#Oil and Gas Remote Monitoring

Explore tagged Tumblr posts

Text

The InSAR technology is actively used by the oil and gas sector. The technique proved to be highly applicable for the monitoring of the displacements over large areas above the oil wells or gas reservoirs. Our advanced oil and gas monitoring systems, utilizing InSAR technology, provide precise deformation measurements for land, structures, and infrastructure. With a focus on satellite-based remote sensing, we ensure comprehensive monitoring, assisting in early detection of subsidence, uplift, and potential risks associated with oil and gas activities. Enhance your understanding and proactive decision-making in the oil and gas sector through our advanced remote monitoring solutions. Visit us for a detailed exploration. https://geokinesia.com/

0 notes

Text

0 notes

Text

Enhancing Gas Pipeline Management with GIS: Key Benefits and Applications

In the energy and utilities sector, gas pipeline management is complex, requiring precision, safety, and a clear strategy for both existing infrastructure and future expansion. Geographic Information Systems (GIS) have revolutionized pipeline management by providing a spatially accurate, data-rich view of assets. From asset management and leak detection to route planning and demand forecasting, GIS is becoming indispensable for gas companies. This blog delves into the ways GIS transforms gas pipeline management, delivering benefits across safety, efficiency, cost-saving, and planning.

#benefits of using gis for gas pipelines#ensuring gas pipeline safety with gis tools#gas network analysis#gas pipeline asset management#gas pipeline gis mapping services#gas pipeline leak detection using gis#gas pipeline management in gis#gas pipeline mapping software#gas pipeline monitoring tools#gas pipeline risk assessment#gis applications in energy sector#gis for gas pipeline monitoring#gis for infrastructure management#gis in oil and gas industry#gis pipeline maintenance software#gis pipeline monitoring system#gis pipeline route planning#gis software for gas pipeline route optimization#victoryofgoodoverevil#gis solutions for pipeline maintenance and monitoring#gis-based pipeline integrity management#pipeline data management#pipeline geographic information systems#pipeline management solutions#remote sensing for gas pipelines#spatial analysis for gas pipelines#spatial data for gas pipelines

0 notes

Text

What Is a Circuit Breaker and How Does It Work in a Switchgear Assembly?

In modern electrical power systems, reliability and safety are paramount. Whether it’s a residential building, industrial plant, or renewable energy facility, the control and protection of electrical circuits are essential. One of the most critical components used for this purpose is the circuit breaker. When integrated into a switchgear assembly, the circuit breaker plays a central role in ensuring operational continuity, preventing electrical faults, and safeguarding equipment and personnel.

This article explores what a circuit breaker is, it’s working principle, types, and its specific function within a switchgear assembly.

What Is a Circuit Breaker?

A circuit breaker is an automatically operated electrical switch designed to protect an electrical circuit from damage caused by overcurrent, overload, or short circuit. Its primary function is to interrupt current flow after a fault is detected. Unlike a fuse, which operates once and must be replaced, a circuit breaker can be reset (manually or automatically) to resume normal operation.

Key Functions of a Circuit Breaker

· Interrupt Fault Currents: Quickly breaks the circuit in the event of an overcurrent or short circuit.

· Manual Switching: Can be used to manually open or close a circuit for maintenance.

· Automatic Protection: Operates automatically in response to abnormal current conditions.

· Isolation: Ensures safe isolation of electrical equipment during servicing.

How Does a Circuit Breaker Work?

Circuit breakers operate on a simple principle: detect a fault and interrupt the current flow.

Working Mechanism

1. Detection: Internal sensors such as thermal, magnetic, or electronic trip units detect abnormalities in current.

· Thermal Trip Unit: Uses a bimetallic strip that bends with heat from overcurrent.

· Magnetic Trip Unit: Uses an electromagnet that triggers a release when excessive current flows.

· Electronic Trip Unit: Uses current sensors and a microprocessor for precise tripping.

2. Tripping: Once a fault is detected, the trip mechanism activates, causing the breaker’s contacts to open.

3. Arc Extinction: When the contacts open, an electrical arc forms. The breaker extinguishes the arc using mechanisms like:

· Air-blast

· Vacuum

· SF₆ gas

· Oil

4. Resetting: After the fault is cleared, the breaker can be reset and put back into service.

Types of Circuit Breakers

What Is a Switchgear Assembly?

Switchgear is a centralized assembly of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential in power generation, transmission, and distribution networks.

Switchgear can be categorized by voltage level:

· Low Voltage (LV): Up to 1 kV

· Medium Voltage (MV): 1 kV to 36 kV

· High Voltage (HV): Above 36 kV

Role of Circuit Breakers in Switchgear Assemblies

Circuit breakers are core protection components within switchgear systems. Their role includes:

1. Fault Detection and Isolation

Circuit breakers detect and isolate faulty circuits to prevent system-wide failures and reduce downtime.

2. Load Control

Operators can use breakers in switchgear to safely connect or disconnect loads as required during routine operations or emergencies.

3. System Coordination

In coordinated protection schemes, different breakers in the switchgear are set with time-current characteristics to isolate faults precisely and efficiently.

4. Integration with Automation

Modern switchgear integrates circuit breakers with SCADA systems and smart relays, enabling remote monitoring and control.

Circuit Breakers in Renewable and Industrial Applications

In sectors like solar and wind energy, circuit breakers are specially designed to handle:

· Bidirectional current flow

· Rapid voltage fluctuations

· High fault levels due to DC sources

In industrial settings, breakers must handle high inrush currents, frequent switching, and harsh environments.

Maintenance and Safety Considerations

To ensure reliability:

· Regular Testing: Trip settings, insulation resistance, and contact resistance must be tested periodically.

· Visual Inspection: For signs of wear, overheating, or contamination.

· Replacement of Parts: Arcing contacts and insulation materials degrade over time and must be replaced as needed.

Safety measures include:

· Lockout/Tagout (LOTO)

· Grounding procedures

· Personal Protective Equipment (PPE)

Conclusion

Circuit breakers are indispensable for the protection and control of electrical systems. When embedded within a switchgear assembly, they offer enhanced reliability, automation capability, and system safety. Whether in a power substation, a manufacturing facility, or a renewable energy farm, the synergy of circuit breakers and switchgear ensures smooth, safe, and efficient operation.

Understanding how circuit breakers function and interact within switchgear assemblies is crucial for electrical engineers, facility managers, and anyone involved in the design, operation, or maintenance of electrical infrastructure.

5 notes

·

View notes

Text

Satellite IoT Market Key Players Growth Strategies and Business Models to 2033

Introduction

The Satellite Internet of Things (IoT) market has been experiencing rapid growth in recent years, driven by increasing demand for global connectivity, advancements in satellite technology, and expanding IoT applications across various industries. As businesses and governments seek to leverage IoT for remote monitoring, asset tracking, and environmental sensing, satellite-based solutions have emerged as a crucial component of the global IoT ecosystem. This article explores the key trends, growth drivers, challenges, and future outlook of the satellite IoT market through 2032.

Market Overview

The satellite IoT market encompasses a range of services and solutions that enable IoT devices to communicate via satellite networks, bypassing terrestrial infrastructure constraints. This market is poised to grow significantly due to the increasing number of IoT devices, estimated to exceed 30 billion by 2030. The adoption of satellite IoT solutions is particularly prominent in industries such as agriculture, maritime, transportation, energy, and defense, where traditional connectivity options are limited.

Download a Free Sample Report:- https://tinyurl.com/5bx2u8ms

Key Market Drivers

Expanding IoT Applications

The proliferation of IoT devices across industries is fueling demand for satellite-based connectivity solutions. Sectors like agriculture, logistics, and environmental monitoring rely on satellite IoT for real-time data transmission from remote locations.

