#Modicon

Text

BMXDDI3202K - module đầu vào rời, Modicon X80, 32 đầu vào, 24V DC dương

0 notes

Photo

Icefall is Here Again, Two Critical Vulnerabilities found in Schneider Electric's Modicon

0 notes

Text

Details Disclosed After Schneider Electric Patches Critical Flaw Allowing PLC Hacking

Details Disclosed After Schneider Electric Patches Critical Flaw Allowing PLC Hacking

Home › ICS/OT

Details Disclosed After Schneider Electric Patches Critical Flaw Allowing PLC Hacking

By Eduard Kovacs on September 29, 2022

Tweet

Schneider Electric in recent months released patches for its EcoStruxure platform and some Modicon programmable logic controllers (PLCs) to address a critical vulnerability that was disclosed more than a year ago.

The flaw in question, tracked as…

View On WordPress

0 notes

Text

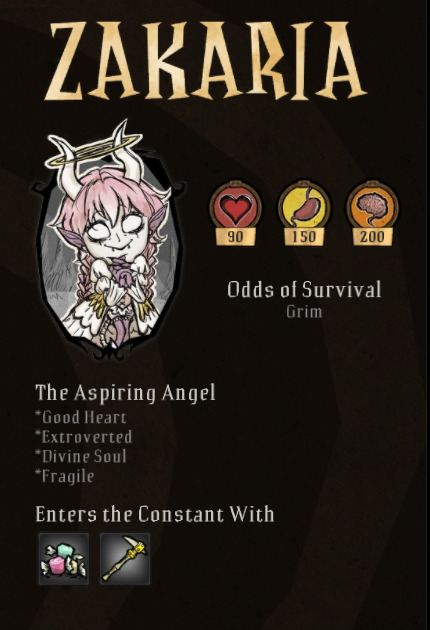

my journey in DST modding: day 7

yes, today is the final day for art. the "Tale of Tails" didnt end exactly how i wanted it to, but it was the best i could do with what i had.

.

first thing i did was tackle the ghost part: i cut her horns from the headbase, resized the ghost pngs and pasted them on there. with a few adjustments. but of course resizing the fucking file means i have to edit the eye placement.

.

my first try vs messing with the pivot point in under a minute:

a good start already.

.

i changed some minor stuff in the other files (added the modicon, silho, swap icon, etc), but now im proud to say that i have a working, fully animated demon girl:

obviously she doesnt look perfect, but at least it's decent.

.

some problems that i havent been able to fix:

the scale. she looks fine next to wilson, but hats still look fucked up on her.

the fact that some things STILL move out of place. the back view is the worst of all three because there are too many things moving all the time. as much as i tried to camouflage the tail into the coat, it still moves on its own cause thats how it's animated. (would be awesome if yall just ignored it)

she can't wear any skins. all the parts are too dependant on each other for that to work, especially the tail.

.

these are her final looks (changed some info in the select screen):

.

i can't believe this is finally over. it's been one hell of a week. we are still not done, but now it's out of my hands and into my friend's. ill keep you posted of anything that happens.

.

thanks for reading!

#don't starve together#don't starve together mod#dst mod#dst modding#dst oc#original character#oc#oc art#sunny speaking

8 notes

·

View notes

Text

Automation Components: Essential Parts for Streamlining Your Industrial Processes

Automation components are the fundamental and essential elements of most contemporary industries. They are used to ensure that the machines and the processes are in tandem and optimized. Here, we’ll discuss what automation components are, why such components are necessary, as well as how they can change your work for the better.

What Are Automation Components?

Automation parts are auto components that are involved in the machinery and systems to perform automated operations. These components can include:

· Sensors:

These are used for identifying changes in its surroundings such as temperature or pressure. They assist some machinery to respond one way or the other depending on the prevailing circumstances.

· Actuators:

These are devices that either operate a device or are used to do so. For example, it can open the valve or move the robotic arm. In addition, such systems can be managed by a few workers not promptly monitoring the equipment.

· Controllers:

Two of the most used are Programmable Logic Controllers (PLCs), and Distributed Control Systems (DCS).

· Relays and Switches:

These regulate the intensity of current going to the various regions of a given gadget.

· Communication Devices:

These ensure that the various components of a system can communicate. They inform various components of a system.

All of these components are very useful and serve a very important task of ensuring that machinery is fully functional and effective.

