#PCB reverse engineering

Explore tagged Tumblr posts

Text

Get Simplified PCB Reverse Engineering at SZOROD Learn the secrets of reverse engineering with SZOROD. With 20 years of expertise, we’ve mastered handling complicated multi-layer boards with blind holes and unlocking challenging IC chips. Our PCB reverse engineering service ensures high-quality product enhancement and cost savings. Benefit from our 100% success rate in PCB board copying, modification, schematic diagram derivation, BOM list creation, and PCB production. At SZOROD, we guarantee transparency and reliability. Try us for quick and accurate reverse engineering solutions. https://pcb-reverse-engineering.com/

0 notes

Text

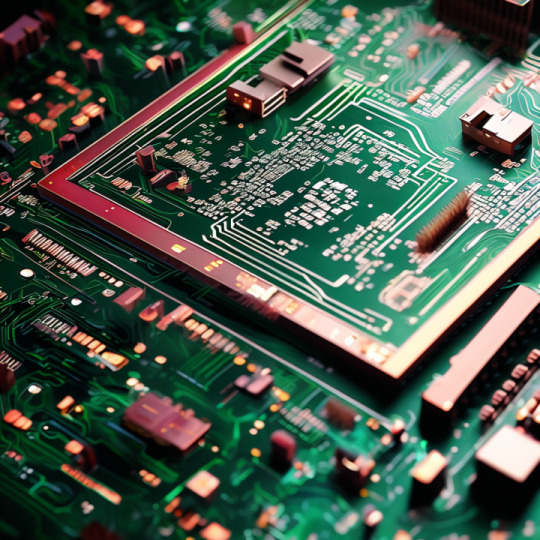

PCB Reverse Engineering: Unlocking the Secrets of Electronics

Understanding PCB Reverse Engineering

PCB Reverse Engineering is a critical process in electronics. It involves analyzing and replicating existing circuit boards to understand their functionality. This practice is essential for troubleshooting, product development, and even recreating obsolete hardware.

The Importance of Reverse Engineering in Electronics

Reverse Engineering Electronics helps companies and individuals gain insight into existing designs. This knowledge can lead to innovation, improved performance, and cost-effective solutions. By dissecting the PCB, engineers can identify components, trace connections, and recreate the design.

Steps in PCB Reverse Engineering

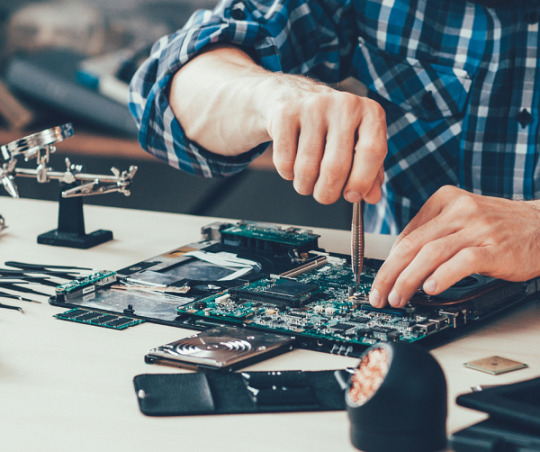

1. Visual Inspection and Documentation

The first step involves a thorough visual inspection. Engineers document the board's layout, component placement, and labeling. This documentation serves as the foundation for the reverse engineering process.

2. Component Identification

Identifying each component is crucial. Engineers analyze and catalog resistors, capacitors, integrated circuits, and other elements. This step ensures accurate replication of the original PCB design.

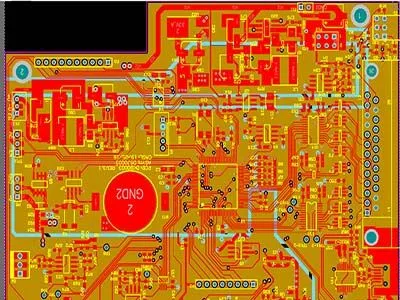

3. Tracing Circuitry Paths

Tracing the circuitry is a meticulous task. Engineers follow the copper traces that connect components. This step reveals the electrical connections and overall structure of the PCB.

4. Schematic Capture

Once the circuitry is traced, engineers create a schematic diagram. This visual representation of the circuit provides a blueprint for replication or modification.

5. PCB Layout Recreation

After the schematic is captured, the next step is recreating the PCB layout. Engineers use software tools to design a new PCB that matches the original. This layout is then ready for manufacturing.

Applications of PCB Reverse Engineering

PCB reverse engineering has diverse applications across industries. It is used in:

• Product Improvement: Enhancing existing designs by understanding and optimizing components.

• Obsolete Hardware Recreation: Reproducing outdated electronics for continued use.

• Troubleshooting: Diagnosing and fixing issues in existing PCBs.

