#Inspection Rewinding Manufacturer

Link

We thank you for your interest in Inspection and Rewinding Machines ECO HSR 1300 Manufacturer, Supplier, Exporter by UFlex! Please fill up the information below. We thank you for your interest in machinery manufactured by Uflex! Please fill up the information below. This will help us in understanding your requirements better.

0 notes

Text

Professional Fabric Inspection machine Presentation :

Fabric inspection machines are used to inspect fabric materials in order to find manufacturing defects(weave), mechanical defects (holes) and dirty spots. For convenience of operator inspection machines have an illuminated panel, under the material. This machines rewinds and measures fabric in order to verify declared by the manufacturer length of roll oraz precisely mark distances between defects on the inspected roll of fabric. Yet another very important feature of the inspection machine is to ensure even tension of rewinded fabric. This is a very important condition for spreading and cutting operations in future. Fabric inspection machines are used by manufacturers, where high quality of manufactured products forces additional quality check before materials are sent for spreading and cutting.

0 notes

Text

A paper tube cutting machine is a versatile and essential machine used in the paper industry. It is designed to cut large rolls of paper into smaller, more manageable rolls of desired width and length. This machine is crucial in various sectors, including printing, packaging, and converting industries.

Unwinding: The process begins with loading a large roll of paper onto the unwinding shaft. The machine then unwinds the paper roll at a controlled speed.

Slitting: The unwound paper is then passed through sharp blades or rotary knives that slit the paper into smaller widths. The number of blades can be adjusted based on the number of rolls required.

Rewinding: The slit paper is then rewound onto separate cores to form smaller rolls. The tension and speed of rewinding can be controlled to ensure the rolls are wound tightly and evenly.

Cutting: Some machines also have an integrated cutting mechanism that cuts the rewound rolls to the desired length.

Quality Control: Many Paper Slitter Rewinders come with built-in inspection systems that check for defects or irregularities in the paper.

The Paper Slitter Rewinder is known for its high efficiency, precision, and speed. It can handle a wide range of paper types and thicknesses, making it a versatile choice for businesses. With its robust construction and advanced features, this paper core machine ensures smooth and consistent operation, enhancing productivity and reducing waste. Whether you’re a small print shop or a large paper mill, a Paper Slitter Rewinder can be a valuable addition to your production line.

Paper Slitter Rewinder: Enhancing Efficiency in Manufacturing

The Paper Slitter Rewinder is a game-changer in the manufacturing industry, significantly enhancing efficiency and productivity. This machine is designed to transform large rolls of paper into smaller ones, tailored to specific requirements. Here’s how it contributes to manufacturing efficiency:

High-Speed Operation: paper tube winder machine operate at high speeds, capable of processing large volumes of paper in a short time. This speed significantly reduces production time, enabling businesses to meet high demand quickly.

Precision Cutting: With adjustable blades, the machine ensures precise and consistent cuts every time. This precision eliminates waste from inaccurate cuts, saving materials and costs.

Automation: Many models come with automated features, reducing the need for manual intervention. This automation not only saves labor costs but also minimizes human error, ensuring consistent quality.

Quality Control: With built-in inspection systems, the machine can detect and rectify defects or irregularities in the paper. This feature ensures that only high-quality paper rolls reach the end of the production line.

Space Efficiency: Despite its robust capabilities, the Paper Slitter Rewinder has a compact design that saves valuable floor space in manufacturing facilities.

By investing in a Paper Slitter Rewinder, businesses can significantly enhance their manufacturing efficiency. This core pipe-making machine not only speeds up the production process but also ensures the consistent quality of the final product, leading to increased customer satisfaction and profitability.

Paper Slitter Rewinders for Every Industry Need

Paper slitter rewinders play a pivotal role across diverse industries, addressing unique needs with precision and efficiency:

Printing Industry: In printing, these machines facilitate the production of custom-sized paper rolls, optimizing printing processes and reducing waste.

Packaging Sector: The packaging industry benefits from the adaptability of paper slitter rewinders, ensuring the creation of tailored rolls for various packaging applications, enhancing efficiency and minimizing material costs.

Converting Industries: Paper converting relies on these machines to transform large paper rolls into smaller, usable rolls with specific dimensions, meeting the requirements of different product lines.

Flexibility in Width and Length: The versatility of paper slitter rewinders allows for the customization of roll width and length, catering to the unique specifications of each industry and product.

Enhanced Productivity: With precise cutting and rewinding capabilities, these machines contribute to increased productivity, reducing downtime and enhancing overall operational efficiency in multiple sectors.

