#Industry 4.0-based controllers

Explore tagged Tumblr posts

Text

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

How to Choose the Best Low Voltage Switchgear for Your Project

Low voltage switch gears are significant to an industry, commercial or residential installation in ensuring the safe and effective power distribution. Selecting the right switchgear is key in making sure the system will be reliable, preventing electrical faults, and optimizing energy efficiency. Buying switchgear may appear challenging, given the number of options available in the market. The guide below will assist in grasping the vital aspects to consider in choosing low-voltage switchgear in 2025.

What is Low Voltage Switchgear?

Low voltage (LV) switchgear is an assembly of circuit breakers, disconnects, fuses, relays, and other protective equipment for controlling and protecting electric systems in voltages of up to 1,000V AC. It is commonly used in:

Industrial power distribution systems;

Commercial buildings;

Data centers;

Hospitals;

Renewable energy systems.

Choosing Low Voltage Switchgear: Important Considerations

1. Understand Your Project Requirements

Understanding your project requirements for assessing power distribution should include:

Voltage and current rating. This is for ensuring compatibility of load.

Type of application: For example, both industrial and commercial as well as residential and renewable sources.

The fault current rating: Ensure that it can withstand the maximum possible fault current.

Number of feeders and expansion requirements: Be sure to plan for possible future growth.

2. Safety and Compliance with Standards

As far as safety is concerned, the other critical consideration when selecting switchgear is to ensure that it has met the following:

IEC 61439 or ANSI/NEMA standards-Properly complying with international safety and performance standards.

Arc flash protection-Reduces the risk of being exposed to electrical hazards.

Short-circuit withstand capability-Makes sure switchgear withstands those high fault conditions.

3. Type of Switchgear Configuration

The correct configuration should be selected based on the size and complexity of the project:

Fixed Type Switchgear — Cost-wise, the cheapest and most suitable for small installations.

Withdrawable Type Switchgear — Provides ease of maintenance expected for an industrial facility.

Compartmentalized Switchgear — Offers improved safety and isolation of components.

4. Energy Efficiency and Sustainability

Modern switchgear are also designed to optimize energy usage and reduce losses. Look for: Low power loss components — More efficient. Eco-friendly insulation materials — Leverage the environment. Smart grid compatibility — Include renewables.

5. Smart Features and Digitalization-

Soon after Industry 4.0 and IoT, digital switchgear became a standard. Consider: Remote monitoring and diagnostics-The predictive maintenance help. Automated fault detection-Reduced downtime, and increased safety. Data logging and analytics-Optimizes power usage.

6. Brand Reputation and After-Sales Support

Choosing a reliable brand ensures long-term performance and support. Some of the top low voltage switchgear Suppliers are:

Al Mayar Electric Switchgear Ind LLC is the new milestone in the mastering of Mayar Holding in electrical technology. The company is committed to cater quality electrical and switchgear products in Middle East, Asia, Europe & Africa ensuring high standards and reliability

Enza Electric stands out as the best manufacturer of electrical switchgear in the GCC countries, providing top-notch products that lead the market and offer reliable electrical solutions.

Al Daleel Electrical Switch Gear Trading LLC is one of the leading Supplier and Distributor of Electrical Switchgear Products in GCC.

Civaux Electric proudly stands at the forefront of electrical manufacturing, delivering a diverse range of premium products, including Panel Fans & Filters, Panel Heaters, Cabinet LED Lamps, Regulators, and Indication Lamps & Switches.

Stefan Electric based in Germany, specializes in manufacturing and distributing a wide range of switchgear products such as Current Transformers, Analog and Digital Meters, Relay and Timer Meters, and Door Limit Switches across the UAE, including Dubai, Qatar, Oman, Bahrain, Sharjah, and Saudi Arabia.

Additionally, check for:

Spare parts availability, thereby facilitating easy maintenance and repair.

Local service centers for a quick troubleshooting and support.

Warranty and possible extended service offerings would enhance long-term value.

7. Budget and Cost Considerations

The performance-to-cost trade-off is thus an important consideration. One could consider comparing:

- Initial costs versus future savings: Although more energy-efficient switchgear might entail higher initial costs, the operational expenses are going to be much lesser.

- Customization options: Some brands are more conducive to modular designs to accommodate specific budgets.

- Installation and maintenance costs: Include considerations for servicing and availability of spare parts.

7 notes

·

View notes

Text

Pottery's beginnings

By che(Please credit as "Petr Novák, Wikipedia" in case you use this outside Wikimedia projects.)guidance: Danny B. - che, CC BY-SA 2.5, https://commons.wikimedia.org/w/index.php?curid=2682270 and By http://fotos.noticias.bol.uol.com.br/entretenimento/ - http://fotos.noticias.bol.uol.com.br/entretenimento/2012/06/01/imagens-do-mes-junho2012.htm#fotoNav=60, CC BY-SA 4.0, https://commons.wikimedia.org/w/index.php?curid=73162369

The oldest use of fired clay we've found are figurines like the the Venus of Dolni Věstonice, which is about 31,000-27,000 years old. It was about 20,000 years ago that pottery took on the shape of a vessel in East Asia, from the area of present day China and Japan, which were joined by a land bridge at the time. They were simple objects, purely utilitarian, and some had scorching that indicate they were used for cooking. This was during the Late Glacial Maximum, when people were still living in mobile hunting and gathering groups, before the advent of settled agriculture

By ALFGRN - https://www.flickr.com/photos/156915032@N07/47705525691/, CC BY-SA 2.0, https://commons.wikimedia.org/w/index.php?curid=78369343 By Dmharvey - English Wikipedia, Public Domain, https://commons.wikimedia.org/w/index.php?curid=4081440

In Western Asia, stone like alabaster and calcite were used until about 9000 years ago (about 7000 BCE), especially around the upper Euphrates, in modern day Syria. Once settled agriculture was adopted, pottery began to be made, starting with coiling ropes of clay that were then smoothed before the vessel was fired. The decorations on pottery were very localized, as were the styles, so much so that archaeologists name pre-writing cultures by their pottery. Early pottery was fired in bonfires, possibly by accident at first, which could reach temperatures of 900 °C (1,650 °F). Because clay was used without any tempering in it at first, the vessels made had rounded bases to prevent cracking. Gradually, with the addition of sand, crushed shell or pottery, or grit, the shrinkage of clay while it was drying was better controlled, allowing for flatter bottoms and more creative shaping methods.

By 三猎 - Own work, CC BY-SA 4.0, https://commons.wikimedia.org/w/index.php?curid=47581230

In about 4000 BCE (6000 years ago), the potter's wheel was developed in eastern Europe, along with higher temperature kilns that could fire pottery at 1050-1200 °C (1920-2190 °F), making a broader array of pottery shapes possible. Potters began to be a separate occupation, which allowed more artistic freedom such that items like cooking utensils and rat traps were made from pottery. Glazing also became much easier with the higher temperature kilns.

