#LOTO Installation Process

Explore tagged Tumblr posts

Text

How to Install Lockout Tagout Devices to Protect Worker and Equipment

Ensure workplace safety and compliance with this step-by-step guide to Lockout Tagout device installation. This video demonstrates the proper application of various LOTO devices, helping you secure hazardous energy sources and protect workers.

Whether you’re new to LOTO or refining your safety protocols, this guide simplifies the process with clear visuals and expert insights. Watch now to enhance your safety procedures.

To check more detail about Lockout Tagout, visit - https://www.safetylock.net

#Lockout Tagout Video#How to install Lockout Tagout Devices#Lockout Tagout#How to LOTO#LOTO Installation Process#LOTO Application#E-Square Alliance

0 notes

Text

The Importance of Reliable Indication Lamps in Electrical Safety

In the intricate world of electrical systems, safety is paramount. While primary protective devices like circuit breakers and fuses often take center stage, the seemingly humble indication lamp plays a vital, yet often underestimated, role in ensuring operational safety and preventing potential hazards. Reliable indication lamps act as the eyes of the electrical system, providing immediate visual feedback on the status of circuits, equipment, and power availability. In critical applications across industries in Sharjah, UAE, and beyond, the dependability of these small components can have significant implications for personnel safety, equipment integrity, and overall operational efficiency. This article delves into the crucial importance of reliable indication lamps in maintaining a safe electrical environment.

The Silent Guardians of Electrical Systems:

Indication lamps, also known as pilot lights or indicator lights, are visual signaling devices that communicate the operational state of an electrical circuit or piece of equipment. They provide instant, at-a-glance information, allowing operators and maintenance personnel to quickly assess whether a system is powered on or off, if a fault has occurred, or if a specific process is active. Their simplicity belies their significance in preventing human error and ensuring safe interaction with electrical installations.

Why Reliability Matters in Indication Lamps for Electrical Safety:

The effectiveness of indication lamps as safety tools hinges entirely on their reliability. A faulty or malfunctioning indicator can lead to misinterpretations, potentially resulting in dangerous actions. Consider the following scenarios where unreliable indication lamps can compromise electrical safety:

· False Off Indication: If a machine or circuit is actually live but the indication lamp shows it as “off,” maintenance personnel could unknowingly come into contact with energized parts, leading to severe electric shock.

· False On Indication: Conversely, if an indication lamp remains illuminated even after a circuit has been de-energized, it could mislead someone into believing the system is still live, causing unnecessary delays or incorrect procedures.

· Intermittent or Unclear Indication: Flickering or dimly lit indication lamps can lead to ambiguity and uncertainty about the true status of the system, potentially leading to rushed or incorrect decisions.

· Complete Failure: A completely failed indication lamp provides no information at all, leaving operators blind to the actual state of the electrical system.

Key Contributions of Reliable Indication Lamps to Electrical Safety:

When indication lamps function reliably, they significantly contribute to electrical safety in numerous ways:

· Visual Confirmation of System Status: They provide immediate and unambiguous visual confirmation of whether equipment is energized or de-energized, allowing personnel to safely interact with electrical systems during operation, maintenance, and troubleshooting.

· Prevention of Accidental Energization/De-energization: Clear “on” and “off” indicators help prevent the accidental activation or deactivation of equipment during critical processes or maintenance procedures, safeguarding both personnel and machinery.

· Rapid Fault Identification: In the event of a fault or abnormal condition, dedicated indication lamps (often with specific colors like red or amber) can provide immediate visual cues, allowing for quicker identification of the problem area and faster response times, minimizing potential damage and safety risks.

· Enhanced Lockout/Tagout (LOTO) Procedures: Reliable indication lamps can complement LOTO procedures by providing a visual confirmation that the energy source has indeed been isolated before maintenance or repair work begins.

· Improved Communication and Awareness: In complex electrical panels and control systems, clearly labeled and functioning indication lamps enhance communication between operators and maintenance teams, ensuring everyone has a clear understanding of the system’s state.

· User-Friendly Interface: Well-placed and reliable indication lamps contribute to a more intuitive and user-friendly interface for electrical equipment, reducing the likelihood of human error.

Choosing Reliable Indication Lamps for Enhanced Safety:

Selecting high-quality and reliable indication lamps is crucial for ensuring electrical safety. Consider the following factors:

· Quality of Components: Opt for lamps from reputable manufacturers known for using durable and long-lasting components.

· Clear and Consistent Illumination: Choose lamps that provide bright, consistent, and easily visible light output.

· Appropriate IP Rating: Select lamps with an ingress protection (IP) rating suitable for the environmental conditions of their application (e.g., dust and moisture resistance in industrial settings in Sharjah).

· Correct Voltage and Current Ratings: Ensure the lamps are compatible with the voltage and current of the circuits they are indicating.

· Vibration and Shock Resistance: In industrial environments with potential vibrations or impacts, choose robust lamps designed to withstand these conditions.

· Compliance with Safety Standards: Ensure the indication lamps meet relevant national and international safety standards.

· Clear Labeling: Ensure the purpose of each indication lamp is clearly and durably labeled on the electrical panel.

Conclusion:

In the realm of electrical safety, even the smallest components can play a critical role. Reliable indication lamps, often overlooked, serve as essential visual indicators that provide immediate feedback on the status of electrical systems. Their dependable operation is crucial for preventing accidents, facilitating safe maintenance procedures, and ensuring the overall integrity of electrical installations across various industries in UAE, Gcc and globally. By recognizing the importance of reliable indication lamps and making informed choices during selection and maintenance, we can significantly enhance electrical safety and create a safer working environment for everyone interacting with electrical systems.

#ElectricalSafety#SafetyFirst#ElectricalEngineering#IndustrialSafety#PowerSystems#ElectricalComponents#IndicationLamps#PilotLights#IndicatorLights#PanelLights#LEDIndicators#VisualSignaling#ReliableIndicators#SafetyCritical#PreventAccidents#OperationalSafety#MaintenanceSafety#DowntimePrevention#UAE#Sharjah#UAEElectricians#ElectricalContractorsUAE#IndustrialUAE#MEPContracting#ELVSystems#FacilityManagement#IndustrialAutomation#CommercialElectrical#LockoutTagout#LOTO

0 notes

Text

Key Safety Standards in Substation Installation and Construction

Introduction

Substation installation and construction are critical processes that require strict adherence to safety standards. Ensuring the safety of personnel, equipment, and the surrounding environment is paramount. In this blog, we’ll discuss the key safety standards that govern substation projects and the best practices for compliance.

1. Understanding Electrical Safety Regulations

Electrical safety regulations are designed to protect workers and the public from electrical hazards. Key standards to be aware of include:

National Electrical Safety Code (NESC): Provides guidelines for the safe installation, operation, and maintenance of electric supply and communication lines.

Occupational Safety and Health Administration (OSHA) Standards: Mandates safe work practices and identifies hazards in the workplace, including electrical safety protocols.

2. Personal Protective Equipment (PPE)

Personal Protective Equipment is essential for protecting workers during substation installation and construction. Essential PPE includes:

Insulated Gloves: Protect against electrical shock during equipment handling.

Hard Hats: Shield against falling objects and electrical hazards.

Flame-Resistant Clothing: Reduces the risk of burns in the event of an electrical arc.

3. Site Safety Assessment

Before beginning construction, conducting a thorough site safety assessment is crucial. This involves:

Hazard Identification: Recognizing potential risks such as overhead power lines, underground utilities, and environmental hazards.

Access Control: Ensuring that only authorized personnel are allowed on-site to prevent accidents and injuries.

4. Safe Equipment Handling and Operation

Proper handling and operation of equipment are vital for ensuring safety during installation. Key practices include:

Training and Certification: All personnel should be trained and certified to operate heavy machinery and electrical equipment.

Equipment Inspection: Regularly inspect tools and equipment to ensure they are in good working condition and safe to use.

5. Implementing Lockout/Tagout Procedures

Lockout/Tagout (LOTO) procedures are essential for ensuring that machinery is properly shut off and not accidentally started during maintenance or installation. This includes:

Locking Out Energy Sources: Physically locking and tagging equipment to prevent accidental activation.

