#Micro Injection Molding Machine Size

Explore tagged Tumblr posts

Text

Micro Injection Molding Machine Market Research Insights Shared in Detailed Report

The Micro Injection Molding Machine Market was valued at USD 0.4 billion in 2023-e and will surpass USD 0.8 billion by 2030; growing at a CAGR of 9.4% during 2024 - 2030. The report focuses on estimating the current market potential in terms of the total addressable market for all the segments, sub-segments, and regions. In the process, all the high-growth and upcoming technologies were identified and analyzed to measure their impact on the current and future market.

Micro injection molding is a specialized form of injection molding that focuses on producing very small, highly detailed plastic parts. These parts typically weigh less than 1 gram and have dimensions measured in micrometers. The process involves injecting molten plastic into a mold cavity with extreme precision to achieve the desired shape and features. This technology is essential for manufacturing components that require tight tolerances and intricate geometries.

Read More about Sample Report:

Market Trends and Growth Drivers

Miniaturization in Electronics: The relentless pursuit of smaller, more powerful electronic devices has significantly driven the demand for micro injection molding machines. Components such as connectors, sensors, and micro gears used in smartphones, wearables, and other compact devices require high precision and reliability, which micro injection molding can deliver.

Advancements in Medical Devices: The medical industry is a major contributor to the growth of this market. The production of micro-sized components for minimally invasive surgical instruments, drug delivery systems, and diagnostic equipment necessitates the use of micro injection molding. The ability to produce biocompatible and high-precision parts is critical for medical applications.

Automotive Industry Innovations: As the automotive industry moves towards more sophisticated electronic systems and lightweight materials, the demand for micro-molded parts is increasing. Micro injection molding machines are used to produce connectors, sensors, and other small components that are integral to modern automotive technology.

Sustainability and Material Efficiency: The micro injection molding process is highly efficient in terms of material usage, which aligns with the growing emphasis on sustainability. The ability to produce tiny parts with minimal waste is an attractive feature for industries looking to reduce their environmental footprint.

Challenges in the Micro Injection Molding Machine Market

Despite the promising growth prospects, the micro injection molding machine market faces several challenges:

High Initial Investment: The cost of acquiring micro injection molding machines and the associated tooling can be substantial. This high initial investment may deter small and medium-sized enterprises from entering the market.

Technical Complexity: The process requires a high level of expertise and precision. Maintaining consistent quality and tolerances in micro-molded parts can be challenging, necessitating advanced technology and skilled operators.

Material Selection: Not all materials are suitable for micro injection molding. The selection of appropriate materials that meet the stringent requirements of various applications can be a complex task.

Ask for Customization Report: https://intentmarketresearch.com/ask-for-customization/micro-injection-molding-machine-market-3232.html

Future Prospects

The future of the micro injection molding machine market looks promising, with several factors likely to drive further growth:

Technological Advancements: Ongoing innovations in machine design, process control, and materials will enhance the capabilities of micro injection molding. Developments such as multi-material micro molding and the integration of automation and AI will open new avenues for this technology.

Expansion into New Applications: As industries continue to innovate, new applications for micro-molded parts will emerge. Fields such as aerospace, defense, and biotechnology are expected to adopt micro injection molding for their specialized requirements.

Global Market Expansion: The market is set to expand geographically, with growing demand in regions like Asia-Pacific, driven by the electronics and automotive industries. Increasing industrialization and technological adoption in emerging economies will contribute to market growth.

Customization and Personalization: The trend towards customization in various industries, particularly in medical devices and consumer electronics, will fuel the demand for micro injection molding machines capable of producing tailored parts.

Conclusion

The micro injection molding machine market is poised for significant growth, driven by advancements in technology, increasing demand for miniaturized components, and the pursuit of material efficiency and sustainability. While challenges remain, the industry's future prospects are bright, with ongoing innovations and expanding applications set to propel the market forward

#Micro Injection Molding Machine#Micro Injection Molding Machine Size#Micro Injection Molding Machine Trends#Micro Injection Molding Machine Outlook

0 notes

Text

0 notes

Text

Why the World Is Turning to Small Servo Motors for Big Industrial Challenges

You’ve probably never looked twice at a small servo motor. It’s compact, quiet, and almost too unassuming to be a game-changer. But if you’re working in robotics, automation, or fluid power systems, that little motor might just be your secret weapon.

In this post, you’re going to explore how small servo motors are transforming industries—from precision manufacturing to energy-efficient hydraulics—and why your next system upgrade might be a lot more compact than you imagined. Whether you're designing a robotic arm or looking for smarter ways to power a hydraulic motor pump, this read will equip you with real insights and modern thinking.

Let’s dive in.

1. The Big Potential in a Small Servo Motor

Imagine needing precise control in a small space—like a robotic gripper, a micro CNC machine, or a medical automation device. That’s where the small servo motor thrives. These motors offer:

Compact size

High torque-to-weight ratio

Precise control over motion, speed, and position

What’s fascinating is how industries that once relied on bulky systems are now turning to miniaturized alternatives. This isn’t just about saving space—it’s about smarter control and energy savings.

If you’ve dealt with complex motion systems before, you know the headaches that come from bulky motors that lack finesse. With a small servo motor, those problems shrink, quite literally.

2. The Rise of Compact Power: How It’s Reshaping Automation

Let’s say you’re developing a lightweight industrial robot or building a portable device that requires high accuracy. Large motors just won’t cut it.

That’s why the demand for small servo motors has spiked in areas like:

Electronics assembly

Medical robotics

Portable packaging systems

Drones and inspection bots

Even in the hydraulic world—traditionally dominated by size and force—you’re now seeing a shift. Smart engineers are integrating small servo motors with small hydraulic pumps to get the best of both worlds: precision and power.

In companies like THM Huade, engineers often explore such hybrid solutions—melding servo control with hydraulics to meet modern demands without compromising on reliability.

3. Integrating Small Servo Motors with Small Hydraulic Pumps

Now, here’s where things get interesting.

You’ve got a small servo motor on one hand, and a small hydraulic pump on the other. Together, they create a system that is:

Energy-efficient (thanks to variable-speed control)

Space-saving (essential for mobile equipment)

Exceptionally responsive (ideal for dynamic load changes)

This is particularly valuable in applications like:

Injection molding machines

Servo-hydraulic presses

Construction machinery

AGVs (Automated Guided Vehicles)

When you combine electronic precision with hydraulic muscle, you're no longer choosing between finesse and force—you get both. This approach is at the heart of innovation at forward-thinking motion companies like THM Huade.

4. What Makes These Setups So Valuable?

Let’s walk through the benefits from your perspective as a system designer, plant operator, or maintenance engineer.

✅ Size Matters (In a Good Way)

A small servo motor can fit into tight spaces. When integrated with compact hydraulic components, you reduce machine footprints—perfect for OEMs targeting mobile or modular designs.

✅ Reduced Energy Waste

Older hydraulic systems often run continuously. With servo-driven pumps, you only power what you need. The result? Lower energy bills and reduced system heat.

