#Hydraulic Load Testing

Explore tagged Tumblr posts

Text

Manhole Cover Compression Testing Machine

Reliable and Accurate Testing for Manhole Covers The Manhole Cover Compression Testing Machine is a specialized testing device designed to assess the structural integrity of manhole covers under extreme pressure. This testing machine plays a crucial role in ensuring that manhole covers meet the required safety standards and durability expectations. Whether used for quality control in…

#ASTM Manhole Cover Test#Civil Engineering Testing#Compression Resistance#Compression Strength Test#Compression Testing#Construction Equipment Testing#Custom Testing Solutions#EN 124 Testing#Hydraulic Load Testing#Hydraulic Testing Machine#Industrial Testing Machines#ISO Manhole Cover Standards#Jinan Wangtebei Instrument#Load Cell Testing#Load Testing#Manhole Cover Compliance#Manhole Cover Deformation Test#Manhole Cover Performance Test#Manhole Cover Quality Control#Manhole Cover Strength#Manhole Cover Testing Equipment#manhole cover testing machine#Pressure Test Machine#Testing Equipment for Infrastructure#Testing Machine Manufacturer

0 notes

Text

“We’ll need something to be compressing these ingredients when we have them all collected and refined. By loading three chambers within this unit, they can use strong hydraulic arms to create a tight vacuum that will draw all ingredients into a central chamber before releasing all built up pressure in one final burst. During my testing, I have noticed that this creates a large pulse of energy at the moment of union - safety should be a priority when handling these units, and finding somewhere to keep them out of the way will probably be beneficial…”

Watch the trailer for Last Sprout: A Seedling of Hope at this link! 🌱

You can support me on Patreon for £1 and see concept art, assets, and snippets of story for the game!

#🌱#Game#Game dev#Art#game design#indie game#concept art#indie animation#art#artwork#animation#animated#animators on tumblr#artists on tumblr#illustrators on tumblr#digital illustration#illustration#digital painting#digital art#digital#fantasy#fantasy art#fantasy writing#pretty#aesthetic#Last sprout

58 notes

·

View notes

Text

New Nozzle

If you know cars or trucks, you might think this is a big fuel nozzle. It's a nozzle for a 500 kW auxiliary engine.

But this is the nozzle for our 12000 kW main engine, both 4 stroke 6 in line funny enough.

Let's install it on the fuel valve/ nozzle body. We need a nut, a small spanner and a bit of hydraulics to torque it to the required 1600 Nm.

Now we put the internals in it, those allow us to regulate the opening pressure. This injector came out of the engine with a broken spring!

Testing! The opening pressure is set to 600 bar.

[video in a reblog, I hope, it doesn't want to load?? why tumblr?]

All good, let's wrap it up and put it stand by for future use. Oh, and a picture of how dirty the nozzles come out of the engine, (running on Heavy Fuel Oil), yes these nozzle tips are use and throw away parts for us.

#Did i finally post something about what I actually do on this boat?#I guess I did#weergang#merchant navy#yes I need a chain hoist to move it around#its a 300kg piece of steel

19 notes

·

View notes

Text

notes from fp1 - silverstone

four rookie drivers in this session: ollie bearman for kevin, franco colapinto for logan, jack doohan for pierre and isack hadjar for perez

lots of updates as well: vcarb have a new halo winglet and sauber have new floor fences - to improve airflow

merc have a new rear corner and redbull have a new floor body & edge - to improve local load

aston have new front wing elements and rear corner - to improve airflow and load

haas have a new floor body, fences & edge, new sidepod inlets & engine cover, new mirror stay and rear corner - to improve local load and airflow

mclaren have brought three different beam wings (high, med. and low load) and are testing their front wing

lance struggled initially w/ a long brake pedal, maybe a "bbw [brake by wire] fail" - just needed a electronic reset

red flag, 8 mins in - yuki went wide through brooklands, lost rear grip through luffield and ended up beached in the gravel - recovered, but out of the session

lewis told to aim for "tom and the guys" as he came into the pits - pitlane layout is different here, fan favourites are moved to the middle so they can be seem from the grandstand

isack hadjar was doing lots of tests so his times are not evidence of his ability

jack doohan again had a tricky fp1 - spent a lot of time in the garage bc of a problem w/ the rear left corner, maybe his brake duct

jack also had to avoid two cars ahead who were dawdling on the racing line

charles struggled behind a slow lance which had a knock on effect for carlos behind them, having to slow and swerve

oscar reported "a hydraulics problem" and trundled back towards the pits but stopped in the pit entry road - recovered back to the garage but end of his session

charles had a second issue w/ lance, "i nearly crashed", who was slow at the entry of a highspeed corner

lando had to take massive avoiding action bc isack was also going very slow through a highspeed corner - lando locked his front right, and nearly lost the rear of the car - impeding to be investigated after the session

the mercs, ferraris and redbulls didnt run any softs

most laps - carlos and alonso w/ 27

least laps - yuki w/ 5, isack w/15 and oscar w/18

26 notes

·

View notes

Note

I’m a huge fan of Seldus’s wheelchair that can transform into a spider and his walking cane gun, did he build those? Is the spider form faster than the wheelchair? I’m interested in the contexts he’d use the different forms in

sorry for the giant text dump. a seldus-based question, but rose can't help herself. i'll put the text transcript under the cut! note: seldus did build his own prosthetic. sometime I'll actually post what it looks like... LOL

"Those would be my babies and I'm so happy y'all asked! The cane was an idea I had when Seldus rejected my request to retrofit his prosthetic with a prototype easy-loading blunderbus design I've been working on... again... Anyway, while the silhouette and design would lead y'all to believe it's a powder rifle, its actually cartridge loaded! Still single shot, for now; upgrades pending, but a lot less cumbersome in the heat of battle. Especially on a prosthetic leg or while seated. Very much a last resort, not a main weapon. 'Course, I obviously reinforced the frame to support his weight without risk of warpin' the barrel or compromisin' the weapon!

As for his wheelchair, I tried not to go reinventin' the wheel on this one, pun intended. I wanted to give him another way of gettin' around on difficult terrain, stairs, uneven ground, gravel, sand, those sorts of things. But it is rather attention grabbing, so I went and fitted it with an arcane liquid fuel-powered analog transmogrification system. She's still got a long ways to go, but so far, it's saved plenty of time when we go out in the field! Don't tell Seldus, but I'm working on a hydraulic leaping system. Still in testing phase, but I'm really likin' the results so far; just gotta work out some kinks on the landin'...don't know how many more times I can blame these bruises on droppin' tools..."