By Altamura Painter - Walters Art Museum: Home page Info about artwork, Public Domain, https://commons.wikimedia.org/w/index.php?curid=18846300 and By Jastrow - own work, from the Iliade exhibition at the Colosseum, September 2006–February 2007, Public Domain, https://commons.wikimedia.org/w/index.php?curid=1284759

The ancient Greeks developed elaborately painted pottery showing scenes from mythology, life, and heroic exploits, most often with black against the red clay figures. Though glazing was possible, it wasn't often used by them, instead using a slip type clay as decoration. The Romans changed the focus from painted decoration to applied shapes in a newly (about 600 BCE) discovered molding process. Their pottery was typically made in areas like Germany or France in industrial scale, rather than in Rome itself, and was imported. Though pottery was widely and abundantly produced, it wasn't used as tableware by the Greeks and Romans, instead being used for storage and decoration.

By Photograph: Andreas Praefcke - Self-photographed, Public Domain, https://commons.wikimedia.org/w/index.php?curid=16265914

In contrast, Chinese pottery began using glazing around 1500 BCE, though the elite preferred plain colored pottery that was elegantly formed. The elite also used pottery for tableware and for religious purposes. Porcelain began to appear during the Tang dynasty (618-906 CE), but didn't gain its now well-known blue and white decorations until the Yuan dynasty (1271-1368 CE).

By Simon Burchell (Own work), CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=6011244 and By Cullen328 - Own work, CC0, https://commons.wikimedia.org/w/index.php?curid=39136893

Pottery was independently developed in the Americas as it didn't appear until about 9500 years ago (7500 BCE) in Brazil being the earliest known pottery. In Mesoamerica, pottery began to appear in the Archaic Era (from 3500-2000 BCE), which included finely decorated pottery but not glazing, stoneware, or porcelain, but did include terracotta and sculptures as well as vessels. As in the Old World, each civilization developed particular styles and decorations for their pottery.

#pottery#ceramics#human history#ancient egypt#ancient greece#native american history#chinese history#roman history#ancient culture#archaeology

8 notes

·

View notes

Text

Innovations in Electrical Switchgear: What’s New in 2025?

The electrical switchgear industry is undergoing a dynamic transformation in 2025, fueled by the rapid integration of smart technologies, sustainability goals, and the growing demand for reliable power distribution systems. As a key player in modern infrastructure — whether in industrial plants, commercial facilities, or utilities — switchgear systems are becoming more intelligent, efficient, and future-ready.

At Almond Enterprise, we stay ahead of the curve by adapting to the latest industry innovations. In this blog, we’ll explore the most exciting developments in electrical switchgear in 2025 and what they mean for businesses, contractors, and project engineers.

Rise of Smart Switchgear

Smart switchgear is no longer a futuristic concept — it’s a necessity in 2025. These systems come equipped with:

IoT-based sensors

Real-time data monitoring

Remote diagnostics and control

Predictive maintenance alerts

This technology allows for remote management, helping facility managers reduce downtime, minimize energy losses, and detect issues before they become critical. At Almond Enterprise, we supply and support the integration of smart switchgear systems that align with Industry 4.0 standards.

2. Focus on Eco-Friendly and SF6-Free Alternatives

Traditional switchgear often relies on SF₆ gas for insulation, which is a potent greenhouse gas. In 2025, there’s a significant shift toward sustainable switchgear, including:

Vacuum Interrupter technology

Air-insulated switchgear (AIS)

Eco-efficient gas alternatives like g³ (Green Gas for Grid)

These options help organizations meet green building codes and corporate sustainability goals without compromising on performance.

3. Wireless Monitoring & Cloud Integration

Cloud-based platforms are transforming how switchgear systems are managed. The latest innovation includes:

Wireless communication protocols like LoRaWAN and Zigbee

Cloud dashboards for real-time visualization

Integration with Building Management Systems (BMS)

This connectivity enhances control, ensures quicker fault detection, and enables comprehensive energy analytics for large installations

4. AI and Machine Learning for Predictive Maintenance

Artificial Intelligence is revolutionizing maintenance practices. Switchgear in 2025 uses AI algorithms to:

Predict component failure

Optimize load distribution

Suggest optimal switchgear settings

This reduces unplanned outages, increases safety, and extends equipment life — particularly critical for mission-critical facilities like hospitals and data centers.

5. Enhanced Safety Features and Arc Flash Protection

With increasing focus on workplace safety, modern switchgear includes:

Advanced arc flash mitigation systems

Thermal imaging sensors

Remote racking and switching capabilities

These improvements ensure safer maintenance and operation, protecting personnel from high-voltage hazards.

6. Modular & Scalable Designs

Gone are the days of bulky, rigid designs. In 2025, switchgear units are:

Compact and modular

Easier to install and expand

Customizable based on load requirements

Almond Enterprise supplies modular switchgear tailored to your site’s unique needs, making it ideal for fast-paced infrastructure developments and industrial expansions.

7. Global Standardization and Compliance

As global standards evolve, modern switchgear must meet new IEC and IEEE guidelines. Innovations include:

Improved fault current limiting technologies

Higher voltage and current ratings with compact dimensions

Compliance with ISO 14001 for environmental management

Our team ensures all equipment adheres to the latest international regulations, providing peace of mind for consultants and project managers.

Final Thoughts: The Future is Electric

The switchgear industry in 2025 is smarter, safer, and more sustainable than ever. For companies looking to upgrade or design new power distribution systems, these innovations offer unmatched value.

At Almond Enterprise, we don’t just supply electrical switchgear — we provide expert solutions tailored to tomorrow’s energy challenges. Contact us today to learn how our cutting-edge switchgear offerings can power your future projects.

6 notes

·

View notes

Text

CNC Press Brake Machine in India: Shaping the Future of Metal Bending

In the dynamic world of metal fabrication, CNC Press Brake Machines have become indispensable. These machines are critical in industries that demand precision bending and forming of sheet metal components. In India, the rising focus on infrastructure development, automotive manufacturing, and localized production has driven the adoption of CNC press brake technology across various sectors.

From small workshops to large-scale factories, CNC press brakes are revolutionizing how Indian manufacturers handle metal forming—efficiently, accurately, and consistently.

What is a CNC Press Brake Machine?

A CNC (Computer Numerical Control) Press Brake Machine is used to bend and shape metal sheets with precision. It uses a punch and die to perform various bends, guided by a CNC system that ensures exact specifications for angle, length, and repetition.

Modern CNC press brakes are far more advanced than traditional mechanical or hydraulic versions. They come with programmable controls, automated back gauges, and advanced sensors to deliver high-speed and high-precision bending.

Why CNC Press Brakes are Gaining Popularity in India

1. Precision and Consistency

In sectors like automotive, aerospace, and electronics, even minor deviations in part dimensions can lead to quality issues. CNC press brakes eliminate human error and ensure consistent output across batches.

