#Inspection Winding Rewinding Machine

Text

A paper tube cutting machine is a versatile and essential machine used in the paper industry. It is designed to cut large rolls of paper into smaller, more manageable rolls of desired width and length. This machine is crucial in various sectors, including printing, packaging, and converting industries.

Unwinding: The process begins with loading a large roll of paper onto the unwinding shaft. The machine then unwinds the paper roll at a controlled speed.

Slitting: The unwound paper is then passed through sharp blades or rotary knives that slit the paper into smaller widths. The number of blades can be adjusted based on the number of rolls required.

Rewinding: The slit paper is then rewound onto separate cores to form smaller rolls. The tension and speed of rewinding can be controlled to ensure the rolls are wound tightly and evenly.

Cutting: Some machines also have an integrated cutting mechanism that cuts the rewound rolls to the desired length.

Quality Control: Many Paper Slitter Rewinders come with built-in inspection systems that check for defects or irregularities in the paper.

The Paper Slitter Rewinder is known for its high efficiency, precision, and speed. It can handle a wide range of paper types and thicknesses, making it a versatile choice for businesses. With its robust construction and advanced features, this paper core machine ensures smooth and consistent operation, enhancing productivity and reducing waste. Whether you’re a small print shop or a large paper mill, a Paper Slitter Rewinder can be a valuable addition to your production line.

Paper Slitter Rewinder: Enhancing Efficiency in Manufacturing

The Paper Slitter Rewinder is a game-changer in the manufacturing industry, significantly enhancing efficiency and productivity. This machine is designed to transform large rolls of paper into smaller ones, tailored to specific requirements. Here’s how it contributes to manufacturing efficiency:

High-Speed Operation: paper tube winder machine operate at high speeds, capable of processing large volumes of paper in a short time. This speed significantly reduces production time, enabling businesses to meet high demand quickly.

Precision Cutting: With adjustable blades, the machine ensures precise and consistent cuts every time. This precision eliminates waste from inaccurate cuts, saving materials and costs.

Automation: Many models come with automated features, reducing the need for manual intervention. This automation not only saves labor costs but also minimizes human error, ensuring consistent quality.

Quality Control: With built-in inspection systems, the machine can detect and rectify defects or irregularities in the paper. This feature ensures that only high-quality paper rolls reach the end of the production line.

Space Efficiency: Despite its robust capabilities, the Paper Slitter Rewinder has a compact design that saves valuable floor space in manufacturing facilities.

By investing in a Paper Slitter Rewinder, businesses can significantly enhance their manufacturing efficiency. This core pipe-making machine not only speeds up the production process but also ensures the consistent quality of the final product, leading to increased customer satisfaction and profitability.

Paper Slitter Rewinders for Every Industry Need

Paper slitter rewinders play a pivotal role across diverse industries, addressing unique needs with precision and efficiency:

Printing Industry: In printing, these machines facilitate the production of custom-sized paper rolls, optimizing printing processes and reducing waste.

Packaging Sector: The packaging industry benefits from the adaptability of paper slitter rewinders, ensuring the creation of tailored rolls for various packaging applications, enhancing efficiency and minimizing material costs.

Converting Industries: Paper converting relies on these machines to transform large paper rolls into smaller, usable rolls with specific dimensions, meeting the requirements of different product lines.

Flexibility in Width and Length: The versatility of paper slitter rewinders allows for the customization of roll width and length, catering to the unique specifications of each industry and product.

Enhanced Productivity: With precise cutting and rewinding capabilities, these machines contribute to increased productivity, reducing downtime and enhancing overall operational efficiency in multiple sectors.

0 notes

Text

Fabric Rewinding Machine

With a lot more effective winding unit (from your roll cradle on to the tube), duration measurement gadget.

Vital characteristics:

- Fabric rewinding machine / inspection machines with backlighting display deliver quickly, quick good quality Command and measure material size.

- Equipment can have a created-in lay handbook (version /R) or semi-automatic (Model /A) finish-cutter for greater performance within the office.

- A wonderful choice for all textile suppliers and businesses that manage any type of fabric.

- The device winds material from a roll positioned Within the cradle over a Main put on a winding shaft.

- Superior winding velocity (fifty m/min or sixty m/min).

- Mechanical counter (yards or meters).

- Easy fabric roll installation.

- Body made from powder-coated steel.

