#Hard chrome plated rods manufacturer

Text

Hard chrome plating, commonly known as industrial chrome plating, is a standard surface treatment process used in industries to enhance metal material, especially in wear and tear conditions. This hard chrome plating process improves the corrosion resistance and increases the overall durability of the component.

0 notes

Text

Hard Chrome Plated Rod Manufacturer - Kamal Shaft Pvt Ltd

Kamal Shaft Pvt Ltd is a leading manufacturer and supplier of hard chrome plated rods based in Ahmedabad, Gujarat, India. We specialize in manufacturer of hard chrome plated rods, offering a robust and reliable solution for various industrial applications. Kamal Shafts' strong chrome-plated rods are well-known for their exceptional strength and durability. The chrome plating process produces a strong, wear-resistant surface that highly enhances the rods' long time. This makes them perfect for demanding industry in which friction, corrosion, and wear are primary concerns. We are also producing Hard Chrome Rods, LM Shaft, Honed Tube, Induction Harden Rod, and Hard Chrome Plated Round Rod etc. Need Hard Chrome Plated Rods at leatest price? Visit for more info- https://www.kamalshaft.in/ or Contact- +91-83201-67484

#hard chrome plated rod#chrome plated rod#hard chrome rod#induction hardened chrome bar#chrome rod for hydraulic cylinders#chrome plated rod manufacturers#hard chrome rod suppliers#hard chrome plated rod supplier#hard chrome plated rod in ahmedabad#chrome plated piston rod manufacturers

0 notes

Text

Induction Hardened Rod Manufacturers and Suppliers from Gujarat, India - Kamal Shaft

Kamal Shaft Pvt. Ltd is the Manufacturer and Supplier of Induction Hardened Shafts from Ahmedabad, Gujarat, India. Our products are made in accordance with industry standards and are available in a wide range of sizes, shapes and materials.More Info visit our site.https://www.kamalshaft.in/induction-harden-rod

#Hard Chrome Plated Rod Suppliers in India#Hard Chrome Plated Rod Manufacturers in India#Induction Harden Rod Suppliers in India#Induction Harden Rod Manufacturers in India#L M Shaft Manufacturers in India#L M Shaft Suppliers in India#Honed Tube Suppliers in India#Honed Tube Manufacturers in India#Ready Honed Tube Suppliers in India#Ready Honed Tube Manufacturers in India#CDS Ready To Honed Tube Suppliers in India#CDS Ready To Honed Tube Manufacturers in India#Seamless Honed Tube Suppliers in India#Seamless Honed Tube Manufacturers in India#Honed Cylinder Tube Suppliers in India#Honed Cylinder Tube Manufacturers in India

0 notes

Text

https://www.kamalshaft.in

Hard Chrome Plated Rod Manufacturer and Supplier in Ahmedabad, Gujarat, India

Manufacturer and supplier of a comprehensive range of Hard Chrome Plated Rod & Hydraulic Piston Rod, Induction Hardened Steel Shaft, Linear Motion Bearing Shaft and Peeled and Ground Steel Rod

2 notes

·

View notes

Text

Hard Chrome Plating, Global Market Size Forecast, Top Ten Players Rank and Market Share

Hard Chrome Plating Market Summary

According to the new market research report “Global Hard Chrome Plating Market Report 2023-2029”, published by QYResearch, the global Hard Chrome Plating market size is projected to reach USD 2316.3 million by 2029, at a CAGR of 4.2% during the forecast period.

Figure. Global Hard Chrome Plating Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Global Hard Chrome Plating Market Report 2023-2029.

Market Drivers:

Corrosion Resistance: Hard chrome plating offers excellent corrosion resistance, making it a preferred choice for industries such as automotive, aerospace, and manufacturing, where components are exposed to harsh environments.

Wear Resistance: It provides exceptional wear resistance, extending the lifespan of components like hydraulic rods, industrial rolls, and molds, thereby reducing maintenance costs.

Enhanced Surface Hardness: The process significantly increases surface hardness, improving the durability of parts and their ability to withstand friction and abrasion.

Improved Performance: Components with hard chrome plating exhibit improved performance, making them suitable for applications where high precision and reliability are essential.

Versatility: The technology can be applied to various materials, including steel, aluminum, and copper, broadening its applicability across different industries.

