#Micro Injection Molding Machine

Explore tagged Tumblr posts

Text

#Micro Injection Molding Machine Market#Micro Injection Molding Machine#Micro Injection Molding#Injection Molding Machine#Molding Machine#Injection Molding

0 notes

Text

Micro Injection Molding Machine Market Research Insights Shared in Detailed Report

The Micro Injection Molding Machine Market was valued at USD 0.4 billion in 2023-e and will surpass USD 0.8 billion by 2030; growing at a CAGR of 9.4% during 2024 - 2030. The report focuses on estimating the current market potential in terms of the total addressable market for all the segments, sub-segments, and regions. In the process, all the high-growth and upcoming technologies were identified and analyzed to measure their impact on the current and future market.

Micro injection molding is a specialized form of injection molding that focuses on producing very small, highly detailed plastic parts. These parts typically weigh less than 1 gram and have dimensions measured in micrometers. The process involves injecting molten plastic into a mold cavity with extreme precision to achieve the desired shape and features. This technology is essential for manufacturing components that require tight tolerances and intricate geometries.

Read More about Sample Report:

Market Trends and Growth Drivers

Miniaturization in Electronics: The relentless pursuit of smaller, more powerful electronic devices has significantly driven the demand for micro injection molding machines. Components such as connectors, sensors, and micro gears used in smartphones, wearables, and other compact devices require high precision and reliability, which micro injection molding can deliver.

Advancements in Medical Devices: The medical industry is a major contributor to the growth of this market. The production of micro-sized components for minimally invasive surgical instruments, drug delivery systems, and diagnostic equipment necessitates the use of micro injection molding. The ability to produce biocompatible and high-precision parts is critical for medical applications.

Automotive Industry Innovations: As the automotive industry moves towards more sophisticated electronic systems and lightweight materials, the demand for micro-molded parts is increasing. Micro injection molding machines are used to produce connectors, sensors, and other small components that are integral to modern automotive technology.

Sustainability and Material Efficiency: The micro injection molding process is highly efficient in terms of material usage, which aligns with the growing emphasis on sustainability. The ability to produce tiny parts with minimal waste is an attractive feature for industries looking to reduce their environmental footprint.

Challenges in the Micro Injection Molding Machine Market

Despite the promising growth prospects, the micro injection molding machine market faces several challenges:

High Initial Investment: The cost of acquiring micro injection molding machines and the associated tooling can be substantial. This high initial investment may deter small and medium-sized enterprises from entering the market.

Technical Complexity: The process requires a high level of expertise and precision. Maintaining consistent quality and tolerances in micro-molded parts can be challenging, necessitating advanced technology and skilled operators.

Material Selection: Not all materials are suitable for micro injection molding. The selection of appropriate materials that meet the stringent requirements of various applications can be a complex task.

Ask for Customization Report: https://intentmarketresearch.com/ask-for-customization/micro-injection-molding-machine-market-3232.html

Future Prospects

The future of the micro injection molding machine market looks promising, with several factors likely to drive further growth:

Technological Advancements: Ongoing innovations in machine design, process control, and materials will enhance the capabilities of micro injection molding. Developments such as multi-material micro molding and the integration of automation and AI will open new avenues for this technology.

Expansion into New Applications: As industries continue to innovate, new applications for micro-molded parts will emerge. Fields such as aerospace, defense, and biotechnology are expected to adopt micro injection molding for their specialized requirements.

Global Market Expansion: The market is set to expand geographically, with growing demand in regions like Asia-Pacific, driven by the electronics and automotive industries. Increasing industrialization and technological adoption in emerging economies will contribute to market growth.

Customization and Personalization: The trend towards customization in various industries, particularly in medical devices and consumer electronics, will fuel the demand for micro injection molding machines capable of producing tailored parts.

Conclusion

The micro injection molding machine market is poised for significant growth, driven by advancements in technology, increasing demand for miniaturized components, and the pursuit of material efficiency and sustainability. While challenges remain, the industry's future prospects are bright, with ongoing innovations and expanding applications set to propel the market forward

#Micro Injection Molding Machine#Micro Injection Molding Machine Size#Micro Injection Molding Machine Trends#Micro Injection Molding Machine Outlook

0 notes

Text

0 notes

Text

vickers hardness test malaysia

Enhancing Quality Control in Manufacturing: Why Malaysian Industries Trust CMM, Optical Measuring Machines, and Hardness Testers

In Malaysia’s rapidly evolving manufacturing sector, precision and quality assurance are more crucial than ever. Whether producing automotive components, aerospace parts, or medical devices, manufacturers must meet strict international standards to remain competitive. That’s where advanced metrology equipment like CMM measuring machine Malaysia, optical measuring machines, and hardness testers play a critical role.

At the forefront of providing cutting-edge metrology solutions is Takumiprecision.com.my, a trusted name in the Malaysian precision engineering market. With a robust product portfolio that includes Rockwell hardness testers, Vickers hardness testers, and advanced coordinate and optical measuring systems, Takumi Precision empowers industries across Malaysia to achieve flawless accuracy and consistency.

The Growing Need for Precision in Malaysian Manufacturing

Malaysia has become a key player in global manufacturing, especially in electronics, automotive, and high-tech sectors. As a result, the demand for reliable quality control tools has surged. Metrology equipment ensures that every part produced meets exact dimensional and material specifications. Without it, costly errors, rejected batches, and even safety hazards could occur.