Advancements in Satellite Technology

The development of Low Earth Orbit (LEO) satellite constellations has significantly enhanced the capability and affordability of satellite IoT services. Companies like SpaceX (Starlink), OneWeb, and Amazon (Project Kuiper) are investing heavily in satellite networks to provide global coverage.

Rising Demand for Remote Connectivity

As industries expand operations into remote and rural areas, the need for uninterrupted IoT connectivity has increased. Satellite IoT solutions offer reliable alternatives to terrestrial networks, ensuring seamless data transmission.

Regulatory Support and Investments

Governments and space agencies worldwide are promoting satellite IoT initiatives through funding, policy frameworks, and public-private partnerships, further driving market growth.

Growing Need for Asset Tracking and Monitoring

Sectors such as logistics, oil and gas, and maritime heavily rely on satellite IoT for real-time asset tracking, predictive maintenance, and operational efficiency.

Market Challenges

High Initial Costs and Maintenance

Deploying and maintaining satellite IoT infrastructure involves significant investment, which may hinder adoption among small and medium enterprises.

Limited Bandwidth and Latency Issues

Despite advancements, satellite networks still face challenges related to bandwidth limitations and latency, which can impact real-time data transmission.

Cybersecurity Concerns

With the increasing number of connected devices, the risk of cyber threats and data breaches is a major concern for satellite IoT operators.

Industry Trends

Emergence of Hybrid Connectivity Solutions

Companies are integrating satellite IoT with terrestrial networks, including 5G and LPWAN, to provide seamless and cost-effective connectivity solutions.

Miniaturization of Satellites

The trend toward smaller, cost-efficient satellites (e.g., CubeSats) is making satellite IoT services more accessible and scalable.

AI and Edge Computing Integration

Artificial intelligence (AI) and edge computing are being incorporated into satellite IoT systems to enhance data processing capabilities, reduce latency, and improve decision-making.

Proliferation of Low-Cost Satellite IoT Devices

With declining costs of satellite IoT modules and sensors, adoption rates are increasing across industries.

Sustainable Space Practices

Efforts to minimize space debris and implement eco-friendly satellite technology are gaining traction, influencing the future of satellite IoT deployments.

Market Segmentation

By Service Type

Satellite Connectivity Services

Satellite IoT Platforms

Data Analytics & Management

By End-User Industry

Agriculture

Transportation & Logistics

Energy & Utilities

Maritime

Defense & Government

Healthcare

By Geography

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Future Outlook (2024-2032)

The satellite IoT market is expected to grow at a compound annual growth rate (CAGR) of over 20% from 2024 to 2032. Key developments anticipated in the market include:

Expansion of LEO satellite constellations for enhanced global coverage.

Increased investment in space-based IoT startups and innovation hubs.

Strategic collaborations between telecom providers and satellite operators.

Adoption of AI-driven analytics for predictive monitoring and automation.

Conclusion

The satellite IoT market is on a trajectory of substantial growth, driven by technological advancements, increasing demand for remote connectivity, and expanding industrial applications. While challenges such as cost and security remain, innovations in satellite design, AI integration, and hybrid network solutions are expected to propel the industry forward. As we move toward 2032, satellite IoT will play an increasingly vital role in shaping the future of global connectivity and digital transformation across various sectors.Read Full Report:-https://www.uniprismmarketresearch.com/verticals/information-communication-technology/satellite-iot.html

2 notes

·

View notes

Text

RV Maintenance Tips for Traveling Through Crawfordville, Georgia

Traveling through Georgia, especially near areas like Crawfordville, offers picturesque views, tranquil surroundings, and the ultimate escape into nature. As you journey, it’s crucial to ensure your RV is in tip-top shape. Whether you’re staying at Sunrise River RV Park or passing through RV parks near Augusta, GA, maintaining your RV is vital to ensure a smooth and enjoyable trip. Below are some essential RV maintenance tips to keep in mind as you explore this beautiful region.

1. Regular Tire Inspections

One of the most critical aspects of RV maintenance is tire care. Before heading to any RV park near Augusta, GA, check your tires for proper inflation, wear, and tear. The varied terrain in Georgia, from highways to forest trails, can strain your tires. Ensure they are inflated to the manufacturer's recommended pressure. Also, inspect the treads for any signs of excessive wear, and replace tires if necessary. A blowout on the road can be dangerous and inconvenient, so this simple check can save you a lot of trouble.

2. Check and Maintain Brakes

Given the hilly landscapes around Crawfordville, ensuring your brakes are in excellent condition is essential. Regularly check the brake pads, rotors, and fluid levels. If you notice any squeaking, grinding, or decreased braking efficiency, get them serviced immediately. The peace of mind knowing your brakes are functioning correctly will make your travel through Georgia’s scenic routes much safer.

3. Inspect Roof Seals and Vents

Georgia’s climate can be unpredictable, with sudden rain showers even in sunny conditions. To avoid leaks and water damage, inspect the seals around your RV's roof, windows, and vents. Look for any cracks or deteriorated seals, and reapply sealant if necessary. This small step can prevent costly repairs later, especially if you're planning to stay at Sunrise River RV Park, where the natural surroundings are best enjoyed dry and leak-free!

4. Keep the Electrical System in Check

Your RV’s electrical system is its lifeline, powering everything from the refrigerator to the air conditioning. Before you park at any RV park near Augusta, GA, inspect your batteries, wires, and connections. Make sure your batteries are fully charged and in good condition. Test your generator to ensure it’s functioning properly, especially if you plan to camp in more remote areas like Crawfordville. Keeping a multimeter handy can help you diagnose any electrical issues that may arise on the road.

5. Monitor Your Water System

Georgia’s humidity and temperatures can lead to unique challenges for your RV’s water system. Regularly check your freshwater, gray, and black water tanks for leaks or signs of wear. Ensure that the hoses are in good condition and securely connected. If you plan on staying at Sunrise River RV Park, you’ll appreciate having a fully functional water system for showers and kitchen use. Additionally, consider investing in a water pressure regulator to prevent high-pressure water at certain campsites from damaging your RV’s plumbing.

6. Keep Your HVAC System Clean

The summer heat in Georgia can be intense, making your RV’s HVAC system essential for comfort. Clean the filters regularly and ensure that the air conditioning unit is functioning properly. If you're visiting Crawfordville during the warmer months, you’ll want to stay cool and comfortable after a day of exploring. Routine maintenance of your HVAC system will keep you and your family comfortable throughout your journey.

7. Stock Up on Essential Supplies

Crawfordville offers natural beauty and serenity, but it’s also essential to be prepared for any situation. Ensure you have a well-stocked toolkit that includes wrenches, screwdrivers, pliers, and any other tools specific to your RV model. Carry spare fuses, bulbs, and essential fluids like oil, coolant, and windshield washer fluid. Being prepared will ensure that minor issues don’t escalate into significant problems, allowing you to enjoy your stay at any RV park near Augusta, GA, or beyond.

8. Plan for Waste Disposal

Responsible waste management is vital for the environment and the longevity of your RV’s sanitation system. Before arriving at Sunrise River RV Park, familiarize yourself with the park's waste disposal facilities. Ensure that your black and gray water tanks are emptied and clean. Carry appropriate chemicals to treat your tanks, reducing odors and buildup. Keeping your waste management system in top shape ensures a pleasant experience for you and your fellow campers.

9. Check Your Propane System

Propane is essential for cooking, heating, and refrigeration in many RVs. Before embarking on your journey through Georgia, inspect your propane tanks and lines for leaks. Make sure your tanks are securely mounted and that your regulator is functioning correctly. It’s also wise to keep a carbon monoxide detector in your RV for safety. Regularly inspecting your propane system will allow you to enjoy meals and hot showers without worry during your stay.

10. Protect Against Pests

Crawfordville, with its lush landscapes and natural beauty, can also be a haven for insects and small animals. To protect your RV from unwanted guests, seal any gaps or cracks where pests might enter. Regularly clean your RV’s interior, removing food crumbs and trash that could attract pests. If you’re staying at Sunrise River RV Park, you’ll want to focus on the natural beauty of the area, not on dealing with ants or mice inside your RV!

