Identification for Carbon Steel: Carbon steel is widely used in many industries, and its proper identification is crucial. Our PMI services for carbon steel ensure that the correct material is used, preventing potential failures and ensuring the safety and reliability of your structures and products.

PMI Chemical Analysis: Our PMI chemical analysis services provide detailed information about the chemical composition of materials, helping you make informed decisions about material selection and usage.

Positive Material Inspection: Regular positive material inspections are essential for maintaining the integrity of your materials and ensuring they meet the required specifications. Our team conducts thorough inspections to verify the composition of your materials, reducing the risk of costly errors.

Why Choose Integrated NDE Solutions for PMI in Pune?

Expertise: Our team of skilled technicians has extensive experience in PMI material analysis, identification, and inspection. We understand the critical importance of accurate material identification and are committed to delivering reliable results.

Advanced Technology: We use state-of-the-art PMI equipment, including XRF technology, to ensure precise and efficient material identification. Our technology allows us to perform inspections quickly and accurately, minimizing downtime.

Comprehensive Services: Whether you need PMI for a single material or a comprehensive inspection of an entire project, we offer tailored services to meet your specific needs.

Compliance: We ensure that all PMI services comply with industry standards and regulations, giving you peace of mind that your materials meet the necessary requirements.

Conclusion

Positive Material Identification (PMI) is an essential process in ensuring the safety, reliability, and compliance of materials used in various industries. At Integrated NDE Solutions, we are dedicated to providing top-quality PMI services in Pune, using advanced technology and expertise to deliver accurate results. Whether you require PMI for carbon steel, chemical analysis, or regular inspections, our team is here to support your needs. Contact us today to learn more about our PMI services and how we can help you ensure the integrity of your materials.

#positive material identification#pmi#pmi positive material identification#xrf pmi#pmi inspection#material identification#positive material#positive material inspection#pmi material identification#pmi material#positive materials identification#pmi material inspection#positive material identification for carbon steel#positive material identification equipment#identification of pmi#pmi chemical analysis#pmis#pmi identification#pmi material analysis#positive material identification standard

0 notes

Text

IVD Raw Materials: Ensuring Quality Control From Procurement to Production

Raw Material Procurement and Quality Testing

The procurement of quality raw materials is the first and crucial step in the production of in vitro diagnostic devices. Various materials like reagents, antigens, antibodies, polymers and minerals are required as raw inputs. To ensure only materials meeting stringent specifications are procured, suppliers undergo a rigorous qualification and audit process.

Critical parameters like purity, potency, IVD Raw Materials composition and contamination levels are evaluated. Certificates of analysis are reviewed to check if the raw material meets pre-defined acceptance criteria. Periodic re-qualification of suppliers is done to verify they maintain consistent quality over time.

Random sampling and testing is conducted on incoming raw material shipments. Tests include identity verification, quantitative analysis, bioburden screening, endotoxin checks and validation of sterile filtration for heat sensitive components. Any deviations from specifications warrant an investigation and corrective actions before material acceptance. Comprehensive documentation and traceability is maintained for all incoming raw lots.

IVD Raw Materials Storage and Stability Monitoring

After acceptance, raw materials are stored as per labeled storage requirements - some may need refrigeration or freezing, while others can be kept at ambient conditions. Designated quarantine and warehouse areas ensure proper segregation.

Environmental conditions of storage areas are continually monitored and recorded to confirm maintenance of set limits. Periodic reviews check for any excursions, equipment breakdowns or process deviations that could impact material stability.

Regular stability monitoring programs assess critical quality attributes of stored raw materials over time. Tests help prove labeled shelf-life or re-test periods and validate that materials maintain suitability for production throughout their intended lifespan. Out-of-specification results prompt corrective measures including rejection or re-processing.

Raw Material Change Control

Minor modifications to approved supplier sites, transportation routes or raw material specifications require review and approval to address any potential quality impacts.