0 notes

Link

#Winding Rewinding Machine Manufacturer#Winding Rewinding Machine#Winding Rewinding System#Winding Machine#Rewinding Machine

1 note

·

View note

Link

#Doctoring Rewinding Machine Manufacturer#Doctoring Rewinding Machine#Winder Rewinder Machine Manufacturer#Winder Rewinder Machine

0 notes

Link

KEW ENGG. & MFG. PVT. LTD. have been manufacturing, exporting and supplying various types of Winding Rewinding Machine. Different types of Winding Rewinding Machine with high quality and heavy duty equipment. Winding Rewinding Machines Like, Film Winding Rewinding For Batch Coding, Winding Rewinding For Batch Printing, Winding Rewinding With Inkjet Printer and with Multihead Inkjet Printer, Winding Rewinding With Thermal Transfer Overprinter, Doctoring Film Strip Winding Rewinding, Winding Rewinding With and Without Slitting System, Coil Winding etc.

#Film Winding Rewinding Machine For Batch Coding#Rewinding Machine#Film Winding Rewinding For Batch Coding#Winding Rewinding For Batch Printing#Winding Rewinding With Inkjet Printer#Winding Rewinding With Thermal Transfer Overprinter#Doctoring Film Strip Winding Rewinding#Winding Rewinding With and Without Slitting System#Doctoring Rewinding Machines#Heavy Duty Doctoring Rewinding Machine#Film Winding Rewinding Machine#Doctoring Rewinding Machine#Winding Unwinding Machine#Roll to Roll Rewinding Machine#Automatic Roll Rewinder Machine#Inspection Winding Rewinding Machine

1 note

·

View note

Link

Cantilever design-balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner). Mechanical 1.5 / 2.5 Kg. Optional Magnetic powder brake with tension controller & Torque control potentiometer. Provision for incorporating Inkjet Printing System with Hot air ink drying. Winder Rewinder Machine, Inspection Rewinding Machine, Winding Rewinding Machine, Doctoring Rewinder Machine, Inspection Winding Rewinding Machine

#Winder Rewinder Machine#Inspection Rewinding Machine#Winding Rewinding Machine#Doctoring Rewinder Machine#Inspection Winding Rewinding Machine

1 note

·

View note

Link

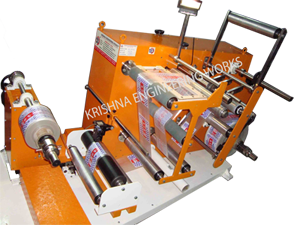

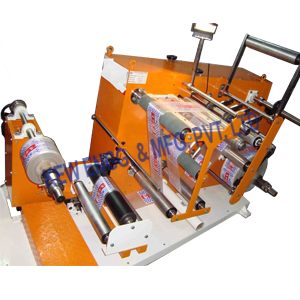

We are Manufacturer of Inspection Winding Rewinding Machine, Inspection Rewinding Machine, Doctoring Slitting Machine, Doctoring Inspection Manufacturer, Rewinding Machine, Winding Rewinding Machine India. Our Inspection Rewinding Machine, specially designed to meet the standards that effectively meet the client’s requirements for Inspection and Slitter Rewinder Machine, Slitting Machine. All our Inspection Rewinding Machine is used highly for checking and for inspection of bad printed materials on Rotogravure Printing, Flexo Printing Machine, Batch Printing.

#Inspection Winding Rewinding Machine#Inspection Winding Rewinding#Inspection Rewinding Machine#Inspection Rewinding Machine Manufacturer#Inspection Rewinding#Doctoring Slitting#Doctor Rewinder Machine#Doctor Rewinder Machine Manufacturer#Doctor Rewinder#Rewinding Machine#Winding Rewinding Machine#Winding Rewinding Machine Manufacturer#Winding Rewinding

0 notes

Link

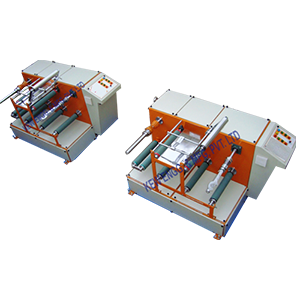

Krishna Engineering Works Manufacturers, exports & supplies Table Top Doctoring Rewinding. Our Table Top Doctoring Rewinding Machine is used for all types of Laminates like, Foil, Paper, LDPE, HDPE, PVC, etc. Our Table Top Doctoring Rewinding Machine is manufactured with us most precision which ensure zero maintenance up to 10 years. We have been manufacturing various types of Doctoring Rewinding Machine for different industries and for different applications per client’s requirement. For more information contact our sales team: [email protected]