#rose tag#seldus tag#by association LOL#apologies she does love to yap#about her work and nothing else

6 notes

·

View notes

Text

SIFT TEST PREP STRATEGIES

The SIFT test is a crucial exam for those aiming to become U.S. Army aviation officers. It assesses multiple cognitive skills, including math, mechanical knowledge, spatial awareness, and aviation information.

Use the Process of Elimination If unsure of an answer, eliminate obviously incorrect choices to improve your odds of guessing correctly. Skip tough questions and return to them if time permits. Don’t spend too much time on a single question. Move on and come back later if necessary. Take SIFT Practice Tests 👈 to identify weak spots.

Some important question about mechanical comprehension for SIFT TEST:

What is the effect of increasing the diameter of a pulley in a system of pulleys?

A) It increases the speed of the load.

B) It decreases the speed of the load.

C) It increases the force exerted on the load.

D) It has no effect on the load speed.

Answer: B) It decreases the speed of the load.

Explanation: Increasing the diameter of a pulley generally causes the load to move slower, as the larger pulley takes more time to complete one full rotation. This is because a larger pulley moves a greater distance for each rotation, leading to a decrease in speed of the load. However, this can increase the mechanical advantage, making it easier to lift the load with less force.

Which of the following correctly describes a hydraulic system?

A) It operates using air pressure to move pistons.

B) It uses fluids under pressure to perform work.

C) It uses a mechanical belt to transfer power.

D) It requires no external power source.

Answer: B) It uses fluids under pressure to perform work.

Explanation: A hydraulic system operates by transmitting force through a fluid under pressure, typically oil or water. The pressure applied to the fluid is used to move pistons or perform mechanical work. This is the basis for hydraulic systems in machines like car brakes, lifts, and excavators, allowing them to amplify force efficiently.

Join Us At SIFT Test Study Materials 👈 & get video tutorial 👈 For Preparation.

#carrier aviation#military#air force#us army#us marines#navy#royal navy#us navy#marine biology#helicopter#sift exam#sift online test#sift exam prep#sift online classes#sift test prep#asvab online courses#asvab test prep#asvab study tips#asvab online classes#asvab prep#asvab test

2 notes

·

View notes

Note

What do you think about Ferrari's seemingly bad tire deg? Like, real bad. Some people said it might be because they didn't bring wings with heavier load for Bahrain specific need (unlike McL and Mrcd)? And that's why they packed up half an hour before it ended because they realized it's something they couldn't fix right then. (And I think lewis didn't do race sims at all) But why didn't they bring them? Sure the wings they did bring would be used in more circuits, but it's testing, seems a waste to not, you know, test them. Or maybe they actually don't have the heavier wings for Bahrain a la rbr not having wings for Vegas? Idk how soon they can fix the balance, seems impossible in 2 weeks 😭 but hoping for a miracle 🙏

I don't agree with people saying they shouldn't change the suspension. It's high risk, but I think last year's version had run out of potential imo.

And there was also some brake issue with charles. But I don't think it'd be much of a problem for Australia? Idk, hopefully that one could be fixed soon

All in all, what's sure is that McL is clearly heads above any teams at the moment. Some say Mrcd is coming second since they seemed to have solved their deg issue in the last day. But idk I'm still counting Ferrari, RBR, and Mrcd at the same level for now.

In the end, it's testing. Finding problems is the goal so that they can fix them for the races. The question is will they be able to fix them or not, so while it is kinda worrying, I don't think this is a totally doom and gloom situation (Or at least I hope so....)

My first big disclaimer is that I'm still working my way through watching testing, so I haven't watched the final session myself yet (I'm also a little bit more disconnected this season because I don't need this sport to run my life lol)— but I have seen that Lewis was brought in early because of a hydraulics issue with the transmission.

As far as the whole tire deg situation, I don't think we can truly judge that yet because a) the conditions in Bahrain have been unexpectedly varied and b) they were apparently running some setups that weren't specifically geared toward Bahrain and the current weird weather in an effort to learn as much as possible about the car.

And working toward that goal, I've heard that they were using a wing configuration for Australia, which makes sense given that's where the first race is, while Bahrain won't happen until April— when it's likely to be much warmer, so anything teams have learned on this track at these temperatures won't really matter. I also wouldn't assume that just because they didn't pop on a wing with more downforce means that they don't have one. There's a lot to learn about the balance with that brand new suspension geometry and not a lot of time to do it, so they might be focused on trying to find what will help them in these early races rather than nailing a single perfect setup for this track.

All of this to say, if they have good correlation with the sim, they have time to find a better balance before Australia. And any kind of mechanical issues like brakes or hydraulics should usually be sorted easily because that's likely a one-off with a faulty part or not being installed quite right! These cars are essentially prototypes taken apart and rebuilt by human beings at every track, so they are never put together quite exactly the same.

I would think it's safe to say that the Mcl is the most hooked up right out of the gate, which is entirely expected, but I agree with you that Ferrari had to be punchy with their changes because the SF-24 likely reached its development ceiling (we saw this when they tried to pile on more downforce midseason and it was a disaster, which I believe was chalked up to the suspension not being able to handle it?). Early reports are suggesting that it may take them a bit of time to find their stride, but the development potential could be higher! There's also the chance that Merc have completely understood and solved their problems, but the car they had last year really loved a cold track (and had quite a narrow setup window), so there could still be some uncertainty there! RBR also seems to be continuing from last year of being fast enough to maybe be in the mix, but generally pretty unpredictable.

It is definitely just testing and the fact that the first race is at a different track makes the full picture even less clear. We also can't forget that we'll get new regulations on flexi-wings in Barcelona, so the field could still reshuffle then! It's going to be a long season and anything can happen, so there's no use in being doom and gloom about it now! Also, I love yapping about this stuff, so thanks for asking 🥹💜

(and a special thank you to @saiyanwitcher for providing the rundown on the sessions I haven't seen yet!!)

5 notes

·

View notes

Text

How Car Carrier Truck Drivers Maintain the Safe Delivery of Your Car

Transporting a vehicle over long distances requires precision, skill, and a commitment to safety. When trusting a car transport company to handle your vehicle, understanding the safety measures involved can provide peace of mind. Nationwide car shipping companies, such as Florida car shipping companies offer fully insured car carrier service, rely on experienced drivers and strict guidelines to guarantee reliable service.