Training Workers: Educating all personnel on LOTO procedures and the importance of compliance.

6. Emergency Preparedness and Response

Having a plan in place for emergencies is crucial for maintaining safety during substation projects. Key components include:

Emergency Action Plans (EAP): Develop and communicate plans for various emergency scenarios, including electrical accidents and fires.

First Aid Training: Ensure that personnel are trained in first aid and CPR to respond to medical emergencies on-site.

7. Regular Safety Audits and Reviews

Continuous monitoring and improvement of safety practices are essential for compliance and risk reduction. Regular safety audits should include:

Safety Inspections: Conduct periodic inspections to identify and rectify potential safety hazards.

Feedback Mechanism: Establish a system for workers to report safety concerns and suggest improvements.

Adhering to key safety standards in substation installation and construction is vital for protecting workers and ensuring project success. By understanding and implementing these safety measures, companies can minimize risks and create a safer working environment.

If you need assistance with safety compliance in your substation projects, contact ATSPower today! Our team of experts is here to help you navigate safety standards and ensure the success of your projects.

Call to Action

For more information about our services, visit atspower.com.bd or call us at +8801724-826148.

0 notes

Text

LOTO.

By Manoj Kumar([email protected]/+91–8252771261).

I was familiar with LOTO Procedure from my first company”Alstom Projects India Limited”. Lots of training literature,books and online and offline courses provided by Alstom. Second time I was once again selected for doing job as an EHS Officer from Noida,Sector-65 desk under construction manager Shri Ashutosh Garg sir ,Shri Yogish Ojha(EHS-DGM) & Shri Yogesh Srivastava Sir(Country Head-Alstom). Third time was selected from same desk from Shri Yogesh Srivastava Srivastava Sir(Country Head,EHS,Alstom),Shri Pradipta Kumar Nandi Sir(DGM-EHS,Alstom) for S1 Project.Our Principal Employer was Power Grid Corporation Limited. It was an extension project. I joined at Bhinmal(Rajasthan),Amritsar(Chabba),Kartarpur(Jalandhar),Jind(Haryana),Kaithal(Haryana).

Lets talk about a topic of LOTO.

Importance of LOTO:

Safety devices such as barrier guards or guarding devices are installed on systems to maintain worker safety while these systems are being operated. When activities such as maintenance, repair, or set-up; or the removal of jams, clogs or misaligned feeds are performed, these safety devices may be removed if there are other controls in place to reduce or eliminate the hazards.

Having a lockout/tag out program and procedures for these scenarios will reduce the risk of injury due to the unintended or inadvertent release of hazardous energy.

Purpose of LOTO:

Identify the types of:

Hazardous energy in the workplace

Energy-isolating devices

De-energizing devices

Guide the selection and maintenance of protective devices, hardware, and personal protective equipment (PPE)

Assign duties and responsibilities

Describe lockout procedures for all machines, equipment, and processes

Determine shutdown, de-energizing, energizing, and start-up sequences

Describe training requirements for authorized and affected workers

Be audited for effectiveness

An effective lockout/tag out program will help prevent:

Contact with a hazard while performing tasks that require the removal, by-passing, or deactivation of safeguarding devices.

The unintended release of hazardous energy (including stored energy).

The unintended start-up or motion of machinery, equipment, or processes.

Responsible for the lockout program.

Each party in the workplace has a responsibility in the lockout program. In general:

Management is responsible for:

Drafting, reviewing, and updating lockout procedures and program.

Identifying the employees, machines, equipment, and processes included in the program.

Providing the necessary protective equipment, hardware and appliances.

Monitoring and measuring conformance with the program.

Supervisors are responsible for:

Distributing protective equipment, hardware, and any appliance; and ensuring its proper use by employees.

Making sure that equipment-specific procedures are established for the machines, equipment and processes in their area.

Making sure that only properly trained employees perform service or maintenance that require lockout.

Making sure that employees under their supervision follow the established lockout procedures where required.

Authorized individuals are responsible for:

Following the procedures that have been developed.

Reporting any problems associated with those procedures, the equipment, or the process of locking and tagging out.

Lockout procedures and work instructions:

An organization will have one overall lockout program; however for each unique machine or equipment, there will be a detailed procedure or work instruction that describes the steps to control the hazardous energy.

The written lockout procedure should specify:

The specific machine, equipment, or process involved in the shutdown and isolation process.

The hazardous energy present and the type of energy-isolating or de-energizing devices required.

Where the lockout devices are required and how they are installed.

The steps for shutting down, isolating, blocking, securing, and relieving stored or residual energy.

The steps for placing and removing all lockout devices.

How the isolation can be verified.

How others in the area will be informed of the lockout and the return into service.

Basic steps of locking and tagging out:

Lockout and tag out processes involve more than putting a lock on a switch. They are comprehensive step-by-step processes that involve communication, coordination, and training.

General steps of a lockout/tag out procedure include:

1. Prepare for Shutdown

The authorized person will identify the machine, equipment, or process that requires lockout, which sources of energy are present and must be controlled, and what lockout device will be used. This step involves gathering all required equipment (e.g., lockout devices, tags, etc.).

2. Notify all Affected Personnel

The authorized person will communicate the following information to notify affected persons:

What is going to be locked/tagged out.

Why it is going to be locked/tagged out.

For approximately how long the system be unavailable.

Who is responsible for the lockout/tag out, if not themselves.

Who to contact for more information.

This information should also be present on the tag required for the lockout.

3. Equipment Shutdown

Follow shutdown procedures (either established by the manufacturer or employer). Equipment shutdown involves ensuring controls are in the off position, and verifying that all moving parts such as flywheels, gears, and spindles have come to a complete stop.

4. Isolation of System (De-energization)

Follow the lockout procedure for the identified machine, equipment, or process. Review the following isolation practices for various forms of hazardous energy:

Electrical energy — Switch electrical disconnects to the off position. Visually verify that the breaker connections are in the off position. Lock the disconnects into the off position. NOTE: Only disconnect switches or breakers that you are trained or authorized to do so, especially at high voltages.

Hydraulic and pneumatic potential energy — Set the valves in the closed position and lock them into place. Bleed off the energy by slowly opening the pressure relief valves. Some procedures for pneumatic energy control may require that pressure relief valves be locked in the open position. Some procedures for hydraulic energy, for example in lifting devices, may require blocking.

Figure 2: Hydraulic and pneumatic lockout

Mechanical potential energy — Carefully release energy from springs that may still be compressed. If this is not feasible, block the parts that may move if there is a possibility that the spring can transfer energy to it.

Gravitational potential energy — Use a safety block or pin to prevent the part of the system that may fall or move.

Chemical energy — Locate chemical supply lines to the system and close and lockout the valves. Where possible, bleed lines and/or cap ends to remove chemicals from the system.

5. Dissipation (Removal) of Residual or Stored Energy

In general, examples include:

Electrical energy — To find a specific method to discharge a capacitor for the system, contact the manufacturer for guidance. Many systems with electrical components, motors, or switch gears contain capacitors. Capacitors store electrical energy. In some cases, capacitors hold a charge and may release energy very rapidly. In other cases, capacitors are used to remove spikes and surges to protect other electrical components. Capacitors must be discharged in the lockout process in order to protect workers from electrical shock.

Hydraulic and pneumatic potential energy — Setting the valves in the closed position and locking them into place only isolates the lines from more energy entering the system. In most cases, there will still be residual energy left in the lines as pressurized air or fluid. This residual energy can be removed by bleeding the lines through pressure relief valves. Verify depressurization or use flange-breaking techniques. Contact the manufacturer for more specific details, or if no pressure relief valves are available, what other methods are available.

Gravitational potential energy — If possible, bring the equipment or machine to ground level.

Chemical energy — If available, bleed lines and/or cap ends to remove chemicals from the system.

6. Lockout/Tag Out

When the system’s energy sources are locked out, there are specific guidelines that must be followed to make sure that the lock cannot be removed, and the system cannot be inadvertently operated. These guidelines include:

Each lock should only have one key (no master keys are allowed).

All keys must be removed from locks and kept with the person who applied the lock.

