#High-Speed Tablet Production Line

Explore tagged Tumblr posts

Text

Pharmaceutical Tablet Production Line

Sieving, Blending, Milling, Drying, Granules Forming, Lubrication, Tablet Compression, and Tablet Blister Packaging Machines are all part of the Pharmaceutical Tablet Production Line (Tablet Processing Line), which includes the Tablet Manufacturing Line. Both dry and wet granulation tablet compression lines are available from us. Every machine satisfies cGMP standard production specifications. The Adinath series provides both a High-Speed Tablet Production Line and a Small Production Tablet Line.

Tablet Production Process

Compressed powdered, crystalline, or granular active materials (API) can be used alone or in combination with other exponents as needed, such as lubricants, diluents, flavors, and colorants, binders, disintegrants, and prolonged release polymers, to make tablets. Wet granulation, dry granulation, and direct compression are the three main processes that make up the tablet production process. The process you should choose depends on the type of product you are manufacturing. We have included detailed information on each of the three tablet production processes below:

#Tablet Blister Packaging Machines#Tablet Processing Line#Tablet Manufacturing Line#granulation tablet compression lines#High-Speed Tablet Production Line#Small Production Tablet Line

0 notes

Text

Mass Effect Lore: Common technologies in the 2180‘s (Part 2)

This post is both a collection of canon technologies in the Mass Effect universe, and personal headcanon which may be borrowing common concepts from sci fi.

Infrastructure:

Autonomous public transportation vessels of all sorts. As seen with the tram on Noveria. Trains, buses and cabs are also autonomous. Rude bus drivers, trains and buses being cancelled or too late are problems of the past.

Some of those buses and cabs drive on land; others are flying vessels that travel through the sky.

Trains travel at immense speed, with most trains being able to travel at least 1000km/h. Low pressure tunnels allow for this level of speed.

Suspension railways are a common means of public transportation and are widely featured all across the galaxy on various space station, colonies and in most Earth countries. This also includes maglevs (magnetic levitation trains).

Cities commonly not only feature terminals providing rentable e-bikes, e-scooters or even e-rollerblade, but also rent flying hoverboards.

Medicine & Health:

Needles have become obsolete. Technologies akin to Star Trek's hypospray have replaced them. (This contradicts with Mordin's line in ME3: „Fear of needles. Common phobia." I know.)

Genetic therapy has advanced so far as to being able to cure almost any genetic disease. (Book canon).

Cybernetics can fix deafness and blindness.

(Canon implied, I believe?)

Advancement in technology and medicine have slowed down human aging significantly. Women can have healthy children in their sixties. (Book canon). Anti aging therapies and cybernetics can allow humans to reach ages of up to 250 years.

Education:

Paper and pens being used in schools is a thing of the past. Students use tablets (which are made of ultra-light also foldable) with either keyboards or tablet pens for handwritten notes.

(Book canon implied - Gillian uses a computer to work on her assignments in Mass Effect:

Ascension).

Some teachers and students would prefer to have their textbooks in form of super light datapads (like e books) rather than have them all digitally stored on their computer.

Learning programs are highly advanced and VI‘s provide students with custom tailored, individualized exercises and study plans and games.

Food:

Liquid food drinks, nutrient pastes and bars that replace entire meals are available just about everywhere. With biotics burning huge amount of calories, the asari have perfected such products. Being cheaper than freshly cooked take out meals and coming in all sorts of flavors and textures, such nutrient pastes proved to be a saving grace for poorer individuals. Some poor people nearly only eat 3D printed nutrient paste, which does not have the same feeling as eating real meals, but nutrient paste in Mass Effect is of such high quality that it provides the body with all nutrients it needs while being free of unhealthy ingredients.

People-prepared foods (by humans/aliens) are still appreciated, but many foods available in grocery stores are 3D printed. Cafés tend to feature feature people-prepared foods. A café selling 3D printed cakes for instance would be looked down upon.

Synthetic flavors have been perfected. While technology has been advanced to the point where you could grow strawberries on Omega without issues (using environmental control systems in a hydroponic bay), the ultimate cheapest way to replicate the flavor is using synthetic ingredients. This way, you can find foods of any flavor, no matter what exotic fruit from Palaven or Khar'Shan it might be, anywhere.

Sugar free snacks and candy are as common as the sugar variants. Ice cream cates feature sugar free ice cream options. Sugar free chocolate or cookies are available at any grocery store.

Various synthetic ingredients are used to replace sugar.

Lab grown meat is incredibly common (canon) and meat from Earth animals found on space stations is grown from animal stem cells.

Home:

Significantly less time is spent on chores due to robots doing most of the work. With floor wiping and vacuum robots being affordable for middle class people in the 21st century, in the 22nd, the majority of cleaning is done by robots in a middle class household. Advanced kitchen aid machines are found in most households and make cooking less time consuming and complicated for most people.

Blinds, curtains, light, air filtration systems, thermal regulation systems (air conditioning or heating systems) and television are typically navigated via a voice command (for example, „Light on“ or „Television off).

Holographic home ambiences like in Cyberpunk 2077 are common. Windows can be made to look like they‘re displaying a galaxy full of stars via holographic projections. Some people use those home ambience holographs to create the appearance of a luxurious club lounge, or to project beautiful landscapes into a corner of their room.

Personal Care:

Like in Star Trek, sonic showers can be used to clean the body effectively. Ultrasonic vibrations remove dirt, bacteria, excess oil and dead skin cells without requiring soap or water. While more expensive than typical showers, the use of sonic showers saves water. This sort of technology is found within quarian environmental suits. Drell with Kepral's Syndrome generally use sonic showers rather than water showers.

In addition to having an inbuild shower function, quarian environmental suits are equipped with a dental hygiene program that cleans the teeth and mouth of the wearer effectively using ultrasonic vibrations.

Certain suit upgrades can even use nanobots to moisturize the body.

Toothbrushes are also generally sonic toothbrushes that use the same technology as showers do; ultrasonic vibrations.

Clothes are typically self-cleaning with nanoparticles that kill bacteria and prevent the build up of odor.

