#HMI with PLC Controllers

Explore tagged Tumblr posts

Text

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

Unlock the Power of Employee Automation Control Training

At BIN95, we understand the importance of equipping your team with the skills they need to excel in today's fast-paced world. That's why we offer an unbeatable deal - half off of our comprehensive training program and unlimited user and installation licenses.

Imagine the possibilities when every member of your organization (company or School) has access to cutting-edge training materials and resources. Our program covers everything from basic concepts to advanced techniques, ensuring that your team is well-equipped to handle any automation challenge that comes their way.

But time is running out! Don't let this opportunity slip through your fingers. Visit https://bin95.com/educational-site-licenses/ for more details and secure your purchase order today.

Invest in the future of your business or institution with Automation Control Training. Together, let's unlock a world of endless possibilities!

#automation control software#automation training#plc training#training solutions#tech school#STEM education#corporate training#community colleges#vocational training#plc#Motor Controls#hmi#vfd

2 notes

·

View notes

Text

Top Automation Engineers in Illinois | Innovating Industrial Solutions

Automation engineers are specialized professionals who design and implement systems that reduce human intervention in industrial processes. They blend knowledge from multiple fields—mechanical, electrical, software, and control engineering—to create intelligent systems that operate efficiently, reliably, and autonomously.

Their typical responsibilities include:

Designing automation systems from concept to installation

Programming PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces)

Integrating robotics and motion control

Developing SCADA (Supervisory Control and Data Acquisition) systems

Testing and troubleshooting automated equipment

Ensuring safety and compliance with industrial standards

In Illinois, automation engineers are indispensable to manufacturing, logistics, food processing, energy, and life sciences.

Why Illinois Is a Powerhouse for Automation Engineering

Several key factors contribute to Illinois’s prominence in automation engineering:

1. Diverse Industrial Base: Illinois boasts industries ranging from automotive and agriculture to pharmaceuticals and aerospace. This diversity fuels consistent demand for custom automation solutions.

2. Strong Educational Ecosystem: Top-tier institutions like the University of Illinois, Northwestern University, and Southern Illinois University produce highly skilled engineers with expertise in robotics, AI, and industrial systems.

3. Strategic Location: Illinois's central location offers excellent logistics, making it a favored site for advanced manufacturing, warehousing, and distribution centers—all of which benefit from automation.

4. Innovation-Friendly Climate: The state supports innovation through tech incubators, grants, and public-private partnerships that empower engineers to develop and deploy cutting-edge automation solutions.

Key Services Offered by Automation Engineers in Illinois

Automation engineers in Illinois provide an extensive range of services tailored to the specific needs of businesses across the state. Common services include:

System Integration: Designing and installing complete automation solutions that synchronize machines, robots, and control systems.

PLC & HMI Programming: Writing and testing software that governs system behavior and interfaces.

Robotics Engineering: Installing and configuring robotic arms and automated material handling systems.

Industrial IoT Integration: Connecting machines to networks for real-time data exchange and monitoring.

Retrofitting & Upgrades: Enhancing legacy equipment with modern control technologies.

Safety System Design: Implementing fail-safes, emergency stops, and safety protocols in compliance with OSHA and ISO standards.

Whether working on a small assembly cell or a full-scale production line, Illinois automation engineers prioritize reliability, scalability, and efficiency.

Industries Benefiting from Automation Engineers in Illinois

The work of automation engineers touches nearly every corner of Illinois’s economy. Key sectors include:

Food and Beverage: Automating sorting, bottling, and packaging processes to ensure hygiene and speed.

Pharmaceuticals and Medical Devices: Ensuring precision, compliance, and traceability through automated filling, labeling, and inspection.

Automotive and Aerospace: Deploying robotic arms and motion systems for parts assembly and quality control.

Agriculture and Grain Processing: Integrating automation into storage, sorting, and packaging facilities.

Warehousing and Logistics: Developing conveyor systems, pick-and-place robots, and automated guided vehicles (AGVs).

Energy and Utilities: Implementing SCADA and remote control systems to manage plant operations.

By adopting automation, these industries reduce labor strain, improve accuracy, and increase throughput—critical in today’s competitive global marketplace.

The Future of Automation Engineering in Illinois

As we move further into the age of Industry 4.0, the role of automation engineers is evolving. Engineers in Illinois are not just builders of machines—they are architects of data-driven, intelligent systems. The future will include:

Edge Computing and AI: Allowing systems to make real-time decisions at the source.

Cloud-Connected Automation: Centralized data storage and analysis across multiple plants.

Predictive Maintenance: Using machine learning to anticipate equipment failures before they occur.

Digital Twins: Creating virtual replicas of physical systems for simulation and optimization.

Green Manufacturing: Designing systems that reduce energy use and support sustainability.