There should be as many locks on the system as there are people working on it. For example, if a maintenance job requires 3 workers, then 3 locks should be present — each of the individuals must place their OWN lock on the system. Locks can only be removed by those who installed them and should only be removed using a specific process (See № 09 Points).

7. Verify Isolation

Verify that the system is properly locked out before beginning any work. Verification can take place in several ways:

The machine, equipment, or process controls (push buttons, switches, etc.) are engaged or activated and the result is observed. No response means isolation is verified. Return controls to the safe position (off).

Visual inspection of:

Electrical connections to make sure they are open.

Suspended parts are lowered to a resting position or blocked to prevent movement.

Other devices that restrain machine or process movement.

Valve positioning for double block and bleed (for pipes or ducts) — closing two valves of a section of a line, and then bleeding (or venting) the section of the line between the two closed valves.

Presence of solid plate used to absolutely close a line — called line blanking (for pipes or ducts).

Any other acceptable method of energy isolation.

Testing of the equipment:

Test circuitry (should be done by a certified electrician) — Note: equipment with capacitors needs to be cycled until all energy is drained.

Check pressure gauges to make sure hydraulic and pneumatic potential energy has been removed.

Check temperature gauges to make sure thermal energy has been discharged.

Choose the method that will make sure that the energy to the system has been isolated without creating other hazards during the verification.

8. Perform Maintenance or Service Activity

Complete the activity that required the system to be locked out.

9. Remove Lockout/Tag out devices

To remove locks and tags from a system that is now ready to be put back into service, the following general procedure can be used:

Inspect the work area to make sure all tools and items have been removed.

Confirm that all employees and persons are safely located away from hazardous areas.

Verify that controls are in a neutral position.

Remove devices in the opposite order in which they were installed and re-energize the system.

Notify affected employees that servicing is completed.

#N.B.: It is good practice to make sure any individual who placed a lock on the system should also be present when the system is re-started. This practice helps make sure those employees working on the system are not in a hazardous area when the machine is restarted.

1 note

·

View note

Audio

LOTO lift is one of the top-rated boat lift manufacturers in the industry. They create boat lifts, docks, and accessories according to their customers' demands using cutting-edge technology and pneumatic boat lift brands. They only service and repair LOTO Lift boat lifts to provide the greatest convenience and dependability when people need it most. They also offer boat lift installation and removal to make the process easy and effective.

http://lotolift.com

1 note

·

View note

Text

LOTO Lift Boat Lifts: Revolutionizing the Boating Experience with Advanced Boat Hoists

youtube

In the world of boating, convenience, safety, and efficiency are paramount. Whether you're a passionate boat owner or a marina operator, having a reliable boat hoist is essential for seamlessly launching, storing, and maintaining your watercraft. LOTO Lift Boat Lifts understands the importance of a dependable boat hoist, and they have emerged as a leading provider of innovative and high-quality boat lifts. This article will explore the exceptional features and benefits of LOTO Lift Boat Lifts, revolutionizing the boating experience for enthusiasts and professionals alike.

Uncompromised Quality and Durability: When it comes to boat hoists, durability is a non-negotiable aspect. LOTO Lift Boat Lifts sets the industry standard by utilizing top-grade materials and employing state-of-the-art engineering techniques. Their boat hoists are built to withstand the harsh marine environment, ensuring long-lasting performance and peace of mind for boaters. With meticulous attention to detail and rigorous quality control measures, LOTO Lift Boat Lifts guarantees a product that meets and exceeds expectations.

Versatility for All Watercraft: LOTO Lift Boat Lifts recognizes that different boats have unique requirements. Whether you own a fishing boat, a pontoon, a sailboat, or a speedboat, they offer a diverse range of boat hoists to accommodate various sizes and types of watercraft. With customizable options and adjustable settings, LOTO Lift Boat Lifts ensures a perfect fit for every boat, guaranteeing secure lifting, lowering, and storage operations.

Innovative Design Features: LOTO Lift Boat Lifts stands out from the competition with its innovative design features that make boating operations more efficient and convenient. Their boat hoists come equipped with advanced remote control systems, allowing boat owners to effortlessly operate the lift from a distance. Additionally, LOTO Lift Boat Lifts employs cutting-edge technology, such as precision sensors and intelligent programming, to ensure smooth and precise boat positioning during lifting and lowering operations.

Superior Safety Measures: Safety should never be compromised when it comes to boat hoists, and LOTO Lift Boat Lifts prioritizes the well-being of boaters. Their boat hoists are engineered with comprehensive safety features, including automatic stop systems, emergency stop buttons, and overload protection mechanisms. These measures ensure that the boat hoists halt operations immediately in case of any anomalies, preventing accidents and minimizing potential damage to the watercraft.

Easy Installation and Maintenance: LOTO Lift Boat Lifts understands the value of time for boat owners and marina operators. Their boat hoists are designed with user-friendly installation features, enabling a hassle-free setup process. Furthermore, routine maintenance is made simple, thanks to LOTO Lift Boat Lifts' commitment to accessible components and easy-to-follow maintenance guidelines. These aspects reduce downtime and ensure that the boat hoists remain in optimal condition, ready for seamless boat handling at all times.

Exceptional Customer Support: In addition to providing top-of-the-line boat hoists, LOTO Lift Boat Lifts takes pride in delivering exceptional customer support. Their team of knowledgeable and experienced professionals is readily available to assist customers with any inquiries or concerns. From pre-purchase guidance to post-installation support, LOTO Lift Boat Lifts strives to establish long-lasting relationships with their customers, built on trust, reliability, and unmatched service.

Conclusion: LOTO Lift Boat Lifts has revolutionized the boating experience with their advanced and reliable boat hoists. By combining uncompromised quality, versatility, innovative design features, superior safety measures, easy installation and maintenance, and exceptional customer support, LOTO Lift Boat Lifts has become the go-to choice for boat owners and marina operators alike.

1 note

·

View note

Text

Types of Lockout/Tagout Devices

When implementing lockout tagout processes, a real locking mechanism must be installed on either the electrical supply cord or the location where the machinery is hooked in. Then, on or near the locking mechanism, a tag, thus the term lockout tags, must be affixed to identify the source of energy as well as who is working on the machine at the moment. These gadgets act as a physical barrier as well as a visual reminder to prevent others from accidentally turning on a machine.

Lockout/tagout equipment and arc flash ppe, not only safeguards employees working on de-energized machinery, but they also safeguard the firm from regulatory violations. Knowing this, it's critical to remember that LOTO devices exist because they've been shown to keep people safe from potentially harmful equipment during routine maintenance operations.

Breaker Device for LOTO

A corporation can utilize a variety of various types of LOTO devices for machinery and equipment. Getting to know these devices and how they function will help you select the best one for your institution.

Lockout/Tagout Devices:

There are several different types of lockout/tagout systems to choose from. Of course, the design and kind of LOTO device used will depend on the sort of efforts being made as well as any state or federal regulations that must be observed during the lockout/tagout procedure. The following is a list of some of the most often utilized LOTO devices in facilities.

· Safety padlock are gadgets that are attached to the socket or another element of the electrical system to prevent it from being utilized. There are a variety of sizes and types of padlocks available, so make sure you select one that can be fastened to the place where it will be utilised in your business.

· Breaker with a Clamp– Breaker with a clamp-on design The LOTO device will open up and clamp down on the electrical points, preventing power from being restored while it is in place. This solution is useful in many places since it may be used with a variety of various electrical systems.

· The Lockout Box is a simple device that fits over the electrical plug and shuts around the cable. The box is then locked, making it impossible to open. Unlike many other kinds, this one separates the power cable in a big box or tube construction that can't be hacked without the keys.

· Valve Lockout — these devices can lockout a broad array of pipe diameters, protecting employees from hazardous substances. The valve is locked in the off position, which makes it operate. Pipe maintenance, pipe replacement, and just shutting down pipes to prevent them from being accidently opened may need this.

· Electrical lockout devices are usually fashioned like a cylinder and enable the plug to be withdrawn from its outlet and placed within the device, prohibiting personnel from plugging in the cable.

· Variable Cable Lockout - This lockout device is special in that it may be used in circumstances when numerous lockout sites are required.

· Hasp - Unlike adjustable cable, which is concerned with the number of energy sources that must be secured, a hasp entails just one machine but several persons executing individual duties.