43 notes

·

View notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Power up your Smartphone anywhere, anytime with bArrett 2.4A portable USB Charger. It is compatible with most Smartphones and is your perfect companion in providing your Smartphone with required charging and it is your perfect companion in providing your Smartphone with required charging. Constant voltage charging mode for safe usage. Compact and light weight for ease of convenience to carry around.Universally compatible: works with all phones and tablets. Smart charge: auto detects the connected device and charges it at the fastest speed of the device up to 2. 4A indian connectors: the indian connects allow you to plug the wall charger into a socket and charge without having to use an adapter. Connector independent: works with micro usb, lightning and type c cables all round safety: built in over-voltage / over current / short circuit and surge protection unit so you never have to worry about your device. PRODUCT FEATURES: PRODUCT FEATURES: FLASH CHARGING: Equipped with Flash Charging, you can rest easy knowing that all your devices are getting juiced at maximum speeds. All Round Safety: In- Built safety checks like voltage, temperature and current control, protects your connected device from damage due to inconsistencies in the power output. Indian Connectors: Made for Indian sockets, the wall charger lets you plug in without the need for an adapter And Over-current, Short-circuit and Over-temperature protect your device Smart Charge: Auto Detects the connected device and charges it at the fastest speed of the device Multi-Protection: It provides exclusive surge protection, short circuit prevention, temperature control, and more to deliver unbeatable protection to you and your devices Premium-Design with Compact-Size: High-gloss detailing and comfort grip design gives a sleek look to this powerful device. ★EXCLUSIVE TECHNOLOGY: India's smallest charger with 2.4 amp power supply. ★ Exclusive quick charge technology automatically detects and delivers the optimal charging current for any connected device - ensuring the quick and most efficient charge. ★ Small & Lightweight: Slightly heavier than simply slip it into bag when you are out and about. ★ SMART CHARGE: Auto Detects the connected device and charges it at the fastest speed of the device. ★INDIAN CONNECTORS: Made for Indian sockets, the wall charger lets you plug in without the need for an adapter And Over-current, ★ Short-circuit and Over-temperature protect your device. ★ Multiple Protections : Over-current, Short-circuit and Over-temperature protect your device, Auto Cut : On Over Heat. ★ Adaptive Fast Charging Technology & Slim and Compact Design, Over Current and Over Voltage Protection. ★FIRE-RESISTANT: Hardened plastic outer shell for durability, built-in premium circuitry and microchip ensure device safety. ★ Triple Lays Protection Built-in 3 layers anti-interference films, ensure this line works well when you use it. ★ Smart Charge: Auto Detects the connected device and charges it at the fastest speed of the device. ★ Small & Lightweight: Slightly heavier than simply slip it into bag when you are out and about. ★GOOD CHARGING SPEED : Most Powerful - Charge any V8 USB powered devices at top speed continuously. ★ Quick Charge & Data Transmission ★ V8 USB support fast charge (5V/3A) and sync data simultaneously at a rapid speed, ★ save you time. Safe & Durable 24 awg wire, built-in identification resistor (56kΩ resistor for safety) & premium PVC coated make it dependable and sturdy enough for everyday use, save your money. ★COMPATIBLE WITH: Android and Windows phones, tablets and many other Micro Usb devices including Samsung / Nexus / HTC / Motorola / Nokia / LG / Sony / OnePlus / Blackberry / PS4 / Kindle / Xbox / PS Vita / DS / GPS devices / battery packs / bluetooth speakers / wireless keyboards / cameras / camcorders / games consoles / hard drives / e-readers / printers and Micro Usb Compatible devices. Only From bArrett

0 notes

Text

Why Tablube® is the Go-To Pharma Excipient for Efficient Tablet Manufacturing

In the world of pharmaceuticals, consistency, quality, and performance are non-negotiable—especially when it comes to tablet manufacturing. That’s where Tablube®, a premium-grade tablet lubricant, stands out. Manufactured by Nitika Pharmaceutical Specialities Pvt. Ltd., Tablube® is designed to meet the demanding needs of modern pharma production with efficiency, safety, and precision.

If you’re a pharmaceutical manufacturer or buyer seeking reliable solutions for smooth tablet production, this blog will show you why Tablube® is becoming a preferred choice across the industry.

What is Tablube®?

Tablube® is a high-performance pharmaceutical excipient developed specifically for tablet manufacturing. It’s used as a lubricant to prevent tablets from sticking to punches and dies during compression, making the process faster, cleaner, and more cost-effective.

Compared to traditional excipients like Magnesium Stearate IP, Tablube® offers consistent results and improved processability, all while maintaining the integrity of the active ingredients.

Key Features & Benefits of Tablube®

Excellent Lubrication Efficiency Tablube® reduces friction during tablet compression, ensuring smooth ejection and preventing mechanical wear on equipment.

Improved Blend Uniformity It distributes evenly throughout the formulation, eliminating common issues like sticking or uneven mixing.

Enhanced Tablet Quality Tablube® helps produce tablets with uniform weight, good hardness, and smooth surfaces — essential for both functionality and appearance.

Compatible with Various APIs This excipient is designed to work well with different types of active ingredients, ensuring broad formulation compatibility.

Optimized for High-Speed Production In fast-paced manufacturing environments, Tablube® supports seamless production without frequent stoppages.

Applications of Tablube® in Pharma

Tablube® is primarily used in tablet and capsule formulations across a wide range of therapeutic categories. Its role is critical in ensuring:

High-speed manufacturing without breakdowns

Minimal product waste

Improved product uniformity and patient compliance

Whether you’re formulating vitamins, antibiotics, or pain relievers, Tablube® can be a reliable partner in your production line. As a tablet lubricant manufacturer in India, Nitika ensures that every batch of Tablube® is quality-checked and compliant with international standards.

Why Tablube® is a Smarter Choice

When compared to conventional lubricants like Magnesium Stearate IP, Tablube® offers enhanced processing benefits without compromising tablet quality or drug efficacy. Its formulation has been optimized through years of R&D and is trusted by pharmaceutical excipient users worldwide.

Choosing Tablube® also means partnering with a manufacturer committed to technical support, regulatory compliance, and customer satisfaction — all backed by Nitika’s reputation in the industry.

Ready to Upgrade Your Formulations?

If you're seeking a lubricant that improves efficiency, reduces formulation risk, and supports scalable production, Tablube® is your solution.

Let’s Talk Quality and Performance 📞 Nitika Pharmaceutical Specialities Pvt. Ltd. 🌐 https://nitikapharma.com 📧 [email protected] 📱 +91 7122554812

#Magnesium Stearate#Pharma-grade Magnesium Stearate#Tablet lubricant#Tablet binder#Pharmaceutical excipients#Tablube Magnesium Stearate#Magnesium Stearate manufacturer in India#Nitika#Nitika Pharma#Nitika Pharmaceutical#Nitika Pharmaceutical Specialities Pvt Ltd#Tablube

0 notes

Text

Understanding Board-to-Board Connectors

In the world of electronic hardware, where space, speed, and signal integrity define performance, board-to-board connectors are critical components that quietly enable innovation. These specialized connectors join printed circuit boards (PCBs) directly without the need for cable assemblies, supporting compact, high-performance electronic designs used in everything from smartphones and laptops to industrial machinery and aerospace systems.Get more news about Board-to-board Connector,you can vist our website!

