#LinearMotionSystem

Explore tagged Tumblr posts

Text

Clean, Quiet, and Cost-Efficient – Meet drylin®

When cleanliness and silence are essential, drylin® linear guides stand out. These maintenance-free components are ideal for environments like cleanrooms, food processing units, and medical devices. The absence of grease means fewer contaminants and longer intervals between servicing. It’s smart motion – simplified.

0 notes

Text

Linear Motion Solutions

Linear motion solutions refer to the various technologies and systems designed to provide controlled, precise linear movement. These solutions are used across a wide range of industries and applications, including industrial automation, robotics, machinery, and more.

Here are some key aspects of linear motion solutions:

Types of Linear Motion Systems: Ball screw systems,Lead screw systems,Linear motor systems,Belt-driven systems,Air/fluid bearing systems,Rack and pinion systems,Linear slide systems Key Components:, Linear actuators (e.g. ball screws, lead screws, linear motors),Linear guides (e.g. linear bearings, rails, slides),Drive mechanisms (e.g. stepper motors, servo motors),Control systems (e.g. motion controllers, drivers),Feedback sensors (e.g. encoders, limit switches) Design Considerations: Application requirements (e.g. load, speed, precision),Environmental factors (e.g. temperature, humidity, contaminants),Space constraints and mounting configurations,Integration with other systems and equipment,Maintenance and lubrication needs Common Applications: Industrial automation and robotics,CNC machines and machine tools,Semiconductor manufacturing equipment,Packaging and material handling systems,Medical devices and instrumentation,Test and measurement equipment,3D printing and additive manufacturing Trends and Advancements:,Increased use of linear motors for high-speed, high-accuracy applications,Integration of smart sensors and Industry 4.0 connectivity,Advancements in control algorithms and software,Developments in materials and lubrication for improved performance and reliability

You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#Linearbearingsandshafts#LinearGuides#LinearMotionBearings#LinearMotionComponents#Linearmotionsolutionsandapplications#LinearMotionStages#Linearmotionsystems#linearslidesandpositioningsystems#LinearXYStages#MotionControlSystem#Top-QualityLinearMotionSupplies

0 notes

Photo

Seimitsu has model HRX roller type LM Guide for ultra-highrigidity and ultra-heavyloads readily in stock

For more Detail about product information please visit our website: www.seimitsu.in

Please reach on below details for further clarifications:

Email Id: [email protected]

Phone no.: +91 (20) - 46212700

Mobile No.: +919028121211

#seimitsu#seimitsufactoryautomationpvtltd#factoryautomation#industrialautomation#distributor#standardlinearguides#linearguides#linearmotion#linearmotionguide#Thkdistributor#lmguidesystem#lmguide#linearmotionsystem#linearbearings#linearshaft#THKdealer#railguides#fullball#linearguiderails#blockssuppilers

0 notes

Text

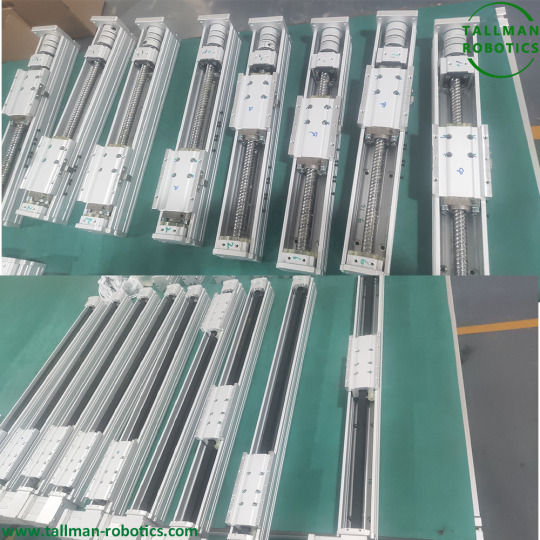

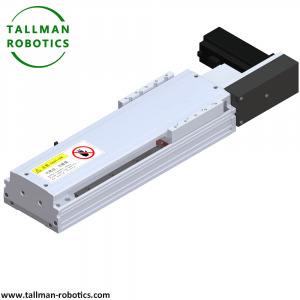

High Speed Linear Modules Will Be Delivered To India

High Speed Linear Modules have been finished for clients from India.