Aesthetic Appeal: In addition to its functional benefits, hard chrome plating can enhance the visual appeal of products, making it popular in the design-driven sectors.

Growing Industrial and Manufacturing Activities: Increasing industrialization and manufacturing activities worldwide drive the demand for hard chrome plating, as many industrial components require its benefits.

Restraint:

Environmental Concerns: The hard chrome plating process involves the use of hazardous chemicals, including hexavalent chromium, which poses environmental risks and requires strict compliance with regulations. This has led to increased scrutiny and potential restrictions on its use.

Opportunity:

Alternative Coating Technologies: The shift towards more environmentally friendly coating technologies, such as thermal spray coatings, PVD (Physical Vapor Deposition), and CVD (Chemical Vapor Deposition), presents an opportunity for innovation and development within the hard chrome plating industry. Companies that can provide eco-friendly alternatives to traditional hard chrome plating may capture a growing market segment concerned about environmental sustainability.

Emerging Markets: Expansion into emerging markets with growing industrial sectors, such as Asia-Pacific and Latin America, can open up new opportunities for hard chrome plating companies as they cater to the increasing demand for durable and high-performance components.

Diversification of Applications: Exploring new applications beyond the traditional sectors, such as medical devices, electronics, and renewable energy, can create additional growth avenues for hard chrome plating technology.

Research and Development: Continued research and development efforts focused on improving the efficiency, cost-effectiveness, and environmental friendliness of the hard chrome plating process can help companies stay competitive and seize new opportunities in the market.

Collaboration and Partnerships: Collaborating with other industries, research institutions, or governmental bodies to address environmental concerns and regulatory compliance can lead to innovative solutions and market expansion opportunities.

Figure. Hard Chrome Plating, Global Market Size, The Top Five Players Hold 11.3% of Overall Market

Based on or includes research from QYResearch: Global Hard Chrome Plating Market Report 2023-2029.

This report profiles key players of Hard Chrome Plating such as Element Solutions, Atotech, Hausner Hard Chrome, CCA Hardchrome, Omori Chrome Industry Co., Ltd., Trinity Holdings, US Chrome, Electro-Coatings, Verbrugge, Pioneer Metal Finishing

In 2022, the global top five Hard Chrome Plating players account for 11.3% of market share in terms of revenue. Above figure shows the key players ranked by revenue in Hard Chrome Plating.

About The Authors

Tongtong Niu - Lead Author

Email: [email protected]

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Exploring Stainless Steel: Wire Mesh, Round Bars, Plates & Fittings of 304, 316, & 904L Grades

Stainless Steel metal is a flexible and durable cloth significantly used in several industries for its corrosion resistance, power, and aesthetic enchantment. Jay Steel Corporation will be the most fine destination for all your chrome steel desires. Renowned as a prime producer, supplier, stockist, and exporter, we concentrate on top-first-rate stainless-steel products globally. Our huge stock consists of a extensive variety of objects which include Stainless Steel Wire Mesh, Round Bars, Strips, Sheets & Plates, Tube & Pipes, Fittings, Flanges, Welding Rods, and Fasteners. We offer huge answers for all of your undertaking requirements.

In this weblog placed up, we're capable of delve into the location of chrome steel, in particular focusing on wire mesh, round bars, plates, and fittings made from grades 304, 316, and 904L.

Let us explore the specific traits of those stainless steel applications.

304 Grade:

Known for its corrosion resistance and simplicity of production, Grade 304 is the cross-to preference for a whole lot of programs. From kitchen appliances to architectural ornament this grade stars in Wire Mesh, Round Bars, Strips, Sheets & Plates, Tube & Pipes, Fittings, Flanges, Welding Rods, and Fasteners

Grade 316:

Taking corrosion resistance a step similarly, molybdenum-wealthy Grade 316 is hard in harsh environments. Its use in twine makes it durable and flexible, making it best for marine packages and chemical packages.

Grade 904L:

Engineered for excessive corrosion resistance, Grade 904L reveals its domestic in harsh chemical environments. Wire meshes, round bars, plates, and fittings manufactured from grade 904L are crucial within the petrochemical, pharmaceutical, and offshore oil and fuel industries.