Popular Brands and Products in Automation Components

1. Allen-Bradley

Overview: Allen-Bradley is a well-established brand that is a subsidiary of Rockwell Automation Company. Their products are highly regarded. They supply moderate range of components that you can find useful in different fields.

Popular Products:

Programmable Logic Controllers (PLCs)

Human-Machine Interfaces (HMIs)

Safety Components

2. Siemens

Overview: Automation technology is the specialty of Siemens which is a global company. They encompass many industries such as the manufacturing industry and energy industries.

Popular Products:

SIMATIC PLCs

SENSORs

Drive Systems

3. Schneider Electric

Overview: Schneider Electric is a company that only deals with energy management as well as automation solutions. The products they offer are made in a very efficient and sustainable way. Popular Products:

Modicon PLCs

Variable Frequency Drives (VFDs)

Smart Sensors

4. Honeywell

Overview: Honeywell is known for its innovative solutions in automation and control. They provide products that enhance safety and efficiency.

Popular Products:

Honeywell R4343 E1048 Flame Detector Relay

Pressure Transmitters

Control Systems

5. Danfoss

Overview: Danfoss is renowned for its high-quality components focused on energy efficiency and sustainability.

Popular Products:

Danfoss MBS 5100 Pressure Transmitter

Danfoss MBS 5150 Pressure Transmitter

Danfoss MBC 5100 Pressure Control

Final Words

If you're considering automation for your business, Ram Automations offers a wide range of quality components from trusted brands. With a focus on quality, reliability, and customer satisfaction, we help our clients streamline their processes and achieve their goals.

0 notes

Text

How to use BLIIoT ARM Embedded Computers ARMxy Series with LabVIEW to Easily Collect Modbus Data?

What is LabVIEW?

LabVIEW is a graphical programming software developed by National Instruments (NI). It provides an intuitive way to design measurement and control systems and is widely used in scientific research, engineering design, industrial automation and other fields. LabVIEW uses a graphical programming language G (Graphical Language), which allows users to quickly build applications by dragging icons and connecting lines, thereby simplifying the development process of complex systems.

What is Modbus?

Modbus is an open standard serial communication protocol, originally introduced by Modicon (now part of Schneider Electric) in 1979, for connecting industrial electronic equipment. It is widely used in industrial automation systems as a means of communication between master devices (such as PLCs) and slave devices (such as sensors and actuators). Modbus supports multiple physical layer protocols, including RS-232, RS-485, etc., and also supports TCP/IP networks.

The Modbus protocol defines a series of standard message structures that can be used to request or send data. The two most common data types are Coil Status and Holding Registers. Through these data types, Modbus can query the status of remote devices and control operations.

The biggest advantage of using LabVIEW to collect Modbus data is that its graphical programming environment greatly simplifies the development process. Built-in Modbus support and wide hardware compatibility make data acquisition more efficient and flexible. At the same time, powerful error handling capabilities and cross-platform compatibility ensure the stability and portability of the system.

How to collect Modbus data with LabVIEW?

Preparation

Install LabVIEW: ARM industrial computer has LabVIEW software installed.

Prepare Modbus device: Make sure the Modbus device is correctly configured and connected to the computer or network.

Programming

Select Modbus library: LabVIEW provides a built-in set of Modbus functions, which can be found in the function palette. In addition, you can also consider using third-party toolkits, such as MCC Modbus Toolkit.

Configure Modbus communication: Use the Modbus configuration function in LabVIEW to set communication parameters, including serial port, device address, baud rate, etc.

Read register data: Use the Modbus Read Holding Registers function to read register data on the Modbus device.

Write register data: If necessary, you can also use the Modbus Write Holding Register function to modify the register value on the device.

Testing and debugging

Simulation test: Before actual deployment, you can use simulation equipment for preliminary testing.

Field test: Connect the program to the actual Modbus device for testing to ensure that data collection is accurate.

Conclusion

In conclusion, using LabVIEW to collect Modbus data can not only improve development efficiency, but also ensure the accuracy and stability of data acquisition. LabVIEW is an indispensable tool in the field of industrial automation. By making full use of its advantages, a high-performance and reliable data acquisition system can be built.

