#PLC-based automation solutions

Explore tagged Tumblr posts

Text

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

Need Siemens LOGO! PLC Installation Services in Dhaka?

Looking to boost your business's automation systems in Bangladesh? Apical Industrial Solution & Technology is your trusted provider for Siemens LOGO! PLC services. Our skilled engineers specialise in the installation and maintenance of Siemens LOGO! PLCs, ensuring seamless automation for your operations. Whether you're based in Dhaka, Chittagong, or anywhere across the country, we've got you covered!

Why Choose Us?

✅ Expert Siemens LOGO! PLC Installation✅ Local support across Dhaka and beyond ✅ Tailored solutions for small to medium-sized automation projects ✅ On-site troubleshooting and maintenance services

Take your business automation to the next level with our expert team!

Call Us Today to schedule your consultation or visit our website for more information. Let's transform your automation processes and elevate your productivity!

📍 Apical Industrial Solution & Technology, Dhaka, Bangladesh 📞https://maps.app.goo.gl/FnY8mTekL35zSLxT9 🌐 https://apicalindustrialsolution.com/

#DhakaAutomation #SiemensLOGOPLC #BangladeshAutomation #PLCServicesDhaka #IndustrialAutomationBangladesh #ApicalIndustrialSolutions

#DhakaAutomation#SiemensLOGOPLC#BangladeshAutomation#ApicalIndustrialSolutions#IndustrialAutomationBangladesh#PLCServicesDhaka

2 notes

·

View notes

Text

A Comprehensive Guide to Power Systems Protection for Engineers

Introduction:

Power systems protection is a critical aspect of electrical engineering that focuses on safeguarding electrical equipment, personnel, and the power grid from faults, failures, and abnormal operating conditions. This comprehensive guide aims to provide engineers with valuable insights into key principles, techniques, and best practices in power systems protection.

1. Understanding System Operation and Fault Types:

Before delving into protection strategies, it is essential to have a solid understanding of how power systems operates and the various types of faults that can occur. This includes studying system components, such as generators, transformers, transmission lines, circuit breakers, relays, and protective devices. Familiarity with fault types like short circuits, open circuits, ground faults, and transient overvoltages is crucial as a foundation.

2. Principles of Protection Coordination:

Effective power systems protection requires proper coordination among protective devices. Engineers must understand the concept of selectivity to ensure that only the device closest to a fault operates, minimizing disruption to the rest of the system. Proper coordination involves selecting appropriate current settings, time delays, and coordination curves for relays and circuit breakers.

3. Relay Device Fundamentals:

Relays are an integral part of power systems protection, serving as the first line of defense against electrical faults. Engineers should have a thorough knowledge of different relay types, including overcurrent relays, differential relays, distance relays, and directional relays. Understanding their operating principles, features, and limitations aids in choosing the most suitable relays for specific applications.

4. Protective Device Coordination:

Coordinating protective devices within a system is critical to maintaining stability and preventing cascading failures during faults. Engineers must carefully analyze and design protection schemes that consider factors such as fault impedance, fault currents, relay response characteristics, and coordination margins. Advanced techniques like time grading and impedance grading can be employed to achieve optimal coordination.

5. Fault Analysis and System Modeling:

Performing fault analysis and system modeling helps engineers gain insights into power flow, fault currents, voltage profiles, and system stability. Engineers must be proficient in using software tools like ETAP, PSCAD, and DSA Tools to accurately simulate fault scenarios and assess the performance of protection schemes. Detailed knowledge of system modeling techniques enables engineers to make informed decisions regarding relay settings and coordination.

6. Communication-Based Protection:

With the increasing complexity of modern power systems, communication-based protection plays a crucial role in maintaining reliability. Knowledge of communication protocols such as IEC 61850, GOOSE (Generic Object-Oriented Substation Event), and SCADA (Supervisory Control and Data Acquisition) systems is essential for engineers to design and implement advanced protection solutions that utilize real-time data exchange between substations and control centers.

7. Integration of Automation and Control Systems:

Incorporating automation and control systems into power systems protection enhances operational efficiency and reduces response time during faults. Engineers need to understand concepts like remote terminal units (RTUs), programmable logic controllers (PLCs), and human-machine interfaces (HMIs). Familiarity with protocols like Modbus, DNP3 (Distributed Network Protocol), and OPC (OLE for Process Control) enables seamless integration of protection systems with wider control infrastructure.

8. Commissioning, Testing, and Maintenance:

Implementing effective protection strategies requires thorough commissioning, testing, and maintenance procedures. Engineers should be well-versed in practices like primary injection testing, secondary injection testing, relay calibration, fault simulation, and periodic inspections. Adhering to manufacturer guidelines, industry standards, and safety protocols ensures equipment reliability and optimal performance.

9. Access to Resources and Industry Awareness:

Staying connected with organizations like the IEEE (Institute of Electrical and Electronics Engineers) and IET (Institution of Engineering and Technology) is crucial for access to valuable resources. Engineers should actively seek research papers, technical articles, conferences, and networking opportunities. Staying informed about relay technology advancements from prominent manufacturers aids in adopting the latest protection techniques.

10. Software Applications for Enhanced Protection:

Utilizing software applications is vital in power systems protection. Advanced tools like ETAP, PSCAD, and DSA Tools aid in relay coordination analysis, fault simulation, and system modeling. Acquiring proficiency in these common industry software packages enables engineers to design and optimize protection schemes effectively.

11. Compliance with Local National Codes:

Adhering to local national codes and regulations is paramount in power systems protection. Understanding and implementing specific electrical codes and standards relevant to the country of operation is crucial. Compliance ensures safe and reliable system design, installation, and operation aligned with legal requirements and best practices.

Conclusion:

By encompassing the principles, techniques, and best practices discussed in this guide, engineers pursuing careers in power systems protection can develop a strong foundation. Continuous learning, staying updated on industry advancements, and compliance with local national codes will ensure engineers can design, implement, and maintain robust and reliable protection schemes for the power grid and its critical assets.

The Author Biography: Qusi Alqarqaz

Qusi Alqarqaz is an experienced professional in power system protection, specializing in sharing knowledge and guiding young engineers. With a career spanning utility and oil and gas industries in Texas, New Mexico, and Qatar, he has amassed extensive industry experience.

