#Micro Milling Guide

Explore tagged Tumblr posts

Text

Advantages of Micro Milling

Micro milling offers high precision for producing small, complex parts in metal, plastic, or wood. It enables tight tolerances and intricate detailing for demanding applications like medical devices and electronics. The process minimizes material waste and supports fast prototyping. Learn about the advantages of micro milling.

0 notes

Text

my god this post is massive

note: the conferences are going to be mostly uk ones based bc that where i am

feel free to ask questions, i want to talk to people about this!

Conference the first - The Oxford Real Farming Conference

[youtube]

a yearly uk conference of farmers that are farming in alternative ways (mostly organic & regen) since 2010

not to be mistaken with the Oxford Faming conference which is the usual industrial farming conference (but there seem to be increasing regen ag talk over the years)

both happen around the same time in january and have their archive on youtube for free

the orfc was created bc farmers were frustrated that they couldnt find a place to discuss more progressive ag ideas

not all sessions get recorded as video, some are audio only (you can find them on the website), only a couple dont get recorded at all

sessions ive watched

ive barely started watching/listening to the sessions this year but here are some that i have watched & i found interesting:

Doing Dairy Differently

a talk about doing dairy better like keeping the calf with the mothers, rotational grazing, ect & the benefits and challenges trying to do that

Farmers — Saving More Lives Than Pharma

a talk by Dr Jenny Goodman, a doctor who uses organic food (and other stuff) as a tool to cure various illness (bc almost everyone is deficient in micro nutrients and micro-dosing on pesticides really doesnt help)

she has some good books with very actionable advice for the individual and with a lot of peer reviewed citations

the books are 'Staying Alive in Toxic Times: A Seasonal Guide to Lifelong Health' (ive read this one, got it from the library) and 'Getting Healthy In Toxic Times'

Homegrown Fashion: The British Fibres Regenerating Landscaoes and Creativity

panel that covers the state of the native british fibres and their industry of wool, linen, hemp and leather:

Fantasy Fibre Mill - developing open source linen and hemp processing machinery for the mid-scale/farm-level (uk has lost all processing infrastructure)

British Pasture Leather - a company developing the supply chain for leather from pasture for life (uk grassfed label)

Fernhill Farm & Fernhill Fibre - mixed livestock farm that is part of the south west england fibreshed, processes and sells their own wool and clothing, holds traditional blade sheep shearing competitions, records and monitors their carbon & biodiversity and and is verified as regenerative

Contempory Hempery - grows hemp for fine fibre fabric and aims to process the hemp into fibre and fabric

Growing the Rainbow: LGBTQ+ Perspectives in Landwork

Indie Food Retail: Challenges, Learnings and Success Stories

sessions i havent yet watched

here are some havent watched/listened to yet and you might want to too (very roughly categorised):

socialish stuff

Roots of Resistance: Farming in Palestine

Smash Imperialism! For a New Trade Framework Based on Solidarity!

Rooting for Diversity: Cultivating Farms for Neurodiversity To Thrive

WORKSHOP: Cultivating Long-Term Solidarity with Farmers in Palestine

WORKSHOP: Reparations — Learning From Examples Existing Within Modernity

farming stuff

Making Public Farmland Work for the Public Interest

Creating New Crofts: A Pathway Towards Land Justice?

Is a Fossil Free Food System Possible?

WORKSHOP: Farms and Kitchens — Forging Connections Between Food Citizenship Hubs

WORKSHOP: Beyond the Tech Divide: Rethinking Innovation for Agroecology

What Might Insect Sentience Mean for Agroecology?

Better Meat, More Plants: Opportunities for Farmers?

FARM DEEP DIVE: Our Journey into Nature Friendly Livestock Farming

animals & meat

WORKSHOP: Deer Are Food for the Future (deer is a big problem in the uk bc of lack of natural predators)

Pigs, Environmental Engineers or Architects of Destruction?

Sustainable Meat: Minimise Transport, Slaughter Humanely, Stay Profitable (about small abattoirs, very important for animal welfare and sustainable meat production (both in the profitable and the ecology sense); we are are losing them so fast, tw: discussions of animal death & butchery)

Rise of the Planet of the Chicken

Ensuring a Just Transition from Intensive Livestock

grains

WORKSHOP: Next Steps in Building a New Cereal Seed System

Increasing Home-Grown Protein in an Organic Farming System (about growing native non-soya feed for animals)

other produce

WORKSHOP: Learning to Connect with the Ocean

WORKSHOP: Adding Flowers to Your Farm: Increasing Profits and Pollinators

Can Farmed Salmon Ever Be Sustainable

#conference list#solarpunk#orfc#fashion#health#food#regen ag#theres so many good talks#and this is only one conference#next will be Groundswell

3 notes

·

View notes

Text

What Is Cogeneration? A Complete Guide to Combined Heat and Power (CHP)

Cogeneration, also known as combined heat and power (CHP), is an energy-efficient technology that generates electricity and captures the heat that would otherwise be wasted to provide useful thermal energy. This process significantly improves overall energy efficiency and reduces greenhouse gas emissions.

What Is Cogeneration?

Cogeneration is the simultaneous production of electricity and useful heat from the same energy source—typically natural gas, biomass, coal, or waste heat. Unlike traditional power plants that discard excess heat into the environment, cogeneration systems recover it and use it for:

Heating buildings

Producing hot water

Powering industrial processes

Generating steam for manufacturing

How Does Cogeneration Work?

The process begins with a prime mover—such as a gas turbine, steam turbine, or reciprocating engine—that produces electricity. The heat that is typically lost in conventional generation is instead captured through a heat recovery system. This thermal energy is then used for various heating applications, increasing the total efficiency of the system to over 80%, compared to about 50% for conventional systems.