2. Growing Industrialization

India’s expanding industrial base, especially in Tier 2 and Tier 3 cities, is fueling demand for reliable fabrication equipment. CNC press brakes allow businesses to scale up production without compromising on accuracy.

3. Labour Efficiency

With a skilled labor shortage and rising wages, automation is becoming more attractive. CNC press brakes require minimal human intervention, reducing labor costs and dependency on manual operators.

4. Government Incentives

Government initiatives like Make in India and Production Linked Incentive (PLI) Schemes are encouraging manufacturers to invest in advanced machinery, including CNC press brakes, for higher productivity.

Key Features of CNC Press Brake Machines in the Indian Market

High-Tonnage Capability: Machines ranging from 30 to 1000+ tons to suit various applications.

CNC Control Systems: Brands like Delem, ESA, and Cybelec offer intuitive interfaces for programming and automation.

Servo-Electric or Hydraulic Drive Systems: Depending on precision, energy efficiency, and speed requirements.

Multi-Axis Back Gauge: Enables complex bends and reduces setup time.

Automatic Tool Changers (ATC): For higher production environments.

Leading Indian and International Brands

India has a strong presence of both domestic and international CNC press brake manufacturers. Some notable names include:

Hindustan Hydraulics

Electropneumatics

Energy Mission

LVD India

Amada (Japan)

Durma (Turkey)

Yawei (China)

These companies offer machines tailored to the needs and budget of Indian manufacturers.

Applications in India

Automobile Body & Chassis Manufacturing

Kitchen Equipment Fabrication

Electrical Enclosures & Cabinets

Elevator and Escalator Components

Construction and Infrastructure Products

Railways and Defence Equipment

Challenges for Indian Buyers

High Initial Investment: CNC press brakes can be capital intensive, though the ROI is excellent over time.

Skill Development: Operators need training to use CNC systems effectively.

After-Sales Service: Choosing a vendor with reliable local support is crucial for maintenance and uptime.

The Road Ahead: Smart Factories & Industry 4.0

India is steadily moving towards smart manufacturing. CNC press brakes are now integrating with IoT, ERP systems, and robotic automation, enabling real-time monitoring, predictive maintenance, and remote troubleshooting. This evolution is making Indian factories more agile and globally competitive.

Conclusion

The CNC Press Brake Machine is no longer a luxury—it's a necessity in modern Indian manufacturing. With its unmatched accuracy, efficiency, and automation capabilities, it empowers businesses to meet rising customer expectations while optimizing operational costs.

As India continues to climb the global manufacturing ladder, CNC press brake machines will play a pivotal role in shaping the future—quite literally.

2 notes

·

View notes

Text

Robert F. Kennedy Jr. may now Make America Healthy Again. One of his first measures will be removing “an industrial waste product” from America’s water supply that has been deliberately added since 1945.

On January 25, 1945, Grand Rapids, Michigan, began water fluoridation. By 1960, water fluoridation had reached 50 million households and doubled to 100 million by 1975. Why? The government began adding fluoride to the water based on a 1930s study that stated a small amount of NATURALLY OCCURRING fluoride could protect teeth from decay.

It is odd that the government does not force insurance companies to treat teeth as a medical expense. It is difficult to gauge if these measures have actually prevented tooth decay, as access to dental health is far greater now than it was when trials began in the 1930s and 1940s. Who is responsible for adding fluoride to the water? California, Delaware, Georgia, Illinois, Kentucky, Louisiana, Minnesota, Mississippi, Nebraska, Nevada, Ohio, and South Dakota have state mandates requiring fluoridated water. Other states like Maine, Utah, and New Hampshire permit the public to vote. Water utilities companies are responsible for maintaining water fluoridation systems. The EPA has federal oversight over the process and set a maximum contaminant level for fluoride at 4.0 mg/L. The Safe Drinking Water Act of 1974 forbids the EPA from actually mandating fluoride or any additive substances to the water supply, but they do have oversight.

So what’s the problem? “On January 20, the Trump White House will advise all U.S. water systems to remove fluoride from public water. Fluoride is an industrial waste associated with arthritis, bone fractures, bone cancer, IQ loss, neurodevelopmental disorders, and thyroid disease,” Kennedy posted on X. Kennedy believes that fluoride does not have a clear health benefit to the public, but it is responsible for causing an array of life-altering ailments.

On September 25, 2024, a federal court in California ruled against the Environmental Protection Agency (EPA) in a case involving fluoride. The court said that current levels of fluoride violate the Toxic Substances Control Act. Judge Edward Chen declared that there is “substantial and scientifically credible evidence” that fluoride poses a serious health risk and emphasized concern over fluorides effect on the developing brains of infants.

“In all, there is substantial and scientifically credible evidence establishing that fluoride poses a risk to human health; it is associated with a reduction in the IQ of children and is hazardous at dosages that are far too close to fluoride levels in the drinking water of the United States,” the judge wrote in his ruling.

2 notes

·

View notes

Text

The Evolution of ERP Software: How it is Transforming Engineering and Manufacturing in 2023

In today’s dynamic world of engineering and manufacturing industry, maintaining competitiveness and operational efficiency is of paramount importance. Enterprise Resource Planning (ERP) software has become a fundamental tool for optimising processes, improving efficiency, and facilitating smooth operations in the engineering and manufacturing industries. As we progress into the year 2023, it becomes apparent that enterprise resource planning (ERP) software has experienced a substantial transformation, adapting to the unique requirements of the industry in question. Unlock the full potential of your manufacturing company with ERP software designed and developed by STERP (Shanti Technology). Contact today for a tailored ERP solution for manufacturing company in India that aligns perfectly with your business objectives.

This blog article aims to examine the growth of Enterprise Resource Planning (ERP) software and its significant impact on the fields of engineering and manufacturing.

Historical Perspective: A Brief Overview of ERP Software

The evolution of ERP software since its establishment in the 1960s has been significant, with a notable shift from its initial emphasis on inventory management and order processing. Over the course of several decades, enterprise resource planning (ERP) systems have seen significant growth and development, resulting in the integration of a wide range of corporate functions. These functions include but are not limited to accounting, human resources, procurement, and other related operations. The advancement of technology has led to the evolution of ERP software into a centralised platform that offers real-time data, enhances decision-making processes, and fosters communication across various departments within an organisation.

· Integration of IoT and Industry 4.0:

The combination of the Internet of Things (IoT) and Industry 4.0 technologies represents a notable revolution in ERP software during the year 2023. The Internet of Things (IoT) facilitates the interconnection of various devices and sensors, enabling the collection and sharing of data. This capability offers real-time insights into the industrial process. Enterprise Resource Planning (ERP) systems have the capability to effectively integrate this data, so facilitating manufacturers in making informed decisions based on data analysis and enhancing their operational efficiency.

The principles of Industry 4.0 place significant emphasis on the integration of automation, digitization, and connectivity, which have now been easily included in enterprise resource planning (ERP) software. The integration described enables enterprises to establish a smart industrial setting, increase their control of the supply chain, and optimise operational efficiency.

