#Inspection Slitting Rewinding Machine

Explore tagged Tumblr posts

Text

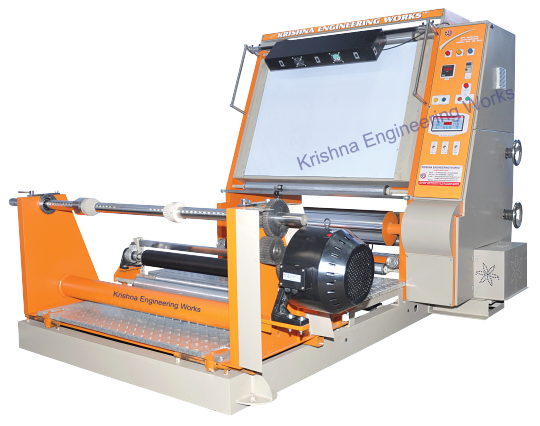

Narrow Web Slitting Rewinding Machine – Precision & Efficiency by KEW ENGG. & MFG. PVT. LTD.

KEW ENGG. & MFG. PVT. LTD. has designed and developed a cutting-edge Narrow Web Slitting Rewinding Machine, engineered for slitting, salvage winding, and de-lamination of rolls. With precision engineering and superior technology, this machine guarantees accurate inspection and high-performance web slitting.

#kewengg#machinemanufacture#exporter#supply#services#industry#narrowwebslittingrewindingmahcine#slittingrewindingmachine#windingrewindingmachine#printingindustry#flexiblepackaging

1 note

·

View note

Text

An Overview of Stretch Film Manufacturing Machines: Types and Functions

Stretch Film Manufacturing Machines are specialized pieces of equipment used to produce stretch film, which is commonly used for packaging and securing products during transportation and storage. These machines play a crucial role in ensuring the durability, elasticity, and quality of the stretch film. Here's an overview of the types of stretch film manufacturing machines and their functions:

1. Blown Film Extrusion Machines:

Description: These machines use the blown film extrusion process to produce stretch film. The process involves melting polymer granules and extruding them through an annular slit die, followed by blowing to expand the film into a tube and cooling it to form the film.

Function: Blown film extrusion machines provide films with higher puncture resistance and more strength compared to other types. They allow for better control over film thickness and quality.

2. Cast Film Extrusion Machines:

Description: In contrast to blown film machines, cast film extrusion machines use a flat die to extrude the molten polymer. The extruded film is then cooled on chilled rollers.

Function: These machines produce films that are clearer and have better cling properties than blown films. Cast film machines generally have higher production rates and produce films with more consistent thickness.

3. Co-extrusion Film Machines:

Description: Co-extrusion machines combine multiple layers of material into a single stretch film product. These machines can have two or more extruders to process different types of polymers or the same polymer with different properties.

Function: The primary function is to produce multilayer stretch films, where each layer can impart different characteristics such as strength, cling, puncture resistance, or barrier properties.

4. Pre-stretch Film Machines:

Description: These machines are designed to stretch the film mechanically before it is wound onto rolls. The pre-stretching process improves the film's yield and can significantly reduce material costs.

Function: They elongate the film by using rollers rotating at different speeds. The resulting film is thinner but has increased strength and is more economical due to reduced material usage.

5. Rewinding Machines:

Description: After the film is extruded and wound onto large rolls, rewinding machines are used to convert these large rolls into smaller, more manageable rolls for commercial distribution.

Function: These machines rewind the film from the larger rolls to smaller ones, often adding a secondary layer of packaging. They can also be used to inspect the film for defects and ensure quality control.

6. Recycling Machines:

Description: In an effort to promote sustainability, some stretch film manufacturing setups include recycling machines that process production waste or used stretch film.

Function: These machines clean, melt, and pelletize the waste film, turning it back into a usable form for manufacturing, thus reducing waste and promoting circular economy practices.

Choosing the Right Machine:

The choice of machine depends on the desired film properties, production volume, and specific application requirements. For example, high-clarity film requirements might favor cast film machines, while high-strength films might be better produced with blown film machines.