Significant changes warrant additional verification activities like method validation, real time and accelerated stability studies on materials manufactured using the changed process. Comparability assessments prove no adverse changes to performance, safety or effectiveness.

Only after successful change validation are revised materials released for commercial production. Rigorous change control safeguards maintain consistent quality of inputs vital for finished product quality and reliability.

Raw Material Quality in the Manufacturing Process

Raw material quality directly influences finished product quality. Manufacturing processes are validated to demonstrate robustness even for slight input variability. In-process checks monitor critical parameters.

Materials are properly identified at all stages and batch records capture complete traceability. Environmental controls of manufacturing areas are maintained within pre-set action limits. Cross contamination prevention strategies are in place.

Process simulators and real time release testing help detect early if any raw material deviation may lead to failure to meet pre-defined acceptance criteria for the produced medical devices. Out of specification results trigger investigations.

IVD Raw Materials Related Nonconformities

Despite preventive controls, raw material or supplier nonconformities sometimes arise necessitating containment actions. Impacted lots are immediately quarantined and prevented from further use.

Root cause analysis determines corrective measures and extent of trace forward and backward impact on finished devices. Possible device recalls are evaluated if patient safety could be compromised. Lessons learned help strengthen procurement and control strategies.

An effective raw material management system supported by science-based quality oversight enables consistent production of safe and effective IVD products. Continuous improvement further enhances the reliability of this critical first link in the diagnostic device value chain.

Get More Insights On, IVD Raw Materials

For More Insights Discover the Report In language that Resonates with you

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

About Author:

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)

#IVD Raw Materials#Diagnostic Materials#Laboratory Supplies#Biomedical Science#Diagnostic Reagents#Raw Materials

0 notes

Text

Quality Assurance in Cast Iron Supply: Ensuring Consistency and Reliability

In the manufacturing industry, cast iron remains a vital material due to its durability, machinability, and excellent thermal properties. However, the quality of cast iron can vary significantly, making it essential for manufacturers to source materials from reliable cast iron suppliers. To maintain high production standards and minimise defects, it is important to ensure the consistency and reliability of cast iron supplies.

The Importance of Quality Assurance for Cast Iron Suppliers

Quality assurance (QA) in cast iron supply involves a systematic process of ensuring that the iron meets specific standards and requirements. This process is vital for several reasons:

Consistency: Consistent quality in cast iron is essential for maintaining the integrity of manufactured products. Variations in quality can lead to defects, product failures, and increased costs due to rework and scrap.

Reliability: Reliable cast iron ensures that the final products meet performance expectations, particularly in applications where safety and durability are critical.

Customer Satisfaction: High-quality materials lead to high-quality products, which in turn result in satisfied customers. This satisfaction is crucial for building a solid reputation and customer loyalty.

Critical Aspects of Quality Assurance in Cast Iron Supply

Material Selection and Specification

The first step in quality assurance is the careful selection of raw materials. Cast iron suppliers must source high-quality raw materials and adhere to strict specifications regarding the composition and properties of the iron. This includes ensuring the correct balance of carbon, silicon, manganese, and other alloying elements that affect the iron's characteristics.

Manufacturing Processes and Control

Cast iron quality is determined by the manufacturing process. The following are key processes:

Melting: The melting process must be carefully controlled to achieve the desired chemical composition and avoid impurities. This involves precise temperature control and the use of clean, high-quality materials.

Moulding and Casting: The quality of the moulds and casting methods directly impacts the surface finish, dimensional accuracy, and internal soundness of the cast iron. Using advanced moulding techniques and high-quality moulds can minimise defects.

Inspection and Testing

Quality assurance includes both inspection and testing. Cast iron suppliers must implement strict inspection protocols to detect any defects. Standard inspection methods include:

Visual Inspection: Surface defects, such as cracks and porosity.

Dimensional Inspection: Ensuring that the cast iron components meet the specified dimensions and tolerances.