· Other Types and Styles of LOTO Devices - Other types and styles of lockout/tagout devices are also available. Some businesses even have specialized gadgets made to match the specific context in which they will be utilized.

0 notes

Text

What is Machine Specific Procedure (MSP) and its Benefits

Machine Specific Lockout Tagout procedures are an integral part of any Energy control program. E-Square customized MSP procedures are the most sought after by its customers who value the life of their workers and safety of their establishments.

A Machine Specific Procedure (MSP) is a customized procedure drafted for each individual piece of equipment / machine that shows the location of isolation point, instructions for the isolation, energy sources & proper methods for isolation along with prescribed Lockout devices.

MSP will have pictorial representation for isolation, installed images of LOTO Device for making it easier to understand regular & the new workers.

Inadequate awareness of isolation process can lead to big hazards & many lives could be affected by the resulted accidents. MSP helps to eliminate such possibilities of incidences by providing instruction in written format.

Periodic inspections are mandatory to help ensure that the energy control procedures and the requirements of the standard are being properly followed.

E-Square is dedicated in providing Lockout Tagout procedure services for all the establishments & industries. On the basis of the onsite evaluations and analysis conducted by our engineers - procedures are drafted. The company provides the MSPs and the related products like the Energy Source Tags, supply of complete range of LOTO solutions, Tags with required Text / Graphics / languages, etc. are designed to fit to the requirements & budgets and at the same time meet the OSHA standard requirements.

Get more details about machine specific procedures and how to create those - https://www.safetylock.net/services/loto-machine-specific-procedure-msp/

#LockoutTagout#MachineSpecificProcedures#LockoutTagoutProcedures#MSP#EnergyControlProgram#LockoutTagoutProcedure#LockoutTagoutProgram#CustomizedMSP#LOTOSolutions#LOTO#ESquare#ESquareAlliancePvtLtd

0 notes

Text

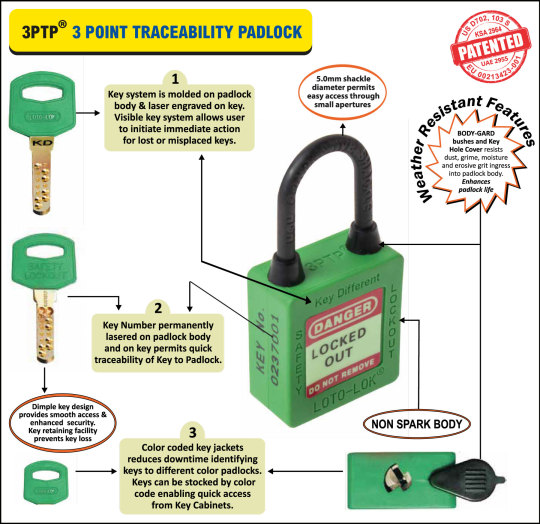

LOTO PADLOCKS – THE 3PTP™ (3 Point Traceability Padlock)

The ubiquitous plastic padlock used for immobilizing a wide range of energy sources in lockout tagout programs has come a long way in 30 years from the date when OSHA enforced energy isolation guidelines on industry to prevent injuries and fatalities in the workplace.

The metamorphosis of the LOTO padlock over the past few years has led to several additional features being inculcated along with a higher degree of tamper resistance and traceability by various manufacturers.

https://www.lotosafetyproducts.com/product-category/lockout-tagout/safety-lockout-padlocks/

https://www.lotosafetyproducts.com/product/plastic-lockout-padlocks/

https://lockouttagoutmuscatoman.com/product/premium-plastic-safety-lockout-padlocks-2/

CONSIDER THIS:

For over 2 decades, the market was dominated by 2 American brands who made plastic padlocks which had little or no information other than a number lasered on the key.

Additional features viz: individual names, logos and key number engraving on padlock body were customized at additional costs to be incurred by the buyer.

The key system of the padlock, ie: Keyed Different OR Keyed Alike OR Master Keyed was generally recorded in the system but did not appear anywhere on the padlock. In the event of key loss or misplacement informed decisions could not be made on whether the lock had to be destroyed or if a spare key was available.

Padlock covers to protect dust, dew and grit ingress were available as an additional product from some manufacturers.

https://www.lotosafetyproducts.com/product-category/lockout-tagout/safety-lockout-padlocks/

https://www.lotosafetyproducts.com/product/plastic-lockout-padlocks/

https://lockouttagoutmuscatoman.com/product/premium-plastic-safety-lockout-padlocks-2/

THE 3PTP STORY:

As a relative newbie in the LOTO scene in 2011, we were always brainstorming on how we could add value and address gaps to provide additional features out-of-the-box to save downtime on tracing keys to locks, knowing the key system without having to refer to documents as well as retrieving keys quickly from cabinets to open locks during the re-energization process.

The 3 Point Traceability Padlock (3PTP) was born from various inputs derived from end user interactions.

The features we inculcated into the padlock helped save substantial downtime and increased the life of the padlock with it’s weather protection features.

Key system molded on body and one side of key – KD (Keyed Different), KA (Keyed Alike), KD+MK (Keyed Different + Master Keyed).

Key number lasered on padlock body and key enabling quick key to lock tracing.

Key jacket matching padlock color resulted in saving substantial downtime when tracing keys from cabinets.

A sliding key cover which prevented dust, grime, dew and grit ingress into the cylinder.

2 additional rubber bushes which if needed could be installed on the shackle to prevent ingress into the plastic body of the padlock.

SUCCESS LIES IN THINKING FROM THE CUSTOMER VIEWPOINT:

The patented 3PTP padlocks were launched in 2012 and over time ended up establishing the gold standard for energy isolation padlocks. The popularity increased over time leading to most customers specifying the 3PTP features as a minimum standard for their LOTO programs thereby forcing the competition to comply.

Not content to rest on our laurels, we kept working on improvements to make a more aesthetic + higher tamper resistance padlock.

REVAMPING THE 3PTP OVER A DECADE:

Steel chrome plated shackle changed to SS304 to prevent corrosion in chemical / saline atmospheres.

Normal plastic non-conductive shackle re-engineered with a stainless steel metal insert. The 3PTP had a 5.0mm shackle diameter as standard which was more susceptible to breaking than the standard 6.0mm version on other brands. To enhance the cut / break resistance, we inserted a SS304 metal rod internally and molded over with a hard bearing PA6 nylon end to end.

Colors were revamped from slightly darkish to a more brighter range thereby increasing visibility.

The individual box packing was redesigned with a transparent window allowing color and key number visibility without having to remove the padlock.

* The author of this blog is Qaid Zohar – Director at LOTO Safety, Dubai. This blog is written to educate interested parties on Lockout Tagout products.

#LockoutTagout#cablelockout#arcflash#architecture#ppe#ppe equipment#padlock#3ptp padlock#lotosafety#safetyproducts#safety#uae#oman#lotolok#cable#protection#mechnical#electrical#thermal

0 notes

Text

Lockout Tagout Solutions – Five Key Elements to Successful LOTO Program

We all know the significance of lockout Tagout solutions. Installing them at the workplace ensures the safety and well-being of employees. If you are all set to install a new LOTO, then knowing about the key elements to its success would help you a lot. So, here we go.

Mark And Identify Energy Isolation Points.

Identify and locate all energy control and isolation points such as plugs, breakers, valves, and switches, with permanently placed and standardized tags or labels. It is important to keep into

consideration that these tags and labels must be consistent with machine-specific procedures.

Develop and document a LOTO policy or program.

It is the first step to the success of the lockout tagout program. Develop and document the equipment energy control program or policy. A well-written lockout document explains and establishes different elements of your program. It is imperative to take into consideration the guidelines of OSHA and custom requirements of your workforce to make sure they do not only understand the program but also apply it to their workday.

A program is more than a one-time fix. It has to be reviewed yearly to make sure it is relevant and protects employees against hazards. Creating and developing a lockout program is a collaborative effort from different levels of the organization.

Lockout Tagout Periodic Audits/Inspection and Training.

The safety of employees starts by taking the right steps. Make sure you train your employees, conduct periodic inspections, and communicate procedures to make sure the program is running properly and effectively. Training includes more than OSHA requirements. It should also include your own program elements like equipment-specific processes.

