#PLC Hardware Components

Explore tagged Tumblr posts

Text

110-CPU-411-01 Schneider Electric

Micro CPU AC I/O 115V with DC Interrupt

To more information click here

#plc world#PLC Equipment#PLC Hardware Components#Allen Bradley Plc Parts#Eaton Electrical Components#Siemens Plc Systems#Schneider Components

0 notes

Text

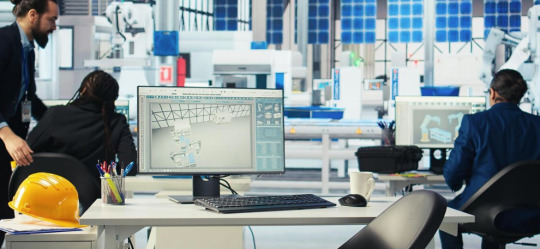

The Mechatronic Design Engineer: Powering Automation with CODESYS

Mechatronic design engineering is a multidisciplinary field that blends mechanical engineering, electronics, control systems, and software development to create intelligent, automated systems. Mechatronic design engineers are at the forefront of innovation, designing solutions for industries like robotics, automotive, aerospace, and manufacturing. CODESYS, an IEC 61131-3-compliant development platform, is a critical tool for these engineers, enabling them to program and integrate control systems for complex mechatronic applications. This article explores the role of a mechatronic design engineer, how CODESYS supports their work, key responsibilities, required skills, and real-world applications, highlighting the impact of this profession on modern automation.

The Essence of Mechatronic Design Engineering

Mechatronic design engineering focuses on creating systems that integrate mechanical components, electronic circuits, sensors, actuators, and software to achieve precise, reliable performance. These systems, such as robotic arms, autonomous vehicles, or CNC machines, require seamless coordination between hardware and software. Mechatronic design engineers ensure that these components work together to meet performance, safety, and efficiency goals, making them essential in industries embracing Industry 4.0 and smart automation.

CODESYS is a cornerstone for mechatronic design engineers, offering a versatile, hardware-independent platform for programming embedded control systems. Its compliance with IEC 61131-3, support for multiple programming languages, and robust tools for simulation and debugging make it ideal for developing sophisticated mechatronic systems.

Responsibilities of a Mechatronic Design Engineer

Mechatronic design engineers undertake a variety of tasks to bring complex systems to life:

System Design and Integration: Designing integrated systems that combine mechanical structures, electronics, and control software to meet specific functional requirements.

Control System Programming: Developing control algorithms to manage sensors, actuators, and motion systems, ensuring precise operation.

Simulation and Testing: Using simulation tools to validate system performance before deployment, minimizing errors and risks.

Prototyping and Commissioning: Building prototypes, integrating components, and deploying systems in real-world environments.

Optimization and Troubleshooting: Analyzing system performance, debugging issues, and optimizing designs for efficiency and reliability.

Collaboration: Working with mechanical, electrical, and software teams to ensure cohesive system development.

How CODESYS Empowers Mechatronic Design Engineers

CODESYS provides a comprehensive environment tailored to the needs of mechatronic design engineers:

IEC 61131-3 Programming Languages: CODESYS supports Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). These languages enable engineers to develop control logic for diverse applications, from simple discrete controls to advanced motion systems.

Hardware Flexibility: Compatible with PLCs and embedded controllers from vendors like Beckhoff, WAGO, and Siemens, CODESYS allows engineers to choose hardware that suits project budgets and requirements.

Motion Control Libraries: CODESYS offers libraries for motion control, supporting tasks like servo motor control, trajectory planning, and multi-axis coordination, critical for mechatronic systems like robotics.

Simulation and Debugging Tools: The built-in simulation mode enables testing without physical hardware, while debugging features like breakpoints and real-time monitoring help identify and resolve issues quickly.

HMI Development: CODESYS provides tools to create Human-Machine Interfaces (HMIs) for operator interaction, including graphical displays and web-based visualizations.

Communication Protocols: Support for EtherCAT, CANopen, Modbus, and OPC UA ensures seamless integration with sensors, actuators, and other devices in mechatronic systems.

Safety Standards: For safety-critical applications, CODESYS supports IEC 61508 (SIL 2/3), enabling engineers to design systems for industries like automotive and aerospace.

Example: Robotic Arm Control Program

Below is a sample Structured Text (ST) program for controlling a robotic arm’s position in a mechatronic system:

RoboticArmControl.st

plain

Show inline

This program implements a proportional control loop to adjust a robotic arm’s joint angle, ensuring precise positioning in a mechatronic application.

Essential Skills for Mechatronic Design Engineers

To succeed, mechatronic design engineers need a diverse skill set:

Multidisciplinary Knowledge: Proficiency in mechanical design, electronics, and control systems programming, including CODESYS and IEC 61131-3 languages.

Control Theory: Understanding of control algorithms, such as PID control, for precise system management.

Software Development: Experience with embedded systems programming and real-time operating systems (RTOS).

Problem-Solving: Analytical skills to troubleshoot and optimize complex systems.

Teamwork: Collaboration with cross-functional teams to integrate hardware and software components.

Adaptability: Staying updated with emerging technologies like IoT, AI, and cybersecurity.

Benefits of Using CODESYS

Streamlined Development: The integrated IDE and simulation tools reduce development time and errors.

Cost Efficiency: Hardware independence and code reusability lower project costs.

Scalability: CODESYS supports projects from small prototypes to large-scale industrial systems.

Flexibility: Multiple programming languages and protocols cater to diverse project needs.

Community Support: A global user base and resources like the CODESYS Store provide access to libraries and tutorials.