What Are Board-to-Board Connectors? Board-to-board connectors are designed to provide reliable electrical and mechanical connections between two or more PCBs within a device. Unlike wire-to-board or cable-based systems, these connectors allow signal and power transmission through directly mated interfaces, which helps reduce bulk and improve data integrity. They are essential for stackable or modular designs and are particularly favored in applications where internal space is limited.

Types and Configurations These connectors come in several configurations depending on the orientation and spacing needs:

Parallel (Mezzanine) Connectors: Used when two boards are stacked vertically. These are common in compact electronic devices and offer high-density signal transmission.

Coplanar Connectors: For side-by-side board connections, maintaining the same plane and allowing broader layout designs.

Right-Angle Connectors: Used when a 90-degree connection is required between boards, useful in folded or L-shaped PCB assemblies.

Pitch (the spacing between pins), stack height, current rating, and number of contacts are customizable depending on application requirements. High-speed data connectors often require shielding and controlled impedance to prevent signal loss and crosstalk.

Key Features and Advantages Modern board-to-board connectors are engineered for precision and durability. Key features include:

Miniaturization: Compact design supports smaller electronic devices.

High-Density Pin Configuration: Enables transmission of large volumes of data and signals.

Durability and Reliability: Designed for multiple mating cycles and resistance to shock and vibration.

High-Speed Signal Transmission: Particularly in designs requiring signal integrity for data communication or computing.

Manufacturers also offer versions with alignment guides, locking mechanisms, and surface-mount or through-hole mounting options, ensuring seamless assembly even in automated production lines.

Applications Across Industries Because of their versatility and performance, board-to-board connectors are used in a wide range of industries:

Consumer Electronics: Smartphones, tablets, laptops, and wearables.

Industrial Automation: PLCs, sensors, and motor controllers.

Medical Devices: Diagnostic imaging machines, patient monitors, and handheld tools.

Automotive: Advanced Driver Assistance Systems (ADAS), infotainment, and battery management systems in EVs.

Aerospace and Defense: Flight systems, navigation equipment, and satellite electronics.

As electronics become smarter and more integrated, the demand for connectors that balance power, data throughput, and mechanical integrity has never been higher.

Innovation and Market Outlook The global board-to-board connector market is expected to grow steadily, driven by trends such as miniaturization, 5G deployment, IoT integration, and automation. Emerging materials and manufacturing techniques—like laser welding and micro molding—are allowing for even smaller, faster, and more durable connectors.

Asian countries, particularly China, South Korea, and Taiwan, dominate production, but leading global manufacturers like Samtec, TE Connectivity, and Hirose Electric continue to drive innovation with proprietary designs optimized for high-speed and harsh-environment applications.

Conclusion Board-to-board connectors might not be visible to end users, but they are indispensable to modern technology. As we continue to demand more from our devices—in performance, portability, and connectivity—these small yet powerful components ensure that everything works as one cohesive system. Their evolution mirrors our own digital advancement: quietly essential, endlessly adaptable, and critical to progress.

0 notes

Text

How Vibro Motors Improve Efficiency in Industrial Automation

How Vibro Motors Improve Efficiency in Industrial Automation

The manufacturing and industrial sectors are continuously evolving, driven by technological advancements that enhance productivity, reduce downtime, and optimize costs. One such innovation that has significantly contributed to industrial automation is the vibro motor. These powerful, precision-engineered motors play a crucial role in various industrial applications, offering efficiency, reliability, and cost-effectiveness.

In this comprehensive guide, we will explore how vibro motors work, their key applications, benefits, and why JK Industries, a leader among Vibro Motor Manufacturers in India, is at the forefront of this revolution.

Understanding Vibro Motors and Their Mechanism

A Vibro Motor, also known as a vibratory motor, is an electric motor designed to generate mechanical vibrations. It achieves this by rotating eccentric weights attached to both ends of the motor shaft, creating centrifugal force. This force induces vibrations, which can be harnessed for various industrial applications.

Key Features of Vibratory Motors:

Compact and robust design for heavy-duty applications

Low maintenance with high durability

Variable frequency and amplitude settings

Energy-efficient operation

Customizable options for specific industrial needs

Applications of Vibro Motors in Industrial Automation

The adaptability of vibratory motors makes them indispensable across numerous industries. Here are some of the primary applications:

1. Material Handling and Conveying

Industries such as mining, construction, and agriculture rely on Vibro motors to power vibratory feeders and screens. These motors facilitate the efficient movement of bulk materials, preventing blockages and enhancing throughput.

Mining Industry: Vibratory screens separate minerals based on size, improving sorting efficiency.

Construction: Vibrating conveyors transport cement, sand, and other materials efficiently.

Agriculture: Used in grain processing plants for sorting and grading.

2. Food Processing Industry

In food production, vibratory motors enable precise movement and handling of food products without causing damage.

Ensures uniform distribution of food particles in processing lines

Helps in quality control by removing unwanted elements

Used in vibrating sieves for separating contaminants from food products

3. Pharmaceutical & Chemical Industries

Precision and contamination-free processing are critical in the pharmaceutical and chemical sectors. Vibratory motors help maintain stringent quality control standards.

Used in tablet coating machines for uniform application

Facilitates precise powder mixing and sieving

Enhances drying processes by evenly distributing chemicals

4. Packaging Industry

In automated packaging systems, vibro motors help streamline the movement of goods on conveyor belts, ensuring accurate positioning, filling, and sorting.

Ensures even distribution of products in containers

Reduces spillage and packaging errors

Speeds up automated sorting and packing lines

5. Concrete Compaction

Construction sites extensively use vibratory motors in concrete compactors, which help remove air voids and improve the density of concrete structures.

Enhances the structural integrity of concrete

Reduces the likelihood of cracks and defects

Improves the longevity of buildings and infrastructure

Benefits of Incorporating Vibro Motors in Industrial Automation

1. Enhanced Operational Efficiency

By integrating vibratory motors into automation systems, industries can achieve faster and more precise operations. These motors facilitate consistent movement and sorting, significantly reducing manual intervention and labor costs.

2. Energy Efficiency and Cost Savings

Modern vibro motors consume less energy while delivering optimal performance. Their efficient design reduces power wastage, leading to lower operational costs and sustainable manufacturing.

3. Improved Precision and Quality Control

The ability to control vibration frequency and amplitude allows for precise handling of materials, ensuring uniform quality and reducing defects.

4. Reduced Downtime and Maintenance Costs

Designed for continuous operation under tough conditions, vibratory motors require minimal maintenance. Their durable construction ensures long service life, reducing unplanned downtime.