This demand has led many companies to invest in state-of-the-art measuring systems, including:

CMM Measuring Machines in Malaysia

Optical Measuring Machines in Malaysia

Hardness Testers (including Rockwell and Vickers)

Let’s take a closer look at each category and why they are essential for today’s manufacturers.

CMM Measuring Machine Malaysia – The Gold Standard of Dimensional Accuracy

A Coordinate Measuring Machine (CMM) is a precision instrument that measures the physical geometry of an object using a probe that detects discrete points. It’s the cornerstone of modern dimensional inspection, offering high accuracy and repeatability.

In Malaysia, CMM measuring machines are widely used in aerospace, defense, tool making, and medical device manufacturing. They are ideal for inspecting complex geometries, ensuring every curve and angle falls within tolerance.

Takumiprecision.com.my supplies a variety of CMM solutions ranging from manual to fully automated models. Their systems can be customized to suit both small job shops and large-scale manufacturing lines.

Key Benefits of CMM Machines in Malaysia:

Accurate measurement of 3D objects

Automated inspection processes

Integration with CAD models

Reduced human error in quality control

Optical Measuring Machine Malaysia – Fast, Non-Contact Inspection

While CMMs offer high accuracy through contact-based probing, optical measuring machines in Malaysia provide a non-contact alternative that’s both fast and highly efficient. These machines use cameras and light-based sensors to scan and measure components with intricate details and soft materials.

Optical systems are especially useful for:

Fragile or soft parts

Tiny components in electronics

Parts with reflective or dark surfaces

Takumiprecision.com.my offers advanced optical metrology solutions that combine precision with speed, ideal for high-throughput environments such as electronics and plastic injection molding. Their optical systems support 2D and 3D measurements, with high-resolution imaging for detailed surface analysis.

Advantages of Optical Measuring Machines:

Fast measurement cycle time

No wear and tear on the part

High-resolution image capture

Ideal for micro and nano components

Hardness Tester Malaysia – Ensuring Material Durability and Quality

When it comes to verifying the strength and durability of a material, a hardness tester is indispensable. In Malaysia, manufacturers rely on hardness testing equipment to ensure their products can withstand wear, pressure, and stress in real-world applications.

There are different types of hardness testing methods, but the most widely used in Malaysia are the Rockwell and Vickers hardness tests.

Rockwell Hardness Tester Malaysia – The Industrial Standard

The Rockwell hardness tester in Malaysia is the preferred choice for its simplicity and speed. It measures the depth of penetration under a specific load, giving a direct readout on hardness. It’s suitable for testing metals like steel, aluminum, and brass.

Takumiprecision.com.my provides Rockwell hardness testers with digital interfaces, automated loading systems, and easy data export features. These machines are robust, easy to operate, and deliver consistent results—making them ideal for production environments.

Why Malaysian Industries Use Rockwell Testers:

Quick and reliable hardness readings

Minimal operator training required

Suitable for flat and round specimens

High repeatability

Vickers Hardness Test Malaysia – Precision for Thin and Small Samples

The Vickers hardness test, on the other hand, is ideal for very thin materials or small precision parts. It uses a diamond-shaped indenter and a microscope to measure the impression. This method provides more detailed and accurate results, especially when measuring surface coatings or microstructures.

Vickers hardness testers in Malaysia, as offered by Takumiprecision.com.my, come equipped with automatic image analysis, powerful microscopes, and software to calculate and document results efficiently.

Applications of Vickers Hardness Test:

Coatings and thin layers

Small precision parts (watchmaking, electronics)

Research and material science

Why Choose Takumiprecision.com.my for Your Measuring Needs?

Takumiprecision.com.my is not just a supplier—they are a metrology partner. With years of experience in precision engineering, they understand the challenges Malaysian industries face. Their team offers consultation, installation, training, and after-sales support to ensure you get the most out of your investment.

What Sets Takumi Precision Apart:

Wide range of measuring and testing machines

Customized solutions for different industries

Expert support and service across Malaysia

Affordable pricing without compromising quality

0 notes

Text

Top 5 Emerging Trends in MIM Sintering Technology for 2025

Metal Injection Molding (MIM) sintering is a present process a rapid evolution, and 2025 is shaping up to be a landmark year for innovation. As industries continue to call for smaller, stronger, and more complicated components, MIM Sintering is stepping up with technological improvements that can set new requirements in production precision and performance.

Let’s take a more in-depth take a look at the 5 developments reshaping the destiny of this powerful procedure.

1. AI-Powered Process Optimization

Artificial Intelligence is reworking MIM sintering with the aid of permitting smarter, data-driven management over temperature, atmosphere, and cycle instances. Machines getting to know algorithms can now expect and adapt sintering parameters in real-time, meaning more regular part first-rate and reduced waste. With this degree of precision, producers can improve yield prices and shorten manufacturing cycles.

2. Advanced Materials for High-Performance Applications

2025 will see a surge in the use of advanced materials tailor-made for MIM tactics. From excessive-temperature superalloys to magnetic stainless steels, engineers are pushing the limits of what may be sintered. These new materials are making their way into aerospace, protection, and medical devices, in which failure isn't an option.

3. Sustainability and Energy Efficiency Initiatives

Environmental issues are using innovation in sintering furnace layout and strength intake. Low-electricity sintering techniques and recyclable binders are being developed to lessen the carbon footprint of the process. This is not just going inexperienced—it’s additionally approximately value savings and complying with global regulations, a main difficulty for Sintered Metal Manufacturers seeking to hold compliance and profitability.