Unveiling applications: wire mesh, round bars, plates & fittings in production

Stainless steel wire mesh:

Stainless metallic twine mesh is a popular cloth in diverse industries because of its versatility and durability. For filtration, filtration, or fencing, cord mesh in grades 304/304L/310S, 317/317L, 321, 347, or 904L guarantees grade 316 electricity and corrosion resistance /316L/316Ti is the preferred fabric for twine mesh programs in which corrosive substances interference is a situation Wherever it occurs, it occurs. As a depended on Stainless Steel Wire Mesh exporter, we offer they all at very cheap fees.

Stainless Steel Round Bars:

Stainless steels made of these materials show off fantastic power and corrosion resistance. Grade 304/304L/304H, 13-8 Mo, 15-five pH, 17-4 pH, 310/310S, 317/317L, 321, 347, 430, 440C, & 446 rounds are commonly used in applications into use in throughout States. How grade316/316L/316Ti unearths its place in marine chemical vegetation. Grade 904L spherical bars, with their superior alloy design, provide outstanding overall performance in intense conditions. As Stainless Steel Round Bar exporters, we make certain that our products meet the highest requirements.

Stainless steel strips, sheets, and plates:

Stainless metallic Strips, Sheets & plates offer power and aesthetic attraction, making them suitable for construction and commercial programs. Grade 304/304L/304H, 17-7 PH, 17-4 PH, 310/310S, 317/317L, 321, 347, 430, & SMO 254 Rope, Sheet & Plate Balance Resistance to Corrosion and Value Production Grade 316/1. 316L/316Ti Strips, Sheets & plates, with added molybdenum, ensure durability in competitive environments, even as Grade 904L Strips, Sheets & Plates excel in the freshest situations.

Stainless Steel Fittings: Specific to each connection

Stainless Steel fittings insert play a vital function in developing a reliable and sturdy system. Whether it’s piping, tubing, or structural connections, the grade you pick is essential. Products of grades 17-4 PH, 17-7PH, 304/304L/304H, 316/316L/316Ti, 317/317L, 321, 347, or SMO 254 are preferred in regions with an immoderate chance of corrosion while grade 904L fittings handiest for the very excellent corrosion resistance long-lasting packages Important. Also, as a candidate for stainless steel inserts and stainless steel fasteners.

Final Words!

Start your stainless steel journey with confidence by trusting Jay Steel Corporation for its unmatched quality, product range, and global availability. Discover the versatility of stainless steel grades 304, 316, and 904L in our full selection of products, including wire mesh, tape rounds, tapes, fabrics and plates, tubes and pipes, cargo inserts, flanges, welding rods, and fasteners. Choose the best option for your business by choosing Jay Steel Corporation as a reliable Stainless Steel Wire Mesh Exporter and Stainless Steel Round Bar Exporter. As a trusted stainless steel plate and stainless steel insert, we provide the solution you need. Count us as your Stainless Steel Fasteners Stockist for unparalleled service. Contact us today at [email protected] or [email protected] for a quote and up your industry with the pinnacle of stainless steel quality.

#Stainless Steel Wire Mesh Expotes#Stainless Steel Round Bar Exporters#Stainless Steel Fasteners Stockist#Stainless Steel Fittings Supplier

0 notes

Text

Hard Chrome Plated Rod Manufacturer & Supplier from Ahmedabad | RP Son Shaft

0 notes

Text

PU Material ESD Chair | Measuring Ergonomics

Several height adjustment ranges are provided for Messung's ergonomic ESD chair. The spindle pipe and piston rod are hard chrome-plated for added dependability and resistance against corrosion.

0 notes

Text

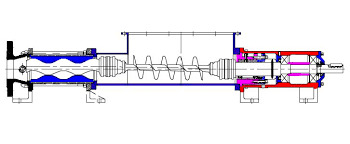

JW HYDRAULIC designs and manufactures hydraulic cylinder components and parts, including cylinder barrel (cylinder tube), piston rod, piston, gland, bush, head cap, end cap, earring, clevis, flanges, mounting trunnion, and so on. The max bore of the cylinder barrel we can process is 1200mm, and the max piston rod diameter is 1000mm. Hard chrome plating, nickel plating, and ceramic plating are all available here per clients' different requirements.

