#Maintenanceefficiency

Explore tagged Tumblr posts

Text

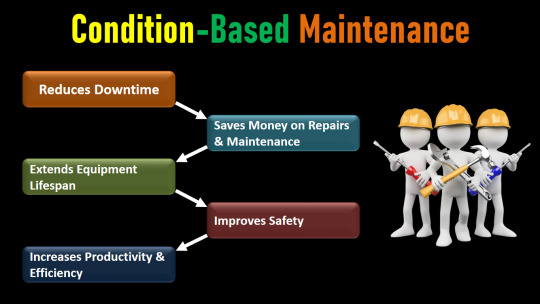

Condition-Based Maintenance: How It Works & Why It Matters

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

0 notes

Text

⚙️ Keep Your Equipment Running Smoothly with SAP PM! 🔧

From preventive maintenance to cost tracking, this cheat sheet covers everything you need to master Plant Maintenance and optimize asset performance. 🚀

📋 Key T-Codes | Maintenance Plans | Notifications | Reports

Ensure minimal downtime, improved asset lifespan, and efficient maintenance operations! ✅

✨ Empower your plant with smarter maintenance solutions!

For more info, call us at 📞 +91 8282824781 / +91 8282826381

visit 🌐 www.mentortechsystems.com

🔑 ✨

#SAPPM#PlantMaintenance#AssetManagement#PreventiveMaintenance#EnterpriseSolutions#DowntimeReduction#MaintenanceEfficiency#ERPSoftware#SAPforBusiness#TechTips

0 notes

Text

Preventing Power System Failures: How Arteche Trip Circuit Supervision Relays Improve Protection

In the modern power industry, reliability and protection are essential to ensuring smooth operations. Electrical systems are intricate, and any failure can lead to significant losses, both operationally and financially. One critical aspect of these systems is the trip circuit, which plays a vital role in the safe disconnection of faulty components. The Arteche VDF-10 Trip Circuit Supervision Relay and other Arteche supervision relays are designed to ensure that trip circuits remain reliable and functional, preventing system failures and enhancing protection.

In this blog, we will explore how Arteche’s supervision relays help prevent power system failures, their essential role in maintaining safety, and why they are critical for the protection of modern electrical infrastructures.

Understanding Trip Circuits and Their Importance

In power systems, trip circuits are part of the protective relaying scheme. When a fault occurs, such as a short circuit or overload, the trip circuit activates the circuit breaker, which disconnects the faulty part from the system to prevent damage or failure. Essentially, trip circuits are the backbone of system protection, as they ensure that the system responds appropriately to any malfunction.

However, trip circuits can sometimes fail due to wiring issues, mechanical faults, or component deterioration. If a trip circuit fails, the breaker may not operate when required, leaving the system vulnerable to extensive damage. Therefore, monitoring and ensuring the health of trip circuits is critical, and this is where Arteche VDF-10 Trip Circuit Supervision Relays come into play.

What is the Arteche VDF-10 Trip Circuit Supervision Relay?

The Arteche VDF-10 Trip Circuit Supervision Relay is a specialized device designed to continuously monitor the integrity of trip circuits in electrical systems. It ensures that the trip circuit is always operational, providing real-time supervision and instant detection of any faults.

Some key features of the Arteche VDF-10 include:

Continuous Supervision: The VDF-10 continuously monitors the trip circuit, detecting wiring faults, open circuits, or component failures.

Instant Alerts: If any malfunction occurs in the trip circuit, the relay sends an immediate alarm to alert the maintenance team of the issue.

Compact Design: The VDF-10 is designed to fit into compact spaces within substations and other electrical environments.

Versatility: It can be used in a wide range of voltage systems, making it applicable across different power system configurations.

By using the Arteche Relay, operators can detect potential issues early, before they cause system failures, and take preventive measures to maintain uninterrupted operations.

How Arteche Trip Circuit Supervision Relays Improve Protection

Let’s dive deeper into how Arteche trip circuit supervision relays, such as the VDF-10, contribute to the protection and reliability of power systems:

1. Real-Time Monitoring for Early Fault Detection

One of the biggest challenges in power systems is identifying problems before they escalate into full-scale failures. The Arteche VDF-10 Trip Circuit Supervision Relay continuously monitors the trip circuit in real-time, ensuring that the circuit is always functional. It checks for open circuits, wiring failures, loose connections, and other issues that may compromise the trip circuit’s ability to operate.