Challenges in Reverse Engineering Electronics

While PCB reverse engineering is valuable, it comes with challenges. These include complex designs, multilayer boards, and proprietary components. Engineers must navigate these hurdles to achieve accurate results.

Future of PCB Reverse Engineering

The future of PCB reverse engineering is promising. As technology advances, so do the tools and techniques used in this field. With the rise of AI and machine learning, reverse engineering will become more efficient, enabling quicker and more accurate replication of complex electronics.

Conclusion

PCB reverse engineering is a powerful tool in the world of electronics. It unlocks the potential to innovate, recreate, and troubleshoot with precision. Whether for product development or preserving legacy systems, reverse engineering remains a cornerstone of the electronics industry.

0 notes

Text

#pcb design#pcb factory#pcb manufacturer#pcb production#pcb prototype#pcb supplier#pcb fabrication#pcb reverse engineering

0 notes

Text

China PCB Reverse Engineering Services in France

Discover fastpcbcopy, your premier destination for China PCB reverse engineering in France Specializing in replicating and optimizing PCB designs from China, we ensure top-notch quality and confidentiality. Break barriers and unleash innovation with us today Contact fastpcbcopy for seamless solutions tailored to your needs.

1 note

·

View note

Text

The Benefits of Electronic Reverse Engineering for Optimum Product Design

When it comes to product design, businesses must consider every element to guarantee that they can meet the expectations of their customers. The unique combination of electronic hardware and software solutions that bring a product to life is one of the most important parts of product design. Electronic reverse engineering services have become the cornerstone for producing goods that fulfill the needs of today’s customers in today’s ever-changing technological landscape. For more details visit :-https://medium.com/@icunlock/the-benefits-of-electronic-reverse-engineering-for-optimum-product-design-1f0b854a806c

0 notes

Text

0 notes

Text

the second worst thing about the recent surge (no pun intended) in robotgirl posting is that I'm a reverse engineer, and an asexual one at that. if I met a robotgirl we wouldn't have weird sex, I'd open up all her panels and take pictures of her PCBs and figure out what all the chips are and dump her EEPROMs and hard drive image and upload this to archive.org

20K notes

·

View notes

Text

PCB Manufacturing-PCB Assembly-Hitech Circuits

Hitech Circuits is a lеаding PCB Manufacturing & PCB Assembly company with more than 20 years experience in the electronics manufacturing industry. We focus on PCB Design, PCB Layout, Circuit board fabrication, Turnkey PCB assembly, and electronic parts sourcing services.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

We offer a full range of Electronic manufacturing services.

-LED PCB

-Heavy Copper PCB

-Multilayer PCB

-HDI PCB

-Flexible PCB

-Rigid-Flex PCB

-High Speed PCB

-High Frequency PCB

-PCB Reverse Engineering

7 notes

·

View notes

Text

Analyze and document printed circuit boards with ease. Capture PCB images using your camera or import existing photos, then add component annotations like resistors, capacitors, diodes, and ICs to create detailed circuit documentation. Draw wire connections and traces to map out circuit paths and connections. Save your analysis projects for future reference and export annotated images to share your work. Perfect for electronics enthusiasts, students, and professionals who need to reverse-engineer or document Simple circuit boards.

#PCBanalysis#circuitboarddocumentation#electronicsreverseengineering#componentidentification#circuittracing#PCBannotation#electronicstools#circuitdiagram#componentlabeling#wiremapping#electronicseducation#PCBdesign#circuitanalysis#electronicshobbyist#engineeringtools#schematiccapture#PCBphotography#componentsymbols#circuitdocumentation#electronicsreference#PCBreverseengineer#circuitboardmapping#electronicslearning#componentannotation#tracerouting#PCBviewer#electronicsstudent#circuitboardanalysis#PCBmarkup#electronicsdocumentation

0 notes

Text

How to Choose the Right EMS Provider in India for Quality and Faster Time-to-Market

Choosing the right Electronics Manufacturing Services provider in India can significantly impact your product quality, production efficiency, and speed to market. With India's growing reputation as a global electronics manufacturing hub, thanks to initiatives such as Make in India and robust infrastructure development, more businesses are turning to Indian EMS partners for their end-to-end electronic assembly needs.

In this answer, I’ll walk you through the key aspects to consider when selecting an EMS provider in India and how a trusted partner like Resolute GOC can help you accelerate innovation while maintaining high standards.

Why India for Electronics Manufacturing Services?

India has rapidly evolved into a preferred destination for electronics manufacturing for several reasons:

Cost Efficiency: Lower labor and operational costs make Indian EMS providers globally competitive.

Skilled Workforce: A large pool of engineering talent and trained technicians ensures production precision.

Government Support: Policies such as the PLI (Production Linked Incentive) scheme have incentivized electronics production.