From comprehensive training to post-delivery inspections, every step ensures your car arrives in the same condition as when it left, giving you confidence in those companies with reliable nationwide car transportation reviews. Below, we explore the detailed procedures and practices involved.

Extensive Driver Training and Qualifications

The backbone of a secure vehicle transfer lies in the expertise of car carrier truck drivers who undergo rigorous training. This training emphasizes core driving competence, attention to detail, and familiarity with handling delicate cargo.

Meeting Industry Standards through Safety Training

Truck drivers play a critical role in maintaining safety throughout the car transport process. Companies prioritize driver training and qualifications to ensure drivers meet or exceed industry standards.

Drivers are educated on safety protocols covering traffic laws, defensive driving, and operating large vehicles. The importance of safety training cannot be overstated—proper instruction reduces accidents and fosters safe work habits. Training programs also include classroom lessons on hazard awareness, preparing drivers for unforeseen challenges.

Physical and Technical Driver Requirements

Beyond training, physical health and technical expertise are key requirements for drivers. Drivers must meet strict health standards, including vision, reflexes, and endurance tests, to handle long trips.

Additionally, technical skills, such as understanding vehicle mechanics and operating hydraulic systems, are critical. Licensed and fully insured car carrier operators enhance reliability by addressing potential tech issues on the road, ensuring uninterrupted service.

Pre-Trip Vehicle Inspections and Maintenance Protocols

Before every journey, nationwide auto transport companies implement thorough inspections and maintenance guidelines. These practices minimize risks and uphold performance standards, helping companies remain trusted within the industry.

Inspecting Equipment Before Every Journey

Every successful trip begins with pre-trip vehicle inspections performed by the driver and technical teams. These checks include reviewing brakes, axles, lights, and tire pressure.

By carefully inspecting every component, including hydraulic ramps and securing straps, they identify potential risks before departure. Pre-trip vehicle inspections act as a first line of defense against breakdowns, contributing to overall safety and reliability.

Scheduled Maintenance for Vehicle Longevity

Apart from pre-trip checks, scheduled maintenance ensures trucks remain in optimal condition. From oil changes to engine tune-ups, routine service extends the lifespan of transport vehicles while improving safety. The importance of proper vehicle maintenance is clear—broken equipment can disrupt routes or cause delays, compromising delivery timelines.

By prioritizing maintenance, companies add an additional layer of confidence and professionalism.

Secure Loading and Weight Distribution Techniques

The safe delivery of vehicles heavily depends on how cars are loaded and secured. Proper and secure loading procedures and balanced weight distribution are important for avoiding complications during transit.

Taking these steps ensures your vehicle arrives safely and in excellent condition. Right preparations and proper planning made by a reliable car shipping services will lead to safe and secured transport experience.

When it’s time to ship your car, you can rely in these procedures for a safe and hassle-free auto transport experience. Get started today and transport your vehicle with confidence.

youtube

5 notes

·

View notes

Text

What are the Key Mechanical Properties of Solids?

Mechanical properties of solids refer to the characteristics that define how a material responds to external forces, such as stress, strain, and deformation. These properties include elasticity, plasticity, hardness, toughness, strength, and ductility, among others. They are fundamental in determining a material’s suitability for various applications, influencing its behaviour under different conditions.

The significance of mechanical properties spans numerous fields. In engineering, these properties ensure the safety and durability of structures like bridges, buildings, and dams. In construction, they guide the selection of materials for specific purposes, such as load-bearing or flexibility. Material science relies heavily on these properties to develop innovative materials that meet evolving industrial demands.

This article aims to delve into the science behind mechanical properties, their key characteristics, real-world applications, and their indispensable role in innovation and progress.

The Science Behind Mechanical Properties

Stress and Strain: Fundamentals

Stress is the force per unit area exerted on a material. It can be mathematically expressed as:

where is the applied force and is the cross-sectional area of the material. Strain, on the other hand, measures the deformation caused by stress. It is defined as the ratio of the change in length to the original length: where is the change in length and is the original length.

Types of Stress and Strain

Tensile Stress and Strain: Occurs when forces act to stretch a material. Examples include the stretching of rubber bands and cables.

Compressive Stress and Strain: Results from forces that compress or squeeze a material. Concrete in buildings often experiences compressive stress.

Shear Stress and Strain: Arises when forces are applied parallel to a surface. Scissors cutting paper is an example of shear stress in action.

Hooke’s Law and Elasticity

Elasticity is the ability of a material to return to its original shape and size after the removal of stress. Hooke’s Law describes this behaviour:

where is the Young’s modulus, a measure of a material’s stiffness. Elasticity is crucial for applications requiring temporary deformation, such as springs.

Plasticity and Permanent Deformation

When stress exceeds a material’s elastic limit, it undergoes plastic deformation, leading to permanent changes in shape or size. Metals like aluminium and copper exhibit plasticity, making them ideal for moulding and shaping processes.

Key Mechanical Properties

1. Young’s Modulus (Stiffness)

Represents a material’s resistance to deformation under tensile stress.

Example: Steel has a high Young’s modulus, making it ideal for construction.

2. Shear Modulus and Bulk Modulus

Shear Modulus measures resistance to shape changes under shear stress.

Bulk Modulus evaluates a material’s response to uniform compression.

Applications include hydraulic systems and pressure vessels.

3. Poisson’s Ratio

Describes the ratio of lateral strain to longitudinal strain. Materials with low Poisson ratios, like cork, are used for sealing applications.

4. Strength

Includes tensile, compressive, and shear strength. Determines how much load a material can bear without failure.

Example: Carbon fiber composites are used in aerospace for their high strength-to-weight ratio.

5. Ductility and Malleability

Ductility is the ability to be stretched into a wire. Copper’s ductility makes it suitable for electrical wiring.

Malleability is the ability to be hammered into sheets. Gold’s malleability is utilized in jewellery making.

6. Brittleness and Toughness

Brittleness: Materials like glass break without significant deformation.

Toughness: Measures a material’s ability to absorb energy before fracturing. Rubber is an example of a tough material.

7. Hardness

Resistance to indentation or scratching. Hardness tests include the Mohs scale and the Brinell test.

Example: Diamond, the hardest known material, is used in cutting tools.

Applications in Engineering and Design

Civil Engineering

Bridges: Steel and reinforced concrete combine high strength and ductility to withstand loads.

Buildings: Materials like concrete and glass are chosen based on compressive strength and aesthetic appeal.