✅ Precise Feedback Loops

Need to hold a load mid-cycle or change directions quickly? Servo control offers real-time feedback—critical in applications like testing systems or forming machines.

✅ Simplified System Architecture

Modern industrial servo drives support multi-protocol control (EtherCAT, CANopen, etc.), which makes integration with PLCs and IoT platforms smoother.

This is especially true in THM Huade’s servo-hydraulic system designs, where precision, modularity, and performance converge.

5. Looking Ahead: What the Future Holds

The trend is clear—systems are getting smarter, smaller, and more connected. You’ll see more machines built with embedded intelligence, real-time diagnostics, and plug-and-play modules.

In that context, small servo motors aren’t just filling a niche—they’re setting the stage for the next wave of industrial automation. Paired with compact hydraulic systems and sophisticated industrial servo drives, the applications are endless.

From flexible manufacturing lines to autonomous maintenance systems, the drive toward smarter machines is gaining momentum. Companies like THM Huade are responding by designing systems that are adaptable, efficient, and intelligent at every scale.

Conclusion:

You started this read wondering what role a small servo motor could play in your big-picture system. Now you know—it could be the very component that simplifies your design, cuts your energy usage, and enhances your performance.

And when paired with modern hydraulic motor pumps or industrial servo drives, the possibilities are even broader. These compact solutions are no longer just for lightweight robots or medical tools—they're reshaping the future of industrial control and motion systems across the board.

If you're in the research or design phase of your next industrial project, take a closer look at the power of small servo motors and servo-hydraulic systems. Explore how compact control could be the smartest move you make this year.

#SmallServoMotor#IndustrialAutomation#SmartHydraulics#ServoDriveTechnology#MotionControl#CompactPower#ServoHydraulicSystem#HydraulicInnovation#FutureOfIndustry#THMHuade

0 notes

Text

Precision in Every Spark: Why CNC EDM Die Sinking Machines Are Shaping the Future of Tooling

In today’s fast-paced manufacturing industry, the demand for high-precision components and intricate tooling is ever-increasing. As traditional machining methods struggle to meet the needs of complex geometries and tough materials, a new hero emerges—the CNC EDM Die Sinking Machine. Known for its ability to machine hard metals with extreme accuracy, this technology is rapidly becoming a cornerstone in mold and die-making industries around the world.

In this blog, we’ll explore what a CNC EDM Die Sinking Machine is, how it works, and why it’s a smart investment for manufacturers seeking precision, efficiency, and reliability.

What is a CNC EDM Die Sinking Machine?

EDM stands for Electrical Discharge Machining, a non-traditional process that uses electrical sparks to erode material from a workpiece. Unlike traditional cutting tools, EDM doesn’t involve physical contact. Instead, it uses a controlled electrical discharge between an electrode and the workpiece, both submerged in a dielectric fluid.

The CNC EDM Die Sinking Machine, also known as a sinker EDM or ram EDM, is a specialized variant of this process. It uses pre-shaped electrodes to “sink” cavities or intricate shapes into metal components, making it especially useful in the creation of molds, dies, and precision parts.

With the integration of Computer Numerical Control (CNC), these machines offer unmatched accuracy, repeatability, and automation.

How Does It Work?

The CNC EDM die sinking process involves:

Electrode Creation: A copper or graphite electrode is shaped according to the desired cavity or feature.

Workpiece Setup: The workpiece, usually made of hard metal like tool steel, is placed in the dielectric tank.

Machining: Controlled electrical discharges remove metal from the workpiece to form the required shape.

Flushing: The dielectric fluid helps remove debris and cools the machining area.

CNC Control: All operations are automated and optimized via a CNC program for high consistency.

This method allows manufacturers to create highly detailed, complex, and precise shapes that would be difficult—or even impossible—with traditional machining.

Key Benefits of Using a CNC EDM Die Sinking Machine

🎯 Precision and Accuracy

With tolerance levels as tight as ±2 microns, CNC EDM Die Sinking Machines deliver precise results essential for mold and die manufacturing, aerospace parts, medical tools, and more.

⚙️ Ability to Machine Hard Materials

Materials like titanium, hardened steel, carbide, and Inconel can be effortlessly machined without tool wear or thermal damage.

🔁 Repeatability

Thanks to CNC automation, complex parts can be produced repeatedly with consistent quality and finish.

🌀 Complex Geometries

Intricate cavities, fine details, undercuts, and sharp internal corners are easy to create—something nearly impossible with conventional milling.

🧼 Smooth Surface Finish

EDM machines provide a naturally smooth finish, often eliminating the need for secondary polishing processes.

Applications Across Industries

A CNC EDM Die Sinking Machine is a go-to solution for multiple industries that demand intricate, high-strength, and precise components:

Tool & Die Manufacturing: For injection molds, stamping dies, and casting tools.

Aerospace & Defense: For high-stress parts made from exotic alloys.

Automotive Industry: Precision engine components and mold tooling.

Medical Equipment: Surgical instruments and implants with tight tolerances.

Electronics: Micro molds and connectors.

Choosing the Right CNC EDM Die Sinking Machine

When investing in a CNC EDM machine, consider the following factors:

✅ Machine Size & Work Area: Choose a model that suits your workpiece size and production volume.

✅ Electrode Compatibility: Ensure it supports your preferred electrode material (graphite or copper).

✅ Control System: Look for intuitive software with advanced machining strategies and automation.

✅ Build Quality: A rigid frame and reliable components ensure stability and durability.

✅ After-Sales Support: Partner with a supplier that offers maintenance, training, and spare parts.

Future of EDM: Smart, Automated, and Connected

With Industry 4.0 taking hold, modern CNC EDM Die Sinking Machines are integrating IoT capabilities, real-time monitoring, and data-driven optimization. Predictive maintenance, automation compatibility, and AI-driven cutting strategies are helping businesses reduce downtime and boost productivity.

As the demand for complex, high-performance parts grows, EDM technology continues to evolve—offering solutions that traditional machining cannot match.

0 notes

Text

Technical Breakthrough in Small-Batch Custom Production of Rocker Switches: SMED Flexible Manufacturing and Full-Chain Collaboration Strategies

Introduction

In the industrial equipment manufacturing sector, rocker switches, as critical human-machine interface components, are experiencing surging demand for customization due to the rise of niche markets. Differentiated scenarios in industries such as medical devices, new energy charging stations, and smart home systems have spawned numerous "micro-orders" below 10,000 pieces. However, traditional rocker switch manufacturers, long reliant on mass production models, face significant challenges with small-batch orders, including "high mold-change costs, prolonged delivery cycles, and quality fluctuations." This article focuses on Single-Minute Exchange of Die (SMED) technology, integrating digital process design, modular supply chains, and intelligent quality control to systematically deconstruct the technical pathways for small-batch customization. Practical case studies validate its feasibility.