Illinois is well-positioned to remain at the forefront of this transformation, with a workforce ready to meet the challenges and opportunities ahead.

Choosing the Right Automation Engineer in Illinois

When selecting an automation engineer or firm, businesses should look for:

Experience Across Industries

Proficiency with Major Platforms (Allen-Bradley, Siemens, Beckhoff, etc.)

Commitment to Safety and Compliance

Strong Project Management and Communication Skills

Local Support and Maintenance Services

A collaborative approach ensures solutions that align with business goals, budget, and operational scale.

Your Automation Engineering Partner: Xtreme Automation LLC

If your Illinois-based business is ready to embrace the future of smart manufacturing, Xtreme Automation LLC is here to help. With decades of experience in automation design, PLC programming, robotics integration, and system retrofitting, Xtreme Automation provides comprehensive engineering solutions tailored to your industry. From planning and development to implementation and support, their team ensures your automation journey delivers real results. Learn more at xtremeautomationllc.com.

#Automation Engineers Illinois#Industrial Automation Services#Robotics Engineering Illinois#Control System Engineers IL#Automation Integration Companies#Smart Manufacturing Illinois#PLC and HMI Programming#Engineering Solutions Illinois#Industrial Robotics Experts#Factory Automation Consultants

0 notes

Text

Essential Components of Industrial Automation & Control Systems

Industrial automation and control systems rely on essential components to enhance efficiency, accuracy, and productivity. Programmable Logic Controllers (PLCs) manage operations with precision, while sensors and transducers collect real-time data. Human-Machine Interfaces (HMIs) enable seamless interaction, and motor drives control speed and movement. SCADA systems ensure remote monitoring, while industrial networking connects devices for smooth communication. Power supplies and circuit breakers safeguard equipment, preventing failures. Together, these components create a reliable automation ecosystem, optimizing production, reducing downtime, and improving safety across industries. Investing in high-quality automation components ensures long-term operational success.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Control systems#Industrial Control systems#Plc#sensor#motor#hmi

0 notes

Text

Essential Protection for Electrical Systems with Moulded Case Circuit Breakers

What are Moulded Case Circuit Breakers?

The term MCCB represents Moulded Case Circuit Breaker. MCCB is one of the important electrical protection tools that are implemented to prevent electrical damage caused due to the free flow of too much current in the circuit. A standard fuse has to be replaced after its sensing of the fault. MCCB, on the other hand, can be reset and may be used repeatedly. It finds its applications in low voltage circuits where the correctness and reliability during protection are critically required.

The moulded case circuit breaker has a moulded insulation case, which serves to insulate the components of the circuit breaker for safety and durability. The devices are used as protective gears against electrical faults within industries, businesses, and homes.

How Do Moulded Case Circuit Breakers Work?

MCCBs operate based on thermal and magnetic principles:

Thermal Protection: The circuit has excess current for a more extended period of time. It generates heat in the bimetallic strip of MCCB. The strip bends because of that heat, and hence it causes break in that portion which results in power supply getting isolated. Thus, it reduces overheating, and it is also ruling out any chance of fire.

Magnetic Protection: In the case of sharp short circuit, a strong magnetic field is developed. As a result, the breaker trips immediately. It does not cause much harm to electrical elements.

Once the fault is cleared, MCCBs can be manually reset, restoring the electrical connection without requiring replacements.

Benefits of Using Moulded Case Circuit Breakers

The Moulded Case Circuit Breakers offer several advantages over traditional circuit protection devices:

Enhanced Safety: MCCBs ensure a safe electrical fault free from fires and harm to equipment.

Reusability: There is no replacement for MCCBs, while fuses need to be replaced time to time; hence the long-term savings will be enormous.

Adjustable Settings: The most MCCBs allow users to set the threshold of tripping, according to their requirement, in order to achieve better protection.

Durability: MCCBs have been designed with superior materials making the MCCB used in hostile environments.

Wide Range of Applications: Applications for an extremely wide range of fields range from industrial plants to residential buildings, MCCBs can be applied anywhere.

Applications of Moulded Case Circuit Breakers

Due to their reliability and effectiveness, Moulded Case Circuit Breakers are used in numerous industries and applications:

1. Industrial Sector

MCCBs are mainly used in a big manufacturing plant, factories, and power stations to protect the machinery and electrical systems from overcurrent conditions. As a high power load device, MCCBs are heavily utilized in industrial applications.

2. Commercial Buildings

Shopping malls, office complexes, and hospitals will always utilize MCCBs to protect the electrical networks and prevent disconnection that results from electrical faults.

3. Residential Installations

Home electrical panels also use MCCBs to protect appliances, wiring, and people from electrical risks.

4. Renewable Energy Systems

Solar and wind power systems need strong protection systems; therefore, MCCBs ensure that fluctuations and faults do not cause failures in critical parts of the equipment.