Here are some additional details about high-speed linear modules, Speed and Acceleration: High-speed linear modules are designed to achieve rapid motion along the linear axis. They can reach velocities ranging from a few centimeters per second to several meters per second, depending on the specific model and application requirements. Acceleration capabilities are also important, as they determine how quickly the module can start, stop, or change direction. Load Capacity: High-speed linear modules are engineered to handle different load capacities. The load capacity refers to the maximum weight or force that the module can effectively support and move along the linear axis. It's crucial to consider the anticipated loads in your application and select a module with an appropriate load capacity to ensure optimal performance and safety. Stroke Length: The stroke length refers to the total distance the linear module can travel along its linear axis. It's an essential specification to consider as it determines the range of motion available. Stroke lengths can vary significantly, ranging from a few centimeters to several meters. Manufacturers often offer different stroke length options to accommodate various application requirements. Precision and Repeatability: High-speed linear modules are designed for precise positioning and repeatability. Precision refers to the degree of accuracy in achieving a target position, while repeatability refers to the module's ability to return to the same position repeatedly. These modules often incorporate feedback sensors, such as encoders or linear scales, to provide accurate position feedback and ensure precise control over the linear motion. Integration and Mounting Options: High-speed linear modules are designed to be easily integrated into existing systems or equipment. They may feature mounting holes or slots for convenient attachment to frames, platforms, or other components. Additionally, manufacturers often provide mounting accessories and brackets to facilitate installation. Environmental Considerations: Depending on the application environment, high-speed linear modules may need to meet specific requirements. Some modules are designed to operate in cleanroom environments, while others have protection against dust, moisture, or harsh conditions. It's important to consider the environmental factors and choose a module that is suitable for your specific application. Control and Communication: High-speed linear modules are typically controlled through a dedicated motion control system. They can be integrated into a larger automation setup or controlled individually. Communication protocols such as Ethernet, Modbus, or CAN bus may be used to interface the module with other devices or control systems. Safety Features: To ensure safe operation, high-speed linear modules may incorporate safety features such as limit switches, emergency stop buttons, or motion detection sensors. These features help prevent accidents, protect the equipment and operators, and comply with relevant safety standards. When selecting a high-speed linear module, it's important to consider your specific application requirements, such as speed, load capacity, stroke length, and environmental factors. Consulting with manufacturers or suppliers can provide you with detailed information about the available options and help you choose the most suitable module for your needs. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#Highspeedlinearmodulesystem#HighSpeedLinearModulesforAutomation#Highspeedlinearslidemodule#HighSpeedLongStrokeBeltDrivenLinearModule#HighSpeedMotorizedLinearActuators#High-speedLinearShiftMechanism#LinearMotionSystems#StainlessSteelLinearModuleHighSpeedBallScrewRail

0 notes

Text

Single Axis Guide Arms are Under Test for Clients from Germany

Single Axis Guide Arms for Clients from Germany are under test, and will be delivered. Single axis guide arms are mechanical components used in various applications, such as industrial automation and robotics, to provide linear guidance and support for moving parts. They are typically used when a single degree of freedom or linear motion is required.

These guide arms consist of a rigid structure or frame that houses a linear guide system. The linear guide system usually consists of a rail and a carriage, where the rail provides a smooth and precise path for the carriage to move along. The carriage is attached to the moving component or load, allowing it to travel along the rail in a linear direction. Single axis guide arms are often used in applications where there is a need for controlled and accurate linear motion. They can be found in assembly lines, pick-and-place systems, packaging machinery, CNC machines, and other automated systems. These guide arms help to ensure precise positioning, smooth movement, and reduced friction between moving parts. The design of single axis guide arms can vary depending on the specific application and load requirements. They may incorporate different types of linear guides, such as ball bearing guides or roller guides, to accommodate different load capacities and operating conditions. The guide arms may also include additional features like adjustable stops, damping mechanisms, or lubrication systems to enhance performance and longevity. Overall, single axis guide arms play a crucial role in providing linear guidance and support in various industrial and robotic applications, enabling precise and controlled movement of components or loads along a single axis. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#LinearCarriagesAndSlides#LinearGuideSystems#LinearMotionGuide#LinearMotionGuideActuators#LinearMotionStages#LinearMotionSystems#LinearSlideSystem#SingleAxislinearmotion