5. Versatility Across Industries

From mining to food processing and pharmaceuticals, vibratory motors can be adapted for a wide range of industrial applications, making them a valuable investment for businesses.

JK Industries: Leading the Vibro Motor Revolution in India

When it comes to sourcing high-quality vibratory motors, JK Industries is a trusted name among Vibrator Motor Manufacturers in India. With decades of experience, JK Industries has established itself as a leader in providing reliable and innovative vibration solutions.

Why Choose JK Industries?

Cutting-Edge Technology: Implements the latest advancements in vibration engineering to develop high-performance motors.

Custom Solutions: Offers tailored vibro motors to meet specific industrial requirements.

Superior Durability: Designs motors with high-grade materials for extended lifespan.

Energy-Efficient Designs: Focuses on reducing power consumption without compromising performance.

Exceptional Customer Support: Provides expert guidance for selecting the right motor for your application.

How to Select the Right Vibro Motor for Your Industrial Needs

Choosing the right vibratory motor depends on several factors, including:

1. Application Type

For bulk material handling: High-capacity vibratory motors with adjustable speed.

For food or pharmaceutical use: Hygienic, stainless steel motors with precise control.

For concrete compaction: Heavy-duty motors with high-frequency vibration.

2. Vibration Intensity & Frequency

Low-frequency motors are ideal for coarse materials.

High-frequency motors work best for fine materials and precision applications.

3. Power and Load Capacity

Ensure the motor has adequate power to handle the required load without excessive wear.

4. Environmental Conditions

Consider factors like temperature, humidity, and exposure to chemicals when selecting a motor.

5. Mounting and Installation Requirements

Choose motors that align with your existing system for easy installation and minimal modifications.

Future Trends in Vibro Motor Technology

The field of vibratory motors continues to evolve, with innovations focused on enhancing efficiency and performance. Some key trends include:

Smart Vibration Technology: Integration of IoT-enabled sensors for real-time monitoring and predictive maintenance.

Eco-Friendly Motors: Development of energy-efficient motors with reduced carbon footprint.

Advanced Material Engineering: Use of lightweight, high-durability materials to enhance motor lifespan.

0 notes

Text

Bottle Capping Machine: The Ultimate Guide to Efficient and Secure Bottling

What is a Bottle Cap Sealing Machine?

A bottle cap sealing machine (also known as a bottle capping machine) is designed to seal caps or closures onto bottles of various shapes and sizes. These machines ensure a consistent, tight seal that prevents leaks, contamination, or tampering. They are used in both manual and fully automated production lines, depending on the scale and speed required.

From screw caps to flip-tops and aluminum ROPP (Roll-on Pilfer Proof) caps, these machines handle them all with accuracy, speed, and repeatability.

Types of Bottle Cap Sealing Machines

1. Manual Bottle Capping Machines

Ideal for low-volume production

Simple hand-press or torque-based designs

Used by startups and small-scale operations

2. Semi-Automatic Cap Sealing Machines

Operator places the cap; machine seals it with consistent torque

Increases productivity and accuracy

Suitable for SMEs

3. Automatic Bottle Cap Sealing Machines

Fully automated cap placement and sealing

Integrated with bottle filling lines

Designed for high-speed mass production

4. ROPP Cap Sealing Machines

Specifically for aluminum roll-on caps

Common in wine, liquor, and pharmaceutical industries

5. Induction Cap Sealing Machines

Uses electromagnetic induction to heat and bond foil seals inside caps

Provides tamper-evident and leak-proof sealing

Essential in food, pharma, and chemical applications

6. Screw Capping Machines

Applies threaded screw caps

Compatible with plastic or metal caps

7. Lug Capping Machines

For twist-off caps, mainly used in food jars like pickles and sauces

Applications of Bottle Cap Sealing Machines

Pharmaceutical Industry

Air-tight, tamper-evident caps for syrups, tablets, and tonics

Ensures product safety and regulatory compliance

Food & Beverage

Bottling of juices, sauces, mineral water, milk, oils

Prevents spoilage and leakage

Cosmetics & Personal Care

Bottles for shampoos, lotions, perfumes

Demands aesthetic as well as secure seals

Chemical & Agrochemical

Bottling of detergents, cleaners, pesticides

Requires leak-proof and resistant sealing

Core Features of High-Performance Cap Sealing Machines

1. Adjustable Torque Control

Ensures caps are neither too tight nor too loose

Prevents spillage, breakage, or product damage

2. High-Speed Capping

Cap sealing rate from 30 to 300 bottles per minute, depending on machine type

3. Automatic Cap Feeding System

Vibratory bowl or cap elevator for continuous cap supply

4. PLC-Based Operation

Intuitive touch panel for setting speeds, torque, and diagnostics

5. Changeover Flexibility

Quick adjustments for different bottle shapes or cap sizes

6. Stainless Steel Construction

Rust-proof, durable, and compliant with hygiene regulations

Benefits of Using a Bottle Cap Sealing Machine

Leak-Proof Packaging: Prevents product loss during transport or storage

Tamper-Proof Seals: Especially critical in pharmaceuticals and food

Speed and Consistency: Uniform torque and sealing reduce rejection rates

Reduced Labor Costs: Automation cuts manual handling

High Production Output: Meets increasing market demands

Regulatory Compliance: Helps meet standards like FDA, ISO, FSSAI, WHO-GMP

0 notes

Text

Technological Advancements Boost Global LVDS Interface IC Market

According to a comprehensive industry analysis, the global Low-Voltage Differential Signaling (LVDS) Interface IC Market was valued at USD 545.8 Mn in 2022 and is projected to reach USD 885.0 Mn by 2031, growing at a CAGR of 5.5% during the forecast period (2023–2031). This growth is attributed to the surge in demand for high-speed, low-power data communication in sectors such as automotive, consumer electronics, industrial automation, aerospace, and defense.

Market Overview

Low-Voltage Differential Signaling (LVDS) is a high-speed, low-power data transmission standard widely used in video displays, automotive systems, telecommunications, and industrial automation. LVDS Interface ICs enable rapid data exchange while minimizing electromagnetic interference and power consumption.

Its advantages such as low noise, energy efficiency, and high transmission rates make it a preferred choice for OEMs and system integrators across applications like LCD displays, notebooks, telecom infrastructure, and automotive infotainment.

Market Drivers & Trends

Industrial Digitization: Increased adoption of Industry 4.0 technologies has driven demand for robust and high-speed communication systems. LVDS Interface ICs are ideal for robotics, factory automation, and data acquisition systems, thanks to their noise immunity and long-distance transmission capabilities.