Collaborating with leading manufacturers such as SEL, ABB, Siemens, Schneider, among others, Qusi has gained proficiency in a range of protective relays. He actively pursues continuing education, completing professional development courses with software providers including ETAP and Milsoft, enabling him to utilize advanced tools for power system analysis and protection design.

Qusi's dedication to staying up-to-date with industry advancements led him to pursue additional training. He completed professional development courses at Wisconsin University, equipping him with specialized knowledge crucial for working with high-voltage power systems. He also studied power generation extensively at Strathclyde University in the UK.

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals. Through his posts, he aims to offer guidance and mentorship for young engineers in power system protection. His practical advice and personal experiences will empower the next generation of experts in this field.

Contact the Author:

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals.

Qusi Alqarqaz

9 notes

·

View notes

Text

U.S. Meter Sockets Market Size, Share, Trends, Key Drivers, Demand and Opportunities

Executive Summary U.S. Meter Sockets Market :

Data Bridge Market Research analyses that the U.S. meter sockets market is expected to reach a value of USD 10,403.36 million by 2031, at a CAGR of 6.8% during the forecast period. The U.S. meter sockets market report also comprehensively covers pricing analysis, patent analysis, and technological advancements.

Transparent, trustworthy and extensive market information and data included in this report will definitely help develop business and improve return on investment (ROI). This U.S. Meter Sockets Market report provides an exhaustive survey of key players in the market which is based on a range of objectives of an organization such as profiling, the product outline, the quantity of production, required raw material, and the financial health of an organization. One of the sections in the report covers evaluation of probabilities of the new investment projects and overall research conclusions are offered.

U.S. Meter Sockets Market report helps the firm in exploring new uses and new markets for its existing products and thereby, increasing the demand for its products. This global market report offers research and consulting services focused on achieving competitive leverage, with acquiring and preserving market position as key aims of the program. The base year for calculation in the report is taken as 2017 and the historic year is 2016 which will tell you how the U.S. Meter Sockets Market is going to perform in the forecast years by informing you what the market definition, classifications, applications, and engagements are.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive U.S. Meter Sockets Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/us-meter-sockets-market

U.S. Meter Sockets Market Overview

**Segments**

- By Material: The U.S. meter sockets market can be segmented by material into stainless steel, aluminum, and others. Stainless steel meter sockets are known for their durability and resistance to corrosion, making them a popular choice for outdoor installations. Aluminum meter sockets, on the other hand, are lightweight and cost-effective, making them suitable for various residential applications. - By Application: In terms of application, the market can be divided into residential, commercial, and industrial segments. The residential segment dominates the market due to the increasing demand for smart meters and the renovation of existing infrastructure. The commercial and industrial segments are also witnessing growth as businesses focus on energy management and efficiency.

**Market Players**

- Eaton Corporation plc: Eaton is a key player in the U.S. meter sockets market, offering a wide range of products that cater to different customer needs. The company's focus on innovation and technology has enabled it to maintain a strong position in the market. - Schneider Electric: Schneider Electric is another prominent player in the market, known for its sustainable energy solutions and smart metering products. The company's emphasis on sustainable practices and energy efficiency has helped it gain a competitive edge in the market. - ABB: ABB is a global leader in power and automation technologies, including meter sockets. The company's focus on digitalization and smart grid solutions has positioned it as a key player in the U.S. market. - Siemens: Siemens is a well-established player in the meter sockets market, offering a range of products that meet the needs of residential, commercial, and industrial customers. The company's commitment to innovation and sustainability has helped it maintain a strong presence in the market.

The U.S. meter sockets market is poised for significant growth in the coming years as the demand for efficient energy management solutions continues to rise across residential, commercial, and industrial sectors. One of the emerging trends within the market is the increasing focus on sustainability and energy efficiency. Market players are investing heavily in developing smart metering products that not only provide accurate and real-time data but also help consumers and businesses optimize their energy consumption. This trend is being driven by stringent regulations aimed at reducing carbon emissions and promoting sustainability in the energy sector.

Another key trend shaping the U.S. meter sockets market is the rapid adoption of digitalization and smart grid technologies. As the need for reliable and secure energy distribution systems grows, there is a rising demand for advanced metering solutions that can support two-way communication between utilities and consumers. This shift towards smart grid technologies is expected to drive the market for meter sockets as utilities and energy providers seek to modernize their infrastructure and improve grid efficiency.

Furthermore, the market is witnessing a surge in investments in research and development activities focused on enhancing the performance and functionality of meter sockets. Market players are increasingly focusing on developing next-generation meter sockets that offer improved durability, connectivity, and data analytics capabilities. These advancements are aimed at meeting the evolving needs of consumers and businesses in a rapidly changing energy landscape.

One of the challenges facing the U.S. meter sockets market is the presence of stringent regulations and standards governing the installation and operation of metering devices. Compliance with regulatory requirements poses a significant challenge for market players, as non-compliance can lead to fines and penalties. To address this challenge, companies operating in the market are investing in technologies that ensure regulatory compliance and improve the overall efficiency and accuracy of metering systems.

In conclusion, the U.S. meter sockets market is witnessing robust growth driven by factors such as increasing demand for energy management solutions, adoption of smart grid technologies, and focus on sustainability and efficiency. Market players are actively engaged in developing innovative products and solutions to meet the evolving needs of consumers and businesses, positioning the market for sustained growth in the future.The U.S. meter sockets market is experiencing a profound transformation as technological advancements and changing consumer preferences shape the industry landscape. One of the noteworthy trends in the market is the increasing convergence of meter sockets with smart technologies, enabling real-time monitoring and data analytics for enhanced energy management. This shift towards smart metering solutions reflects a growing demand for more efficient and sustainable energy practices across residential, commercial, and industrial sectors. Market players are responding to this trend by investing in R&D to develop innovative meter socket products that not only ensure accurate metering but also contribute to better energy optimization and cost savings for end-users.

Moreover, sustainability is emerging as a key driving force in the U.S. meter sockets market, with both consumers and businesses showing a heightened interest in energy-efficient solutions. As environmental concerns continue to escalate, there is a pressing need for meter socket manufacturers to focus on eco-friendly materials and energy-efficient designs. This shift towards sustainable practices aligns with regulatory initiatives aimed at reducing carbon emissions and fostering a greener energy ecosystem. Market players are increasingly incorporating sustainability features into their meter socket offerings to cater to the evolving demands of environmentally conscious customers.