0 notes

Text

Linear Motor

A linear motor is an electric motor that operates in a straight line, as opposed to the rotary motion of a conventional electric motor. It converts electrical energy directly into linear motion without the need for any mechanical transmission such as belts, gears, or pulleys. Technical parameters of Linear Motors: High Thrust Series Model Number TML135-CM-PM090 TM135-CM-PM130 TML170-CM-PM250 TML170-CM-PM400 TML220-CM-PM750 Positioning Repeatability(mm) ±0.002 ±0.002 ±0.002 ±0.002 ±0.002 Continuous Thrust(N) 90 130 250 400 750 Max Thrust(N) 270 390 750 1200 2250 Continuous Load(kgs) 20 30 50 80 150 Max Acceleration Speed (G) 3 3 3 3 3 Max Speed(mm/s) 2500 2500 2500 2500 2500 Standard Stroke(mm) 0-5500 0-5500 0-5500 0-5500 0-5500 Feedback Ruler Manufacturer Germany siko / Spain FAGOR Reading Head MSK200-1-0107 / EXA Feedback Ruler Resolution(mm) 0.0005/0.001 Linear Guide Rail (mm 15×12.5-2 15×12.5-2 15×12.5-2 15×12.5-2 20×15.5-2

Linear electric motors can be classified into different types based on their operating principle, such as linear induction motors, linear synchronous motors, and linear stepper motors. They are used in a wide range of applications, including transportation systems (such as maglev trains), industrial automation, robotics, and high-precision positioning systems. In the currently feasible field of Linear drives technology, we can provide the widest range of supply. From components or split motors, a complete positioning platform, to a complete customized engineering system, we can provide a perfect solution for any linear motion requirement. Typical applications include: Industry application fields of Linear drives • Semiconductor and electronic products • Flat panel displays, solar panels • Medicine and Life Sciences • Machine tools • Optical imaging and optoelectronics • Large printing, scanning, and digital equipment Design advantages of linear motors from Tallman Robotics • High speed • High acceleration • Fast response -100 times that of a mechanical system • Stiffness - Elastic stiffness is better than mechanical systems • Zero Gap - Direct Drive Technology • Maintenance free operation - due to reduced number of components, the machinery is relatively simple • Long travel without loss of performance • Suitable for vacuum and extreme environments You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#ElectricLinearMotor#Linearinductionmotors#Linearmagneticactuators#Linearmagneticdrives#Linearmotionsystems#linearmotors#Linearpropulsionsystems#Linearservomotors#Linearsynchronousmotors#sLineardrives

0 notes

Text

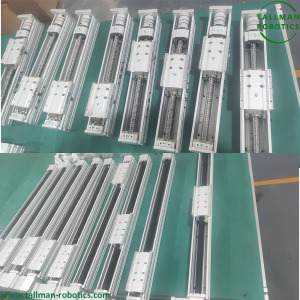

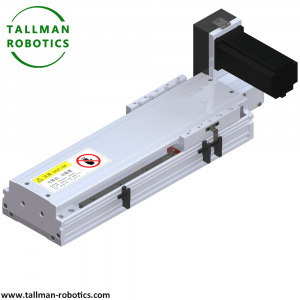

Industrial Linear Motion Modules Are Picked Up to Germany

Industrial Linear Motion Modules Are Picked up to Germany.