Applications in Industry

Mechatronic design engineers leverage CODESYS in various sectors:

Robotics: Developing control systems for industrial and collaborative robots.

Automotive: Designing ECUs for engine management, braking, and autonomous driving.

Manufacturing: Automating production lines, CNC machines, and material handling systems.

Aerospace: Controlling actuators and sensors in aircraft and spacecraft.

Medical Devices: Creating precise control systems for surgical robots and diagnostics.

Challenges in Mechatronic Design Engineering

Interdisciplinary Complexity: Integrating mechanical, electrical, and software components requires broad expertise.

Learning Curve: Mastering CODESYS and IEC 61131-3 languages can be time-intensive for beginners.

Resource Constraints: Embedded systems often have limited processing power, necessitating optimized code.

Safety Requirements: Meeting standards like IEC 61508 for safety-critical applications adds complexity.

Getting Started with CODESYS

To begin as a mechatronic design engineer using CODESYS:

Install CODESYS: Download the free IDE from the official website.

Learn Programming: Study IEC 61131-3 languages through tutorials and documentation.

Select Hardware: Choose a compatible PLC or embedded controller.

Develop and Simulate: Write control logic, test in simulation mode, and debug.

Deploy: Compile and deploy code to the target hardware.

Future Trends

As industries embrace digital transformation, mechatronic design engineers will increasingly use CODESYS for IoT-enabled systems, cloud-based monitoring, and AI-driven control. Support for protocols like OPC UA and MQTT positions CODESYS for smart manufacturing, while advancements in cybersecurity ensure its relevance in safety-critical applications.

Conclusion

Mechatronic design engineers by Servotechinc are key to creating the intelligent systems that drive modern automation, from robotics to autonomous vehicles. CODESYS empowers these professionals with a flexible, IEC 61131-3-compliant platform for programming, testing, and deploying control systems. Its robust features, hardware independence, and support for motion control and communication protocols make it indispensable for mechatronic applications. As technology advances, CODESYS and mechatronic design engineers will continue to shape the future of automation, delivering innovative, efficient, and reliable solutions.

0 notes

Text

Understanding Board-to-Board Connectors

In the world of electronic hardware, where space, speed, and signal integrity define performance, board-to-board connectors are critical components that quietly enable innovation. These specialized connectors join printed circuit boards (PCBs) directly without the need for cable assemblies, supporting compact, high-performance electronic designs used in everything from smartphones and laptops to industrial machinery and aerospace systems.Get more news about Board-to-board Connector,you can vist our website!

What Are Board-to-Board Connectors? Board-to-board connectors are designed to provide reliable electrical and mechanical connections between two or more PCBs within a device. Unlike wire-to-board or cable-based systems, these connectors allow signal and power transmission through directly mated interfaces, which helps reduce bulk and improve data integrity. They are essential for stackable or modular designs and are particularly favored in applications where internal space is limited.

Types and Configurations These connectors come in several configurations depending on the orientation and spacing needs:

Parallel (Mezzanine) Connectors: Used when two boards are stacked vertically. These are common in compact electronic devices and offer high-density signal transmission.

Coplanar Connectors: For side-by-side board connections, maintaining the same plane and allowing broader layout designs.

Right-Angle Connectors: Used when a 90-degree connection is required between boards, useful in folded or L-shaped PCB assemblies.

Pitch (the spacing between pins), stack height, current rating, and number of contacts are customizable depending on application requirements. High-speed data connectors often require shielding and controlled impedance to prevent signal loss and crosstalk.

Key Features and Advantages Modern board-to-board connectors are engineered for precision and durability. Key features include:

Miniaturization: Compact design supports smaller electronic devices.

High-Density Pin Configuration: Enables transmission of large volumes of data and signals.

Durability and Reliability: Designed for multiple mating cycles and resistance to shock and vibration.

High-Speed Signal Transmission: Particularly in designs requiring signal integrity for data communication or computing.

Manufacturers also offer versions with alignment guides, locking mechanisms, and surface-mount or through-hole mounting options, ensuring seamless assembly even in automated production lines.

Applications Across Industries Because of their versatility and performance, board-to-board connectors are used in a wide range of industries:

Consumer Electronics: Smartphones, tablets, laptops, and wearables.

Industrial Automation: PLCs, sensors, and motor controllers.

Medical Devices: Diagnostic imaging machines, patient monitors, and handheld tools.

Automotive: Advanced Driver Assistance Systems (ADAS), infotainment, and battery management systems in EVs.

Aerospace and Defense: Flight systems, navigation equipment, and satellite electronics.

As electronics become smarter and more integrated, the demand for connectors that balance power, data throughput, and mechanical integrity has never been higher.

Innovation and Market Outlook The global board-to-board connector market is expected to grow steadily, driven by trends such as miniaturization, 5G deployment, IoT integration, and automation. Emerging materials and manufacturing techniques—like laser welding and micro molding—are allowing for even smaller, faster, and more durable connectors.

Asian countries, particularly China, South Korea, and Taiwan, dominate production, but leading global manufacturers like Samtec, TE Connectivity, and Hirose Electric continue to drive innovation with proprietary designs optimized for high-speed and harsh-environment applications.

Conclusion Board-to-board connectors might not be visible to end users, but they are indispensable to modern technology. As we continue to demand more from our devices—in performance, portability, and connectivity—these small yet powerful components ensure that everything works as one cohesive system. Their evolution mirrors our own digital advancement: quietly essential, endlessly adaptable, and critical to progress.