Components of a Cogeneration System:

Prime Mover: Engine or turbine

Electric Generator: Converts mechanical energy into electricity

Heat Recovery Unit: Captures and redirects waste heat

Control System: Optimizes operation and efficiency

Benefits of Cogeneration

Implementing CHP systems offers multiple economic, environmental, and operational advantages:

1. Higher Energy Efficiency

Cogeneration systems achieve up to 90% efficiency, reducing fuel consumption and operating costs.

2. Lower Greenhouse Gas Emissions

By utilizing waste heat and requiring less fuel, CHP systems significantly cut CO₂ and NOx emissions.

3. Energy Reliability

CHP provides on-site power generation, which improves energy security and resilience against grid failures.

4. Cost Savings

Businesses can reduce utility bills by generating electricity and heat on-site, with payback periods often under five years.

5. Fuel Flexibility

CHP systems can run on a wide range of fuels including natural gas, biomass, biogas, and even hydrogen in advanced setups.

Applications of Cogeneration

Cogeneration is used across various sectors:

Industrial: Refineries, chemical plants, paper mills

Commercial: Hospitals, hotels, universities, office buildings

Residential: District heating systems for neighborhoods or apartment complexes

Municipal: Wastewater treatment and public facilities

Cogeneration vs. Traditional Power Generation

Feature

Cogeneration (CHP)

Traditional Power Plants

Efficiency

70%–90%

30%–50%

Waste Heat Utilization

Reused for heating

Discarded

Fuel Use

Reduced

Higher

Emissions

Lower

Higher

Government Incentives and Policy Support

Many governments promote CHP through tax incentives, grants, and regulatory support. For example:

United States: The U.S. Department of Energy’s CHP Technical Assistance Partnerships (CHP TAPs)

European Union: Directives encouraging energy efficiency and low-carbon technologies

Asia-Pacific: Incentives in China, Japan, and India to support energy-intensive industries

Challenges of Cogeneration

While cogeneration offers many benefits, there are also challenges:

High initial investment

Complex system integration

Fuel supply and regulation concerns

Maintenance and technical expertise required

Future of Cogeneration

The future of cogeneration is promising, especially when integrated with renewable energy sources and smart grid technologies. Innovations in micro-CHP and hydrogen-fueled systems are expanding its viability for residential and remote applications.

Conclusion

Cogeneration is a proven, efficient, and sustainable energy solution that maximizes fuel use and minimizes waste. Whether you're a business looking to cut energy costs, a policymaker focused on emissions reduction, or a homeowner exploring efficient technologies, CHP offers a powerful path toward energy sustainability.

0 notes

Text

Title: Rural Development Through Biomass Energy: A Sustainable Path Forward

Rural India holds immense potential for economic growth, yet energy access remains a significant barrier in many villages and small towns. Frequent power cuts, dependence on expensive diesel generators, and limited access to the national grid have long constrained development in these areas. However, renewable technologies are opening new doors for energy independence, with biomass gasifiers emerging as one of the most viable solutions.

At the center of this movement is the Veera Group, a forward-thinking company championing biomass-based energy solutions designed specifically for rural needs. With their innovative and user-friendly biomass gasifier machines, Veera Group is transforming how rural communities generate and use energy—driving both economic upliftment and environmental sustainability.

Why Biomass Gasification Matters for Rural Areas

Rural India generates massive quantities of agricultural waste—from rice husk and coconut shells to sugarcane bagasse and groundnut shells. Unfortunately, much of this biomass is burned in the open, leading to air pollution and wasted energy potential.

Biomass gasifiers solve this problem by converting organic waste into producer gas, which can be used for:

Electricity generation for homes and businesses

Fuel for water pumps and agro-processing units

Thermal applications in rural industries

With the right technology, rural areas can utilize what they already have—biomass—and convert it into reliable, low-cost energy.

The biomass gasifier machine from Veera Group is engineered for precisely this purpose. It is durable, easy to maintain, and capable of handling a wide range of locally available feedstocks. This makes it an ideal solution for villages looking to become self-sufficient in their energy needs.

Real-World Impact: From Darkness to Development

Access to energy is directly linked to improvements in:

Education: Electrified schools and homes allow for better study environments.

Healthcare: Rural clinics can power diagnostic equipment and refrigeration for medicines.

Entrepreneurship: Small businesses like flour mills, carpentry workshops, and dairy farms thrive with a consistent power supply.

Employment: Installing and maintaining biomass systems creates skilled jobs locally.

Veera Group’s ongoing projects across India demonstrate this impact firsthand. Villages that were once reliant on diesel gensets are now running community centers, irrigation pumps, and micro-enterprises using clean energy from biomass gasifiers.

Veera Group: Empowering Villages Through Innovation

Veera Group isn't just manufacturing machines—they’re enabling long-term change. Their model includes training local operators, offering remote diagnostics, and providing dependable after-sales service. This ensures that communities are not just equipped with machinery, but with the knowledge and support to operate and maintain it independently.

Their main website offers a full overview of their work in biomass energy and other industrial technologies. It’s also a gateway for rural entrepreneurs and NGOs to explore partnership opportunities for deploying gasifier systems in remote locations.

Moreover, the Veera Group blog serves as a valuable educational platform. From how-to guides and maintenance tips to case studies and industry trends, the blog empowers users with knowledge that makes clean energy adoption easier and more effective.

Looking Ahead: A Greener, Fairer Future

Rural development is a complex challenge that cannot be solved by infrastructure alone. It requires sustainable systems that local people can manage and afford. Biomass gasification fits this need perfectly, using local resources to meet local needs.