0 notes

Text

An Overview of Stretch Film Manufacturing Machines: Types and Functions

Stretch Film Manufacturing Machines are specialized pieces of equipment used to produce stretch film, which is commonly used for packaging and securing products during transportation and storage. These machines play a crucial role in ensuring the durability, elasticity, and quality of the stretch film. Here's an overview of the types of stretch film manufacturing machines and their functions:

1. Blown Film Extrusion Machines:

Description: These machines use the blown film extrusion process to produce stretch film. The process involves melting polymer granules and extruding them through an annular slit die, followed by blowing to expand the film into a tube and cooling it to form the film.

Function: Blown film extrusion machines provide films with higher puncture resistance and more strength compared to other types. They allow for better control over film thickness and quality.

2. Cast Film Extrusion Machines:

Description: In contrast to blown film machines, cast film extrusion machines use a flat die to extrude the molten polymer. The extruded film is then cooled on chilled rollers.

Function: These machines produce films that are clearer and have better cling properties than blown films. Cast film machines generally have higher production rates and produce films with more consistent thickness.

3. Co-extrusion Film Machines:

Description: Co-extrusion machines combine multiple layers of material into a single stretch film product. These machines can have two or more extruders to process different types of polymers or the same polymer with different properties.

Function: The primary function is to produce multilayer stretch films, where each layer can impart different characteristics such as strength, cling, puncture resistance, or barrier properties.

4. Pre-stretch Film Machines:

Description: These machines are designed to stretch the film mechanically before it is wound onto rolls. The pre-stretching process improves the film's yield and can significantly reduce material costs.

Function: They elongate the film by using rollers rotating at different speeds. The resulting film is thinner but has increased strength and is more economical due to reduced material usage.

5. Rewinding Machines:

Description: After the film is extruded and wound onto large rolls, rewinding machines are used to convert these large rolls into smaller, more manageable rolls for commercial distribution.

Function: These machines rewind the film from the larger rolls to smaller ones, often adding a secondary layer of packaging. They can also be used to inspect the film for defects and ensure quality control.

6. Recycling Machines:

Description: In an effort to promote sustainability, some stretch film manufacturing setups include recycling machines that process production waste or used stretch film.

Function: These machines clean, melt, and pelletize the waste film, turning it back into a usable form for manufacturing, thus reducing waste and promoting circular economy practices.

Choosing the Right Machine:

The choice of machine depends on the desired film properties, production volume, and specific application requirements. For example, high-clarity film requirements might favor cast film machines, while high-strength films might be better produced with blown film machines.

By understanding the different types of Stretch Film Manufacturing Machines and their functions, manufacturers can select the most appropriate equipment to meet their production needs and produce high-quality stretch film for various packaging applications.

0 notes

Text

Nonwoven Rewinder: Unraveling Efficiency and Quality

Nonwoven materials have become integral to various industries, from textiles to healthcare. To ensure the efficient production and utilization of these materials, Nonwoven Rewinders play a pivotal role.

The Basics of Nonwoven Rewinders

Nonwoven Rewinders are specialized machines designed to handle and process nonwoven materials. These machines are essential for rewinding, cutting, and inspecting nonwoven fabrics, ensuring they meet industry standards.

Key Features of Nonwoven Rewinders

Precision Rewinding: Nonwoven Rewinders offer precise rewinding capabilities, resulting in consistent and high-quality rolls of nonwoven material.

Inspection Systems: Many Nonwoven Rewinders are equipped with advanced inspection systems that detect and address defects, enhancing product quality.

Versatility: These machines can handle various types of nonwoven materials, making them adaptable for different industries.

Applications of Nonwoven Rewinder

Nonwoven Rewinder find applications in several industries, including:

Textiles: They play a crucial role in processing nonwoven textiles for clothing and upholstery.

Medical: Nonwoven materials are widely used in medical supplies, and Nonwoven Rewinders ensure their quality and reliability.

Packaging: They are used for rewinding nonwoven materials used in packaging solutions.

Benefits of Nonwoven Rewinder

Investing in Nonwoven Rewinder can bring several advantages to businesses:

Improved Efficiency: These machines streamline the production process, reducing downtime and increasing productivity.

Quality Assurance: Nonwoven Rewinders ensure that the final product meets the required quality standards.

Cost Savings: Enhanced efficiency and reduced material wastage result in cost savings over time.

LSI Keywords for Enhanced SEO

Nonwoven Rewinder advantages

Nonwoven Rewinder applications

Nonwoven Rewinder inspection

Nonwoven Rewinder industries

Expert Insights

Drawing from extensive industry experience, we can confidently assert that Nonwoven Rewinders are indispensable for any business involved in nonwoven materials. Their ability to improve efficiency, maintain quality, and reduce costs makes them a valuable asset.