Non-Destructive Testing (NDT): Techniques like ultrasonic testing, radiography, and magnetic particle inspection help detect internal defects without damaging the product.

Chemical and Mechanical Property Testing

To ensure that the cast iron meets the required specifications, suppliers must conduct tests to determine its chemical composition and mechanical properties. Key tests include:

Chemical Analysis: Determines the composition of the iron, ensuring it meets the specified alloying elements' content.

Tensile and Hardness Testing: Assess mechanical properties such as tensile and hardness to ensure that the materials meet the required standards.

Certification and Documentation

Reliable cast iron suppliers provide certification and documentation for their products. This includes material test reports (MTRs) and certificates of compliance, which verify that the cast iron meets the required specifications and standards. Proper documentation is essential for traceability and accountability, providing manufacturers with the assurance that they are using high-quality materials.

Conclusion

To ensure consistency and reliability, AKP Ferrocast must adhere to strict quality assurance standards. From material selection and manufacturing control to inspection and testing, every step must be carefully managed to maintain high standards. Manufacturers need to partner with reputable suppliers of cast iron, such as AKP Ferrocast, in order to obtain materials that meet performance and specification criteria. Suppliers and manufacturers who prioritise quality assurance can create reliable, high-quality goods that meet the expectations of customers and are able to withstand various applications.

0 notes

Link

Fan Services can provide you Failure Analysis services For Composite,Plastic,Metal,Alloy,Corrosion, Building Material, Fabric,Weld,Metallurgical,Wood,Oils & Lubricant, Biomedical,Wood, Polymer, Rubber,Dental,Rocks & Minerals Products in Mumbai, Pune, Nashik, Chennai, Ahmedabad, Aurangabad, Hyderabad,Bangalore, Baroda, Nagpur,India

0 notes

Text

What is LIRA? How Much Does It Cost in Mumbai?

When it comes to electrical systems there are two premium qualities that are always valued – safety and reliability. The proper flow and compliance with the necessary safety standards are vital components of maintaining cable lines for any company. There are several sophisticated ways of accomplishing this, which include Line Impedance Resonance Analysis (LIRA). In this blog, we will discuss what LIRA is, why is it essential, and the current market price if one avails service from the best cable line impedance resonance analysis service provider in Mumbai – Diagnostic Technologies India Pvt Ltd. (Diatech.in).

Understanding LIRA: A Critical Tool for Electrical Safety

Line Impedance Resonance Analysis is one of the non-destructive testing methods applied to determine the state of electrical cables. This is in contrast to other forms of testing that may necessitate the physical removal of cables, a scenario that is not possible in the real-world business environment especially when the health of the cables is being assessed using LIRA since the results are obtained without interfering with the normal business processes of the organization. This makes it an invaluable tool in industries where time means money such as manufacturing and processing industries.

LIRA operates by calculating the impedance characteristic frequencies of the cable lines. Initially, these parameters may change due to insulation degradation, moisture, or mechanical damage to the composite structure of the aircraft. To avoid such catastrophe, businesses should detect these problems early in order to avoid devastating failures, lower maintenance costs and maintain continuity.

The Importance of LIRA for Business Owners

For business owners, especially those managing large-scale operations or critical infrastructures, the benefits of cable line impedance resonance analysis services are multi-fold:

Minimized Downtime: As LIRA is a non-invasive technique, power shutdowns are not required during the testing process and the business activities will run apace.

Cost-Effective Maintenance: This way, when one is conducting LIRA tests frequently, he will identify areas that deserve attention before they turn into costly repairs or even replacements of new parts.

Enhanced Safety: Thus, protecting the insulation of electrical cables, LIRA minimizes possible electric fire, short circuit, and any other dangerous situation.

Regulatory Compliance: By using LIRA, businesses are able to adhere to safety regulation and safety standards which is very important in order to avoid being penalized and also offer safety working environment to clients and employees.