Geopolitical Stability: Compared to some other Asian countries, India offers a more stable business environment.

What Should You Look for in an EMS Provider?

When evaluating an Electronics Manufacturing Services provider in India, consider the following factors:

1) Technical Capabilities: Look for a provider with extensive experience in Surface Mount Technology (SMT), Through-Hole Technology (THT), box builds, printed circuit board (PCB) assembly, testing, and final packaging. The more technically diverse the provider is, the more they can support your growth.

2) Quality Certifications: Your EMS partner should comply with international quality standards, such as ISO 9001, ISO 14001, IATF 16949 (for the automotive industry), and IPC-A-610. These certifications ensure that the manufacturer adheres to global quality benchmarks.

3) Design and Engineering Support: An ideal EMS partner should offer Design for Manufacturability (DFM) and Design for Testing (DFT) services to optimize your product from the early stages. Engineering support helps avoid costly mistakes later in the production cycle.

4) Scalability and Flexibility: Can the provider handle your volume requirements as you scale? Whether you're a startup launching a new product or an enterprise managing large-scale production, the ability to ramp up or down without compromising quality is critical.

5) Turnaround Time and Supply Chain: Efficient supply chain management and faster turnaround times will reduce your time-to-market. Look for a provider that maintains strong relationships with component suppliers and demonstrates expertise in managing supply chain risks.

6) Testing and Quality Assurance: A strong EMS partner will have automated and manual testing capabilities, including in-circuit testing, functional testing, burn-in testing, and environmental stress screening. This ensures product reliability and performance.

7) Aftermarket Services: Support doesn’t end with assembly. Services like repair, rework, and reverse logistics demonstrate a provider’s commitment to the entire product lifecycle.

How the Right EMS Partner Can Transform Your Business

Choosing a reliable EMS provider isn’t just about outsourcing production; it’s about establishing a strategic partnership that supports innovation and growth. Here's how:

Improved Product Quality: High-precision assembly processes, real-time monitoring systems, and rigorous quality assurance protocols ensure consistently high-quality output. This results in fewer returns, lower defect rates, and better customer satisfaction.

Faster Time to Market: A full-service EMS provider accelerates the design-to-delivery process. Their expertise in prototyping, tooling, and rapid manufacturing enables you to launch new products more quickly than if you were managing everything in-house.

Cost Reduction: From minimizing BOM (Bill of Materials) costs to reducing labor and operational expenses, EMS companies in India offer significant cost advantages without compromising quality.

Innovation Enablement: Providers like Resolute GOC support innovation with integrated services, including prototyping, product development, and scalable production. This means more time and resources for your team to focus on design and market strategy.

Why Consider Resolute GOC?

Resolute GOC is one of the leading Electronics Manufacturing Services providers in India, offering comprehensive solutions for companies across various sectors, including automotive, industrial, medical, telecom, and consumer electronics. Here’s what sets them apart:

Comprehensive Capabilities: SMT, PCB assembly, product design, and system integration under one roof.

State-of-the-Art Infrastructure: Modern facilities equipped with high-speed pick-and-place machines, AOI, X-ray inspection, and automated testing systems.

Scalability: From low-volume prototypes to high-volume production, Resolute GOC adapts to your needs.

Strong Engineering Backbone: Their engineering team offers DFM and DFT support to improve manufacturability and reliability.

Quality First Approach: Stringent quality control measures and internationally certified processes ensure consistency and compliance.

Whether you’re a startup looking to bring a prototype to life or an OEM seeking volume production, Resolute GOC can serve as a reliable partner throughout your product lifecycle.

Conclusion

Selecting the right Electronics Manufacturing Services provider in India is a strategic decision that influences your product’s success, your brand’s credibility, and your company’s bottom line. By focusing on capabilities, quality, scalability, and reliability, you can find a partner that not only meets your current manufacturing needs but also evolves with you.

As Indian EMS companies continue to invest in advanced technologies and quality frameworks, the opportunity to build globally competitive products has never been more accessible. Explore providers like Resolute GOC, who are well-positioned to deliver innovative, efficient, and scalable solutions tailored to your specific requirements.

If you’re looking to optimize your electronics manufacturing strategy and expand your reach, India’s EMS landscape is ready; the only question is, are you?

0 notes

Text

The Art and Science of PCB Reverse Engineering: A Comprehensive Guide

In the world of electronics, understanding how a printed circuit board (PCB) works can be crucial for troubleshooting, innovation, and learning. PCB reverse engineering is a process that allows engineers, hobbyists, and researchers to dissect and comprehend the intricate designs of existing PCBs. Whether you're looking to replicate an old design, learn about advanced technologies, or modify existing hardware, PCB reverse engineering offers valuable insights and opportunities. In this blog post, we’ll explore the essentials of PCB reverse engineering, its benefits, and practical tips for getting started.