When OSHA evaluates the lockout tagout performance and compliance of your company, it looks for the training of employees In the categories mentioned below.

Affected Employees – This category comprises employees who do not perform lockout requirements however use equipment that is getting maintenance.

Authorized Employees – This category includes those who perform the lockout processes on equipment and machinery for repair and maintenance.

Other Employees – It includes employees who do not make use of the equipment, however, who are present in the area where a piece of device is being maintained.

Provide Proper LOTO Devices

There is no dearth of products available in the market that are solely designed for keeping your employees and workforce safe. Choosing the most effective and apt for your application is the key to lockout tagout effectiveness. It is crucial to document and make use of devices that best suit each lockout point.

Write task/machine-specific lockout tagout processes.

Lockout procedures have to be formally documented. They should identify the equipment covered. The procedures should provide the detail to the particular steps required for blocking, securing, shutting down, and isolating machines for controlling hazardous energy along with the steps for transfer, placement, and removal of lockout tagout equipment or devices.

Going beyond compliance is further recommended for creating the best practice processes including equipment-specific photos that identify energy isolation points. These details should be posted at the point of use for providing employees with visually intuitive and clear instructions.

These are the five key elements of a successful lockout tagout solutions program. Consult an expert who can further help you developing and documenting guidelines for use of the LOTO program.

0 notes

Text

Best Plasma Cutter Reviews

There is more to having the best plasma cutter than being able to cut metal. Before the introduction of the plasma cutter, cutting metal was hell of a work. This is due to the intense human effort that goes into the process of cutting metal, you struggle, physically exhaust yourself, sweat, and waste a lot of time all in a bid to cut out sheets of metal.

The introduction of the Plasma cutter came as a savior to the welding industry. It is not only the best tool to cut metal, it also has several other varieties of advantages to a welder.

In simple terms, a plasma cutter is a piece of tool that employs a high-speed inert gas to cut through metals or alloys of various thickness with ease. A plasma cutter makes use of an inert gas with an electrical current, the result is a torch that does the cutting process.

On this note, I welcome you to this plasma cutting review where I will pick out the top 30 plasma cutter available in the market today and give my honest opinion on each of them, I will also discuss on what you can do with a plasma cutter, the essential safety gear mandatory for use while cutting with a plasma cutter, the safety hazards involved and the essential tools needed to run a plasma cutter.

Join me as I introduce the best plasma cutters available in the industry.

Top 30 Best Plasma Cutter Reviews

1. Lotos LTP5000D 50Amp Non-Touch Pilot Arc Plasma Cutter

Seeking a compact plasma cutter with the capacity to divide through various metal thickness and size, the Lotos LTP5000D 50Amp Non-Touch Pilot Arc Plasma is the best choice. It has the capacity to seamlessly divide aluminum, copper, mild steel, stainless steel and all sort of metal.

The plasma cutter works with a Pilot arc torch that can pierce through any surface – painted, rough, hard or rust surface to produce a fine and smooth cut. It also features an advanced German cooling system

Pros

checkAutomatic dual frequency and voltage system (110/229v and 50/60Hz)

checkPilot torch allows plasma to cut effectively without having contact with the metal. This gives a longer consumable life

checkAbility to cut up to a thickness of 0.75 inches

checkUses a non-toxic air for cutting

checkIt is very portable

Cons

It is best suited for light jobs and small DIY projects

Exclamation TriangleThe cut produced is too large

2. Lotos LT5000D Plasma Cutter 50Amps Dual Voltage Compact Metal Cutter

LOTOS, one of the largest manufacturer of plasma cutters is a highly trusted brand. The Lotos LT5000D Plasma Cutter was designed for rugged and extensive use in all forms of working condition. It is suitable for light home jobs as well as industrial fabrication.

Like most plasma cutters, it comes with an automatic dual voltage as well as PAPST Advanced German Cooling System. When used at a High-frequency DC, the plasma cutter can cut thicker materials than the standard frequency DC.

Pros

checkIt is suitable for all sort of metals – mild steel, Aluminum, copper, etc.

checkIt requires less maintenance and less cleaning

checkSuitable to operate at two different frequency and voltages

checkIt is cheaper than the oxyacetylene cut

checkThe torch trigger is able to give a custom fit

checkOne can get faster cut with a high-frequency plasma cut

Cons

The consumables are expensive to replace

3. PRIMEWELD Premium & Rugged 50A Air Inverter Plasma Cutter Automatic Dual Voltage

The PRIMEWELD premium & Rugged Plasma cutter is the best choice for welders that value precision work. It is a 50 Amp Digital Air Inverter Plasma cutter that can cut metal with thickness as much as 0.34 inch seamlessly.

This is a plasma cutter suitable for both industrial and home use. It can cut several varieties of metal including mild steel, alloy steel, copper aluminum and many more with ease. It can work between 110v and 220volts power supply.

PRIMEWELD is a highly trusted brand when it comes to manufacturing welding accessories. Hence, they can boast of the manufacture of various high-quality plasma cutters that can handle metal of all sizes and shapes.

Pros

checkCan cut through several varieties of metal, steel and stainless steel

checkIt is very portable

checkQuite a lot of customers have derived satisfaction from the PRIMEWELD premium & Rugged Plasma cutter

checkIt comes with a warranty worth three years

checkMade with high-quality materials

checkIt is very durable

Cons

Some customers experienced leak with the machine

4. SUPER DEAL DC Inverter Plasma Cutter Welding Machine With Screen Display

Seeking a classy plasma cutter that can deliver a smooth cut at excellent speed? The SUPER DEAL DC Inverter Plasma Cutter is the best choice available! It gives a clean cut without slag or dross. It is a 240Volts plasma cutter that comes with digital display, it makes cutting so easy!

The SUPER DEAL DC Inverter Plasma Cutter features a current regulator which allows you to work comfortably and efficiently. It consumes low amount of energy which makes it very fair to the environment.

Pros

checkIt is very affordable

checkIt lasts very long with good heat dissipation

checkIt is made of heavy duty material, which makes it last very long

checkThe Digital LCD Display gives an easy read Front panel

checkIt has high cutting speed with less noise

checkBuilt-in safety feature – wire and mask to prevent you from hurting yourself

checkSuitable for light and industrial use

checkIt uses cheap and easily accessible consumables

Cons

Some user prefers having an O-ring on the panel for efficient use!

5. PrimeWeld Ct520d 50 Amps Plasma Cutter

The PrimeWeld Ct520d 50 is the best multipurpose plasma cutter available. It features a 3 in 1 multipurpose plasma cutter with the ability to handle multiple cutting and welding functions. It can also alternate between DC STICK and DC TIG welding easily.

It is suitable for professional and DIY jobs. This plasma cutter is very portable, also, it operates on 50A power source. It can perform TIG/Stick welding, plasma cutting, and the arc welding function in a single unit!

Pros

checkIt comes with a 3-year warranty

checkIt has a 3-in-one function

checkIt is very easy to move around

checkIt has a power efficiency of 85%

Cons

Long leads are needed for the plasma cutting

6. Lotos Technology 04-ZVGR-0O8D Lotos LTPDC2000D Plasma Cutter Tig Stick Welder 3 in 1 Combo Welding Machine

The Lotos Technology 04-ZVGR-0O8D is a 50 Amp Non-touch plasma cutter that gives an efficient cut for various surfaces – painted, rusty, rough etc. It is compact and very portable. This plasma cutter is able to handle various types of metal without using a hazardous gas

It gives a 3 in one function – a 200 Amp stick welder, a 50 Amp Pilot Arc Plasma cutter and 200 DC TIG Welder, all with the flip of a switch. It is appropriate for industrial and DIY uses. It has the HF hand start control and also support the dual voltage system. The Pilot arc technology allows for cutting without contact with the metal tip.

Pros

checkAble to cut varieties of metal without using any hazardous air

checkIt can weld with various acids and basic electrodes

checkIt comes with one year warranty

checkIt has a multipurpose (3 in 1) unit

checkCreates precise cut with less slag

checkConsumable last longer

checkAutomatic dual voltage and frequency enabled

Cons

The consumables are specific to the machine!