4. Micro-MIM for Miniaturized Components

As products come to be smaller and smarter, micro-MIM is gaining critical traction. This fashion specializes in developing extremely small, elaborate parts with unmatched precision, specifically useful in electronics, scientific implants, and wearable tech. Expect similarly breakthroughs in tooling, feedstock components, and submit-processing strategies designed particularly for miniaturized manufacturing.

5. Hybrid Manufacturing with 3-D Printing Integration

MIM sintering is being incorporated with additive production to release hybrid production workflows. 3-D printing allows for the creation of complex green elements, which are then densified through MIM sintering. This hybrid approach gives extra layout flexibility and the capability to create formerly “not possible” geometries with mass production scalability.

Conclusion: The Future is Sintered, Smart, and Sustainable

From AI to sustainability and hybrid manufacturing, the future of MIM sintering is bright and full of potential. These rising developments are not handiest improving the performance and skills of producers but also opening doors to new programs throughout high-tech industries.

If you’re inside the commercial enterprise of precision manufacturing or factor engineering, now's the time to discover those innovations and adapt. Stay aggressive, reduce waste, and supply greater value with modern-day MIM technology.

Ready to lead the exchange?

Partner with ahead-wondering sintered steel manufacturers and start transforming your manufacturing line these days.

0 notes

Text

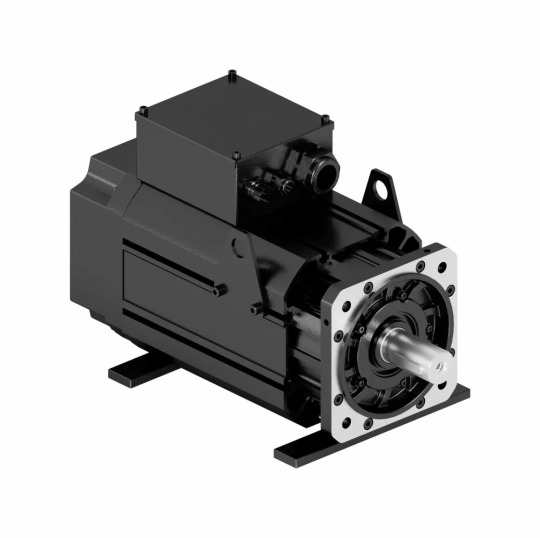

Why the World Is Turning to Small Servo Motors for Big Industrial Challenges

You’ve probably never looked twice at a small servo motor. It’s compact, quiet, and almost too unassuming to be a game-changer. But if you’re working in robotics, automation, or fluid power systems, that little motor might just be your secret weapon.

In this post, you’re going to explore how small servo motors are transforming industries—from precision manufacturing to energy-efficient hydraulics—and why your next system upgrade might be a lot more compact than you imagined. Whether you're designing a robotic arm or looking for smarter ways to power a hydraulic motor pump, this read will equip you with real insights and modern thinking.

Let’s dive in.

1. The Big Potential in a Small Servo Motor

Imagine needing precise control in a small space—like a robotic gripper, a micro CNC machine, or a medical automation device. That’s where the small servo motor thrives. These motors offer:

Compact size

High torque-to-weight ratio

Precise control over motion, speed, and position

What’s fascinating is how industries that once relied on bulky systems are now turning to miniaturized alternatives. This isn’t just about saving space—it’s about smarter control and energy savings.

If you’ve dealt with complex motion systems before, you know the headaches that come from bulky motors that lack finesse. With a small servo motor, those problems shrink, quite literally.

2. The Rise of Compact Power: How It’s Reshaping Automation

Let’s say you’re developing a lightweight industrial robot or building a portable device that requires high accuracy. Large motors just won’t cut it.

That’s why the demand for small servo motors has spiked in areas like:

Electronics assembly

Medical robotics

Portable packaging systems

Drones and inspection bots

Even in the hydraulic world—traditionally dominated by size and force—you’re now seeing a shift. Smart engineers are integrating small servo motors with small hydraulic pumps to get the best of both worlds: precision and power.

In companies like THM Huade, engineers often explore such hybrid solutions—melding servo control with hydraulics to meet modern demands without compromising on reliability.

3. Integrating Small Servo Motors with Small Hydraulic Pumps

Now, here’s where things get interesting.

You’ve got a small servo motor on one hand, and a small hydraulic pump on the other. Together, they create a system that is:

Energy-efficient (thanks to variable-speed control)

Space-saving (essential for mobile equipment)

Exceptionally responsive (ideal for dynamic load changes)

This is particularly valuable in applications like:

Injection molding machines

Servo-hydraulic presses

Construction machinery

AGVs (Automated Guided Vehicles)

When you combine electronic precision with hydraulic muscle, you're no longer choosing between finesse and force—you get both. This approach is at the heart of innovation at forward-thinking motion companies like THM Huade.

4. What Makes These Setups So Valuable?

Let’s walk through the benefits from your perspective as a system designer, plant operator, or maintenance engineer.

✅ Size Matters (In a Good Way)

A small servo motor can fit into tight spaces. When integrated with compact hydraulic components, you reduce machine footprints—perfect for OEMs targeting mobile or modular designs.

✅ Reduced Energy Waste

Older hydraulic systems often run continuously. With servo-driven pumps, you only power what you need. The result? Lower energy bills and reduced system heat.