1. Industry Pain Points in Small-Batch Customization and the Value of SMED

1.1 Deep Analysis of Industry Challenges

Excessive Mold-Change Cost Ratios: Traditional injection mold switching takes 2–4 hours. For an order of 5,000 pieces, per-unit mold-change costs can reach ¥0.8–1.2, accounting for 15%–25% of total costs.

Unpredictable Delivery Times: Mold debugging and first-article inspections extend standard 100-hour lead times to over 200 hours for small batches.

Lack of Production Flexibility: Single production lines struggle to handle parallel demands for multi-material (e.g., PA66 vs. PBT) and multi-structural (e.g., IP65 vs. IP67 sealing) configurations.

1.2 Core Value of SMED Technology

SMED (Single-Minute Exchange of Die) reduces mold-change times to under 10 minutes through standardized workflows, separation of internal/external tasks, and parallel operations. Its value grows exponentially in small-batch scenarios:

Cost Reduction: Mold-change time decreases by 80%, lowering per-unit costs to below ¥0.2.

Shorter Lead Times: Production line efficiency improves, enabling 72-hour delivery for 5,000-piece orders.

Enhanced Flexibility: Supports multi-batch daily production (e.g., 16mm red LED-backlit switches and 19mm non-illuminated metal buttons in one order).

2. Implementation of SMED in Rocker Switch Production

2.1 Mold and Equipment Adaptations

Modular Mold Design: Standardize positioning systems, cooling channels, and ejection mechanisms.Case Study: A manufacturer developed "quick-release alignment pins" for medical device switches, replacing threaded locks with taper fits to reduce mold disassembly time from 45 to 8 minutes.

Preheating/Precooling Systems: Preheat molds to 80°C (optimal for PBT injection) during external preparation to eliminate downtime.

Multi-Purpose Fixtures: Use magnetic fixtures compatible with molds of varying sizes to minimize adjustments.

2.2 Process Standardization and Parallelization

Externalizing Internal Tasks:Complete mold cleaning and lubrication before changeovers.Case Study: "Mold pre-loading carts" prepare the next batch’s molds during ongoing production.

Parallel Operations:Robotic arms remove molds while operators scan QR codes to input new parameters into MES systems.Data Support: RFID tags cut mold-data transmission time from 15 minutes to 20 seconds.

2.3 Workforce Training and Organizational Upgrades

Skill Matrix Development: Train multi-skilled workers in injection molding, electrical testing, and SMED.

"Swarm" Collaboration: Three-person teams handle mechanical disassembly, parameter setup, and initial QC, reducing manual intervention to 3 minutes.

3. Beyond SMED: Full-Chain Collaboration Strategies

3.1 Digital Process Design (DFM)

Parametric Modeling: Use CAD software to predefine mounting hole spacing, contact gaps, and waterproof groove depth, accelerating 3D model generation.Case Study: A customer requested anti-mishap bumps on switch panels. Engineers modified bump height (0.5mm→1.2mm) using templates, slashing design time from 3 days to 4 hours.

Simulation Validation: Moldflow software simulates melt flow and cooling deformations, reducing trial runs.

3.2 Modular Supply Chain Agility

"Lego-Style" Contact Component Inventory: Standardize silver contacts (AgNi), copper bases, and springs for rapid assembly.Cost Comparison: Traditional custom molds cost ~¥20,000; modular assembly lowers this to ¥5,000.

Regional Micro-Warehouses: Stock universal housings and PCBs in Yangtze River Delta and Pearl Delta hubs for 48-hour delivery.

3.3 Intelligent Quality Control

Machine Vision Inspection: High-resolution cameras check contact flatness (±0.02mm) and housing burrs (≤0.1mm).Data Improvement: AI-powered inspection cut defect rates from 500ppm to 80ppm.

Blockchain Traceability: Assign unique IDs to track materials, process parameters, and test data for rapid fault diagnosis.

4. Case Study: Customization Success for an Industrial Equipment Manufacturer

4.1 Requirements

5,000 high-temperature-resistant rocker switches:Material: PA66 + 30% glass fiber (UL94 V-0).Contacts: Double-break AgSnO₂.IP67 waterproofing (96-hour salt spray test).Lead time: 7 days.

4.2 Implementation

SMED Optimization:Mold-change time reduced from 120 to 18 minutes.Preloaded silicone gaskets and AgSnO₂ contacts.

Modular Assembly:Used PA66 housings from stock, switching only to glass-fiber-reinforced material.Pre-assembled "contact-spring" modules simplified assembly.

Digital QC:Infrared thermography ensured ±5°C mold temperature uniformity.Automated testers simulated 10,000-cycle durability.

4.3 Results

Lead Time: Reduced to 5 days.

Cost: Per-unit cost down 22%.

Customer Feedback: 99.3% first-pass yield, 80% reorder rate.

5. Challenges and Long-Term Competitiveness

5.1 Technical Challenges

High Initial Investment: SMED requires mold standardization and smart equipment (¥500k–1M).Solution: Government subsidies (30–50% coverage) and installment payments.

Multi-Product Wear: Frequent mold changes accelerate equipment wear.Solution: Predictive health monitoring (PHM) cuts downtime.

5.2 Organizational Challenges

Resistance to Change: Workforce hesitancy toward flexible production.Solution: Efficiency-based bonuses tied to mold-change time reductions.

Data Silos: Disconnected R&D, production, and supply chain teams.Solution: PLM platforms enable real-time data sharing.

5.3 Market Challenges

Client Education: SMEs prefer low-cost standard products.Solution: Offer "free design simulation + pay-per-production" models.

6. Conclusion: The Future of Small-Batch Customization

Under Industry 4.0 and personalized demand, rocker switch competition shifts from "scale-driven costs" to "agile response." SMED-enabled minute-level mold changes, modular supply chains, and digital QC transform "cost disadvantages" into "service premiums." With 3D-printed molds and AI scheduling, sub-10,000pcs "micro-orders" will drive profitability.

en.dghongju.com

0 notes

Text

Protolabs Tolerances: A Comprehensive Guide

Protolabs is a prominent digital manufacturing business focusing on low-volume production and quick prototyping. It is renowned for its accuracy and fast turnaround times, and it provides tight tolerances to satisfy various manufacturing requirements. This article examines Protolabs' tolerances, their uses, and the variables influencing accuracy.

What Are Tolerances?

Tolerances define the permissible range of a produced part's dimensions. They guarantee that components fit and work correctly in assemblies. Tolerances are essential in sectors where accuracy is crucial, such as aerospace, automotive, and medical devices.

Standard Tolerances for Protolabs

Various tolerances are offered by Protolabs based on the manufacturing process:

Tolerances in CNC Machining

Linear Dimensions: The typical linear dimensions are ±0.005 inches (±0.13 mm).

Hole Diameters: ±0.002 inches (±0.05 mm) is the hole diameter.

Surface Finishes: The standard finish is 63–125 µin Ra (micro inches).

Tolerances for Injection Molding

Components made of plastic: ±0.13 mm per 25.4 mm (±0.005 inches per inch).

Tool Tolerances: Up to ±0.002 inches (±0.05 mm) for essential regions.