7. Plasma Cutter, Inverter, Spectrum 375 by Miller Electric

Seeking for a plasma cutter for your day to day job requirement and industrial use? The Plasma Cutter Spectrum 375 is the answer you’ve been searching for. With a rated output of 30 A, it gives a fine precision cut for all sort of metal, alloys, carbon, steel etc.

It is very light in weight, compact and performs it’s duties seamlessly. It’s Manufactured by Miller, one of the giants in the welding accessory industry, the Plasma Cutter Spectrum 375 is a reliable tool to take your welding experience to the next level.

Pros

checkit’s very compact and light in weight

checkQuite of a lot of customers expressed satisfaction with the product

checkit has the ability to deliver a seamless cutting experience

checkit’s equipped with all the necessary accessories

checkIt comes with extra consumables

Cons

No warranty information

8. Hobart 500566 Airforce 40i Plasma Cutter 240V

Seeking for an efficient plasma cutter that can cut just like a hot knife going through butter? The Hobart 500566 Airforce 40i is the answer you’ve been searching for. Using about 40 Amps of power, the Hobart 500566 Airforce 40i is able to slice through 5/8 in. and sever cut 7/8 in. steel.

It is a heavy duty plasma cutter weighing just 31 pounds hence it’s very light in weight. The wind tunnel technology guards against particles and abrasive dust from damaging the internal parts of the machine.

Pros

checkIt is excellent for both DIY jobs and heavy-duty assignments

checkErgonomic design that makes usage safe!

checkIt is very portable

checkAuto-Refire technology giving the device the ability to slice through perforated or expanded metals

checkSetting up the machine is very easy

Cons

It is quite pricey!

9. SUNCOO Cut-50 Plasma Cutter Electric DC Inverter Machine with Digital Display

Seeking for a cheap and effective plasma cutter? This is your answer. The SUNCOO Cut-50 Plasma Cutter Electric DC Inverter is a 50 Amp Plasma cutter, it is suitable for copper, iron, stainless steel and all sort of metal. It performs excellently, and can be applied in many areas like site work, ducting work, repair and maintenance service etc.

The SUNCOO is pretty easy to assemble, with a comprehensive manual to guide the user through the installation process. The voltage ranges from 110 to 220V, and the machine has the capacity to adapt.

Pros

checkCan cut varieties of metals, including very thick metal plate

checkFinds application in home and industrial use

checkIt releases less toxic gases

checkIt has protection pilot lamp for the welder’s safety

checkIt is pretty light in weight

checkIt is pretty cheap

Cons

The strap handle is not preferred

10. Goplus Plasma Cutter Cut-50 50A 220V Electric DC Inverter Air IGBT Cutting Machine

The Goplus Plasma Cutter Cut-50 is a new plasma cutting machine that features a new technology with an advanced inverter. It comes with a high-quality plasma torch engineered to give users a new cutting experience.

The Goplus Plasma Cutter Cut-50 is applicable for individual DIY projects and industrial use. It was designed with your maximum comfort in mind, hence it’s very easy to operate. It’s also equipped with the necessary accessories to make using it very safe. It can be applied in ducting work, repair work, automotive work, maintenance service.

Pros

checkThe unit is made from materials of high quality hence, will last long

checkComes with safety features to prevent you from hurting yourself while working

checkIt has the ability to work effectively and efficiently with it’s smooth and high cutting speed, and continuous current regulation.

checkVery easy to assemble with clear and straight to the point instructions

checkIt saves energy and makes no noise

checkIt is safe, reliable and very cheap

Cons

No information on warranty

11. Hobart 500564 Airforce 12ci Plasma Cutter with Built-In Air Compressor

Seeking for a light, portable, and compact plasma cutter? The Hobart 500564 Airforce 12ci Plasma Cutter is the best choice. It comes with very capable size breaker and requires a 30 amps source.

It has a built-in compressor with the ability to cut through all types of metal. When performing flame tuning, there is no gas pressure required. The Hobart 500564 Airforce 12ci Plasma Cutter gives a very accurate cut with a thin kerf and less sla

Pros

checkRequires no gas pressure setting

checkIt gives very precise cut

checkIt is portable and light in weight

checkEquipped with a size breaker

Cons

You have to be patient while cutting through very heavy metals

12. Lotos LT3500 35Amp Air Plasma Cutter, 2/5 Inch Clean Cut

Seeking a plasma cutter to comfortably handle light cutting projects? The Lotos LT3500 35Amp Air Plasma Cutter is the best choice. It is the most compact plasma cutter available on the market but, it is only powerful enough to handle a metal with 15 mm thickness.

It comes with an air filter and air gauge that works perfectly with your air compressor. It is an excellent choice for light projects and DIY jobs. Assembling it is very easy as the whole machine can be set up in just a minute.

Pros

checkIt is light in weight

checkIt is very compact

checkIt can be easily set up

checkSuitable for cutting all sort of metal

checkCuts safely at low cost

checkComes with consumables, ground clamp, cutting torch etc.

Cons

The ground lead cable is pretty short

13. ZENY DC Inverter Plasma Cutter 50AMP CUT-50 Dual Voltage 110-220V Cutting Machine

The ZENY DC Plasma cutter features the latest cutting technology. It is recommendable for all metal cutting work, it’s suitable for both industrial and DIY jobs. The high-quality plasma torch which it has, gives it an enhanced and improved cut quality.

It features a double voltage adapter with a current range of 20 to 50 Amps. It is equipped with essential accessories like AIR regulator and earth clamp as well as many safety accessories needed to ensure a seamless cutting operation.

Pros

checkSuitable for both professional and personal use

checkComes with the necessary safety accessories to ensure a seamless operation

checkThe consumables are very cheap

checkThe price is very reasonable

checkIt doesn’t get too hot

checkCuts very fast

checkSetting up the unit is pretty easy

Cons

It comes with ground and cable wires that are very short

Exclamation TriangleUser manual not explanatory enough

14. Hypertherm 088079 Powermax30 XP Building America Edition Hand Plasma System

The Hypertherm 088079 Powermax30 XP plasma cutting machine is a 2 in 1 plasma cutting machine. It works with high vigor to cut through metal with ease. It delivers a very high-performance cutting experience with the ability to handle thick metal of all sorts – up to 16mm. It comes with Fine Cut consumables that give detailed cutting.

It comes with various accessories that ensures you work safely. The automatic voltage setting allows it to adapts to either 120V or 240V circuit. The Kit comes with nozzles, electrodes, shields, retaining cap etc.

Pros

checkIt is equipped with necessary safety accessories to enable you work without suffering an injury

checkit features an LT Torch which is resistant to heat and very compact giving it a comfortable grip

checkThe company has a very responsive customer support service

checkIt is very portable and light in weight

checkDual voltage application

Cons

Requires an external air compressor

15. Hobart 500565 Airforce 27i Plasma Cutter 120/240V

The Hobart 500565 Airforce 27i Plasma Cutter is a strong heavy duty plasma cutter. It comes with an inverter based design and reliable technology. It’s very portable and easy to use.

The Hobart 500565 Airforce 27i Plasma Cutter features multi-voltage plug that allows it to work effectively with either a 120V or 240V power supply. Setting it up is pretty easy as all you have to do is connect and start cutting!

Pros

checkThe Wind Tunnel technology guards against particles and abrasive dust from settling inside the machine

checkAble to work with either the 120Vor 240V power supply.

checkGives a very accurate cut with reduced slag

checkIt is portable

Cons

The plasma cutter tends to overheat at times

16. JEGS 81545 Plasma Cutter 20-40 Amp 110/220VAC

Seeking a reliable plasma cutter able to handle all form of metal and aluminum? The JEGS 81545 Plasma Cutter is your answer. It comes with all necessary and useful accessories that makes it deliver a seamless working and cutting experience!

Pros

checkIt comes with a year warranty

checkIt has a dual voltage function – 110VAC/220VAC

checkAbility to slice through steel and iron with ease

checkIt is suitable for small business and DIY processes

checkComes with all necessary accessories

Cons

Warranty period too limited (1 year)

17. SUNGOLDPOWER 50A Air Plasma Cutter Inverter DC Digital Display IGBT Portable

The SUNGOLDPOWER 50A Air Plasma Cutter comes with a superior IGBT tech, giving it the ability to slice through as much as 15mm thick metal. Like most plasma cutter, it uses a dual voltage technology. It’s less power consumption from the high duty cycle makes it more efficient.