Another significant aspect impacting the U.S. meter sockets market is the expansion of digitalization and smart grid technologies. The integration of smart grid solutions is revolutionizing the energy sector by enabling seamless communication between utilities and consumers, thereby facilitating more efficient energy distribution and consumption patterns. This digital transformation is reshaping the meter sockets market, driving the adoption of advanced metering infrastructure and fostering greater grid reliability and resilience. Market players are leveraging these technological advancements to develop intelligent meter socket solutions that can address the complex energy management requirements of modern infrastructure.

Furthermore, alongside the opportunities presented by technological innovations and sustainability trends, market players in the U.S. meter sockets industry are also grappling with regulatory challenges and compliance issues. The stringent regulations governing metering devices necessitate a rigorous approach to product development and operational practices to ensure adherence to legal requirements. Companies operating in this market are focusing on enhancing their regulatory compliance mechanisms and investing in technologies that enable seamless integration with existing grid systems while meeting stringent industry standards.

In essence, the U.S. meter sockets market is poised for dynamic growth driven by the intersection of smart technologies, sustainability imperatives, and regulatory dynamics. Market players are strategically positioned to capitalize on these trends by offering cutting-edge meter socket solutions that cater to the evolving needs of energy consumers and support the transition towards a more sustainable and efficient energy landscape. The market's trajectory towards innovation and sustainability underscores its resilience and potential for long-term expansion in the face of evolving market dynamics and consumer expectations.

The U.S. Meter Sockets Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/us-meter-sockets-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

Table of Contents:

U.S. Meter Sockets Market Overview

Economic Impact on Industry

Competition by Manufacturers

Production, Revenue (Value) by Region

Supply (Production), Consumption, Export, Import by Regions

Production, Revenue (Value), Price Trend by Type

Market by Application

Manufacturing Cost Analysis

Industrial Chain, Sourcing Strategy and Downstream Buyers

U.S. Meter Sockets Market Strategy Analysis, Distributors/Traders

U.S. Meter Sockets Market Effect Factors Analysis

U.S. Meter Sockets Market Forecast

Appendix

Browse More Reports:

Global Digital Holographic Display Market Global Animal Feed Acidifier Market Global Polyvinyl Butyral Market Global Lyme Disease Drug Market Asia-Pacific Reverse Logistics Market Middle East and Africa Remote Patient Monitoring and Care Market Global Hepatitis C Diagnosis and Treatment Market Global Sleep Tech Devices Market Global Paperboard Beverage Packaging Market Global Single-use Bioprocessing Systems Market Global Nanobots Market Global Oxidative Stress Assay Instruments Market Global Plastic Baby Food Packaging Market North America Conversational AI Market Global In-Memory Computing Market North America Reverse Logistics Market Global Imaging Infrared Light Emitting Diode (LED) Market Global Inherited Retinal Diseases Market Global Broadband Internet Access Services Market Global Plant Based Food Packaging Market Global Rare Earth Elements Market Global Automotive Natural Gas Vehicle Market North America Automotive DC-DC Converters Market Europe Non-stick Cookware Market Global Connected Care Market Global Triple A Syndrome Treatment Market North America Fluoroscopy - C Arms Market Global Video Conferencing Systems Market Global Automotive DC-DC Converters Market Global High Performance Lubricant Market North America Clinical Chemistry Analyser Market Global Performance Chemicals Market Global Vehicle Diagnostics Market Global Meatless Flavor Additives Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

Tag:- U.S. Meter Sockets, U.S. Meter Sockets Size, U.S. Meter Sockets Share, U.S. Meter Sockets Growth

0 notes

Text

The Mechatronic Design Engineer: Powering Automation with CODESYS

Mechatronic design engineering is a multidisciplinary field that blends mechanical engineering, electronics, control systems, and software development to create intelligent, automated systems. Mechatronic design engineers are at the forefront of innovation, designing solutions for industries like robotics, automotive, aerospace, and manufacturing. CODESYS, an IEC 61131-3-compliant development platform, is a critical tool for these engineers, enabling them to program and integrate control systems for complex mechatronic applications. This article explores the role of a mechatronic design engineer, how CODESYS supports their work, key responsibilities, required skills, and real-world applications, highlighting the impact of this profession on modern automation.

The Essence of Mechatronic Design Engineering

Mechatronic design engineering focuses on creating systems that integrate mechanical components, electronic circuits, sensors, actuators, and software to achieve precise, reliable performance. These systems, such as robotic arms, autonomous vehicles, or CNC machines, require seamless coordination between hardware and software. Mechatronic design engineers ensure that these components work together to meet performance, safety, and efficiency goals, making them essential in industries embracing Industry 4.0 and smart automation.

CODESYS is a cornerstone for mechatronic design engineers, offering a versatile, hardware-independent platform for programming embedded control systems. Its compliance with IEC 61131-3, support for multiple programming languages, and robust tools for simulation and debugging make it ideal for developing sophisticated mechatronic systems.

Responsibilities of a Mechatronic Design Engineer

Mechatronic design engineers undertake a variety of tasks to bring complex systems to life:

System Design and Integration: Designing integrated systems that combine mechanical structures, electronics, and control software to meet specific functional requirements.

Control System Programming: Developing control algorithms to manage sensors, actuators, and motion systems, ensuring precise operation.

Simulation and Testing: Using simulation tools to validate system performance before deployment, minimizing errors and risks.

Prototyping and Commissioning: Building prototypes, integrating components, and deploying systems in real-world environments.

Optimization and Troubleshooting: Analyzing system performance, debugging issues, and optimizing designs for efficiency and reliability.

Collaboration: Working with mechanical, electrical, and software teams to ensure cohesive system development.

How CODESYS Empowers Mechatronic Design Engineers

CODESYS provides a comprehensive environment tailored to the needs of mechatronic design engineers:

IEC 61131-3 Programming Languages: CODESYS supports Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). These languages enable engineers to develop control logic for diverse applications, from simple discrete controls to advanced motion systems.

Hardware Flexibility: Compatible with PLCs and embedded controllers from vendors like Beckhoff, WAGO, and Siemens, CODESYS allows engineers to choose hardware that suits project budgets and requirements.

Motion Control Libraries: CODESYS offers libraries for motion control, supporting tasks like servo motor control, trajectory planning, and multi-axis coordination, critical for mechatronic systems like robotics.

Simulation and Debugging Tools: The built-in simulation mode enables testing without physical hardware, while debugging features like breakpoints and real-time monitoring help identify and resolve issues quickly.