What is PCB Reverse Engineering?

PCB reverse engineering is the process of analyzing and deconstructing a PCB to understand its layout, design, and functionality. This typically involves examining the physical board and its components to recreate or modify the circuit’s schematic diagram and design files. The goal is to uncover the design details that are not readily available from the manufacturer, enabling you to replicate or improve the existing design.

Why Engage in PCB Reverse Engineering?

Learning and Education: For students and hobbyists, reverse engineering provides a hands-on way to learn about electronic circuit design, component functions, and board layout. It’s a practical method to understand how various components interact within a circuit.

Repair and Maintenance: When dealing with older or discontinued hardware, PCB reverse engineering can help in diagnosing faults and replacing faulty parts. This is particularly useful for repairing vintage electronics where original schematics are no longer available.

Innovation and Design: Engineers often use reverse engineering to analyze competitor products, understand their design choices, and find areas for improvement. By learning from existing designs, they can innovate and create better, more efficient products.

Legacy Support: Companies maintaining legacy systems may need to reverse engineer PCBs to continue providing support, upgrades, or replacements for outdated technology.

The PCB Reverse Engineering Process

Reverse engineering a PCB involves several steps, each requiring precision and careful analysis. Here’s a simplified overview of the process:

Disassemble the PCB

Carefully remove the PCB from its enclosure or casing. Use tools like tweezers and anti-static mats to handle the board and avoid damaging sensitive components.

Document the Board

Take high-resolution photographs of both the top and bottom layers of the PCB. These images will serve as reference material during the reverse engineering process. Ensure that the images are clear and well-lit.

Identify Components

Label and identify all components on the PCB. This includes resistors, capacitors, integrated circuits (ICs), and connectors. Use a multi meter or component tester to help identify and measure components if necessary.

Trace the Circuit

Use the photographs to trace the circuit connections. This involves mapping out the paths of electrical connections between components. Tools like PCB design software can assist in recreating the circuit schematic.

Create the Schematic Diagram

Based on your tracing, create a schematic diagram that represents the electrical design of the PCB. This step is crucial for understanding how the circuit functions and for making any modifications.

Design the PCB Layout

Once the schematic is complete, design a PCB layout that matches the original design. PCB design software can be used to create and refine the layout, ensuring that it accurately reflects the original board’s design.

Verify and Test

Before finalizing the design, verify that the recreated PCB functions as intended. Build a prototype and test it to ensure that it meets the required specifications and performs correctly.

PCB reverse engineering is a powerful technique for understanding and working with electronic circuits. Whether you’re aiming to repair vintage hardware, learn about circuit design, or innovate in the field of electronics, mastering the art of PCB reverse engineering can provide significant advantages. By following the steps outlined in this guide and utilizing the right tools, you can delve into the intricate world of PCB design and uncover the secrets behind your favorite electronic devices.

0 notes

Text

Rethinking Logistics: The Rise of Returnable Transport Packaging for Industrial Goods

In today’s rapidly evolving industrial landscape, efficiency, sustainability, and cost-effectiveness have become crucial drivers for success. Among the many innovations gaining traction in supply chain and logistics, returnable transport packaging for industrial goods is emerging as a key solution for addressing modern challenges. Unlike traditional single-use packaging methods, returnable systems offer a reusable, long-term approach to transporting goods — significantly reducing environmental impact while improving operational efficiency.

This blog explores the concept, benefits, and applications of returnable transport packaging for industrial goods, providing insight into why more industries are making the switch.

What is Returnable Transport Packaging?

Returnable transport packaging (RTP), also referred to as reusable packaging, consists of durable containers, pallets, and sleeves specifically designed to be used multiple times in the transportation and storage of products. These systems are engineered to withstand repeated handling, loading, unloading, and transit, all while protecting goods during the entire supply chain cycle.

Typically made from robust materials such as high-density polyethylene (HDPE), polypropylene, or metal, returnable transport packaging for industrial goods is ideal for sectors with high-volume, repetitive shipping cycles — including automotive, electronics, FMCG, and pharmaceuticals.

Why Returnable Packaging Matters in Industrial Supply Chains

Traditional one-way packaging, like cardboard boxes and wooden crates, may serve short-term needs but often lead to inefficiencies and waste. They are prone to damage, limited in durability, and contribute heavily to landfill waste.

By contrast, returnable transport packaging for industrial goods is built for longevity. The focus is not only on reducing packaging waste but also on streamlining logistics, lowering overall packaging costs, and improving material handling.

Here’s why this shift matters:

1. Environmental Sustainability

One of the most compelling reasons for adopting RTP systems is the environmental benefit. The reduction in single-use packaging materials means fewer trees are cut, less plastic ends up in oceans, and carbon emissions from packaging production are significantly decreased. Most RTP solutions are also fully recyclable at the end of their usable life.