Tolerances in 3D printing

Stereolithography (SLA): ±0.002 inches per inch plus ±0.005 inches (±0.13 mm) for the first inch.

Laser Sintering (SLS) with selectivity: ±0.010 inches (±0.25 mm).

Tolerances for Sheet Metal Fabrication

Cutting and Bending: ± 0.25 mm (0.010 inches).

Position of the Hole: ±0.020 inches (±0.50 mm).

Factors Influencing Protolabs Tolerances

Several factors influences the tolerances that Protolabs can reach:

Material Selection: The rate at which various materials expand and compress affects accuracy.

Design Complexity: To account for manufacturing difficulties, intricate designs may call for looser tolerances.

Manufacturing Process: Compared to 3D printing, CNC machining usually produces tighter tolerances.

Part Size and Geometry: More significant parts frequently call for wider tolerances because of tool deflection and thermal expansion.

Surface Finish Requirements: Finer finishes need more manufacturing steps, which may affect tolerances.

Protolabs Tolerance Applications

Tolerances from Protolabs support a variety of sectors and uses, such as:

Aerospace Components: High-precision components such as turbine blades and housings are examples of aerospace components.

Medical Devices: Medical devices include implants and surgical instruments that need to be extremely precise.

Automotive Prototypes: Engine parts and functional testing components are examples of automotive prototypes.

Consumer Products: Consumer goods include functional enclosures, connectors, and casings.

Why Choose Protolabs for Tolerances?

Fast Turnaround: Accuracy is maintained while production proceeds quickly.

Versatility: Support for sheet metal production, injection moulding, 3D printing, and CNC machining.

Quality Assurance: Strict quality control procedures are used to ensure accuracy in quality assurance.

Material Options: Numerous metals, polymers, and composites are available as material options.

FAQs

What is the typical tolerance for CNC machining at Protolabs?

For linear dimensions, the standard tolerance is ±0.005 inches (±0.13 mm), while for holes, it is ±0.002 inches (±0.05 mm).

Can Protolabs produce custom designs with stricter tolerances?

Unique requests allow tighter tolerances depending on the material and procedure.

What are the differences in tolerances between Protolabs' 3D printing and CNC machining processes?

The tolerances for 3D printing vary depending on the technique, with SLS at ±0.010 inches, but CNC machining offers tighter tolerances (±0.005 inches).

Which industries gain the most from tolerances offered by Protolabs?

The exact tolerances offered by Protolabs are advantageous to sectors such as consumer electronics, automobiles, medical devices, and aerospace.

Conclusion

Protolabs are an excellent option for quick prototyping and production since they provide consistent tolerances across various manufacturing processes. Engineers and designers can produce high-quality, practical products that satisfy industry standards by comprehending the tolerances they offer. Protolabs offers solutions to meet your needs, whether you require functional flexibility for prototypes or strict aerospace standards.

0 notes

Text

Common Injection Molding Processes

Injection molding is a plastic processing technology widely used in the manufacturing industry, and common types of injection molding include the following:

Conventional injection molding: Conventional injection molding refers to the heating and melting of plastic materials into the mold, cooling to obtain a variety of different shapes of plastic products. Conventional injection molding is suitable for the production of various specifications, shapes and materials of plastic products, such as plastic tableware, home appliance shell and so on.

Two-color injection molding: Two-color injection molding refers to the injection molding of two different colors or materials of plastic materials in the same mold, so as to form different colors or materials on the same product. Two-color injection molding is suitable for the production of complex plastic products requiring multi-color or multi-material combinations, such as automotive interiors.

High-speed injection molding: High-speed injection molding refers to the use of high-speed injection, high-pressure injection and other technologies in the injection process, so as to achieve rapid production of plastic products. High-speed injection molding is suitable for the production of large volume, simple structure of plastic products, such as bottle caps.

Precision injection molding: Precision injection molding refers to the use of high-precision molds and high-precision injection machines in the injection process, so as to achieve high-precision, high-quality plastic products production. Precision injection molding is suitable for the production of precision, complex, high-quality plastic products, such as mobile phone shells, optical lenses, etc.

Pneumatic injection molding: Pneumatic injection molding refers to the use of air pressure to drive plastic materials into the mold during the injection process, so as to achieve efficient and high-quality plastic product production. Pneumatic injection molding is suitable for the production of high-volume, thin-wall, high-transparency plastic products, such as plastic cups, plastic glass and so on.

Large injection molding: Large injection molding refers to the production of large size, large weight and large volume plastic products through large injection molding machines and large molds, such as auto parts and engineering plastic products.

Thin-wall injection molding: Thin-wall injection molding refers to the production of thin-wall plastic products with wall thickness below 0.5mm through high-speed injection molding and high-precision molds, such as plastic containers, boxes, etc.

Micro-injection molding: Micro-injection molding refers to the production of micro-size plastic products through micro-injection molding machines and micro-molds, such as micro-parts, micro-devices, etc.

Composite injection molding: Composite injection molding refers to the injection of plastic materials of different materials into the same mold, thereby forming plastic products of composite materials, such as plastic metal composite products, plastic rubber composite products, etc.

Hot runner injection molding: Hot runner injection molding refers to the setting of heating elements in the mold, by controlling the temperature and position of the heating elements, to achieve the precise control of plastic materials into the mold, so as to produce high-quality, high-precision plastic products.

Injection molding is a very flexible and efficient plastic processing technology that is suitable for the production of a wide variety of plastic products. With the continuous progress of technology and the constant change of market demand, injection molding technology is also constantly developing and innovating, and the types and application fields of injection molding are also constantly expanding and deepening.

0 notes

Text

Exploring the frontiers of vibration damping and energy absorption technology: Uncovering the differences and uses of leading material technologies.

The key to industrial progress is the development of material technology, but vibration and noise all the time filled with industrial life, restricting the development of enterprises, affecting industrial progress.

There are some excellent performance vibration absorbing materials on the market, due to good cushioning, abrasion resistance, fatigue resistance or adjustable widely used, where different material properties corresponding to different areas, the following list of common or quite potential vibration absorbing materials in the sports and industrial industries.

Rubber is a natural or synthetic polymer elastomer with good elasticity and fatigue resistance, and is one of the most widely used shock absorbing materials.

01 Characteristics

Good elasticity: able to deform in a wide range and quickly return to its original state.Adjustability: can be customized in various sizes according to demand.

Abrasion resistance: good resistance to friction and abrasion.

02 Advantages

Low cost: natural rubber is widely available and synthetic rubber is easier to prepare.

Easy to process: can be processed into various shapes through injection molding and extrusion

03 Uses

Automotive industry: for shock absorbers, suspension systems, etc.

Sports equipment: such as sports shoes, rackets, etc.

Automotive Suspension Springs

According to statistics, the global revenue of rubber shock pads is approximately $17,010 million in 2021 and is expected to reach $19,550 million in 2028.