0 notes

Text

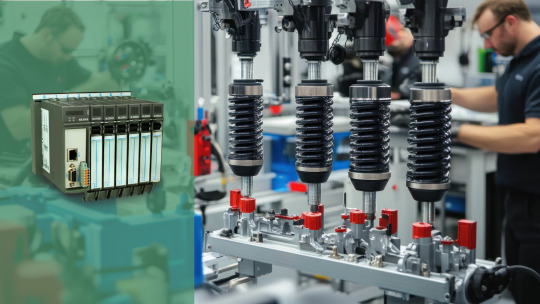

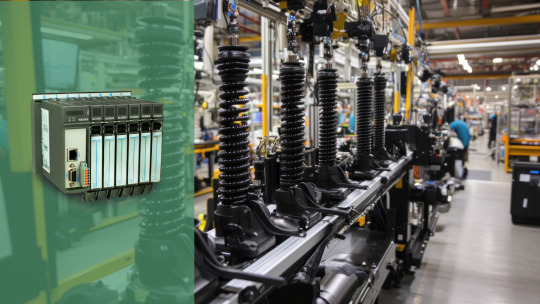

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

What We Recycle: Accepted Electronics and E-Waste at 3R Technology

At 3R Technology, we don’t just recycle devices; we provide a responsible, secure, and scalable solution for managing electronic waste. Our facility is equipped to handle a broad spectrum of electronics and peripheral equipment, from individual consumer devices to enterprise-level infrastructure. If it has a circuit board or a wire, chances are we can recycle it. Materials accepted include a wide range of electronic components and devices, ensuring comprehensive e-waste management.

Our goal is simple: recover usable materials, protect sensitive data, and divert e-waste from landfills through environmentally sound practices.

Electronics We Accept

We accept a wide range of electronics, including but not limited to:

Computers & Laptops: Whether outdated, broken, or surplus, desktops and laptops are among the most common items we process.

Servers, Networking, & Data Centre Equipment: We handle enterprise-grade hardware such as servers, switches, routers, firewalls, and related gear.

Monitors & Displays: We recycle LCD, LED, and flat-panel monitors. CRTs are accepted with restrictions. Contact us in advance.

Devices: Smartphones, tablets, and other portable electronics are accepted, regardless of age or condition.

Printers, Scanners & Peripherals: Workplace devices, from multi-function printers to external hard drives and keyboards, are recyclable through our facility's services.

Cabling & Wiring: Power cords, data cables, and electrical wiring are all accepted, as copper and metals can be recovered during processing.

Speciality & Industrial Electronics

In addition to standard electronics, we also process equipment used in specialised or industrial environments:

Medical Electronics: Monitors, imaging equipment, and diagnostics systems (non-hazardous) can be evaluated for responsible recycling.

Laboratory Instruments: Items used in research or testing settings, including analysers, oscilloscopes, and measuring devices.

Point-of-Sale Systems: Barcode scanners, card readers, registers, and related accessories.

Manufacturing Controls: PLCs, automation hardware, and embedded systems often contain valuable recoverable components.

If you’re unsure whether your item qualifies, we are here to review it.

What We Don’t Accept

While our facility can handle a wide range of materials, there are a few exceptions due to safety and compliance regulations:

Household appliances (e.g., refrigerators, microwaves)

Hazardous materials (e.g., items with chemical, biological, or radioactive exposure)

CRT monitors with damaged tubes (accepted on a case-by-case basis)

Light bulbs, batteries, and loose toner cartridges (unless part of a larger electronics load)

If you're managing a large project or facility decommission, we encourage you to contact us for a tailored solution. Based on volume and overall condition, we may accept items not listed here.

Why Choose 3R Technology

We’re not just a drop-off point, but a full-service electronics lifecycle partner. We adhere to R2v3 and ISO 14001 standards for responsible recycling and data security. Every item is processed to maximize recovery while minimizing environmental impact.

Our team also provides certified data destruction services, both on-site and off-site. Whether it’s a single device or a thousand, we ensure data-bearing devices are sanitised to NIST and DoD standards.

We work with businesses, schools, healthcare providers, government agencies, and individual residents across the Pacific Northwest. Our services scale to meet the needs of small offices or multi-site corporations.

Contact us to schedule a pickup or drop-off.

3R Technology, a CTL Company

8002 S 208th St Suite E105 Kent, WA 98032

(206) 582-7100

0 notes

Text

Enhancing Industrial Efficiency: The Role of Motors, Adapters & Circuit Breakers

In the age of Industry 4.0, automation is no longer just about moving parts—it’s about intelligent power management, secure connectivity, and system safety. At Dropship Automation Solutions, we supply the essential components that support high-performance industrial systems and resilient infrastructures.

In this blog, we explore three foundational elements of automation hardware: electric motors, industrial adapters, and circuit breakers—each playing a vital role in energy transfer, system compatibility, and operational safety.

1. Motors: Driving Industrial Motion

What Motors Do

Electric motors convert electrical energy into mechanical motion, making them fundamental in powering conveyor belts, pumps, fans, and more. Their reliability and precision keep operations running smoothly across countless industries.

Types & Applications

Types: AC motors, DC motors, servo motors, stepper motors

Applications: Conveyor systems, HVAC units, manufacturing robots, elevators

Benefits: High efficiency, consistent torque, reduced manual labor

Why Motors Matter

Motors are the force behind physical movement in automated systems. With high energy efficiency and precise control, modern motors minimize downtime and optimize mechanical output.

2. Adapters: Connecting Systems Seamlessly

What Adapters Do

Adapters serve as connectors that allow two otherwise incompatible devices or systems to work together. In industrial settings, they enable cross-device compatibility for data, power, or signal transmission.