✅ Precise Feedback Loops

Need to hold a load mid-cycle or change directions quickly? Servo control offers real-time feedback—critical in applications like testing systems or forming machines.

✅ Simplified System Architecture

Modern industrial servo drives support multi-protocol control (EtherCAT, CANopen, etc.), which makes integration with PLCs and IoT platforms smoother.

This is especially true in THM Huade’s servo-hydraulic system designs, where precision, modularity, and performance converge.

5. Looking Ahead: What the Future Holds

The trend is clear—systems are getting smarter, smaller, and more connected. You’ll see more machines built with embedded intelligence, real-time diagnostics, and plug-and-play modules.

In that context, small servo motors aren’t just filling a niche—they’re setting the stage for the next wave of industrial automation. Paired with compact hydraulic systems and sophisticated industrial servo drives, the applications are endless.

From flexible manufacturing lines to autonomous maintenance systems, the drive toward smarter machines is gaining momentum. Companies like THM Huade are responding by designing systems that are adaptable, efficient, and intelligent at every scale.

Conclusion:

You started this read wondering what role a small servo motor could play in your big-picture system. Now you know—it could be the very component that simplifies your design, cuts your energy usage, and enhances your performance.

And when paired with modern hydraulic motor pumps or industrial servo drives, the possibilities are even broader. These compact solutions are no longer just for lightweight robots or medical tools—they're reshaping the future of industrial control and motion systems across the board.

If you're in the research or design phase of your next industrial project, take a closer look at the power of small servo motors and servo-hydraulic systems. Explore how compact control could be the smartest move you make this year.

#SmallServoMotor#IndustrialAutomation#SmartHydraulics#ServoDriveTechnology#MotionControl#CompactPower#ServoHydraulicSystem#HydraulicInnovation#FutureOfIndustry#THMHuade

0 notes

Text

Clixroute – Leading the Way in Precision Plastic Injection Molding in India

In today's world, where innovation meets efficiency, precision plastic injection molding stands out as a key manufacturing process for industries ranging from automotive and electronics to healthcare and consumer goods. At the forefront of this technology in India is Clixroute, a trusted name known for quality, precision, and consistency.

As a leading provider of plastic injection molding in India, Clixroute combines cutting-edge machinery with technical expertise to deliver products that meet the highest global standards.

🔧 What is Precision Plastic Injection Molding?

Precision plastic injection molding is a manufacturing process that involves injecting molten plastic into a custom mold to produce highly detailed and complex plastic components. The precision aspect ensures tight tolerances, smooth finishes, and consistent dimensions — ideal for applications where accuracy matters.

🌟 Why Choose Clixroute for Plastic Injection Molding in India?

✅ Unmatched Precision

At Clixroute, we use state-of-the-art injection molding machines to deliver micro-level accuracy in every product. Whether it’s a small medical component or an automotive part, precision is non-negotiable.

✅ Customized Solutions

We understand that every client has unique needs. From mold design to prototyping and full-scale production, we offer tailor-made solutions that align with your product goals.

✅ High-Quality Materials

Only top-grade thermoplastics and polymers are used in our processes. We ensure durability, strength, and performance in every piece molded.

✅ End-to-End Services

Clixroute is more than a manufacturer — we’re your complete injection molding partner. From concept to delivery, we manage every step to ensure seamless execution.

🏭 Serving Diverse Industries Across India

With a robust infrastructure and a team of skilled professionals, Clixroute caters to a wide range of industries:

Automotive Components

Medical Devices

Consumer Electronics

Industrial Applications

Packaging Solutions

Whether you're a startup looking for a reliable plastic molding partner or an enterprise needing bulk production with tight tolerances, Clixroute delivers with confidence.

🌍 Made in India, Trusted Worldwide

India is becoming a global hub for high-quality manufacturing, and Clixroute is proud to be a part of this revolution. Our facilities are equipped with globally benchmarked technology, and we comply with international quality standards to serve both domestic and global markets.

🚀 Let’s Build Precision Together

Looking for reliable plastic injection molding in India? Choose Clixroute — where innovation, precision, and reliability come together.

📞 Contact us today for a consultation 🌐 Visit our website: www.clixroute.com 📧 Email: [email protected]

1 note

·

View note

Text

Precision in Every Spark: Why CNC EDM Die Sinking Machines Are Shaping the Future of Tooling

In today’s fast-paced manufacturing industry, the demand for high-precision components and intricate tooling is ever-increasing. As traditional machining methods struggle to meet the needs of complex geometries and tough materials, a new hero emerges—the CNC EDM Die Sinking Machine. Known for its ability to machine hard metals with extreme accuracy, this technology is rapidly becoming a cornerstone in mold and die-making industries around the world.

In this blog, we’ll explore what a CNC EDM Die Sinking Machine is, how it works, and why it’s a smart investment for manufacturers seeking precision, efficiency, and reliability.

What is a CNC EDM Die Sinking Machine?

EDM stands for Electrical Discharge Machining, a non-traditional process that uses electrical sparks to erode material from a workpiece. Unlike traditional cutting tools, EDM doesn’t involve physical contact. Instead, it uses a controlled electrical discharge between an electrode and the workpiece, both submerged in a dielectric fluid.

The CNC EDM Die Sinking Machine, also known as a sinker EDM or ram EDM, is a specialized variant of this process. It uses pre-shaped electrodes to “sink” cavities or intricate shapes into metal components, making it especially useful in the creation of molds, dies, and precision parts.