Automotive Innovation: The proliferation of ADAS, infotainment, and vehicle-to-vehicle (V2V) communication systems in modern vehicles is creating a rising demand for LVDS SerDes (serializer/deserializer) ICs. These components enable seamless onboard communication, improving vehicle safety and performance.

Consumer Electronics Growth: The increasing complexity and demand for high-resolution displays in TVs, tablets, monitors, and medical imaging devices is pushing OEMs toward LVDS for its high bandwidth and signal integrity.

Latest Market Trends

Integration of Full-HD SerDes in Vehicles: In October 2022, ROHM Semiconductor introduced full-HD compatible SerDes ICs for vehicle displays, supporting enhanced infotainment and driver assistance experiences.

Regulatory Push for Safety: Compliance with mandates such as the NHTSA rear-view camera requirement in the U.S. is spurring OEMs to adopt LVDS transceivers to enhance visibility and safety features in vehicles.

Rise of Smart Manufacturing: LVDS ICs are seeing strong adoption in machine vision systems, enabling precise quality checks and operational efficiency in production lines.

Key Players and Industry Leaders

The LVDS Interface IC market is consolidated with a strong presence of global semiconductor giants. Key players include:

Texas Instruments

Analog Devices/Maxim Integrated

Microchip Technology

onsemi

Diodes Incorporated

NXP

Renesas Electronics

STMicroelectronics

Rohm Semiconductor

THine Electronics

ams AG

Skyworks Solutions, Inc.

Kinetic Technologies

These companies invest heavily in R&D to develop next-gen LVDS solutions with higher data rates, lower power consumption, and broader compatibility.

Download to explore critical insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=83539

Recent Developments

STMicroelectronics, in March 2022, launched radiation-hardened LVDS ICs for budget-sensitive satellite applications, targeting the emerging ‘New Space’ sector.

THine Electronics, in 2018, collaborated with a leading Chinese automaker to provide image transmission LSIs for a compact SUV’s Center Information Display (CID), solidifying its footprint in the automotive sector.

Market Opportunities

Emerging Automotive Tech: The rise of EVs and autonomous vehicles presents new opportunities for LVDS interfaces in high-resolution camera systems, radar, and LiDAR data integration.

Healthcare Electronics: Growing demand for medical imaging and diagnostic systems with real-time data exchange is creating new application areas for LVDS SerDes solutions.

Telecommunication Infrastructure: The deployment of 5G and edge computing is set to boost the need for high-speed, interference-resistant data transmission, benefiting LVDS IC manufacturers.

Future Outlook

Looking forward, Asia Pacific is expected to dominate the LVDS interface IC market, led by countries such as China, Japan, South Korea, and Taiwan. These nations are home to many electronics manufacturers and are experiencing rapid growth in automotive electronics, smartphones, and consumer appliances.

Meanwhile, North America and Europe are projected to show stable growth due to increasing investments in automotive innovation, aerospace, and advanced manufacturing.

Key challenges that may impact growth include intense competition from alternate interface technologies such as MIPI, HDMI, and USB, as well as the constant need for cost-competitive solutions.

Market Segmentation

By Type:

LVDS Serializer and Deserializer

LVDS Repeater

LVDS Buffer

LVDS Transmitter

LVDS Receiver

By Application:

Backplane

Clock Distribution

LCD/LED Display

PC/Notebook/Tablet

Printer/Scanner

Telecom Device

Others

By End-use Industry:

Aerospace and Defense

Automotive and Transportation

Consumer Electronics

Industrial

Media and Entertainment

Others (IT & Telecommunication, Healthcare)

By Region:

North America (U.S., Canada)

Europe (U.K., Germany, France)

Asia Pacific (China, India, Japan, South Korea, ASEAN)

South America (Brazil)

Middle East & Africa (GCC, South Africa)

Regional Insights

Asia Pacific accounted for the largest share of the LVDS interface IC market in 2022 and is expected to continue leading. The presence of high-volume manufacturing hubs, strong R&D activity, and the expansion of automotive electronics fuel the region's dominance.

North America is witnessing growing adoption of LVDS ICs in ADAS systems, data centers, and aerospace communication modules.

Europe remains a strong market with robust demand from automotive giants and an established electronics ecosystem.

Why Buy This Report?

This comprehensive research offers:

In-depth analysis of global and regional LVDS interface IC markets.

Detailed insights into key growth drivers, trends, and opportunities.

Competitive landscape profiling leading players and emerging technologies.

Cross-segment and cross-regional forecasts from 2023 to 2031.

Market sizing in both revenue (US$ Mn) and volume (Million Units).

Access to Porter’s Five Forces analysis, value chain assessment, and emerging application trends.

The report equips stakeholders from OEMs and investors to semiconductor designers and suppliers with actionable intelligence to tap into evolving demand and maintain a competitive edge.

Explore Latest Research Reports by Transparency Market Research: Metal X-Ray Mirror Lens Market: https://www.transparencymarketresearch.com/metal-x-ray-mirror-lens-market.html

Electronic Testing Services Market: https://www.transparencymarketresearch.com/electronic-testing-services-market.html

Objective Lens Market: https://www.transparencymarketresearch.com/objective-lenses-market.html

Photonic Integrated Circuits (PIC) Market: https://www.transparencymarketresearch.com/photonic-integrated-circuit.html

GaAs Photodiode Market: https://www.transparencymarketresearch.com/gaas-photodiodes-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

What is an SMT PCB Board and How Does it Revolutionize Electronics Manufacturing?

In the world of modern electronics, the word SMT PCB board often occur on surfaces when discussing condition -Art -art -construction methods. The SMT surface stands for mounting technology, referring to a technique where electronic components are used directly on the surface of a printed circuit board (PCB). An SMT PCB card is a type of circuit board designed specifically for this process, which allows more efficiency, compactness and performance in electronic devices.

Understanding the SMT Circuit Board

SMT Circuit Board is in a general sense distinctive from its predecessor—the through-hole PCB. In conventional through-hole Technology, component leads are embedded into gaps penetrated into the board and at that point patched. SMT, on the other hand, dispenses with the require for gaps by permitting components to be set straightforwardly on the board’s surface.

The components used in SMT are usually very small and lightweight, which allows manufacturers to create a smooth and compact electronic device. This component called SMD (Surface Mount device) is mixed into the board using reflow masks, which are faster and more reliable than traditional hand soldiers.

How SMT PCB Boards Revolutionize Electronics Manufacturing

1. The miniature of equipment

One of the main advantages of using a PCB of surface mounting is the ability to design small and light electronic products. With components directly on the surface and without requirements for holes, engineers can use both edges on the board for circuit design. It leads to more compact devices such as smart phones, tablets and wearable techniques.