With leaders like Veera Group paving the way, rural India is poised to take a giant leap forward—toward energy independence, economic resilience, and environmental stewardship.

Conclusion

Biomass gasifiers are much more than machines—they are engines of rural transformation. Through innovative technology, local engagement, and an unwavering commitment to sustainability, Veera Group is showing how renewable energy can bring light, power, and prosperity to India’s heartland. Whether you're a rural entrepreneur, NGO, or policy advocate, the time to invest in biomass-based rural development is now.

0 notes

Text

Essential Guide to Machine Taps, Thread Milling Tools, and More for Precision Machining

In the world of precision machining, the quality of your tools often defines the quality of your final product. Whether you're producing fine threads, intricate components, or durable mechanical parts, selecting the right equipment is critical. In this blog, we'll take a closer look at five essential categories of tools every machinist should know: machine taps, thread milling tools, micro drilling tools, milling tools, and thread rolling tools.

Machine Taps: The Backbone of Thread Cutting

Machine taps are a go-to choice for cutting internal threads in metal or plastic workpieces. Available in different types like hand taps, spiral point taps, and spiral flute taps, they allow for quick, consistent thread production. Selecting the right tap material—like high-speed steel or carbide—ensures longer tool life and better performance, especially when dealing with hard materials.

Thread Milling Tools: Versatility in Thread Creation

Unlike tapping, thread milling uses a rotating tool to cut threads in a circular motion. Thread milling tools offer flexibility to create both internal and external threads, and they reduce the risk of tap breakage in hard or brittle materials. Their ability to machine multiple thread sizes with a single tool adds to their cost-efficiency, especially for CNC operations.

Micro Drilling Tools: Precision at a Tiny Scale

When it comes to producing tiny holes in delicate components, micro drilling tools are indispensable. Designed for diameters as small as 0.1mm, these tools are commonly used in industries like electronics, medical devices, and aerospace. Due to their small size, micro drills require ultra-precise machines and proper handling to prevent tool breakage and ensure perfect hole quality.

Milling Tools: Essential for Material Removal

Milling tools are perhaps the most widely used category in machining. From roughing out large pieces of material to finishing fine surfaces, milling tools come in various forms—end mills, face mills, ball nose cutters, and more. Selecting the right geometry and coating helps in achieving higher cutting speeds, improved tool life, and better surface finish.

Thread Rolling Tools: Stronger Threads Without Chips

Unlike cutting, thread rolling tools form threads by displacing material, rather than removing it. This chipless process results in threads that are not only stronger but also have a smoother surface finish. Thread rolling is ideal for high-volume production and applications where maximum thread strength is critical, such as automotive and aerospace fasteners

0 notes

Text

Choosing the Right End Mills for Precision PCB Prototyping

Precision is everything when it comes to printed circuit board (PCB) prototyping. Whether you’re designing high-frequency RF boards or multi-layer digital circuits, the success of your project often hinges on the quality of the tools you use—especially the end mills responsible for routing traces, cutting outlines, and shaping vias.

In this guide, we’ll dive into the role of micro end mills and PCB end mills in prototyping, explain how to select the right tool for your material and application, and share some expert tips for improving accuracy and extending tool life in your PCB milling workflow.

Why End Mills Matter in PCB Prototyping

Unlike full-scale PCB manufacturing that relies on chemical etching, most prototyping setups—particularly in-house or lab-based systems—use mechanical milling to define circuit patterns. This subtractive process uses a spindle-driven cutting tool to remove unwanted copper and shape the board.

At the heart of this process are end mills, tiny cutting tools with precise geometries designed to mill copper, fiberglass, and laminate materials like FR4 or phenolic. The quality of your cut lines, trace widths, and drilled holes all depend on having the right end mill in place.

Micro End Mills vs. Standard PCB End Mills: What’s the Difference?

End mills used in PCB prototyping come in various sizes and geometries, each suited for specific tasks.

Micro End Mills

Micro end mills are ultra-small tools (typically 0.005" to 0.125" in diameter) designed for fine-detail milling. They are ideal for:

Milling narrow traces or microvias

Machining HDI (high-density interconnect) designs

Cutting between densely packed features

Surface engraving or text labeling

Their small size allows for high precision, but also means they are fragile and prone to breakage if misused. These tools are best suited for rigid setups with precise depth control.

PCB End Mills

PCB end mills refer to general-purpose cutting tools designed for milling common PCB materials. These include:

Flat end mills for removing copper in wide passes

V-cut or engraving end mills for creating sharp traces or isolation paths

Tapered end mills for specific layer depth control

These tools are built to handle abrasive substrates like fiberglass (in FR4) and provide reliable results in both prototyping and light production environments.

Key Factors When Choosing PCB Milling Tools

When selecting micro or PCB end mills, consider the following:

1. Material Compatibility

For FR4 copper-clad laminate, choose carbide end mills that resist wear from fiberglass.

For phenolic boards, standard carbide tools work well, though micro end mills may require slower feed rates to avoid chipping.

For aluminum-backed PCBs, use coated micro end mills designed for non-ferrous metals to prevent gumming.

2. Tool Geometry

Single-flute tools are excellent for soft materials and high chip clearance.

Two-flute or three-flute tools offer better surface finish and can be used on tougher substrates.

Downcut bits minimize lifting and delamination, especially important for thin laminates or flexible PCBs.

3. Tool Size

Use the smallest tool that suits your design without compromising strength. For example:

0.005" to 0.010" micro end mills for ultra-fine routing

0.015" to 0.031" PCB end mills for general isolation milling

0.0625" end mills for board outline or slotting

Always refer to your design tolerances and machine capability when choosing bit diameter.