With the integration of Computer Numerical Control (CNC), these machines offer unmatched accuracy, repeatability, and automation.

How Does It Work?

The CNC EDM die sinking process involves:

Electrode Creation: A copper or graphite electrode is shaped according to the desired cavity or feature.

Workpiece Setup: The workpiece, usually made of hard metal like tool steel, is placed in the dielectric tank.

Machining: Controlled electrical discharges remove metal from the workpiece to form the required shape.

Flushing: The dielectric fluid helps remove debris and cools the machining area.

CNC Control: All operations are automated and optimized via a CNC program for high consistency.

This method allows manufacturers to create highly detailed, complex, and precise shapes that would be difficult—or even impossible—with traditional machining.

Key Benefits of Using a CNC EDM Die Sinking Machine

🎯 Precision and Accuracy

With tolerance levels as tight as ±2 microns, CNC EDM Die Sinking Machines deliver precise results essential for mold and die manufacturing, aerospace parts, medical tools, and more.

⚙️ Ability to Machine Hard Materials

Materials like titanium, hardened steel, carbide, and Inconel can be effortlessly machined without tool wear or thermal damage.

🔁 Repeatability

Thanks to CNC automation, complex parts can be produced repeatedly with consistent quality and finish.

🌀 Complex Geometries

Intricate cavities, fine details, undercuts, and sharp internal corners are easy to create—something nearly impossible with conventional milling.

🧼 Smooth Surface Finish

EDM machines provide a naturally smooth finish, often eliminating the need for secondary polishing processes.

Applications Across Industries

A CNC EDM Die Sinking Machine is a go-to solution for multiple industries that demand intricate, high-strength, and precise components:

Tool & Die Manufacturing: For injection molds, stamping dies, and casting tools.

Aerospace & Defense: For high-stress parts made from exotic alloys.

Automotive Industry: Precision engine components and mold tooling.

Medical Equipment: Surgical instruments and implants with tight tolerances.

Electronics: Micro molds and connectors.

Choosing the Right CNC EDM Die Sinking Machine

When investing in a CNC EDM machine, consider the following factors:

✅ Machine Size & Work Area: Choose a model that suits your workpiece size and production volume.

✅ Electrode Compatibility: Ensure it supports your preferred electrode material (graphite or copper).

✅ Control System: Look for intuitive software with advanced machining strategies and automation.

✅ Build Quality: A rigid frame and reliable components ensure stability and durability.

✅ After-Sales Support: Partner with a supplier that offers maintenance, training, and spare parts.

Future of EDM: Smart, Automated, and Connected

With Industry 4.0 taking hold, modern CNC EDM Die Sinking Machines are integrating IoT capabilities, real-time monitoring, and data-driven optimization. Predictive maintenance, automation compatibility, and AI-driven cutting strategies are helping businesses reduce downtime and boost productivity.

As the demand for complex, high-performance parts grows, EDM technology continues to evolve—offering solutions that traditional machining cannot match.

0 notes

Text

Technical Breakthrough in Small-Batch Custom Production of Rocker Switches: SMED Flexible Manufacturing and Full-Chain Collaboration Strategies

Introduction

In the industrial equipment manufacturing sector, rocker switches, as critical human-machine interface components, are experiencing surging demand for customization due to the rise of niche markets. Differentiated scenarios in industries such as medical devices, new energy charging stations, and smart home systems have spawned numerous "micro-orders" below 10,000 pieces. However, traditional rocker switch manufacturers, long reliant on mass production models, face significant challenges with small-batch orders, including "high mold-change costs, prolonged delivery cycles, and quality fluctuations." This article focuses on Single-Minute Exchange of Die (SMED) technology, integrating digital process design, modular supply chains, and intelligent quality control to systematically deconstruct the technical pathways for small-batch customization. Practical case studies validate its feasibility.

1. Industry Pain Points in Small-Batch Customization and the Value of SMED

1.1 Deep Analysis of Industry Challenges

Excessive Mold-Change Cost Ratios: Traditional injection mold switching takes 2–4 hours. For an order of 5,000 pieces, per-unit mold-change costs can reach ¥0.8–1.2, accounting for 15%–25% of total costs.

Unpredictable Delivery Times: Mold debugging and first-article inspections extend standard 100-hour lead times to over 200 hours for small batches.

Lack of Production Flexibility: Single production lines struggle to handle parallel demands for multi-material (e.g., PA66 vs. PBT) and multi-structural (e.g., IP65 vs. IP67 sealing) configurations.

1.2 Core Value of SMED Technology

SMED (Single-Minute Exchange of Die) reduces mold-change times to under 10 minutes through standardized workflows, separation of internal/external tasks, and parallel operations. Its value grows exponentially in small-batch scenarios:

Cost Reduction: Mold-change time decreases by 80%, lowering per-unit costs to below ¥0.2.

Shorter Lead Times: Production line efficiency improves, enabling 72-hour delivery for 5,000-piece orders.

Enhanced Flexibility: Supports multi-batch daily production (e.g., 16mm red LED-backlit switches and 19mm non-illuminated metal buttons in one order).

2. Implementation of SMED in Rocker Switch Production

2.1 Mold and Equipment Adaptations

Modular Mold Design: Standardize positioning systems, cooling channels, and ejection mechanisms.Case Study: A manufacturer developed "quick-release alignment pins" for medical device switches, replacing threaded locks with taper fits to reduce mold disassembly time from 45 to 8 minutes.