FAQs

Q: Are Nonwoven Rewinders suitable for small-scale businesses? A: Yes, there are models designed for small-scale operations, offering cost-effective solutions.

Q: Can Nonwoven Rewinders handle delicate nonwoven materials? A: Absolutely, advanced models come with precision control to handle delicate materials.

Q: What maintenance is required for Nonwoven Rewinders? A: Regular cleaning and servicing are necessary to ensure optimal performance.

Q: Are there safety precautions for operating Nonwoven Rewinders? A: Yes, operators should receive training and follow safety guidelines to prevent accidents.

Q: Do Nonwoven Rewinders come with warranties? A: Many reputable manufacturers offer warranties, ensuring peace of mind for buyers.

Q: Where can I purchase quality Nonwoven Rewinders? A: Reputable suppliers and manufacturers offer a range of options, and online research can help you find the right one.

Conclusion

Nonwoven Rewinders are the unsung heroes of industries reliant on nonwoven materials. Their ability to enhance efficiency, ensure quality, and reduce costs makes them indispensable. Whether you're in textiles, healthcare, or packaging, Nonwoven Rewinders are your ticket to improved productivity and superior product quality.

0 notes

Text

How long should a Gould well pump last?

The lifespan of a Gould well pump can vary depending on various factors, including the specific model, usage patterns, maintenance practices, water quality, and installation conditions. However, Goulds pumps are generally designed to be durable and long-lasting.

With proper installation, regular maintenance, and appropriate usage, a Gould well pump can typically last anywhere from 15 to 25 years or more. Some well pumps have been known to operate efficiently for even longer periods.

It's important to note that the well pump's motor and other components may have different lifespans. In some cases, the motor may require replacement or rewinding before the rest of the pump.

To maximize the lifespan of your Gould well pump, it's recommended to follow these guidelines:

1. Proper installation: Ensure the well pump is installed correctly, adhering to the manufacturer's instructions and local codes. Improper installation can lead to premature wear and damage.

2. Regular maintenance: Schedule routine maintenance for your well pump, including inspecting the system, checking for leaks, monitoring pressure and performance, and cleaning or replacing filters as needed. Consult the manufacturer's recommendations for specific maintenance intervals and tasks.

3. Water quality management: Address any issues with water quality that could affect the pump's performance or cause damage. This may include addressing sediment, sand, or other contaminants that can cause premature wear.

4. Avoiding excessive cycling: Minimize frequent on-off cycling of the pump, as it can increase wear and shorten the pump's lifespan. Consider using a pressure tank or other devices to regulate water pressure and reduce unnecessary cycling.

5. Power surge protection: Install surge protection devices to safeguard the well pump against power surges, which can damage electrical components.

6. Prompt repairs: Address any issues or malfunctions promptly by contacting a professional well pump technician. Timely repairs can prevent further damage and extend the lifespan of the pump.

It's advisable to consult the manufacturer's documentation or contact Goulds Pumps directly for more accurate information related to your specific model.

0 notes

Text

WEBTECH INTERNATIONAL MACHINERIES

GST 06AACFW8816A1ZC

IndiaMART Verified Leading Supplier

~ https://www.webtechengg.com/

~ https://www.webtechmachineries.com/

BRIEF INTRODUCTION :

Established in the year 1998, “WEBTECH GROUP” is the leading Manufacturer of Wide Range of Printing and Paper Converting Machineries :

~ Wide Web & Narrow Web Flexographic Printing Machine

~ Web Offset Printing Machines

~ ATM POS & Other Thermal Roll Slitting Rewinding Machines

~ Other Reel to Reel Slitting Rewinding Machines

~ Servo Controlled Reel to Sheet Cutting Machines

~ E-COMMERCE Courier Bag Making Machines

~ Automatic A4 Copier Manufacturing Machines

~ Blank Label Die Cutting Machines

~ High Speed Label Inspection Machines etc.