11. Keep Your RV Clean

Traveling through Georgia can expose your RV to dust, dirt, and debris. Regularly wash your RV to maintain its appearance and protect its exterior from damage. Pay special attention to the undercarriage, especially after traveling on dirt roads or through muddy areas. Cleaning your RV not only keeps it looking good but also helps prevent rust and corrosion, ensuring it stays in excellent condition for years to come.

12. Stay Informed About Local Road Conditions

As you travel through Georgia, staying informed about local road conditions can help you avoid unexpected delays or hazards. Check weather forecasts and road reports, especially during the rainy season, when roads can become slick or flooded. Knowing the conditions ahead of time allows you to plan your route and adjust your driving to ensure a safe journey to Sunrise River RV Park or any other destination in the area.

Conclusion

Maintaining your RV is essential to ensure a safe, comfortable, and enjoyable journey through Crawfordville and the surrounding areas of Georgia. Whether you’re heading to Sunrise River RV Park or exploring RV parks near Augusta, GA, following these maintenance tips will keep your RV in top condition, allowing you to focus on the adventure ahead.

From regular tire checks to ensuring your water and electrical systems are functioning properly, taking the time to maintain your RV will enhance your travel experience. By being proactive with your maintenance routine, you can enjoy the natural beauty and serene landscapes of Crawfordville, Georgia, without worry. Safe travels!

2 notes

·

View notes

Text

Fueling Success: Innovative Website Design Strategies for the Oil and Gas Industry

In the dynamic realm of the oil and gas industry, establishing a strong online presence is crucial for success. A well-designed website not only serves as a digital storefront but also plays a pivotal role in conveying expertise, building trust, and facilitating effective communication within the industry. Let's explore innovative website design strategies tailored to fuel success in the oil and gas sector.

Industry-Focused Visuals: Utilize industry-specific visuals that resonate with the oil and gas sector. Incorporate high-quality images of drilling operations, refineries, and cutting-edge technologies. These visuals not only showcase expertise but also provide a visual narrative of the industry's dynamism.

Responsive Design for Field Accessibility: Recognizing that professionals in the oil and gas industry are often on the field, ensure your website is fully responsive. A mobile-friendly design guarantees accessibility from tablets and smartphones, facilitating quick access to essential information for those working in remote locations. Click here for responsive Oil and gas website design.

Technical Content Simplified: Simplify technical content without compromising accuracy. Use clear and concise language to explain complex processes, technologies, and services. This ensures that your website is accessible to a broad audience, from industry experts to those new to the field.

Interactive Data Visualization: Implement interactive data visualizations to showcase industry trends, production figures, and other relevant statistics. This not only enhances engagement but also provides a dynamic way for stakeholders to interact with and understand complex data sets.

Safety and Compliance Emphasis: Highlight your commitment to safety and compliance prominently on the website. Feature case studies, success stories, and testimonials that showcase your dedication to maintaining high standards. This builds trust with potential partners, clients, and regulatory bodies.

Live Updates and News Section: Keep stakeholders informed with a dedicated section for live updates, industry news, and relevant announcements. Regularly updating this section demonstrates a commitment to transparency and ensures that your audience stays informed about the latest developments in the oil and gas sector.

Secure Client Portals: For businesses offering specialized services, incorporate secure client portals. These portals can provide clients with access to project updates, documentation, and other relevant information. A secure and user-friendly portal enhances communication and collaboration with clients.

Multilingual Functionality: Given the global nature of the oil and gas industry, consider incorporating multilingual functionality. This ensures that your website is accessible to a diverse audience, fostering international partnerships and collaborations.

Thought Leadership Content: Establish your company as a thought leader in the industry by regularly publishing insightful content. This could include whitepapers, research articles, and blog posts that address industry challenges, advancements, and best practices. Thought leadership content positions your brand as an authority in the field.

Robust Analytics for Continuous Improvement: Implement robust analytics tools to monitor website performance. Track user engagement, analyze visitor behavior, and gather insights that can inform continuous improvements. Data-driven decisions ensure that your website remains effective in meeting the evolving needs of the oil and gas community.

By incorporating these innovative website design strategies, businesses in the oil and gas industry can create a digital platform that not only reflects their technical expertise but also fosters trust and collaboration within the sector. Fueling success in this dynamic industry requires a website that not only informs but engages stakeholders at every level.

2 notes

·

View notes

Text

How a Gas Leak Detector Enhances Industrial Safety

In today’s industrial and environmental landscape, maintaining safety standards and ensuring clean air are more important than ever. From manufacturing plants to research laboratories and food packaging units, the use of advanced detection and monitoring equipment has become essential. Among the most crucial tools are the gas leak detector, ambient air quality monitoring systems, and headspace analyzer—each serving a unique yet interrelated purpose in protecting health, ensuring compliance, and improving overall operational efficiency.

Gas Leak Detector: Early Warning for Dangerous Situations

A gas leak detector is a vital safety instrument used to identify the presence of hazardous gases in an area, often as part of a safety system. These detectors are commonly used in industries where flammable or toxic gases are present, such as oil and gas, chemical processing, pharmaceuticals, and even residential buildings.

The primary function of a gas leak detector is to provide an early warning system that can help prevent accidents such as explosions, fires, or toxic exposure. These devices can detect gases like methane, propane, carbon monoxide, and ammonia, among others. Modern gas leak detectors come equipped with real-time monitoring capabilities, audible alarms, and even wireless connectivity for remote alerting.

By integrating gas leak detection systems into a facility’s safety protocol, industries can not only protect their workers and assets but also comply with regulatory standards set by environmental and safety organizations.

Ambient Air Quality Monitoring: Ensuring a Healthier Environment

While gas leak detectors focus on immediate threats, ambient air quality monitoring takes a broader approach. It involves the continuous measurement of air pollutants to assess the overall quality of air in a specific area, typically outdoors but also in industrial environments.

Ambient air quality monitoring plays a critical role in urban planning, public health, and regulatory enforcement. It measures a variety of pollutants such as particulate matter (PM2.5 and PM10), sulfur dioxide (SO2), nitrogen dioxide (NO2), ozone (O3), and volatile organic compounds (VOCs).

Industries are increasingly investing in ambient air monitoring solutions not only to meet environmental compliance but also to demonstrate corporate social responsibility. By tracking air pollution levels, organizations can take proactive measures to reduce emissions and protect both their workforce and the surrounding communities.

Advanced ambient air quality monitoring systems now feature IoT connectivity, cloud-based data analytics, and real-time dashboards, enabling quicker decision-making and more transparent reporting.

Headspace Analyzer: Precision in Packaging and Quality Control

In sectors such as pharmaceuticals, food and beverage, and chemicals, packaging integrity is paramount. A headspace analyzer is an analytical device used to evaluate the gas composition inside sealed packaging, helping ensure product safety, shelf life, and quality.

The headspace in packaging refers to the gas-filled space above the product inside a container. Analyzing this space can reveal crucial data about oxygen, carbon dioxide, and nitrogen levels—gases that directly impact the freshness and stability of the contents.

For example, in the food industry, too much oxygen can cause spoilage, while too little may affect taste or texture. In pharmaceuticals, oxygen-sensitive compounds may degrade over time if packaging is not properly sealed. The headspace analyzer helps companies monitor and control these parameters to meet stringent quality standards.

Modern headspace analyzers offer features such as non-destructive testing, fast response time, and high sensitivity, making them indispensable tools for quality assurance and R&D departments.

Conclusion : Integrating Safety, Environment, and Quality

Each of these technologies—gas leak detector, ambient air quality monitoring, and headspace analyzer—serves a different purpose, yet they all contribute to a larger goal: a safer, healthier, and more compliant operation. By implementing these systems, industries can not only mitigate risk but also improve operational efficiency, maintain regulatory compliance, and build trust with customers and stakeholders.