What is The Cost of Cable Line Impedance Resonance Analysis in Mumbai?

The pricing of Line Impedance Resonance Analysis in the region depends on some factors such as the number of panels in the facility, the type of electrical system, and the frequency of the test. In other words the approximate cost which may be incurred by an organization for each business session may range from INR 50000 to INR 150000 approximately.

While selecting a contractor to purchase electrical services for LIRA, it is critical not only to consider the price but also the quality of the services to be provided. Diatech as the best electrical service provider in Mumbai, we deliver the best cable line impedance resonance analysis services that are adequate and competitively priced.

Why Choose Diatech for LIRA Services?

Diatech stands as a premier service provider offering quality electrical services to clients in Mumbai. This is why business owners prefer Diatech for their LIRA needs:

Expertise and Experience: Diatech has been providing its services in the international market for more than one and half decade and hence is well experienced. in has a strong team of competent and well trained professionals who are particularly conversant with LIRA methods that allow for proper efficiency.

State-of-the-Art Equipment: Diatech employs state of the art technology and equipment to ensure that these LIRA tests are carried out effectively to provide the best results possible.

Tailored Solutions: Realizing that every enterprise has its specific needs, Diatech provides special LIRA services in accordance with certain specifications.

Competitive Pricing: While maintaining competitive service standards, Diatech terms of pricing strategy it also emerges as suitable choice for business as they can afford its services.

Comprehensive Reporting: After Raoul had performed the LIRA, Diatech provides detailed reports that help business owners determine the status of their electrical system and the need for any repair work to be done.

Conclusion

Such concepts as best cable line impedance resonance analysis are indispensable tools for evaluating the safety of electrical systems in any business environment. For business people in Mumbai, they should schedule the Cable Line Impedance Resonance Analysis from the best LIRA testing service such as Diatech. Therefore, it is advisable when it is actually carried out; it helps in cutting down on such expenses and reduces downtime incidences.

If you're looking to maintain the integrity of your electrical systems, consider reaching out to Diatech.in With their expertise, state-of-the-art technology, and commitment to quality, you can be assured that your business is in safe hands.

Resource: https://diatechin.blogspot.com/2024/08/What-is-LIRA-How-Much-Does-It-Cost-in-Mumbai.html

#Best Electrical cable testing services#Best VLF cable testing services#Damped ac testing solution providers in india

0 notes

Text

Understanding the Oil Testing Process: What to Expect from a Laboratory in Abu Dhabi

In the bustling industrial landscape of Abu Dhabi, maintaining the quality and efficiency of machinery is critical for operational success. One of the key factors in achieving this is through regular oil testing. Oil testing laboratories in Abu Dhabi provide essential services that ensure lubricants and oils meet the required standards for performance and safety. Understanding the oil testing process can help industrial clients make informed decisions and ensure that their machinery runs smoothly. In this blog, we will explore what to expect from an oil testing laboratory in Abu Dhabi and how the process works.

The Importance of Oil Testing

Oil testing is vital for several reasons:

Prevention of Equipment Failures: Regular testing helps detect contaminants and wear metals early, preventing costly breakdowns.

Optimization of Performance: Ensures that oils maintain their effectiveness and support optimal machinery performance.

Regulatory Compliance: Helps in meeting industry standards and regulations, avoiding potential legal issues.

Extended Equipment Lifespan: Proper oil maintenance contributes to the longevity of machinery by reducing wear and tear.

The Oil Testing Process: Step-by-Step Overview

Oil testing involves a series of steps designed to evaluate the condition of the oil and its suitability for use. Here’s what you can expect from the process:

1. Sample Collection

The first step in the oil testing process is the collection of oil samples. Proper sample collection is crucial for accurate results.

Sampling Procedures: Laboratories follow specific procedures to collect oil samples to avoid contamination. Samples are usually taken from the machinery in a clean and controlled environment.

Documentation: Accurate documentation of the sample source and conditions is essential for traceability and analysis.