More information about BLIIoT ARM Embedded Computer ARMxy series: https://www.bliiot.com/industrial-computer-p00462p1.html

0 notes

Text

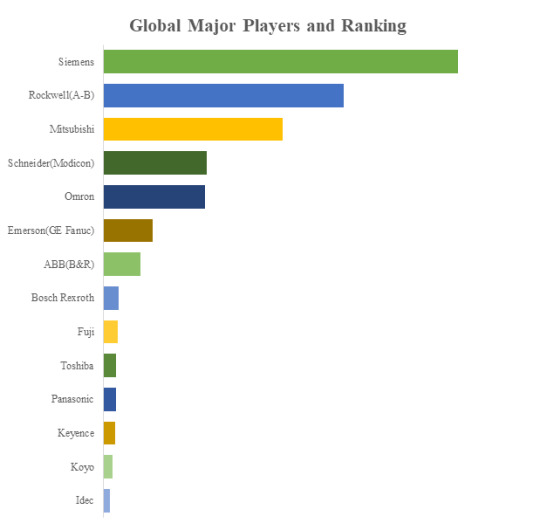

Contrôleur Logique Programmable (PLC), Prévisions de la Taille du Marché Mondial, Classement et Part de Marché des 14 Premières Entreprises

Selon le nouveau rapport d'étude de marché “Rapport sur le marché mondial de Contrôleur Logique Programmable (PLC) 2024-2030”, publié par QYResearch, la taille du marché mondial de Contrôleur Logique Programmable (PLC) devrait atteindre 21840 millions de dollars d'ici 2030, à un TCAC de 4,3% au cours de la période de prévision.

Figure 1. Taille du marché mondial de Contrôleur Logique Programmable (PLC) (en millions de dollars américains), 2019-2030

Figure 2. Classement et part de marché des 14 premiers acteurs mondiaux de Contrôleur Logique Programmable (PLC) (Le classement est basé sur le chiffre d'affaires de 2023, continuellement mis à jour)

Selon QYResearch, les principaux fabricants mondiaux de Contrôleur Logique Programmable (PLC) comprennent Siemens, Rockwell(A-B), Mitsubishi, Schneider(Modicon), Omron, Emerson(GE Fanuc), ABB(B&R), Bosch Rexroth, Fuji, Toshiba, etc. En 2023, les dix premiers acteurs mondiaux détenaient une part d'environ 91,0% en termes de chiffre d'affaires.

À propos de QYResearch

QYResearch a été fondée en 2007 en Californie aux États-Unis. C'est une société de conseil et d'étude de marché de premier plan à l'échelle mondiale. Avec plus de 17 ans d'expérience et une équipe de recherche professionnelle dans différentes villes du monde, QYResearch se concentre sur le conseil en gestion, les services de base de données et de séminaires, le conseil en IPO, la recherche de la chaîne industrielle et la recherche personnalisée. Nous société a pour objectif d’aider nos clients à réussir en leur fournissant un modèle de revenus non linéaire. Nous sommes mondialement reconnus pour notre vaste portefeuille de services, notre bonne citoyenneté d'entreprise et notre fort engagement envers la durabilité. Jusqu'à présent, nous avons coopéré avec plus de 60 000 clients sur les cinq continents. Coopérons et bâtissons ensemble un avenir prometteur et meilleur.

QYResearch est une société de conseil de grande envergure de renommée mondiale. Elle couvre divers segments de marché de la chaîne industrielle de haute technologie, notamment la chaîne industrielle des semi-conducteurs (équipements et pièces de semi-conducteurs, matériaux semi-conducteurs, circuits intégrés, fonderie, emballage et test, dispositifs discrets, capteurs, dispositifs optoélectroniques), la chaîne industrielle photovoltaïque (équipements, cellules, modules, supports de matériaux auxiliaires, onduleurs, terminaux de centrales électriques), la chaîne industrielle des véhicules électriques à énergie nouvelle (batteries et matériaux, pièces automobiles, batteries, moteurs, commande électronique, semi-conducteurs automobiles, etc.), la chaîne industrielle des communications (équipements de système de communication, équipements terminaux, composants électroniques, frontaux RF, modules optiques, 4G/5G/6G, large bande, IoT, économie numérique, IA), la chaîne industrielle des matériaux avancés (matériaux métalliques, polymères, céramiques, nano matériaux, etc.), la chaîne industrielle de fabrication de machines (machines-outils CNC, machines de construction, machines électriques, automatisation 3C, robots industriels, lasers, contrôle industriel, drones), l'alimentation, les boissons et les produits pharmaceutiques, l'équipement médical, l'agriculture, etc.