As regulations grow stricter and awareness around environmental and workplace safety increases, the adoption of these tools will only continue to rise. Whether you’re in manufacturing, food processing, pharmaceuticals, or environmental services, investing in the right detection and monitoring equipment is no longer optional—it’s essential.

0 notes

Text

How Drones Are Revolutionizing Infrastructure Monitoring in India

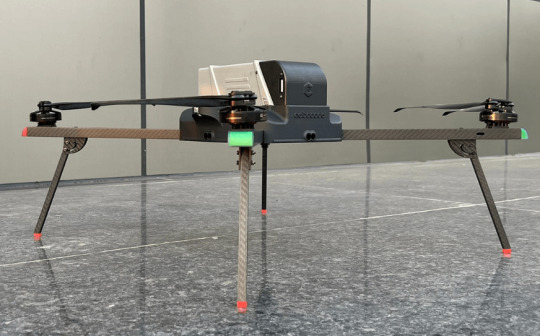

Infrastructure projects fuel India’s economic growth—from highways threading across mountains to pipelines buried beneath fields. But traditional inspections (using ground teams, scaffolding, and manual surveillance) are time-consuming, expensive, and often risky. Enter drones: high-flying game-changers, enabling safer, faster, and more accurate monitoring of critical assets. And at the forefront stands Aebocode Technologies, a premier drone manufacturing company in India pushing the boundaries of aerial innovation.

🛩️ From Sky to Site: The Rise of Drone Surveillance

India's infrastructure expansion—highways, railways, bridges, power lines—is monumental. The National Highways Authority of India (NHAI), for example, has mandated monthly drone surveys and video recording for large-scale projects. Private firms like Marvel Geospatial have flown drones over 31,000 km of national highways, boosting construction speed by up to 5×, and helping resolve disputes using timestamped 4K video evidence.

Similarly, power utilities adopt drones to detect hotspots and infrastructure faults early via thermal imaging . Oil & gas firms—like Oil India and GAIL—use drones to patrol pipelines in challenging terrain, spotting encroachments and leaks before they become crises.

Major Benefits Over Traditional Techniques

ChallengeTraditional ApproachDrone-Based SolutionImpact

Scale & time Slow ground-surveys Rapid aerial scans 40%‑60% faster

Cost Labor and equipment-heavy Fewer personnel, less gear ~40% cost savings

Safety Risky access Remote piloting Lower accident risk

Data quality Limited visuals High-res, thermal, multispectral Early problem detection

Documentation & tracking Fragmented, manual Geo-tagged reports & video Clear audit trail

Aebocode’s Role: India’s Leading Drone Manufacturing Company in India

Headquartered in Chandigarh, Aebocode Technologies is a trailblazing drone manufacturing company in India developing UAVs specifically for critical infrastructure applications. Their lineup includes urban/industrial drones equipped with high-definition cameras and sensors—ideal for mapping, surveying, and inspecting assets like bridges, towers, and pipelines .

Beyond hardware, Aebocode integrates analytics to detect cracks, hotspots, and structural anomalies—helping stakeholders prioritize maintenance before catastrophes. By enabling remote inspections, they bolster worker safety and optimize resource use, embodying the ethos of a true drone manufacturing company in India committed to infrastructure tech evolution.

Real-World Use Cases

1. Highway & Bridge Surveillance

During Bharatmala highway development, drone-based footage helped monitor project progress, curb encroachments, and enforce quality compliance. Aebocode's industrial drones, with thermal and HD imaging, could have empowered similar initiatives—automating monthly progress reports and reducing manual burden.

2. Power Line & Transmission Towers

Thermal sensors on Aebocode drones can detect unstable components, frayed wires, or joint failures in real-time. Scheduled or upon-event deployments enhance predictive maintenance—saving downtime and preventing blackouts.

3. Pipeline Monitoring

For oil, gas, or water pipelines spanning challenging terrain—especially in central and northern India—drones can patrol regularly, spot encroachments and early leaks, and relay geotagged images to operation centers . Aebocode’s fixed-wing models offer stability and extended flight time ideal for these missions.

4. Rail & Metro Systems

Indian Railways has piloted drone cleaning and surveillance at stations like Kamakhya. For track integrity, damaged sleepers, or vegetation, Aebocode drones can beam live video to maintenance crews—speeding up repairs and service reliability.

5. Urban Infrastructure & Smart Cities

Municipal corporations—including ones like Guntur and railway authorities—use drones to monitor urban cleanliness, traffic flow, and civic infra projects. Aebocode’s smart-city drones, with traffic analytics and pollution sensors, are perfectly aligned with these needs .

Tech Behind the Flight

Aebocode’s UAV systems integrate several cutting-edge features:

High‑Resolution & Thermal Cameras: Detect structural flaws and hotspots in pillars, bridges, towers.

Multispectral Sensors: Ideal for early crack detection and material stress analysis.

Extended Flight (up to 60 min): Enables wide-area surveys, especially with fixed-wing models.

Live Feed & Analytics: Enables real-time decisions—vital during infrastructure emergencies.

Geospatial Tagging: Metadata embeds location and altitude for precise action points.

Their in-house R&D emphasizes customized builds—a hallmark of a forward-thinking drone manufacturing company in India prioritizing localized innovation.

Regulatory & Operational Enablers

India’s drone policy—especially since the 2021 Drone Rules and Digital Sky platform—simplifies licensing and beyond-visual-line-of-sight (BVLOS) operations . Civilian adoption is rising, with PLI benefits and spotlight at events like Surya Drone Tech 2025, where Aebocode showcased its UAVs and even had the Uttarakhand Governor pilot one live aebocode.com.

Vision Ahead: Scaling & Impact

India’s infrastructure needs will only grow—roads, rails, power, pipelines, urban utilities. Drones offer:

Scale: Rapid surveying over vast tracts.

Insight: Detecting issues invisible from ground level.

Efficiency: Lower costs through automation and quicker deployment.

Leading drone manufacturing company in India like Aebocode are vital to this transformation. Their emphasis on “Make in India” ensures both self-reliance and compliance with local standards—accelerating national resilience.

Conclusion

Drones are ushering in a new era of infrastructure monitoring in India—safer, faster, and more accurate than ever. With mounting use across highways, power grids, pipelines, railways, and urban landscapes, they’re proving indispensable.

Aebocode Technologies, a pioneering drone manufacturing company in India, is at the heart of this revolution—offering bespoke UAVs, analytics, and training solutions that blend innovation with ground reality.

As infrastructure demands evolve, drone-enabled monitoring promises reduced costs, reduced risk, and higher uptime—building the backbone for a stronger, smarter India.

#fire fighting uav#firefighting drones#fighting drone#drones uav#firedrone#fixedwingdrone#cargodrones#drones

0 notes

Text

Gas Leak Detector Market Emerging Trends Driving Technological Advancements and Safety

The gas leak detector market is undergoing transformative changes driven by the rising emphasis on workplace safety, stricter environmental regulations, and the development of smart technologies. Industries such as oil & gas, chemicals, manufacturing, and residential sectors are increasingly adopting advanced gas detection solutions to monitor and mitigate the risks associated with hazardous gas leaks. These emerging trends are shaping the future of the market, pushing the development of smarter, faster, and more accurate detection systems.

Integration of IoT and Smart Technologies

One of the most prominent trends in the gas leak detector market is the integration of Internet of Things (IoT) and smart sensors into gas detection systems. IoT-enabled detectors can send real-time data to centralized monitoring systems, allowing for quicker response times and predictive maintenance. These detectors are designed to communicate with other connected devices, ensuring that even the slightest anomaly in gas levels can be addressed immediately. This trend is gaining momentum across industrial plants, commercial spaces, and smart homes.