2. Cost Efficiency Over Time

While the initial investment in returnable transport packaging for industrial goods may be higher than disposable options, the long-term savings are substantial. Fewer purchases, lower waste disposal fees, reduced damage claims, and decreased labor costs in packing and unpacking lead to significant cost reductions over time.

3. Improved Product Protection

Durable materials and smart design make RTP systems highly effective at protecting industrial goods during transport. Whether it’s preventing moisture intrusion, cushioning against impacts, or avoiding contamination, these packaging solutions are engineered to offer superior performance under tough conditions.

4. Operational Efficiency

Many RTP solutions are collapsible, stackable, and easy to clean, allowing businesses to optimize warehouse space, reduce reverse logistics costs, and automate handling processes. Their uniformity in size and shape further simplifies inventory management and shipping.

Applications of Returnable Transport Packaging in Industrial Sectors

Returnable transport packaging for industrial goods has proven to be highly adaptable, with applications across a wide range of industries:

Automotive Manufacturing: Reusable trays and sleeve packs help in transporting precision parts like gears, engine components, and assemblies, while reducing the risk of damage.

Electronics: Sensitive components like PCBs and semiconductors benefit from anti-static RTP containers that ensure safe delivery without environmental contamination.

Food Processing: Hygienic, easy-to-clean RTP bins are used for moving perishable goods within the production and distribution chain.

Pharmaceuticals: Reusable packaging solutions maintain product integrity during storage and transit, ensuring regulatory compliance.

Key Considerations When Choosing Returnable Transport Packaging

Adopting returnable transport packaging for industrial goods requires careful planning and analysis. Here are some factors to consider:

- Durability and Material Selection:

Select materials based on the goods being transported, environmental exposure, and handling conditions.

- Stackability and Nestability:

Opt for designs that maximize space utilization in both forward and return logistics.

- Ease of Cleaning and Maintenance:

Ensure that the packaging can be sanitized easily, especially for industries with strict hygiene protocols.

- Tracking and Traceability:

Integrate technologies like RFID or QR codes to monitor movement and ensure accountability across the supply chain.

Challenges and Solutions in Implementation

While the benefits are clear, transitioning to a returnable system isn't without its hurdles. High upfront costs, the need for reverse logistics infrastructure, and managing packaging return cycles can be challenging. However, with proper planning, partnerships, and technology integration, these challenges can be overcome.

For example, third-party logistics (3PL) providers can assist in managing the return flow of packaging materials, while digital platforms can track and analyze usage patterns to reduce losses and optimize distribution.

The Future of Sustainable Industrial Packaging

With increasing regulatory pressure and consumer demand for sustainable practices, industries are moving toward more circular models. In this context, returnable transport packaging for industrial goods is not just a trend but a transformative shift.

Forward-thinking companies are already investing in long-term solutions that combine sustainability with cost-effectiveness. As more stakeholders in the supply chain recognize the value, the adoption of returnable systems is expected to accelerate.

Conclusion

In an age where efficiency and environmental responsibility are non-negotiable, returnable transport packaging for industrial goods stands out as a practical, forward-thinking solution. By reducing waste, cutting long-term costs, and enhancing product safety, it offers a smarter way to manage logistics in industrial settings.

Organizations that proactively adopt these systems are not only investing in better logistics but also contributing to a more sustainable and resilient supply chain for the future.

0 notes

Text

Zero Liquid Discharge Plant Manufacturer in Delhi: Leading the Way Toward Sustainable Water Management

Zero Liquid Discharge Plant Manufacturer in Delhi

As industries continue to expand and environmental regulations become stricter, the need for sustainable and eco-friendly waste management systems is more important than ever. One such advanced technology that is transforming industrial wastewater treatment is the Zero Liquid Discharge (ZLD) system. If you're searching for a Zero Liquid Discharge Plant Manufacturer in Delhi, this article will help you understand the importance of ZLD systems and guide you in choosing the best manufacturer in the capital city of India.

What is a Zero Liquid Discharge (ZLD) System?

Zero Liquid Discharge is a water treatment process designed to eliminate all liquid waste from a system. In simple terms, ZLD ensures that no industrial effluent or wastewater is released into the environment. Instead, all water is treated, recycled, STP and reused, leaving behind solid waste that can be safely disposed of.

Why ZLD is Crucial for Industries

Industries such as textiles, pharmaceuticals, chemicals, power plants, and food processing produce a large volume of wastewater. If not treated properly, RO this can lead to environmental pollution and health hazards.