2. Sample Preparation

Once the samples are collected, they need to be prepared for testing. This step involves:

Labeling and Storage: Samples are labeled with relevant information and stored under controlled conditions to maintain their integrity.

Pre-Treatment: Depending on the type of test, samples may undergo pre-treatment to remove impurities or adjust their properties.

3. Testing and Analysis

The core of the oil testing process involves a series of tests and analyses to assess various properties of the oil. Here are some common tests performed:

Viscosity Testing: Measures the thickness of the oil, which affects its lubrication properties. Proper viscosity ensures that the oil can effectively lubricate moving parts.

Wear Metals Analysis: Identifies and quantifies wear metals present in the oil. Elevated levels of wear metals can indicate potential issues with machinery components.

Contaminant Detection: Tests for contaminants such as water, dirt, and fuel dilution. Contaminants can degrade oil performance and damage equipment.

Chemical Composition Analysis: Determines the chemical properties of the oil, including its acidity and alkalinity. This helps in understanding how the oil interacts with the machinery.

4. Interpretation of Results

After the tests are completed, the results are interpreted by skilled technicians to provide meaningful insights.

Data Analysis: Technicians analyze the test data to identify any anomalies or deviations from standard parameters.

Report Generation: A detailed report is generated, summarizing the test results and providing recommendations based on the findings.

5. Recommendations and Follow-Up

Based on the test results, the laboratory provides recommendations to address any issues and optimize oil usage.

Maintenance Recommendations: Suggestions for maintenance or corrective actions if issues are detected, such as changing the oil or addressing contaminants.

Follow-Up Testing: In some cases, follow-up testing may be recommended to monitor the effectiveness of the implemented actions.

Key Factors to Consider When Choosing a Laboratory in Abu Dhabi

When selecting an oil testing laboratory in Abu Dhabi, consider the following factors to ensure you receive high-quality services:

1. Accreditation and Certifications

Choose a laboratory that is accredited by recognized bodies and adheres to international standards. Accreditation ensures that the laboratory meets quality and reliability standards.

ISO Certification: Look for laboratories with ISO 9001 for quality management and ISO 17025 for testing and calibration competence.

2. Range of Testing Services

Ensure that the laboratory offers a comprehensive range of testing services tailored to your specific needs.

Comprehensive Tests: Check if the laboratory performs a wide range of tests, including viscosity, wear metals analysis, and contaminant detection.

3. Technological Capabilities

Advanced technology and equipment are crucial for accurate and reliable testing.

Modern Equipment: Verify that the laboratory uses state-of-the-art technology for testing and analysis.

4. Expertise and Experience

The experience and expertise of the laboratory staff play a significant role in the accuracy of the results.

Skilled Technicians: Ensure that the laboratory has experienced technicians who are knowledgeable in oil testing and analysis.

5. Turnaround Time

Efficient processing and quick turnaround times are essential for timely maintenance and decision-making.

Prompt Service: Choose a laboratory known for its prompt and efficient service delivery.

6. Customer Support

Good customer support ensures that any questions or issues are addressed promptly.

Responsive Support: Look for a laboratory with a responsive and helpful customer support team.

Leading Oil Testing Laboratories in Abu Dhabi

Several reputable oil testing laboratories in Abu Dhabi offer high-quality testing services. Here are a few notable examples:

1. METS Laboratories

METS Laboratories is known for its comprehensive oil testing services and adherence to international standards. With advanced technology and experienced staff, METS Laboratories provides accurate and reliable results.

2. SGS UAE

SGS UAE offers a range of oil testing services and is recognized for its global expertise and adherence to international standards. The laboratory provides detailed analysis and valuable insights for industrial clients.

3. Intertek UAE

Intertek UAE provides a wide range of testing services, including those for oils and lubricants. Known for its advanced technology and quick turnaround times, Intertek UAE is a reliable choice for oil testing.