5. Data Centers

Choosing the Right Moulded Case Circuit Breaker

MCCBs are crucial in data centers to protect servers and IT infrastructure from electrical failure, keeping them running without interruptions.

Selecting the right MCCB depends on various factors, including:

Current Rating: Ensure the MCCB can handle the expected electrical load.

Breaking Capacity: Choose an MCCB with a sufficient breaking capacity to interrupt fault currents effectively.

Adjustability: Look for MCCBs with adjustable trip settings to customize protection levels.

Environmental Factors: Temperature, humidity, and installation conditions should be considered before choosing an MCCB.

Maintenance and Safety Tips for MCCBs

To ensure the longevity and effectiveness of Moulded Case Circuit Breakers, follow these maintenance and safety tips:

Regular Inspections: One should always inspect MCCBs for signs of wear, overheating, and damages at appropriate time intervals.

Proper Installation: It is expected that MCCBs must be installed only by experienced technicians following manufacturer guidelines.

Keep Clean and Dust-Free: Dust can degrade MCCB’s performance, and hence should clean them.

Test Periodically: Test to check if everything works properly.

Avoid Overloading: Avoid overloading the MCCB rated capacity so that frequent tripping may be avoided, and even a failure is prevented.

Future Trends in Moulded Case Circuit Breakers

As technology advances, MCCBs are evolving to meet modern electrical demands. Some emerging trends include:

Smart MCCBs: The IoT integration will help in the remote monitoring and control of MCCBs for efficiency and safety enhancement.

Enhanced Arc Fault Protection: Advanced MCCBs are now designed with the ability to detect and prevent arc faults, thus reducing fire risks.

Compact and Lightweight Designs: Newer MCCBs are becoming compact and lightweight without compromising protection levels.

Conclusion

Moulded Case Circuit Breakers are a part of the greater electrical safety and efficiency. It is what makes it a necessity in all walks of life, in industrial plants, commercial buildings, or residential properties, MCCBs are peace of mind and protection against overloads, short circuits, and any other type of electrical fault that can possibly affect the circuit.

With quality MCCBs, safety in the long run can be attained along with reduced losses due to the failure of supply in electricity. In addition, because of improving technology day by day, MCCBs are getting much more sophisticated nowadays and an important item of modern systems of electrical setup.

Therefore, with the significance and its application, moulded case circuit breakers should be known better to businesses or house owners so one can make decisions accordingly towards protection of the power network.

Originally Published Here:-

1 note

·

View note

Text

"The Crucial Role of Industrial Control Integrators: Driving Efficiency and Innovation in Modern Industry"

The Essential Role of an Industrial Control Integrator in Modern Industry

In today’s fast-paced industrial environment, the expertise of an Industrial Control Integrator has become indispensable. These professionals or companies specialize in designing, implementing, and maintaining complex control systems that are critical for optimizing industrial processes. This blog delves into the pivotal role of an Industrial Control Integrator, explaining their key responsibilities and the impact they have on industrial efficiency.

What is an Industrial Control Integrator?

An Industrial Control Integrator is a specialized expert or firm responsible for creating and managing control systems that automate and regulate industrial machinery and processes. These control systems encompass both hardware and software components, which work together to enhance performance, increase reliability, and streamline operations.

Core Responsibilities of an Industrial Control Integrator

Control System Design and Engineering:

Needs Analysis: The integrator begins with a comprehensive assessment of the client’s specific requirements. This involves understanding their industrial processes and defining the desired outcomes.

Custom System Design: Based on the assessment, the integrator designs a bespoke control system, selecting the appropriate sensors, controllers, and communication protocols to meet the client’s needs.

Integration and Installation:

Hardware Setup: The integrator manages the installation of essential components such as Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and other field instruments.

Software Configuration: They also configure the software that governs the control system, ensuring seamless communication between hardware and other operational systems.

Testing and Commissioning:

System Testing: Before full deployment, the integrator conducts rigorous testing to identify and rectify any issues, simulating real-world conditions to verify system performance.

Commissioning: Once testing is complete, the integrator supervises the final commissioning process, making any necessary adjustments to ensure optimal functionality.

Training and Ongoing Support:

Staff Training: Integrators provide training for the client’s personnel, equipping them with the knowledge to operate and maintain the new system effectively.

Continued Support: They offer ongoing maintenance and support services to resolve any issues and ensure the system continues to operate smoothly.

Why Industrial Control Integrators are Vital

Boosting Efficiency:

Industrial Control Integrators streamline processes by automating operations, which reduces manual input and enhances precision. This leads to improved productivity and reduced operational costs.

Enhancing Safety:

Integrators implement advanced control systems that monitor conditions in real time, increasing workplace safety by triggering alarms or shutdowns when necessary.

Ensuring Reliability:

By designing systems with redundancy and fail-safes, integrators help minimize downtime, which is crucial for meeting production targets and maintaining product quality.