By understanding the different types of Stretch Film Manufacturing Machines and their functions, manufacturers can select the most appropriate equipment to meet their production needs and produce high-quality stretch film for various packaging applications.

0 notes

Text

From Pulp to Roll: Understanding the Manufacturing Process of Toilet Paper Machines

Toilet paper is a ubiquitous household item that we often take for granted. However, behind every roll of toilet paper lies a complex manufacturing process that involves specialized machines. Understanding the intricacies of toilet paper machine production can shed light on the journey from pulp to the final product that we use daily. In this blog, we will explore the key steps involved in the manufacturing process of toilet paper machines.

Pulp Preparation:

The first step in producing toilet paper is the preparation of the pulp. Wood chips or recycled paper are processed in large machines called pulpers. The pulpers break down the raw material, removing impurities and creating a slurry-like mixture called pulp. This pulp will serve as the foundation for the toilet paper production process.

Paper Machine:

Once the pulp is ready, it is fed into a paper machine. The paper machine consists of a series of sections and components that work together to transform the pulp into thin sheets of paper. These sheets are then pressed, dried, and rolled onto large spools.

Rewinding and Slitting:

The large spools of paper are then transferred to rewinding machines. In this step, the paper is unwound from the spools and rewound onto smaller rolls, which are more convenient for consumer use. The rewinding machines also have slitting blades that cut the large sheets of paper into narrower strips, which will form individual toilet paper rolls.

Embossing and Perforation:

Toilet paper often features patterns or embossed designs on its surface. This is achieved through embossing rolls that press decorative patterns onto the paper during the rewinding process. Additionally, perforation blades create small dotted lines along the paper strip, allowing for easy tearing and separating of individual sheets.

Cutting and Packaging:

After embossing and perforation, the toilet paper strips are cut into individual rolls. These rolls are then packaged using automated packaging machines. The packaging machines wrap each roll in plastic or paper, ensuring hygiene and protection during transportation and storage.

Quality Control:

Throughout the manufacturing process, quality control measures are implemented to ensure that the toilet paper meets industry standards. These measures include monitoring the thickness, strength, and softness of the paper, as well as inspecting the embossing and perforation patterns. Any defective rolls are removed to maintain the overall quality of the final product.

Conclusion

The manufacturing process of toilet paper machine involves several intricate steps, from pulp preparation to cutting and packaging. Specialized machines and quality control measures ensure that the toilet paper meets the necessary standards of thickness, strength, softness, and hygiene. By understanding the manufacturing process behind toilet paper, we gain a deeper appreciation for the complexity involved in producing this essential everyday product.

0 notes

Text

WEBTECH INTERNATIONAL MACHINERIES

GST 06AACFW8816A1ZC

IndiaMART Verified Leading Supplier

~ https://www.webtechengg.com/

~ https://www.webtechmachineries.com/

BRIEF INTRODUCTION :

Established in the year 1998, “WEBTECH GROUP” is the leading Manufacturer of Wide Range of Printing and Paper Converting Machineries :

~ Wide Web & Narrow Web Flexographic Printing Machine

~ Web Offset Printing Machines

~ ATM POS & Other Thermal Roll Slitting Rewinding Machines

~ Other Reel to Reel Slitting Rewinding Machines

~ Servo Controlled Reel to Sheet Cutting Machines

~ E-COMMERCE Courier Bag Making Machines

~ Automatic A4 Copier Manufacturing Machines

~ Blank Label Die Cutting Machines

~ High Speed Label Inspection Machines etc.