· Cloud-Based ERP Solutions:

Cloud-based enterprise resource planning (ERP) solutions have significantly transformed the operational landscape of enterprises. This paradigm shift can be attributed to the revolutionary impact of cloud technology on ERP software. In the year 2023, an increasing number of engineering and manufacturing companies are using cloud-based Enterprise Resource Planning (ERP) solutions. The aforementioned solutions possess several benefits, including the ability to scale, adaptability, reduced initial expenses, and convenient availability, rendering them exceedingly appealing to organisations of all sizes. Moreover, the utilisation of cloud-based enterprise resource planning (ERP) systems facilitates the instantaneous exchange of data and promotes collaboration among all parties involved, hence enhancing operational efficiency and cultivating a culture of innovation. Invest in the future of manufacturing. Choose advanced ERP software for engineering companies in India developed by STERP (Shanti Technology) to enhance agility and competitiveness.

· Advanced Analytics and Business Intelligence:

In the current business environment, data holds significant value. Enterprise Resource Planning (ERP) software has evolved to incorporate sophisticated analytics and business intelligence functionalities, enabling the generation of visually appealing data representations and the utilisation of predictive analytics techniques. Manufacturers have the ability to utilise this data in order to anticipate market trends, enhance production schedules, effectively manage inventories, and rapidly make well-informed business decisions. The utilisation of advanced analytics enables engineering and manufacturing enterprises to maintain flexibility and effectively respond to market fluctuations in a timely manner.

· Enhanced User Experience and Mobility:

The optimisation of user experience and mobility is a crucial element in contemporary enterprise resource planning (ERP) systems. In the year 2023, the primary emphasis of ERP software lies in delivering an intuitive and user-friendly interface, with the aim of facilitating smooth adoption and utilisation throughout all hierarchical levels within the organisation. Furthermore, the use of mobility enables stakeholders to conveniently access essential data and capabilities while on the move, hence enhancing productivity and facilitating informed decision-making. Stay ahead in the competitive manufacturing landscape. Reach out to an expert - STERP (Shanti Technology) - the most reliable Engineering ERP Software Company in India and elevate your business operations.

· Cybersecurity and Compliance:

The increasing prevalence of cyber risks has prompted ERP software developers to prioritise the integration of robust cybersecurity capabilities. In the year 2023, enterprise resource planning (ERP) systems place significant emphasis on the paramount importance of data security, adherence to industry laws, and the implementation of effective authentication procedures. This practice guarantees the preservation of confidential corporate information, hence cultivating a sense of trust and assurance among users.

Final Thoughts:

The evolutionary progression of Enterprise Resource Planning (ERP) software in the year 2023 signifies a significant and transformational change within the realm of engineering and manufacturing. The convergence of the Internet of Things (IoT), Industry 4.0 technologies, cloud-based solutions, sophisticated analytics, improved user experience, and heightened cybersecurity measures enables organisations to effectively streamline operations, boost efficiency, and attain long-term, environmentally conscious expansion. With the increasing use of these technological developments, the engineering and manufacturing sectors are poised to witness unparalleled levels of efficiency and creativity, hence setting a bright trajectory for the industry.

In order to remain competitive in today's ever-changing corporate landscape, it is imperative to be informed and capitalise on the capabilities of enterprise resource planning (ERP) software. Ready to streamline your manufacturing operations? Contact STERP (Shanti Technology) a renowned company offering manufacturing ERP software in India and see how it can simplify processes, boost efficiency, and drive profitability.

#ERP for manufacturing company in India#ERP software for engineering companies in India#Engineering ERP Software Company in India#Manufacturing ERP software in India#ERP India#Business Solutions#ERP software#Manufacturing#Engineering#business#shantitechnology#STERP

9 notes

·

View notes

Text

Looking forward to China’s industrial development prospects in the next 10 years

Looking forward to China's industrial development in the next 10 years, analysis and predictions can be made based on existing development trends, policy orientations and the global economic environment:

Industrial upgrading and structural optimization:

China will continue to promote the upgrading of its industrial structure from labor-intensive to technology- and capital-intensive. Mid- to high-end manufacturing will be the key development direction, including aerospace, high-end equipment, new energy vehicles, new materials and other fields. With the deepening implementation of the "Made in China 2025" strategy and subsequent planning, China will accelerate the in-depth integration of industrialization and informatization, and promote the development of emerging industries such as intelligent manufacturing and the industrial Internet. Innovation drive and technological progress:

Against the background of intensified global technological competition, China will further increase investment in technological innovation, especially in fields such as 5G, artificial intelligence, Internet of Things (IoT), quantum information, and biotechnology, to enhance the core competitiveness of the industry. Industry 4.0 related technologies and digital transformation will become mainstream. Enterprises will improve production efficiency and product quality through automation and intelligent transformation, and achieve personalized customization and flexible production. Green and sustainable development:

Environmental protection policies are becoming stricter, and low-carbon economy and circular economy will have a profound impact on the path of industrial development. China's industry will be committed to energy conservation and emission reduction, clean production, and the development of green manufacturing systems, such as new energy, energy-saving and environmental protection equipment and services.

Globalization and industrial chain reconstruction:

Taking into account the rise of trade protectionism and the adjustment trend of global supply chains, Chinese industry will actively build independent and controllable industrial and supply chains, seek a higher position in the global value chain, and enhance international competitiveness. While low-end industries are being transferred, China will strengthen international cooperation in some areas, actively participate in the global industrial division of labor, and build international brands and multinational companies. Talent training and system reform:

Facing the challenge of aging, China will pay more attention to the cultivation and introduction of talents, improve the quality of the labor force, especially the construction of highly skilled talent teams, to support the development needs of high-end industries. Deepen institutional reform, create a better business environment, encourage innovation and entrepreneurship, promote the development of small, medium and micro enterprises, and stimulate market vitality. To sum up, in the next ten years, China's industry will focus on high-quality development, focus on technological innovation, industrial chain upgrading, green development and improvement of global competitiveness, and strive to achieve the leap from a manufacturing country to a manufacturing power. At the same time, we will also respond to the challenges brought about by changes in the internal and external environments, continue to deepen reforms, and ensure the stable and healthy development of the industrial economy.

2 notes

·

View notes

Text

Semiconductor & Remote Testing Boost Auto Testing Services

The Mexico automotive testing market is projected to grow at a compound annual growth rate (CAGR) of 3.7% from 2023 to 2030. This upward trend is driven by increasingly stringent vehicle emissions and safety standards, expanding demand for electric vehicle (EV) testing, and growing adoption of advanced Testing, Inspection, and Certification (TIC) services in the country.

Mexico plays a strategic role in the global automotive supply chain, and as vehicle production accelerates, so does the demand for high-quality testing to ensure compliance, performance, and safety.