Facilitating Scalability:

As businesses expand, their control systems must adapt. Integrators create flexible solutions that can be easily scaled or upgraded to meet growing demands.

Incorporating Emerging Technologies:

With the rise of Industry 4.0, integrating new technologies such as the Internet of Things (IoT), advanced analytics, and Artificial Intelligence (AI) is becoming increasingly important. Control integrators are key to incorporating these innovations into existing systems.

The Future of Industrial Control Integration

The field of industrial control integration is continuously evolving, driven by technological advancements and shifting industry needs. Future trends include:

AI and Machine Learning Integration: Enhancing predictive maintenance and process optimization.

IoT Integration: Enabling more detailed data collection and real-time analytics.

Enhanced Cybersecurity: Addressing the increasing need for robust security measures to protect industrial control systems from cyber threats.

Conclusion

Industrial Control Integrators are essential in ensuring the efficiency, reliability, and safety of modern industrial processes. Their expertise in designing, implementing, and maintaining control systems is crucial for optimizing operations and keeping pace with technological advancements. For businesses looking to upgrade or implement control systems, partnering with a skilled Industrial Control Integrator can be the key to achieving greater efficiency and performance.

#Industrial Control Integrator#Industrial Automation#Control Systems Engineering#Programmable Logic Controllers (PLCs)#Human-Machine Interfaces (HMIs)#Industrial Process Optimization#Automation Solutions#System Integration#Industrial Efficiency#Operational Reliability#Advanced Control Systems#Industry 4.0#Internet of Things (IoT)#Artificial Intelligence (AI) in Industry#Predictive Maintenance#Industrial Cybersecurity#Control System Design#Industrial Technology Trends#Engineering and Integration Services#Manufacturing Automation

0 notes

Text

Siemens Automation Products: The future of Industrial Automation

Siemens has emerged as a frontrunner in the constantly changing landscape of industrial automation, offering cutting-edge solutions that boost productivity, efficiency, and dependability. They provide a wide selection of automation goods for various industries, ranging from simple control functions to complicated production procedures. In this article, we will look at some of Siemens automation products and how they have shaped present-day industry.

SIMATIC Controllers

SIMATIC S7-1200 and S7-1500:

SIEMENS is known for their automation portfolio that has SIMATIC S7-1200 and S7-1500 series at its core. Due to their versatility, efficiency and user-friendliness, these controllers have gained a great name. The S7-1200 is compact and has an inbuilt input/output ports making it suitable for small applications. On the other hand, S7-1500 is suitable for high-end performance when it comes to complicated tasks because it has sophisticated diagnostic systems, built-in security features as well as wide-ranging communication facilities.

SIMATIC S7-200 SMART:

S7-200 SMART has been purposed for minor automation undertakings that represent a value for money while also being very strong. It can be used in numerous cases; it has either a functional format or embedded communication facilities hence making it flexible enough to serve various functions like controlling machines and organizing buildings.

HMI (Human-Machine Interface) Systems

SIMATIC HMI Panels:

Siemens' HMI panels provide operators with a user-friendly and intuitive interface for surveillance and control of industry processes. The panels go from simple text-to-speech displays to sophisticated touch screen displays with high resolution graphics. It can be easily integrated with the SIMATIC controllers, meaning that data is exchanged effectively, and timely monitoring done continuously.

SCADA Systems

SIMATIC WinCC:

SCADA (Supervisory Control and Data Acquisition) system is a highly efficient system made by Siemens and its name is WinCC (Windows Control Center). It has been fitted to work by providing solutions in the field of monitoring and control for industries. Databasing, allowing for real time viewing of data as well as offering of advanced analytical tools are some of these features found in WinCC that help businesses to improve their performance thus keeping them abreast about what is going on within their operations.

Industrial Communication

PROFINET and PROFIBUS:

Siemens has strong industrial communication offerings with PROFINET and PROFIBUS standards. PROFINET is an Ethernet-based protocol designed for high-speed, deterministic communication; this makes it ideal for real-time systems. On the other hand, PROFIBUS is a fieldbus protocol that guarantees reliable communication in difficult industrial settings.

Industrial Ethernet Switches:

Siemens’ Industrial Ethernet switch allows for quick and safe communication among devices in an industrial network. This kind of switch is made to survive difficult situations, which guarantees consistent transfer of information even in tough conditions.

Drives and Motion Control

SINAMICS Drives:

Siemens’ sacramental SINAMICS lifts cover everything from basic frequency converters to high-end servo drives. These drives ensure precise motor control, and high energy efficiency while at the same time helping to optimize processes. They are utilized in a variety of applications including conveyor belts, pumps, fans and machine tools.

