#Material Engineering

Explore tagged Tumblr posts

Text

Margo moment - today’s 8h course on all the possible materials for space use

9 notes

·

View notes

Text

Two insect-like robots, a mini-bug and a water strider may be the smallest, lightest and fastest fully functional micro-robots ever known to be created. Such miniature robots could someday be used for work in areas such as artificial pollination, search and rescue, environmental monitoring, micro-fabrication or robotic-assisted surgery. Reporting on their work in the proceedings of the IEEE Robotics and Automation Society's International Conference on Intelligent Robots and Systems, the mini-bug weighs in at eight milligrams while the water strider weighs 55 milligrams. Both can move at about six millimeters a second.

...

Both can move at about six millimeters a second.

"That is fast compared to other micro-robots at this scale although it still lags behind their biological relatives," said Conor Trygstad, a PhD student in the School of Mechanical and Materials Engineering and lead author on the work.

An ant typically weighs up to five milligrams and can move at almost a meter per second.

The key to the tiny robots is their tiny actuators that make the robots move.

Trygstad used a new fabrication technique to miniaturize the actuator down to less than a milligram, the smallest ever known to have been made.

"The actuators are the smallest and fastest ever developed for micro-robotics," said Néstor O. Pérez-Arancibia, Flaherty Associate Professor in Engineering at WSU's School of Mechanical and Materials Engineering who led the project.

The actuator uses a material called a shape memory alloy that is able to change shapes when it's heated

#robotics#biomimicry#microrobots#engineering#mechanical engineering#materials science#Material engineering#Shape memory alloy

2 notes

·

View notes

Text

PTFE Filled Modified Materials: The Key to Enhancing Wear Resistance and Mechanical Strength

In the world of advanced polymer materials, PTFE (Polytetrafluoroethylene) stands out for its exceptional properties. However, when enhanced with filler materials, PTFE transforms into an even more remarkable engineering solution. This article explores how PTFE filled modified materials significantly improve wear resistance and mechanical strength for demanding industrial…

#filled polymers#industrial materials#material engineering#mechanical strength#Polymer Materials#PTFE#wear resistance

0 notes

Text

MnBi6Te10 Semiconductor: Thinnest Junction For Quantum Tech

Researchers Find the world's thinnest semiconductor junction in quantum material. Unexpected discovery enables ultra-small, energy-efficient circuits.

Electronic properties of MnBi6Te10

The crystal structure of a quantum material spontaneously creates a semiconductor junction, essential to modern electronics. Our connection is 3.3 nanometres thick. It is 25,000 times thinner than paper and one of the thinnest semiconductor junctions.

Small, energy-efficient electronics may result from the surprise discovery. Additionally, it gives critical electron behaviour information in materials for advanced quantum applications.

Pennsylvania State University and the University of Chicago Pritzker School of Molecular Engineering (UChicago PME) were studying MnBi6Te10, a topological material that allows electricity to flow without resistance.

Researchers hope to use this topological material in ultra-efficient electronics or quantum computers.

Surprise and Experiment

Materials like MnBi6Te10 need evenly distributed and balanced electrons to work. The researchers believed they had achieved this balance by adding antimony to MnBi6Te10. Preliminary electrical tests showed the material was neutral.

The scientists discovered something odd using temporal-and angle-resolved photoemission spectroscopy (trARPES), which uses ultrafast laser pulses to analyse electron distribution and energy levels in real time. Electronics were unevenly placed in the crystal's few-atom-thick repeating layers. Instead, they left certain places with fewer electrons and clumped others. This unequal distribution created tiny, intrinsic electric fields in the material.

Without trying, the material developed one of the thinnest connections ever seen.

In an ideal quantum material, charges should be uniform, says the first author, a PhD student at the University of Chicago PME. This unequal distribution is another helpful phenomenon, although it may not permit quantum applications as anticipated.

Nature's P-N Junction

These little areas were p-n junctions due to electric fields. P-n junctions with internal electric fields make diodes for computers and phones. They spontaneously developed in MnBi6Te10's crystal structure, unlike artificial p-n junctions. Junction thickness was consistently 3.3 nanometres.

Researchers attribute the spontaneous formation of p-n junctions to the addition of antimony to MnBi₆Te₁₀. Modelling suggests that antimony and manganese atoms moving locations in the crystal lattice cause these charge differences and localised electric fields across the material.

Aftereffects on Quantum and Electronic Applications

Its implications are significant. Naturally occurring p-n junctions are light-responsive. It benefits solar cells, LEDs, and spintronics.

Unlike electronics, spintronics stores and alters data using electron spin. This may make spintronic devices faster and more energy-efficient. Spintronics is used in quantum computing, logic gates, data storage, and non-volatile memory.