HMI Development: CODESYS provides tools to create Human-Machine Interfaces (HMIs) for operator interaction, including graphical displays and web-based visualizations.

Communication Protocols: Support for EtherCAT, CANopen, Modbus, and OPC UA ensures seamless integration with sensors, actuators, and other devices in mechatronic systems.

Safety Standards: For safety-critical applications, CODESYS supports IEC 61508 (SIL 2/3), enabling engineers to design systems for industries like automotive and aerospace.

Example: Robotic Arm Control Program

Below is a sample Structured Text (ST) program for controlling a robotic arm’s position in a mechatronic system:

RoboticArmControl.st

plain

Show inline

This program implements a proportional control loop to adjust a robotic arm’s joint angle, ensuring precise positioning in a mechatronic application.

Essential Skills for Mechatronic Design Engineers

To succeed, mechatronic design engineers need a diverse skill set:

Multidisciplinary Knowledge: Proficiency in mechanical design, electronics, and control systems programming, including CODESYS and IEC 61131-3 languages.

Control Theory: Understanding of control algorithms, such as PID control, for precise system management.

Software Development: Experience with embedded systems programming and real-time operating systems (RTOS).

Problem-Solving: Analytical skills to troubleshoot and optimize complex systems.

Teamwork: Collaboration with cross-functional teams to integrate hardware and software components.

Adaptability: Staying updated with emerging technologies like IoT, AI, and cybersecurity.

Benefits of Using CODESYS

Streamlined Development: The integrated IDE and simulation tools reduce development time and errors.

Cost Efficiency: Hardware independence and code reusability lower project costs.

Scalability: CODESYS supports projects from small prototypes to large-scale industrial systems.

Flexibility: Multiple programming languages and protocols cater to diverse project needs.

Community Support: A global user base and resources like the CODESYS Store provide access to libraries and tutorials.

Applications in Industry

Mechatronic design engineers leverage CODESYS in various sectors:

Robotics: Developing control systems for industrial and collaborative robots.

Automotive: Designing ECUs for engine management, braking, and autonomous driving.

Manufacturing: Automating production lines, CNC machines, and material handling systems.

Aerospace: Controlling actuators and sensors in aircraft and spacecraft.

Medical Devices: Creating precise control systems for surgical robots and diagnostics.

Challenges in Mechatronic Design Engineering

Interdisciplinary Complexity: Integrating mechanical, electrical, and software components requires broad expertise.

Learning Curve: Mastering CODESYS and IEC 61131-3 languages can be time-intensive for beginners.

Resource Constraints: Embedded systems often have limited processing power, necessitating optimized code.

Safety Requirements: Meeting standards like IEC 61508 for safety-critical applications adds complexity.

Getting Started with CODESYS

To begin as a mechatronic design engineer using CODESYS:

Install CODESYS: Download the free IDE from the official website.

Learn Programming: Study IEC 61131-3 languages through tutorials and documentation.

Select Hardware: Choose a compatible PLC or embedded controller.

Develop and Simulate: Write control logic, test in simulation mode, and debug.

Deploy: Compile and deploy code to the target hardware.

Future Trends

As industries embrace digital transformation, mechatronic design engineers will increasingly use CODESYS for IoT-enabled systems, cloud-based monitoring, and AI-driven control. Support for protocols like OPC UA and MQTT positions CODESYS for smart manufacturing, while advancements in cybersecurity ensure its relevance in safety-critical applications.

Conclusion

Mechatronic design engineers by Servotechinc are key to creating the intelligent systems that drive modern automation, from robotics to autonomous vehicles. CODESYS empowers these professionals with a flexible, IEC 61131-3-compliant platform for programming, testing, and deploying control systems. Its robust features, hardware independence, and support for motion control and communication protocols make it indispensable for mechatronic applications. As technology advances, CODESYS and mechatronic design engineers will continue to shape the future of automation, delivering innovative, efficient, and reliable solutions.

0 notes

Text

Sheet Fed Paper Bag Machines

In the global push toward sustainable solutions, the paper bag industry has stepped into the spotlight. As consumer demand shifts from plastic to paper, manufacturers have embraced advanced machinery to meet market needs. Among the most transformative technologies is the sheet fed paper bag machine, a system designed to convert flat sheets of paper into eco-friendly bags with efficiency, precision, and speed.Get more news about sheet fed paper bag machine manufacture,you can vist our website!

Unlike roll-fed machines, sheet fed paper bag machines utilize pre-cut sheets rather than continuous paper rolls. This method offers several advantages: it allows for greater material control, better printing alignment, and more customized production runs. Particularly useful for boutique retailers, luxury packaging, and small to medium enterprises, sheet fed systems support flexibility without sacrificing performance.

How It Works

The process begins with loading stacks of printed or unprinted sheets into the feeder section. The machine then guides each individual sheet through a series of mechanical stages: gluing, folding, bottom forming, and gusseting. Advanced models also include inline printing, die-cut handles, and bottom pasting options, resulting in fully formed paper bags ready for distribution.

An important aspect of this equipment is automation. Modern sheet fed machines integrate PLC control systems, touchscreen interfaces, and automatic error detection features. These enhancements reduce manual labor, increase output, and minimize waste—making them ideal for eco-conscious manufacturers.

Benefits to Businesses and the Environment

Environmentally, the switch from plastic to paper bags is only meaningful if production itself is sustainable. Sheet fed paper bag machines typically accommodate recyclable kraft paper and water-based adhesives, minimizing environmental impact. What’s more, manufacturers can use paper made from responsibly managed forests or even recycled stock.

Economically, these machines reduce dependency on long material rolls, simplify logistics, and enable just-in-time production. Businesses can respond swiftly to small orders, seasonal packaging designs, or localized branding—all without committing to excessive inventory or waste.

Industry Applications

This technology finds application in several sectors: food and beverage (think bakery bags or takeout carriers), fashion retail, cosmetics, and even pharmaceuticals. The flexibility to adjust bag sizes, handle types, and printed content makes sheet fed machines suitable for a variety of branding needs.

With e-commerce growth driving demand for attractive and sustainable packaging, many firms are investing in in-house paper bag production. Sheet fed machines offer a compact footprint, making them ideal even for urban factories or decentralized workshops. For global brands seeking green credentials and fast turnarounds, this is a valuable investment.