This real-time monitoring provides early detection of faults, allowing maintenance teams to address the problem before it leads to a critical failure. By proactively identifying issues, the VDF-10 prevents costly outages and reduces the risk of equipment damage.

2. Enhanced System Reliability

The reliability of the trip circuit directly impacts the reliability of the entire electrical system. When a fault occurs in the power network, the trip circuit must operate swiftly to disconnect the faulty section and protect the rest of the system. A malfunctioning trip circuit could lead to a delay in the breaker operation, resulting in extensive damage and prolonged downtime.

The Arteche VDF-10 Trip Relay enhances system reliability by ensuring that the trip circuit is always in good working order. By providing constant supervision, it ensures that power systems can respond promptly to any fault, improving overall reliability and system uptime.

3. Prevention of Catastrophic Failures

In the absence of trip circuit supervision, undetected faults can accumulate over time, increasing the risk of catastrophic system failures. A simple wiring issue in the trip circuit could prevent the breaker from disconnecting a faulty part, leading to large-scale damage to transformers, generators, and other critical equipment.

Arteche’s trip circuit supervision relays, like the VDF-10, prevent such failures by offering continuous supervision and immediate alerts. By ensuring that the trip circuit functions as intended, Arteche supervision relays safeguard electrical equipment and prevent failures that could lead to costly repairs or replacements.

4. Reduction of Maintenance Downtime

In traditional power systems, maintenance teams often conduct periodic manual checks to ensure the integrity of trip circuits. However, this process is time-consuming and prone to human error. By using Arteche VDF-10 Trip Circuit Supervision Relays, operators can automate the supervision process and receive alerts in real-time when a fault occurs.

This real-time fault detection reduces the need for manual inspections and allows maintenance teams to focus on addressing actual issues rather than spending time on routine checks. As a result, the system experiences less maintenance downtime, improving operational efficiency.

5. Improved Safety for Operators and Equipment

Electrical systems can be hazardous, and faults that go undetected in trip circuits can pose serious safety risks to operators. Without proper trip circuit supervision, an operator might unknowingly engage with a faulty system, leading to injury or damage.

Arteche trip circuit supervision relays improve safety by ensuring that operators are informed of any issues in the trip circuit before they interact with the system. Immediate alerts and fault detection give operators the necessary information to act safely, preventing accidents and protecting both personnel and equipment.

Arteche Supervision Relays: A Broader Perspective

While the Arteche VDF-10 Trip Relay plays a specific role in monitoring trip circuits, Arteche also offers a wide range of supervision relays designed to enhance the protection and functionality of electrical systems. These relays are used to monitor critical parameters such as voltage, current, and circuit continuity, ensuring that power systems operate efficiently and safely.

Arteche’s supervision relays are known for their reliability, ease of use, and versatility. They can be integrated into various power system configurations, making them suitable for substations, power plants, industrial facilities, and other electrical infrastructures.

Conclusion

In today’s highly interconnected and complex power systems, ensuring the reliability and functionality of trip circuits is essential for preventing system failures. The Arteche VDF-10 Trip Circuit Supervision Relay and other Arteche supervision relays offer a proactive solution to monitoring and protecting trip circuits, ensuring that electrical systems can respond swiftly to faults and maintain uninterrupted operations.

By providing real-time monitoring, early fault detection, and enhanced protection, Arteche’s supervision relays improve the safety, reliability, and efficiency of power systems. For operators seeking to prevent catastrophic failures and enhance system reliability, the Arteche Trip Circuit Supervision Relay is an indispensable tool.

At Digital & Smart Grid Enterprises, we are committed to providing industry-leading supervision relay solutions, including the reliable Arteche VDF-10 Trip Relay. Our team of experts specializes in ensuring the safety and operational efficiency of your power systems through comprehensive testing, commissioning, and monitoring services. Whether it’s enhancing the reliability of your trip circuits or safeguarding your infrastructure against potential faults, we utilize advanced diagnostic tools to deliver precise and dependable results.

Contact us today at +917021624024 or email [email protected] to learn how we can help you protect and optimize your electrical systems.Click here to explore our Supervision Relay Services.