The result challenges the use of MnBi6Te10 for quantum effects that need a uniform charge distribution or magnetic properties, even while its uneven electron distribution and p-n junctions are desirable for electronic applications. The discovery also allows for material engineering that may achieve quantum engineering uniformity.

Enhancing Material Properties

Instead of three-dimensional crystals, the UChicago PME team is making thin MnBi6Te10 films. This technology may let them control material electrons more precisely. Modifying its characteristics can improve the yield and qualities of small, naturally growing p-n junctions for semiconductor applications or raise the material's quantum features. This project aims to develop technology-specific materials.

The study emphasises the material's potential for high-speed, energy-efficient electronics but admits the need for further development to overcome quantum application limits.

This emphasises the need of fundamental scientific research and transparency. It started with one goal, but a surprise led us in a fascinating new route.

MnBi6Te10 may improve electronic device performance and miniaturisation, however applications and manufacturing viability remain challenges.

Nanoscale published the discovery on April 2, 2025, under the title “Spectroscopic evidence of intra-unit-cell charge redistribution in a charge-neutral magnetic topological insulator”. Project funding came from the National Science Foundation and DOE.

#technology#technews#govindhtech#news#technologynews#MnBi6Te10#P-N Junction#quantum applications#uantum engineering#material engineering#p-n junctions

0 notes

Text

Global Silicone Elastomer Market Analysis Business Revenue Forecast Size Leading Competitors And Growth Trends

Global Silicone Elastomer Market: Key Drivers, Trends, and Regional Growth Analysis

The Global Silicone Elastomer Market is experiencing remarkable growth as industries increasingly shift toward advanced, high-performance materials. From automotive and electronics to healthcare and construction, the demand for silicone elastomers is expanding rapidly due to their exceptional thermal stability, flexibility, and resistance to environmental stress.

With global infrastructure developments and industrial innovations accelerating, the silicone elastomer sector is projected to nearly double in value over the next decade.

Market Overview

Silicone elastomers are synthetic rubber-like materials made from silicone polymers and curing agents. Known for their durability and resistance to heat, UV radiation, and chemicals, these materials perform reliably under extreme conditions where traditional rubbers often fail.

According to recent forecasts, the global market is expected to reach USD 9.3 billion by 2025 and grow at a CAGR of 7.7%, hitting USD 18.3 billion by 2034. This growth reflects their increasing adoption in industries demanding superior material performance.

Major Growth Drivers

1. Expanding Automotive Applications

Silicone elastomers are essential in the automotive sector for components like gaskets, seals, and hoses. The transition toward electric vehicles (EVs) and lighter, more efficient car designs is increasing demand for heat-resistant and long-lasting materials.

2. Rapid Growth in Construction

With urbanization on the rise, especially in Asia and developing markets, silicone elastomers are widely used in window glazing, roofing, and structural seals. Their weather resistance and flexibility make them a preferred choice for long-term construction performance.

3. Rising Healthcare and Medical Use

In the medical field, silicone elastomers are valued for their biocompatibility and flexibility. They are used in products ranging from catheters and tubing to implants. As healthcare advances and populations age, demand in this sector continues to grow.

4. Increasing Use in Electronics

Silicone elastomers are vital for insulating materials, protective covers, and keypads in consumer electronics and telecommunications. Their excellent dielectric properties ensure safety and reliability in compact and high-efficiency devices.

📄 Download your free PDF sample report now: https://dimensionmarketresearch.com/report/silicone-elastomer-market/request-sample/

Regional Breakdown: Asia Pacific Taking the Lead

Asia Pacific

Expected to hold approximately 48.2% of the global market share by 2025, Asia Pacific dominates due to fast-paced industrialization and urban development. Countries like China, India, and Japan are spearheading growth through large-scale manufacturing, automotive expansion, and infrastructure investment.

Other Key Regions:

North America: Driven by medical innovation and electric vehicle production.

Europe: Focused on sustainable construction and advanced automotive technologies.

Latin America & Middle East: Emerging opportunities due to growing industrialization and infrastructure projects.

📨 Submit custom report requests here: https://dimensionmarketresearch.com/enquiry/silicone-elastomer-market/

Core Applications

Silicone elastomers are used across numerous applications:

Automotive: Employed in engine components, seals, and vibration dampers due to their resistance to heat and mechanical stress.

Healthcare: Used in prosthetics, surgical tools, and drug delivery systems for their non-toxic, hypoallergenic properties.

Electronics: Provide moisture and thermal protection to delicate electronic parts.

Construction: Found in sealants, adhesives, and weatherproofing applications, enhancing structural durability.