Future Trends

As artificial intelligence, machine learning, and the Internet of Things (IoT) continue to influence industrial manufacturing, we can expect sheet fed paper bag machines to evolve. Smart sensors for real-time diagnostics, predictive maintenance, and energy-efficient motors will shape the next generation of machines.

Ultimately, as consumers become more environmentally aware and legislative pressure builds against single-use plastics, the role of the sheet fed paper bag machine becomes not just practical—but essential.

0 notes

Text

Automation and Integration Needs Power Robust Growth in System Integrator Market

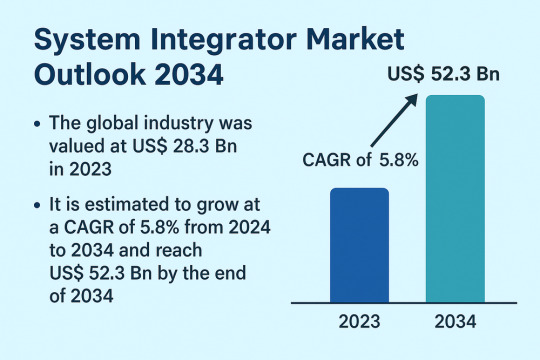

The global System Integrator Market is poised for significant growth, projected to rise from US$ 28.3 Bn in 2023 to US$ 52.3 Bn by 2034, growing at a CAGR of 5.8% from 2024 to 2034. This growth is driven by the widespread adoption of industrial robots, technological advancements, and a pressing need among businesses to optimize operational efficiencies through connected systems.

System integrators play a pivotal role in designing, implementing, and maintaining integrated solutions that bring together hardware, software, and consulting services. These services support organizations in unifying internal and external systems, such as SCADA, HMI, MES, PLC, and IIoT, to enable seamless data flow and system interoperability.

Market Drivers & Trends: One of the primary market drivers is the rise in adoption of industrial robots. As industries accelerate automation, robotic system integrators have become vital in delivering customized, scalable, and high-performing solutions tailored to complex manufacturing needs.

Another major catalyst is the surge in technological advancements. Integrators are deploying cloud-based tools and platforms that provide real-time data insights, improve developer productivity, and support hybrid architectures. The increasing use of Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) in integration solutions is fostering innovation and growth.

Latest Market Trends

Several emerging trends are shaping the system integrator landscape:

Cloud modernization platforms such as IBM’s Z and Cloud Modernization Center are enabling businesses to accelerate the transition to hybrid cloud environments.

Modular automation platforms are gaining popularity, allowing companies to rapidly deploy and scale integration solutions across multiple industry verticals.

Edge computing and cybersecurity solutions are increasingly being integrated to support secure, real-time decision-making on the production floor.

Digital hubs and scalable workflow engines are being adopted by integrators to support multi-specialty applications with high adaptability.

Key Players and Industry Leaders

The system integrator market is characterized by a strong mix of global leaders and regional specialists. Key players include:

ATS Corporation

Avanceon

Avid Solutions

Brock Solutions

JR Automation

MAVERICK Technologies, LLC

Burrow Global, LLC

BW Design Group

John Wood Group PLC

TESCO CONTROLS

These companies are actively investing in next-generation technologies, enhancing their product portfolios, and pursuing strategic acquisitions to strengthen market presence. For instance, in July 2023, ATS Corporation acquired Yazzoom BV, a Belgian AI and ML solutions provider, expanding their capabilities in smart manufacturing.

Recent Developments

Olympus Corporation launched the EASYSUITE ES-IP system in July 2023 in the U.S., offering advanced visualization and integration solutions for procedure rooms.

IBM introduced key updates in 2021 and 2022 to streamline mission-critical application modernization using cloud services and hybrid IT strategies.

Asia-Pacific companies have led the charge in deploying advanced integrated systems, reflecting the rapid industrial digitization in countries such as China, Japan, and South Korea.

Market Opportunities

Opportunities abound in both mature and emerging markets:

Smart factories and Industry 4.0 transformation offer immense potential for integrators to offer comprehensive solutions tailored to real-time analytics, predictive maintenance, and remote monitoring.

Government-led infrastructure modernization projects, particularly in Asia and the Middle East, are increasing demand for integrated control systems and plant asset management solutions.

The energy transition movement, including renewables and electrification of industrial processes, requires new types of integration across decentralized assets.

Future Outlook

As industries pursue digital transformation, the role of system integrators will evolve from traditional project implementers to long-term strategic partners. The future will see increasing demand for intelligent automation, cross-domain expertise, and real-time adaptive solutions. Vendors who can provide holistic, secure, and scalable services will dominate the landscape.

With continued advancements in AI, IoT, and robotics, the system integrator market will continue to thrive, transforming operations across diverse sectors, from automotive and food & beverages to oil & gas and pharmaceuticals.

Review critical insights and findings from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=82550

Market Segmentation

The market is segmented based on offering, technology, and end-use industry.

By Offering:

Hardware

Software

Service (Consulting, Design, Installation)

By Technology:

Human-Machine Interface (HMI)

Supervisory Control and Data Acquisition (SCADA)

Manufacturing Execution System (MES)

Functional Safety System

Machine Vision

Industrial Robotics

Industrial PC

Industrial Internet of Things (IIoT)

Machine Condition Monitoring

Plant Asset Management

Distributed Control System (DCS)

Programmable Logic Controller (PLC)

By End-use Industry:

Oil & Gas

Chemical & Petrochemical

Food & Beverages

Automotive

Energy & Power

Pharmaceutical

Pulp & Paper

Aerospace

Electronics

Metals & Mining

Others

Regional Insights

Asia Pacific leads the global system integrator market, holding the largest market share in 2023. This leadership is attributed to:

Rapid industrialization and digital transformation in China, Japan, and India.

Strong investments in smart manufacturing and Industry 4.0 initiatives.

Government support for infrastructure modernization, especially through Smart City programs and cybersecure IT frameworks.

North America and Europe also show strong demand, driven by the presence of established manufacturing facilities and a robust focus on sustainable operations and green automation.

Why Buy This Report?

Comprehensive Market Analysis: Deep insights into market size, share, and growth across all major segments and geographies.

Detailed Competitive Landscape: Profiles of leading companies with analysis of their strategy, product offerings, and key financials.

Actionable Intelligence: Understand technological trends, regulatory developments, and investment opportunities.

Forecast-Based Strategy: Develop long-term strategic plans using data-driven forecasts up to 2034.