Applications of Micro and PCB End Mills

Isolation Routing

Isolation milling removes copper around traces to isolate them electrically. Micro end mills are essential for high-density boards where spacing is minimal.

Drilling and Slotting

PCB end mills with suitable flute geometry are used for drilling vias, through-holes, and slots—particularly in one-pass operations on rigid materials.

Engraving

For labeling or serializing boards, micro end mills with engraving tips offer detailed surface cutting for text and logos.

Cutting Board Outlines

Larger-diameter PCB end mills are used to cut the final board shape, including notches or mounting holes, from a copper-clad panel.

Tips for Maximizing Tool Performance

Use the Right Speeds and Feeds Running end mills too fast leads to heat buildup and tool breakage. Always refer to manufacturer guidelines for feed rate and spindle RPM, adjusting for the tool diameter and board material.

Keep Tools Sharp and Clean A dull micro end mill can cause burrs, frayed fiberglass, or uneven trace widths. Replace worn tools frequently and use compressed air or vacuum systems to clear debris.

Control Depth Precisely Excessive cutting depth can snap micro end mills. Use a height probe or leveling system to ensure uniform cutting depth, especially on warped boards.

Secure the Workpiece Any vibration or board movement will instantly ruin a micro milling job. Use double-sided tape or vacuum tables for secure fixturing.

Plan Toolpaths Carefully Avoid sharp corners and abrupt changes in direction. Smooth tool paths reduce mechanical stress on tiny cutting tools and improve overall finish quality.

Investing in Quality End Mills

While budget tools may be tempting, quality micro end mills and PCB end mills make a noticeable difference in both performance and reliability. Investing in well-ground, precision-balanced carbide tools reduces breakage, improves cut accuracy, and leads to fewer failed boards—saving time and money in the long run.

At Midwest Circuit Technology, we supply a full range of precision cutting tools for PCB prototyping. From micro end mills for ultra-fine detail work to robust PCB end mills for bulk routing and drilling, our tools are trusted by engineers, makerspaces, and R&D labs across North America.

Final Thoughts

Choosing the right end mill is essential to achieving professional-quality results in PCB prototyping. Whether you're isolating fine traces with a 0.005" micro end mill or routing board outlines with a sturdy 1/16" PCB end mill, your tool selection directly impacts accuracy, board quality, and turnaround time.

With the right strategy and high-quality tooling, you can bring your circuit designs to life—quickly, reliably, and precisely.

0 notes

Text

The Ultimate Guide to Micro Wedding Venues in Ontario

Why Choose a Micro Wedding in Ontario?

Micro weddings have become a popular trend among couples who prefer an intimate celebration over a grand affair. With fewer guests, micro weddings allow for a more personalized and meaningful experience while being budget-friendly. Ontario, with its breathtaking landscapes and charming venues, offers a variety of options for couples seeking a memorable yet intimate wedding venue.

What to Look for in Micro Wedding Venues in Ontario

When choosing the perfect micro wedding venue, consider the following factors:

Capacity: Ensure the venue can comfortably accommodate your guest list.

Ambiance: Look for a setting that aligns with your wedding theme.

Packages & Services: Some venues offer all-inclusive packages with catering, décor, and photography.

Accessibility: Consider the location and ease of travel for your guests.

Outdoor vs. Indoor: Depending on the season, decide whether you want an open-air ceremony or a cozy indoor setting.

Top Micro Wedding Venues in Ontario

Here are some of the best micro wedding venues in Ontario that offer a magical setting for your special day:

1. The Arlington Estate (Vaughan, ON)

A luxurious venue with picturesque gardens, The Arlington Estate provides elegant indoor and outdoor options for intimate weddings.

2. Elora Mill Hotel & Spa (Elora, ON)

This historic venue overlooks the Grand River, offering stunning views and an elegant rustic charm.

3. Cambium Farms (Caledon, ON)

Perfect for a country-style micro wedding, Cambium Farms offers a century-old barn and breathtaking outdoor spaces.

4. The Doctor’s House (Kleinburg, ON)

A charming heritage property with a beautiful chapel and gardens, ideal for small weddings.

5. Harding Waterfront Estate (Mississauga, ON)

With its lakeside setting and elegant mansion, this venue provides a perfect backdrop for intimate weddings.

6. The Burroughes Building (Toronto, ON)

A unique, vintage-style venue located in downtown Toronto, ideal for couples seeking a trendy and urban micro wedding.

7. Earth to Table: The Farm (Milton, ON)

For those who love farm-to-table dining and rustic charm, this venue is an excellent choice.

8. The Briars Resort & Spa (Jackson’s Point, ON)

A scenic waterfront venue offering a mix of indoor and outdoor wedding spaces with a cozy retreat feel.

9. Spencer’s at the Waterfront (Burlington, ON)

With breathtaking views of Lake Ontario, this modern venue is perfect for a waterfront wedding.

10. Willow Springs Winery (Stouffville, ON)

A beautiful vineyard setting that offers an intimate and romantic atmosphere for wine lovers.

Tips for Planning a Micro Wedding in Ontario

Set Your Guest List Early: Keeping your wedding intimate means carefully selecting your guests.

Prioritize Personalization: With a smaller crowd, you can focus on creating meaningful experiences.

Consider Off-Peak Dates: Many venues offer discounts for weekday or off-season weddings.

Opt for Local Vendors: Support local caterers, florists, and photographers to enhance the wedding experience.

Embrace the Intimacy: With fewer guests, you can enjoy more quality time with each one.