Industrial Linear Motion Modules are mechanical systems designed to provide linear motion to various industrial applications. They consist of a combination of linear guides, actuators, and other components that enable precise and controlled movement of a load along a straight line. These modules are widely used in various industries such as manufacturing, automation, robotics, and material handling. Some common types of industrial linear motion modules include: - Linear Guides: These are mechanical components that provide support and guidance to the moving parts of a linear motion system. Linear guides typically consist of a rail and a carriage, with the rail providing a smooth surface for the carriage to slide along. - Linear Actuators: These are electromechanical devices that convert rotational motion from a motor into linear motion. Linear actuators can be divided into several types, such as screw-driven, belt-driven, and direct-drive actuators. - Ball Screws: A ball screw is a type of mechanical actuator that translates rotational motion into linear motion. It consists of a screw shaft and a ball nut, with ball bearings positioned between them to reduce friction and increase efficiency. - Linear Motors: These are direct-drive motors that generate linear motion without the need for any mechanical transmission components like gears or belts. They use magnetic fields to produce force, which moves the load along a linear path. - Linear Bearings: These are mechanical components that provide low-friction movement for linear motion systems. Linear bearings can be divided into several types, such as ball bearings, roller bearings, and plain bearings. - Linear Slides: These are pre-assembled systems that combine linear guides, actuators, and other components to provide a ready-to-use linear motion solution. Linear slides can be customized to meet specific application requirements. When selecting an industrial linear motion module, it is essential to consider factors such as load capacity, speed, accuracy, repeatability, and environmental conditions to ensure the chosen system meets the requirements of the specific application. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#HighSpeedLinearModules#linearmodulesforprecisionmotionandindustrialautomationapplications#LinearMotionModules#LinearMotionProducts#LinearMotionSystems#MotorizedLinearStage

0 notes

Text

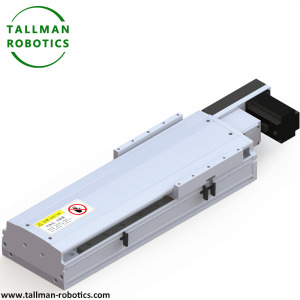

Modular Electric Slides

Modular Electric Slides You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects. Modular Electric Slides, also can be named as High Precision Linear Modules, Linear Motion Module, Industrial Linear Motion, Linear Actuator Bundle, etc in this industrial automation. Tallman Robotics’s Modular Electric Slides type TM220 with body with by 220mm have 4 series. These Linear slides have 0 mm to 3500 mm stroke, and 8kgs up to 150kgs input payload. TM Modular Electric Slides can be integrated with many brand motors by 50W,100W,200W/400W /750W/1000W or 42, 57,86 stepper motors or NMEA17, NMEA23, NMEA34 stepping motors in extruded super quality AL frame system to ensure requirement of precision and common projects. Precision, Stroke, lead, Brake and no Brake can be selected depending on your specific details. TM by Tallman Robotics, which is located in Shenzhen, has strong ability in design and engineering experience. We have exported all kinds of Modular Electric Slides such as screw driven modules, belt driven modules, and also ,also there are semi sealed type and fully sealed type for common and dust free applications. Our Modular Electric Slides perform all kinds of application such as: Winding Machine by eliminating the clearance of the traverse axis Circuit Board Mounting with linear modules used in high-precision and compact circuit board mounted. Driller with high rigidity linear module used in the drilling machine Positioning Device with linear module used for the moving parts of the work piece and the welding moving parts. Dispenser with linear module used in the dispenser, the movement is smooth and the coating is even., Laser Marking with linear module used in the laser marking machine in a clean room, etc.