0 notes

Text

The Schneider TSXASY800 is a reliable analog output module designed for industrial automation. It provides precise control and monitoring of various processes, with 8 analog output channels for smooth signal conversion. Compatible with Modicon TSX Micro and TSX Premium PLCs, it ensures seamless integration and easy setup. The TSXASY800 delivers accurate performance, enhancing system efficiency and reliability. Ideal for applications requiring precise analog signal management, this module supports a wide range of industrial operations. Robust and versatile, the Schneider TSXASY800 is essential for optimizing process control in modern automation systems.

#auto2mation#industrial automation#industrial equipment#industrial and marine automation#industrial spare parts#industrial automation equipment#industrial and marine automation equipment#Schneider#analog output module#industrial innovation

0 notes

Text

Magnumpihonhi Wholesale Deals

https://www.ebay.com/str/magnumpihonhiwholesaledeals

About us

Welcome to my eBay Store. Please add me to your list of favorite sellers and visit often. Thank you! Magnumpihonhi Wholesale Deals Selling of Industrial automation controls surplus parts, New & Used - Industrial - Electrical - Mechanical Motors - Transformers - PLCs - Pumps- Valves-Brakes- Power Transmission-electrical distribution- circuit breakers- sensors-Material Handling Equipment- HVAC and so much more.

Allen Bradley, Modicon, Siemens, Square D, Dynapar, Omron, Reliance Electric, Sick Optic,Symax,Texas Instruments,Graco,Titan, Spraytech, Binks HVAC Rockwell Software, Rockwell Automation, Anorad, CEDES, Guardmaster, Hengsheng, Hinz, HIPROM, ICS Triplex, LeKtroniX, Pavilion Technologies, ProsCon, SoftSwitching Technologies, TESCH, vMonitor

https://www.ebay.com/str/magnumpihonhiwholesaledeal

0 notes

Text

Renegade Electrics - Automation + Control Limited - PLC Controller Programming in New Zealand

Renegade Electrics introduces Modicon PLC Controllers in New Zealand, revolutionizing automation with precision and reliability. Trust our cutting-edge solutions to optimize your operations efficiently. Elevate your control systems with Renegade Electrics - Automation + Control Limited.

#PLC Controller Programming in new zealand#Low-cost PLC controllers in new zealand#PLC controller in new zealand#PLC controllers in new zealand#PLC control systems in new zealand#Low-cost PLC controller in new zealand#PLC control services in new zealand

0 notes

Text

What is the future of PLC in industrial automation?

Introduction.

The evolution of Programmable Logic Controllers (PLCs) has profoundly shaped the landscape of industrial automation. From their origins in relay logic systems to their integration with cutting-edge technologies, PLCs have been instrumental in revolutionizing how industries operate. This journey has seen significant milestones, including the birth of relay logic, the creation of the first true PLC by Dick Morley, and the adoption of industry standards. Today, PLCs continue to dominate manufacturing and extend their influence into energy management, building automation, and more. However, they face challenges in scalability, integration, and maintenance. Looking ahead, the future of PLCs holds promise, with emerging technologies like IoT, AI, and machine learning poised to enhance efficiency, sustainability, and adaptability, albeit accompanied by concerns regarding cybersecurity and workforce adaptation.

Past Innovations and Achievements.

The history of Programmable Logic Controllers (PLCs) is a story of important developments and how they've changed the way we make things. PLCs have been a big deal in the world of automation, making factories and other processes work better and faster.

Milestones in PLC Technology.

Milestones are important moments in the history of PLC technology when it made significant advancements, allowing for more automation. These key points in the evolution of PLCs include:

1. Birth of Relay Logic:

PLCs started from relay logic, an old way of controlling machines using switches and wires. This old method from the early 1900s was the starting point for developing PLCs.

2. Introduction of the Modicon 084:

In 1968, a big step forward happened with the creation of the Modicon 084 made by Dick Morley. This device is seen as the first real PLC and it changed the way control systems worked, shifting from relying on physical parts to using computer programs to control things.

3. Evolution of the PLC-3 and PLC-5:

In the 1970s and 1980s, Allen-Bradley created the PLC-3 and PLC-5. These machines were better because they could do multiple tasks at once and store more information which made industries work better.

4. Adoption of the IEC 61131 Standard:

The IEC 61131 standard made it easier for engineers to talk to PLCs by creating common languages like ladder logic and function block diagrams. This helped make things more consistent and compatible in the industry.

Early Origins and Development

To truly understand how PLC technology came to be it's important to know about its early stages which can be broken down into these phases:

1. Emergence of Relay-Based Control Systems:

Before PLCs were invented industries used relay-based systems to control machines and processes. These systems worked but had limitations because they couldn't easily adapt or grow.