Frequently Asked Questions (FAQs)

1. What is the projected value of the system integrator market by 2034? The global system integrator market is projected to reach US$ 52.3 Bn by 2034.

2. What is the current CAGR for the forecast period 2024–2034? The market is anticipated to grow at a CAGR of 5.8% during the forecast period.

3. Which region holds the largest market share? Asia Pacific dominated the global market in 2023 and is expected to continue leading due to rapid industrialization and technology adoption.

4. What are the key growth drivers? Key drivers include the rise in adoption of industrial robots and continuous advancements in integration technologies like IIoT, AI, and cloud platforms.

5. Who are the major players in the system integrator market? Prominent players include ATS Corporation, JR Automation, Brock Solutions, MAVERICK Technologies, and Control Associates, Inc.

6. Which industries are adopting system integrator services the most? High adoption is seen in industries such as automotive, oil & gas, food & beverages, pharmaceuticals, and electronics.

Explore Latest Research Reports by Transparency Market Research:

Multi-Mode Chipset Market: https://www.transparencymarketresearch.com/multi-mode-chipset-market.html

Accelerometer Market: https://www.transparencymarketresearch.com/accelerometer-market.html

Luminaire and Lighting Control Market: https://www.transparencymarketresearch.com/luminaire-lighting-control-market.html

Advanced Marine Power Supply Market: https://www.transparencymarketresearch.com/advanced-marine-power-supply-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

The Future of Thermoform Packaging: Global Forecasts and Key Industry Trends

In a product-driven world, packaging is more than just a container—it's a strategic tool for protection, branding, and sustainability. Among the most versatile and cost-effective solutions leading this transformation is thermoform packaging. Widely adopted across food, pharmaceuticals, electronics, and consumer goods, thermoforming continues to reshape the way products are packaged, preserved, and presented.

This form of packaging is created by heating plastic sheets until they become pliable, then forming them into specific shapes using molds. It’s a process that offers design flexibility, material efficiency, and low tooling costs, making it ideal for businesses looking to scale up with agility and precision.

How Thermoform Packaging Works—and Why It Matters

The thermoforming process involves three key steps: heating, forming, and trimming. A flat plastic sheet is first heated to a pliable temperature, then shaped over a mold using vacuum, pressure, or mechanical force, and finally trimmed to create the desired packaging profile.

This method allows for both rigid and semi-rigid packaging, suitable for an array of applications. There are two main types:

Vacuum Thermoforming – Uses suction to draw the heated sheet onto the mold. Best for shallow or simple shapes.

Pressure Thermoforming – Applies both vacuum and pressure, allowing for finer detail and deeper cavities—often used in medical trays and consumer electronics.

Why does this matter? Because businesses today need packaging that’s not only functional and attractive, but also adaptable to ever-changing supply chain and consumer demands. Thermoform packaging meets these expectations with speed and cost efficiency.

Market Growth and Key Drivers

The global Thermoform Packaging Market is projected to grow USD 65.6 billion by 2028, at a CAGR of 4.7%. This upward trajectory is powered by several critical drivers:

Boom in Packaged Food Demand – Single-serve, ready-to-eat meals and frozen foods have surged post-pandemic, with thermoformed trays and clamshells meeting hygiene and freshness demands.

Medical and Pharma Sector Expansion – Custom thermoformed trays ensure sterile barriers and are compliant with stringent regulatory requirements.

Sustainable Material Adoption – Recyclable PET, PLA, and bio-based plastics are increasingly being used, aligning with circular economy goals.

E-commerce Packaging Shift – Lightweight, shock-resistant designs are ideal for shipping sensitive electronics, cosmetics, and personal care items.

Cost Efficiency for High-Volume Runs – Lower tooling costs and fast production cycles make thermoforming ideal for industries needing quick turnaround.

Leading Players in the Thermoform Packaging Space

Top global manufacturers are constantly innovating to improve material sustainability, packaging performance, and production efficiency. Some of the key players include:

Amcor plc (Switzerland) – Offers sustainable thermoformed solutions using mono-material PET and high-barrier packaging for healthcare and food.

Sonoco Products Company (USA) – Known for customized medical trays and consumer product packaging with robust design and global distribution.

Berry Global Inc. (USA) – Focuses on lightweight, recyclable solutions and has a strong footprint in dairy, produce, and personal care packaging.

DS Smith (UK) – Invests in recyclable fiber-based thermoform alternatives and partners with brands for circular packaging models.

Huhtamaki Oyj (Finland) – Pioneers in renewable and compostable thermoformed trays, especially in food service and retail-ready packaging.

These players are prioritizing sustainability and innovation—combining material science with automation and smart packaging technologies.

The Strategic Edge of Thermoforming

Thermoform packaging isn’t just about containment—it offers tangible advantages that align with broader business goals:

Design Freedom – Enables intricate, product-specific forms that enhance shelf appeal and usability.

Reduced Waste – Material usage is optimized, and many thermoform materials are recyclable or compostable.

Cost Advantage – Lower mold and tooling expenses make it more affordable than injection molding or blow molding for many applications.

High-Speed Production – Ideal for scaling up operations quickly while maintaining precision and consistency.

Sustainability Impact – Brands can meet plastic reduction targets by choosing bio-based or mono-material options.

These benefits make thermoform packaging a strategic fit for CPG companies, medical device manufacturers, and food processors aiming for both performance and environmental responsibility.

Download PDF Brochure :

Thermoform packaging is a proven solution with staying power. Its adaptability, cost-effectiveness, and sustainability potential position it at the forefront of next-generation packaging strategies. As consumer expectations evolve and global regulations tighten, companies that invest in smart, sustainable thermoform solutions will be better equipped to lead in their markets.

For manufacturers and brand owners, now is the time to explore thermoforming as not just a packaging choice, but a value-driving differentiator.

#thermoform packaging#sustainable packaging#Amcor#Berry Global#packaging innovation#food packaging trends#medical packaging solutions

0 notes

Text

Upgrade Your Industrial Cleaning Process with a Multi Stage Washer from Leela Electronics

Introduction: Industrial Cleaning Beyond the Basics

In today's competitive industrial landscape, maintaining cleanliness and operational hygiene is more important than ever. Whether in automotive, aerospace, manufacturing, or healthcare sectors, proper component cleaning can directly influence performance, product quality, and safety compliance. One of the most advanced tools available today is the Multi Stage Washer—a system that offers efficient, repeatable, and deep-cleaning performance.