Key Benefits of ZLD Systems:

Environmental Protection: Prevents discharge of harmful chemicals into water bodies

Water Reuse: Treated water can be reused in industrial processes, saving fresh water

Regulatory Compliance: Meets strict pollution control norms from authorities like the CPCB (Central Pollution Control Board)

Cost-Efficiency: Long-term savings on water procurement and disposal

Sustainability: Supports corporate social responsibility (CSR) and green initiatives

ZLD Technology Overview

A Zero Liquid Discharge system is typically composed of:

Pre-treatment Units (for removing large particles and oil)

Evaporators (concentrate the wastewater)

Crystallizers (convert dissolved solids into crystals)

Reverse Osmosis (RO) Systems (recover water from waste streams)

Multi-Effect Evaporators (MEE) and Mechanical Vapor Recompression (MVR) for energy efficiency

Each component plays a crucial role in separating clean water from sludge and contaminants.

Growing Demand for ZLD Plants in Delhi

Delhi, being one of the most industrialized and densely populated cities in India, faces significant challenges with water scarcity and pollution. To tackle these issues, both the government and private sector are promoting the use of ZLD systems across industries.

Whether it's textile dyeing units in Bawana or pharmaceutical manufacturers in Okhla, many industries in Delhi are now looking for reliable Zero Liquid Discharge Plant Manufacturers to ensure regulatory compliance and environmental safety.

Top Qualities of a Trusted ZLD Plant Manufacturer in Delhi

If you’re in the market for a ZLD plant, it's vital to choose the right manufacturer. Here's what you should look for:

1. Experience and Expertise

Choose a manufacturer with a proven track record in designing and installing ZLD plants for a variety of industries.

2. Customized Solutions

Each industry has unique wastewater characteristics. A good manufacturer will offer tailor-made solutions based on your specific needs.

3. Advanced Technology

Check if the company uses the latest energy-efficient components like RO, MVR, and advanced membrane systems.

4. Compliance Support

A reliable manufacturer will ensure your plant meets CPCB and state PCB guidelines.

5. After-Sales Service

24/7 technical support, regular maintenance, and training services are essential for uninterrupted plant operation.

Services Offered by ZLD Plant Manufacturers in Delhi

Turnkey ZLD Solutions

Design and Engineering

Installation and Commissioning

Operation and Maintenance

ZLD Plant Upgrades

Retrofitting and Expansion

Online Monitoring Systems

Industries That Use ZLD Plants in Delhi

ZLD technology is versatile and can be adapted for various industrial sectors:

Textile and Dyeing Units

Tanneries

Pharmaceutical Plants

Chemical and Fertilizer Industries

Beverage and Food Processing Units

Power Plants

Electroplating Units

Challenges in Implementing ZLD Systems

While ZLD offers numerous benefits, it also comes with certain challenges:

High Initial Investment: ZLD systems can be capital-intensive, but the ROI is high in the long term.

Energy Consumption: Evaporators and crystallizers require substantial energy. Opting for MEE and MVR systems can reduce this burden.

Sludge Management: Handling and disposal of residual solids must be done responsibly.

Operational Expertise: Requires skilled operators for efficient functioning.

These challenges make it all the more important to choose a reputed ZLD plant manufacturer who can provide smart, efficient, and scalable solutions.

Government Regulations and ZLD

The National Green Tribunal (NGT) and Central Pollution Control Board (CPCB) have made it mandatory for highly polluting industries to adopt ZLD technologies. In Delhi NCR, industries are under pressure to treat and reuse their effluents or risk closure and penalties.

This regulatory environment is pushing demand for reliable and certified Zero Liquid Discharge Plant Manufacturers in Delhi.

How to Choose the Best ZLD Plant Manufacturer in Delhi

Here’s a step-by-step guide:

Assess Your Requirements: Know your industry’s effluent load, type of waste, and reuse objectives.

Research Vendors: Shortlist companies with certifications like ISO, CE, and CPCB approval.

Request Proposals: Compare technical offers, energy consumption, treatment efficiency, and total cost.

Visit Existing Installations: See running plants and ask for client feedback.

Check After-Sales Support: Ensure the company offers regular maintenance, training, and emergency services.

Conclusion

With Delhi’s rising industrial output and strict environmental norms, installing a Zero Liquid Discharge Plant has become more of a necessity than a choice. ZLD systems not only help industries become more environmentally responsible but also reduce long-term water costs by enabling water reuse.

Partnering with the right Zero Liquid Discharge Plant Manufacturer in Delhi ensures that your business stays compliant, eco-friendly, and future-ready. Whether you're setting up a new factory or upgrading your existing water treatment facility, now is the time to invest in ZLD for a cleaner, greener tomorrow.

FAQs

1. What is the main purpose of a Zero Liquid Discharge Plant? To treat industrial wastewater in such a way that no liquid waste is discharged, promoting complete water recycling and environmental safety.

2. Are ZLD systems mandatory for all industries in Delhi? While not all, certain high-polluting industries like textiles, tanneries, and pharmaceuticals are required to install ZLD systems by the CPCB.