To Get Free Sample Report : https://www.datamintelligence.com/download-sample/mexico-automotive-testing-market

Key Market Drivers

1. Stricter Emission and Safety Regulations Mexico has tightened its regulatory framework in alignment with global standards, enforcing rigorous emissions controls and safety mandates. This includes the enforcement of soot-free vehicle emission norms and more stringent crash-testing protocols, prompting automakers and parts suppliers to expand testing operations.

2. Growth in TIC Services The automotive TIC (Testing, Inspection, and Certification) market in Mexico was valued at approximately USD 635 million in 2022 and is expected to exceed USD 1.3 billion by 2030. Rising demand for emissions testing, component validation, and homologation processes is fueling this segment’s rapid growth.

3. Rise of Electric and Connected Vehicles The expansion of electric and connected vehicle production has introduced new testing requirements, such as high-voltage battery certification, electromagnetic compatibility (EMC) testing, and ADAS system verification. The EV testing market alone is projected to grow at over 13% CAGR, supporting battery durability and charging system validation.

4. Increase in Automotive Production Mexico remains one of the top vehicle-producing nations globally, with strong exports to North America and Europe. The growth in vehicle output especially in SUVs, EVs, and light trucks is increasing the need for robust local testing capabilities.

5. Industry 4.0 and Digitalization Automotive testing in Mexico is increasingly powered by automation, data analytics, and cloud-based platforms. These technologies streamline quality checks, accelerate certification, and improve data-driven insights for both OEMs and regulators.

Market Segmentation

The automotive testing market in Mexico is broadly segmented by:

Test Type: Engine and transmission testing, chassis testing, durability and vibration analysis, emissions testing, electrical and electronics testing.

Product Type: Emission analyzers, battery testers, chassis dynamometers, alignment systems, and digital diagnostic tools.

Vehicle Type: Passenger cars, commercial vehicles, and electric vehicles.

Engine and transmission testing accounts for the largest share, while EV-related testing is the fastest-growing segment due to increasing vehicle electrification and regulatory requirements.

Regional & Industry Trends

North American Integration Under trade agreements such as USMCA, Mexico aligns its automotive testing standards with the U.S. and Canada. This harmonization ensures products meet stringent export requirements and drives demand for localized testing labs.

EV Component Testing Expansion Mexico’s growing role in the EV supply chain especially in battery and power electronics has created a surge in testing facilities dedicated to thermal safety, high-voltage stress, and software validation.

Underinvestment in R&D Infrastructure Despite strong production capabilities, many Mexican OEMs and Tier 1 suppliers lack advanced R&D labs. This gap presents opportunities for third-party testing providers and international TIC firms to expand service offerings.

Market Challenges

1. Limited In-House Capabilities Many domestic automotive manufacturers depend on external partners for emissions and safety testing due to underdeveloped internal facilities.

2. Capital Intensive Equipment Needs Modern test benches, EMC chambers, and battery validation systems require substantial investment, creating barriers for small-to-medium testing service providers.

3. Regulatory Complexity Automotive testing in Mexico must meet both domestic standards and international certification protocols, which can increase the cost and complexity of compliance.

Get the Demo Full Report : https://www.datamintelligence.com/enquiry/mexico-automotive-testing-market

Future Outlook

EV Testing Growth The demand for electric vehicle testing services particularly battery certification, charger compliance, and motor control system validation is expected to accelerate sharply by 2030.

Digital TIC Platforms AI-driven diagnostics, cloud-based monitoring, and remote inspection capabilities are emerging as core features of next-generation testing services in Mexico.

Government Support and Investment As the Mexican government encourages local automotive innovation, public-private partnerships may fund R&D labs, skill development, and infrastructure upgrades to meet growing testing demand.

Cybersecurity and Software Validation As connected and autonomous vehicle systems expand, there will be a growing emphasis on secure software validation, over-the-air update testing, and data protection protocols.

Competitive Landscape

Key players in Mexico’s automotive testing and TIC ecosystem include:

SGS

TÜV Rheinland

Intertek

DEKRA

Robert Bosch

Siemens

Rohde & Schwarz

AVL

UL Solutions

Anritsu

These firms are expanding their local footprint by offering integrated mechanical, electrical, and digital testing solutions tailored to OEM needs and regulatory requirements.

Conclusion

Mexico’s automotive testing market is undergoing a transformation, driven by tighter regulations, increasing EV adoption, and the rise of smart vehicle technologies. As the country reinforces its position as a key player in global automotive manufacturing, demand for high-quality testing services is set to grow steadily through 2030. With targeted investment, digital innovation, and strategic partnerships, Mexico can not only meet domestic testing needs but also serve as a testing hub for the broader Latin American and North American regions.

0 notes

Text

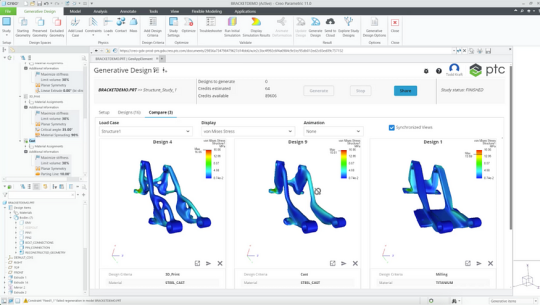

PTC Creo 12: New Tools for Smarter, Faster 3D Design

Discover what’s new in PTC Creo 12 — enhanced simulation, AI-driven design, MBD, and manufacturing tools. Upgrade now with ANH, the trusted PTC Creo reseller in the Delhi NCR region.

Top New Features in Creo 12

1. AI-Driven Design Guidance

Creo 12 takes intelligent design to the next level with built-in AI tools that offer real-time suggestions and improvements.

Get feedback during modeling

Reduce trial-and-error

Improve efficiency with every click

2. Enhanced Model-Based Definition (MBD)

Creo 12 makes MBD more practical and powerful, eliminating the need for traditional 2D drawings.

Improved PMI (Product Manufacturing Information)

Better GD&T annotation support

Clearer data for downstream users

3. Performance & Usability Upgrades

PTC has improved the overall speed, responsiveness, and ease of use:

Faster model regeneration

Smart mini toolbars

Enhanced model tree filters

Customizable dashboards for quick access

4. Creo Simulation Live — More Powerful Than Ever

Simulation Live has been expanded to cover:

Structural & thermal simulations

Better support for nonlinear materials

Real-time design feedback

5. Advanced Multi-Body Design

Creo 12 makes it easier to work with complex parts and assemblies:

Better control over multiple bodies in a single part

New body operations and organization tools

Improved part-to-part interactions

It’s ideal for high-detail engineering and intricate product development.

6. Additive and Subtractive Manufacturing Enhancements

Manufacturing has never been smoother in Creo:

More control over lattice structures

Enhanced 5-axis CAM functionality

New machine support and output formats

Whether you’re 3D printing or using CNC, Creo 12 has you covered.

7. Improved ECAD–MCAD Collaboration

With electronics becoming a bigger part of mechanical products, Creo 12 improves:

PCB visualization

Layer management

Synchronization between electrical and mechanical teams

This helps avoid costly errors during development.