Aerospace and Automotive Industries

Lightweight yet strong materials like titanium alloys ensure efficiency and safety in aircraft.

Automotive components use materials with high impact resistance, such as advanced polymers.

Manufacturing Tools and Machinery

Machine tools rely on hard materials like tungsten carbide for durability and precision.

Conveyor belts require toughness and flexibility to handle wear and tear.

Product Design and Safety Analysis

Consumer goods, such as smartphones, use materials that balance hardness and toughness.

Safety-critical systems, like helmets and airbags, are designed with energy-absorbing materials.

Material Science and Advancements

Developing New Materials

Nanomaterials and composites offer superior strength and lightweight properties.

Innovations like graphene enhance conductivity and mechanical strength.

Sustainability and Recycling

Recyclable materials, such as aluminium, reduce environmental impact.

Bio-based polymers provide eco-friendly alternatives for packaging and construction.

Future Trends

Smart materials, such as shape-memory alloys, adapt to environmental changes.

Research focuses on enhancing the durability of materials under extreme conditions.

The mechanical properties of solids are the backbone of modern engineering, construction, and material science. They ensure the safety, functionality, and efficiency of structures and products. By understanding and leveraging these properties, we can drive innovation, create sustainable solutions, and meet the challenges of an ever-evolving world.

As we continue to explore new materials and techniques, the importance of mechanical properties will remain at the forefront of progress, shaping a future of resilience and ingenuity.

For more simplified explanations like the one above, visit the physics blogs on the Tutoroot website. Elevate your learning with Tutoroot’s personalised Physics online tuition. Begin your journey with a FREE DEMO session and discover the advantages of online tuitions.

2 notes

·

View notes

Text

"Manufacturing Processes Used by Mild Steel Dowel Bars Manufacturers in Sweden"

INTRODUCTION

Mild steel dowel bars are indispensable in the construction industry, especially for enhancing the durability and stability of concrete structures. Known for their exceptional strength and adaptability, these bars play a crucial role in ensuring efficient load transfer across joints in pavements, slabs, and other structural applications. This article explores the intricate manufacturing processes employed by Mild Steel Dowel Bars Manufacturers in Sweden, focusing on precision, quality, and innovation.

1. Raw Material Selection

The manufacturing process begins with selecting high-quality mild steel, known for its optimal balance of strength and ductility. Manufacturers in Sweden adhere to stringent quality standards to ensure that the raw material meets the requirements for construction-grade dowel bars.

2. Cutting and Sizing

Once the raw mild steel is procured, it is cut into specific lengths based on the application requirements. Precision cutting ensures uniformity, which is essential for effective load transfer and durability in concrete structures. Advanced cutting tools, including laser and hydraulic cutters, are often used to achieve accuracy.

3. Surface Preparation

Surface preparation is a vital step in the manufacturing process. The steel is cleaned to remove impurities, such as rust, grease, or mill scale, that may affect its bonding with concrete or its durability. Abrasive blasting or chemical treatments are commonly used for thorough cleaning.

4. Heat Treatment for Strength Enhancement

To enhance the mechanical properties of mild steel, manufacturers employ heat treatment techniques. This process improves the tensile strength and resilience of the bars, making them suitable for high-stress applications. Controlled heating and cooling cycles ensure uniformity and consistent quality.

5. Corrosion-Resistance Coating

Mild steel is susceptible to corrosion, especially in harsh weather conditions or when exposed to moisture. To mitigate this, manufacturers in Sweden apply protective coatings, such as epoxy or galvanization. These coatings not only extend the lifespan of the dowel bars but also ensure compliance with environmental and safety standards.

6. Straightening and Finishing

After heat treatment and coating, the bars are straightened to ensure they meet precise alignment specifications. Advanced machinery is used for this step, eliminating any deformations and achieving a smooth, uniform surface.

7. Quality Inspection and Testing

Quality assurance is a cornerstone of the manufacturing process. Mild Steel Dowel Bars Manufacturers in Sweden conduct rigorous testing to ensure that the bars meet international construction standards. Key tests include tensile strength analysis, corrosion resistance evaluation, and dimensional accuracy checks.

8. Packaging and Distribution

Once the dowel bars pass all quality checks, they are packaged using materials that protect them during transportation and storage. Proper labeling and documentation ensure that the bars reach their destination with traceability and compliance intact.

Advantages of Swedish Manufacturing Processes

Precision Engineering: Swedish manufacturers utilize advanced machinery and technology to achieve unmatched precision in dowel bar production.

Sustainability Practices: The focus on eco-friendly methods, such as recycling and reducing waste, aligns with Sweden's commitment to sustainability.

Compliance with Global Standards: By adhering to stringent international construction norms, Swedish manufacturers ensure that their products are recognized worldwide for quality and reliability.

Conclusion

The meticulous manufacturing processes employed by Mild Steel Dowel Bars Manufacturers in Sweden highlight their dedication to quality and innovation. From raw material selection to final packaging, each step ensures that the dowel bars are robust, durable, and suited for a wide range of construction applications. These processes set a benchmark for the global industry, making Sweden a leader in the production of high-quality mild steel dowel bars.

3 notes

·

View notes

Text

Fitting a Home Elevator in a Closet

Elevators are no longer confined to towering skyscrapers. With advancements in technology and design, home elevators are becoming increasingly popular and accessible. Installing a home elevator in a closet provides a convenient and stylish solution for navigating multi-story homes, especially for those with mobility challenges, aging individuals, or large families. This comprehensive guide explores the feasibility, benefits, and considerations when fitting a home elevator in a closet, empowering you to make an informed decision for your home.

Assessing Feasibility: Evaluating Your Closet Space

Before embarking on the installation process, it's crucial to assess the suitability of your closet space. Here are essential factors to consider:

Size and Dimensions: Measure the closet's height, width, and depth. Ensure there's sufficient headroom and space for the elevator car, pit, and overhead machinery.

Structural Integrity: Consult with a structural engineer to evaluate the closet's load-bearing capacity and determine if it can safely support the weight of an elevator.

Existing Wiring and Plumbing: Assess the closet's proximity to electrical outlets and water sources. This information will help determine the complexity of the installation process.

Choosing the Right Type of Home Elevator:

The type of home elevator best suited for your closet space depends on several factors:

Hydraulic Elevators: These elevators use hydraulic cylinders to lift the car. They are suitable for smaller spaces but might require a pit deeper than other options.