~ Honeycomb Paper Die Cutting Machine

☎️ Call us at : +91 9999779973

Also Please Subscribe to our YouTube Channel for more latest updates : 💫 👇

https://www.youtube.com/channel/UCKpciPWoG7D-AMaTOHbmbPg/videos?view_as=subscriber

0 notes

Link

We have been manufacturing various types of Doctoring Rewinding Machine for separate industries and for different request per client’s requirement. Custom and proper Application for Doctoring Rewinding Machine, 28 separate type of Doctoring Rewinding Machine Manufacturer, exporter, supplier. Doctoring Rewinding Machine with Slitting System like, Standard Doctoring Rewinding Machine, High Speed Doctoring Rewinding, Heavy Duty Doctoring Rewinding, Doctoring Rewinding with Slitting System, Table Top Doctoring Rewinding etc.

#Doctoring Rewinding Machine#Doctoring Machine#Doctoring Rewinding Machine with Slitting System#Doctoring Rewinding Machine Manufacturers#Inspection Machine#Doctoring Rewinding Machine Price#Heavy Duty Doctoring Rewinding Machine#Film Winder Rewinder Machine#Winding Rewinding Machine#Slitting Rewinding Machines

7 notes

·

View notes

Link

Krishna Engineering Works Manufacturers, exports & supplies Table Top Doctoring Rewinding. Our Table Top Doctoring Rewinding Machine is used for all types of Laminates like, Foil, Paper, LDPE, HDPE, PVC, etc. Our Table Top Doctoring Rewinding Machine is manufactured with us most precision which ensure zero maintenance up to 10 years. We have been manufacturing various types of Doctoring Rewinding Machine for different industries and for different applications per client’s requirement. For more information contact our sales team: [email protected]

#Doctoring Rewinding Machine#Standard Doctoring Rewinding Machine#Table Top Doctoring Rewinding#High Speed Doctoring Rewinding#Heavy Duty Doctoring Rewinding#Doctoring Rewinding With Slitting System#Doctoring Slitting Rewinding#Doctoring Rewinding Winding Unwinding#Doctoring Rewinding Winding Rewinding For Batch Printing#Doctoring Winding Rewinding With Inkjet Printer#Industrial Inkjet Printer with Winder Rewinder Machine#Inspection Doctoring Rewinding Machine

4 notes

·

View notes

Link

Krishna Engineering Works is a leading manufacturer, exporter and supplier of Rewinding Machine, Roll-to-Roll Processing Machines for a variety of processes such as Rewinding Machine, Slitting, Docking Rewinding, Winding Rewinding, Rewinding Unwinding, Jumbo Roll to Small Roll Folding, etc. Different types of Winding Rewinding Machine with high quality and heavy duty equipment. Winding rewinding machine with 25 different types per client's application and industry specific requirements. Also a manufacturer of doctoring rewinding machine, Rotogravure printing machine.

#Winding Rewinding Machine for Inkjet Printer#Winding Rewinding Machine#Film Winder Rewinder Machine#Rewinder for Inkjet Printer#Industrial Inkjet Printer with Winder Rewinder Machine#Heavy Duty Doctoring Rewinding Machine#Doctoring Rewinding Machines#Doctoring Machine#Doctoring Re-Reeling Machine#Doctoring Inspection Machine with Slitting System

6 notes

·

View notes

Link

We CON-PAP-TEX are been successfully Manufacturing, Exporting & Supplying all types of Heavy Duty Doctoring Rewinding Machine and Winding Rewinding Machine for Inkjet Printer & Batch Printing, Slitter Rewinder Machine at best price. Doctoring Rewinding Machine industrialist to make doctoring process for your flexible Packaging Roll with high-quality equipment. It is actually designed and built for the heavy-duty procedure of doctoring rewinding.