2. Dick Morley and the "Father of the PLC":

Dick Morley, an American engineer is known as the "Father of the PLC." He became famous for inventing the Modicon 084 a device that replaced complicated relay systems. This all started with a bet made during a casual drink with friends. The bet was to create a controller that could do the job of those complex relays. And Morley succeeded changing the way industrial automation works.

3. Transition to Digital Logic:

PLC technology changed how we control things. It went from using older less advanced methods to using computers with memory. This made it easier for engineers to make and change control programs.

Advancements in Programmable Logic Controllers

As technology got better, PLCs also improved a lot. Some important changes were made to make them more powerful and useful. These changes include:

1. Microprocessor Integration:

Adding tiny but powerful chips to PLCs made them much better. They can now follow instructions and do difficult math stuff much faster.

2. Enhanced Communication Protocols:

PLCs have changed to work better with modern technology. They can now talk to other machines using things like Ethernet/IP, Profibus and Modbus TCP/IP. This makes it easier to share information and check on things from far away.

3. Scalability and Modularity:

Modern PLCs can be adjusted and changed to fit the needs of different industries like car factories or food processing.

Real-World Applications

The real value of any new technology is seen in how it's used in the real world. PLCs are now being used in many different situations changing how industries work.

1. Manufacturing and Assembly Lines:

PLCs are like secret champions in factories. They manage tricky tasks like putting things together just right and making sure everything moves smoothly. They're in charge of robots and conveyor belts making sure everything is made perfectly.

2. Building Automation:

In building automation PLCs control things like heating, cooling, lights and security making buildings use less energy and safer.

3. Energy Management:

PLCs are important for managing energy, controlling how power is sent around, keeping an eye on how much energy is used and making smart grids work better.

4. Water Treatment and Wastewater Management:

Water treatment plants use special computer systems to make sure our drinking water is clean and safe. These systems also help manage dirty water to keep our environment clean.

Current Landscape of PLC in Industrial Automation

In today's world of advanced automation Programmable Logic Controllers (PLCs) play a crucial role in coordinating and controlling various tasks in different industries. These devices are particularly important in manufacturing. They make things run smoothly, but there are some issues like expanding the system and keeping it in good shape. Let's take a closer look at what's happening in this field and the challenges it faces.

The Dominance of PLC in Manufacturing

PLCs are vital in manufacturing. They work seamlessly on assembly lines and production floors, making things run efficiently. They control various tasks from robots to conveyor belts to ensuring everything works smoothly.

In the world of automation PLCs give manufacturers an advantage as they can control things in real-time and adjust to changing needs with accuracy. As manufacturing changes, the PLCs are still essential for keeping quality high, improving production and reducing mistakes.

Key Industries Utilizing PLC

PLCs are not just for factories other important industries use them too. These industries are:

1. Energy and Utilities:

PLCs are like energy superheroes in the power world. They help control where electricity goes, keep an eye on how much is used and make sure smart grids work smoothly. They're like the protectors of energy efficiency.

2. Building Automation:

In smart buildings, PLCs are like the brain that controls things to make the place comfy and safe. They manage the temperature, air, lights and security.

3. Food and Beverage:

In cooking and making drinks, PLCs make sure everything is done just right. They help keep the taste and safety the same every time from following recipes to checking the quality of what's made.

4. Water Treatment and Wastewater Management:

Water treatment and cleaning our used water wouldn't work well without PLCs. They are like silent helpers that make sure our water is safe and stays around for a long time.

Challenges Faced by Traditional PLC Systems

PLCs are known for making things work automatically and efficiently but old systems face problems in today's fast-changing technology world.

1. Scalability:

Older PLCs can struggle to adapt to the changing needs of today's industries. Making them bigger or changing them to handle more work can be really hard.

2. Integration Issues:

As industries rely more on data and connect different machines making them talk to each other can be tricky. Making sure that computers (PLCs) can talk to all kinds of equipment needs careful planning and doing things carefully.

3. Maintenance and Downtime Concerns:

PLCs like complex machines those needed to be taken care of. But when we stop them for maintenance it can slow down work and make things less efficient. Hence, industries have to find a balance between keeping the system healthy and not causing too much disruption.

The Future of PLC in Industrial Automation

Industrial automation is changing, and the key to this change is the Programmable Logic Controller (PLC). In the future, PLCs will adapt to new technologies and global trends making it an exciting journey to see how they'll be used in industrial automation.