SIMOTION:

Siemens’ SIMOTION is its motion control system that offers highly efficient solutions for complicated motion tasks. It brings together motion control, logic control and technology functions at one site, thus ensuring machines and processes are controlled with precision and effectiveness.

Process Automation

SIMATIC PCS 7:

Siemens’ PCS 7 is an advanced process control system for large-scale industrial processes. It has features like integrated engineering, scalable architecture and advanced control functions. As a result, it is commonly used in the chemical, pharmaceutical and oil & gas sectors where precision and reliability in process control are vital.

Conclusion

Siemens automation products have drastically modified the industry scene in terms of increased efficiency, reliability and productivity. Industrial automation is still dominated by Siemens through strong controllers and intuitive human machine interfaces (HMIs) besides sophisticated SCADA systems and durable communication protocols. For businesses out there that want higher automation, reduced operational costs and remain competitive in a changing environment code these technologies in one code.

#siemens automation products#siemens dealers in ahmedabad#siemens industrial automation#siemens programmable logic controller#siemens controller#siemens#siemens plc controller#siemens hmi#siemens ac drive#siemens servo motor#Siemens SCADA

0 notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Text

We provide a reliable, cost effective and efficient service to various industries throughout the UK and indeed worldwide. Our key areas of expertise are repairing, variable speed drives including; Frequency Inverters, Spindle, Servo, Stepper; HMI’s, Power Supplies, Programmable Logic Controller’s (PLC’s), Printed Circuit Boards (PCB’s), Servo Motors, Encoders and many other types of industrial equipment. Occasionally we use our worldwide network of suppliers to effect a repair.

#electronic restoration services#circuit board repair#printed circuit board repair#electronics repairs#pcb repair

2 notes

·

View notes

Text

How SCADA, HMI & PLC work together

SCADA (Supervisory Control and Data Acquisition), HMI (Human-Machine Interface), and PLC (Programmable Logic Controller) work together as key components in industrial automation and control systems.

#automation#trending#tumblr trends#viral#viralpost#trendingnow#bestdeals#rockwell automation#allen bradley#plc#hmi#scadatraining#scada

2 notes

·

View notes

Text

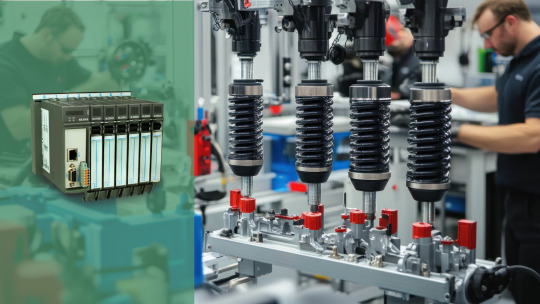

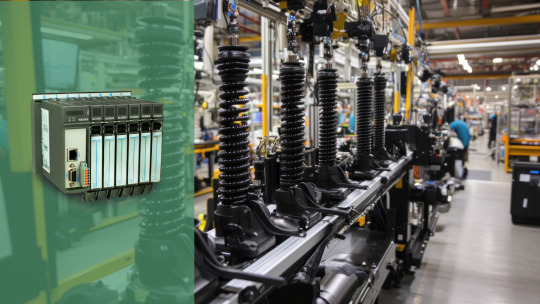

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

A Comprehensive Guide to Power Systems Protection for Engineers

Introduction:

Power systems protection is a critical aspect of electrical engineering that focuses on safeguarding electrical equipment, personnel, and the power grid from faults, failures, and abnormal operating conditions. This comprehensive guide aims to provide engineers with valuable insights into key principles, techniques, and best practices in power systems protection.

1. Understanding System Operation and Fault Types:

Before delving into protection strategies, it is essential to have a solid understanding of how power systems operates and the various types of faults that can occur. This includes studying system components, such as generators, transformers, transmission lines, circuit breakers, relays, and protective devices. Familiarity with fault types like short circuits, open circuits, ground faults, and transient overvoltages is crucial as a foundation.

2. Principles of Protection Coordination:

Effective power systems protection requires proper coordination among protective devices. Engineers must understand the concept of selectivity to ensure that only the device closest to a fault operates, minimizing disruption to the rest of the system. Proper coordination involves selecting appropriate current settings, time delays, and coordination curves for relays and circuit breakers.

3. Relay Device Fundamentals:

Relays are an integral part of power systems protection, serving as the first line of defense against electrical faults. Engineers should have a thorough knowledge of different relay types, including overcurrent relays, differential relays, distance relays, and directional relays. Understanding their operating principles, features, and limitations aids in choosing the most suitable relays for specific applications.

4. Protective Device Coordination:

Coordinating protective devices within a system is critical to maintaining stability and preventing cascading failures during faults. Engineers must carefully analyze and design protection schemes that consider factors such as fault impedance, fault currents, relay response characteristics, and coordination margins. Advanced techniques like time grading and impedance grading can be employed to achieve optimal coordination.