4. Bureau Veritas UAE

Bureau Veritas UAE offers comprehensive oil testing services and ensures compliance with global standards. The laboratory is known for its rigorous testing procedures and expert analysis.

5. Al Hoty Stanger Laboratories

Al Hoty Stanger Laboratories is a well-established name in Abu Dhabi, offering a range of oil testing services with a focus on accuracy and reliability.

Conclusion

Understanding the oil testing process is essential for industrial clients in Abu Dhabi who want to maintain the quality and efficiency of their machinery. By knowing what to expect from an oil testing laboratory, you can make informed decisions and ensure that your equipment operates at its best. From sample collection and preparation to testing, analysis, and recommendations, oil testing laboratories play a crucial role in optimizing performance and preventing equipment failures. Choosing a reputable laboratory with the right accreditation, technology, and expertise will help you achieve the highest standards of quality and safety in your operations.

0 notes

Text

A Comprehensive Guide to Transformer Health Verification (HV) Testing

Transformers are critical components in power transmission and lightning protection studies distribution systems, playing a vital role in maintaining the reliability and efficiency of the electrical grid. Ensuring the health and proper functioning of transformers is essential to prevent unexpected failures and costly downtime. One key aspect of transformer maintenance is Health Verification (HV) testing, which provides a comprehensive assessment of a transformer's condition.

In this comprehensive guide, we'll explore the importance of transformer HV testing, the various tests involved, and how to interpret the results to make informed decisions about transformer maintenance and replacement.

Importance of Transformer HV Testing

Transformer HV testing serves several crucial purposes:

Identifying Potential Issues: HV testing helps detect early signs of deterioration, insulation problems, or other issues that could lead to transformer failure. By proactively addressing these problems, you can extend the transformer's lifespan and avoid unexpected outages.

Optimizing Maintenance Schedules: The data gathered from HV testing can be used to develop predictive maintenance strategies, allowing you to schedule maintenance and repairs based on the transformer's actual condition rather than a fixed schedule.

Ensuring Reliability: Maintaining the health of transformers is essential for ensuring the reliability and stability of the electrical grid. HV testing helps you identify and address issues before they escalate, reducing the risk of unexpected failures and service disruptions.

Compliance and Safety: Many regulatory bodies and industry standards require periodic HV testing to ensure transformers are operating within safe and acceptable parameters. Adhering to these requirements helps maintain compliance and minimize safety risks.

Key Transformer HV Tests

Transformer HV testing typically involves a suite of diagnostic tests to assess the overall health of the transformer. Some of the most common tests include:

Dissolved Gas Analysis (DGA): This test analyzes the composition and concentration of dissolved gases in the transformer's insulating oil. Specific gas patterns can indicate issues such as overheating, partial discharges, or oil degradation.

Insulation Resistance (IR) Test: This test measures the insulation resistance between the transformer windings, as well as between the windings and ground. Low insulation resistance can indicate moisture, contamination, or other insulation-related problems.

Dielectric Frequency Response (DFR) Test: Also known as the Frequency Domain Spectroscopy (FDS) test, this method analyzes the dielectric properties of the transformer's insulation system across a wide range of frequencies. It can help identify issues like aging, moisture, or paper insulation degradation.

Power Factor (PF) Test: This test measures the power factor of the transformer's insulation system, which can provide insights into the condition of the insulation and the presence of contaminants.

Transformer Turns Ratio (TTR) Test: This test measures the ratio of turns between the primary and secondary windings of a transformer, which can help detect winding issues or problems with the core.

Sweep Frequency Response Analysis (SFRA): This test compares the transformer's electrical signature across a range of frequencies, allowing for the detection of mechanical and electrical issues within the transformer.

Infrared (IR) Thermography: Thermal imaging can be used to identify hot spots or uneven heating within the transformer, which may indicate problems with the windings, connections, or cooling system.