Common Adapter Types & Uses

Types: Electrical plug adapters, signal adapters, communication protocol converters

Applications: Sensor integration, PLC expansion, international power conversion

Benefits: Device compatibility, simplified upgrades, reduced wiring complexity

Why Adapters Matter

Industrial adapters bridge gaps between old and new technologies, allowing systems to scale without costly replacements. They’re key to maintaining flexible and future-proof automation architectures.

3. Circuit Breakers: Safeguarding Electrical Systems

What Circuit Breakers Do

Circuit breakers protect electrical circuits from overloads or short circuits by interrupting power flow when abnormal conditions are detected. They ensure both equipment and personnel safety.

Types & Use Cases

Types: Miniature circuit breakers (MCB), molded case circuit breakers (MCCB), ground fault circuit interrupters (GFCI)

Applications: Control panels, power distribution, renewable energy systems

Benefits: Overcurrent protection, system isolation, fire prevention

Why Circuit Breakers Matter

Without circuit breakers, electrical faults could lead to equipment damage, fires, or system-wide failures. These devices serve as first-line defenders, ensuring your facility operates within safe power limits.

Building a Safer, Smarter Industry

Imagine an automated facility where:

Motors drive production lines with precision,

Adapters ensure seamless system connectivity,

Circuit breakers protect everything from faults and overloads.

This combination supports efficiency, safety, and adaptability—all key ingredients in modern industrial success.

Conclusion: Power Your Automation with Confidence

Smarter factories rely on trusted components for performance, safety, and scalability. At Dropship Automation Solutions, we provide robust motors, versatile adapters, and reliable circuit breakers to help build your next-gen industrial environment.

Empower your automation strategy—today.

📞 Contact: +1 (234) 288-1755 📧 Email: [email protected] 📍 Location: 1440 W. Taylor St #2555, Chicago, IL 60607

0 notes

Text

Seamless Integration with EtherCAT Master Technology

In today’s fast-paced industrial landscape, the ability to integrate systems with minimal complexity and maximum performance is not just beneficial — it’s essential. As industries adopt smarter, more agile automation solutions, EtherCAT Master technology is emerging as the gold standard for achieving high-speed, synchronized control across a wide array of devices and applications.

What is EtherCAT Master Technology?

EtherCAT (Ethernet for Control Automation Technology) is an open, real-time Ethernet-based fieldbus system developed for automation applications. At the heart of every EtherCAT network lies the EtherCAT Master, which acts as the central controller that manages all communication and synchronization between slave devices such as sensors, actuators, drives, and PLCs.

The EtherCAT Master sends out a data packet that travels through all devices and returns with status updates, ensuring real-time control with minimal latency and jitter.

Why Seamless Integration Matters

In industrial environments, integration isn't just about plugging devices into a network — it's about ensuring those devices can communicate effectively, reliably, and without unnecessary delays. Seamless integration with an EtherCAT Master offers:

Plug-and-Play Connectivity: Most EtherCAT-compatible devices are designed for rapid configuration and interoperability, enabling quick setup and reduced engineering time.

Real-Time Communication: Achieve deterministic data exchange that ensures systems respond in real-time — critical for applications like motion control, robotics, and CNC.

Hardware & Software Compatibility: Modern EtherCAT Masters are compatible with a broad range of automation components and support various operating systems including Windows and real-time operating systems (RTOS).

Scalability: As systems grow or change, EtherCAT networks can be expanded easily without impacting performance, allowing industries to scale operations without redesigning infrastructure.

Key Benefits of EtherCAT Master Integration

Low Latency and High Precision EtherCAT Masters deliver cycle times as low as 100 µs, enabling tight synchronization across distributed nodes — ideal for high-speed manufacturing or robotic control.

Simplified Network Design The daisy-chain architecture of EtherCAT reduces the need for complex switches or hubs, resulting in simpler wiring and lower installation costs.

Robust Diagnostics and Monitoring Built-in monitoring features enable quick detection of failures, cable breaks, or device malfunctions, improving uptime and maintainability.

Cost Efficiency By using standard Ethernet hardware and cables, EtherCAT reduces the cost of integration compared to proprietary solutions.

Applications of Seamless EtherCAT Integration

Industrial Automation: From packaging lines to material handling, seamless EtherCAT Master integration improves responsiveness and reliability.

Robotics: Enables tight coordination between axes and components, improving accuracy and performance.

CNC Machines: Provides the speed and synchronization needed for precision cutting, milling, and forming.

Testing and Measurement Systems: Real-time data acquisition and control for high-speed, data-driven environments.

Conclusion

Whether you're building a new automation system or upgrading an existing one, seamless integration with EtherCAT Master technology offers unmatched speed, flexibility, and reliability. By reducing complexity and boosting performance, it enables manufacturers to stay competitive in an increasingly connected and automated world. https://kingstar.com/products/ethercat/

Interested in learning how EtherCAT Master integration can transform your operations? Visit us or get in touch:

200 Fifth Avenue, FL 6, STE 6020 Waltham, MA 02451 Phone: +1 781 209 2810 Fax: +1 781 795 0158 Email: [email protected]

0 notes

Text

What Is the difference Between SCADA and HMI

SCADA (Supervisory Control and Data Acquisition) and HMI are both crucial elements in industrial automation, but they serve different roles. SCADA is a comprehensive system used to monitor, control, and analyze industrial processes across multiple locations. It integrates hardware and software to gather real-time data from sensors, devices, and PLCs, allowing operators to manage large-scale operations remotely. HMI (Human-Machine Interface) is a user interface, on the other hand, that links a human operator to the machinery or equipment. It displays process data visually—such as alarms, trends, and system status—enabling operators to interact directly with machines. While HMI is a component of SCADA systems, SCADA includes additional layers like data logging, communications infrastructure, and centralized control, making it more expansive and network-oriented than a standalone HMI.