3. How much does a ZLD plant cost? The cost varies based on the industry, wastewater volume, and technology used. It ranges from ₹20 lakhs to several crores.

4. What is the lifespan of a ZLD plant? With proper maintenance, a ZLD system can last 15–20 years.

5. Can a ZLD system reduce my company’s water bills? Yes. By recycling and reusing water, your dependence on fresh water is reduced, leading to lower water procurement costs.

#Zero Liquid Discharge Plant Manufacturer in Delhi#TOP Zero Liquid Discharge Plant Manufacturer in Delhi#SALE Zero Liquid Discharge Plant Manufacturer in Delhi#BEST Zero Liquid Discharge Plant Manufacturer in Delhi

0 notes

Text

Explore the Leading Electronics Manufacturing Companies in Florida (2025 Guide)

Florida is more than just a tourist destination—it's quickly becoming a hotbed for electronics manufacturing. With growing demand from industries like aerospace, defense, healthcare, and telecommunications, the state is now home to some of the top electronics manufacturing companies in the U.S.

In this 2025 guide, we highlight the most reputable and capable top electronics manufacturing companies in Florida, known for their technical expertise, high-quality production, and end-to-end EMS solutions.

Why Florida is a Growing Electronics Manufacturing Hub

Here’s why many OEMs and startups are turning to Florida for their electronic manufacturing needs:

Strategic Location: Ideal for logistics with access to ports, Latin America, and major U.S. markets.

Diverse Industries: From medical to defense, demand spans across sectors.

Skilled Workforce: Engineering talent from top universities and tech programs.

Supportive Environment: Tax benefits and innovation-friendly policies.

Let’s dive into the top EMS providers making a mark in Florida.

1. Jabil Inc. – St. Petersburg, FL

Website: jabil.com Specialties: Full EMS, PCB Assembly, Design Services, Supply Chain Management

Jabil is one of the largest electronics manufacturing services (EMS) companies globally. Headquartered in St. Petersburg, it delivers full product lifecycle support—from concept to volume production.

Key Industries:

Healthcare

Automotive

Consumer Tech

Industrial Equipment

Why They Lead: Global presence, innovation capabilities, and turnkey manufacturing make Jabil a trusted partner for major brands.

2. Ultra Electronics – Fort Lauderdale, FL

Website: ultra.group Focus Areas: Defense Electronics, RF Systems, Secure Communications

Ultra Electronics delivers high-reliability electronics for defense and aerospace markets. Their Florida location develops mission-critical communication systems and sensor solutions.

Standout Strength: Defense-grade engineering with a strong focus on cybersecurity and precision electronics.

3. DEX – Data Exchange Corporation – Miramar, FL

Website: dex.com Core Services: Electronics Manufacturing, Repairs, Reverse Logistics

DEX offers both manufacturing and aftermarket services such as refurbishment and returns processing. Their Miramar center supports global brands with a full electronics lifecycle approach.

Best For: OEMs looking for long-term product support, including repairs and upgrades.

4. ICS Inc. – Palm Bay, FL

Website: ics-fl.com Capabilities: PCB Assembly, Cable Harnessing, Testing, Conformal Coating

ICS specializes in small-to-medium batch PCB manufacturing and assembly. They are known for fast prototyping and IPC-certified quality standards.

Why They're Trusted: Customer-focused service, tight tolerances, and excellent quality control.

5. PCB Solutions – Orlando, FL

Website: pcb-solutions.com Services: Custom PCB Fabrication, Assembly, Component Sourcing

PCB Solutions offers flexible options for prototyping and low-to-mid volume production. Based in Orlando, they provide single- and multi-layer PCB solutions.

Industries Served:

Industrial Controls

Smart Devices

Renewable Energy

What Makes Them Unique: Speed, flexibility, and a focus on early-stage product development.

6. Control Technology Inc. – Riviera Beach, FL

Website: controltechnology.com Specialties: Embedded Electronics, Motion Control Systems, PCB Design

Control Technology offers complete EMS services tailored for high-reliability sectors. Their experience spans over 35 years, building rugged electronic systems for industrial automation.

Ideal For: Companies needing embedded control solutions with engineering support.

7. Alpha Contract Manufacturing – Melbourne, FL

Website: alpha-cm.com Key Services: PCB Assembly, Box Builds, System Integration

Alpha CM provides full-service electronics manufacturing, from surface-mount tech to final system assembly. Their Melbourne facility supports clients in defense and commercial sectors.

Top Features:

ISO-certified

Prototyping to production

Functional testing

Customer Advantage: Scalable EMS with strong customer service and tight process control.

8. E-Tronics Manufacturing – Tampa, FL

Website: etronicsmfg.com Core Offerings: Contract Manufacturing, PCB Assembly, Prototyping

E-Tronics supports small and mid-size companies with agile, cost-effective electronics manufacturing. Their Tampa facility offers fast prototyping and box builds.