5. Fault Analysis and System Modeling:

Performing fault analysis and system modeling helps engineers gain insights into power flow, fault currents, voltage profiles, and system stability. Engineers must be proficient in using software tools like ETAP, PSCAD, and DSA Tools to accurately simulate fault scenarios and assess the performance of protection schemes. Detailed knowledge of system modeling techniques enables engineers to make informed decisions regarding relay settings and coordination.

6. Communication-Based Protection:

With the increasing complexity of modern power systems, communication-based protection plays a crucial role in maintaining reliability. Knowledge of communication protocols such as IEC 61850, GOOSE (Generic Object-Oriented Substation Event), and SCADA (Supervisory Control and Data Acquisition) systems is essential for engineers to design and implement advanced protection solutions that utilize real-time data exchange between substations and control centers.

7. Integration of Automation and Control Systems:

Incorporating automation and control systems into power systems protection enhances operational efficiency and reduces response time during faults. Engineers need to understand concepts like remote terminal units (RTUs), programmable logic controllers (PLCs), and human-machine interfaces (HMIs). Familiarity with protocols like Modbus, DNP3 (Distributed Network Protocol), and OPC (OLE for Process Control) enables seamless integration of protection systems with wider control infrastructure.

8. Commissioning, Testing, and Maintenance:

Implementing effective protection strategies requires thorough commissioning, testing, and maintenance procedures. Engineers should be well-versed in practices like primary injection testing, secondary injection testing, relay calibration, fault simulation, and periodic inspections. Adhering to manufacturer guidelines, industry standards, and safety protocols ensures equipment reliability and optimal performance.

9. Access to Resources and Industry Awareness:

Staying connected with organizations like the IEEE (Institute of Electrical and Electronics Engineers) and IET (Institution of Engineering and Technology) is crucial for access to valuable resources. Engineers should actively seek research papers, technical articles, conferences, and networking opportunities. Staying informed about relay technology advancements from prominent manufacturers aids in adopting the latest protection techniques.

10. Software Applications for Enhanced Protection:

Utilizing software applications is vital in power systems protection. Advanced tools like ETAP, PSCAD, and DSA Tools aid in relay coordination analysis, fault simulation, and system modeling. Acquiring proficiency in these common industry software packages enables engineers to design and optimize protection schemes effectively.

11. Compliance with Local National Codes:

Adhering to local national codes and regulations is paramount in power systems protection. Understanding and implementing specific electrical codes and standards relevant to the country of operation is crucial. Compliance ensures safe and reliable system design, installation, and operation aligned with legal requirements and best practices.

Conclusion:

By encompassing the principles, techniques, and best practices discussed in this guide, engineers pursuing careers in power systems protection can develop a strong foundation. Continuous learning, staying updated on industry advancements, and compliance with local national codes will ensure engineers can design, implement, and maintain robust and reliable protection schemes for the power grid and its critical assets.

The Author Biography: Qusi Alqarqaz

Qusi Alqarqaz is an experienced professional in power system protection, specializing in sharing knowledge and guiding young engineers. With a career spanning utility and oil and gas industries in Texas, New Mexico, and Qatar, he has amassed extensive industry experience.

Collaborating with leading manufacturers such as SEL, ABB, Siemens, Schneider, among others, Qusi has gained proficiency in a range of protective relays. He actively pursues continuing education, completing professional development courses with software providers including ETAP and Milsoft, enabling him to utilize advanced tools for power system analysis and protection design.

Qusi's dedication to staying up-to-date with industry advancements led him to pursue additional training. He completed professional development courses at Wisconsin University, equipping him with specialized knowledge crucial for working with high-voltage power systems. He also studied power generation extensively at Strathclyde University in the UK.

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals. Through his posts, he aims to offer guidance and mentorship for young engineers in power system protection. His practical advice and personal experiences will empower the next generation of experts in this field.

Contact the Author:

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals.

Qusi Alqarqaz

9 notes

·

View notes

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support

Edwardsville benefits from strong academic institutions like Southern Illinois University Edwardsville (SIUE), which offers programs in engineering, computer science, and industrial technology. These institutions help build a local talent pipeline of engineers and programmers equipped to design and maintain next-generation automation systems.

Additionally, ongoing partnerships between automation companies and local manufacturers ensure that workforce development aligns with real-world needs. On-the-job training and technical certifications are increasingly available to support career growth in automation programming.

Looking Ahead: Smarter Factories on the Horizon

With the rise of Industry 4.0, the future of manufacturing in Edwardsville is smart, connected, and data-driven. Automation programming is a key enabler of this future. Companies are beginning to adopt:

Remote Monitoring and Control

Cloud-Based Data Storage and Analytics

AI-Enhanced Predictive Maintenance

Digital Twin Simulations

These technologies offer unprecedented visibility and flexibility, allowing businesses to operate more efficiently and react quickly to changes in demand or supply chain conditions.