#powersystems#ElectricalEngineering#ReliabilityEngineering#CircuitProtection#TripCircuit#SupervisionRelay#Arteche#PowerGrid#ElectricalSafety#FaultDetection#SmartGrid#IndustrialAutomation#MaintenanceEfficiency#ElectricalInfrastructure#EnergyManagement

0 notes

Text

To ensure safe access to the underside of an inclined conveyor located above a busy internal road at a steel plant.

Our innovative WEB Deck™ - Mega Truss system was installed, featuring multi-level suspended platforms arranged in a "stepped" formation, to maximize safety and productivity at the site.

To know more visit: https://web-international.com/web-deck.php

#websystems#construction#maintenance#WebDeck#InfrastructureAccess#MaintenanceEfficiency#SafetyFirst#Innovation#Safety#CostEffective#Customised#Engineered#Service#Repair#Inspection#UnderDeck#AccessTechnology#infrastructure

0 notes

Text

#OptimalContact#DynamicAlignment#WasherTechnology#PrecisionMachinery#VersatileDesign#EngineeringInnovation#AlignmentSolutions#MaintenanceEfficiency#ReliabilityInDesign#EngineeringAdvancements

0 notes

Text

#cmms#cmmssystem#MaintenancePlanning#PreventiveMaintenance#AssetManagement#MaintenanceStrategy#EquipmentMaintenance#CMMSSoftware#ReliabilityEngineering#WorkOrderManagement#MaintenanceScheduling#MaintenanceBestPractices#MaintenanceOptimization#ConditionBasedMaintenance#MaintenanceEfficiency#MaintenanceManagement#MaintenanceAutomation#FacilityManagement#PredictiveMaintenance#MaintenanceMetrics#MaintenanceAnalytics#lts#lean#leantransitionsolutions

1 note

·

View note

Text

Piping Design & 3D Modeling: Streamlining Maintenance and Inspection Processes Piping Design & 3D Modeling significantly enhances maintenance and inspection processes. By integrating detailed 3D models with real-time data, engineers can streamline workflows, reducing downtime and improving safety. Recent advancements in digital twin technology allow for precise visualization of piping systems, enabling quicker identification of issues. This proactive approach minimizes manual searches for equipment, thus accelerating maintenance tasks. As industries adopt these innovations, the efficiency of inspections and repairs continues to rise, ensuring optimal system performance. #PipingDesign #3DModeling #MaintenanceEfficiency #DigitalTwins #EngineeringInnovation For more information, visit: https://inclinedengg.com/csa-delivery/

0 notes

Text

Condition-Based Maintenance: How It Works & Why It Matters

Imagine if your car could tell you exactly when it needs an oil change rather than following a fixed schedule. Instead of guessing or changing the oil too early, you’d only do it when it’s actually necessary, saving time and money while keeping your engine in top shape. That’s the core idea behind Condition-Based Maintenance (CBM) in industries.

CBM is a smart maintenance strategy that monitors the real-time condition of machines and equipment. Instead of performing maintenance on a fixed schedule (like every three months), CBM uses sensors and data analysis to determine when maintenance is truly needed. This approach helps prevent unnecessary servicing while avoiding unexpected breakdowns.

➥ How Does Condition-Based Maintenance Work?

CBM relies on real-time monitoring and data-driven decision-making. Here’s a simple breakdown of how it works:

✅ 1. Sensors Collect Real-Time Data

Machines are equipped with sensors that track critical performance indicators such as:

Temperature – Helps detect overheating issues.

Vibration – Identifies misalignments or wear in rotating equipment.

Pressure Levels – Ensures pumps, compressors, and hydraulic systems are working properly.

Oil Quality – Measures contamination or degradation in lubricants.

✅ 2. Data Is Analyzed to Detect Problems

The collected sensor data is continuously monitored and compared to normal operating conditions. If the system detects unusual behavior, like excessive vibration or rising temperature, it signals a potential issue.

For example, if a motor starts vibrating abnormally, it could indicate a misalignment, loose parts, or an upcoming failure. Maintenance teams receive an alert, allowing them to inspect and fix the issue before the motor breaks down.