~ Honeycomb Paper Die Cutting Machine

☎️ Call us at : +91 9999779973

Also Please Subscribe to our YouTube Channel for more latest updates : 💫 👇

https://www.youtube.com/channel/UCKpciPWoG7D-AMaTOHbmbPg/videos?view_as=subscriber

0 notes

Link

#Winding Rewinding Machine Manufacturer#Winding Rewinding Machine#Winding Rewinding System#Winding Machine#Rewinding Machine

1 note

·

View note

Link

#Doctoring Rewinding Machine Manufacturer#Doctoring Rewinding Machine#Winder Rewinder Machine Manufacturer#Winder Rewinder Machine

0 notes

Link

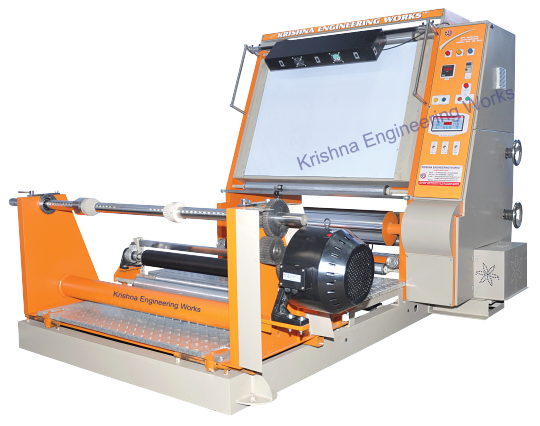

Doctoring Rewinding Machine Manufacturer India. Doctor Rewinder Machine price, Inspection Rewinding Manufacturer, Standard Doctoring Rewinding Machine, Table Top, High Speed Doctoring Rewinding, Heavy Duty Doctoring Rewinding Machine with Slitting System, Winding Rewinding With Multihead Inkjet Printer, with Thermal Transfer Overprinter, Label Stock, Special Application for Doctoring Rewinding, Doctoring Film Strip Winding Rewinding, Coil Winding, Inspection Doctoring Slitting, Film Winding Rewinding for Batch Coding, Doctor Re Reeling and many more per client’s requirement and application. Doctoring Rewinding Winding Unwinding, Doctoring Rewinding Winding Rewinding For Batch Printing, Doctoring Winding Rewinding With Inkjet Printer, Doctoring Film Strip Winding Rewinding, Doctoring Rewinding Coil Winding, Doctoring Rewinding Roll To Roll Batch Printing Machine, Doctoring Slitting, Doctor Re Reeling, Doctoring Rewinding Industrial Inkjet Printer, Doctoring Rewinding Batch Coding Machine, Doctoring Rewinding Batch Printing Machine, Doctoring Rewinding Repairing & Servicing, Doctoring Rewinding Spare Parts. Cantilever design balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner) in Doctoring Rewinding Machine. High quality Doctoring Rewinding, Heavy duty Doctoring Rewinding, Standard equipment for various types of Doctoring Rewinding, Mechanical 1.5 / 2.5 Kg. Optional Magnetic powder brake with tension controller & Torque control potentiometer. Provision for incorporating Ink Jet Printing System with Hot air ink drying in Doctoring Rewinding Machine.

https://youtu.be/dzoyR9rKV58

#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitter Rewinder Machine Price#Heavy Duty Slitter Rewinder Machine#Drum Type Slitter Rewinder Machine#Doctoring Rewinding Machine#Inspection Rewinding Manufacturer#Slitting Rewinding Machine#Slitting Machine#Rewinder Machine#Rewinding Machine#Doctor Rewinder Machine price#Film Slitter Rewinder Machine

0 notes

Link

Krishna Engineering Works India, we have been manufacturing, exporting, and supplier of all types of Doctor Re Reeling Machine, Doctoring Rewinding Machine, Inspection Rewinding Manufacturer, Winding Rewinding Machine, Roll Batch Printing Machine, Doctoring Slitting. Doctor Re Reeling Machine. Cantilever design-balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner). It is great substitute to online coding / batching operation.

#Doctor Re Reeling Machine#Doctor Re Reeling Machine Manufacturer#Doctoring Slitting Machine#Doctoring Rewinding Machine#Doctoring Rewinding Machine Manufacturer#Doctoring Rewinding#Inspection Rewinding Manufacturer#Inspection Rewinding#Winding Rewinding Machine#Winding Rewinding Machine Manufacturer#Winding Rewinding#Roll Batch Printing Machine#Doctoring Slitting#Edge guiding System

0 notes

Link

We have been manufacturing various types of Doctoring Rewinding Machine for separate industries and for different request per client’s requirement. Custom and proper Application for Doctoring Rewinding Machine, 28 separate type of Doctoring Rewinding Machine Manufacturer, exporter, supplier. Doctoring Rewinding Machine with Slitting System like, Standard Doctoring Rewinding Machine, High Speed Doctoring Rewinding, Heavy Duty Doctoring Rewinding, Doctoring Rewinding with Slitting System, Table Top Doctoring Rewinding etc.