#automation#trending#tumblr trends#viral#bestdeals#viralpost#trendingnow#allen bradley#rockwell automation#plc#SCADA#HMI#human machine interface#GIF#trending know#solutions provider#solutions#scada software#software.

1 note

·

View note

Text

Power Meets Precision: Advanced Forging Presses for Every Metal Need

Engineered by Mankoo Presses – Built to Perform, Trusted Worldwide

In the fast-evolving world of metal forming and heavy fabrication, manufacturers demand machines that can deliver exceptional power, consistent precision, and reliable performance—day after day, year after year. This is where forging presses come into play, and when you’re talking about quality, Mankoo Presses is a name that stands tall.

With a legacy of engineering excellence, Mankoo Presses has carved out a niche in designing and manufacturing advanced forging presses that serve industries across the globe—from automotive and agriculture to aerospace, defense, and railway components.

What Are Forging Presses?

Forging presses are mechanical or hydraulic machines used to shape metal using compressive forces. Unlike traditional hammers or dies, forging presses deliver a slow, controlled, and powerful force, making them ideal for producing parts that require tight tolerances, dense microstructures, and high durability.

They are used to form everything from gears, flanges, crankshafts, and axles to complex aerospace components. In short, they are the heartbeat of precision forging operations.

Mankoo Presses: Pioneering the Future of Forging

For over 40 years, Mankoo Presses has been at the forefront of innovation in forging press technology. Known for robust construction, cutting-edge design, and client-focused customization, Mankoo has become a go-to solution provider for companies seeking durable and high-performance forging machines.

Key Features of Mankoo Forging Presses

Mankoo offers a wide range of forging presses in mechanical, hydraulic, and pneumatic configurations. Each machine is engineered to meet the most demanding requirements of modern metalworking industries.

1. High Tonnage Capacity

Mankoo presses are available in tonnages ranging from 100 tons to 2000+ tons, offering unmatched strength for shaping the most stubborn metals.

2. Precision Control

With PLC-based automation and servo-hydraulic control systems, Mankoo presses allow precise adjustment of stroke, pressure, and speed, ensuring consistency and repeatability.

3. Heavy-Duty Build

Built using stress-relieved steel frames and hardened components, Mankoo’s forging presses are designed to last in the most rugged environments.

4. Energy Efficiency

New-generation Mankoo presses are equipped with energy-saving hydraulic systems, helping reduce power consumption without compromising output.

5. Safety First

Each machine is integrated with advanced operator safety features, including:

Emergency stop controls

Light curtains

Safety interlocks

Overload protection systems

Applications Across Industries

Mankoo’s forging presses are versatile, making them suitable for a wide array of industrial applications:

Automotive:

Axles

Engine parts

Gears

Wheel hubs

Aerospace:

Landing gear components

Structural elements

Precision metal brackets

Tools & Hardware:

Spanners

Pliers

Hand tool parts

Agriculture:

Harrow discs

Tractor parts

Tillage equipment components

Mankoo ensures each press is customized to the client’s product profile, whether it's open die forging, closed die forging, or warm/cold forging applications.

Case Study: Automotive Gear Manufacturer

One of India’s largest gear manufacturers partnered with Mankoo Presses for a custom 1000-ton mechanical forging press. The result?

30% faster production cycle

50% reduction in rejection rates

Improved metallurgical properties

ROI achieved within 18 months

The client now runs three Mankoo presses in parallel and continues to expand production with the same trusted partner.

Support Beyond the Machine

Buying a forging press is a long-term investment, and Mankoo ensures you’re supported at every step:

Pre-Sales Consultation

Mankoo’s technical team provides on-site analysis and helps design the right solution based on:

Metal type

Output requirement

Automation level

Budget and space constraints

Installation & Training

Complete on-site installation, trial runs, and operator training are part of Mankoo’s commitment to your success.

After-Sales Service

With a vast network of service engineers and a dedicated support line, Mankoo ensures minimum downtime and maximum uptime.

Export-Ready Quality Standards

Mankoo Presses follows international manufacturing standards and exports machines to over 20+ countries, including:

Germany

UAE

South Africa

Vietnam

Turkey

Bangladesh and more

Every exported machine undergoes rigorous quality checks, certifications, and containerized packaging for safe delivery.

About Mankoo Presses

Mankoo Presses is a leading manufacturer of mechanical and hydraulic power presses, forging presses, and custom press solutions. With over 40 years of industry experience and a global client base, Mankoo stands for engineering excellence, quality craftsmanship, and customer satisfaction. From small workshops to large manufacturing plants, Mankoo continues to be a trusted partner in shaping the future of metalworking.

0 notes

Text

Europe Commercial Air Traffic Management Market Demand, Supply, Growth Factors, Latest Rising Trends and Forecast (2022-2030)

The Europe commercial air traffic management market is expected to grow from US$ 1,442.97 million in 2022 to US$ 2,734.54 million by 2030. It is estimated to grow at a CAGR of 8.3% from 2022 to 2030.

Growing Aircraft Delivery Volumes is Driving the Europe Commercial Air Traffic Management Market

The uptick in aircraft deliveries is fueling a greater need for diverse aircraft operations, which in turn opens up new avenues for commercial air traffic management market suppliers throughout various regions. The increasing demand for robust aircraft communication, navigation, pilot interfaces, flight plan negotiation, and other flight essentials is a key catalyst behind the global rise in aircraft deliveries. As a result, the growing number of aircraft deliveries worldwide is anticipated to bolster the expansion of the commercial air traffic management market. Moreover, the emergence of next-generation fuel-efficient commercial aircraft and the proliferation of low-cost carriers are leading to higher volumes of aircraft movement at airports globally. This phenomenon is prompting civil aviation authorities in both established and emerging economies to develop new airports to support the expanding aircraft fleet. The ongoing construction of new airports across different countries is also boosting the demand for commercial air traffic management. These factors not only increase the aircraft fleet within a country but also aid in the installation of air traffic management systems in these new facilities. Such developments are expected to significantly contribute to the growth of the Europe commercial air traffic management market.