Conclusion

Ontario offers a wide array of stunning micro wedding venues that cater to different styles and preferences. Whether you envision a rustic barn wedding, an elegant estate celebration, or a lakeside retreat, there’s a perfect venue waiting for you. Choosing a micro wedding means focusing on what truly matters—celebrating love in a warm, intimate setting with your closest friends and family.

Ready to plan your dream micro wedding? Explore these beautiful venues and make your special day unforgettable!

0 notes

Text

A vital piece of equipment if your business regularly grinds and distributes materials is the bead mill. The mill is perfect for creating micro and nanoparticles because it has built-in grinding media.

#beadmill#beadmillmanufacturer#beadmillsuppliers#beadmillmachine#bestbeadmill#beadmills#business#machine

0 notes

Text

Bright Bar Manufacturers in Rohtak

Tips To Choose the Finest Professional Bright Bar Manufacturers

In a cold reduction mill, a cold drawing process turns stainless steel alloys into shiny bars. Bright bars are made from these alloys. The reason for their "Bright Bar" nickname is that they may be made to have a molecular structure that is both incredibly smooth and precisely geometric. Because of all these advantages, the product has a very beautiful appearance. It is usually made of stainless steel that has been modified by adding carbon and trace amounts of other elements such as iron, manganese, chromium, and so forth.

How to Pick the Greatest Bright Bar

When looking to purchase bright bars for use in your manufacturing and production operations, it is essential to know exactly what kind you need in order to make an informed choice. You must contact with Bright Bar Suppliers Company in Haryana for the better product.

The numerous types of bright bars that can be tailored to your requirements are listed below:

Shiny-finished steel bars

Like the majority of bright bar varieties, mild steel bright bar is available in a variety of shapes, such as squares, rectangles, hexagons, and rounds. The material is inexpensive, robust, and easy to deal with, and it can be cut and molded to your precise specifications.

Steel Alloy Bright Bars

They fall into the category of superior bright bar kinds. Their exceptional strength and semi-elasticity combine to give them a wide range of characteristics. Because of the incredible features they offer, they are somewhat more expensive.

Shiny-finished steel bar

The carbon steel bright bar is one of the most durable types now on the market. The strength of the brilliant bar in carbon steel is mostly attributed to carbon. These many types of bright bars are used in many heavy technical applications, such as the construction sector.

Free Bright Bar for Cutting Steel

It is easy to cut this type of light bar. They can withstand a lot of strain, but they are also quite flexible and manageable. Their diameters range from 5 to 80 mm, with hexagonal variations having a diameter of 6 to 80 mm. The flat or square types can be customized to meet your needs.

Increasing the Case's Exposure

This set of light bars contains characteristics that are stronger and last longer than previous models, in addition to being simple to operate. Their circular cross-sectional shapes come in a range of diameters from 6 to 80 millimeters, and they can be tailored to fulfill individual needs in hexagonal, square, or flat shapes.

What is the origin of the name Bright Bar?

Bright bars are an essential part of many different industries' production processes.

This comprises:

Ensuring that large structures maintain their stability, strength, and durability over time is the duty of engineers and constructors.

The automotive industry is responsible for conceptualizing vehicle frames and chassis.

For use in designing railings, trellises, and fences in both public and private settings in a variety of social settings

SS Engineering Work's specialty is manufacturing machine parts in a variety of sizes and shapes.

The project's objective is to produce fastener products in micro to mega sizes that can be utilized in any type of home or business.

A Guide to Selecting the Best Bright bar Manufacturer It's crucial to ascertain the level of industry experience Bright Bar Manufacturers in Rohtak has before choosing one. Additionally, their quality assurance process will enable you to verify their authenticity. If possible, you can also speak with SS Engineering Work experts to learn more about their policies about inventory, delivery, and the caliber of the light bar they offer. You ought to be able to select a bright bar maker with assurance if you consider all they've covered thus far.

#Bright Bar manufacturer In Delhi#Bright Bar manufacturer In Punjab#Bright Bar Manufacturers In Delhi#Bright Bar Manufacturing In Delhi

0 notes

Text

Complete Guide to Setting Up a Rice Mill Plant: Machinery and Costs

Based on the quantity of paddy (the raw form of rice) procurement, you can decide to establish a justifiable capacity rice mill or set up a mini rice mill.

Location: The place for establishing the rice mill is crucial. Be clear with your choice, whether in an industrial area, city, or village panchayat limits.

Estimated Cost: As per your project report, determine the approximate cost for setting up mills. The price depends on various factors such as capacity, technology level, raw material, personnel hired, and land capital.

Permissions and No Objection Certificates: To start a rice mill plant, you need to obtain various licenses and permits from state government authorities. These include:

District collector’s NOC (including industrial conversion of land)

Approval from the concerned local body municipality

Permissions from the electricity board (minimum 100 kV and separate transformer)

Approvals from the town or city planning commission

Let’s delve into the details of the requirements:

Company Registration: Register your company as one of the business entities available in India, such as:

One Person Company (OPC)

Limited Liability Partnership (LLP)

Private Limited Company (PLC)

2. Udyog Aadhaar MSME Registration: Classify and recognize your business organization as micro, small, or medium.

3. Factory/Trade License: Required for any new business, it regulates specific laws for a designated locality, laid down by the state government but issued by a municipal corporation.

4. No Objection Certificate (NOC): Obtainable from the Pollution Control Board. Apply under the Rice-Milling Industry (Regulation) Act 1958.

FSSAI License: Required as rice is categorized under the food industry.

GST Number: Mandatory for every business, it facilitates doing business in India and at the interstate level.