Why Creo 12 is a Must-Have Upgrade

PTC Creo 12 isn’t just for big enterprises — it’s built for everyone who values smart, high-quality design. Whether you’re a design engineer, manager, or product innovator, Creo 12:

Saves time

Reduces errors

Encourages innovation

Supports industry 4.0 goals

Get Creo 12 from Delhi NCR’s Trusted PTC Reseller — ANH

Looking to upgrade your CAD tools or switch to Creo 12? ANH is a leading authorized PTC reseller in the Delhi NCR region. From licensing to training, we help businesses unlock the full potential of Creo.

Contact ANH today to get started with Creo 12!

✅ Conclusion: Welcome to the Future of Design

PTC Creo 12 is more than just an upgrade — it’s a gateway to smarter design, quicker development, and stronger innovation. With new AI tools, advanced simulations, and seamless usability, it’s built to give your team a competitive edge.

Design faster. Design smarter with Creo 12.

0 notes

Text

Enhancing Salt Spray Chamber Performance with PLC Automation – Powered by NX-ERA Xpress

In the industrial domain, corrosion is not just a problem, it's a stealthy destroyer. From car parts to ocean gear to electronics, the shadow of rust looms over all. That's where the salt spray chamber comes in useful, enabling us to simulate the most extreme conditions. However, the catch is that manual systems don’t cut it anymore.

Enter the NX-ERA Xpress PLC—a smart, compact PLC for industrial automation that’s changing the game for good.

We at Messung have a strong expertise in programmable logic controllers, and today we're demonstrating to you why a salt spray chamber needs a rugged modular PLC for demanding environments that's fluent in Industry 4.0.

What is a Salt Spray Chamber?

A salt spray chamber is a specialized testing environment that helps industries evaluate the durability of coatings, components, and materials under harsh environments. These rooms are intended to:

● Simulate corrosive environments

● Test the metals, coatings, and components

● Provide accelerated ageing tests in controlled environments

Industries that swear by it:

● Automotive Companies

● Paint and Coating Producers

● Marine Equipment Manufacturers

Electronics OEMS

Why Automate Salt Spray Chambers with a PLC?

Consider switching temperatures, humidity levels, and spray intervals by hand every hour. Time-consuming, prone to error, and a time-waster. A PLC (Programmable Logic Controller) coordinates the whole process—managing logic, control, timing, and communication like a maestro directing a symphony.

Meet the NX-ERA Xpress PLC – your multi-protocol, multi-project, one seamless controller. It never sleeps, never messes up, and always provides you with accurate data. From Messung Industrial Automation, a cost-effective PLC that is MQTT and OPC UA enabled, UL certified, and ready for the most demanding automation tasks.

Key Roles of a PLC in Salt Spray Chambers

Behind each reliable corrosion test is a smart PLC working diligently to maintain consistency, compliance, and control. What it provides to the chamber is:

Precise Temperature Regulation - Dry bulb, wet bulb, ambient—all held constant with surgical accuracy by PID loops. No ups and downs, just stable, calibrated climates.

Humidity Control - Because one droplet too much or too little throws the test off balance. A smart PLC fine-tunes every moisture movement to mimic real-world conditions.

Spray System Management - Controls mist cycles, nozzle diameters, sizes, and flows to ASTM/BIS/ISO specifications. No guessing—only predictable, programmable spray patterns.

Test Cycle Automation - Start, stop, repeat—all done without ever lifting a finger. Install it once, and the PLC takes care of complex test schedules with ease and accuracy.

Alerts & Notifications - Monitors for anomalies, alerts you in real-time, and records deviations for later reference. The watchdog your lab never knew it had.

In short, a robust PLC is not just a controller—it's the brain behind every flawless salt spray test. Accuracy-driven, standards-enabled, and always on the job.

How NX-ERA Xpress PLC Transforms Salt Spray Testing

In the high-pressure world of corrosion testing, consistency and accuracy are not just a good idea, but a necessity. Manual control isn't capable of keeping up with tight industry regulation or sophisticated test cycles. That's where the NX-ERA Xpress PLC comes in—turning laborious processes into error-free, data-driven automation that produces perfect results, every time.

Let's break it down.

Accuracy with PID Control - Control temperature and humidity like an expert, with advanced PID algorithms that make continuous adjustments in both dry and wet bulb parameters. This ensures every salt spray cycle is to your exact specification—no overshoots, no drift—so you achieve flawless repeatability in every test.

Versatile I/O for Complete Control - From compressors and solenoid valves to heating coils and compressors, the modular I/O design lets you mix analogue and digital channels in any combination necessary. You have total control over each chamber component, expanding and contracting as test demands vary or grow.

Communication-Ready - Native support for MQTT, OPC UA, Modbus TCP, PROFINET, and EtherCAT allows for plug-and-play real-time data logging to your SCADA/HMI dashboards. Remote monitoring of vital parameters, automatic export of logs, and integration with your Industry 4.0 configuration become a breeze.

Custom Tests, Custom Logic - Whether ASTM B117, ISO 9227, or your own proprietary cycle, programmable sequences allow you to specify start/stop times, spray cycles, and number of repetitions. Switch to new standards with ease without re-wiring or re-engineering your setup.

Remote Diagnostics - Eliminate extraneous lab trips with integrated troubleshooting capabilities. See live status, detect faults, and edit logic remotely—so you can maintain tests operating smoothly, even from miles away.

With the NX-ERA Xpress PLC, salt spray testing is smarter, faster, and more reliable. Upgrade your chamber control today and see your lab's efficiency—and confidence—take flight.

Industry Applications

From the lab to the great outdoors, salt spray testing holds up over time in any sector. It's the gold standard for corrosion resistance testing, subjecting your products to the ultimate test of the harshest conditions, without breaking a sweat.

Automotive - Rust-proofing bumpers, body panels, and alloy wheels. Because no one wants corrosion writing their brand off.

Paint & Coating - Verify finish quality in tough conditions. Observe how your coat stands up when the weather gets nasty.

Electronics - Ensure devices do not short or fail in high-salt air zones. Because reliability should not vanish with the sea breeze.

Marine & Offshore - Replicate real sea spray on metal parts and composite structures. For wave-riding performance and not rust.

Whether you're creating for highways, oceans, or skies, salt spray testing subjects your innovations to the elements, rain or shine. Test smart. Build bold. Trust durability.

Unique Features of the NX-ERA Xpress PLC

Where ruggedness, connectivity, and accuracy meet, the NX-ERA Xpress PLC is the ideal controller for the industrial automation of the new age. Built to satisfy the tough requirements of the new factory and laboratory, it provides an ideal combination of cutting-edge features designed for accuracy.

Small, and robust structure - Designed to be flexible and space-efficient installation without sacrificing strength.

IoT-based PLC for automation control in real-time - Enables end-to-end data exchange and remote monitoring to enhance Industry 4.0 capabilities.