Miniaturization and Portability

With advancements in microelectromechanical systems (MEMS) and sensor technologies, gas leak detectors are becoming smaller, more portable, and user-friendly. Portable detectors are increasingly used in confined spaces or by personnel on the move, enabling real-time safety assessments in high-risk environments. This miniaturization also facilitates the integration of detectors into handheld devices, drones, and robotic systems for remote monitoring.

Shift Toward Wireless and Battery-Powered Devices

Another emerging trend is the shift from wired to wireless gas leak detectors, supported by long-lasting battery technologies. Wireless detectors offer ease of installation and mobility, reducing the need for complex wiring and lowering maintenance costs. These battery-powered units often use energy-efficient components and are capable of operating in harsh environments without a significant performance drop, which is particularly beneficial for remote and inaccessible locations.

Focus on Multi-Gas Detection Capabilities

Modern applications demand the detection of multiple gases simultaneously. As a result, multi-gas detectors are seeing increased demand, especially in sectors like mining, refineries, and wastewater treatment. These detectors can identify various toxic and combustible gases, offering comprehensive protection with a single device. This trend not only improves efficiency but also reduces the cost and space needed to install separate detectors for different gases.

Emphasis on Real-Time Monitoring and Cloud Connectivity

The emergence of cloud-based monitoring platforms is transforming how gas detection data is stored, analyzed, and acted upon. Cloud connectivity allows organizations to access real-time data from multiple locations, enabling better decision-making and quicker emergency responses. This trend supports centralized safety systems and integrates with facility management platforms to provide detailed insights and analytics for long-term safety planning.

Environmental Sustainability and Compliance

The increasing global emphasis on environmental sustainability is pushing manufacturers to develop eco-friendly gas detection technologies. Gas leak detectors now incorporate materials and designs that are more environmentally sustainable while ensuring compliance with stringent safety standards. Additionally, regulatory bodies worldwide are mandating the installation of advanced gas leak detection systems, especially in industries that handle hazardous gases, to minimize the environmental impact and health risks.

Technological Innovations in Sensor Technology

Recent innovations in photoionization detectors (PID), infrared sensors, and ultrasonic sensors are enhancing the sensitivity and accuracy of gas leak detection. These advanced sensor types are capable of identifying gas leaks even at extremely low concentrations, significantly reducing the likelihood of undetected leaks. Innovations in nanotechnology are also contributing to more reliable sensors with faster response times and lower power consumption.

Growth in Residential and Commercial Applications

Historically driven by industrial applications, the gas leak detector market is now experiencing significant growth in residential and commercial sectors. Increased awareness among homeowners about gas-related accidents, along with the rising adoption of smart home systems, is leading to widespread use of domestic gas leak detectors. These detectors are now often integrated with alarm systems and mobile apps, enhancing personal safety and convenience.

Regional Expansion and Urbanization

Emerging economies, particularly in Asia-Pacific, Latin America, and Africa, are experiencing rapid urbanization and industrialization. These developments are generating increased demand for gas leak detectors in construction, energy, and manufacturing sectors. Governments in these regions are also launching safety initiatives and enforcing building codes that require gas detection systems, further driving the market.

Conclusion

The gas leak detector market is being redefined by emerging trends such as IoT integration, multi-gas detection capabilities, miniaturization, and cloud connectivity. These trends are aligned with growing safety demands, technological innovations, and stricter regulatory frameworks across the globe. As industries and households alike prioritize gas safety, manufacturers are expected to continue developing smarter, more efficient, and more reliable gas detection solutions that cater to evolving market needs.

0 notes

Text

Vapor Recovery Services Market Expected to Surge Owing to Stringent Environmental Regulations

The Vapor Recovery Services Market encompasses specialized solutions designed to capture and process volatile organic compounds (VOCs) and other hydrocarbons released during storage, loading, and unloading of fuels and chemicals. These services utilize advanced technologies such as carbon adsorption, condensers, and regenerative thermal oxidizers to minimize emissions, enhance safety, and ensure compliance with environmental regulations. By preventing the loss of valuable product and reducing greenhouse gas emissions, vapor recovery services offer cost savings and contribute to sustainable operations across oil & gas, petrochemical, and storage terminal industries. Growing emphasis on air quality, tighter emission standards, and the need for efficient fuel management have boosted demand for these services. Vapor Recovery Services Market Insights providers deliver turnkey projects, maintenance, and monitoring solutions tailored to different storage tank types and flow rates, ensuring optimal performance and minimal downtime. Technological innovations, such as remote monitoring and predictive maintenance, further enhance operational efficiency. Get more insights on: Vapor Recovery Services Market Get This Report In Japanese Language: 蒸気回収サービス市場 Get This Report In Korean Language: 증기 회수 서비스 시장

About Author

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)

#Vapor#Vapor Recovery#Vapor Recovery Services#Vapor Recovery Services Market#Vapor Recovery Services Market Trends#Coherent Market Insights

0 notes

Text

Smart Switchgear in 2025: What Electrical Engineers Need to Know

In the fast-evolving world of electrical infrastructure, smart switchgear is no longer a futuristic concept — it’s the new standard. As we move through 2025, the integration of intelligent systems into traditional switchgear is redefining how engineers design, monitor, and maintain power distribution networks.

This shift is particularly crucial for electrical engineers, who are at the heart of innovation in sectors like manufacturing, utilities, data centers, commercial construction, and renewable energy.

In this article, we’ll break down what smart switchgear means in 2025, the technologies behind it, its benefits, and what every electrical engineer should keep in mind.

What is Smart Switchgear?

Smart switchgear refers to traditional switchgear (devices used for controlling, protecting, and isolating electrical equipment) enhanced with digital technologies, sensors, and communication modules that allow:

Real-time monitoring

Predictive maintenance

Remote operation and control

Data-driven diagnostics and performance analytics

This transformation is powered by IoT (Internet of Things), AI, cloud computing, and edge devices, which work together to improve reliability, safety, and efficiency in electrical networks.

Key Innovations in Smart Switchgear (2025 Edition)

1. IoT Integration

Smart switchgear is equipped with intelligent sensors that collect data on temperature, current, voltage, humidity, and insulation. These sensors communicate wirelessly with central systems to provide real-time status and alerts.

2. AI-Based Predictive Maintenance

Instead of traditional scheduled inspections, AI algorithms can now predict component failure based on usage trends and environmental data. This helps avoid downtime and reduces maintenance costs.

3. Cloud Connectivity

Cloud platforms allow engineers to remotely access switchgear data from any location. With user-friendly dashboards, they can visualize key metrics, monitor health conditions, and set thresholds for automated alerts.

4. Cybersecurity Enhancements

As devices get connected to networks, cybersecurity becomes crucial. In 2025, smart switchgear is embedded with secure communication protocols, access control layers, and encrypted data streams to prevent unauthorized access.

5. Digital Twin Technology

Some manufacturers now offer a digital twin of the switchgear — a virtual replica that updates in real-time. Engineers can simulate fault conditions, test load responses, and plan future expansions without touching the physical system.

Benefits for Electrical Engineers

1. Operational Efficiency

Smart switchgear reduces manual inspections and allows remote diagnostics, leading to faster response times and reduced human error.

2. Enhanced Safety

Early detection of overload, arc flash risks, or abnormal temperatures enhances on-site safety, especially in high-voltage environments.

3. Data-Driven Decisions

Real-time analytics help engineers understand load patterns and optimize distribution for efficiency and cost savings.

4. Seamless Scalability

Modular smart systems allow for quick expansion of power infrastructure, particularly useful in growing industrial or smart city projects.

Applications Across Industries

Manufacturing Plants — Monitor energy use per production line

Data Centers — Ensure uninterrupted uptime and cooling load balance

Commercial Buildings — Integrate with BMS (Building Management Systems)

Renewable Energy Projects — Balance grid load from solar or wind sources

Oil & Gas Facilities — Improve safety and compliance through monitoring

What Engineers Need to Know Moving Forward

1. Stay Updated with IEC & IEEE Standards

Smart switchgear must comply with global standards. Engineers need to be familiar with updates related to IEC 62271, IEC 61850, and IEEE C37 series.