#Doctoring Rewinding Machine#Standard Doctoring Rewinding Machine#Table Top Doctoring Rewinding#High Speed Doctoring Rewinding#Heavy Duty Doctoring Rewinding#Doctoring Rewinding With Slitting System#Doctoring Slitting Rewinding#Doctoring Rewinding Winding Unwinding#Doctoring Rewinding Winding Rewinding For Batch Printing#Doctoring Winding Rewinding With Inkjet Printer#Industrial Inkjet Printer with Winder Rewinder Machine#Inspection Doctoring Rewinding Machine

4 notes

·

View notes

Link

We are Manufacturer and exporting of High-quality equipment Inspection Winding Rewinding Machine Manufacturer, Find Here best quality Winder Rewinder Machine Manufacturer, Winding Rewinder Machine, Doctoring Rewinding Machine, Inspection Rewinding Machine. Our Inspection Rewinding Machine used majorly for checking of bad printed materials on Rotogravure Printing Machine, Flexo Printing Machine , Batch Printing Machine on Doctoring Rewinding Machine, etc. Inspection Rewinding Machine with advanced feature like, adjustable slitting assembly and many more per client’s requirement.

#Inspection Winding Rewinding Machine#Inspection Winding Rewinding#Winding Rewinding Machine#Winding Rewinding Machine Manufacturer#Doctoring Rewinding Machine#Doctoring Rewinding Machine Manufacturer#Doctoring Rewinding Machines#Doctoring Rewinding#Winding Rewinding#Inspection Rewinding Machine#Inspection Rewinding Machine Manufacturer#Inspection Rewinding#Inspection Rewinding Machines#Batch Printing Machine#Batch Printing Machine manufacturer

0 notes

Link

Krishna Engineering Works is a leading manufacturer, exporter and supplier of Rewinding Machine, Roll-to-Roll Processing Machines for a variety of processes such as Rewinding Machine, Slitting, Docking Rewinding, Winding Rewinding, Rewinding Unwinding, Jumbo Roll to Small Roll Folding, etc. Different types of Winding Rewinding Machine with high quality and heavy duty equipment. Winding rewinding machine with 25 different types per client's application and industry specific requirements. Also a manufacturer of doctoring rewinding machine, Rotogravure printing machine.

#Winding Rewinding Machine for Inkjet Printer#Winding Rewinding Machine#Film Winder Rewinder Machine#Rewinder for Inkjet Printer#Industrial Inkjet Printer with Winder Rewinder Machine#Heavy Duty Doctoring Rewinding Machine#Doctoring Rewinding Machines#Doctoring Machine#Doctoring Re-Reeling Machine#Doctoring Inspection Machine with Slitting System

6 notes

·

View notes

Link

We CON-PAP-TEX are been successfully Manufacturing, Exporting & Supplying all types of Heavy Duty Doctoring Rewinding Machine and Winding Rewinding Machine for Inkjet Printer & Batch Printing, Slitter Rewinder Machine at best price. Doctoring Rewinding Machine industrialist to make doctoring process for your flexible Packaging Roll with high-quality equipment. It is actually designed and built for the heavy-duty procedure of doctoring rewinding.

#Doctoring Rewinding Machine#Doctoring Machine#Heavy Duty Doctoring Rewinding Machine#Inspection Rewinding Machine#Rewinding Machine#Rewinding Machine Price#Automatic Rewinding Machine#Heavy Duty Winding Rewinding Machine#Doctoring Inspection Machine with Slitting System#Winding Rewinding Machine#Doctoring Rewinding#Winder Rewinder#Slitter Winder

1 note

·

View note

Link

We are specialised manufacturer & exporter of Air Pneumatic Shaft, high quality equipment Inspection Slitting Machine Manufacturer, Winder Rewinder. Our Air Pneumatic Shaft for Winding Rewinding Machine is used for all types of Laminates like, Foil, Paper, LDPE, HDPE, PVC, etc. Our Air Pneumatic Shaft for Winding Rewinding Machine. Cantilever design-balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner). Mechanical 1.5 / 2.5 Kg. Optional Magnetic powder brake with tension controller & Torque control potentiometer. Provision for incorporating Inkjet Printing System with Hot air ink drying.