Polymer Materials

Polymer materials, also known as polymer materials, is a polymer compound as a substrate, and then equipped with other additives (additives) composed of materials, according to the application of functional classification can be divided into general-purpose polymer materials, special polymer materials and functional polymer materials of three major categories.

01 Characteristics

Fatigue resistance: can be high-speed collision or multiple impact forces, can maintain stable performance.

Adjustability: by changing the molecular structure and crosslinking density, can optimize its performance.

Stability: good resistance to temperature and chemical corrosion.

2 Advantage

Variety of properties: material properties can be customized according to demand.

Good processing performance: it can be processed into complex shapes through a variety of processes.

Lightweight: Lightweight design of structure can be realized.

03 Uses

Aerospace: used in aircraft and spacecraft, the return chamber of the shock absorption system.

Electronic equipment: such as cell phones, laptop computers, anti-vibration protection

Sports: such as extreme sports protective equipment, advanced sports shoes, etc.

Industrial shock absorption: used in large machine tools, mechanical equipment, air conditioning compressors, production equipment and other vibration sources with vibration absorption protection.

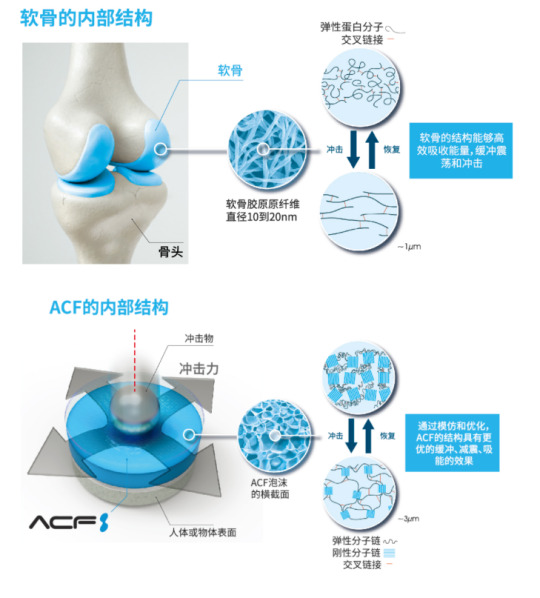

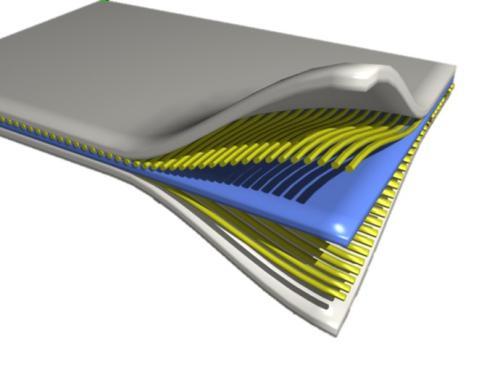

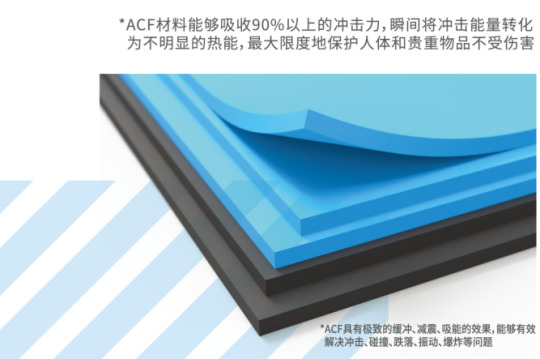

ACF material (full name "ACF artificial cartilage material") is an advanced invention in China in the past 10 years, belonging to the polymer material category of bionic energy-absorbing materials, its technical principle is to adjust and control its micro-nanometer structure by imitating the human articular cartilage, so that it is infinitely close to the articular cartilage structure, with excellent cushioning and energy absorption, and in addition, the ACF material has a good adjustability and stability, and it is the new rising star of the management and control in the scenarios of sports, industry, automobile and other impact protection, vibration, noise, sealing and so on.

Composites are new materials made by combining two or more materials with different properties through physical or chemical methods.

01 Characteristics

Strong comprehensive performance: the advantages of various materials can be utilized comprehensively, such as high strength, good shock absorption, etc.

Strong designability: the proportion and arrangement of each component can be adjusted according to the demand.

02 Advantage

High performance: combines the advantages of various materials.

Lightweight: Lightweight structural design is possible.

03 Uses

Automotive industry: used for lightweighting and vibration damping of body structure, chassis and other components.

Sports equipment: such as golf clubs, bicycle frames, etc.

Automotive Suspension Springs

The share of composites in the automotive industry is increasing year by year, and according to data disclosed by Lucintel, it is expected that the share of lightweight materials used in automobiles will exceed 47% by 2025.

Nanomaterials

Nanomaterials are materials that measure between 1 nanometer and 100 nanometers in at least one dimension.

01 Characteristics

Large specific surface area: nanomaterials have a large ratio of surface atoms to total atoms, giving them unique physical and chemical properties.

High interfacial activity: easy to combine with other materials to form composites with high interfacial activity.

02 Advantages

High performance: excellent performance in vibration damping and energy absorption.

Versatility: nanomaterials are available in a wide variety of types to meet different application needs.

03 Uses

Aerospace: used in shock absorption systems for airplanes and spaceships, return bins.

Sports: such as advanced sports shoes, protective equipment, etc.

The use of nanomaterials in vibration damping, although currently a relatively small percentage of applications, is growing rapidly and is expected to grow significantly over the next few years.

Explore the frontiers in the field of vibration damping and energy absorption technology: these vibration damping and energy absorption materials have their own unique characteristics and are widely used in a number of fields. As a representative of polymer science and technology materials, ACF artificial cartilage materials of Linzhi Technology Group have continuously improved their vibration-damping performance through continuous research and innovation, providing important technical support in the fields of sports, electronics and semiconductors, industrial vibration-damping, automotive, aerospace and rail transportation, and so on. In the future, with the continuous progress of technology, we believe that ACF artificial cartilage material will show its unique advantages in more fields and make greater contribution to the development of society.

400-6543-699

www.acf.com

0 notes

Text

0 notes

Photo

Are you looking for DIN 2738 ( P20 + Ni) Steels in India ? Have you understand the advantages of using DIN 2738 Steel (P20 +Ni)?

Virat Special Steels announced as the largest stockiest of DIN 2738 ( P20 + Ni) which is supposed to be an upgraded version of the plastic mold steel 2311. Just like plastic mold steel 2311, DIN 2738 is also supplied in a pre hardened condition. The most specific use of DIN 2738 is that for the purpose of making plastic injection die molds.

Besides the fact that DIN 2738 is supplied in pre hardened condition, some of the other important characteristics of this steel are s follows:

In the state, when the same is supplied to the customers, the level of hardness of the steel is at 280-320 HB. The nickel content in the steel increases by 0.8% – 1.5% on further hardening.