Emerging Technologies and Trends

In today's fast-paced digital era industrial automation systems are adopting new technologies and trends that will change how things work. Some important trends include:

1. Integration with IoT and Industry 4.0:

When industrial machines (PLCs) join forces with the Internet of Things (IoT) and Industry 4.0. It lets them share information instantly watch them from afar and predict when they need repairs. As PLCs get more connected industries can take charge of their operations like never before.

2. AI and Machine Learning in PLC:

Combining AI and Machine Learning with PLCs is like giving them a smart brain. These smart PLCs can adjust to changing situations, make processes work better and figure out when they need fixing. This teamwork between PLCs and AI is making automation even smarter and more advanced.

Potential Benefits and Transformations

In the future, PLCs (Programmable Logic Controllers) will bring lots of good changes to different industries. This will help them in many ways.

1. Enhanced Efficiency and Productivity:

Advanced algorithms and predictive analytics in PLCs will make operations better, reduce downtime, and help us work faster. These PLCs can make quick decisions and adjust to changes, which will make things work really well.

2. Sustainability and Green Automation:

As the world focuses more on being eco-friendly, Programmable Logic Controllers (PLCs) will be really important in making machines and systems more environmentally friendly. They'll use smart and efficient methods to save energy, control power usage and cut down on waste. This way the industrial automation will be in harmony with taking care of the environment.

Addressing Challenges

As PLCs get better, they need to deal with problems that come with new tech and ideas. Some of these problems are:

1. Cybersecurity and Data Protection:

As we become more connected, the risk of cyberattacks goes up. It's crucial to protect important industrial systems and data. To do that, we need strong cybersecurity and data protection rules for the future.

2. Training and Workforce Adaptation:

As technology gets better, people who work with machines need to learn new things. They will need training and education to learn how to use the new technology in machines called PLCs.

In conclusion

Programmable Logic Controllers (PLCs) have come a long way, revolutionizing industrial automation through significant milestones, from relay logic to advanced digital systems. They continue to dominate manufacturing and find applications in various industries, ensuring efficiency and reliability. However, they face challenges like scalability, integration issues, and maintenance concerns. The future of PLCs lies in their adaptation to emerging technologies such as IoT, AI, and Industry 4.0, promising enhanced efficiency and sustainability. Addressing cybersecurity and workforce adaptation will be crucial in this evolving landscape. PLCs are poised to play a pivotal role in the ever-changing world of industrial automation.

Read the full article

0 notes

Text

Sona Power Controls Proffers PLC Repairing Services In Noida Which Is Widely Appreciated By An Impressive List Of Clientele. We Are A Group Of Well Equipped Professionals Endeavoring To Provide Supreme Quality PLC Repairing Services For Process And Industry Automation At An Affordable Price Range. We’re Proceeding With The Advancement In Technologies And Utilize State-Of-The-Art Techniques For Precise Execution Of Our PLC Repairing Services Those Are In Compliance With Industry Standards. Sona Power Controls Is Indulged In The Domain Of Peddle And Repairing Services Of Programmable Logic Controller (PLC). Dominating This Distinct Sector With A Wide Array Of PLC Cards From The Eminent Manufacturers Such As Siemens, Allen Bradley, Delta, Beckhooff, HI-Tech, Artech, GE Fanuc, GE, Weintek, Proface, Mitsubishi, Omron, Hitachi, Modicon, L & T, Schneider Electric, Toshiba, Panasonic, Honeywell.

We Are A Team Of Highly Skilled And Vast Experience In The Sector Of PLC Repairing

We Ensure 6 Months Warranty.

We Value Your Money.

We Reply In Actual Time.

On Time Delivery Of Services.

#actor#jensen ackles#accessories#action#assassins creed#electric utilities#electric vehicles#elecciones#electric cars#the electric mayhem#electricity#abbott elementary#electronic#electronic music#edm

1 note

·

View note

Text

Modicon: Revolutionizing Industrial Automation for Enhanced Efficiency

Modicon, a leading brand in industrial automation, has been at the forefront of transforming manufacturing processes and optimizing industrial operations. With its innovative solutions and robust product offerings, Modicon empowers businesses to achieve higher efficiency, productivity, and flexibility. In this article, we will explore how Modicon is revolutionizing industrial automation and…

View On WordPress

0 notes

Text

[Media] Schneider plc #exploit

Schneider plc #exploit

Modicon M580/M340 Safety Protection bypass and utils.

https://github.com/0xedh/schneider_plc_exploit

0 notes