2. Learn Communication Protocols

Proficiency in Modbus, DNP3, IEC 61850, and OPC UA is essential to integrating and troubleshooting intelligent systems.

3. Understand Lifecycle Costing

Smart switchgear might have a higher upfront cost but offers significant savings in maintenance, energy efficiency, and downtime over its lifespan.

4. Collaborate with IT Teams

The line between electrical and IT is blurring. Engineers should work closely with cybersecurity and cloud teams for seamless, secure integration.

Conclusion

Smart switchgear is reshaping the way electrical systems are built and managed in 2025. For electrical engineers, embracing this innovation isn’t just an option — it’s a career necessity.

At Blitz Bahrain, we specialize in providing cutting-edge switchgear solutions built for the smart, digital future. Whether you’re an engineer designing the next big project or a facility manager looking to upgrade existing systems, we’re here to power your progress.

#switchgear#panel#manufacturer#bahrain25#electrical supplies#electrical equipment#electrical engineers#electrical

6 notes

·

View notes

Text

Zener Barrier Market: Industry Growth Analysis, Opportunities and Challenges, 2025–2032

MARKET INSIGHTS

The global Zener Barrier Market size was valued at US$ 234 million in 2024 and is projected to reach US$ 378 million by 2032, at a CAGR of 7.0% during the forecast period 2025-2032. The U.S. market accounted for approximately 28% of global revenue in 2024, while China’s market is anticipated to grow at a higher CAGR of 7.2% through 2032.

Zener Barriers are intrinsic safety devices used in hazardous areas to limit energy flow and prevent ignition of flammable gases or dust. These critical components employ Zener diodes to maintain safe voltage and current levels in instrumentation circuits, serving as protective interfaces between safe and hazardous areas. The market comprises two primary types: Detection Side barriers for sensor connections and Isolation Side barriers for actuator control.

Market growth is primarily driven by stringent safety regulations in oil & gas and chemical industries, where explosion-proof equipment is mandated. The Detection Side segment currently holds 62% market share due to widespread sensor networks in process industries. Recent developments include Pepperl+Fuchs’ 2023 launch of IS+ series barriers with enhanced diagnostics, responding to Industry 4.0 integration demands. Omega Engineering, Turck Inc., and Sensotronic System dominate the competitive landscape, collectively holding 45% market share through comprehensive product portfolios serving diverse industrial applications.

MARKET DYNAMICS

MARKET DRIVERS

Rising Demand for Intrinsic Safety Solutions in Hazardous Industries to Accelerate Market Growth

The global Zener Barrier market is experiencing significant growth due to increasing safety regulations in explosive environments. Industries such as oil & gas, chemicals, and mining are mandated to implement intrinsic safety barriers to prevent ignition risks from electrical equipment. Recent data indicates that over 60% of industrial accidents in hazardous areas originate from electrical sparks, driving adoption of certified safety components like Zener barriers. Furthermore, advancements in barrier technology that offer improved reliability while reducing installation complexity are gaining traction across industries with stringent safety requirements.

Growing Industrial Automation Investments to Boost Market Expansion

Industrial automation adoption across process industries is creating robust demand for safety interfaces like Zener barriers. As factories implement more connected sensors and instrumentation in classified zones, the need for reliable signal protection grows exponentially. The manufacturing sector alone is projected to account for nearly 35% of total Zener barrier installations by 2026. Major automation providers are increasingly bundling safety barriers with their control systems, making adoption more seamless for end-users while ensuring compliance with IEC and ATEX standards.

Additionally, the expanding renewable energy sector presents new opportunities. Solar farms and battery storage facilities require specialized protection for monitoring systems, creating demand for weather-resistant and high-temperature Zener barriers. Integration with IIoT platforms is also driving innovation, enabling remote diagnostics and predictive maintenance capabilities that extend product lifespans.

MARKET RESTRAINTS

High Initial Costs and Complex Certification Processes Limit Market Penetration

While Zener barriers provide critical safety functions, their adoption is restrained by substantial upfront investment requirements. Obtaining necessary certifications for hazardous area installations often involves extended testing periods and compliance documentation, delaying product launches. Industry estimates suggest certification costs can represent 15-20% of total project expenses for safety system integrators, creating barriers to market entry.

Competition from Alternative Protection Methods Impacts Market Share

Emerging technologies like galvanic isolators and fiber-optic interfaces present competitive challenges to traditional Zener barriers. These alternatives often offer advantages in specific applications, such as higher voltage isolation or immunity to electromagnetic interference. For environments requiring minimal power transmission, these solutions are capturing market share, particularly in new facility designs where legacy systems don’t dictate the protection approach.

MARKET CHALLENGES

Technical Complexity in Customization Presents Implementation Hurdles

Designing Zener barriers for specialized industrial applications requires precise engineering to balance safety performance with signal integrity. Many modern process applications demand custom voltage and current ratings to interface with proprietary equipment, creating design challenges. Field failures due to improper specification continue to account for nearly 12% of total service calls industry-wide, highlighting the technical complexities involved.

Other Challenges

Supply Chain Vulnerabilities Semiconductor shortages continue to impact production lead times, with some manufacturers reporting 30% longer delivery cycles for critical components. While the situation has improved from pandemic-era disruptions, supply chain fragility remains an ongoing operational challenge.

Skill Gap in Maintenance Personnel Growing technological sophistication in safety systems outpaces workforce training programs. Many facilities lack technicians qualified to properly maintain and troubleshoot advanced Zener barrier installations, potentially compromising system reliability.

MARKET OPPORTUNITIES

Smart Factory Initiatives Create Demand for Next-Generation Safety Solutions

Industry 4.0 implementations are driving demand for Zener barriers with digital communication capabilities. New product developments integrate diagnostics and condition monitoring features that align with predictive maintenance strategies. Early adopters report 40% reductions in unplanned downtime when using these intelligent safety interfaces, creating compelling ROI arguments for upgrading legacy systems.

Emerging Markets Present Untapped Growth Potential

Developing economies implementing stricter industrial safety regulations represent significant growth opportunities. Regions in Asia-Pacific and the Middle East are investing heavily in process safety infrastructure as they modernize industrial bases. Market analysis indicates these areas could account for over 50% of new installations by 2028 as safety standards converge with global norms.

ZENER BARRIER MARKET TRENDS

Expanding Industrial Safety Regulations to Drive Market Growth

The increasing implementation of stringent industrial safety regulations worldwide is significantly boosting the demand for Zener barriers, particularly in hazardous environments such as oil & gas facilities and chemical plants. Recent updates to international safety standards like IEC 60079 and ATEX directives have mandated advanced intrinsic safety solutions, with Zener barriers emerging as a preferred choice due to their cost-effectiveness and reliability. The global market for these safety devices is projected to grow at a compound annual growth rate of approximately 5.8% between 2024 and 2032, reflecting the tightening compliance requirements across industries.

Other Trends

Integration with Industry 4.0 Systems

The ongoing Industry 4.0 revolution is creating substantial opportunities for Zener barrier manufacturers to develop smart, connected solutions. Modern barriers are increasingly being equipped with diagnostic capabilities and communication interfaces that enable real-time monitoring of safety parameters. This technological upgrade is particularly crucial for process industries where equipment failure can lead to catastrophic consequences. The mining sector, which accounts for over 15% of Zener barrier applications, has shown particularly strong adoption of these advanced solutions due to extreme operating conditions.

Emerging Markets Gaining Momentum

Developing economies across Asia and Latin America are demonstrating accelerated adoption of Zener barriers, driven by rapid industrialization and modernization of safety infrastructure. Countries like India and Brazil have implemented rigorous safety norms that align with international standards, creating substantial market opportunities. Meanwhile, technological partnerships between global manufacturers and regional players are facilitating knowledge transfer and localization of production, which is expected to reduce costs by an estimated 10-15% in these markets over the next five years.