This steel is micro alloyed. The best characteristic of this steel, which makes it perfect for the making of plastic injection die molds, is the fact that it is very good in machining. As a result of this, it becomes absolutely suitable for various purposes like Texturing, polishing of the outsides of various products, provides excellent corrosion resistance to the products, etc.

Other than the making of plastic injection die molds, there are many other applications of this steel. Some of those applications have been discussed below:

This steel can be used for making dies for many different industries like the automotive industry, domestic goods industry, etc.

Plastic molds of various sizes, big as well as small, can be easily made from the use of DIN 1.2738 (AISI P20).

It is useful in the manufacturing of numerous dies and products like high finishing plastic die, Boaster plates used in presses, shoe / Sow blocks and die hammers, which are used for the making of drop hammers, press cassetes, forging dies, Upsetter blockers, and various other dies and molds made for different plastic products.

This steel has a very high demand in the market for the simple reason that this modern and upgraded version of plastic mold steel 2311, offers increased alloy element, which not only increases its hardness, but it also provides extra life. Thus, the parts manufactured through the use of this steel last for a much longer duration.

At the same time, the quality of polishing that is done on this steel is also very good. The hardness present in the steel is also uniform throughout the product. Almost all Leading steel company like Virat Special Steels is Stocking and supplying this product and the demand for the same is increasing on a constant basis.

Virat Special Steels is the largest stockist and supplier of P20 + Ni and P20 tool steel in flat, square and round bars. We provide steel in all sizes as your requirements. P20 Steels is available in flat, square and round shape.

Consult our team who will assist you for the PlasticMouldSteels query.

Learn more : https://www.viratsteels.com/plastic-mould-steel.html

Any queries feel free to contact us : [email protected] or on mobile number +91-9814021775

#viratsteels#plasticmouldsteels#metalworking#metallurgy#iso9001#engineering#steel#alloy steel#cold work steel#die steels#high speed steel#toolsteel#toolsteelsupplier#viratsteelindia#p20#p20ni#plasticmould#diesteel#nipponsteel#mouldsteelstockist#gurgaon#ludhiana#pune#india

2 notes

·

View notes

Text

How Are Colored Contact Lenses Made?

The contact lens is a device worn in the eye to correct vision, although some people wear colored contact lenses to enhance or change their eye color. The thin plastic lens floats on a film of tears directly over the cornea. For some forms of eye disease, contact lenses correct vision better than conventional spectacles. Many people prefer contact lenses over glasses for cosmetic reasons, and active sports enthusiasts prefer contact lens because of the freedom it provides them. There are basically three types of lenses: soft, hard, and gas-permeable. Soft contact lenses are usually more comfortable to wear, but they also tear more easily than hard contact lenses. Hard lenses also tend to "pop" out more frequently. Gas-permeable lenses are a compromise between the hard and soft, allowing greater comfort than hard lenses but less chance of tearing than soft lenses. Contacts are usually worn during the day and taken out every night for cleaning. Extended-wear lenses allow users to leave in their contacts for longer periods of time, even when they're sleeping. More recently, one-a-day contact lenses are gaining popularity among lens wearers. These contacts are worn for only one day and thrown away, eliminating the hassle of cleaning them every night.

Raw Materials

The raw material for contact lenses is a plastic polymer. (A polymer is a blend of materials created by linking the molecules of different chemical substances.) Hard contact lenses are made of some variant of polymethyl methacrylate (PMMA). Soft contact lenses are made of a polymer such as poly hydroxyethyl methacrylate (pHEMA) that has hydrophilic qualities, that is, it can soak up water and still retain its shape and optic functions. The science of lens material is always being updated by lens manufacturers, and the specific material of any contact lens may differ depending on the maker.

The Manufacturing Process

Contact lenses may be produced by cutting a blank on a lathe, or by a molding process. The forming of the lens involves shaping the plastic into specified curvatures. The major curves of the lens are named the central anterior curve (CAC) and the central posterior curve (CPC). The CAC refers to the overall curve of the side of the lens that faces out. This outer contour produces the correct refractive change to fit the patient's visual needs. The CPC is the concave inner side of the lens. This conforms to the measurements of the patient's eye. Usually these two curves are formed first, and the lens is then called semi-finished. The lens is deemed finished when peripheral and intermediate curves are formed, and the edge is shaped.

Molding method

1 Molding the lens can be carried out in several different ways. The lenses first developed in Prague were spin-cast. Three different fluids were poured into open rotating molds. The outside curvature of the lens was shaped by the mold, and the inside curvature was formed according to the speed of the rotation of the mold. The centrifugal force of the spinning mold led to the polymerization of the fluids so that the molecular chains linked to form the required hydrophilic plastic. A more reliable mass-production Contact Lens method is injection molding. In injection molding, the molten plastic is injected into the mold under pressure. Then the lens is removed from the mold and cooled. The lens is then finished on a lathe. It is also possible to produce lenses entirely through molding, that is, they need no lathe cutting. This is a recent development, made possible through highly automated, computer controlled mold production.

Lathe process

2 The initial forming of the lens can also be done by cutting on a lathe. First a blank is made. The blank is a circle only slightly larger than the size of the finished lens. This can be cut from a plastic rod, or stamped from a plastic sheet. Next the blank is fastened to a steel button with a drop of molten wax. The button is then centered on a lathe, which begins to spin at high speed. A cutting tool, which may be a diamond or a laser, makes concave cuts in the blank to form the CPC. Indicators on the lathe measure the depth of the cuts to guide the lens operator.

The button holding the blank is next moved to a lapping machine. The lapping machine holds the blank against a lapper, which is a revolving disk coated with an abrasive compound. The shape of the lapper matches the CPC of the lens. The lapping machine spins the blank in one direction, and the lapper in the other. It also moves the blank in a small figure eight motion. The abrasion polishes the lens surface.

The polished lens is then mounted on a steel shaft called an arbor. The end of the arbor has been ground to match the CPC so the lens will fit on the shaft. The arbor is installed in a lathe, and the operator makes convex cuts in the lens to form the other major curve, the CAC. Now this side of the lens is polished, and the lapper is modified to fit the convex CAC. When this second side of the lens is polished, the lens is considered semi-finished.

Finishing

3 The contact lens requires several more curves to be ground before the lens will fit exactly on the patient's eye. The final curves are the peripheral anterior and posterior curves and the intermediate anterior and posterior curves, which govern the shape of the lens nearest and next-nearest the edge. The lens is mounted on an arbor again by suction or with double-sided tape. The arbor is installed in the lathe or grinding machine. These shallower cuts may be ground with emery paper or cut with a razor blade. The diameter of the lens may also be trimmed at this time.

Quality control

4 Quality control is very important for contact lenses, since they are medical devices and they must be custom fit. The lenses are inspected after each stage of the manufacturing process. The lenses are examined under magnification for anomalies. They are also measured by means of a shadow graph. A magnified shadow of the lens is cast on a screen imprinted with a graph for measuring diameter and curvature. Any errors in the lens shape show up in the shadow. This process may be automatically performed by computer.