At Leela Electronics, we specialize in manufacturing high-performance Multi Stage Washer systems tailored for demanding applications. Our washers are built to deliver consistent cleaning results across multiple industries while ensuring sustainability, reliability, and efficiency.

What Is a Multi Stage Washer?

A Multi Stage Washer is a comprehensive cleaning system that integrates several stages—such as washing, rinsing, ultrasonic cleaning, drying, and more—into a single unit. Each stage serves a specific purpose, allowing for complete and consistent cleaning of parts or components.

Unlike traditional single-tank machines, a Multi Stage Washer is engineered to handle high-throughput operations, clean complex parts, and reduce manual intervention. At Leela Electronics, our washers are customizable based on the industry, material, and level of contamination.

Why Choose a Multi Stage Washer from Leela Electronics?

1. Custom-Built Systems for Your Industry

Our Multi Stage Washer machines are not off-the-shelf solutions. We design them specifically for the unique requirements of each industry—be it heavy grease removal for automotive parts or precision cleaning for surgical tools. You choose the number of stages, type of cleaning, and automation level. We handle the engineering.

2. Advanced Ultrasonic Cleaning Integration

Many of our systems include ultrasonic cleaning stages that use cavitation to reach microscopic crevices. This non-invasive technology allows for the effective removal of stubborn contaminants without damaging the surface.

3. Eco-Friendly and Cost-Efficient

At Leela Electronics, sustainability is a priority. Our Multi Stage Washer systems use water and chemical solutions efficiently, often recycling them to reduce waste. This minimizes both your environmental footprint and operational costs.

4. High-Grade Construction and Durability

All our Multi Stage Washers are constructed with industrial-grade stainless steel, designed to endure 24/7 operations in demanding environments. Our machines are robust, corrosion-resistant, and built to last.

5. Automation and Safety

Equipped with digital PLC controls, programmable cleaning cycles, and safety interlocks, our Multi Stage Washer systems are easy to operate and monitor. They reduce human error, improve efficiency, and ensure operator safety.

Core Stages in a Multi Stage Washer

While configurations can vary, a typical Multi Stage Washer may include:

Stage 1: Pre-Wash or Degreasing Removes heavy oils, dirt, and particulates from surfaces.

Stage 2: Ultrasonic Cleaning Cavitation bubbles reach into fine grooves and complex geometries.

Stage 3: Rinsing Flushes away loosened contaminants and detergent residues.

Stage 4: Final Rinse (Optional with DI Water) Ideal for precision applications where purity matters.

Stage 5: Drying Hot air or vacuum drying ensures parts are moisture-free and ready for use or assembly.

Each Multi Stage Washer can be configured with more or fewer stages based on cleaning requirements.

Industries That Benefit from a Multi Stage Washer

Leela Electronics serves a wide range of industries with our advanced Multi Stage Washer solutions:

Automotive – Cleaning engine blocks, gear parts, and transmission components

Aerospace – Precision cleaning of avionics and turbine parts

Electronics – Removing flux, oils, and particulates from PCBs

Medical & Pharmaceutical – Cleaning surgical tools and lab equipment

Metalworking & Fabrication – Preparing parts for coating or welding

No matter your industry, a Multi Stage Washer improves efficiency, reduces rework, and supports better end-product quality.

Key Features of Leela Electronics’ Multi Stage Washer

Our Multi Stage Washer units are designed for performance and flexibility:

Modular design for easy scalability

Custom tank sizes and layouts

Digital temperature and timer control

Oil skimmers and filtration systems

Stainless steel baskets and lifts

Optional conveyor-based or robotic handling

This attention to engineering detail ensures that every Multi Stage Washer we build provides unmatched performance and value.

Why Leela Electronics?

Founded in 2007, Leela Electronics has grown into a leading manufacturer of ultrasonic and industrial cleaning systems. We combine technical expertise with a customer-first approach, ensuring that each Multi Stage Washer meets your exact specifications.

We don’t just sell machines—we deliver complete cleaning solutions backed by:

Consultation and design services

On-site installation and training

Preventive maintenance support

Spare parts availability and upgrades

Client Testimonials

"Our production line experienced a major quality boost after installing Leela Electronics' Multi Stage Washer. The cleaning process is now faster, more consistent, and eco-friendly." — Operations Manager, Automotive OEM

Conclusion: A Smarter Way to Clean

Industrial cleaning has evolved—and so should your equipment. With a Multi Stage Washer from Leela Electronics, you get more than just clean parts. You get improved efficiency, consistent quality, reduced downtime, and long-term savings.

Whether you're looking to improve an existing process or build a new cleaning line from scratch, our expert team is here to guide you every step of the way.

Contact Us

Looking to invest in a powerful, reliable Multi Stage Washer? Reach out to Leela Electronics today and let us design a customized cleaning solution for your facility.

1 note

·

View note

Text

Enhancing AHU Performance with PLC-Based Control Systems

Imagine a world where your building breathes in oxygen. Where comfort meets air quality, and where energy is saved. It is the world where AHUs and PLC control systems are the starting point of everything in the domain of Energy management systems.

These AHU controllers (Air Handling Units) are the primary components of any new HVAC system. They serve as the lungs. But to make those lungs breathe better, smarter, and cleaner, you need a brain—enter the Programmable Logic Controllers (PLC).

We at Messung Industrial Automation are not just manufacturing PLC automation systems. We engineer intelligence. Smart PLC control is our ambition, and we aim to revolutionize the way AHU controllers operate, using a range of technologies, including Modbus, MQTT, compact PLCs, or IOT-enabled PLC.

What is a PLC-Based AHU Control System?

A PLC-based AHU control system is the ultimate HVAC master conductor. The flow, cooling, heating, and energy consumption of air are all controlled by real-time logic and precision through automation controllers.

Decision-making is the primary responsibility of a IoT enabled PLC (programmable logic controller), not just following instructions. Your AHU is designed to respond to data, adjust to changing surroundings, and function like a finely tuned machine with the help of intelligent controllers.

Whether it’s a mini PLC for a compact setup or a modular PLC for a multi-zone building, this IEC 61131-3 standard controller is the heartbeat of your air management system.

Core Functions of PLC Automation in AHU Controllers Applications

Sensor Integration

Temperature, humidity, CO2, and differential pressure are all sensors that your AHU controllers are equipped with. When it comes to Energy management systems, PLC control systems are necessary for reading, interpreting, and operating raw data.