Interpreting HV Test Results

Interpreting the results of transformer HV tests requires expertise and a deep understanding of the relationship between test results and transformer condition. Factors such as the transformer's age, operating history, and environmental conditions must be taken into account when analyzing the data.

In general, the test results should be compared to industry standards, manufacturer recommendations, and the transformer's historical data to identify any abnormal trends or deviations. Significant changes in test results over time, or values that fall outside of the acceptable range, may indicate the need for further investigation, maintenance, or even replacement of the transformer.

It's important to note that HV test results should be considered in the context of the overall condition of the transformer, as a single test result may not provide a complete picture. A holistic approach, incorporating multiple test results and other maintenance data, is essential for making informed decisions about the transformer's health and future.

Transformer Health Verification (HV) testing is a critical component of a comprehensive transformer maintenance program.hv transformer testing By regularly conducting a suite of diagnostic tests, you can gain valuable insights into the condition of your transformers and make informed decisions about their maintenance and replacement.

By understanding the importance of HV testing, the various tests involved, and how to interpret the results, you can ensure the reliability and efficiency of your power transmission and distribution systems, ultimately contributing to the overall resilience of the electrical grid.

0 notes

Text

Drop Weight Impact Tester: Ensuring Durability and Reliability in Product Testing

Introduction

In the fast-paced world of manufacturing, ensuring the durability and reliability of products is paramount. The Drop Weight Impact Tester, a crucial piece of equipment offered by Pacorr Testing Instruments, is designed to meet these exact needs. This article delves into the features, applications, and benefits of the Drop Weight Impact Tester, highlighting why it is an indispensable tool for industries striving for excellence in product quality.

Introduction to Drop Weight Impact Testing

Drop Weight Impact Testing is a method used to determine the impact resistance of materials. This type of testing simulates real-world conditions where products might be subject to sudden and forceful impacts. The Drop Weight Impact Tester is engineered to replicate these conditions, providing accurate and reliable data on a material's toughness and durability.

Key Features of the Drop Weight Impact Tester

Precision Engineering: The Drop Weight Impact Tester is built with high-quality materials and advanced technology, ensuring precise and consistent results.

Versatility: This tester is capable of evaluating a wide range of materials, including plastics, metals, composites, and ceramics.

User-Friendly Interface: Equipped with an intuitive control panel, the Drop Weight Impact Tester allows for easy operation and data collection.

Adjustable Impact Energy: The device features adjustable impact energy settings, enabling users to customize tests according to specific material requirements.

Safety Measures: Built-in safety features, such as automatic shut-off and secure enclosures, ensure the safety of operators during testing.

Applications of the Drop Weight Impact Tester

The Drop Weight Impact Tester is widely used across various industries, including:

Automotive: Assessing the impact resistance of components such as bumpers, dashboards, and interior panels.

Packaging: Evaluating the durability of packaging materials to ensure they can withstand rough handling and transportation.

Construction: Testing building materials like concrete, steel, and glass for their ability to endure sudden impacts.

Consumer Goods: Ensuring the robustness of products such as smartphones, appliances, and sports equipment.

Benefits of Using the Drop Weight Impact Tester

Enhanced Product Quality: By identifying weak points in materials, manufacturers can make informed decisions to improve product design and quality.

Compliance with Standards: The tester helps companies comply with international quality standards and regulations, fostering trust and credibility in the market.

Cost Efficiency: Early detection of material defects reduces the risk of product failures, saving costs associated with recalls and repairs.

Innovation and Development: Continuoustesting and analysis contribute to the innovation of new materials and products with superior impact resistance.

How to Use the Drop Weight Impact Tester

Using the Drop Weight Impact Tester involves several key steps:

Preparation: Secure the material sample on the testing platform.

Setting Parameters: Adjust the impact energy settings according to the material type and desired test conditions.

Testing: Initiate the test by releasing the drop weight from a predetermined height.

Data Collection: Record and analyze the data to assess the material's impact resistance.