Market Challenges

Despite their advantages, the market faces certain hurdles:

High production costs: Raw materials and complex manufacturing processes elevate product pricing.

Environmental concerns: Silicone materials are not biodegradable, and recycling options are still limited.

Supply chain issues: Global disruptions and raw material shortages can impact production and costs.

Emerging Trends

Several innovations are influencing the future of silicone elastomers:

Sustainable materials: Development of eco-friendly or recyclable silicone formulations.

Silicone 3D printing: Used to create custom parts for healthcare and electronics.

Smart silicone technologies: Materials that respond to heat, pressure, or light for use in sensors and wearable tech.

🛒 Secure your copy or customize your report here: https://dimensionmarketresearch.com/checkout/silicone-elastomer-market/

Frequently Asked Questions (FAQs)

What are silicone elastomers? Flexible, durable materials made from silicone polymers that resist heat, UV, and chemicals.

Which industries are boosting market growth? Primarily automotive, healthcare, electronics, and construction sectors.

Why is Asia Pacific the largest market? Due to industrial growth, urban development, and strong demand from manufacturing and construction sectors.

What is the market outlook? Expected to grow from USD 9.3 billion in 2025 to USD 18.3 billion by 2034, with a 7.7% CAGR.

Are silicone elastomers sustainable? They are long-lasting but not biodegradable. Research into recyclable and eco-friendly versions is underway.

Conclusion

The Global Silicone Elastomer Market is poised for impressive growth, thanks to rising demand for durable, high-performance materials across essential industries. As countries invest in smarter infrastructure, electric vehicles, and advanced healthcare, silicone elastomers will play an even larger role in shaping the future.

While challenges like cost and environmental impact persist, ongoing innovation and regional expansion — particularly in Asia Pacific — will ensure this market remains dynamic and highly relevant.

#Silicone Elastomer#Global Market#Elastomer Suppliers#Automotive Materials#Medical Grade Silicone#Electronics Manufacturing#Innovation Trends#Industrial Materials#Silicone Rubber#R&D Insights#Chemical Manufacturing#Thermal Stability#Flexible Polymers#Supply Chain Trends#Market Forecast#Advanced Polymers#Strategic Sourcing#Product Development#Material Engineering#Healthcare Materials

0 notes

Text

Sharing

AJSJJDKSJD THE QUILTING SHOW MY GMA WANTS TO GO TO HAS A “FREE TICKET FOR UNDER 30s” IM!!!!! that’s SO funny ?? They wanna encourage young ppl SO much to get into quilting

#useful information#fibercraft#material engineering#adopt a grandma#adopt an aunt#networking through hobbies

49K notes

·

View notes

Text

the return of captain poppy space babies >>> the story and the engine

#doctor who#dwedit#space babies#the story and the engine#mine#i get it i too am still haunted by space babies from time to time#anyway. man imagine if they didn't film poppy's new scene with a 2005 potato and you could actually see her clearly#i'd considered giffing the credits too so you could see that it is poppy (and the same actress) but i'm too lazy#anyway this episode hit me with at least like 3 rumors/spoilers that i didn't expect to materialize in the ways they did#absolutely no idea what to expect from the next episode at this point

3K notes

·

View notes

Text

The Automotive Elastomer Market is Led by the APAC Region

The automotive elastomers market was USD 34.6 billion in 2023, and it will power at a compound annual growth rate of 5.7% by the end of this decade, to touch a value of USD 50.6 billion in 2030. The industry is mainly boosted by the growing requirement for novel cars and growing per-capita income. Also, governments’ strict standards and guidelines to reduce pollution levels, surge mileage, and…

View On WordPress

#automotive components#Automotive Elastomer Market#Automotive Industry#Design Flexibility#Durability#Elastic Materials#Elastomer Innovations#Industry Insights#Market dynamics#market trends#Material Engineering#Sealing Applications#Technological advancements#Tire Manufacturing#Vehicle Performance

0 notes

Text

DEATH SHIP (1980) dir. Alvin Rakoff

#death ship#death ship 1980#horroredit#filmedit#filmgifs#moviegifs#horrortvfilmsource#junkfooddaily#cinemapix#dailyflicks#userboat#usertj#useremory#classichorrorblog#sdb.gif#1980s#sixdemonedit#fyeahmovies#filmtvcentral#filmtvtoday#the awesome ship was the only good part of this film. and they knew it with how many engine shots they did#idk why i did color isolation on this lol its awful material for it#that isnt blood btw it was like oil or something i just turned it red. how cool would it be if it was blood though#way too cool for these filmmakers smh