Download our Sample PDF Report

@ https://www.businessmarketinsights.com/sample/BMIRE00027914

Europe Commercial Air Traffic Management Strategic Insights

Strategic insights for the Europe Commercial Air Traffic Management offer a data-driven examination of the industry environment, covering current trends, major participants, and regional particularities. These insights deliver practical advice, enabling readers to stand out from rivals by uncovering unexplored market segments or crafting distinctive value propositions. By harnessing data analytics, these insights help industry stakeholders—whether they are investors, manufacturers, or other parties—to foresee market changes. A future-focused outlook is vital, allowing stakeholders to anticipate market shifts and position themselves for long-term achievement in this ever-evolving region. Ultimately, potent strategic insights equip readers to make well-informed choices that drive profitability and meet their business goals within the market.

Europe Commercial Air Traffic Management Market Segmentation

Europe Commercial Air Traffic Management Market By Type

Air Traffic Services

Air Traffic Flow Management

Airspace Management

Europe Commercial Air Traffic Management Market By Component

Hardware

Software

Europe Commercial Air Traffic Management Market By Application

Communication

Navigation

Surveillance

Traffic Control

Europe Commercial Air Traffic Management Market By Airport Class

Class I

Class II

Class III

Class IV

Europe Commercial Air Traffic Management Market Regions and Countries Covered

Europe

UK

Germany

France

Russia

Italy

Rest of Europe

Europe Commercial Air Traffic Management Market leaders and key company profiles

BAE Systems Plc

Honeywell International Inc

Indra Sistemas SA

L3Harris Technologies Inc

Leonardo SpA

NEC Corp

Raytheon Technologies Corp

Saab AB

SITA SC

Thales SA

About Us:

Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications

0 notes

Text

Unlocking Efficiency and Precision with PLC Equipment: A Deep Dive into GE Fanuc PLC Software

Welcome to PLC World, where precision, efficiency, and innovation converge to revolutionize industries worldwide. In today's blog post, we're delving into the realm of Programmable Logic Controller (PLC) equipment, particularly focusing on the cutting-edge GE Fanuc PLC software. Join us on this journey as we explore how PLC technology, coupled with GE Fanuc software, is reshaping the landscape of industrial automation.

#Allen Bradley Automation Components & Integrated Control#plc hardware buy#industrial automation parts

0 notes

Text

Mechatronic Design Engineer: Bridging Mechanics, Electronics, and Innovation

In today’s era of advanced technology and automation, the role of a Mechatronic Design Engineer has become increasingly important. Mechatronics, a multidisciplinary field combining mechanical engineering, electronics, computer science, and control systems, is at the core of many modern innovations. From robotic arms in manufacturing plants to intelligent consumer electronics, the applications of mechatronics are vast and diverse. A Mechatronic Design Engineer is a key contributor to the development of such smart systems, integrating various engineering domains to deliver efficient, intelligent, and reliable solutions.

What is Mechatronic Design?

Mechatronic design involves the integration of mechanical components with electronic control systems and software to create complex, automated products or systems. Unlike traditional mechanical engineering, mechatronic design focuses on building intelligent systems that can sense, process, and respond to environmental inputs in real time.

Examples of mechatronic systems include:

Industrial automation and robotics

Autonomous vehicles

Drones and unmanned aerial systems

Smart home devices and appliances

Medical devices like robotic surgical tools

The demand for mechatronic design engineers is rising in industries such as aerospace, automotive, healthcare, manufacturing, and consumer electronics.

Role and Responsibilities of a Mechatronic Design Engineer

A Mechatronic Design Engineer's job is highly multidisciplinary. They work at the intersection of several engineering fields to design, prototype, and test smart systems. Their key responsibilities include:

1. System Design and Integration

Mechatronic engineers conceptualize and design systems that incorporate mechanical, electrical, and software elements. They create blueprints, 3D models, and simulations to visualize and analyze system behavior.

2. Component Selection

They choose suitable components such as sensors, actuators, microcontrollers, and other hardware needed to achieve the system’s functionality while optimizing cost, efficiency, and reliability.

3. Embedded Systems Programming

Since mechatronic systems rely heavily on software control, these engineers often write and implement embedded code in languages like C, C++, or Python to program microcontrollers and control systems.

4. Prototyping and Testing

Engineers develop physical prototypes to test the functionality of the system. They conduct thorough testing under real-world conditions to ensure system robustness, safety, and efficiency.

5. Troubleshooting and Optimization

If problems arise during testing, Mechatronic Design Engineers must diagnose issues and make necessary changes to mechanical designs, control algorithms, or electrical layouts.

6. Collaboration

They work closely with other engineering professionals, such as mechanical engineers, electrical engineers, software developers, and project managers, ensuring seamless integration of all system components.

Skills Required for a Mechatronic Design Engineer

To succeed in this role, a mechatronic design engineer must possess a blend of technical and soft skills:

Strong Analytical Thinking: Ability to solve complex problems involving multiple engineering principles.

Multidisciplinary Knowledge: Proficiency in mechanical design, electronics, control systems, and computer programming.

CAD and Simulation Tools: Familiarity with tools like SolidWorks, AutoCAD, MATLAB/Simulink, and ANSYS.