Basic Specification of TM220 Modular Electric Slides series Model No TMS220-CM TMS220CR Drive solution Ball screw Sealed or not Semi closed Fully closed Motor power AC (W) 400W/750 Repeatability (mm) ±0.01/±0.005 Ball screw outer diameter (mm) 25 lead (mm) 5 10 25 50 Fastest speed Motor speed 3000 (rpm) 250 500 1250 2500 Max Load(kg) Acceleration Deceleration Horizontal 0.3G 150 150 120 50 Vertical 0.3G 55 45 20 8 Rate Thrust (N) 2100 1050 420 210 Linear guide (mm) 23*18.5-2 Origin sensor: Plug-in EE-SX672(NPN)EE-SX672P(PNP) Inside EE-SX951(NPN)EE-SX951P(PNP) Model No TMB220-CM TMB220-CR Drive solution Timing Belt Timing Belt Sealed or not Semi closed Fully closed Motor power AC (W) 750w Repeatability (mm) ±0.04 Reduction Ratio 1:1 1:2 lead (mm) 90 45 Fastest speed Motor speed 3000 (rpm) 4500 2250 Max Load(kg) Acceleration Deceleration Horizontal 0.3G 35 75 Vertical 0.3G - Rate Thrust (N) 163 326 Linear guide (mm) 23*18.5-2 Origin sensor: Plug-in EE-SX672(NPN)EE-SX672P(PNP) Inside EE-SX951(NPN)EE-SX951P(PNP) Related knowledge: Common problems and countermeasures for installation and use of single-axis and multi-axis robotic arms a. The flatness of the bottom surface of the single-axis manipulator installation does not meet the standard. If the flatness of the bottom surface of the single-axis manipulator is too large, the bottom surface of the electric slide table will be forcibly locked, resulting in strong bending deformation of the bottom surface of the slide table, linear guide rails and ball screws. If it is light, it will increase the running resistance of the single-axis manipulator. If it is heavy, the electric slide may not be able to run, and the life of the electric slide will be shortened sharply. According to the accuracy level of the single-axis manipulator, the flatness of the general installation level should be less than 0.05mm/m. For the precision grade, the flatness of the bottom surface of the installation should be less than 0.02mm/mm. b. The locking order of the fixing screws at the bottom of the single-axis manipulator is wrong. The fixing screw at the bottom of the single-axis manipulator should follow the principle of first middle, then both ends, and then locked in sequence. If the two ends are locked first, the arch deformation caused by the deformation cannot be eliminated, resulting in the linear guide rail not running smoothly, reducing the walking parallelism and straightness accuracy. c. The motor shaft of the single-axis manipulator and the end of the screw shaft are not concentric. Although the coupling can eliminate a certain degree of eccentricity, if the value of the concentricity runout of the shaft end of the single-axis manipulator screw and the motor shaft exceeds the allowable range of the coupling, the damage of the coupling will be accelerated, causing the coupling to be different. Sound, or shrapnel breaks. It should be avoided as much as possible. d. The installation height of both sides of the multi-axis gantry combined mechanical arm is uneven. When the mechanical arm is installed in a gantry type, if the height of the guide rails on both sides is uneven, or the two slides are not parallel, the electric slide will be held back and the damage of the electric slide will be accelerated. f. The single-shaft electric slide timing belt tension is too loose or too tight. The tension of the timing belt of the electric sliding table should be kept moderate. If the belt tension is too tight, the tension of the timing wheel and the timing belt will be too large, and there will be abnormal noise. If the belt tension is too loose, it will cause gaps in the transmission process and reduce accuracy. In severe cases, it will produce tooth skipping. The tension of the synchronous belt is generally determined by the tension and deflection. The measurement method is: use a thrust meter to press the vertical direction of the belt midpoint and apply a certain amount of installation force to measure the resulting deflection value. Reference values corresponding to different center distances and belt specifications. g. The installation of the timing belt of the single-axis electric slide is not aligned. The synchronous belt-driven electric slide table, or the motor-mounted electric slide table on the side of the motor, should keep the synchronous wheel flush, otherwise, it will cause the belt to deviate, and then the belt edge and the synchronous belt rib friction will occur, the synchronous belt within a short time Will be damaged and broken. h. The single axis electric slide induction switch collides with the sensor due to deformation. The induction slide of the electric slide induction switch is damaged due to deformation and collision with the photoelectric switch. Countermeasure: Before energizing and sliding the slider, first check the photoelectric switch. You can pass the photoelectric switch normally. i. The stroke of the cantilever shaft of the mechanical arm (electric slide) is too long, and the overhang length is too large. If the cantilever length of the robot arm is too large, the allowable torque of the guide rail will be overloaded. Under different accelerations and decelerations, the closing time will change. The vibration generated at the end of the beam is finally absorbed by the electric slide table. Long-term vibration will shorten the life of the guide rail. j. The load of the robot arm/electric slide exceeds the range of use. When selecting the robotic arm, in addition to referring to the loadable load data in the selection manual, the effects of the dynamic allowable torque, acceleration and deceleration changes, and cantilever length should also be checked, and sufficient safety factors should be reserved. k. The wiring of the robot arm sensor switch is wrong or burned due to overvoltage. The electric slide induction switch generally uses a photoelectric switch. The reverse connection of the positive and negative poles of the photoelectric switch will cause damage to the photoelectric switch. The photoelectric switch cannot share the power supply with the motor driver or other inductive loads. Otherwise, the back electromotive force generated by the motor or the inductive load will cause a large voltage fluctuation, which will burn the photoelectric switch. Read the full article