397 notes

·

View notes

Text

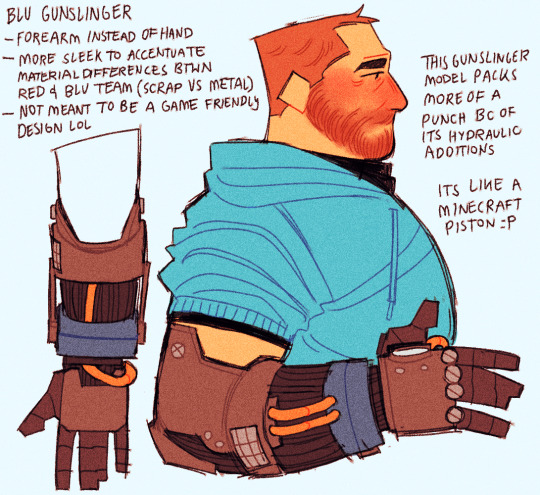

as someone who was in the mines of "drawing a characters robotic arm from increasingly difficult angles" before, i yearn for those times. so heres my take on blu engie's gunslinger, based on modern prosthetic forearms

its worth noting that, before he cloned himself to create red engie, he had the original gunslinger, ie he was only missing his hand. he decided to upgrade himself not only bc he had the means to, but bc he wanted to differentiate himself from his clone so that he would always be distinctly the original, even if he would be the only one to know that

inspired by vi's hextech gauntlets and ofc, johnny silverhand's arm. i miss drawing johnny every day of my life

#tf2#team fortress 2#tf2 engie#engie tf2#doodle#digital art#artists on tumblr#mine#my art#blu engie#yeahh..yeah i dont got much to say in the tags that i havent said already#im not v experienced in designing robot parts so this was a fun exercise#this means his arm works like a normal human arm and cant twist all theway around#the pistons r like bones and the wires are tough enough to be tendons#it still has to be revved up so to say but it also releases steam after being used#i wanted to focus on how blu team was intentionally designed by valve to be more cold and robotic#compared to the wood and other natural materials of red team#the original gunslinger feels scrappy. it feelslike something engie threw together out of spare metal#this is not to say it isnt an engineering wonder#in fact its kitbashed nature is PART of that genius#sorry. did i say i didnt have much to say in the tags#i lied :P

464 notes

·

View notes

Text

For 200 years, scientists have failed to grow a common mineral in the laboratory under the conditions believed to have formed it naturally. Now, a team of researchers from the University of Michigan and Hokkaido University in Sapporo, Japan have finally succeeded, thanks to a new theory developed from atomic simulations. Their success resolves a long-standing geology mystery called the "Dolomite Problem." Dolomite—a key mineral in the Dolomite mountains in Italy, Niagara Falls, the White Cliffs of Dover and Utah's Hoodoos—is very abundant in rocks older than 100 million years, but nearly absent in younger formations. "If we understand how dolomite grows in nature, we might learn new strategies to promote the crystal growth of modern technological materials," said Wenhao Sun, the Dow Early Career Professor of Materials Science and Engineering at U-M and the corresponding author of the paper published today in Science. The secret to finally growing dolomite in the lab was removing defects in the mineral structure as it grows. When minerals form in water, atoms usually deposit neatly onto an edge of the growing crystal surface. However, the growth edge of dolomite consists of alternating rows of calcium and magnesium.

Continue Reading.

1K notes

·

View notes

Text

he lives rent free in my head

#husband material#for real#i love him sm#i need him.#he has me in a chokehold#it's not even funny#team fortress 2#tf2#tf2 engineer#tf2 red engineer#tf2 blu engineer#tf2 comic engineer#they kinda remind me to the engineers from lil pootis#i've finally watched lil pootis. love them#my art#digital art#artists on tumblr

667 notes

·

View notes

Text

Engineers at the University of Nebraska–Lincoln have developed a synthetic “robot muscle” that mimics living tissue by detecting damage through embedded electronic skin and autonomously repairing itself.

77 notes

·

View notes

Text

On the Mechanics of Wet Sand

Sand is a critical component of many built environments. As most of us learn (via sand castle), adding just the right amount of water allows sand to be quite strong. But with too little water -- or too much -- sand is prone to collapse. (Video and image credit: Practical Engineering) Read the full article

71 notes

·

View notes

Text

A collection of all my little paper guys + some new Sonic ones I made today

#pasca pens my beloved <3#they are so expensive but I use the ones in the art room so they’re basically free material#also I just realized I fucked up Sonic’s shoes- ignore that please#my art#traditional art#i guess?#tf2#tf2 engineer#tintin#sonic#sonic the hedgehog

141 notes

·

View notes