#jwhydraulic#hydrauliccylindercomponents#hydrauliccylinderparts#hydrauliccylinder#cylindertube#pistonrod#hydrauliccylinderhead#oemmanufacturer

0 notes

Text

To select the best hard chrome plated rods, consider factors such as material, diameter, surface finish, strength and more. Choose a hard chrome plated rod manufacturer with a reputation, quality certifications, and customer reviews. Ensure compatibility with your machinery and operating conditions for optimal performance and longevity.

0 notes

Text

Hard Chrome Plated Rod Manufacturer - Kamal Shaft Pvt Ltd

Kamal Shaft is a leading manufacturer and supplier of hard chrome plated rods based in Ahmedabad, Gujarat, India. We specialize in manufacturer of hard chrome plated rods, offering a robust and reliable solution for various industrial applications.

Hard Chrome Plated Rods: Strength and Durability

Kamal Shafts' strong chrome-plated rods are well-known for their exceptional strength and durability. The chrome plating process produces a strong, wear-resistant surface that highly enhances the rods' long time. This makes them perfect for demanding industry in which friction, corrosion, and wear are primary concerns.

Kamal Shaft is a well-known brand for the variety of Hard Chrome Plated Rod manufacturers and suppliers:

LM Shaft (Linear Motion Shaft): These high-precision shafts are designed for use in linear bearings, ensuring smooth and accurate linear motion in various machines.

Honed Tubes: Kamal Shaft offers honed tubes with a meticulously smooth inner surface, which makes them excellent for industrial uses that need precise hydraulic cylinder performance.

Induction Hardened Rods: Through induction hardening, Kamal Shaft creates rods with a hardened outer surface for superior wear resistance, while maintaining a tough inner core for maximum strength.

Hard Chrome Plated Round Rods: This offering combines the benefits of both hard chrome plating and round rod, providing a versatile solution for various linear motion industry.

Kamal Shaft prioritizes quality throughout their manufacturing process. They utilize high-grade steel materials like mild steel, carbon steel, stainless steel, and galvanized steel. Their state-of-the-art technology and meticulous attention to detail ensure their products meet stringent global quality standards.

Need Hard Chrome Plated Rods at latest price? Get Superior Wear Resistance from Kamal Shaft

We offer high-quality hard chrome plated rods for superior wear resistance. Get a quote for the size and quantity you need! We also supply LM Shafts, Honed Tubes, Induction Hardened Rods, and more. Contact +91-83201-67484 for pricing information or visit- https://www.kamalshaft.in/

#hard chrome plated rod#chrome plated rod#hard chrome rod#induction hardened chrome bar#chrome rod for hydraulic cylinders#chrome plated rod manufacturers#hard chrome rod suppliers#hard chrome plated rod supplier#hard chrome plated rod in ahmedabad#chrome plated piston rod manufacturers

0 notes

Link

Kamal Shaft are hard chrome plated shaft supplier in Ahmedabad. Exporter of Chrome Plated Tube, Piston Rod , Chrome Plated Piston Rod Suppliers in Ahmedabad, Gujarat, India

#Hard Chrome Plated Shaft Suppliers#Hard Chrome Plated Shaft Manufacturer in Ahmedabad#Chrome plated Piston Rod Mnufacturere in Ahmedabad#Induction Harden Shaft Suppliers#Chrome plated Tube supplier#Induction Hardened Chrome Plated Shaft Suppliers

0 notes

Text

Glock 19 slide - Buy Glock 19 Pistol Slide - Glock 19 gen 3 slide - Glock 19 gen 5 slide - Top Glock 19 slide kit

Glock 19 slide needs Upgrade, your handgun’s performance and enhance its compatibility with popular optics by installing a TRYBE Defense Glock 19 Pistol Slide. These Pistol Slides & Slide Parts from TRYBE Defense are constructed from pre-hardened 416-R stainless steel and finished with a Cerakote coating that improves durability and resistance to corrosion and wear.

This TRYBE Defense Glock 19 Pistol Slide features an aggressive, grippy design for easier cocking and handling. Select the TRYBE Defense G19 Gen 3 Pistol Slide that’s right for you to improve your weapon’s handling, compatibility and aesthetics.