Preheating/Precooling Systems: Preheat molds to 80°C (optimal for PBT injection) during external preparation to eliminate downtime.

Multi-Purpose Fixtures: Use magnetic fixtures compatible with molds of varying sizes to minimize adjustments.

2.2 Process Standardization and Parallelization

Externalizing Internal Tasks:Complete mold cleaning and lubrication before changeovers.Case Study: "Mold pre-loading carts" prepare the next batch’s molds during ongoing production.

Parallel Operations:Robotic arms remove molds while operators scan QR codes to input new parameters into MES systems.Data Support: RFID tags cut mold-data transmission time from 15 minutes to 20 seconds.

2.3 Workforce Training and Organizational Upgrades

Skill Matrix Development: Train multi-skilled workers in injection molding, electrical testing, and SMED.

"Swarm" Collaboration: Three-person teams handle mechanical disassembly, parameter setup, and initial QC, reducing manual intervention to 3 minutes.

3. Beyond SMED: Full-Chain Collaboration Strategies

3.1 Digital Process Design (DFM)

Parametric Modeling: Use CAD software to predefine mounting hole spacing, contact gaps, and waterproof groove depth, accelerating 3D model generation.Case Study: A customer requested anti-mishap bumps on switch panels. Engineers modified bump height (0.5mm→1.2mm) using templates, slashing design time from 3 days to 4 hours.

Simulation Validation: Moldflow software simulates melt flow and cooling deformations, reducing trial runs.

3.2 Modular Supply Chain Agility

"Lego-Style" Contact Component Inventory: Standardize silver contacts (AgNi), copper bases, and springs for rapid assembly.Cost Comparison: Traditional custom molds cost ~¥20,000; modular assembly lowers this to ¥5,000.

Regional Micro-Warehouses: Stock universal housings and PCBs in Yangtze River Delta and Pearl Delta hubs for 48-hour delivery.

3.3 Intelligent Quality Control

Machine Vision Inspection: High-resolution cameras check contact flatness (±0.02mm) and housing burrs (≤0.1mm).Data Improvement: AI-powered inspection cut defect rates from 500ppm to 80ppm.

Blockchain Traceability: Assign unique IDs to track materials, process parameters, and test data for rapid fault diagnosis.

4. Case Study: Customization Success for an Industrial Equipment Manufacturer

4.1 Requirements

5,000 high-temperature-resistant rocker switches:Material: PA66 + 30% glass fiber (UL94 V-0).Contacts: Double-break AgSnO₂.IP67 waterproofing (96-hour salt spray test).Lead time: 7 days.

4.2 Implementation

SMED Optimization:Mold-change time reduced from 120 to 18 minutes.Preloaded silicone gaskets and AgSnO₂ contacts.

Modular Assembly:Used PA66 housings from stock, switching only to glass-fiber-reinforced material.Pre-assembled "contact-spring" modules simplified assembly.

Digital QC:Infrared thermography ensured ±5°C mold temperature uniformity.Automated testers simulated 10,000-cycle durability.

4.3 Results

Lead Time: Reduced to 5 days.

Cost: Per-unit cost down 22%.

Customer Feedback: 99.3% first-pass yield, 80% reorder rate.

5. Challenges and Long-Term Competitiveness

5.1 Technical Challenges

High Initial Investment: SMED requires mold standardization and smart equipment (¥500k–1M).Solution: Government subsidies (30–50% coverage) and installment payments.

Multi-Product Wear: Frequent mold changes accelerate equipment wear.Solution: Predictive health monitoring (PHM) cuts downtime.

5.2 Organizational Challenges

Resistance to Change: Workforce hesitancy toward flexible production.Solution: Efficiency-based bonuses tied to mold-change time reductions.

Data Silos: Disconnected R&D, production, and supply chain teams.Solution: PLM platforms enable real-time data sharing.

5.3 Market Challenges

Client Education: SMEs prefer low-cost standard products.Solution: Offer "free design simulation + pay-per-production" models.

6. Conclusion: The Future of Small-Batch Customization

Under Industry 4.0 and personalized demand, rocker switch competition shifts from "scale-driven costs" to "agile response." SMED-enabled minute-level mold changes, modular supply chains, and digital QC transform "cost disadvantages" into "service premiums." With 3D-printed molds and AI scheduling, sub-10,000pcs "micro-orders" will drive profitability.

en.dghongju.com

0 notes

Text

Protolabs Tolerances: A Comprehensive Guide

Protolabs is a prominent digital manufacturing business focusing on low-volume production and quick prototyping. It is renowned for its accuracy and fast turnaround times, and it provides tight tolerances to satisfy various manufacturing requirements. This article examines Protolabs' tolerances, their uses, and the variables influencing accuracy.

What Are Tolerances?

Tolerances define the permissible range of a produced part's dimensions. They guarantee that components fit and work correctly in assemblies. Tolerances are essential in sectors where accuracy is crucial, such as aerospace, automotive, and medical devices.

Standard Tolerances for Protolabs

Various tolerances are offered by Protolabs based on the manufacturing process:

Tolerances in CNC Machining

Linear Dimensions: The typical linear dimensions are ±0.005 inches (±0.13 mm).

Hole Diameters: ±0.002 inches (±0.05 mm) is the hole diameter.

Surface Finishes: The standard finish is 63–125 µin Ra (micro inches).

Tolerances for Injection Molding

Components made of plastic: ±0.13 mm per 25.4 mm (±0.005 inches per inch).