MRL (Machine Roomless) Elevators: These elevators have the machine room located at the top of the shaft, eliminating the need for a separate machine room. They are ideal for space-constrained installations.

Pneumatic Elevators: These elevators use compressed air to lift the car. They are often smaller and require less space than hydraulic elevators but might have limitations in terms of weight capacity.

Design Considerations for Closet Elevators:

Interior Design: Choose an elevator car design that complements your home's interior style. Consider factors like finishes, lighting, and ventilation.

Noise Reduction: Opt for elevators with noise-reduction features to minimize disruptions within your home.

Accessibility Features: If you have specific accessibility needs, ensure the elevator is equipped with features like handrails, emergency stop buttons, and wheelchair accessibility.

Installation Process and Timeline:

The installation process typically involves the following steps:

Site Preparation: Prepare the closet space by removing any obstructions and ensuring the area is ready for construction.

Shaft Construction: Construct the elevator shaft within the closet space, ensuring it meets safety standards and building codes.

Installation of Elevator Components: Install the elevator car, machinery, and control systems.

Electrical and Plumbing Connections: Connect the elevator to the building's electrical and plumbing systems.

Testing and Commissioning: Conduct thorough testing to ensure the elevator operates safely and efficiently before final commissioning.

The installation timeline can vary depending on factors like the type of elevator, the complexity of the installation, and any required permits or approvals.

Benefits of a Closet Elevator:

Enhanced Accessibility: A home elevator provides easy access to all floors, improving mobility for individuals with disabilities or limited mobility.

Increased Home Value: Installing a home elevator can significantly increase your property's value, making it more attractive to potential buyers.

Improved Quality of Life: For aging individuals or families with young children, a home elevator eliminates the need to climb stairs, enhancing convenience and safety.

Stylish Addition: Modern home elevator designs can seamlessly blend into your home's interior, adding a touch of elegance and functionality.

FAQs: Addressing Common Concerns About Closet Elevators

Q: Will a home elevator significantly reduce my closet space?

A: While a home elevator does require space, modern designs and advancements in technology allow for more compact installations. However, it's essential to assess your closet's dimensions carefully to ensure it can accommodate the elevator without compromising functionality.

Q: Is it noisy?

A: Modern home elevators are designed to be quiet. Noise-reduction features and advanced technology minimize disruptions within your home.

Q: Is a home elevator expensive to install and maintain?

A: The cost of a home elevator varies depending on factors like the type of elevator, size, features, and local installation costs. While there is an upfront investment, the long-term benefits in terms of convenience and accessibility can outweigh the initial cost.

Q: Do I need any special permits or approvals to install a home elevator?

A: Building codes and regulations vary by location. It's essential to consult with local authorities to determine any specific permits or approvals required for your project.

Q: Can I customize the interior of the elevator car?

A: Yes, many home elevator manufacturers offer customization options for the interior design, allowing you to match the elevator's aesthetic to your home's decor.

Conclusion: Elevating Your Home with a Closet Elevator

Installing a home elevator in a closet can transform your living space, providing convenience, accessibility, and a touch of modern elegance. By carefully considering factors like feasibility, design preferences, and installation process, you can make an informed decision that enhances your home's functionality and value. With advancements in technology and a wide range of options available, a home elevator can be a seamless and stylish addition to your Norwich residence.

Read More: Elevator Lifts for Home: Transforming Your Living Space

2 notes

·

View notes

Text

#onthisday in 1940 the first bombing raid on Berlin, Germany of the Second World War by Bomber Command took place. Aircraft including Wellingtons, Hampdens and Whitleys took part.

Vickers Wellington | Classic Warbirds

During September 1932 the Air Ministry issued Specification B.9/32 which required an aircraft with a range of 720 miles and a bomb load of 1,000lb. Vickers design, initially known as the 271 would compete with Handley Page's H.P. 52 design, which would also be ordered into production as the Hampden. Vickers entry would be built using the geodetic construction method, which had first been used on the Vickers Wellesley, power would be supplied by a pair of Rolls-Royce Goshawk engines. This enabled a range of 2,800 miles and a bomb load of 4,500lb. More than four times the amount called for in the specification.

The prototype Wellington was ready by May 1936 and featured the fin and rudder of a Supermarine Stranraer and instead of Rolls-Royce engines, a pair of 915-hp Bristol Pegasus engines were installed. The 15th June 1936 would see Captain Joseph Summers at the controls as the new aircraft prototype made its maiden flight. Later that month, with the nose and tail cupolas of the aircraft covered, the Wellington appeared at the RAF Display, Hendon on the 27th June 1936. This was followed two months later on the 15th August by an order for one hundred and eighty Wellington Mk Is by the Air Ministry. These aircraft would be produced under a different Specification B.29/36, which required a more angular fuselage, the tail unit to be revised and hydraulic powered turrets in the nose, ventral and tail positions.

Testing of the new aircraft was initially done by Vickers before being flown to Martlesham Heath so the Aeroplane and Armament Experimental Establishment could conduct official trials. However as these trials concluded the prototype crashed on the 19th April 1937. The cause was found to be elevator overbalance in a high-speed dive. Despite this set back, development of the Wellington continued and before the year was out, on the 23rd December 1937, the first production Mk I flew. Although originally fitted with the Bristol Pegasus X engine, April 1938 would see the 1,050-hp Pegasus XVIII engine become the engine of choice for Wellington Mk I aircraft produced.

Deliveries of the Royal Air Force's new bomber began on the 10th October 1938, with No. 99 Squadron, RAF Mildenhall the first to receive the new type, with a crew of up to six people, a top speed of 245 mph and able to carry 4,500lb bombs over 1,200 miles, and by the time war broke out the following September a total of ten squadrons were equipped with the Wellington, two of which were reserve squadrons. With larger main wheels and the landing gear strengthened the Mk IA appeared. This new version also had its Vickers turrets replaced with Nash and Thompson ones. The Mk IC followed and this had its ventral turret removed in favour of either a Vickers 'K' or Browning machine-gun firing from the beam position on either side. The Wellington's bomb bay was also strengthen to allow the use of a 4,000lb bomb. Just under one hundred and fifty Mk ICs would be used as torpedo bombers.

With a pair of 1,145-hp Rolls-Royce Merlin X engines the Wellington Mk II appeared with a Mk I adapted to serve as the prototype. Making its maiden flight at Brooklands on the 3rd March 1939, this new version started to enter RAF service in October 1940.