✅ 3. Maintenance Is Performed When Needed

Instead of following a fixed maintenance schedule (which can either be too frequent or too late), CBM ensures maintenance is done only when the data suggests it's necessary. This reduces unnecessary downtime and repair costs while keeping machines running efficiently.

Read in detail: https://www.knowledgewale.com/2025/03/condition-based-maintenance.html

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

1 note

·

View note

Text

TPM Best Practices: Achieve Peak Efficiency & Zero Downtime

In today’s competitive industrial landscape, keeping machines running efficiently is critical to maintaining productivity and reducing costs. Equipment failures and unexpected breakdowns lead to costly downtime, delayed production, and increased maintenance expenses. This is where Total Productive Maintenance (TPM) comes in a structured approach to improving equipment reliability, reducing downtime, and maximizing operational efficiency.

➥ What is Total Productive Maintenance (TPM)?

Total Productive Maintenance (TPM) is a proactive maintenance strategy designed to keep machinery and equipment in optimal condition by involving every employee in maintenance activities. Unlike traditional maintenance, which is often reactive (fixing equipment after it breaks), TPM focuses on preventing breakdowns, minimizing defects, and increasing overall efficiency.

TPM is built on the principle that equipment operators should take ownership of routine maintenance tasks, such as cleaning, lubrication, and minor repairs, while maintenance teams focus on more complex issues. This helps improve machine longevity and ensures that maintenance issues are addressed before they cause failures.

➲ Key Objectives of TPM

✔️ Reduce unplanned downtime

✔️ Improve equipment reliability

✔️ Enhance production efficiency

✔️ Reduce maintenance costs

✔️ Minimize defects and waste

✔️ Improve workplace safety

➥ The 8 Pillars of TPM

Total Productive Maintenance (TPM) is a structured approach to maintaining equipment and improving efficiency in manufacturing and industrial settings. The goal is simple: reduce downtime, prevent failures, and keep machines running at peak performance. TPM is built around 8 key pillars to achieve this, each focusing on maintenance and productivity. Let’s dive into them one by one in a detailed and easy-to-understand manner.

1. Autonomous Maintenance (Jishu Hozen) – Empowering Operators

In many industries, only the maintenance team handles equipment servicing. This often leads to delays, as minor issues go unnoticed or are not fixed on time. Autonomous maintenance gives machine operators the responsibility of performing basic maintenance tasks such as:

✅ Cleaning equipment regularly

✅ Lubricating moving parts

✅ Checking for minor wear and tear

✅ Detecting unusual sounds, vibrations, or leaks

Read more: https://www.knowledgewale.com/2025/03/tpm-best-practices.html

#tpmbestpractices#totalproductivemaintenance#zerodowntime#peakefficiency#tpmimplementation#tpmstrategy#tpmpillars#preventivemaintenance#predictivemaintenance#equipmentreliability#industrialmaintenance#continuousimprovement#leanmanufacturing#maintenanceoptimization#tpmbenefits#tpmtraining#autonomousmaintenance#proactivemaintenance#maintenanceefficiency#reducingdowntime

0 notes

Text

How to effectively frame the Data strategy to enhance your maintenance management?

Data contributes much to maintenance management, streamlining maintenance management operations and maximising returns. Capturing the maintenance data and using it effectively can identify and eliminate the problems caused by unnecessary steps or incorrect instructions in one go.

Read More: https://cmmssoftware.leantransitionsolutions.com/software-blogs-details/Data-strategy-enhance-your-maintenance-management

#DataDrivenMaintenance#MaintenanceAnalytics#MaintenanceManagementStrategy#DataStrategyforMaintenance#OptimisedMaintenance#MaintenanceInsights#DataInformedDecisions#SmartMaintenance#MaintenanceOptimisation#DataManagementForMaintenance#PredictiveMaintenance#MaintenanceEfficiency#DataDrivenOperations#MaintenanceIntelligence#DataVisualisation#MaintenanceMetrics#DataIntegration#MaintenancePerformance#DataQualityManagement#MaintenanceAutomation#DataCollectionProcesses#MaintenanceExcellence#DataGovernance#MaintenanceCostOptimiszation#DataReporting#MaintenanceBestPractices#DataInfrastructure#MaintenanceReliability#DataSecurityMeasures#MaintenanceStrategyPlanning

0 notes