Tool Tolerances: Up to ±0.002 inches (±0.05 mm) for essential regions.

Tolerances in 3D printing

Stereolithography (SLA): ±0.002 inches per inch plus ±0.005 inches (±0.13 mm) for the first inch.

Laser Sintering (SLS) with selectivity: ±0.010 inches (±0.25 mm).

Tolerances for Sheet Metal Fabrication

Cutting and Bending: ± 0.25 mm (0.010 inches).

Position of the Hole: ±0.020 inches (±0.50 mm).

Factors Influencing Protolabs Tolerances

Several factors influences the tolerances that Protolabs can reach:

Material Selection: The rate at which various materials expand and compress affects accuracy.

Design Complexity: To account for manufacturing difficulties, intricate designs may call for looser tolerances.

Manufacturing Process: Compared to 3D printing, CNC machining usually produces tighter tolerances.

Part Size and Geometry: More significant parts frequently call for wider tolerances because of tool deflection and thermal expansion.

Surface Finish Requirements: Finer finishes need more manufacturing steps, which may affect tolerances.

Protolabs Tolerance Applications

Tolerances from Protolabs support a variety of sectors and uses, such as:

Aerospace Components: High-precision components such as turbine blades and housings are examples of aerospace components.

Medical Devices: Medical devices include implants and surgical instruments that need to be extremely precise.

Automotive Prototypes: Engine parts and functional testing components are examples of automotive prototypes.

Consumer Products: Consumer goods include functional enclosures, connectors, and casings.

Why Choose Protolabs for Tolerances?

Fast Turnaround: Accuracy is maintained while production proceeds quickly.

Versatility: Support for sheet metal production, injection moulding, 3D printing, and CNC machining.

Quality Assurance: Strict quality control procedures are used to ensure accuracy in quality assurance.

Material Options: Numerous metals, polymers, and composites are available as material options.

FAQs

What is the typical tolerance for CNC machining at Protolabs?

For linear dimensions, the standard tolerance is ±0.005 inches (±0.13 mm), while for holes, it is ±0.002 inches (±0.05 mm).

Can Protolabs produce custom designs with stricter tolerances?

Unique requests allow tighter tolerances depending on the material and procedure.

What are the differences in tolerances between Protolabs' 3D printing and CNC machining processes?

The tolerances for 3D printing vary depending on the technique, with SLS at ±0.010 inches, but CNC machining offers tighter tolerances (±0.005 inches).

Which industries gain the most from tolerances offered by Protolabs?

The exact tolerances offered by Protolabs are advantageous to sectors such as consumer electronics, automobiles, medical devices, and aerospace.

Conclusion

Protolabs are an excellent option for quick prototyping and production since they provide consistent tolerances across various manufacturing processes. Engineers and designers can produce high-quality, practical products that satisfy industry standards by comprehending the tolerances they offer. Protolabs offers solutions to meet your needs, whether you require functional flexibility for prototypes or strict aerospace standards.

0 notes

Text

Advanced Injection Moulding Machine for High Output

Are you looking for a reliable and efficient C-PVC injection moulding machine then Patel Plastic Machine Manufacturer is perfect machine manufacturer in India. Patel Plastic Machine Manufacturer is provide high performance machine designed for precision and durability. Our advance machine technology make sure that efficient molding, high output and superior product quality for various industrial applications.

Patel Plastic Machinery are equipped with advance technology that allow for precise control over the moulding machine which guarantees superior product quality in every time. We are focusing on durability and ease to operate. Our machine built quality are providing long term value and reducing downtime.

Patel Plastic Machinery is best molding solution for any plastic manufacturer. What are you waiting for pick up your phone and contact pplastmach.com today. We are receive your call anytime.

#plastic injection moulding machine#injection moulding machine#micro injection moulding machine#pvc injection moulding machine#gujarat

0 notes

Text

Innovative Injection Molding Services for Plastic Product Manufacturing

Innovative injection molding services have revolutionized the plastic product manufacturing industry, enabling the creation of complex and precise plastic parts with high accuracy and speed. The injection molding process has been around for decades, but recent advancements in technology and materials have transformed the industry, making it possible to produce high-quality plastic products with unprecedented precision and efficiency. Today, injection molding is used in a wide range of industries, from automotive and aerospace to medical devices and consumer electronics.

Advanced Tooling and Design Capabilities

Innovative injection molding services employ advanced tooling and design capabilities to create complex plastic parts with intricate geometries and precise tolerances. This includes the use of computer-aided design (CAD) software and computer-aided manufacturing (CAM) systems to design and manufacture molds with high accuracy. Advanced tooling materials, such as high-strength steels and advanced polymers, are also used to create molds that can withstand the high pressures and temperatures involved in the injection molding process. Additionally, innovative injection molding services often employ advanced mold design techniques, such as conformal cooling and hot runner systems, to optimize mold performance and reduce production costs.

High-Performance Materials

Innovative injection molding services also utilize high-performance materials that offer superior strength, durability, and resistance to chemicals and heat. These materials include advanced polymers, composites, and thermoplastics that can withstand extreme conditions and meet the demanding requirements of various industries. For example, in the aerospace industry, high-performance materials such as polyetheretherketone (PEEK) and polyimide (PI) are used to produce lightweight and durable components that can withstand the extreme temperatures and stresses involved in flight. Similarly, in the medical device industry, high-performance materials such as polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) are used to produce medical devices that require high strength, durability, and resistance to chemicals and heat.