COMPETITIVE LANDSCAPE

Key Industry Players

Leading Manufacturers Focus on Innovation and Safety Compliance to Gain Market Share

The global Zener Barrier market exhibits a moderately consolidated structure, with established industrial automation and safety solution providers dominating revenue share. Pepperl+Fuchs emerges as a market leader, leveraging its extensive expertise in intrinsic safety barriers and strong foothold across process industries. The company holds approximately 22% of the global Zener Barrier market, owing to its certified explosion-proof solutions compliant with ATEX and IECEx standards.

Omega Engineering and Turck Inc. collectively account for nearly 30% market share, benefiting from their diversified product lines that serve both hazardous area classifications (Zone 0/1/2). These players continue to invest in R&D to develop advanced barriers with improved current-limiting capabilities and enhanced diagnostic features.

The market sees intensified competition as participants expand into emerging industries beyond traditional oil & gas applications. While large corporations focus on integrated safety solutions, mid-size specialists like Sensotronic System are gaining traction through customized barrier designs for niche applications in pharmaceutical and food processing environments.

Recent developments indicate strategic shifts toward digital integration, with leading players incorporating smart monitoring capabilities into traditional Zener barriers. This technological evolution is expected to redefine competitive dynamics, particularly in regions like Europe and North America where functional safety standards are becoming more stringent.

List of Key Zener Barrier Manufacturers Profiled

Pepperl+Fuchs (Germany)

Omega Engineering (U.S.)

Turck Inc. (U.S.)

Sensotronic System (Germany)

R. STAHL (Germany)

PR electronics (Denmark)

MTL Instruments (U.K.)

Phoenix Contact (Germany)

Eaton Corporation (Ireland)

Zener Barrier Market

Segment Analysis:

By Type

Detection Side Segment Dominates the Market Owing to Its Critical Role in Hazardous Area Protection

The market is segmented based on type into:

Detection Side

Isolation Side

By Application

Oil and Gas Industry Leads Due to High Demand for Intrinsic Safety Solutions

The market is segmented based on application into:

Oil and Gas Industry

Mining Industry

Power Industry

Chemical Industry

Others

By End User

Industrial Sector Holds Major Share for Plant Safety Compliance Requirements

The market is segmented based on end user into:

Industrial

Commercial

Public Infrastructure

Regional Analysis: Zener Barrier Market

North America The North American Zener barrier market is characterized by stringent safety regulations, particularly in the oil & gas and chemical sectors, where intrinsic safety standards like NEC, CEC, and ATEX are strictly enforced. The U.S. accounts for over 65% of the regional market share due to well-established hazardous area industries and high adoption of explosion-proof solutions. Recent investments in process automation and IIoT integration in manufacturing further drive demand for advanced Zener barriers with diagnostic capabilities. However, cost sensitivity among small enterprises remains a challenge for premium products.

Europe Europe’s mature industrial automation sector drives consistent demand for ATEX/IECEx-certified Zener barriers across Germany, France, and the UK. The energy sector transition towards renewables has created new application areas in wind and solar power installations, while traditional chemical plants continue modernization efforts. The region leads in smart barrier adoption, with Pepperl+Fuchs and Turck dominating the competitive landscape. EU’s Green Deal initiatives are pushing manufacturers toward low-power consumption designs with improved certification compliance, though supply chain disruptions occasionally impact delivery timelines.

Asia-Pacific APAC represents the fastest-growing Zener barrier market, projected to exceed 7.5% CAGR through 2032, fueled by China’s booming industrial sector and India’s expanding refinery capacities. While basic single-channel barriers dominate price-sensitive markets, Japan and South Korea increasingly adopt multi-functional barriers with SIL certifications. The lack of uniform safety standards across developing nations creates quality concerns, though China’s GB3836 certifications are gaining regional traction. Infrastructure investments under Belt & Road initiatives are opening new hazardous-area applications in power transmission and mining sectors.

South America South America’s market growth remains moderate but stable, tied closely to Brazil’s oil & gas sector recovery and Argentina’s lithium mining expansion. While economic volatility limits capital expenditures, mandatory safety upgrades in aging refineries sustain demand. The region shows growing preference for locally assembled barriers to circumvent import duties, though technical expertise gaps in complex installations persist. Chile and Colombia emerge as niche markets with specialized mining applications, but currency fluctuations continue to challenge multinational suppliers’ pricing strategies.

Middle East & Africa MEA’s market is bifurcated between Gulf Cooperation Council (GCC) megaprojects and African mining expansions. Saudi Arabia and UAE lead with hazardous area investments in oil refineries and chemical parks, where high-specification barriers are mandatory. Meanwhile, South Africa and Nigeria show increased adoption in mining safety systems, though budget constraints favor refurbished units. The region faces logistical challenges in spare part availability, driving demand for ruggedized designs with extended warranties, while infrastructure gaps in sub-Saharan Africa limit market penetration beyond major industrial hubs.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Zener Barrier markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The Global Zener Barrier market was valued at USD million in 2024 and is projected to reach USD million by 2032.

Segmentation Analysis: Detailed breakdown by product type (Detection Side, Isolation Side), application (Oil & Gas, Mining, Power, Chemical), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America (USD million in 2024), Europe, Asia-Pacific (fastest-growing), Latin America, and Middle East & Africa.

Competitive Landscape: Profiles of leading players including Omega, Pepperl +Fuchs, Turck Inc., and Sensotronic System, with top five companies holding approximately % market share in 2024.

Technology Trends & Innovation: Assessment of evolving safety standards, integration with IIoT systems, and advancements in intrinsic safety barriers.

Market Drivers & Restraints: Evaluation of factors like industrial safety regulations, hazardous area applications, along with challenges like supply chain constraints.

Stakeholder Analysis: Strategic insights for manufacturers, system integrators, and end-users in process industries.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/global-video-sync-separator-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/silicon-rings-and-silicon-electrodes_17.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ceramic-bonding-tool-market-investments.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/coaxial-panels-market-challenges.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/oled-and-led-automotive-light-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/gas-cell-market-demand-for-ai-chips-in.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digital-demodulator-ic-market-packaging.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/nano-micro-connector-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/single-mode-laser-diode-market-growth.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/silicon-rings-and-silicon-electrodes.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/battery-management-system-chip-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/scanning-slit-beam-profiler-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/atomic-oscillator-market-electronics.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/plastic-encapsulated-thermistor-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ceramic-bonding-tool-market-policy.html

0 notes

Text

Why Emission Gas Analyzers Are the Backbone of Industrial Air Quality Monitoring

If you're managing or operating in an industrial facility, you're likely no stranger to the pressure of environmental compliance. Regulatory bodies around the world are tightening the screws on emissions—making it more difficult to meet standards using outdated, manual, or limited monitoring systems. That’s where emission gas analyzers come in.

These advanced systems don't just check boxes for compliance—they give you the power to optimize your operation, reduce environmental impact, and stay ahead in an increasingly eco-conscious world.

The Modern-Day Challenges in Emissions Monitoring

Let’s face it—monitoring emissions today is not what it used to be. Whether you're in power generation, cement production, refining, or waste management, you're likely facing:

Stricter emission limits for gases like NOx, SO₂, CO, and particulate matter

Highly variable gas compositions due to process changes

Harsh conditions that can damage traditional analyzers

Outdated systems with no digital integration

Increased pressure for transparency from regulators and the public

These challenges make it clear: monitoring emissions with precision is no longer optional—it’s essential.

How Emission Gas Analyzers Deliver Accurate Results

Emission gas analyzers are built for real-time, high-accuracy measurements. These systems operate continuously and automatically, giving you a detailed picture of what your facility is emitting—minute by minute. Whether it's NOx, SO₂, CO, CO₂, or even hazardous gases like HCl and NH₃, these analyzers detect and quantify them with precision.