Two Wellington Mk III prototypes were produced, the first was a converted Mk I fitted with Bristol Hercules HEISM engines, which made its maiden flight on the 19th May 1939, and the second was a Mk IC designed to take the 1,425-hp Hercules III engine, which flew in January 1941. In the end neither of these two engines were used when the Mk III went into production, with the 1-590-hp Hercules XI used. A new rear FN.20A turret was introduced to the aircraft which had four 0.303-in machine-guns, which was twice the existing armament.

The Mk IV followed and this was powered by a pair of 1,050-hp Pratt & Whitney Twin Wasp R-1830-S3C4-G engines, which had been ordered by France but not delivered and were consequently available for use.

As a result of Vickers being asked to investigate whether a Wellington could be fitted with a pressurised cabin for use as a high altitude bomber/Pathfinder, the Mk V & VI would be developed, at the same time, for this role. The Mk V would be powered by turbocharged Bristol Hercules VII engines and had a service ceiling of 36,800 ft, whilst the Mk VI was powered by 1,600-hp Merlin 60 engines and its service ceiling was 1,700 ft higher at 38,500 ft. Both aircraft featured a FN.20A turret positioned in the tail that could be remotely controlled. It was to be the Mk VI that was the preferred of the two, but only sixty four would be built, four of which served in the pathfinder role. However by this time the de Havilland Mosquito was in service and was used in the role instead.

The next intended Wellington was the Mk VII which was to be powered by a pair of Merlin XX engines, but this only reached the prototype stage. In the end the sole example was used by Rolls-Royce to develop their Merlin 60 engine.

Although Coastal Command had been using the type it wasn't until the production of the Mk GR.VIII that a variant of the Wellington was produced specifically for use within Coastal Command. Based on the Wellington Mk IC the aircraft was fitted with Air-to-Surface Vessel Mk II radar and some versions would have a Leigh Light installed in the ventral turret with the light operator positioned in the nose meaning this armament was removed.

The Wellington Mk X was the last bomber version built and also the most produced, with 3,803 rolling off the production line, with its roots in the Mk III the Mk X would be powered by a pair of either 1,675-hp Bristol Hercules VI or Hercules XVI engines. As well as serving with Bomber Command some would serve with Operational Training Units, and post-war a number would become T.10 crew trainers after conversion work undertaken by Boulton Paul. The Mk X would also provide the basis for the Wellington Mk GR.XI which would have the same engines as the Mk X and would serve with Coastal Command. These would have ASV Mk II radar installed at first before ASV Mk III radar replaced it and this would also equip the 1,735-hp Hercules XVII powered Mk GR.XII, which also featured a Leigh Light.

The Wellington would immediately see action the day after the Second World War (1939 – 1945) broke out, when on the 4th September 1939, alongside the Bristol Blenheim, they carried out the first raids on German territory by Bomber Command when they attacked German shipping at Brunsbuttel. The Wellington would operate during daylight as it was considered that by flying in tight formations its fire power would make them able to fend off attack successfully. However early raids showed that the defensive armament of six 0.303-in machine-guns, two in each turret located in the nose, ventral and tail positions were inadequate. As a result a gun was fitted in the beam position and the Wellington would now operate mainly at night.

The Wellington would play a big part in Bomber Command's early wartime operations. Major operations for the type saw it take part in the first raid on Berlin, Germany on the 25th August 1940 and drop the first 4,000lb 'Blockbuster' bomb on a raid over Emden, Germany on the 1st April 1941. At the height of its time with Bomber Command the Wellington made up 601 of the 1,047 aircraft for Operation Millennium when Cologne, Germany was attacked on the 30th May 1942. By the end of 1942 the Wellington's time as a frontline bomber was coming to an end as by now the four-engined heavy bombers that would form the backbone of Bomber Command from now on, the Avro Lancaster, Handley Page Halifax and Short Stirling, were now in service. The final time the Wellington would be used in major numbers by Bomber Command was on the 8th October 1943. There was still No. 300 Squadron using the type as 1944 got underway but they were only allowed to lay mines and attack minor targets. No. 192 Squadron would also keep using the aircraft for intelligence gathering into 1945.

The type would also serve with Coastal Command, which lead to perhaps one of the more unusual aircraft of the war. Appearing in 1940 with a metal ring under the fuselage, with the idea to detonate magnetic mines by use of a coil which created a field current.

As well as serving in Europe the Wellington would serve in the Middle East and Far East and would also be converted for transport and training duties. By the time the final Wellington, a Mk X, was delivered on the 25th October 1945, 11,461 had been produced and the type would serve until 1953 training pilots and navigators.

Technical Details

Click on the aircraft image to view a larger version.

Top Speed Range Service Ceiling Armament

Wellington Mk I 245 mph 1,200 miles 21,600 ft eight 0.303-in machine-guns

4,500lb bombs

Wellington Mk II 254 mph 1,540 miles 23,500 ft six 0.303-in machine-guns

4,500lb bombs

Wellington Mk II side profile image

Wellington B Mk III 235 mph 1,540 miles 19,000 ft eight 0.303-in machine-guns

4,500lb bombs

Wellington B Mk IV 255 mph 1,500 miles 18,000 ft eight 0.303-in machine-guns

4,500lb bombs

Wellington B Mk VI 300 mph 1,510 miles 38,600 ft four 0.303-in machine-guns

4,500lb bombs

Wellington B Mk X 255 mph 1,885 miles 22,000 ft eight 0.303-in machine-guns

4,500lb bombs

Wellington GR Mk VIII 235 mph 2,500 miles 18,000 ft six 0.303-in machine-guns

and either two depth charges or

torpedos

Wellington GR Mk XI 255 mph 2,020 miles 19,000 ft eight 0.303-in machine-guns

4,500lb bombs

Wellington GR Mk XII 256 mph 1,810 miles 18,500 ft eight 0.303-in machine-guns

5,100lb bombs

Wellington GR Mk XIII 250 mph 1,760 miles 16,000 ft eight 0.303-in machine-guns

5,000lb bombs

Wellington GR Mk XIV 250 mph 1,760 miles 16,000 ft eight 0.303-in machine-guns

5,000lb bombs

Wellington C Mk XX Transport version able to carry eighteen people.

Wellington C Mk XVI Transport version able to carry eighteen people.

Wellington T Mk XVII Trainer version.

Wellington T Mk XVIII Trainer version.

Wellington T Mk XIX Trainer version.

Wellington T Mk X Trainer version.