0 notes

Link

Flexible Packaging & Converting Machinery, Slitter Rewinder Machine, Winding Rewinding Machine, Rotogravure Printing, Lamination, Flexo Printing, Coating, Liner Rewinder Machine, High Efficiency Inspection Machine Batching Machine, Equipment Tyre Cord Dipping Plant, Automatic Tension Control, Web Aligner, Automatic Guiding System, Liner Drying Machine, Web Aligner System is much more than just an energy source. It’s designed for accurate and high quality edge guiding system. However, because it normally furnishes modulated power to the actuating devices. It’s amplifier of control signals, also power source In addition to providing hydraulic power for the actuating circuit the power unit produces pneumatic power for the sensors, Two Stage Winder, Two Stage Unwinder, Liner Drying Machine, Core Cutting Machine, Hydro Pneumo Web Aligner System, Cooling Heating Drums, Fully Automatic Tension Control.

#Slitter Rewinder Machine#Winding Rewinding Machine#Slitter Rewinder#Winder Rewinder#Flexible Packaging#Tyre Cord Machinery#Web Aligner#Web Aligner System#automatic guiding system#Rotogravure Printing#Lamination#flexo printing machine#Converting Machinery#Fully Automatic Tension Control#Inspection Machine#Batching Machine#Rewinder Machine Film Slitter#Textile Slitting Rewinding#Tire – Cord#Textile Machinery & Equipment#Core Cutting Machine

0 notes

Link

Inspection Rewinding Machines, India Krishna Engineering Works. It is used highly for checking and for inspection of bad printed materials on Rotogravure Printing, Flexo Printing Machine, and Batch Printing. It is specially designed and built for high accuracy with adjustable slitting assembly. Also, it allows system for Individual drive for both rewind station synchronize with nip and slitting drive. This Inspection re-winder is a reversible, simplex, single shaft centre winding machine capable of handling all type of printed films for salvaging before lamination. It is designed for easy operation and minimum maintenance. Construction of this machine is suitable for hydro - clamping based fast loading of material and with reversible facilities to keep same direction of printed film.

#Inspection Rewinding Machines#Winding Rewinding Machine#Winding Rewinding#Winder Rewinder#Rewinder Machine#Batch Printing Machines#Flexo Printing Machine#Rotogravure Printing#Rewinding Machines#Winder Rewinders#Rewinder Unwinder#Doctoring Rewinding#Unwinder Rewinder System

1 note

·

View note

Link

KEW High Speed Manufacturer, exporter & supplier Of Winding Rewinding Machines, winding machine, winding machine price, automatic winding machine, winding equipment, winding machine manufacturer, winding machines, winder machine, winder machines, winding rewinding, winding rewinding Machine, winding rewindings. Winding Rewinding Machines Like, Film Winding Rewinding For Batch Coding, Winding Rewinding For Batch Printing, Winding Rewinding With Inkjet Printer and with Multihead Inkjet Printer.

#Winding Rewinding Machines#Winding Rewinding Machine#winding machine#winding machine price#automatic winding machine#winding equipment#winding machine manufacturer#winding machines#winder machine#winder machines#winder machines Manufacturer#Inspection Rewinding Machine#Industrial Inkjet Machine#Doctoring Rewinding Machine#Industrial Thermal Transfer Printer Machine

0 notes

Link

We have been manufacturing various types of Doctoring Rewinding Machine for separate industries and for different request per client’s requirement. Custom and proper Application for Doctoring Rewinding Machine, 28 separate type of Doctoring Rewinding Machine Manufacturer, exporter, supplier. Doctoring Rewinding Machine with Slitting System like, Standard Doctoring Rewinding Machine, High Speed Doctoring Rewinding, Heavy Duty Doctoring Rewinding, Doctoring Rewinding with Slitting System, Table Top Doctoring Rewinding etc.

#Doctoring Rewinding Machine#Doctoring Machine#Doctoring Rewinding Machine with Slitting System#Doctoring Rewinding Machine Manufacturers#Inspection Machine#Doctoring Rewinding Machine Price#Heavy Duty Doctoring Rewinding Machine#Film Winder Rewinder Machine#Winding Rewinding Machine#Slitting Rewinding Machines

7 notes

·

View notes