#BeltdriveLinearMotionGuideActuators#BeltDrivenLinearModules#Gearballscrewdrivenactuators#Leadscrewlinearactuators#Leadscrewlinearmodules#LinearGuideWays#LinearMotionSystems#LinearStages#ModularElectricSlides#ModularStages#Motionbeltdrivelinearactuators#Precisionlinearactuators#StainlessBearingActuators

0 notes

Text

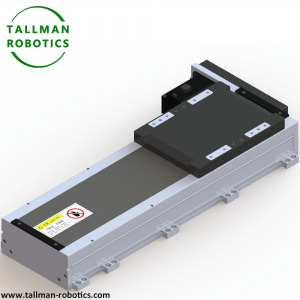

Single Axis Linear Actuator

Single Axis Linear Actuator You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects. Single Axis Linear Actuators, also named as Modular Linear Actuator, Linear Motion Module, Industrial Linear Motion, Linear Axis Actuator etc. TM by Tallman Robotics, as a famous producer to produce linear modules, supplies diverse TM Linear modules such as screw linear modules, belt linear modules, and semi closed and fully closed respectively for different environment application. TM Linear Modular Actuator Modules can run with world famous band motors by 50W,100W,200W/400W /750W/1000W or 42, 57,86 stepper motors or NMEA17, NMEA23, NMEA34 stepping motors in quality aluminum frame system to guarantee precise and speed requirement of various precision and common application projects. You can choose linear modules with brake or without brake. Tallman Robotics’s Single Axis Linear Actuator type TM135 with body with by 135mm have 5 series. Respectively,TM135 can be classified into screw driven semi closed, screw driven fully closed, and belt driven semi closed, belt driven fully closed. These Linear modules perform strokes from 0 mm up to 3500 mm, and payload from 6kg up to 110kgs. It could applied in laser marking, connection insert and pull test, components can be stitched by a condition of a certain thrust, parts from automobile undergo the second picking and positing.