7 notes

·

View notes

Text

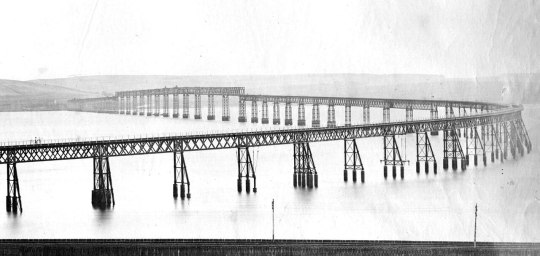

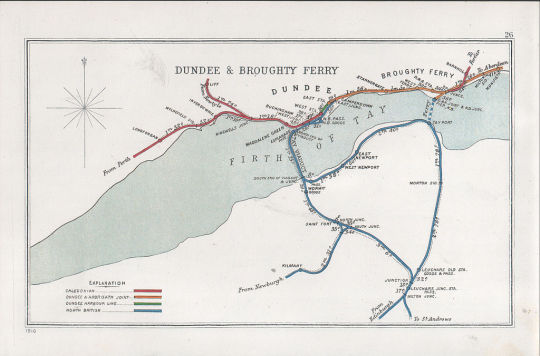

On June 20th 1887 the "new" "Tay rail bridge opened, the longest in the British Isles.

Firstly let’s get the usual dates thing out the way, I have three dates for this after examination, 1st, 10th and 20th of June, you’d think in an age where we photograph things for posterity, we could get the dates right. I’ve chosen today because it flagged up in my alerts, it’s as simple as that.

We have to salute the bravery of those men who worked building bridges like this, I say men, but look t the photos of the construction workers and see how young some of them were!

I think we all know the story behind the Tay bridge disaster so there is now need to go through it all again but after the bridge collapsed the North British Railway and supporters of the Tay Bridge were determined that it should be rebuilt. William Henry Barlow who had sat on the board of enquiry into the old bridge was asked on the best course of action. After thorough investigation of the options, his recommendation was to build a new double line bridge, completely independent of the old.

Barlow’s design for the new bridge was deeply influenced by the presence of the old. To satisfy stipulations made by the Board of Trade, the bridge was to be constructed exactly parallel alongside the old in order to keep navigation channels open, and its height was to be reduced from 88ft in the old bridge to 77ft in the new. As in the old bridge, the railway line was to run on the top of the approach girders, and through the girders of the high, larger navigation spans. Barlow recommended that if the spans of the new bridge were to be kept the same, girders from the old bridge that were unaffected by the collapse of the high girders, were able to be re-used in the new.

The new bridge was to be built 60ft upstream from the old, allowing the old bridge to become ‘staging’ for the men and materials in the construction of the new. The approaches onto the new bridge were altered; to the south the branch lines were joined on brick arches nearer to the shore at Wormitt, and to the North the eastwards curve into Tay Bridge Station (now called Dundee) was softened. Stringent tests on weight and wind loading in the design and construction of the new bridge were also to be undertaken. The proposals for the ‘New Tay Viaduct’ were accepted by Parliament in October 1881, and the firm William Arrol & Co of Glasgow was appointed contractor.

The new bridge took just 5 years to build, thanks in most part to special pontoon equipment with hydraulic legs which were designed by William Arrol. Various arrangements of these hydraulic pontoons were used to sink and construct the brick and concrete foundation columns, to erect the wrought iron piers, to move the old girders into position for the new bridge, and to erect the new navigation spans. The completed bridge is 10711ft in length, 8396ft of which is in a straight line running virtually north / south across the Tay until it curves eastwards towards Dundee. There are 85 piers; 1-28 forming the south approach, 28-41 the ‘navigation spans’ and 41-85 the north approach. The new Tay Bridge was opened to traffic, without ceremony on 20th June 1887.It still stands as testament to what good engineering was used in it's build.

You can find loads more pickoff the bridge during construction here https://www.leisureandculturedundee.com/virtual-gallery-new-bridge-1887

15 notes

·

View notes

Text

Secret Strategies to follow and be prepared about OAR Test

OAR TEST PREP : JOIN US AT PRIVATE STUDY GROUP 👈.

Use the Process of Elimination If unsure of an answer, eliminate obviously incorrect choices to improve your odds of guessing correctly. Skip tough questions and return to them if time permits. Don’t spend too much time on a single question. Move on and come back later if necessary. Take OAR practice tests 👈 to identify weak spots.

Some important mechanical comprehension related objective type question encountered on OAR Test:

Which of the following forces is used in a hydraulic system to lift a heavy load?

a) Gravitational force

b) Pascal's law

c) Frictional force

d) Centrifugal force

Answer: b) Pascal's law

In a car engine, what is the purpose of the crankshaft?

a) To compress the fuel and air mixture

b) To control the exhaust valves

c) To convert the up-and-down motion of the pistons into rotational motion

d) To filter out impurities from the fuel

Answer: c) To convert the up-and-down motion of the pistons into rotational motion

Which of the following statements is true about friction?

a) Friction always helps in the movement of objects

b) Friction increases the efficiency of machines

c) Friction resists the motion between two surfaces

d) Friction has no effect on moving objects

Answer: c) Friction resists the motion between two surfaces

Join Us At OAR Test Study Materials 👈 & get course materials 👈 For Preparation.

#air force#carrier aviation#military#navy#royal navy#us army#us marines#us navy#u.s. agent#u.s. air force#u.s. military#u.s. house of representatives#u.s. navy#u.s. news#u.s. army#oar test prep

3 notes

·

View notes

Text

The Ultimate Guide to Vehicle Cargo Solutions: From Secure Hauling to Innovative Storage

Whether you're an outdoor enthusiast, road trip lover, or DIY mechanic, having the right vehicle cargo solutions can transform your transportation experience. In this comprehensive guide, we'll explore five innovative products and techniques that will help you haul gear safely, protect your vehicle, and enhance your adventures.

1. Secure Cargo Hauling with Rhino USA Retractable Straps

When it comes to cargo hauling with Rhino USA retractable straps, these heavy-duty tie-downs offer unmatched convenience and reliability. Unlike traditional straps that tangle easily, Rhino USA's retractable design allows for quick deployment and compact storage.

These straps feature military-grade materials that withstand extreme weather conditions while maintaining flexibility. The automatic retraction mechanism keeps straps organized when not in use, eliminating the frustration of untangling knots. With multiple length options available, they're perfect for securing everything from rooftop cargo boxes to motorcycles and furniture.