GLOCK 19 SLIDE

The innovators at TRYBE Defense have everything you need to complete your Glock 19 Slide, including a TRYBE Defense Glock 19 Slide Parts Kit , available both with or without a guide rod. You can also pick up TRYBE Defense Universal 9mm Compensator to reduce muzzle rise and sensed recoil. And to wrap up your build, TRYBE’s got your back with a TRYBE Defense Glock 19 Barrel. You’re going to need something to carry all that swag. Finish it off with a TRYBE Tactical Pistol Case to wrap your firearm in cushy, soft protection.

Get ready to JOIN. THE. TRYBE.

*The below information shows the screw sizes, which vary by Optic Cut:

Cover Plates – 6 X 32 X 1/4

RMR Cut – 6 X 32 X 7/16 (both sides)

DeltaPoint Cut – 6 x 32 x 3/4 (left) / 6 x 32 x 5/8 (right)

Venom/Viper Cut – 6 x 32 x 7/16 (left) / 6 x 32 x 3/8 (right)

Other design options available here.WARNING: California`s Proposition 65

Specifications for TRYBE Defense Glock 19 Pistol Slide:

Gun Make:GlockGun Model:Glock 19Caliber:9mm CaliberWidth:1 inFinish:Cerakote, Heat TreatedFabric/Material:416 Stainless Steel BilletReloading Caliber:9mm CaliberWeight:9 oz

Features of TRYBE Defense Glock 19 Pistol Slide:

- Constructed from 416R Stainless Steel hardened to 42-45 HRc after being heat treated

- Aggressive grippy design and multiple windows

- The RMR cut slides will also take a Trijicon SRO, Holosun 507C, or a Swampfox Kingslayer. The Viper cut slides will fit a Burris Fastfire II red dot. The DeltaPoint Pro cut slides will also take a Sig Romeo1 PRO, Sig Romeo Zero, JPoint, Shield RMS, or RMSc

- Rockwell Hardness: 42-45HRc

- Manufacture Method: CNC Machined

Just make us some cool guns," was Lenny's instruction, with little else for direction. With a fully customized Glock easily hitting 4 figures, it just shows the confidence he has placed in our Custom Shop creations.

Kate, our Custom Shop Manager, immediately sent out a request for suggestions for "cool" designs. Our employees from shipping and receiving, packaging, customer service and the retail trade threw all their contributions into the hat. Kate was literally inundated with color suggestions, slide cuts, sharing options and frame modifications

Glock 19 gen 5 slide

One suggestion stood out simply because we had never done it before.

"How about tiger stripes on a chrome slide?" was an exciting proposal from one of the stock market makers. It was exciting because GlockStore has done many camouflage patterns in CeraKote paint as well as Hydro graphic prints, but never in the metal finish on the slide.

Starting with Glock's flagship pistol, the Model 17, we sent it to our machine shop and had an RMR Red Dot sight mount cut into the slide. We chose to use the "co-witness" style so that the shooter could use iron sights if needed.

Our gunsmiths then removed the original factory finish to reveal the bare stainless slide. One of the brush makers polished the slide to a mirror finish and then we sent it out for our Hard Chrome finish. I'd like to tell you the rest of the details of how we created the amazing finish, but I've been sworn to secrecy and I like my job.

Many of our customers are competitive shooters who rely on our Pyramid Trigger to improve their speed and accuracy. Our adjustable Pyramid Trigger systems allow the shooter to choose the weight of their trigger pull, and the length of the trigger pull. This allows for faster follow-up shots as well as better accuracy because the shorter and shorter trigger pull will not "pull the pistol" off target.

Glock 19 slide kit

The 3.5 lb Double Diamond creates the lighter trigger pull. Binder and Competition Spring Kit, which are both included with the Complete and Ultimate trigger kits. Competition Springs include 2lb, 3lb, 4, and 6lb shock springs that allow the shooter to choose the pull weight from a factory 5.5-6lb down to a competition weight of 2lb.

We finished our Tiger Stripe Show Shot pistol with a Chrome Metallic Control Kit & Pins. This 7-part kit consists of a factory extended slide stop lever and an extended slide lock. Also included, a stainless locking block pin, trigger pin, and trigger housing pin…including the Gen3 and the (Gen4 long housing pin).

GlockStore offers this kit in our 8 CeraKote colors (Black, Chrome, Gold, Blue, Dull Dark World, OD Green, Pink and Red) as well as custom colors made to order on demand. We also added a Teardrop Extended Magazine Edition in Gold to match the finish.