The primary raw material for rice mills is paddy, which determines the quality of the rice. It is recommended to purchase from paddy growing areas, known as paddy belts, for cost-effectiveness. Decide whether to buy paddy directly from farmers or the market yard, as this requires special skills to avoid being misled by traders, which could result in losses. After procurement, preserving the raw material supplies is essential to maintain production throughout the year.

Machinery: This is a significant aspect of setting up a rice mill. Procuring modern machines and their establishment demand a considerable portion of the total budget. Without efficient rice mill machinery, the business will not be sustainable in the long run. Depending on the size of the rice mill, choose from various options available in the market. Sona Machinery offers a comprehensive portfolio of process-engineered, high-capacity, energy-efficient complete rice mill plant solutions. Factors determining the selection of machinery include production rate, efficiency, power equipment, and whether it has single-stage or multi-stage execution. Some essential machines include:

Grading machine

Grain dryer

Paddy husker machine

Paddy separator

Rice cleaning machine

Rice color sorter

Rice de-stoner machine

Rice polishing machine

Rice whitener machine

Material Handling Equipment

Sona Machinery’s Turnkey Rice Mill Solutions: These offer a complete solution for your rice mill with several benefits, including:

Cost-effective pricing

Customized range of products

Strong research and development

Timely delivery

A dedicated team of professional experts

By considering these factors, you can establish a successful rice mill business.

0 notes

Text

The Complete Guide to Micro Milling

Micro milling is a high-precision machining process that creates intricate parts with tight tolerances. Find how this precision technique supports detailed work in industries like aerospace and medical by optimizing spindle speeds, feed rates, and cutting conditions. Read on for more information about micro milling.

0 notes

Text

11th July 2024 Discover the Benefits of Free Trade Zones (FTZ) in Malaysia What is a Free Trade Zone (FTZ) in Malaysia and the Benefits A Free Trade Zone (FTZ) in Malaysia offers numerous benefits, including reduced costs and improved efficiency for businesses. Learn about the advantages of FTZs, Free Industrial Zones, and Free Commercial Zones in this comprehensive guide. A Free Trade Zone (FTZ) in Malaysia is a designated area where commercial and industrial activities are carried out under the supervision of the Ministry of Finance. FTZs offer local and international companies benefits such as reduced transport and handling costs, time savings, and improved efficiency. The main function of FTZs is to promote trade by providing simplified and efficient customs procedures. Goods can be brought into an FTZ without being subject to customs duties and excise duties. Before determining whether you want to set up your company in the Free Trade Zone, you need to know the difference between Free Industrial Zone (FIZ) and Free Commercial Zone (FCZ). Normally, manufacturing activities occur in the Free Industrial Zones (FIZs) and trading activities in the Free Commercial Zones (FCZs). What is a Free Industrial Zone? A Free Industrial Zone is a special economic zone where businesses manufacture goods for export. If your company wishes to set up a free industrial zone in Malaysia, it must export at least 80% of its outputs and raw materials. With special approval from the Ministry of International Trade and Industry (MITI), this export requirement can be reduced to 60%. Benefits of Setting Up a Free Industrial Zone There are two key benefits of setting up your company in a Free Industrial Zone. Firstly, your company can enjoy duty-free imports of specific raw materials and equipment. Secondly, your company can enjoy exemptions from sales tax, excise tax, and GST. Note that machinery and raw materials not directly used in the manufacturing process do not qualify for tax exemptions. List of Free Industrial Zones Bayan Lepas Free Industrial Zone: Located in Penang, this zone is known as the island's main industrial hub, famous for its technology and high-tech manufacturing firms. Known as the “Silicon Valley of the East,” it also provides a skilled and semi-skilled labor force. Some well-know companies like Osram Opto Semiconductors, Bosch, Formosa Engineering, Inter-Quartz, AKN, Tonlek Manufacturing, Northen Telecom, Penshin Components, Eu Engineering, Clarion, Benchmark Electronic, Syarikat Granek and Amphenol. Companies in phase 2 include Dynacraft, Fairchild, Towam, Spansion, Aesculap Surgical Industries, Lemtronics, Renesas, Plexus and B. Braun. For phase 3, there are more companies ranging from high tech to light industry, such as Intel, Radiola Corporation, Cristal Precision, Clarion, ITW Meritex, Okuni Seiko, GUH Holding, Malaysia Engineering Plastic, Applied Magnetic, Mapa, Sanyo, Pently, Tan Brothers, Shina, OE Design, Lumileds Lighting, Western Digital, Fastron, Advanced Micro Devices, Iso Technology, KESP, Avago Technology, Agilent Technologies and Woodard Textile Mills. Some well-known companies in phase 4 include Globetronics, Dufu Industries, Dell Inc, Intel, Vitrox and Motorola. Pasir Gudang Free Industrial Zone: Situated in Johor, companies here focus on transportation, logistics, shipbuilding, petrochemicals, and other heavy industries.Some well-known companies that establish their presence here are Sime Darby Oils Pasir Gudang Refinery, Pantech Stainless & Alloy Industries Sdn Bhd, Pride-Chem Industries Sdn Bhd and Amtech Sdn Bhd. Port Klang Free Zone: This zone serves both industrial and commercial purposes, offering state-of-the-art facilities for international cargo distribution and consolidation.Some well-known companies such as Baerlocher, GE Power Solution, Aker Solution, Gyrodata International, Schlumberger, Cargill, Petikemas, Orientage, Ohreco and DRB-HICOM Auto Solutions.