2. Improved Manufacturing Efficiency

SMT PCB Board empower robotized gathering forms, which essentially increment generation speed and decrease labor costs. Pick-and-place machines can precisely position thousands of components per hour onto the SMT circuit board, streamlining the manufacturing line and lessening human error.

3. Enhanced Execution and Reliability

With shorter lead associations and decreased parasitic inductance, SMT PCB boards offer superior electrical execution compared to through-hole boards. The compact plan too implies decreased flag way lengths, which improves speed and decreases electromagnetic interference (EMI).

4. Cost-Effective Mass Production

Despite the beginning venture in hardware, Surface Mount PCB are cost-effective in high-volume generation. Their compact measure implies more boards can be fabricated from a single board, sparing on materials and gathering time.

5. Versatility and Plan Flexibility

SMT permits for a broader extend of component sorts and sizes, giving originators the adaptability to make more modern circuits. This is particularly vital in businesses like car, aviation, and consumer electronics, where complex usefulness is basic in restricted spaces.

Conclusion

The SMT PCB board speaks to a basic move in gadgets manufacturing. By leveraging Surface Mount Technology, producers can create littler, speedier, and more solid gadgets with more noteworthy productivity and lower costs. Whether it's a Smartphone or a therapeutic gadget, SMT circuit boards are the establishment of present day electronic advancement. As Technology proceeds to advance, the significance of Surface Mount PCBs in pushing the boundaries of plan and execution will as it were develop.

0 notes

Text

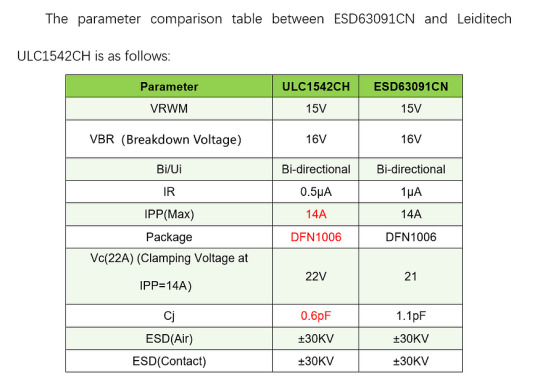

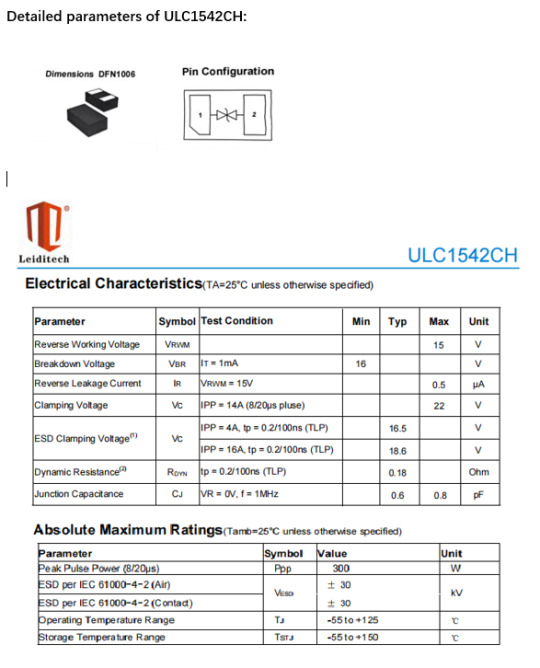

15V Ultra-Low Capacitance High Surge ESD Device

ULC1542CH Fully Replaces ESD63091CN

Leiditech Shanghai introduces a new electrostatic protection device, ULC1542CH, a small-package (DFN1006) electrostatic protection solution designed for 15V signal lines. With a peak pulse current (IPP) capability of 14A, ULC1542CH offers excellent surge protection performance. Its 0.6PF low junction capacitance ensures signal transmission integrity, effectively resisting electrostatic discharge impacts and providing reliable protection for high-speed data transmission lines.

ULC1542CH’s core parameters are fully matched with ESD63091CN, supporting pin-to-pin seamless replacement. It can be directly replaced without modifying the circuit design, providing engineers with a more flexible and efficient component selection scheme.

Key points for judging whether ESD diodes can be replaced:

l Whether VRWM is close

l Whether the package is the same

l Whether the electrostatic protection capability is close

l Whether VBR is close

l Whether IPP is close

l Whether CJ is close

Based on the above parameter comparison, the ULC1542CH can completely replace the ESD63091CN.

Applications:

l In the consumer electronics field, it is suitable for high-speed data interfaces of mobile phones and tablets, as well as precision sensor circuits of smart wearable devices.

l In industrial control scenarios, facing frequent electrostatic threats in complex electromagnetic environments, it can provide reliable protection for PLC control lines, industrial Ethernet interfaces, etc.

l In automotive electronics, from the data cables of in-vehicle entertainment systems to the signal transmission lines of vehicle body electronic control units, this device can help equipment operate stably.

In summary, this device is suitable for various scenarios such as consumer electronics and industrial control. While maintaining high performance, it also has a cost advantage, providing engineers with a more flexible component selection scheme.

For relevant replacement needs, please contact Leiditech sales personnel or the Leiditech EMC specialist.

Leiditech Electronics is committed to becoming a leading brand in electromagnetic compatibility (EMC) solutions and component supply, supplying ESD, TVS, TSS, GDT, MOV, MOSFET, Zener diodes, inductors and other products. Leiditech has an experienced R&D team that can provide personalized customization services according to customer needs and provide customers with the best quality solutions.

If you’d like to learn more or have any questions, don’t hesitate to reach out:

Visit us at [en.leiditech.com]

ESDProtection #TVSDiodes #CircuitProtection #HighSpeedESD #SignalIntegrity #DropInReplacement #Leiditech #ElectromagneticCompatibility #ConsumerElectronics #IndustrialControl #AutomotiveElectronics #SurgeProtection #ESDDevice #PowerElectronics #TechInnovation #PCBDesign #EngineeringSolutions

0 notes

Text

Nichrome Blister Packaging Machine -Medium and high-speed Blister Packaging Machines for Tablet/ Capsules -High-speed Card Blister Packaging with automatic feeding system for cosmetic and other healthcare products -Cartoning Machine range for Blister Strips, Bottles, Tubes and Sachets including complete integrated lines

For more information about blister packaging machine, visit https://bangladesh.nichrome.com/applications/pharmaceutical/tablet-compression.php#pharmapg

#blister packaging#blister packaging machine#nichrome blister packaging machine#blister packaging machine manufacture#blister packaging machine supplier in bangladesh\#automatic blister packaging machine#pharmaceutical packaging machine

0 notes

Text

Tablet Production Line

Sieving, Blending, Milling, Drying, Granules Forming, Lubrication, Tablet Compression, and Tablet Blister Packaging Machines are all part of the Tablet Production Line (Tablet Processing Line), which includes the Tablet Manufacturing Line. Both dry and wet granulation tablet production lines are available from us. Every machine satisfies cGMP standard production specifications. The Adinath series provides both a High-Speed Tablet Production Line and a Small Tablet Production Line.