Your Edwardsville Automation Partner: Xtreme Automation LLC

If you're seeking professional automation programming services in Edwardsville, turn to the experts at Xtreme Automation LLC. With deep experience in PLC programming, HMI development, SCADA integration, and smart system upgrades, Xtreme Automation delivers tailored solutions that boost performance and cut downtime. Whether you're building a new line or upgrading legacy systems, their team ensures seamless automation from design to deployment. Learn more at xtremeautomationllc.com.

#Automation Programming Edwardsville IL#PLC Programming Services Illinois#Industrial Automation Edwardsville#HMI Systems Integration#Custom Control Systems Illinois#Manufacturing Automation Solutions#Programmable Logic Controllers#SCADA Systems Edwardsville#Industrial Software Engineering#Automation Services Metro East IL

0 notes

Text

Your Guide to the Best Options with ABB AC Drive Dealers in Chandigarh

Energy efficiency and automation are critical elements in improving productivity in the modern industrial world. An AC drive is one of the most critical components of industrial automation. ABB, being a leader in power and automation technologies worldwide, offers top-notch AC drives to industries that provide better control over motor speed and energy consumption. ABB AC Drive Dealers in Chandigarh are a few dealers who are known to sell these products. The main ideas that make up this article include benefits and applications of ABB AC drive as well as how to identify the right seller.

What is an ABB AC Drive?

An ABB AC drive is a device employed to control electric motor speed and torque. Through the use of ABB drives, industries boost efficiency, help reduce energy expenditures, and can extend the lifecycle of motors in use. Industries have come to appreciate the ability of ABB AC drives because of their proven reliability, additional features, and the ability of the drives to work in varied industrial applications.

Benefits of Using ABB AC Drives

Before selecting proper ABB AC drive dealers in Chandigarh, let’s understand why ABB AC drives are a good option. Here are some of the reasons why ABB AC drives are good options:

Applications of ABB AC Drives

The ABB AC drives are widely used across all industries for the efficiency and reliability achieved. Some of these common applications include:

How to Choose the Right ABB AC Drive Dealers in Chandigarh

Reliable dealers for ABB AC drives in Chandigarh are required for the best product and services. Here are a few criteria that should be used:

Where to Find ABB AC Drive Dealers in Chandigarh

Chandigarh has a number of industrial suppliers and automation solution providers. To identify some reliable ABB AC drive dealers in Chandigarh, consider the following:

Advantages of Buying from Authorized ABB AC Drive Dealers in Chandigarh

Buying through an authorized distributor has many rewards, including,

Future of ABB AC Drives in Chandigarh’s Industrial Sector

With Chandigarh growing as a hub for industrial and commercial activities, the demand for energy-efficient automation is increasing. ABB AC drives will continue to play a vital role in:

Conclusion

Investing in an ABB AC drive can greatly improve energy efficiency, reduce costs, and enhance automation in industries. When looking for ABB AC drive dealers in Chandigarh, ensure you choose authorized and reputable suppliers to get the best products and services. Whether you need an AC drive for manufacturing, HVAC, water treatment, or any other application, ABB offers reliable solutions for all industrial needs. Take your time to research and find a dealer that meets your requirements for long-term benefits.

Originally Published Here:-

0 notes

Text

Tube Furnace Manufacturer

At furnacemanufacturer, we take pride in being a trusted and leading Tube Furnace Manufacturer, providing high-quality, precision-engineered tube furnaces designed to meet the demanding needs of laboratories, research institutions, and industrial applications. With a commitment to innovation, durability, and customer satisfaction, we deliver advanced thermal processing solutions that exceed industry standards.

What is a Tube Furnace?

A tube furnace is an essential piece of equipment used for high-temperature heat treatment applications, such as material testing, sintering, calcination, annealing, and chemical vapor deposition. These furnaces consist of a cylindrical heating chamber with a heating element and a central tube, typically made of ceramic or quartz, through which samples are heated in a controlled atmosphere.

Why Choose furnacemanufacturer as Your Tube Furnace Manufacturer?

As a reputed Tube Furnace Manufacturer, we understand the critical role that heating systems play in various sectors such as metallurgy, ceramics, semiconductors, and academic research. Here’s what sets us apart:

1. Custom-Built Designs

We design and manufacture tube furnaces in various configurations including horizontal, vertical, and split-type models to suit specific client requirements. Our furnaces are available in single-zone, multi-zone, and gradient temperature zone options to ensure optimal thermal uniformity.

2. Wide Temperature Range

Our furnaces operate efficiently across a wide temperature range, typically from 300°C to 1800°C, depending on the model and the type of heating element used (Kanthal, molybdenum disilicide, or silicon carbide). This makes them suitable for a broad spectrum of scientific and industrial heating processes.