Read the full article

0 notes

Text

Introduction to Wide Throat Progressive Cavity Pump

Wide Throat Progressive Cavity Pump (WTPCP) is a centrifugal pump that has a progressive cavity along with a wide throat and low shear. It is designed to handle difficult fluids and slurries with high solids content. It is the most efficient way to move liquids and solids because it can handle high viscosities without clogging. With this pump, you can move more products faster with less effort. Wide Throat Progressive Cavity creates a strong suction force to draw in the liquid which makes this pump perfect for moving thick or sticky products like honey, molasses, peanut butter, and other viscous liquids. It can also handle grainy or fibrous materials like cornmeal and flour with ease without damaging them or the pump.

This pump has a wide throat that allows large chunks to pass through without getting stuck. The progressive cavity design ensures that the material is moved smoothly and efficiently from beginning to end. Then the wide throat allows for easy passage of the fluid, while the low shear prevents damage to the fluid.

The WTPCP is also great for pumping viscous liquids with high solids content. Because of the wide throat and progressive cavity, this pump can handle these types of liquids without any problems. Wide Throat Progressive Cavity Pump in India are available in both electric and hydraulic versions, so they can be used in a variety of applications.

Component configuration

Wide Throat Progressive Cavity Pump consist of the following components as follows,

Wettable Housing can be made of materials like cast iron, cast stainless steel, fabricated steel, etc.

Stator

Rotor, commonly used material are alloy steel, stainless steel or few other kinds of steel/ material depending upon the use.

Coupling Rod and the shaft is commonly made from alloy steel or stainless steel

Other Exotic Materials such as duplex, super duplex, alloy 20, haste alloy

Rotor Surface Coatings are manufacture of ceramic coating, tungsten carbide, hard chrome plating, etc.

Protective Coatings: rubber lining, epoxy coatings.

Working of WTPCP

Wide Throat Progressive Cavity Pump in India employs the latest technology that helps in pumping viscous and shear sensitive fluids, it has a wide throat or inlet to accommodate large size particles. The pump operates by using an expanding and contracting cone-shaped eccentric rotor that moves within a stationary casing to create a pumping action. This action creates pockets of air and liquid which are drawn into the pump and expelled out the discharge port to the desired container or place

Advantages and Characteristics

Wide Throat Progressive Cavity Pump in India has plenty of advantages some of them are mention in the given list,

It’s self-priming rate is high.

A variety of installation positions are available.

It is possible to reverse the direction of rotation and, therefore, reverse the flow of delivery.

It is possible to handle suspensions with a high solids percentage without clogging a non-clogging system.

Inherently self-priming, it can be used to eliminate Snore

It’s NPSH(R) is low, can withstand high vacuum conditions, and is effective at high suction lift.

Due to the low internal velocity, products that are shear sensitive and abrasive are handled gentle and do not experience excessive internal wear.

Easily interchangeable: by simply switching the rotation direction of the prime mover, the suction and delivery ends can be interchanged.

For more information on Submerged P.C Pumps Supplier in Uttar Pradesh & Barrel Pumps Manufacturer in Uttar Pradesh , please visit : Deepa Pumps.

1 note

·

View note

Text

Ratchet Type / Low profile Hydraulic Torque Wrenches

THL serieTritorc s

The Torque of the Ratchet Type / Low profile Hydraulic Torque Wrench ranges from 230 Nm to 44600 Nm (180 Ft. lbs. to 33038 Ft. lbs) over 5 Models

High nickel alloy steel internal components

Weight of drive unit ranges from 1 kg to 11.4 kg (2.2 lbs to 25.3 lbs)

Weight of ratchet unit ranges from 1.6 kg to 30 kg (3.5 lbs to 66 lbs)

The Hydraulic Torque Wrenches use an Alloy steel high strength hydraulic cylinder

Technical Data

Units

THL-2

THL-4

THL-8

THl-14

THL-32

Min. Torque

Nm

230

240

575

640

1050

1160

1850

4100

4450

Max. Torque

Nm

2350

2420

5865

6480

10950

11780

18525

41890

44600

Min. Torque

Ft. Lbs.