Industries Served:

Security Systems

Smart Lighting

Industrial Electronics

Why They Stand Out: Personalized attention and ISO-certified quality processes.

9. SMTC (formerly MC Assembly) – Melbourne, FL

Website: smtc.com Services: High-Mix EMS, Testing, NPI Support

SMTC builds on MC Assembly’s legacy, offering high-reliability EMS for complex electronics. They serve customers in medical, industrial, and IoT industries.

What They Offer:

DFM/DFT capabilities

Regulatory compliance (ISO 13485, ITAR)

Supply chain optimization

Why Choose SMTC: Perfect for clients with high-mix, low-to-medium volume requirements.

10. KML Labs – Apopka, FL

Website: kmllabs.com Core Focus: Electronic Design, PCB Assembly, Firmware Development

KML Labs is a go-to partner for startups and R&D teams. They specialize in small-batch, complex builds that require custom design and embedded development.

Key Services:

Prototype development

Circuit design

Embedded software

Unique Strength: Full design-to-build capabilities under one roof.

Final Thoughts

Florida is rapidly becoming a center for advanced electronics manufacturing, thanks to its skilled workforce, innovation-friendly environment, and proximity to key industries. Whether you’re a global OEM or a tech startup, these companies represent the best Florida has to offer in electronic manufacturing services (EMS).

Need Help Sourcing Electronics Manufacturers in Florida?

FindingMFG makes it easy to connect with trusted electronics manufacturing companies in Florida. Get instant quotes, track projects, and collaborate with top EMS partners on one powerful platform.

👉 Visit FindingMFG.com to start sourcing now

#top electronics manufacturing companies in Florida#electronics manufacturing companies in Florida#electronics manufacturing

0 notes

Text

Get to know me!

Sup guys I'm Eve!!!! If you found me from my photography hey hi hello!! If you found me from somewhere else and don't know anything about me then that's completely fine too! Lets get to know each other!! Im restarting Tumblr since it keeps itching me so here I go!!

So I'm a part time photographer and a part time technician, I can fix pretty much anything you throw me ranging from computers, phones, camera and camera lenses, and I can kinda fix TVs, I can also break into basically ANYTHING digital you point me at that's not crazy protected, same for reverse engineering!! I also know how to solder and micro solder, if you have any pcb ideas feel free to commission me and I can get it designed and have pcbway make it for you and I can do all the soldering if wanted, or have them do it for you as well!! :]

I have a lot of interests! I love all things grunge, I don't really dress grunge since my adults in life dont like me dressing "homeless" :ugh: but I love the culture and music, I love artists like Nirvana, Mudhoney, Bam Bam, Alice In Chains in terms of grunge artists, I also REALLY like different subcultures of it as well, especially the modern day interpretation of grunge with people associating Memphis rap into grunge culture kinda like how its tied with y2k a little, mainly with social media influence- BUT anyways, I also really like artists like Jak3, Dr Dre, Project Pat, Dababy, Greenday, DJ Smokey, The Paradox, JBroadWay, Radiohead, Rick Ashley, Glorilla, j^p^n, DURAN DURANNNNNNNNN!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! There's others but that's all I feel like listing so suck it up :standing:

I do have some other smaller interests like skating even tho I suck at it, rural and urban exploration, electric vehicles like surrons, dragsters, and go karts--heavy on the go carts, I like bowling, cyber security, CAD modeling, video and photo editing, DIY clothing, shows like Invincibles, Arcane, Steven Universe, Wednesday, anything DC, American Psycho, and I'm getting into some others like Umbrella Academy and back into Starwars!

Lets also get the record straight since I know some people are going to come from places where I'd prefer not, so it's best I address the apparent:

I'm aware I've made some bad decisions prior to the new year, I'm aware of how and why they're wrong and I've done a lot of self reflecting and change, I've made apologies and plan on doing more when I feel appropriate, preferable when I leave school since I graduate soon! None the less, if the people I've hurt are reading this blog, do know I'm sincerely and deeply sorry for everything I've done to harm you whether unintentional, or unfortunately done intentionally done with me believing I was right and believed I was "justified."

With that said, I've changed a lot!! Lots of therapy and lots of self reflection and even cutting off ties with people I knew would get me back into my old ways that I didn't feel would be best for my own self development, I completely understand if new people I meet don't like the old actions I did and chose to avoid me for it--completely understandable I wont have any objections to it

With that said, I hope we can be friends and get along well!! Other photographers please feel free to reach out if you wanna collab or maybe meet up! I'm in central Florida so don't feel afraid to reach out or book me!

And dont forget, youre known by name, loved, valued, and cared for!!

my old church got me into that saying and know its apart of me lolz

1 note

·

View note