#Doctoring Rewinding Machine#Doctoring Machine#Heavy Duty Doctoring Rewinding Machine#Inspection Rewinding Machine#Rewinding Machine#Rewinding Machine Price#Automatic Rewinding Machine#Heavy Duty Winding Rewinding Machine#Doctoring Inspection Machine with Slitting System#Winding Rewinding Machine#Doctoring Rewinding#Winder Rewinder#Slitter Winder

1 note

·

View note

Link

Inspection Slitting Rewinding Machine is used majorly for checking of bad printed materials on Roto Gravure Printing, Flexo Printing Machine. Batch Printing on Doctoring Rewinding Machine, etc. In Inspection slitting rewinding process we allow optional parts like, Line Guide System for Electronic Edge Sensing for Perfect Winding, Air Shaft at Unwinder & Rewinder, Tension Control System for Auto Tension at Unwinder System. Inspection Slitting Rewinding Machine, Doctoring Slitting Rewinding Machine, Doctor Rewinder Machine, Inspection Slitting Machine, Winding Rewinding Machine

#Inspection Slitting Rewinding Machine#Inspection Slitting Rewinding Machine Manufacturer#Doctoring Slitting Rewinding Machine#Doctoring Slitting Rewinding Machine Manufacturer#Doctor Rewinder Machine#Doctor Rewinder Machine manufacturer#Inspection Slitting Machine#Inspection Slitting Machine Manufacturer#Winding Rewinding Machine#Winding Rewinding Machine Manufacturer#Doctoring Rewinding Machine#Doctoring Rewinding Machine Manufacturer

0 notes

Link

We are Leading Manufacturer & Supplier of Inspection Slitting Rewinding Machine Manufacturer India. Inspection Rewinding Machine, inspection rewinding machines, Slitting Rewinding Machine, Inspection Slitting Machine, Inspection Doctoring Machine. It is used highly for checking and for inspection of bad printed materials on Rotogravure Printing, Flexo Printing Machine, Batch Printing Machine. It is specially designed and built for high accuracy with adjustable slitting assembly.

#Inspection Slitting Rewinding Machine#Inspection Rewinding Machine#Inspection Rewinding Machine Manufacturer#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Inspection Rewinder Machine#Inspection Rewinder Machine Manufacturer#Inspection Rewinder#Inspection Doctoring Machine#inspection rewinding machines#Inspection Slitting Machine

0 notes

Link

Inspection Rewinding Machine Manufacturer India, for Non-Woven, Fabric, Film, Cloth Slitter Rewinder, Doctoring Rewinding Machine Manufacturer, Inspection Rewinder. Also, we make Film Inspection Rewinding with the Slitting system, Non-Woven Fabric Inspection Machine. Inspection Rewinding Machine used majorly for checking of badly printed materials on Rotogravure Printing, Flexo Printing Machine, Batch Printing and much more.

#Inspection Rewinding Machine#Inspection Machine Manufacturer#Doctoring Inspection Rewinding Machine#Inspection Slitting Machine#Inspection Rewinding Machine for Inkjet and Batch Printing

2 notes

·

View notes

Link

We are Experienced Manufacturer, Exporter & Supplier of Slitter Rewinder Machine. Cantilever Slitter Rewinder Machine Manufacturer, Stretch Film, LDPE Film, BOPP Film, BOPP Tape, OPP, METPET, Pet Film, OPA, Mini Cantilever Slitter Rewinder Machine, Rubber Slitter Rewinder Machine, Shaft Winder Slitter Rewinder Machine, Inspection Slitter Rewinder Machine, PP Slitter Rewinder Machine, BOPP Tape Slitting Rewinding Machine, Jumbo Roll Slitting Rewinding Machine etc. makes us most experienced manufacturer, exporter & supplier of Slitter Rewinder Machine.

#Cantilever Slitter Rewinder Machine#Cantilever Slitter Rewinder Machines#Cantilever Slitter Rewinder Machine Manufacturer#Slitter Rewinder Machine#Slitter Rewinder Machines#Slitter Rewinder Machine Manufacturer#Slitter Rewinder#Slitting Rewinding Machine#Slitting Rewinding Machines#Slitting Rewinding Machine Manufacturer#Slitting Rewinding#Slitter Rewinding machine#Slitter Rewinding machines#Slitter Rewinding machine Manufacturer#Automatic Slitting Rewinding Machine#Thermal Paper Slitting Rewinding Machine#Slitting rewinder Machine#Inspection Slitter Rewinder Machine#PP Slitter Rewinder Machine#BOPP Tape Slitting Rewinding Machine#Jumbo Roll Slitting Rewinding Machine#Shaft Winder Slitter Rewinder Machine