3. Energy Efficiency & Safety

We incorporate high-quality insulation materials and precision temperature control systems to ensure maximum energy efficiency. Safety features such as over-temperature protection, door interlocks, and digital controllers come standard with every furnace.

4. Advanced Control Systems

Our tube furnaces are equipped with user-friendly digital PID temperature controllers, programmable logic controllers (PLCs), and touchscreen HMI interfaces for accurate and automated operation. Remote monitoring and data logging capabilities are also available for quality assurance and compliance.

5. Robust Construction

Each furnace is built using corrosion-resistant materials and heavy-duty frames to ensure long-term durability and stable performance even under extreme conditions.

Applications of Our Tube Furnaces

As a top Tube Furnace Manufacturer, furnacemanufacturer caters to various industries including:

Research Laboratories – for testing material properties and thermal experiments.

Semiconductor Industry – for annealing wafers, oxidation, and diffusion processes.

Metallurgy – for sintering, brazing, and other high-temperature treatments.

Chemical Processing – for pyrolysis and decomposition of chemical compounds.

Ceramics & Glass – for firing and heat treatment of specialty materials.

Our Commitment to Quality & Support

At furnacemanufacturer, every product undergoes stringent quality checks and testing to ensure compliance with ISO and CE standards. Our experienced team provides technical guidance, customization, installation assistance, and prompt after-sales service to ensure smooth and hassle-free operation for our clients.

Global Reach, Local Support

With a strong distribution network and presence across major cities and industrial hubs, we serve clients both nationally and internationally. Our commitment to timely delivery, transparent communication, and affordable pricing makes us a preferred Tube Furnace Manufacturer among clients worldwide.

Get in Touch

If you are looking for a reliable and experienced Tube Furnace Manufacturer, trust furnacemanufacturer to deliver tailored heating solutions that enhance your productivity and research capabilities. Contact us today for a free consultation, product brochure, or custom quote.

0 notes

Text

Forming the Future: Exploring Double Deck Compression Technology

In the evolving world of materials processing and component manufacturing, efficiency, precision, and space optimization are critical to staying competitive. Enter the Double Deck Compression Forming Machine—an advanced piece of industrial equipment designed to significantly boost productivity in high-volume compression molding operations. This dual-level system is revolutionizing the way manufacturers approach composite material forming by doubling throughput without doubling floor space.Get more news about double deck compression forming machine,you can vist our website!

What Is a Double Deck Compression Forming Machine?

This specialized machine features two vertically aligned forming decks within a single press framework, allowing simultaneous molding operations at two levels. It is primarily used in compression molding—an established method for shaping thermoset and thermoplastic composites—where heat and pressure are applied to form materials into predetermined shapes.

Each deck operates independently or synchronously, depending on the production requirement. The technology is widely used in the automotive, aerospace, household goods, and construction sectors, where high precision and scalability are essential.

Key Components and Operation

The machine typically includes:

Upper and Lower Press Units: Each equipped with its own mold set and hydraulic system. These units apply controlled pressure and heat to shape the material.

Heating Plates: Designed to reach and maintain specific temperatures suitable for curing composite materials.

Advanced PLC Control Systems: Programmable Logic Controllers (PLCs) allow operators to monitor and manage individual cycles for each deck in real time.

Safety and Interlock Systems: Ensure both levels function safely during concurrent operations.

Advantages of the Double Deck Configuration

The defining feature of this machine—two mold decks—translates into several strategic advantages:

Double the Output: Two molds running simultaneously mean a significant increase in production without proportional increases in labor or factory floor requirements.

Space Efficiency: Stacked operation utilizes vertical space, making it ideal for workshops or factories where horizontal expansion is limited.

Energy Optimization: Shared hydraulic and control systems lower overall energy consumption per unit produced.

Flexible Operation: The decks can run similar or different molds, allowing manufacturers to diversify production without additional equipment.

Cost Savings: Enhanced throughput and reduced footprint ultimately lead to lower cost per part.

Application in Modern Industries

In automotive manufacturing, for example, the double deck compression forming machine is used to produce lightweight yet strong components like interior panels, battery enclosures for electric vehicles, and underbody shields—all from composite materials. The aerospace industry uses it to form parts that require both high-performance materials and repeatable manufacturing cycles. Even consumer goods industries apply this technology for molding plastic or fiber-reinforced products at scale.

Technological Trends and Innovations

Modern iterations of these machines are integrating smart manufacturing features, including:

IoT Monitoring: Real-time data collection and remote diagnostics.

Servo-Driven Hydraulics: For improved pressure control and energy efficiency.

Quick Mold Change Systems: Reducing downtime between production runs.

Human-Machine Interfaces (HMIs): Touchscreen interfaces that enhance user control and training efficiency.

Conclusion