#Tablet Compression#Tablet Blister Packaging Machines#Tablet Processing Line#Tablet Manufacturing Line#High-Speed Tablet Production Line#Small Tablet Production Line

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Power up your Smartphone anywhere, anytime with bArrett 2.4A portable USB Charger. It is compatible with most Smartphones and is your perfect companion in providing your Smartphone with required charging and it is your perfect companion in providing your Smartphone with required charging. Constant voltage charging mode for safe usage. Compact and light weight for ease of convenience to carry around.Universally compatible: works with all phones and tablets. Smart charge: auto detects the connected device and charges it at the fastest speed of the device up to 2. 4A indian connectors: the indian connects allow you to plug the wall charger into a socket and charge without having to use an adapter. Connector independent: works with micro usb, lightning and type c cables all round safety: built in over-voltage / over current / short circuit and surge protection unit so you never have to worry about your device. PRODUCT FEATURES: FLASH CHARGING: Equipped with Flash Charging, you can rest easy knowing that all your devices are getting juiced at maximum speeds. All Round Safety: In- Built safety checks like voltage, temperature and current control, protects your connected device from damage due to inconsistencies in the power output. Indian Connectors: Made for Indian sockets, the wall charger lets you plug in without the need for an adapter And Over-current, Short-circuit and Over-temperature protect your device Smart Charge: Auto Detects the connected device and charges it at the fastest speed of the device Multi-Protection: It provides exclusive surge protection, short circuit prevention, temperature control, and more to deliver unbeatable protection to you and your devices Premium-Design with Compact-Size: High-gloss detailing and comfort grip design gives a sleek look to this powerful device. ★EXCLUSIVE TECHNOLOGY: India's smallest charger with 2.4 amp power supply. ★ Exclusive quick charge technology automatically detects and delivers the optimal charging current for any connected device - ensuring the quick and most efficient charge. ★ Small & Lightweight: Slightly heavier than simply slip it into bag when you are out and about. ★ SMART CHARGE: Auto Detects the connected device and charges it at the fastest speed of the device. ★INDIAN CONNECTORS: Made for Indian sockets, the wall charger lets you plug in without the need for an adapter And Over-current, ★ Short-circuit and Over-temperature protect your device. ★ Multiple Protections : Over-current, Short-circuit and Over-temperature protect your device, Auto Cut : On Over Heat. ★ Adaptive Fast Charging Technology & Slim and Compact Design, Over Current and Over Voltage Protection. ★FIRE-RESISTANT: Hardened plastic outer shell for durability, built-in premium circuitry and microchip ensure device safety. ★ Triple Lays Protection Built-in 3 layers anti-interference films, ensure this line works well when you use it. ★ Smart Charge: Auto Detects the connected device and charges it at the fastest speed of the device. ★ Small & Lightweight: Slightly heavier than simply slip it into bag when you are out and about. ★GOOD CHARGING SPEED : Most Powerful - Charge any V8 USB powered devices at top speed continuously. ★ Quick Charge & Data Transmission ★ V8 USB support fast charge (5V/3A) and sync data simultaneously at a rapid speed, ★ save you time. Safe & Durable 24 awg wire, built-in identification resistor (56kΩ resistor for safety) & premium PVC coated make it dependable and sturdy enough for everyday use, save your money. ★COMPATIBLE WITH: Android and Windows phones, tablets and many other Micro Usb devices including Samsung / Nexus / HTC / Motorola / Nokia / LG / Sony / OnePlus / Blackberry / PS4 / Kindle / Xbox / PS Vita / DS / GPS devices / battery packs / bluetooth speakers / wireless keyboards / cameras / camcorders / games consoles / hard drives / e-readers / printers and Micro Usb Compatible devices. Only From bArrett

0 notes

Text

Pharmateq – Precision High-Speed Tablet Counters for Efficient Pharmaceutical Production

Pharmateq specializes in advanced high-speed tablet counters designed to meet the fast-paced demands of modern pharmaceutical manufacturing. Our machines deliver unmatched accuracy, efficiency, and reliability—ensuring every batch is counted with precision. Built with cutting-edge technology and robust construction, our tablet counters are ideal for large-scale production lines where speed and consistency are critical. Pharmateq's commitment to quality and innovation makes us a trusted partner for pharmaceutical companies worldwide. Upgrade your production line with our high-speed tablet counters and experience seamless performance every time.

0 notes

Text

What Makes a Rapid Mixer Granulator Indispensable in Pharmaceutical Manufacturing?

Have you ever wondered what ensures that your tablet medicine has just the right mix of active ingredients? Or how pharmaceutical companies manage to create consistent batches of high-quality drugs at scale? Behind the scenes, one powerful machine often makes it all possible: the Rapid Mixer Granulator (RMG).

At VJ Instruments, we don’t just build machines—we help pharmaceutical research and manufacturing leap forward with confidence. As a leading pharmaceutical instruments manufacturer, our innovation-driven approach has made us a trusted name in Pharmacy and Pre-Clinical research since 2006. One of our standout solutions in solid dosage formulation is the Rapid Mixer Granulator—a machine that lies at the heart of efficient, scalable, and GMP-compliant granulation processes.

Let’s explore what makes an RMG so critical, and how VJ Instruments brings unmatched precision and performance to your lab or production line.

What is a Rapid Mixer Granulator?

A Rapid Mixer Granulator is a high-speed processing machine used extensively in the pharmaceutical industry for mixing powders and preparing granules in the production of tablets and capsules. The equipment combines mixing, wetting, and granulating in a single chamber using an impeller and chopper mechanism.

The result? Uniform, dense granules with excellent flow characteristics—essential for producing tablets that are consistent in weight, hardness, and dissolution profile.

Why Granulation Matters in Pharma

Before diving deeper into the machine itself, it’s important to understand why granulation is such a critical step in tablet manufacturing:

Improved flowability: Fine powders often have poor flow properties. Granulation helps make them easier to process.

Consistent blending: Ensures even distribution of active pharmaceutical ingredients (APIs) and excipients.

Better compaction: Granules compress more easily into solid tablets.

Minimized dust: Granulation reduces airborne particles, improving both safety and cleanliness.