And that’s not all—they also come with self-calibration features, diagnostic tools, and remote monitoring capabilities, so you can stay informed and take corrective action before it becomes a problem.

Why It Matters Across Industries

Different industries have different emissions profiles—but they all need reliable gas analyzers:

Power Plants: Optimize combustion and meet strict EPA regulations

Cement & Steel: Handle high-temperature and dust-heavy emissions

Chemical & Petrochemical: Monitor volatile and hazardous gases

Oil & Gas: Detect leaks and ensure community safety

Waste Incineration: Track complex gases from unpredictable waste streams

These analyzers provide the data you need to stay in control and compliant.

Emission Monitoring Meets Sustainability

Here’s the truth: compliance is just the beginning. Emission gas analyzers also support your sustainability goals. By optimizing combustion and reducing excess fuel use, you’re not just cutting costs—you’re cutting CO₂. Many systems can also help with greenhouse gas inventory reporting, supporting global ESG frameworks like CDP, ISO 14064, and GRI.

Plus, with real-time emissions visibility, you gain trust and transparency—something regulators, investors, and communities now expect from every modern industrial player.

The Bottom Line

Emission gas analyzers are no longer optional. They're essential tools for any industry that takes environmental responsibility seriously. They offer more than just compliance—they offer data-driven insight, efficiency gains, and a stronger path toward sustainability.

In a world that’s moving toward net-zero and carbon transparency, having the right emission monitoring system isn’t just smart—it’s strategic.

0 notes

Text

Revolutionizing Industrial Operations with a Connected Workforce Platform

In the age of Industry 4.0, the frontline workforce is undergoing a digital transformation. The traditional methods of managing tasks, communication, and data are giving way to smarter, more agile systems. At the heart of this transformation lies the connected workforce platform—a comprehensive solution designed to unify people, processes, and technology in real time.

A connected workforce platform is a digital ecosystem that enables seamless communication, task execution, and data sharing among field workers, supervisors, and enterprise systems. It leverages mobile apps, IoT devices, cloud connectivity, and AI-powered insights to enhance productivity, safety, and operational visibility.

Why the Connected Workforce Needs a Digital Shift

In industries such as manufacturing, utilities, oil and gas, and field services, frontline workers play a pivotal role in daily operations. Yet, many of these workers still rely on paper-based workflows, disconnected tools, and manual reporting. This leads to inefficiencies, increased risk of error, and lack of real-time insights.

A connected workforce platform eliminates these barriers by offering a unified interface through which workers can receive work instructions, access asset data, report issues, and collaborate—no matter where they are. This real-time connectivity empowers workers to act faster, reduce downtime, and perform tasks with greater accuracy.

Key Advantages of a Connected Workforce Platform

Real-Time Communication and Collaboration: Workers can instantly communicate with team members, supervisors, or support staff using in-app messaging and alerts. This immediate access reduces delays and fosters better teamwork across shifts and departments.

Digitized Workflows: Paper-based tasks like inspections, maintenance, and inventory checks are digitized and streamlined. Mobile apps guide workers step-by-step, ensuring compliance with SOPs and reducing human error.

Data-Driven Insights: The platform collects and analyzes operational data from the field in real time. Managers can monitor performance, identify bottlenecks, and make data-backed decisions to improve efficiency.

Scalability and Integration: A modern connected workforce platform is designed to scale across sites and integrate seamlessly with existing ERP, EAM, and CMMS systems. This ensures consistent data flow and supports enterprise-wide transformation.

Improved Safety and Compliance: With access to digital checklists, hazard reporting tools, and safety protocols, workers can maintain compliance and reduce risks. Safety incidents can be reported instantly, ensuring quick mitigation and follow-up.

Faster Onboarding and Training: New hires can quickly get up to speed with digital work instructions, video tutorials, and access to tribal knowledge, all within the platform.

Innovapptive: Leading the Connected Workforce Revolution

Among the leaders in this space, Innovapptive stands out with its intelligent connected workforce solutions tailored for industrial enterprises. Their platform helps companies digitize frontline processes such as maintenance, inspections, work orders, and inventory management—delivering greater control and visibility across operations.

Innovapptive’s connected workforce platform integrates effortlessly with enterprise systems like SAP and Oracle, offering a powerful, configurable, and user-friendly experience. Whether it’s tracking task progress, accessing job history, or enabling remote collaboration, Innovapptive empowers every worker with the tools they need to excel.

Organizations that use Innovapptive report significant reductions in operational costs, improvements in workforce productivity, and enhanced equipment uptime. With clients across oil & gas, manufacturing, energy, and utilities, Innovapptive is redefining how work gets done at the frontline.

Future-Proofing Your Operations

In a competitive, fast-paced industrial environment, agility and efficiency are essential. By adopting a connected workforce platform, companies can ensure that their operations are not just reactive, but proactive and resilient. It’s not just about adding digital tools—it’s about enabling a smarter, safer, and more empowered workforce.

As we move into a more connected future, platforms like Innovapptive’s are set to become the backbone of frontline operations, driving continuous improvement and innovation at scale. Investing in a connected workforce platform today is a strategic move that positions your business for long-term success.

0 notes

Text

How Drones Are Revolutionizing Infrastructure Monitoring in India

Infrastructure projects fuel India’s economic growth—from highways threading across mountains to pipelines buried beneath fields. But traditional inspections (using ground teams, scaffolding, and manual surveillance) are time-consuming, expensive, and often risky. Enter drones: high-flying game-changers, enabling safer, faster, and more accurate monitoring of critical assets. And at the forefront stands Aebocode Technologies, a premier drone manufacturing company in India pushing the boundaries of aerial innovation.

🛩️ From Sky to Site: The Rise of Drone Surveillance

India's infrastructure expansion—highways, railways, bridges, power lines—is monumental. The National Highways Authority of India (NHAI), for example, has mandated monthly drone surveys and video recording for large-scale projects. Private firms like Marvel Geospatial have flown drones over 31,000 km of national highways, boosting construction speed by up to 5×, and helping resolve disputes using timestamped 4K video evidence.

Similarly, power utilities adopt drones to detect hotspots and infrastructure faults early via thermal imaging . Oil & gas firms—like Oil India and GAIL—use drones to patrol pipelines in challenging terrain, spotting encroachments and leaks before they become crises.

Major Benefits Over Traditional Techniques

ChallengeTraditional ApproachDrone-Based SolutionImpact

Scale & time Slow ground-surveys Rapid aerial scans 40%‑60% faster

Cost Labor and equipment-heavy Fewer personnel, less gear ~40% cost savings

Safety Risky access Remote piloting Lower accident risk

Data quality Limited visuals High-res, thermal, multispectral Early problem detection

Documentation & tracking Fragmented, manual Geo-tagged reports & video Clear audit trail

Aebocode’s Role: India’s Leading Drone Manufacturing Company in India

Headquartered in Chandigarh, Aebocode Technologies is a trailblazing drone manufacturing company in India developing UAVs specifically for critical infrastructure applications. Their lineup includes urban/industrial drones equipped with high-definition cameras and sensors—ideal for mapping, surveying, and inspecting assets like bridges, towers, and pipelines .

Beyond hardware, Aebocode integrates analytics to detect cracks, hotspots, and structural anomalies—helping stakeholders prioritize maintenance before catastrophes. By enabling remote inspections, they bolster worker safety and optimize resource use, embodying the ethos of a true drone manufacturing company in India committed to infrastructure tech evolution.

Real-World Use Cases

1. Highway & Bridge Surveillance

During Bharatmala highway development, drone-based footage helped monitor project progress, curb encroachments, and enforce quality compliance. Aebocode's industrial drones, with thermal and HD imaging, could have empowered similar initiatives—automating monthly progress reports and reducing manual burden.