Basic Specification of TM135 series Model No TMS135-CM TMS135CR Drive solution Ball screw Sealed or not Semi closed Fully closed Motor power AC (W) 200/400W/750 Repeatability (mm) ±0.01/±0.005 Ball screw outer diameter (mm) 16/20 16/20 16 16/20 16 20 lead (mm) 5 10 16 20 32 40 Fastest speed Motor speed 3000 (rpm) 250 500 800 1000 1600 2000 Max Load(kg) Acceleration Deceleration Horizontal 0.3G 95/110/110 75/110/110 44/68/90 35/50/80 13/30/60 10/15/25 Vertical 0.3G 27/35/35 18/25/35 7/18/25 6/14/20 -/8/10 - Rate Thrust (N) 683/1388/2100 341/694/1050 213/432/840 174/347/528 108/216/380 42/174/320 Linear guide (mm) 15*12.5-2 Origin sensor: Plug-in EE-SX674(NPN)EE-SX674P(PNP) Inside EE-SX951(NPN)EE-SX951P(PNP) Model No TMS135S-CM Drive solution Ball screw Sealed or not Semi closed Motor power AC (W) 200/400W/750 Repeatability (mm) ±0.01/±0.005 Ball screw outer diameter (mm) 16/20 16/20 16 16/20 16 20 lead (mm) 5 10 16 20 32 40 Fastest speed Motor speed 3000 (rpm) 250 500 800 1000 1600 2000 Max Load(kg) Acceleration Deceleration Horizontal 0.3G 70/70/70 47/70/70 30/48/70 24/45/70 13/25/50 10/15/25 Vertical 0.3G 17/17/25 12/12/18 6/8/15 4/6/10 - - Rate Thrust (N) 683/1388/2100 341/694/1050 213/432/840 174/347/840 108/216/380 42/174/320 Linear guide (mm) 15*12.5-2 Origin sensor: Plug-in EE-SX672(NPN)EE-SX672P(PNP) Inside EE-SX951(NPN)EE-SX951P(PNP) Model No TMB135-CM TMB135-CR Drive solution Timing Belt Timing Belt Sealed or not Semi closed Fully closed Motor power AC (W) 200/400W Repeatability (mm) ±0.04 Reduction Ratio 1:1 1:2 lead (mm) 90 45 Fastest speed Motor speed 3000 (rpm) 4500 2250 Max Load(kg) Acceleration Deceleration Horizontal 0.3G 10/21 22/42 Vertical 0.3G - - Rate Thrust (N) 45/91 90/182 Linear guide (mm) 15*12.5-2 Origin sensor: Plug-in EE-SX672(NPN)EE-SX672P(PNP) Inside EE-SX951(NPN)EE-SX951P(PNP) Related knowledge:Which industries are linear modules used for? How should it be classified? 1. Painting The linear module can be accurately positioned and stable operation 2. Image visual inspection device Utilizing the characteristics of high positioning accuracy and telling running stability of the linear slide module, it can be used to perform AOI inspection of appearance 3. Surface treatment Using the sliding table's constant speed and stable movement characteristics, the workpiece can be hung on the sliding table and immersed in the solvent, which can smoothly perform the surface treatment 4. Substrate printing Utilizing the sliding table's constant speed and stable movement characteristics, the substrate can be fixed on the sliding table's moving seat to perform the printing operation 5. Circuit board cutting Use the sliding table to move at a constant speed and stable, with the cutter mechanism to perform the cutting operation 6. Part assembly operations Utilize the characteristics of multi-point positioning and accurate positioning of the servo slide, which can smoothly perform the assembly of parts 7. Production line handling operations Utilize the module's high load and tellable running characteristics, it can be used to carry out the goods handling operation on the conveyor belt 8. Packing entire operation Utilizing the characteristics of high positioning accuracy of single-axis robots, it can be used for the entire movement on the conveyor belt 9. Large items pick and place operation Using the characteristics of high load and high positioning accuracy of the robot, it can be used to replace the manual execution of large items. 10. Machine tool processing pick and place operation Using the high positioning accuracy and high-speed stability of the linear module, it can be used with a machine tool to execute the pick-and-place mechanism for loading and unloading of processed parts 11. Print job Use the feature that the slide can move at the same speed and at the same distance to perform laser printing 12. Pick and place entire columns The linear module can be accurately moved, using a two-axis module sliding table, with a fixture or suction cup can be assembled into a pick and place mechanism 13. Automatic soldering operation Utilizing the characteristics of high positioning accuracy and high stability of the servo slide, it is possible to perform the soldering operation of complex circuit board parts 14. Large LCD glass substrate coating equipment Using the design method of gantry connection, the glue gun is fixed on the Z axis and can be used for high-speed glue application 15. Winding device The characteristics of sliding table can be moved with high precision and accurate and fixed speed operation Main products---electric slide (manipulator, actuator, linear module, electric cylinder) The electric slide table is widely used in precise positioning and moving animal materials, and can be basically used in the automation industry involved. Commonly used in the following industries: Electronics industry equipment: dispensers, placement machines, etc.: Battery equipment: power battery laminator, etc.; Laser equipment: laser welding machine, laser cutting machine, laser marking machine, etc.; Spraying equipment: spraying manipulator, etc.; Cutting equipment; plasma cutting machine, flame cutting machine, etc.; Die-casting machine, injection molding machine reclaiming manipulator, etc. Read the full article

#CurvedRailSystems#Electricaxes#LinearGuideRail#LinearGuideSystems#LinearmotionGuide#LinearMotionGuideModule#LinearMotionGuideRail#linearmotionsystems;linearslidesandcylindersandactuators#Linearmotorsingleaxisrobots#MiniatureLinearGuide#SingleAxis#SingleAxisLinearActuator#SmallLinearActuators

0 notes