Without effective granulation, tablets may suffer from weight variation, poor content uniformity, or even failure to meet regulatory standards.

Key Features of a Rapid Mixer Granulator

At VJ Instruments, our Rapid Mixer Granulator is engineered for speed, precision, and compliance. Here’s what sets our equipment apart:

1. Efficient Impeller-Chopper Design

The impeller ensures uniform mixing of dry and wetted powders, while the chopper breaks down any lumps to produce fine, consistent granules. This dual-action ensures a homogeneous mixture and fast processing.

2. Scalable Models for R&D to Production

From lab-scale units ideal for pre-clinical research to production-grade machines suited for large batch sizes, we offer scalable options to suit your stage of development.

3. GMP-Compliant Construction

Built using SS316/SS316L stainless steel, our machines comply with global pharma standards, ensuring cleanability, durability, and regulatory confidence.

4. User-Friendly Interface

Equipped with digital touchscreens, programmable logic controls (PLC), and data logging options, our RMGs allow users to track, adjust, and replicate granulation parameters with ease.

5. Closed-System Operation

Maintains dust-free and contamination-free conditions. This not only improves product safety but also protects operators during batch processing.

The VJ Instruments Advantage

Innovation Backed by Experience

Since 2006, VJ Instruments has pushed boundaries in pharmaceutical instrument design. Our Rapid Mixer Granulator is a product of years of experience, continual R&D, and real-world collaboration with pharmaceutical researchers and manufacturers.

Custom Solutions

We understand that every lab or production facility is different. Our RMGs can be customized for bowl size, impeller speed, granulation cycle time, and integration with upstream or downstream equipment.

Trusted Across Industries

While primarily designed for pharmaceutical use, our RMGs are also employed in nutraceuticals, chemical industries, and food technology labs—anywhere that consistent, high-speed wet granulation is required.

Applications of Rapid Mixer Granulator in the Pharmaceutical Workflow

Whether you're formulating a new drug or scaling up a successful compound, RMGs play a pivotal role across multiple stages:

Formulation development: Determine optimal binder concentrations, mixing speeds, and wet massing times.

Process scale-up: Move seamlessly from lab-scale RMGs to pilot and production-scale systems.

Manufacturing: Ensure every tablet batch is consistent in texture, density, and active content.

RMG vs. Other Granulation Methods

You might ask, “Why not use fluid bed granulation or high-shear mixing?”

Here’s how Rapid Mixer Granulation stands out: FeatureRapid Mixer GranulatorFluid Bed GranulatorSpeedVery FastModerateSpace RequirementsCompactRequires more spaceEnergy EfficiencyHighMediumCost of OperationLowerHigherBatch SizesFlexibleMedium to Large

For many tablet formulations, especially those requiring robust, fast granulation cycles, RMGs are often the preferred choice.

Maintenance and Support

One of the common challenges with any industrial equipment is ongoing maintenance. At VJ Instruments, we provide:

End-to-end training on machine handling

Preventive maintenance schedules

Genuine spare parts availability

Prompt service and support across India and abroad

We ensure that your RMG continues delivering value long after purchase.

Final Thoughts: The Future of Granulation is Here

In a world where quality, speed, and compliance matter more than ever, the Rapid Mixer Granulator remains a cornerstone of pharmaceutical production. It’s not just a machine; it’s an enabler of precision medicine and scalable manufacturing.

At VJ Instruments, we’re proud to empower researchers, formulation scientists, and manufacturers with equipment that meets the highest standards. Whether you're innovating in a lab or scaling up for commercial launch, our Rapid Mixer Granulator ensures that your granulation process is fast, efficient, and fail-proof.

0 notes

Text

Bottle Labeling Machine: Complete Guide to Precision Product Labeling

What is a Bottle Labeling Machine?

A bottle labeling machine is an automated or semi-automated system used to apply labels onto bottles of various shapes and sizes—round, flat, oval, or square. These machines are engineered for high accuracy, speed, and uniformity, significantly reducing labor costs and errors associated with manual labeling.

Whether it's a wrap-around label on a soda bottle or a front-and-back label on a shampoo container, these machines handle it all with seamless efficiency.

Types of Bottle Labeling Machines

1. Manual Bottle Labeling Machines

Ideal for small-scale or home-based operations

Hand-cranked or foot-pedal operated

Low investment, minimal automation

2. Semi-Automatic Bottle Labeling Machines

Operator places the bottle, and the machine handles the labeling

Perfect for startups and small to mid-sized businesses

Compatible with wrap-around, single-side, and double-side labels

3. Fully Automatic Bottle Labeling Machines

Bottles are fed and labeled automatically on conveyors

Suitable for high-speed production lines

High output, precise alignment, reduced labor needs

4. Rotary Labeling Machines

Designed for ultra-high-speed lines

Uses a carousel system to label multiple bottles simultaneously

Often used in beverages, pharma, and cosmetics industries

5. Shrink Sleeve Labeling Machines

Applies shrink labels using heat tunnels for 360° branding

Common in juice, soft drinks, and energy drink packaging

Applications of Bottle Labeling Machines

Food & Beverage Industry

Juices, mineral water, milk, sauces, syrups, oils, alcohol

Date coding, branding, and compliance labels

Pharmaceuticals

Tablets, syrups, liquid drugs

Includes batch number, expiry date, and dosage information

Cosmetics & Personal Care

Shampoos, conditioners, lotions, perfumes

Requires visually appealing labels to reflect brand identity

Chemicals and Agro-Products

Fertilizers, pesticides, cleaning products

Requires resistant, long-lasting adhesive labels

Core Features of Advanced Bottle Labeling Machines

1. High Labeling Speed

Capable of labeling 20 to 300 bottles per minute, depending on model and label type.

2. Accuracy and Precision

Label placement tolerance as low as ±1 mm, ensuring professional appearance.

3. Label Sensor System

Automatically detects label gaps and bottle positions to prevent misalignment.

4. Adjustable Conveyor System

Compatible with a wide range of bottle sizes and shapes.

5. Integrated Coding Devices

Allows real-time printing of batch numbers, barcodes, and expiry dates.

6. PLC and Touchscreen Control

Easy programming, operation, and error diagnostics through HMI systems.

Benefits of Using a Bottle Labeling Machine

Enhanced Branding: Professionally applied labels elevate product appeal

Time-Saving: Speeds up production lines exponentially

Reduced Human Error: Increases labeling accuracy and consistency

Compliance Assurance: Meets global labeling standards (FDA, FSSAI, EU)

Versatility: One machine can handle different bottle types and label formats

Low Operational Costs: Cuts labor costs while boosting throughput

0 notes