Packaging

5 After the lens has passed inspection, it is sterilized. Lens are boiled in a mixture of water and salt for several hours to soften the lens. Next, the lens are packaged. Standard packaging for lenses is a glass vial, filled with a saline solution and stoppered with rubber or metal. The hydrophilic material of soft contact lenses soaks up the saline solution, which is similar to human tears, and becomes soft and pliable. The lenses in this state are ready to wear.

The Future

The material for contact lenses is the subject of much research. Scientists are investigating different chemical recipes that may give plastic more desirable characteristics. One polymer currently being researched is a silicon-oxygen compound called siloxane. Siloxane forms a thin, flexible film and admits oxygen through to the eye 25 times better than current standard soft lenses. There are disadvantages to this compound, however: siloxane does not wet easily and it attracts lipids (fats) to its surface, causing it to cloud. Researchers have found a way to add flourine molecules to the siloxane compound, causing the material to resist lipids. Then they chemically attach a wetting agent, which changes its molecular shape when boiled in a saline solution, so that the material can soak up water like traditional soft lens. This material may ultimately lead to extended-wear contacts that can be worn for weeks at a time.

Researchers are also investigating new polymers that can be used for sclera lenses. For most people, comeal lenses are the norm, but the large sclera lenses are useful for patients with severely damaged corneas. Depending on the eye problem, some patients cannot regain their sight without a corneal transplant, but sclera lenses may help patients avoid eye surgery. Sclera lenses rest on the white part of the eye and form a vault over the cornea itself. This space over the cornea is filled with artificial tears, which serve to smooth out the cornea's damaged surface. In the past, sclera lenses have been uncomfortable because they do not allow enough oxygen to the eye, but investigations into new materials are focusing on more oxygen-permeable lenses.

Material for oxygen-permeable lenses has also been experimented on the space shuttle Endeavour. The designers of the experiment believe that micro-gravity conditions would promote a lens material that repels debris better and processes oxygen more effectively than polymers made in traditional labs. If commercially feasible, a new generation of contact lenses may be manufactured in space.

3 notes

·

View notes

Text

How Does Injection Molding Work

What is injection molding and exactly how does it work?

Injection molding in addition to extrusion rankings as one of the prime procedures for producing plastic posts. It is a quick process and is made use of to generate lots of similar products from high precision design elements to non reusable consumer goods.

The majority of thermoplastics can be refined by injection molding; one of the most usual materials used include:

Acrylonitrile-Butadiene-Styrene ABS

Nylon PA

Polycarbonate PC.

Polypropylene PP.

Injection moldings count for a substantial percentage of all plastics items from micro parts to large components such as car bumpers and wheelie bins. Virtually all fields of manufacturing use injection molded parts. The adaptability in size and shape feasible through use of this procedure has actually regularly expanded the limits of layout in plastics as well as allowed substantial substitute of conventional products thanks to light weight as well as design freedom.

How Does Injection Molding Work?

Product granules for the part is fed via a receptacle right into a warmed barrel, melted making use of heating unit bands as well as the frictional action of a reciprocating screw barrel. The plastic is after that injection through a nozzle into a mold cavity where it cools as well as hardens to the configuration of the tooth cavity. The mold device is placed on a moveable platen-- when the component has actually solidified, the platen opens up and the component is ejected out making use of ejector pins.

After an item is created, generally by a commercial designer or a designer, molds are made by a moldmaker (or toolmaker) from steel, typically either steel or light weight aluminum, and also precision-machined to form the features of the desired component.

Parts to be injection molded should be very thoroughly created to facilitate the molding process; the material used for the part, the preferred form and also functions of the component, the material of the mold, as well as the properties of the molding machine must all be considered. The flexibility of injection molding is promoted by this breadth of style factors to consider as well as opportunities.

1 note

·

View note

Text

Medical Micro Injection Molding Market Is Likely to Experience a Tremendous Growth in Near Future

Latest business intelligence report released on Global Medical Micro Injection Molding Market, covers different industry elements and growth inclinations that helps in predicting market forecast. The report allows complete assessment of current and future scenario scaling top to bottom investigation about the market size, % share of key and emerging segment, major development, and technological advancements. Also, the statistical survey elaborates detailed commentary on changing market dynamics that includes market growth drivers, roadblocks and challenges, future opportunities, and influencing trends to better understand Medical Micro Injection Molding market outlook. List of Key Players Profiled in the study includes market overview, business strategies, financials, Development activities, Market Share and SWOT analysis:

areSMC (Japan)

BMP Medical (United States)

Stamm AG (Switzerland)

MTD Micro Molding (United States)

PEXCO (United States)

Sovrin Plastics (United Kingdom)

Accumold (United States)

Mikrotech (United States)

Kamek Precision Tools (Canada)

Makuta Technics (United States) Medical Micro Injection Molding is a method by which we are able to mold medical devices or parts into miniature modules with the help of machines with contains high pressure in it. Medical microinjection molding is usually reserved for parts that weigh less than a milligram and are less than 1mm in length and is centered around medical and healthcare applications. These need much more specialized equipment in the medical device world, it’s almost the smallest parts which carry the greatest importance related to the functionality and safety of a medical device. These molds can provide an outstanding and cost-effective alternative to engineering and manufacturing medical devices used in minimally invasive surgery (MIS). Increasing healthcare sector globally will give rise to the medical micro injection molding market.

Key Market Trends: Adopting Trend of Downsizing and Nanotechnology Globally

Adoption of Micro-Optics and Microfluidics

Opportunities: Growing Automotive Industry in APAC

Growing Advancements in Health Care Departments in Developing Nations

Market Growth Drivers: High Demand from the Packaging Industry

Growing Demand from the Healthcare Industry

Challenges: Lack of Awareness Regarding Micro Molding In Developing Nations

Issue Related With High Heating and Hydraulic Pressure

The Global Medical Micro Injection Molding Market segments and Market Data Break Down by Type (PEEK, PVC, PE, Others), Application (Diagnostic Devices, Therapeutic Devices), Machine Type (Hydraulic Injection Molding Machines, All-Electric Injection Molding Machines, Hybrid Injection Molding Machines), Material Type (Plastic, Metal, Ceramic, Rubber)