3 notes

·

View notes

Link

Superior Design and High Quality of Cantilever Slitter Rewinder Machine with Independent rewind tension control, unique core lock and ultra-sonic techniques. Different Types of Slitter Machines are Cantilever Slitter Rewinder Machine, Mini Cantilever Slitter Rewinder Machine, Duplex Slitter Rewinder Machine, HDPE Slitter Rewinder Machine, Rubber Slitter Rewinder Machine, Simplex Slitter Rewinder Machine, Inspection Slitter Rewinder Machine, PP Slitter Rewinder Machine, Mini Cantilever Slitter Rewinder Machine, Unwinder Rewinder Machine with Web Guiding System.

#Cantilever Slitter Rewinder Machine#Cantilever Slitter Rewinder Machine Manufacturer#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitting Machine Manufacturer#Slitter Rewinder#Mini Cantilever Slitter Rewinder Machine#Duplex Slitter Rewinder Machine#HDPE Slitter Rewinder Machine#Rubber Slitter Rewinder Machine#Simplex Slitter Rewinder Machine#Inspection Slitter Rewinder Machine

1 note

·

View note

Link

KEW ENGG. & MFG. PVT. LTD. have been manufacturing, exporting and supplying various types of Winding Rewinding Machine. Different types of Winding Rewinding Machine with high quality and heavy duty equipment. Winding Rewinding Machines Like, Film Winding Rewinding For Batch Coding, Winding Rewinding For Batch Printing, Winding Rewinding With Inkjet Printer and with Multihead Inkjet Printer, Winding Rewinding With Thermal Transfer Overprinter, Doctoring Film Strip Winding Rewinding, Winding Rewinding With and Without Slitting System, Coil Winding etc.

#Film Winding Rewinding Machine For Batch Coding#Rewinding Machine#Film Winding Rewinding For Batch Coding#Winding Rewinding For Batch Printing#Winding Rewinding With Inkjet Printer#Winding Rewinding With Thermal Transfer Overprinter#Doctoring Film Strip Winding Rewinding#Winding Rewinding With and Without Slitting System#Doctoring Rewinding Machines#Heavy Duty Doctoring Rewinding Machine#Film Winding Rewinding Machine#Doctoring Rewinding Machine#Winding Unwinding Machine#Roll to Roll Rewinding Machine#Automatic Roll Rewinder Machine#Inspection Winding Rewinding Machine

1 note

·

View note

Link

Krishna Engineering Works is biggest manufacturer, exporter & supplier of Inspection Doctoring Slitting machine at best price and standard quality. The Model is specially designed for correcting badly wounded reels for inspection & doctoring operation. For more information visit our website at krishnaengineeringworks.com

#Inspection rewinding machine#Doctoring Slitting Rewinding#Slitter Rewinder Machine#Doctoring Slitter Rewinder#Slitter machine manufacturer

7 notes

·

View notes

Link

Krishna Engineering Works we have been manufacturing, exporting, and supplier of all types of Doctor Re Reeling Machine, Doctoring Rewinding Machine, Inspection Rewinding Manufacturer, Winding Rewinding Machine. We have designed and built for accuracy for doctoring use with air brake with reel diameter, Edge Guide with actuator for the Unwind reel, Air shafts for Doctoring Re Reeling Machine units. It is used to salvage badly rewound coils produced on the Slitting and Rewinding Machine.

#Doctoring Re Reeling Machine#Doctoring Slitting Machine#Winding Unwinding Machine#Unwinding & Rewinding Machine#Inspection Doctoring Rewinding Machine#Doctoring Rewinding Machine#Fabric Winding Machine#Inspection Rewinding#Automatic Reeling Machine Price#Textile Reeling Machine#Industrial Slitting#Winding Rewinding Machine#Film Winder Rewinder Machine#Doctoring Inspection Machine

5 notes

·

View notes