Embedded Programming: Hands-on experience with microcontrollers, PLCs, and real-time control systems.

Project Management: Capability to manage timelines, budgets, and resources efficiently.

Teamwork and Communication: Collaborating effectively with cross-functional teams and clearly communicating technical information.

Education and Career Path

Typically, a bachelor's degree in mechatronics engineering, mechanical engineering, electrical engineering, or a related field is the minimum requirement for a career in this domain. Some roles, especially in research and development, may require a master's degree or specialized certifications.

With experience, a Mechatronic Design Engineer can advance into roles such as:

Senior Mechatronics Engineer

Systems Architect

Project Manager

R&D Manager

Automation Consultant

In some cases, engineers may also venture into entrepreneurship, starting their own product development firms or consultancies.

Importance of Mechatronic Design in Industry

Industries around the globe are becoming smarter and more automated. From smart factories driven by Industry 4.0 to intelligent transportation systems and autonomous medical devices, mechatronic design plays a critical role in making these innovations possible.

Some key benefits include:

Increased Efficiency: Automated systems reduce human error and increase productivity.

Precision and Control: Mechatronic systems enable fine control and monitoring, crucial in sectors like healthcare and aerospace.

Cost Savings: Automation reduces labor costs and improves operational efficiency over time.

Customization and Flexibility: Smart machines can be programmed and reconfigured to handle different tasks as needed.

Real-World Applications

To illustrate the versatility of this field, here are a few examples of real-world systems developed by Mechatronic Design Engineers:

Robotic Surgery Devices: Offering high precision in minimally invasive surgeries.

Autonomous Drones: Used for surveillance, delivery, agriculture, and disaster response.

Self-Driving Vehicles: Integrated with AI, radar, and vision systems.

Smart Manufacturing Systems: Including pick-and-place robots and automated inspection systems.

Wearable Health Tech: Devices that monitor vitals and provide real-time feedback.

Future of Mechatronic Design

The future of mechatronic design is closely linked with emerging technologies such as:

Artificial Intelligence (AI)

Internet of Things (IoT)

Machine Learning

Augmented Reality (AR)

Additive Manufacturing (3D Printing)

As these technologies mature, Mechatronic Design Engineers will continue to innovate and develop more intelligent, efficient, and responsive systems that redefine how industries operate.

Conclusion

A Mechatronic Design Engineer by servotechinc is a vital contributor to the development of intelligent machines and systems that improve productivity, safety, and convenience across various industries. By integrating mechanical, electrical, and software components, they are at the forefront of technological advancement and innovation. With strong technical skills and a passion for multidisciplinary collaboration, a career in mechatronic design promises a dynamic, rewarding future filled with endless possibilities.

0 notes

Text

Top Benefits of Implementing ABB Freelance Solutions in Bangalore’s Manufacturing Plants

Modern manufacturing plants in Bangalore are continually seeking ways to boost productivity, increase reliability, and maintain compliance with evolving industry standards. One technology that has gained widespread adoption is ABB Freelance Solutions in Bangalore, a compact Distributed Control System (DCS) designed to offer DCS-level reliability with PLC-like flexibility. As automation advances further, integrating Robotic vision solutions in Bangalore alongside ABB Freelance can deliver even greater benefits. This article explores the key advantages of adopting ABB Freelance in manufacturing facilities and highlights how pairing it with robotic vision enhances operational excellence.

1. Cost-Effective Scalability

Traditional DCS platforms often come with high upfront costs and complex licensing models. ABB Freelance, however, provides a modular architecture that allows manufacturers to add control loops and I/O modules gradually, matching budget constraints and production growth. This pay-as-you-grow model ensures that plants only invest in the capacity they need initially, with the option to expand seamlessly. Over time, this translates to significant savings compared to monolithic DCS installations.

2. Rapid Deployment and Reduced Engineering Effort

One of the standout features of ABB Freelance is its intuitive engineering environment, which leverages the System 800xA interface. Preconfigured function blocks, drag-and-drop graphics, and standardized libraries simplify control logic development. As a result, commissioning times shrink dramatically, enabling plants to achieve faster return on investment. Engineers spend less time on tedious coding and more on optimizing processes, making it ideal for Bangalore’s dynamic manufacturing landscape.

3. High Availability and Robust Reliability

Minimizing unplanned downtime is critical in high-value production environments. ABB Freelance offers redundant controllers, hot-swappable I/O modules, and fault-tolerant communication networks. In the event of a hardware failure, the system automatically switches to backup modules without interrupting control processes. This level of reliability is crucial for sectors like pharmaceuticals, water treatment, and food processing, where any interruption can lead to costly production losses or compliance breaches.

4. Seamless Integration with Existing Infrastructure

Most manufacturing plants in Bangalore already have legacy PLCs, SCADA systems, or fieldbus networks in place. ABB Freelance excels at integrating with these existing components through backplane communication and standardized protocols such as Profibus, Modbus, and Ethernet/IP. This interoperability allows plants to modernize their control strategy without ripping out perfectly functional equipment. Furthermore, combining Freelance with Robotic vision solutions in Bangalore—which rely on real-time process data—enhances quality control and reduces manual inspection tasks.

5. Unified Operations and Situational Awareness

ABB Freelance utilizes the System 800xA HMI to deliver a unified control platform where operators can monitor process variables, alarms, and trends from a single interface. This centralized view improves situational awareness and reduces operator training time. When integrated with robotic vision systems, operators gain real-time visual feedback on product quality, enabling quick adjustments and reducing scrap rates. The synergy between control data and vision analytics empowers teams to make data-driven decisions.