#Doctoring Rewinding Machine#Doctoring Machine#Doctoring Rewinding Machine with Slitting System#Doctoring Rewinding Machine Manufacturers#Inspection Machine#Doctoring Rewinding Machine Price#Heavy Duty Doctoring Rewinding Machine#Film Winder Rewinder Machine#Winding Rewinding Machine#Slitting Rewinding Machines

7 notes

·

View notes

Link

Krishna Engineering works leading Manufacturer of doctoring rewinding machine, winder rewinder machine with inkject printer, winder rewinder machine for inkject printer, winder rewinder machine for batch coding, inkjet printing roll rewinding machine and inkject printer rewinder machine. Doctoring Rewinding Machines Manufacturer to make doctoring process for your flexible Packaging Roll with high-quality equipment. We have been manufacturing various types of Doctoring Rewinding Machine for different industries and for different applications per client’s requirement.

#Doctoring Rewinding Machine#Doctoring Machine#Doctoring Rewinding Machine Manufacturer#Winder Rewinder for Inkjet Printer#Winder Rewinder Machine for Batch Coding#Heavy Duty Doctoring Rewinding Machine#Winding & Rewinding Machine#Inspection Doctoring Rewinding Machine#Doctoring Inspection Machine with Slitting System#Winding Rewinding Machine#Winder Rewinder for Inkjet Printer Thermal Printer#Industrial Inkjet Printer with Winder Rewinder Machine

5 notes

·

View notes

Text

From Pulp to Roll: Understanding the Manufacturing Process of Toilet Paper Machines

Toilet paper is a ubiquitous household item that we often take for granted. However, behind every roll of toilet paper lies a complex manufacturing process that involves specialized machines. Understanding the intricacies of toilet paper machine production can shed light on the journey from pulp to the final product that we use daily. In this blog, we will explore the key steps involved in the manufacturing process of toilet paper machines.

Pulp Preparation:

The first step in producing toilet paper is the preparation of the pulp. Wood chips or recycled paper are processed in large machines called pulpers. The pulpers break down the raw material, removing impurities and creating a slurry-like mixture called pulp. This pulp will serve as the foundation for the toilet paper production process.

Paper Machine:

Once the pulp is ready, it is fed into a paper machine. The paper machine consists of a series of sections and components that work together to transform the pulp into thin sheets of paper. These sheets are then pressed, dried, and rolled onto large spools.

Rewinding and Slitting:

The large spools of paper are then transferred to rewinding machines. In this step, the paper is unwound from the spools and rewound onto smaller rolls, which are more convenient for consumer use. The rewinding machines also have slitting blades that cut the large sheets of paper into narrower strips, which will form individual toilet paper rolls.

Embossing and Perforation:

Toilet paper often features patterns or embossed designs on its surface. This is achieved through embossing rolls that press decorative patterns onto the paper during the rewinding process. Additionally, perforation blades create small dotted lines along the paper strip, allowing for easy tearing and separating of individual sheets.

Cutting and Packaging:

After embossing and perforation, the toilet paper strips are cut into individual rolls. These rolls are then packaged using automated packaging machines. The packaging machines wrap each roll in plastic or paper, ensuring hygiene and protection during transportation and storage.

Quality Control:

Throughout the manufacturing process, quality control measures are implemented to ensure that the toilet paper meets industry standards. These measures include monitoring the thickness, strength, and softness of the paper, as well as inspecting the embossing and perforation patterns. Any defective rolls are removed to maintain the overall quality of the final product.

Conclusion

The manufacturing process of toilet paper machine involves several intricate steps, from pulp preparation to cutting and packaging. Specialized machines and quality control measures ensure that the toilet paper meets the necessary standards of thickness, strength, softness, and hygiene. By understanding the manufacturing process behind toilet paper, we gain a deeper appreciation for the complexity involved in producing this essential everyday product.

0 notes

Link

Krishna Engineering works is biggest manufacturer, exporter and supplier of Inspection rewinding machine at best price. Flexo printing machine, batch printing on rewinding doctor machine, inspection rewinding machine etc. For more information contact us at krishnaengineeringworks.com

1 note

·

View note

Link

Inspection Rewinding Machine Manufacturer India, for Non-Woven, Fabric, Film, Cloth Slitter Rewinder, Doctoring Rewinding Machine Manufacturer, Inspection Rewinder. Also, we make Film Inspection Rewinding with the Slitting system, Non-Woven Fabric Inspection Machine. Inspection Rewinding Machine used majorly for checking of badly printed materials on Rotogravure Printing, Flexo Printing Machine, Batch Printing and much more.

#Inspection Rewinding Machine#Inspection Machine Manufacturer#Doctoring Inspection Rewinding Machine#Inspection Slitting Machine#Inspection Rewinding Machine for Inkjet and Batch Printing

2 notes

·

View notes