Our intelligent PLCs work together with sensors to capture every detail of your indoor environment.

Data Analysis & Decision Making

After submitting the data, the PLC Automation magic begins. Our IEC 61131 based PLCs utilize advanced logic and maintain monitoring of variables such as:

Room occupancy

Outdoor air quality

Return air temperature

The intelligence in this scenario is not confined to automation alone it expands to the action of the PLC Control Systems.

Control Actions via Actuators

Now let's talk about the muscle of the operation. By utilizing PLC and Modbus TCP/IP, your automation controllers can dynamically control VFDs (Variable Frequency Drives) to regulate fan speeds while minimizing energy usage.

Actuated Dampers

Want zoned cooling in your building? Each damper is given precise guidance on when and where it should be opened or closed by our compact PLC, down to the second.

Valves

Our PLC automation system manages both hot and chilled water circuits, ensuring thermal comfort with accuracy.

Humidifiers & Dehumidifiers

System Overview: The NX-ERA JET Advantage

NX-ERA JET PLC is a digital command centre that is agile, adaptive, and always on alert as the AHU controllers. We have developed an intelligent and IEC 61131-3 standard PLC Control Systems that combine advanced logic, seamless connectivity, and flexible scalability. The NX-ERA JET is the key to ensuring that every component of your AHU system, including sensors and actuators, operates in perfect harmony.

Features of this IoT enabled PLC at a Glance

Modular PLC architecture is flexible and can be easily scaled for multi-zone management in large or changing infrastructure

The utilization of PLC with TCP/IP facilitates fast and secure communication between devices, including devices connected to remote systems

The integration of MODBUS RTU, Modbus TCP, and MQTT with BMS, SCADA, or cloud-based IoT platforms is facilitated by the native support provided by these protocols.

An integrated HMI that provides real-time, intuitive monitoring, diagnostics, and manual overrides.

Benefits of IoT enabled PLC for AHUs

In modern air handling, the focus isn’t just on moving air but moving it forward. Why? Integrating PLC control systems into AHUs can offer a transformative advantage in performance, sustainability, and adaptability for buildings. We should examine why PLC automation is the primary driving force behind intelligent HVAC solutions.

Improved Energy Efficiency

The value of energy is high, and PLC for energy systems with IEC 61131-3 standards optimizes every kilowatt. We can use our IoT enabled PLCs to save energy - up to 30% a time with intelligently controlled fan speeds, valve positions and damper angles that are real-time. Measurable reductions through these intelligent controllers help to reduce operational costs and greener footprints are not just numbers.

High Precision Control

AHU controllers equate performance with precision. Why? Our IEC 61131-3 compliant PLCs provide precise control over airflow, temperature and humidity. The result? Consistent comfort, efficient performance and strict environmental regulations.

Advanced Diagnostics

The use of intelligent PLCs with IoT systems means that problems can be prevented rather than delayed. With real-time monitoring and fault detection, teams can receive predictive maintenance insights to minimize downtime and maximize up time.

Scalability and Modularity

Our modular PLCs are designed to accommodate the growth of your building, offering compact systems and multi-zone installations. Do you require an immediate upgrade or expansion? These intelligent controllers can scale without complexity.

BMS Integration

Our PLC Control Systems with IEC 61131-3 standard integrates seamlessly with Building Management Systems, creating one intelligent ecosystem. Whether it’s HVAC, lighting, fire alarms, or access control—everything talks to everything for smoother operations.

In a world where data and efficiency are the primary drivers of change, PLC-controlled AHU controllers provide more than just automation; they also offer confidence. Our IoT enabled PLCs enable buildings to thrive rather than just functioning.

Intelligent PLC Control Systems for Smart Buildings

HMI with PLC Controllers - An HMI with PLC controller enables the observation of invisible areas. The entire package, including fan speed and filter life, is conveniently located at your fingertips.

MQTT based PLC and IoT Systems - The integration of IoT enabled PLC and MQTT support enables your AHU to communicate with the cloud, apps, and analytics platforms, simplifying the process of achieving predictive control and remote access.

Real-World Applications

Through PLC-based AHU control systems, we at Messung are changing the possibilities of environments from sterile labs to busy malls. With precision, adaptability, and unparalleled reliability, our intelligent automation controllers tackle the challenges associated with every application.

Pharma Cleanrooms - The precision of pharmaceutical products is essential in their application. The strict GMP standards are adhered to by our PLC control systems, which involve managing temperature, humidity, pressure differentials. The result? Zones that are sterile, upholding drug integrity and safety.

Commercial Buildings - Employee comfort drives efficiency. Our HVAC automation enables seamless climate management of all floors and departments. By utilizing intelligent design, efficient air circulation, and real-time monitoring, our IoT enabled PLCs enhance the productivity and satisfaction of customers in spaces.

Data Centers - Servers demand a stable climate 24/7. Even minor temperature fluctuations can compromise data. Our intelligent PLC Control Systems with IEC 61131-3 standard ensure uninterrupted cooling performance, reducing thermal risk and operational downtime.

Energy-Efficient Manufacturing - Today's manufacturers must strike a balance between sustainability and production. Without compromising comfort or compliance, our PLCs maximize AHU performance to reduce energy footprints, reduce emissions, and guarantee stable internal environments.

Wherever there's air to manage and performance to perfect, our Compact PLCs lead the way with intelligent control.

Messung’s Expertise in HVAC Automation

We at Messung lead the way in HVAC automation innovation for organizing smart air movement. Our legacy is created on trust, performance, and innovative control systems that transform indoor environments, not only on technology

Why Choose Messung PLC Automation?

We design smart automation systems rather than only selling PLC Control Systems. With more than four decades of engineering expertise, our PLCs are the favoured option of architects, MEP consultants, HVAC contractors, and facility managers across India and globally. Our internal R&D, field-tested dependability, and quick support system turn us into a progress partner rather than just a supplier.

Built on IEC 61131-3 Standard

To ensure every Messung programmable logic controller is consistent, dependable, and compatible with worldwide systems—today and tomorrow — our automation controllers follow this internationally recognized IEC 61131-3 standard.

Flexible Form Factors

Whether you are managing many air zones throughout a smart high-rise or automating a small rooftop AHU, our compact and modular PLCs meet every architectural and functional requirement.