Supports multiple protocols natively - Enables effortless connection to industrial networks of different types like PROFINET, EtherCAT, and Modbus TCP.

Smoother is used as a mission-critical safety PLC - Designed to ensure fail-safe operation where safety is never an option.

Designed to endure tough conditions with rock-solid dependability - Built to last through the toughest conditions, providing smooth operation under trying conditions.

Together, these capabilities make the NX-ERA Xpress PLC a valuable ally in taking your automation journey with confidence and control.

IoT PLC for Industry 4.0 Labs

In a smart lab, you decide in milliseconds. You need a PLC that can talk with your MES, ERP, cloud dashboards, and even mobile applications.

NX-ERA Xpress is an intelligent programmable controller for intelligent manufacturing systems that connects, communicates, and controls. With MQTT over TLS 1.2, OPC UA, and real-time updates, it's your gateway to Industry 4.0.

Why Messung for Your Salt Spray Automation?

Where passion and precision meet, innovation happens. We combine decades of experience with automation driven by innovation to provide smart salt spray solutions designed for performance, efficiency, and durability.

● 4 Decades of Automation Experience

● Strong R&D Backing and Engineering Support

● Global system integrator network

● Economical and UL-approved PLC alternatives

● Backed by a promise—We don't just automate, we enhance.

Join forces with Messung and go beyond mere automation—into a world where quality, reliability, and intelligent control govern every result.

Final Word: Don’t Let Rust Eat Into Your Reputation

Salt spray testing is the ultimate protection in demonstrating your product's endurance. One mistake—whether it's temperature fluctuation or skipped spray cycle—can cause damage to your brand, expense in recalls, or safety malfunction. Why take the risk?

Let NX-ERA Xpress PLC, an intelligent compact PLC for industrial automation, get behind the wheel. With IoT-capable PLC functionality, multi-protocol capability such as Modbus, PROFINET, EtherCAT, OPC UA, and MQTT, it provides reliable precision you can count on. Supported by our 4 decades of automation expertise, the rugged modular PLC for extreme environments guarantees your salt spray chamber operates like clockwork—every time.

Whether you are replacing or starting from scratch, this budget PLC with MQTT and OPC UA future-proofs your test environment. Salt corrodes. But not with our NX-ERA Xpress PLC. Your performance—and your reputation—are never compromised.

FAQs

Why is NX-ERA Xpress superior to other compact PLCs?

It combines tough construction, multiprotocol support, onboard IoT capabilities, and price efficiency—all within a compact size.

Which laboratories can be served by this Smart PLC?

Any corrosion, materials, or environmental testing laboratory requiring precise, automated, and repeatable results will be significantly helped.

Is NX-ERA Xpress suitable for harsh environments?

Indeed. It's a tough PLC that can withstand heat, humidity, and electrical stress—perfect for industrial-strength test labs.

Does NX-ERA Xpress support SCADA systems?

Yes. With natively supported MQTT, OPC UA, and Modbus TCP, it integrates seamlessly with the majority of contemporary SCADA systems.

#compact PLC#programmable logic controllers#rugged modular PLC#Industry 4.0.#salt spray chamber#PLC (Programmable Logic Controller)#cost-effective PLC#robust PLC#PID Control#smart PLC#Modbus#SCADA#salt spray testing#industrial automation#IoT-based PLC for automation control

0 notes

Text

Empowering Smarter Operations: The Role of HMIs & Inverters in Industry 4.0

In today’s connected manufacturing landscape, agility and user-centric control are key to staying ahead. At Dropship Automation Solutions, we specialize in equipping industries with the tools that make intelligent automation possible. In this blog, we highlight two game-changing technologies—Human-Machine Interfaces (HMIs) and Industrial Inverters—which serve as the control and power optimization centers of modern production lines.

Whether you're enhancing operator interaction or fine-tuning motor performance, HMIs and inverters offer real-time insight and precision that define the future of factory automation.

1. HMIs: Bridging Humans and Machines

What HMIs Do Human-Machine Interfaces are interactive platforms that allow operators to control, monitor, and configure machines visually. From touchscreen panels to advanced SCADA systems, HMIs streamline operations by offering real-time system data in a user-friendly format.

Common HMI Types & Industrial Use Cases

Types: Basic Text Panels, Graphic Displays, Web-Based Interfaces, SCADA Systems

Applications: Process visualization, alarm handling, production analytics, remote access

Benefits: Faster decision-making, simplified control, error reduction, centralized monitoring

Why HMIs Matter Without HMIs, navigating industrial systems would require complex, manual processes. HMIs empower workers with intuitive interfaces, real-time diagnostics, and interactive control—making operations more agile, transparent, and efficient.

2. Inverters: Optimizing Energy for Performance

What Inverters Do Inverters convert fixed-frequency electrical power into variable frequency and voltage—allowing motors to operate at optimal speeds based on load demands. They are essential for energy-efficient motor control and system adaptability.

Inverter Types & Industry Applications

Types: General-purpose inverters, vector control inverters, regenerative inverters

Applications: HVAC systems, water treatment plants, material handling, machine tools

Benefits: Energy savings, reduced power surges, extended equipment life, precise control

Why Inverters Matter Inverters not only improve energy efficiency but also add flexibility to production processes. They reduce mechanical stress, cut operational costs, and enable speed variation—essential for adapting to real-time production needs.

Unified Intelligence: The Power of HMIs + Inverters

Now imagine a fully connected workspace where:

HMIs visualize inverter performance and allow on-the-fly adjustments,

Inverters regulate motor speed based on data from the HMI,

Together, they enable energy optimization and simplified control.

This integration fosters predictive maintenance, remote configuration, and faster troubleshooting—building a smarter, leaner manufacturing system.

Conclusion: Unlock Productivity with Next-Gen Interfaces & Control

As the shift to intelligent factories accelerates, investing in responsive control and adaptive power systems becomes non-negotiable. At Dropship Automation Solutions, we provide robust HMIs and cutting-edge inverters designed for the rigors of Industry 4.0.

✅ Ready to improve operational control and energy efficiency? Let’s build your smart factory together.

📞 Contact: +1 (234) 288-1755 📧 Email: [email protected] 📍 Location: 1440 W. Taylor St #2555, Chicago, IL 60607

0 notes

Text

Why the Low Voltage Switchgear Market is Booming in 2025?

The low voltage switchgear market is growing rapidly in 2025 due to growth in electricity consumption, development of intelligent devices, and a strong emphasis on sustainability. Energy efficiency, digital transformation, and security are critical for industries and businesses, which leads to a high demand for new, robust, and intelligent switchgear. This article will discuss key drivers of market growth, emerging trends, and their impact on businesses and industries globally.

1. The Growing Demand for Electricity

Over the past few decades, the increasing demand for efficiency in power distribution systems has become ever imminent with the rise of general energy consumption. Rapid urban expansion, industrial development, and the emergence of data centers have been some of the major driving forces boosting the demand for low-voltage switchgear.