Key benefits include:

Time-saving operation with one-handed adjustment

Superior load security with reinforced hooks

Weather-resistant construction for all-season use

Space-saving storage that fits in your glove compartment

For outdoor enthusiasts who frequently transport gear, these straps provide the perfect balance of strength and convenience. Whether you're heading to the mountains or helping a friend move, Rhino USA retractable straps ensure your cargo stays put throughout the journey.

2. Is the PMRL Portable 2-Post Lift Safe for Home Use?

Many DIY mechanics wonder how safe is the PMRL portable 2-post lift for their home garage. This innovative lifting solution brings professional-grade vehicle access to residential spaces without permanent installation.

The PMRL lift features:

Dual locking mechanisms for fail-safe operation

Heavy-duty steel construction with 6,000 lb capacity

Portable design with locking casters

Low-profile adapters for sports cars

Safety tests show the PMRL meets ANSI standards when properly installed. The hydraulic system includes overload protection, while mechanical locks engage automatically at set heights. Unlike permanent lifts, this portable version can be moved aside when not in use, making it ideal for garages with limited space.

For car enthusiasts wanting professional-level access without construction, the PMRL portable lift offers a safe, convenient solution for oil changes, brake work, and detailing.

3. Protecting Your Vehicle with an In-Garage Car Shield

Learning how to set up your in-garage car shield can save your vehicle from dings, dust, and accidental damage. These protective barriers install easily on garage walls or ceilings, creating a physical buffer between your car and stored items.

Modern car shields feature:

Padded vinyl surfaces that absorb impacts

Modular panels that customize to your space

Reflective strips for visibility in low light

Easy-cleaning materials that resist stains

Installation typically takes under an hour with basic tools. The best systems allow partial deployment when working in the garage and full coverage when parked. For collectors or anyone wanting to preserve their vehicle's condition, an in-garage shield provides affordable protection.

4. Capturing Epic Road Trips with Roof Box Time-Lapse Rigs

Adventure photographers are revolutionizing road trips with roof box time-lapse rigs. These specialized mounts turn your cargo box into a mobile camera platform for stunning travel footage.

Professional-grade rigs include:

Vibration-dampening mounts for smooth footage

Weatherproof housings that protect equipment

Multi-angle adjustment for creative compositions

Power solutions for extended recording

The elevated perspective creates dynamic shots of changing landscapes, sunsets, and cityscapes. Time-lapse enthusiasts can program intervals from seconds to hours, capturing entire journeys in mesmerizing sequences. With proper setup, these systems produce broadcast-quality footage without expensive equipment.

For content creators wanting unique travel visuals, roof box time-lapse rigs offer an innovative solution that combines practicality with creative potential.

5. Eliminating Human Scent with Roof Box Storage for Hunting

Serious hunters understand the importance of roof box scent control for hunting. Specialized cargo boxes now incorporate scent-blocking technology to conceal human odors from game animals.

Advanced systems feature:

Activated carbon lining that absorbs odors

Airtight gaskets preventing scent escape

UV-resistant materials that don't off-gas

Separate compartments for contaminated clothing

Hunters report significantly improved success rates when using these systems to transport gear to remote locations. The roof-mounted position keeps odors elevated away from ground-level game trails. Some models even include ozone generators for complete scent elimination.

For bow hunters needing absolute stealth, scent-control roof boxes provide a critical advantage in the field.

Choosing the Right Solution for Your Needs

Each of these innovative products solves specific transportation challenges:

Rhino USA straps for secure, hassle-free cargo tying

PMRL lifts for safe DIY vehicle maintenance

Car shields for garage protection

Time-lapse rigs for creative travel footage

Scent-control boxes for hunting success

By investing in the right equipment for your activities, you'll enjoy greater convenience, safety, and performance from your vehicle. Whether you're a weekend warrior or daily commuter, these solutions help maximize your vehicle's potential while protecting your valuable gear and investments.

For more detailed information on any of these products, visit the linked articles to discover which solution best fits your lifestyle and needs. With the right cargo management system, every trip becomes safer, more organized, and more enjoyable.

0 notes

Text

High Strength, Flawless Finish: The Superiority of ST52 Seamless Pipes

By Amardeep Steel Centre LLP – Leading ST52 Carbon Steel Pipe Distributor in India

When it comes to structural reliability and mechanical performance, ST52 Seamless Pipes stand out as an industry favorite. Engineered for strength and precision, these pipes offer a perfect balance of durability, machinability, and finish, making them ideal for critical industrial applications.

At Amardeep Steel Centre LLP, we are proud to be one of the top ST52 Pipe suppliers and distributors of DIN 2391 ST52 Seamless Pipes in India and across global markets.

🧱 What Makes ST52 Seamless Pipes Exceptional?

✅ Material Grade: ST52 is a low alloy structural steel with a high yield strength.

✅ Seamless Structure: Manufactured without any welded joints, ensuring no weak points.

✅ Dimensional Accuracy: Excellent surface finish and tight tolerance for precise applications.

✅ High Load Capacity: Perfect for heavy-duty and high-stress environments.

✅ Corrosion Resistance: Long service life even in tough environments.

Whether you're looking for DIN 2391 ST52 Pipe, SCH 40 ST52 Seamless Pipe, or ST52 Carbon Steel Pipe, we provide solutions tailored to your exact needs.

🏭 Applications of ST52 Seamless Pipes:

🏗 Construction & Infrastructure: Ideal for bridges, buildings, and structural frameworks.

🛠 Machinery & Equipment: Widely used in hydraulic systems, cylinders, and mechanical tools.

🚛 Automotive Industry: Preferred for vehicle chassis and precision components.

🛢 Oil & Gas Sector: Used in piping systems under high pressure and load.

🏭 General Engineering: Suitable for heavy fabrication and support systems.

🌟 Why Choose Amardeep Steel Centre LLP?

As a leading ST52 Carbon Steel Pipe distributor in India, we offer:

📦 Ready stock of various sizes and thicknesses

🌍 Export-grade quality for global markets

🧪 Full material test reports and certifications

⚙️ Custom cutting, finishing & third-party inspection

📈 Competitive st52 tubes price in India

We also supply DIN 2391 ST52 Welded Pipe and SCH 40 DIN 2391 ST52 Welded Pipe to meet diverse application requirements.

🔗 Strengthen Your Structures with ST52 Seamless Pipes

Whether you're a fabricator, engineer, or procurement specialist – trust Amardeep Steel Centre LLP for consistent quality and performance.

0 notes