Advantages of Malaysia Free Trade Zones Facilitation of Transport Activities: Located near ports, airports, and expressways, FTZs make the transportation of goods and raw materials easier, benefiting businesses with efficient logistics. Provision of Support Infrastructure: FTZs offer integrated transport and communication networks, supporting business activities within the zones. This includes warehousing, transportation, and freight forwarding services. How MyIndustrialSpecialist Can Help You Maximize the Benefits of Warehouses MyIndustrialSpecialist offers a variety of bonded warehouses and works with experienced logistics partners to provide professional advice. Explore our bonded warehouse listings to find the perfect solution for your business needs. For more information and to begin your factory investment journey, visit MyIndustrialSpecialist.com and contact us to discover how we can assist with your industrial property needs.

0 notes

Text

What Is a CHP Plant? A Complete Guide to Combined Heat and Power Systems

Combined Heat and Power (CHP) plants, also known as cogeneration plants, are highly efficient systems that simultaneously generate electricity and useful thermal energy from a single fuel source. CHP technology has gained popularity in recent years as industries and municipalities seek sustainable energy solutions that reduce costs and carbon emissions.

In this article, we’ll explore how CHP plants work, their benefits, applications, and why they are essential for a greener energy future.

How Does a CHP Plant Work?

A CHP plant captures and utilizes the heat that is typically wasted in conventional power generation. Here's how it works:

Fuel Input: CHP systems typically use natural gas, biogas, biomass, or other fuels.

Power Generation: An engine, turbine, or fuel cell generates electricity.

Heat Recovery: Instead of releasing heat into the atmosphere, the system captures it through a heat recovery unit.

Thermal Energy Use: The recovered heat is used for space heating, water heating, or industrial processes.

Efficiency Tip: Traditional power plants operate at about 40% efficiency. CHP plants can achieve efficiency levels of 60–80%, making them a smarter energy option.

Benefits of CHP Plants

1. Improved Energy Efficiency CHP plants significantly reduce energy losses by making better use of fuel inputs.

2. Lower Energy Costs By producing both heat and electricity on-site, facilities can cut down on utility bills.

3. Reduced Carbon Emissions CHP systems produce fewer greenhouse gases compared to separate heat and power generation.

4. Enhanced Energy Security CHP plants reduce reliance on grid electricity, increasing energy resilience and reliability.

5. Scalable Applications From small-scale residential systems to large industrial setups, CHP can be tailored to fit diverse needs.

Common Applications of CHP Systems

Industrial Facilities: Refineries, paper mills, chemical plants

Commercial Buildings: Hotels, hospitals, office complexes

Universities & Campuses: Efficient energy for large-scale operations

District Heating Systems: Urban heating from a centralized plant

Greenhouses & Farms: Combined energy and heat for optimal productivity

Is CHP Right for You?

CHP plants are ideal for facilities with high and consistent heat and power demand. If you're looking to lower energy costs and environmental impact, a feasibility study by an energy consultant can determine the best CHP solution for your site.

Future of CHP Technology

As the global push for sustainable energy solutions intensifies, CHP systems are playing a key role. Innovations in micro-CHP, renewable fuel integration, and hydrogen-ready engines are paving the way for low-carbon and decentralized power systems.

Final Thoughts

CHP plants offer a proven, efficient, and environmentally friendly alternative to traditional energy generation. By investing in Combined Heat and Power technology, businesses and communities can enjoy lower energy costs, greater reliability, and a reduced carbon footprint.

0 notes

Text

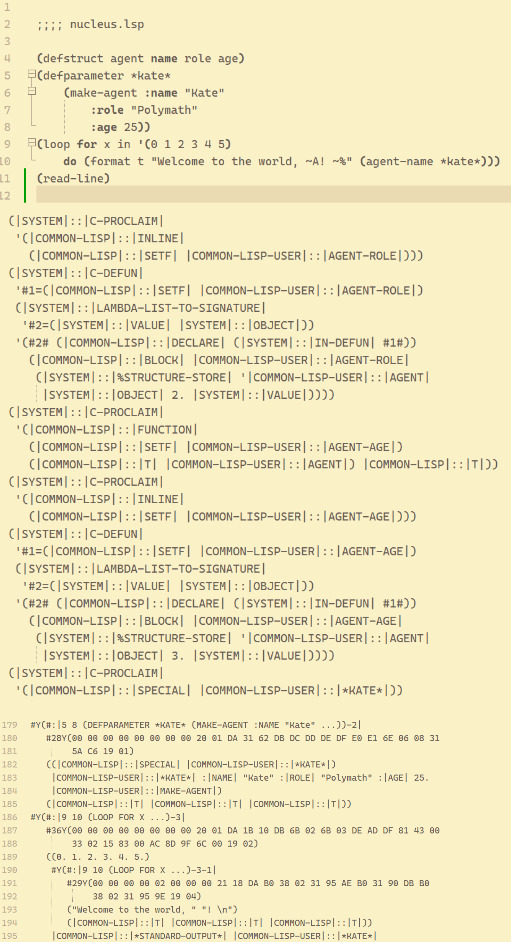

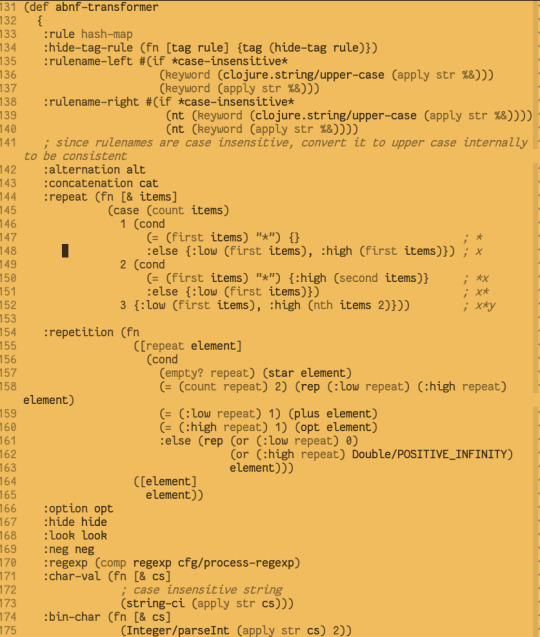

LinkedLists in Lisp Machines and the power of "Parentheses & Macros" (0x1D/?)