180

176

400

474

777

860

1370

3038

3297

Max. Torque

Ft. Lbs.

1850

1784

4500

4800

8111

8726

13722

31030

33038

Across Flat

mm

19-55

55-60

34-65

70-80

41-95

100-105

50-117

110-155

160-175

Inch

3/4-2.3/16

2.3/16-2.3/8

1.5/16-2.9/16

2.3/4-3.1/8

1.5/8-3.3/4

3.7/8-4.1/8

2-4.1/2

4.1/4-6.1/8

6.1/8-6.7/8

Weight

Kg.

1

1

2

2

3.3

3.3

5.5

11.4

11.4

Drive Unit

Lbs.

2.2

2.2

4.4

4.4

7.2

7.2

12.1

25.3

25.3

Weight

Kg.

1.6

1.7

4.4

4.6

8

8.4

11.6

29

30

Ratchet Unit

Lbs.

3.5

3.7

9.6

10.1

17.6

118.4

25.5

63.8

66

A Compact Tool -

Designed from scratch as a tool for operating in constricted spaces, the tool has features such as a small nose radius to make accessing these tight spaces easy.

A Rugged Tool -

The tool is designed to operate in tough conditions, the following features help it achieve the same

The cylinder bore in which the piston travels is cold worked, this ensures that the metal crystal structure allows for continuous heavy-duty use.

The piston itself has hard chrome plating and thus can also bear wear and abrasion

Self-lubricating low Nickel Bronze is used for the drive bush to protect the body from wear.

High pressure sustaining seals keep the Hydraulic Torque Wrenches leak resistant.

A slider prevents wear of piston and drive plate

Stable Tool Operation -

An alignment pin ensures that the ratchet link and cylinder drive unit are connected and the loads exerted on the side plate are balanced

The reaction pad is torsion-free

The drive pawl does not lock and operates for the designed purpose without jamming

The rod engages in the first stroke thus removing any backlash

The ratchet and pawl have a finer tooth for better engagement and torquing

Operator Convenience -

The hydraulic hose coupler can swivel in an arc of 1800 X 3600

The quick connectors for the hydraulic lines are leak-resistant for safety even under pressure

Accessories available -

Spanner holder - an alternative tool for the ratchet link that allows for using accessories such as an open head end and ring-type head spanners.

Hex Reducer

Hex to square drive adaptor

Extended reaction arm

Low point reaction pad

Stack socket

Spider-pattern Features:-

Cold worked cylinder bore: The cylinder bore in which the piston travels is cold worked, this ensures that the metal crystal structure allows for continuous heavy-duty use.

Chrome Plated Piston: The piston itself has hard chrome plating and thus can also bear wear and abrasion

Drive Bush: Self-lubricating low Nickel Bronze is used for the drive bush to protect the body from wear.

Swivelling coupler: The hydraulic hose coupler can swivel in an arc of 1800 X 3600

No lock Drive Pawl: The drive pawl does not lock and operates for the designed purpose without jamming

Drive Plate: The drive plate is made of durable alloy steel and is of slim dimension to fit within the low profile torque wrench.

How does Tritorc ensure that the components manufactured have high strength for the application desired?

Answer: The drive components of the Hydraulic Torque Wrenches are made of alloy steel and are heat treated in a controlled vacuum heat treatment process thus increasing their strength and durability.

How does one lift the tool without having to hold the main body?

Answer: There is a provision for a lifting handle to manually transport the tool and eye bolts are available for bigger tools.

Is there any accessory apart from the reaction arm that is available with the tool?

Answer: The splined shaft allows the fitting of an Extended reaction arm, low point reaction pad apart from the default reaction arm. The reaction arm is fitted on the body with a simple quick-release connecting pin allowing quick switch over while fastening and unfastening bolts.

What are various socket types that come with the tool?

Answer: Several tool inserts like Spanner holder - an alternative tool for the ratchet link that allows for using accessories such as an open head end and ring-type head spanners, Hex Reducer, Hex to square drive adaptor and stack sockets are available for a flexible use profile.

Does Tritorc offer any warranty or after sale service?