Presented By

AMA Research & Media LLP

0 notes

Photo

What is a brushless DC mini water pump

I. Definition of Micro Brushless DC Mini Water Pump Brushless Mini DC water Pump refers to a machine that uses DC 4.5V ~ 24V to drive a brushless motor to run, and the brushless motor rotation drives the impeller to rotate, thereby increasing the pressure of the liquid to achieve the effect of transferring liquid. The water pump is generally composed of pump body, motor stator, shaft, bearing, rotor (magnets and impellers) and so on. There are one inlet and one outlet on the pump body, water enters from the water inlet, and exits through the outlet. Any water pump that adopts this form and in small size is called brushless DC mini water pump. With the development of all walks of life and the progress of science and technology, some customers want to make the pump smaller and lower power consumption, even portable and can be powered by DC. Therefore, miniaturization of water pumps has become an inevitable trend. II. Principle of Micro Brushless Mini DC Water Pump Micro brushless DC water pump adopts advanced magnetic drive technology, liquid through the permanent magnet rotor high-speed rotation, static seal design instead of traditional mechanical shaft seal. The liquid is completely isolated from the motor to avoid liquid leakage and improve product life and performance. The water pump has a built-in frequency conversion brushless DC motor, no need for carbon brush commutation, no mechanical friction and heat generation, low power, and small temperature rise. The brushless magnetic drive overcomes the inherent defects of the brushed motor and replaces the mechanical commutator with an electronic commutator. Therefore, the BLDC motor not only has the characteristics of good speed regulation performance of the DC motor, but also has the advantages of a simple structure of the AC motor. Reversing sparks, reliable operation and easy maintenance.There is no commutator and carbon brush wear, which reduces mechanical noise and prolongs the service life of the water pump. It is not only related to performance indicators, noise, vibration, reliability and service life, etc., but also involves the manufacturing cost of the product. At the same time, the brushless DC motor can also accurately feed back the target number of revolutions, torque, etc. Heat generation and power consumption of the motor can be suppressed by precise control. III. Characteristics of Brushless DC Mini Water Pump 1. No leakage. Using advanced magnetic drive technology, the stator part and rotor part of the water pump are completely isolated, statically sealed, and leak-free. 2. Long life. It can work continuously for 24 hours for a long time; the service life can reach more than 20,000 hours. 3. Low noise. One-piece injection molded silent rotor is adopted, with low rotor unbalance; imported high-precision ceramic shaft, imported materials and high-precision molds, high-precision control of component size and perfect fit, the noise is 5-10dBA lower than that of water pumps with the same parameters in the market. 4. High temperature resistance. Imported high-temperature food-grade plastic parts are used, which can withstand high temperatures of 100°C for a long time without cracking or deformation. 5. Complete certification. Topsflo pumps have passed multiple authoritative certifications such as NSF, FDA, WRAS, and meet food-grade safety requirements. 6. Customization. With strong research and development strength, water pump products can be customized according to the special needs of customers. IV. Application range of Brushless DC Mini Water Pump Micro brushless DC water pumps are widely used in many industries including cooling circulation system, 3D laser printer cooling, battery cooling system, hot water circulation, radiator, heater, water purifier, water dispenser, coffee machine, vending machines, water heaters, water purification humidifier, sweepers, automotive air-conditioning systems, air-conditioning drainage, automotive cooling circulation systems, cleaning equipment, computer CPU cooling circulation, bathroom equipment and many other fields. http://www.topsflo.com/news/dc-mini-water-pump.html

0 notes

Text

Micro Injection Molding Machine Market To Deliver Prominent Growth & Striking Opportunities During 2031 | Nissei Plastic Industrial Co., Limited, Engel Austria GmbH, Chen Hsong Holdings Limited, Toyo Machinery & Metal Co., Ltd.

New York, Global Micro Injection Molding Machine Market Report by Global Insight Services is the single and trusted source of information for the Micro Injection Molding Machine Market. This report provides an analysis of the market impact of the latest market disruptions such as the Russian-Ukraine War and Covid-19. The report provides a qualitative analysis of the market using various frameworks such as Porters' and PESTLE analysis. The report includes in-depth segmentation and market size data by category, product type, application, and region. The report also includes a comprehensive analysis of recent events such as key issues, trends and drivers, restraints and challenges, competitive landscape, and M&A activity in the market.

Get Access to A Free Sample Copy of Our Latest Report –https://www.globalinsightservices.com/request-sample/GIS20991/

Micro injection molding is a process in which plastic is injected into a mold at high pressure to create small, intricate parts. This process is ideal for creating parts with tight tolerances and is often used for medical, electronic, and automotive applications.

Key Players

The key players in the Micro Injection Molding Machine Market are Arburg GmbH + Co KG, Haitian International Holdings Limited, Milacron, Nissei Plastic Industrial Co., Limited, Engel Austria GmbH, Chen Hsong Holdings Limited, Toyo Machinery & Metal Co., Ltd., Husky Injection Molding Systems Ltd, Japan Steel Works Limited, and KraussMaffei Group.

Key Trends

Micro injection molding machines are becoming increasingly popular as companies look for ways to reduce the cost and complexity of manufacturing. The technology is also becoming more accessible, as the machines are becoming smaller and more affordable.

One of the key trends in micro injection molding machine technology is the development of machines that are able to handle more complex and delicate parts. This is being driven by the increasing demand for higher precision and accuracy in manufacturing.

Another trend is the development of machines that are faster and more energy-efficient. This is being driven by the need to reduce manufacturing costs and improve productivity.

Finally, there is a trend towards the development of machines that are more user-friendly and easier to operate. This is being driven by the need to reduce training time and costs, and to improve the overall efficiency of the manufacturing process.

Key Drivers

The key drivers of the market are the rising demand for miniaturization of products, the increasing demand for electric injection molding machines, and the growing adoption of Industry 4.0 technologies.

Miniaturization of products is one of the key trends in the micro injection molding machine market. This trend is driven by the increasing demand for small and compact products from various end-use industries such as healthcare, electronics, and automotive. The micro injection molding machine is ideal for the manufacturing of small and intricate products.

Electric injection molding machines are gaining popularity in the market due to their energy-efficiency and low noise operation. These machines are also easier to maintain as compared to their hydraulic and pneumatic counterparts.

The growing adoption of Industry 4.0 technologies is another major driver of the micro injection molding machine market. Industry 4.0 technologies such as the Internet of Things (IoT), big data, and artificial intelligence (AI) are helping manufacturers to optimize their production processes and achieve better quality control.

Free Customization Available –https://www.globalinsightservices.com/request-customization/GIS20991/

Market Segmentation

By Material

Plastics

Metals

Others

By Technology

Hydraulic

Electric

Hybrid

By End-use

Automotive

Consumer Goods

Packaging

Electronics

Others

By Region

North America

The U.S.

Canada

Mexico

Europe

The UK

Germany

France

Spain

Rest of Europe

The Asia Pacific

China

India

Japan

South Korea

Rest of Asia-Pacific

Rest of the World

Latin America

The Middle East

Buy Now -https://www.globalinsightservices.com/checkout/single_user/GIS20991/

Global Insight Services can help you:

A 10-year forecast to help you make strategic decisions

Deep segmentation that can be customized according to your requirements

Free consultation with the chief analyst of the report

Excel data pack included with every report purchase

Robust and transparent research methodology

About the Global Insights service:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, USA. We are committed to providing the highest quality data, analytics and tools to meet all of our clients' market research needs. With GIS, you can be assured of the quality of your results, robust and transparent research methodology, and excellent service.

Contact us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

Email: [email protected]

Website: https://www.globalinsightservices.com/

Phone: +1–833–761–1700

#Micro Injection Molding Machine Market#Micro Injection Molding Machine Market share#Micro Injection Molding Machine Market trends#Micro Injection Molding Machine Market value

0 notes