Maintenance and Calibration

To ensure the Drop Weight Impact Tester remains in optimal condition, regular maintenance and calibration are essential. Pacorr Testing Instruments provides comprehensive support and services, including:

Routine Inspections: Regular checks to identify and rectify any wear and tear.

Calibration Services: Ensuring the accuracy and reliability of test results through periodic calibration.

Technical Support: Access to expert guidance and troubleshooting assistance.

Conclusion

The Drop Weight Impact Tester from Pacorr Testing Instruments is a vital tool for any industry committed to producing high-quality, durable products. Its advanced features, wide range of applications, and significant benefits make it an invaluable asset for manufacturers. By investing in this tester, companies can enhance their product development processes, ensure compliance with quality standards, and ultimately deliver superior products to the market.

For more information about the Drop Weight Impact Tester and other testing solutions, visit Pacorr Testing Instruments.

Frequently Asked Questions (FAQ) about the Drop Weight Impact Tester

1. What is a Drop Weight Impact Tester?

A Drop Weight Impact Tester is a device used to measure the impact resistance of materials. It simulates real-world conditions where materials might experience sudden and forceful impacts to determine their toughness and durability.

2. How does the Drop Weight Impact Tester work?

The tester works by dropping a specified weight from a set height onto a material sample. The impact energy and resulting data are used to assess the material's ability to withstand sudden impacts.

3. What types of materials can be tested with the Drop Weight Impact Tester?

The tester is versatile and can evaluate a wide range of materials, including plastics, metals, composites, ceramics, and more.

4. What industries benefit from using the Drop Weight Impact Tester?

Industries such as automotive, packaging, construction, and consumer goods benefit from using this tester to ensure the durability and reliability of their products.

5. What are the key features of the Drop Weight Impact Tester?

Precision engineering for accurate results

Versatility in testing different materials

User-friendly interface for easy operation

Adjustable impact energy settings

Built-in safety measures for operator protection

6. Why is impact testing important?

Impact testing is crucial for identifying the weak points in materials, improving product quality, ensuring compliance with standards, reducing costs associated with product failures, and fostering innovation in material development.

7. How do you set up a test using the Drop Weight Impact Tester?

To set up a test:

Secure the material sample on the testing platform.

Adjust the impact energy settings based on the material and test requirements.

Initiate the test by releasing the drop weight.

Collect and analyze the data to assess the material's impact resistance.

8. How often should the Drop Weight Impact Tester be calibrated?

Regular calibration is essential to maintain the accuracy and reliability of test results. The frequency of calibration depends on the usage and the manufacturer's recommendations. Generally, it should be calibrated at least once a year.

9. What maintenance is required for the Drop Weight Impact Tester?

Routine inspections, cleaning, and lubrication of moving parts are necessary to ensure optimal performance. Additionally, regular calibration and professional servicing by the manufacturer or authorized service providers are recommended.

10. Can the Drop Weight Impact Tester be customized for specific testing needs?

Yes, the Drop Weight Impact Tester can be customized with different impact weights, heights, and additional features to meet specific testing requirements.

11. Is training required to operate the Drop Weight Impact Tester?

While the tester is designed to be user-friendly, it is advisable to undergo training to understand its functionalities fully and ensure accurate testing and data collection.

12. What support services does Pacorr Testing Instruments offer for the Drop Weight Impact Tester?

Pacorr Testing Instruments provides comprehensive support services, including installation, training, routine maintenance, calibration, and technical support to ensure the optimal performance of the tester.

13. Where can I find more information or purchase the Drop Weight Impact Tester?

For more information or to purchase the Drop Weight Impact Tester, visit the official Pacorr Testing Instruments website or contact their sales team directly.

14. What safety features are included in the Drop Weight Impact Tester?

The tester includes automatic shut-off, secure enclosures, and other safety mechanisms to protect operators during testing.

15. How can the data from the Drop Weight Impact Tester be utilized?