Answer: Yes Tritorc offers a 1 year warranty for mechanical components against manufacturing defects and after sales services are available worldwide*

0 notes

Text

This is an unconventional accident damage

This method is generally processed and repaired by a professional spray factory, and the cost is still relatively low. Increase the diameter of the barrel due to wear. Also depends on the ratio of repair costs to screw time and renewal costs after repair and updated screw usage time. This phenomenon causes the residence time of the material in the barrel to increase, causing the material to decompose. 3. It is economical to adopt a scheme with a small ratio and is the right choice. Therefore, after the wear of these two parts is repaired or replaced with new ones, it must be comprehensively analyzed from an economic perspective. Under normal circumstances, the homogenization section of the barrel wears faster. If there are fillers such as calcium carbonate and glass fiber in the material, it can accelerate the wear of the screw and the barrel. Since the material is not plasticized evenly, or metal foreign matter is mixed into the material, the torque of the screw is suddenly increased. This section (take 5~7D length) can be trimmed by the boring hole, and then a nitriding alloy steel bushing is used. It is emphasized here that the two important parts of the screw and the barrel are an elongated threaded rod and a small diameter and long hole.

Their quality of work is related to the manufacturing precision and assembly clearance of the two parts. The screw rotates in the barrel, and the friction between the material and the two causes the working surface of the screw and the barrel to wear gradually: the diameter of the screw is gradually reduced, and the diameter of the inner hole of the barrel is gradually increased. Professional surfacing plants have a high cost for such processing, and are rarely used except for special requirements.. 2. Surfacing the wear-resistant alloy on the threaded portion of the wear screw. 4, screw and barrel manufacturing materials to manufacture screws and barrels, the current domestic commonly used materials are 45, 40Cr and 38CrMoAlA. New screw. This torque exceeds the strength limit of the screw, and the screw is broken. Third, the inner surface of the barrel of the repair cylinder is harder than the screw, and its damage is later than the screw. 4, repair screw can also be surface hard chrome plating method, chromium is also wear-resistant and corrosion-resistant metal, but the hard chrome layer is easier to fall off. 3. . 2. The scrapping of the barrel is such that the diameter of the inner diameter increases due to time wear. The manufacturing materials of the screw and barrel in the imported extruder, commonly used alloy steel are 34CrAINi7 and CrMoV9. The yield strength of this material is about 900 MPa. However, since the resistance of the front head and the splitter plate of the barrel is not changed, this increases the leakage flow when the extruded material advances, that is, the amount of material flowing from the diameter gap to the feed direction increases. Depending on the degree of wear of the screw, weld 1 to 2 mm thick and then grind the screw to size. Thus, the matching diameter gap between the screw and the barrel increases little with the PET mould manufacturer gradual wear of the two.

The inner diameter of the barrel is machined and trimmed to recast the alloy, the thickness is between 1~2mm, and then finished to the size. This wear-resistant alloy consists of materials such as C, Cr, Vi, Co, W and B, which increases the anti-wear and corrosion resistance of the screw. After the surface of the thread with the reduced diameter of the wear screw is treated, the wear-resistant alloy is thermally sprayed and then ground to a size. First, the cause of damage to the screw and barrel 1. Its repair method is as follows: 1. . If there is a certain nitriding layer, the inner hole of the barrel can be directly bored, ground to a new diameter size, and then prepared according to this diameter. 3. If the repair cost is lower than the replacement screw cost, it is decided to repair, this is not necessarily the correct choice, the comparison of repair costs and update costs is only one aspect. After nitriding treatment, the hardness is above 1000 HV, which is both wear-resistant and has good corrosion resistance. As a result, the extruder production is reduced. Normally fit the gap and process and prepare. The diameter of the inner hole is referenced to the diameter of the screw. 2. In the case of polyethylene, the decomposition of the gas increases the corrosion of the screw and barrel.Introduction to the causes of the screw and barrel of the extruder and the repair methods

The combined work quality of the two parts, the screw and the barrel, has an important influence on the plasticization of the material, the quality of the product and the production efficiency. This is an unconventional accident damage. Second, the repair of the screw 1, the broken screw should be considered according to the actual inner diameter of the barrel, according to the normal gap with the barrel gives the deviation of the outer diameter of the new screw for manufacturing. When the two parts are seriously worn and the output of the extruder is reduced, the maintenance of the screw and the barrel should be arranged. The machining and heat treatment processes are complicated and the precision is difficult to guarantee

1 note

·

View note