It has a Digital LCD display and a front pane air pressure gauge making it more appealing and effective. It can cut smoothly without any polish demand. It comes with amazing protective features to make the machine safe for use. It can cut through copper, steel, carbon and several other types of metal.

Pros

checkit’s very efficient and economical

checkit has a very high cutting speed

checkit saves energy and works without much noise

checkit has a overheat and overvoltage protection feature

checkit has the ability to cut a 15mm thick metal

checkit’s waterproof and protected from electric shock

Cons

A couple of customers complained of the leaking air hose

18. CUT-50, 50 Amp Pro. Plasma Cutter, DC Inverter 110/230V Dual Voltage Cutting Machine

The CUT-50, 50 Amp Pro Plasma Cutter was designed for small businesses and DIY jobs. This is a new and improved model that uses 15 – 50 Amps with an advanced inverter tech. It comes with plug adapter that makes the voltage adapt automatically to the supplied voltage – 100 to 240 Volts.

It has a comfortable grip and a torch design that allows it to slice through various metal forms seamlessly.

Pros

checkIt is capable of handling cuts up to an inch in thickness

checkIt can cut various types of metal – stainless steel, alloy steel etc.

checkLittle maintenance required

checkRisk of fire hazard is low

checkIt gives a firm, clean and reliable cut

Cons

No warranty information

19. VIVOHOME DC Inverter Plasma Cutter Cutting Machine Dual Voltage 110V/220V CUT-50

The VIVOHOME DC Inverter Plasma Cutter boasts of the most advanced inverter technology in its construction. It has a high cutting ability with a fast cutting speed way better than that of oxy-acetylene cutting.

It features MOSFET technology that steps up the 50 Hz frequency to over 100KHz. It is fast and economical, able to cut through thickness of up to 12 mm. It’s Suitable for wide application – DIY and industrial use.

Pros

checkDual voltage operation

checkComes with essential safety materials – safety mask and welding goggle

checkIt has the ability to slice through metal of thickness between 1 to 12 mm.

checkMOSFET technology helps step up the frequency to any desired range

checkIt is very fast in operation

Cons

Some customers complain that it doesn’t come with a user manual

Exclamation TriangleThe regulator doesn’t come with a hose

20. HYL CUT30C PLASMA CUTTER

The HYL CUT30C plasma is one of the best heavy duty plasma cutter suitable for both home hobby and personal welding. It features a 110/115/120 current type.

It comes with various accessories such as ceramic cups, nozzle, electrodes, ceramic diffusers, replacement torch assembles etc. It can cut a maximum thickness of 0.25 inches.

Pros

checkIt comes with 2 years warranty

checkIt has professional Grade welding accessoriess

checkReadily available spare parts

Cons

The plasma cutter tends to overheat at times

21. Hypertherm 088096 Powermax 30 AIR Hand System

The Hypertherm 088096 Powermax 30 AIR Hand is a small and lightweight plasma cutter designed with an internal air compressor. It’s small and compact in size, it can handle cutting metal of various forms. Unlike most compressors, it doesn’t need an external air supply due to the in-built compressor system.

The Hypertherm 088096 Powermax uses the latest technology with reliable torch and consumables to keep the system running at its peak. It features a New AIR T30 torch which makes it rugged enough to withstand unconducive environments

Pros

checkInner compressor cancels the need for an external compressor support

checkIt has a fast and very reliable cutting speed

checkIt has the ability to work with both 120 V or 240 V power supply

checkIt is very portable, small and light

Cons

No tangible information on warranty

22. Biltek 50Amp Air Plasma Cutter Inverter Dual Voltage

Seeking for a classic plasma cutter that uses advanced technology to slice through metal? The Biltek 50Amp Air Plasma Cutter is what you need. It delivers high cutting performance with a non – pilot arc torch that is able to deliver high cutting performance with longer life for consumables.

It comes with a cutting torch, air hose, air filter and other accessories. It uses clean oil – free and dry air from a compressor to deliver very clean cutting experience.

Pros

checkIt can cut several varieties of metal

checkThe consumables last long

checkIt uses advanced inverter technology that delivers a high cutting performance

checkIt is portable and very easy to set up

Cons

You need to connect an external air supply from the compressor!

23. VEVOR Plasma Cutter 50A 110V/220V Dual Voltage Welding Cutting Machine CUT50 Inverter Digital Welding Machine

The VEVOR Plasma Cutter is a 50 Amp machine. It is very light in structure and compact in design. It saves energy with extra-axial flow fan for forced convention needed to cool the machine. It can cut up to 12 mm with a digital display on the front panel of the machine. It is able to cut various forms of metal like mild steel, stainless steel, alloy steel etc.

The unit comes with various accessories such as gas pipe, cutting torch etc.

Pros

checkIt is light and very compact

checkIt doesn’t generate much noise and saves energy

checkComes with a digital display

checkIt cuts at a very high speed

checkGives smooth cutting with no polish demand

checkComes with an inbuilt fan to cool down the machine

Cons

No information on product warranty

24. Miller Spectrum 625 X-treme Plasma Cutter

The Miller Spectrum 625 X-treme Plasma Cutter is one of the most portable plasma cutter available in the market. It works with a dual voltage setting. It comes with the Auto-Line technology and MVP adapters. It has extra protective features which makes the unit safe during transport and storage.

It comes with essential protection gears to ensure that safety isn’t compromised while working. There is an Ultra-Quick Connect XT 40 torch designed with ergonomic handle that reduces unnecessary fatigue while working. With the Auto – refire technology, it directs the pilot arc when cutting expanded metal

Pros

checkComes with an inbuilt fan to limit overheating

checkWind tunnel technology prevents damage from abrasive dust from damaging the system

checkReduced fatigue while cutting metals

checkSteady and cleaner cuts

checkEasy connection, it’s compatible with either 120V or 240V power supply

Cons

No warranty information available for the unit.

25. Plasma Cutter 40A 220V Electric DC Inverter Air Plasma Cutting Machine CUT40 Metal Cutter HITBOX

Weighing about 16 pounds, the Plasma Cutter by HITBOX can slice through thick Carbon of up to 12 mm thickness. Asides carbon, it cuts steel, copper, and aluminum effectively. It features a digital display and comes equipped with plasma cutting torch consumables.

The Plasma Cutter by HITBOX gives an outstanding cutting performance that is able to work effectively, irrespective of the air pressure. The unit prioritizes safety with various features meant to keep you safe while using the plasma cutter.

Pros

checkIt is light and very compact

checkIt is pretty cheap

checkit can slice through metal as thick as 12 mm

checkIt features a digital display

checkit has an impressive customer care service

Cons

The Unit does not come with an external compressor

26. Everlast SuperCut51P 110v/220v Dual Voltage 50 Amp Pilot Arc Inverter plasma cutter

Seeking for a plasma cutter for your DIY product? The 2017 Everlast SuperCut51P is a perfect fit for you. The SuperCut 51P comes with a high-frequency arc that offers continuous engaging pilot arc. This unit is perfect if you are seeking to make low dross cut, it’s very efficient and easy to use.

Pros

checkIt is quick and very reliable

checkWorks with low current

checkIt comes with 3 years warranty

checkIt has a dual voltage capacity

checkIt’s equipped with essential accessories

Cons

It is quite expensive

27. Air Inverter Plasma Cutting Machine – Tosense CUT50 Dual Voltage 50A Plasma Cutter

The Air Inverter Plasma cutting machine uses the MOSFET inverter technology to give stable, mature and improved cutting experience to its users. It is made with very high-quality components that make the plasma cutter economical with the consumables.

Weighing just 22 pounds, it is compact and portable. Asides, it is applicable for both industrial and personal work. The plasma cutter is able to adjust itself even with a very high air pressure giving a direct and precise cutting experience.