Global Electricity Demand on the Rise:

· The IEA projects electricity demand in developing nations will rise at a rate of 4% each year, as consumption steadily climbs.

· Data facilities and cloud computing require relentless power sources, amplifying the need for resilient switching equipment solutions capable of sustaining operations.

· The proliferation of electric vehicle charging points is compelling utilities to renovate distribution networks, ensuring functionality can accommodate increased demand.

Modernization spreads as industries broaden their scope, making electrically-reliable infrastructure an imperative; low voltage switchgear has become integral to conveying energy throughout the grid in a secure and effective manner.

2. Smart & Digital Switchgear: The Industry’s Future

Traditional switchgear technology has evolved rapidly with the integration of intelligent networking capabilities, making electrical distribution safer, more efficient, and easier to monitor remotely. The new digital switchgear incorporates IoT, AI, and cloud-based monitoring solutions to provide real-time insight into energy usage. This allows businesses to proactively optimize performance and reduce costs through more proactive maintenance strategies.

Major Developments in Intelligent Switchgear by 2025:

✅Online Sensor Networks: Constant telemetry from devices throughout the system helps pinpoint potential weaknesses before failures occur.

✅Self-learning Circuitry: AI-powered hardware and software automatically analyze usage patterns to forecast repairs, minimize outages, and heighten uptime.

✅Wireless Remote Management: Mobile apps and web dashboards give administrators off-site control over power flows to streamline usage according to need.

✅Modular Construction: Interchangeable, compact components facilitate scaling and retrofitting within varied infrastructure environments.

The shift toward automated smart grids and Industry 4.0 production is substantially contributing to the booming market for intelligent switchgear solutions. Widespread installation of these next-generation systems will transform electrical distribution networks.

3. Rising Emphasis on Energy Efficiency & Sustainability

Governments and industries worldwide have increasingly pushed for greener, more energy-efficient power solutions in recent years. This has led electrical equipment manufacturers to develop eco-friendly switchgear technologies that considerably minimize energy loss during transmission and help reduce overall carbon footprints.

Sustainable Advancements in Low Voltage Switchgear Design:

Alternative gases to SF6: Traditional switchgear commonly uses SF6 due to its insulating and arc-quenching capabilities, however this gas has an extremely high global warming potential. Many switchgear producers have since designed SF6-free solutions that substitute the highly potent SF6 with other gases that are safer for the environment.

Energy-Efficient Designs: Optimizing circuitry and components has allowed switchgear to conduct electricity with negligible power loss, enabling connected systems to leverage nearly every watt of power. Careful engineering further trims excess material use and redundant parts.

Renewable Energy Integration: Low voltage switchgear has become increasingly vital in smoothly and reliably integrating power from solar arrays and wind farms into existing electrical networks. Without robust switchgear management, it would be difficult for clean energy sources to efficiently feed power onto transmission lines.

With the implementation of more stringent energy performance mandates in countries worldwide, businesses have sound business reasons for upgrading outdated switchgear infrastructure with advanced low loss solutions both to adhere to regulations and lower long-term energy expenditures.

4. Increasing Investments in Infrastructure & Industrialization

Governments and private investors alike are pouring billions into ambitious infrastructure projects around the world, generating skyrocketing demand for reliable low voltage switchgear solutions. From towering commercial skyscrapers to sprawling industrial complexes, and expanding metro networks to bustling international airports — countless utilities depend on robust yet cost-effective switching systems to ensure continuity of operations.

🔹 Key Infrastructure Drivers Stimulating Growth:

🏗️ Smart Cities Uplift Life: Sweeping investments in digital urbanization are revolutionizing everyday living through connected infrastructure that elevates efficiency.

🏭 Manufacturing Marvels: Production powerhouses across the globe are scaling new heights, intensifying the necessity for advanced low voltage distribution controls to support increased capacity.

🚆 Transportation Transformations: Rapid progress in rail electrification and proliferation of electric vehicles for land and air are necessitating increasingly resilient switchgear designs.

As global development marches forth, low voltage switchgear has become mission critical in enabling commercial and industrial progress through reliable power distribution. The worldwide infrastructure renaissance is cementing its importance for years to come.

5. Safety & Regulatory Compliance Are Driving Upgrades

Governments and regulatory bodies are increasingly implementing strict compliance standards to safeguard electrical infrastructure and minimize hazards, compelling upgrades across many industries. Potential calamities resulting from power faults or failures necessitate vigilance in maintaining reliable and resilient systems.

New Safety Regulations in 2025:

⚡ Updated IEC & NEC Standards: Stringent low voltage switchgear specifications mandated to bolster protection.

⚡ Arc Fault Protection Technology: Novel solutions critical to curb risks of electrical ignitions and incidents.

⚡ Mandatory Energy Audits: Organizations now required to optimize distribution for both personnel and operational efficiency through audits.

With approaching deadlines to satisfy evolving regulations, operators are proactively replacing outdated switchgear to conform with mounting compliance demands, contributing to an accelerating industry transformation.

6. The Rise of Data Centers & Digital Transformation

The digital sphere fundamentally relies upon data hubs that necessitate constant power and exceedingly reliable electric frameworks. As distributed computing, man-made brainpower, and IoT reception develop exponentially, ventures are putting vigorously in cutting edge low voltage switches to ensure their foundation from energy blackouts which could bring about gigantic budgetary misfortunes.

24/7 control is essential for operations yet breakdowns prompt critical money related setbacks. To guarantee uptime, focal points utilize auxiliary switches for extra dependability and security alongside far off checking abilities through IoT innovations which empower ongoing following and administration from anywhere. With worldwide distributed computing selection quickening at a quickening pace, interest for top notch low voltage switches arriving at new statures to guarantee frameworks stay online consistently.

7. Competitive Market & Technological Advancements

The low voltage switchgear sector has seen remarkable changes and fierce competition between prestigious brands. Manufacturers are pouring resources into innovation to craft smarter, smaller, and affordable switchboard alternatives.

🔹 Notable Advancements by 2025:

⚙️ Solid-state systems promise enhanced performance and lessened upkeep. Long and compound sentences mix with short ones.

⚙️ Remote accessibility through wireless means permits control and tracking from afar.

⚙️ Self-mending grids using AI to immediately spot and amend problems, maintaining dependable power seamlessly. Complex automation alleviates faults autonomously for maximum uptime.

Conclusion: The Future of Low Voltage Switchgear Looks Bright

Low Voltage Switchgear is forecasted to experience market growth in the year 2025 due to the growing electricity consumption in countries, the rising applications of smart technologies, the increased implementation of sustainability practices, the expansive growth in various industries, and safety regulations. As these industries are gradually moving to energy-efficient, AI-powered, and environmentally friendly switchgears, this demand is expected to increase further.

5 notes

·

View notes

Text

PICMG Single Board Computer Market: Growth Fueled by Energy Efficiency Demand

MARKET INSIGHTS