Precision Injection Molding

Precision injection molding is a critical aspect of innovative injection molding services, enabling the production of plastic parts with high accuracy and precision. This involves the use of advanced injection molding machines and techniques, such as micro-injection molding and nano-injection molding, to produce small and intricate plastic parts. Precision injection molding also requires the use of advanced quality control systems, such as vision inspection systems and statistical process control (SPC) systems, to ensure that the plastic parts meet the required specifications and tolerances.

Multi-Shot Injection Molding

Multi-shot injection molding is another advanced technique used in innovative injection molding services, allowing for the production of complex plastic parts with multiple materials and colors. This involves the use of specialized injection molding machines that can inject multiple materials and colors in a single molding process. Multi-shot injection molding is commonly used in the production of automotive and consumer electronics components, where multiple materials and colors are required to produce complex and functional parts.

Overmolding and Insert Molding

Overmolding and insert molding are also used in innovative injection molding services to produce complex plastic parts with multiple components and materials. Overmolding involves the molding of a second material over a base material, while insert molding involves the molding of a material around a pre-molded insert. These techniques are commonly used in the production of medical devices, automotive components, and consumer electronics, where multiple materials and components are required to produce complex and functional parts.

Industry Applications

Innovative injection molding services have a wide range of applications across various industries, including automotive, aerospace, medical devices, consumer electronics, and industrial equipment. In the automotive industry, injection molding is used to produce components such as dashboards, bumpers, and engine components. In the aerospace industry, injection molding is used to produce lightweight and durable components such as aircraft seats, engine components, and satellite components. In the medical device industry, injection molding is used to produce medical devices such as syringes, implantable devices, and diagnostic equipment.

Benefits of Innovative Injection Molding Services

The benefits of innovative injection molding services include increased precision and accuracy, improved product quality, reduced production costs, increased efficiency and productivity, and enhanced design flexibility. By leveraging advanced technologies and materials, innovative injection molding services can help manufacturers produce high-quality plastic products that meet the specific needs of their industry, while also improving efficiency, reducing costs, and enhancing product performance.

0 notes

Text

Micro 3D Printer Market Growth Analysis by Emerging Trends, Key Manufacturers and Industry Forecast 2033

The vertical injection molding machine market has gained significant traction as industries increasingly demand versatile and precise manufacturing solutions. Unlike traditional horizontal injection molding machines, vertical machines inject molten plastic into molds from the top, making them ideal for applications that require easy insertion of parts into the mold. Vertical injection molding…

#Micro 3D Printer Market#Micro 3D Printer Market Growth#Micro 3D Printer Market Report#Micro 3D Printer Market Share#Micro 3D Printer Market Size#Micro 3D Printer Market Trends

0 notes

Text

Sustainability in Plastic Injection Molding Trends and Future Developments

Plastic injection molding is a widely used manufacturing process that allows for the mass production of plastic parts with high precision and efficiency. However, its environmental impact, largely due to the extensive use of non-biodegradable plastics and high energy consumption, has brought sustainability to the forefront of industry discussions. To address these concerns, new trends and developments are emerging, shaping the future of the Plastic injection molding machine.

1. Use of Recycled Materials

One of the most significant trends in making injection molding more sustainable is the increased use of recycled plastics. Rather than relying on virgin materials, manufacturers are integrating post-consumer recycled plastics into the production process. By doing this, they are reducing the demand for new plastic, minimizing waste, and lowering carbon emissions. Advanced sorting and cleaning technologies are making it possible to use higher percentages of recycled materials without compromising the quality or durability of the end products. This trend is expected to grow as more companies prioritize circular economy practices.

2. Biodegradable and Bio-based Plastics

The development of biodegradable and bio-based plastics is another major shift towards sustainability. These materials, made from renewable sources like corn starch, sugarcane, or cellulose, offer an alternative to petroleum-based plastics. In Plastic injection molding machine, bio-based plastics are increasingly being used for consumer goods, packaging, and even automotive parts. Although challenges remain in terms of cost and performance compared to traditional plastics, ongoing research and technological advances are making them more competitive. As demand for environmentally friendly products grows, the use of biodegradable plastics in injection molding is expected to rise significantly in the coming years.

3. Energy Efficiency and Process Optimization

The injection molding process is energy-intensive, which contributes to its environmental footprint. However, manufacturers are adopting various strategies to improve energy efficiency. The use of electric and hybrid injection molding machines, which consume less energy compared to their hydraulic counterparts, is one such development. Additionally, process optimization techniques, such as real-time monitoring and automation, are helping to reduce cycle times and energy consumption. Innovations like 3D printing molds and micro-molding further improve the sustainability of the process by reducing material waste and enhancing precision.

4. Closed-Loop Manufacturing

Closed-loop manufacturing is a forward-thinking approach gaining traction in the injection molding industry. This system minimizes waste by capturing and reusing excess material, often grinding down scrap plastic and reintroducing it into the production process. Not only does this reduce material waste, but it also cuts down on the energy required to produce new plastic. As companies adopt closed-loop systems, the industry can move closer to a zero-waste model.

Future Outlook

As sustainability becomes a priority for both manufacturers and consumers, the plastic injection molding industry is evolving. Trends such as the use of recycled and biodegradable plastics, energy-efficient machinery, and closed-loop manufacturing systems are paving the way for a greener future. As technological advances continue and more companies adopt eco-friendly practices, plastic injection molding is poised to become an integral part of the global push for sustainability.

0 notes