Pros

checkIt can cut the metal plate in various routes

checkReduced risk of fire hazards

checkIt requires less maintenance

checkIt is very cheap

checkIt doesn’t produce toxic gases

checkIt is portable and suitable for industrial use

checkPresence of features to protect against power fluctuations

Cons

No warranty information

28. Forney 317 250 P+ Plasma Cutter with Air Compressor

The Forney P+ Plasma Cutter is very easy to use and comes with a 15-inch ground cable. It utilizes compressed air and electrical arc to slice through metal like it’s a piece of meat. It is capable of giving a precise cut due to the drag technology that allows users to move the torch on the metal surface.

It comes with many cutting accessories like electrodes, diffuser ring, compressor shield cup etc. There are features to ensure that using the plasma cutter is completely safe. It features a lightweight inverter power supply and a built-in compressor.

Pros

checkParts like the ground cable, torch and dryer are easily removed for repairs and assemble

checkComes with an internal compressor

checkIt is portable

checkLots of additional accessories for optimum function

checkAbility to make precise cut

Cons

It is pretty expensive

29. Hypertherm Powermax45 XP Hand System w/o CPC – 20’ Leads

Seeking for a heavy duty plasma cutter with the ability to cut up to 16mm of metal? The Powermax45 XP plasma cutter is the best choice. It comes with varieties of features that give it an optimum and improved performance over other brands.

There is the automatic gas adjustment for simple setup operation as well as the new Duramax Lock torch to give it an improved performance. It is able to cut a wide range of metal with various thickness, and it’s also capable of handling precision gouging and part marking.

Pros

checkIt is small in size and very light in weight

checkit has amazing features that makes using the Powermax45 XP plasma cutter seamless for first-time operators

checkThe presence of a smart sensor technology helps make sure that air pressure is always correct

checkCuts really fast with a superior cut quality

Cons

No warranty information

30. LOVSHARE 3 In 1 Plasma Cut/TIG/ Welding Machine 110V Multifunction Inverter DC

The LOVSHARE comes in a compact 3 in 1 structure capable of handling TIG, CUT and ARC/MMA function. It has a compact design. It’s portable, reliable and very easy to use.

It is suitable for DIY jobs and industrial application hence, capable of handling shipbuilding, aerospace, automobile and quite a lot of other functions. This plasma cutter has a 110V Welding Machine Portable CT312Welder with Air Regulator.

Pros

checkIt is reliable and lasts longer

checkit has a 3 in one multiple function system

checkPollution from this plasma cutter is reduced, it’s environmental friendly

checkComes with an advanced MOSFET inverter technology

Cons

No information on warranty

Having analyzed the review of the best plasma cutter available in the market, I will proceed to discuss what you can do with a plasma cutter, as a welder.

WHAT CAN I DO WITH MY PLASMA CUTTER?

Plasma Cutter is recommended for cutting metal, copper, steel, and other non – ferrous materials. When using oxyacetylene for cutting, you have to carefully control the cutting speed in order to keep the oxidizing process going. Plasma cutter stands out in this aspect.

The plasma cutter is very handy and effective if you will cut expanded metal which can’t be done with oxyfuel. Also, plasma cutting is very fast, it produces a clean cut and also good at making a nonlinear cut!

1. Fabricating Metals on the Go

Plasma technology is extremely invaluable in cutting pieces of metal together. This is especially useful to contractors and welders on site. Many times, metals come in lengths that are too big. At times as well, the job specification requires an exact length of metal that can only be gotten with the use of a plasma cutter.

2. Metal recycling

One of the places where the applications of the plasma cutter is irreplaceable is the junkyard. There are scrap metals that might not be useful to a welder again. A plasma is extremely useful as it helps cut pieces of metal down into bits or size that makes storage easy. With this, you increase storage space and improve productivity!

3. Cutting Pipes

There are times you might need to cut a huge length of pipe. You won’t be able to cut this with a standard cutter due to the time it takes. With a plasma cutter you can do this with ease, you also minimize resources wastage. There are pipe cutting jobs that needs to fit perfectly, and with the smooth neat and quick cut a plasma cutter creates; it is the best for the job!

WHAT PROTECTIVE GEAR DO I NEED WITH MY PLASMA CUTTER?

Thanks to the improvement in technology, plasma cutter has been widely accepted in homes, shop, industrial use, fabrication yards, and many cutting industries. Yes, the plasma cutter is a very useful piece of equipment but a risky one as well.

Hence, the necessary safety precautions are very essential to ensure a seamless operation with the plasma cutter. Irrespective of what you desire to do with the plasma cutter, you need to learn about the necessary level of safety required to get the job done with ease.

From my experience, hazards from using a plasma cutter mostly comes from being exposed to metal fumes, ultraviolet radiation, and hot metals. This could lead to cuts, loss of body parts, crushed toes or fingers, eye damage, electric shock, burns etc.

The good news is that you can limit these type of health hazards with the proper PPE (Personal Protective Equipment) and right safety attitude. It is when you use the recommended personal protective equipment that you can be protected from all the hazards associated with the plasma cutting machine.

Hence, in order to work safely, you have got to protect yourself and those around you with the essential safety gears:

Plasma Helmet: this is essential to keep you safe from debris, hot slags, intense length and most especially radiation. The helmet protects not only your face but the eyes and your respiratory system. It limits the inhale of toxic gases and also protects your eyes from the intensely bright light that comes from the cutting process.

Welding Gloves: There are chances you mistakenly handle a hot metal. This is where a good and reliable welding glove comes in. Also, the intense heat produced by the cutting process could be dangerous for your hand. A good welding glove is needed to serve as insulation between your hands and the heat source. Asides this, a good welding glove also protects you from burns, electric shocks, fire etc.

Welding Jacket: There is the possibility of slag and molten metal flying around during the cutting process. This is why you need to keep your whole body protected. They are essential to keep you safe from fires, intense heat, fire etc. A good welding jacket should be heat resistant and nonflammable. The main idea is to protect your skin. Thus, if any hot spark, debris or slag flies around while cutting and comes in contact with you, you are well protected!

Welding beanie: Basically, a welding beanie is essential for keeping your hair, head, neck, and ear protected from the flying debris, spark or slag during the welding process. It essentially serves as an insulation to guard you against heat stroke and burns.

Laced and Tied Boots: A properly laced and tied boots will keep you safe from flying debris, electric shock. There is the possibility of stepping on a wire that could trigger an electric shock but with your boot on, you’re protected. Also, you need a well-tied boot to prevent your feet from getting burned from hot flying sparks.

Set of Jeans: In addition to your welding jacket, you need a good pair of jeans to keep your legs safe from various hazards that could arise as a result of the plasma cutting process, the hot splash could pour on your leg. With a pair of strong jeans, you not only protect your leg from this splashes, but you also guard against heat stroke due to the excessive temperature of the workshop.

Respirator Mask: During plasma cutting, the possibility of hazardous fumes being released is very high. This calls for adequate protection of your nose, and the best way to do this is with the help of a respiratory mask. This will keep you safe from fumes, oxides etc. You need a quality respiratory mask that is able to filter fumes and particles from the air you breathe. This is essential for your comfort and safety while cutting!

Fire Extinguisher: Last but not the least on my set of important protective gears needed during plasma cutting is a fire extinguisher. The essence of a fire extinguisher is very obvious. Welding is a hot job, plasma cutting makes use of excessively hot gas at extreme temperatures. With this excess temperature, there is the risk of fire occurrence. This is why you need a fire extinguisher handy, so you can guard against any incidence of fire outbreak!

While working with a plasma cutter, it is very good to prioritize safety. Hence, on no account should you compromise on this personal protective equipment while working in the workshop. Remember working safely is critical to your health and wellbeing!

Having discussed the essential safety gears needed for plasma cutting, I will also address the safety hazards that are common while using a plasma cutter.

Safety Hazards of The Best Plasma Cutting

Welding is a hot job. And, plasma welding involves cutting iron or other metals at extremely high temperatures. This presents a lot of health risk to you. Asides physical hazards, there are chemical hazards that you can be exposed to.

In order to guard against the injuries and hazards associated with plasma cutting, you need to be aware of the risks involved. When you know the risk, you will be able to protect yourself adequately against the inherent dangers present during plasma cutting.

Here as some safety hazards involved in plasma cutting:

1. Eye Damage