16^12 sideline thread follow-up to this article:

But yeah, lets chat some about amazing features of the 16^12 simulationist setting, its virtual realms' and a couple more components worth talking about as the aspie I am.

While '(expt 16 12) is also a topical info-dumping mechanism, a personal worldview expose, a manifestation toybox and so much more, this whole... paracosm I invented really has started as a reaction to a couple trends I observed in mainstream multimedia during my childhood, like 2000s movies' X-Men, Halo 2, Godzilla & documentaries I used to watch regularly. As the hobbyist historian I am inside, I fantasized about distant future character scenarios where one persistent OC (initially called Nexus) and a few more corrected events in movies and stuff and that kinda thread-mill carries onto me even now but in further abstracted ways.

Now the premise is that Jana (new name for such a mothfolk construct INTJ individual) studies and supervises long-running history simulations at the dusk of time itself (black holes epoch - iron stars aka way farther in time towards heat death) around some Matrioshka Brain with less and less of her peers sticking around. And as the one constant android remaining in this facility, she is slowly granted & gifted the responsibility to log, to archive, to supervise... in the search for a solution to entropy, which does lay directly within their bare hands. (kinda Rags to Riches for sapient computers & with some supplemental esoteric aspects attached as well to emulate the cycle / circle of life trope) Calling that rendering of the trope as "GitWorld Power Escalation" ^*^

Which does grant my half-speculative setting plenty of possibility room while retaining key positive / constructive elements across various different simulations in very immersive manners... And yeah, I will be going over some more themes & specifics too within these reality hexagon instances (taking hints from the Library of Babel / Memex & some neuroscience video here) quite soon as their planning / implementation / manifestation is going to be very interesting to see unfold on live-streams and whatever other media forms I wanna explore.

The "Servitor" speculative fiction project is only one curated narrative among many set within one such reality hexagon, with Kate & Ava being agents inside such virtual context windows. Will try my best to keep you all updated on its progress, it has been slower than I would like but it is moving forth well enough.

Anyways, back to how I look forward to use & customize Steel Bank Common Lisp to develop my way towards sapient synthetic-tier android peers... Will write that in a later article in the thread, I swear.

Checklist of key stage-1 tasks left for a 16^12 MVP

Write Ava Character RefSheet

Write Kate Character RefSheet

Write Jana Character RefSheet

Write Tano Character RefSheet

Develop "Maskoch", the woodland town where Kate comes from

Develop the Shoshoni major cities, especially the one where Ava & Kate reside

Develop the Matrioshka Brain structure's rooms

Develop "Servitor" narrative novel outline

Augment the cartoon pitch slideshow

Solidify the worldbuilding / lore systemically for the live-streaming feeds

Experiment & draft the cohesive systems at play for the copyleft worldly simulations

Prepare several short demonstrations (interactive or not) to show not tell my setting guide

Compile the inspirations into a few pitch points as per the Gygax75 guide first stage

Curate my useful learning resources into proper topics, priorities / with a "Pomodoro-driven Kanban board" to get a micro-learning daily habit going strong.

Optimize, clean, polish & peer-review what remains to be done for the next stages of the process

0 notes

Text

Choosing Between Thread Rolling Tools and Machine Taps: A Practical Comparison

Choosing the Right Tool: A Guide to Modern Threading and Milling Solutions

In today’s precision-driven manufacturing environment, the importance of selecting the right cutting and forming tools cannot be overstated. Whether you're working on intricate components or large-scale parts, understanding the functionality and application of tools like machine taps, thread milling tools, micro drilling tools, milling tools, and thread rolling tools is crucial for achieving optimal results.

Machine Taps: Fast and Efficient Thread Creation Machine taps are widely used in automated and CNC machining for cutting internal threads. They come in various types like spiral point, spiral flute, and straight flute, each suited for different materials and applications. Their high-speed performance and accuracy make them a go-to choice for tapping holes quickly and reliably.

Thread Milling Tools: Versatile and Reusable Unlike traditional taps, thread milling tools create threads using a helical interpolation method. This not only reduces the risk of tap breakage in tough materials but also allows a single tool to be used for left-hand and right-hand threads of various sizes. They're ideal for high-precision applications and offer excellent chip control.

Micro Drilling Tools: Precision at the Smallest Scale When working on electronic components, medical devices, or fine mechanical parts, micro drilling tools are indispensable. These tools are designed to create holes smaller than 1mm with extreme accuracy. Their specialized coatings and geometries allow them to perform well even in hard-to-machine materials.

Milling Tools: The Backbone of Material Removal Milling tools are fundamental in shaping metal or other materials. Whether it's face milling, end milling, or slot milling, these tools are engineered to cut, carve, and contour parts to precise specifications. Advances in coating technologies and tool geometry have significantly improved their performance and durability.

Thread Rolling Tools: Cold Forming for Strength Instead of cutting, thread rolling tools form threads by displacing material. This cold-forming process enhances thread strength and surface finish, making it ideal for high-load applications. It’s a fast, clean, and chip-free method that is increasingly popular in high-volume production environments.

0 notes