6. Simplified Maintenance and Diagnostics

Built‑in diagnostics and asset management tools are hallmarks of ABB Freelance. The system continually monitors hardware health—tracking I/O status, network performance, and controller integrity—and generates proactive alerts. Maintenance teams receive advance warning of potential issues such as sensor drift or network degradation, allowing them to intervene before failures occur. When combined with robotic vision systems that also self-diagnose camera alignment or lighting anomalies, plants achieve a comprehensive predictive maintenance strategy that drastically limits unscheduled shutdowns.

7. Enhanced Safety and Regulatory Compliance

Safety is paramount in manufacturing, and ABB Freelance includes safety controller options that integrate seamlessly into the DCS framework. Plants can implement safety interlocks, emergency shutdown sequences, and fail-safe architectures without deploying separate safety PLCs. This integrated safety approach simplifies compliance with international standards such as IEC 61511. Moreover, pairing automated vision inspection—through Robotic vision solutions in Bangalore—ensures critical safety checks (e.g., weld seam verification or seal integrity) occur consistently, meeting strict regulatory mandates.

8. Future-Proof Architecture

Industry 4.0 demands connected, data-centric ecosystems. ABB Freelance supports Industrial Internet of Things (IIoT) protocols and cloud connectivity, making it straightforward to integrate with higher-level analytics platforms, MES, or ERP systems. As production scales or new technologies emerge, Freelance’s open architecture adapts rapidly. Likewise, robotic vision systems can leverage the same networked infrastructure to feed image and quality data into enterprise analytics, enabling continuous improvement and innovation.

Conclusion

Implementing ABB Freelance Solutions in Bangalore’s manufacturing plants offers clear advantages: cost-effective scalability, fast deployment, high availability, and seamless integration with legacy systems. When paired with Robotic vision solutions in Bangalore, plants gain an additional layer of quality assurance and data-driven process control. As a leading engineering service provider in the region, Madox Technologies excels at delivering turnkey ABB Freelance installations and integrating advanced vision technologies to create smarter, safer, and more efficient production environments. By embracing these combined solutions, Bangalore’s manufacturers can maintain a competitive edge in an increasingly automated world.

visit for more info https://madox.in/product/cobot-welder/

0 notes

Text

Choosing the Right Horizontal Packing Machine: Key Features to Consider

Professional horizontal packing machines play a crucial role in modern packaging solutions, ensuring efficiency, consistency, and precision in wrapping various products. Designed for automated horizontal packaging, these machines are widely used in industries such as food processing, pharmaceuticals, cosmetics, and electronics. This article delves into the advantages, operational mechanisms, and key considerations when choosing a professional horizontal packing machine.Get more news about professional horizontal packing machine,you can vist our website!

Understanding Professional Horizontal Packing Machines A professional horizontal packing machine is an automated system designed to package products in a continuous manner. Unlike vertical packing machines, which require gravity-fed materials, horizontal packing machines handle items that need to be wrapped in a horizontal position. These machines utilize film rolls to encase products before sealing and cutting them into individual packages.

Key Features and Benefits Modern horizontal packing machines offer various advantages, including:

High Efficiency: The automated process significantly increases production speed, reducing manual labor.

Consistent Packaging Quality: Precise control over film wrapping and sealing ensures uniform packaging, minimizing errors.

Versatility: Suitable for packaging diverse products, including food items, medical supplies, and consumer goods.

Durability and Reliability: Built with robust materials, these machines ensure long-term performance with minimal maintenance requirements.

Advanced Technology Integration: Many machines come with programmable logic controllers (PLC) and touchscreen interfaces, allowing easy customization.

Applications in Different Industries Professional horizontal packing machines are widely used across various industries:

Food Industry: Commonly used for wrapping baked goods, frozen foods, snacks, and dairy products.

Pharmaceuticals: Ensuring safe and hygienic packaging for medical supplies and healthcare products.

Consumer Goods: Used in electronics, cosmetics, and personal care packaging.

Industrial Products: Facilitates protective packaging for tools, hardware, and delicate components.

Choosing the Right Machine for Your Needs When selecting a horizontal packing machine, consider the following factors:

Packaging Material Compatibility: Ensure the machine supports the required film types (such as polyethylene, polypropylene, or laminated films).

Production Volume: Choose a machine that matches the production demand to optimize efficiency.

Automation Level: Determine whether fully automated or semi-automatic systems best fit the operational workflow.

Customization Options: Some machines allow adjustable settings for varying product sizes and packaging requirements.

Maintenance and Support: Look for models with easy maintenance features and reliable technical support.

Conclusion Professional horizontal packing machines are essential tools for industries aiming to enhance productivity, packaging consistency, and automation. By understanding their functionalities, benefits, and selection criteria, businesses can choose the best machine to meet their production needs. Investing in high-quality packaging technology ensures long-term efficiency and product protection, making these machines invaluable assets in modern manufacturing.

0 notes

Text

The Role of NX-ERA Xpress PLCs in Modern Boiler Automation: Enhancing Efficiency, Safety & Control

At Messung, we've led the charge of the industrial transformation for more than three decades, driving automation solutions that not just run machines but move industries forward. In a world where steam still drives innovation, boilers are the unheralded workhorses of the manufacturing, energy, pharmaceuticals, and textile industries. But let's be real—manual operation of boilers is a hazardous, inefficient dance.

Welcome to the age of robust programmable logic controller (PLC)-driven automated boilers — tough, smart, and designed to endure. As champions in smart PLCs and industrial automation safety standards, we at Messung think it's time high-pressure boilers joined the Industry 4.0 revolution.

What is Boiler Automation?

Boiler automation is the smooth integration of the most critical parameters, such as:

Temperature

Pressure

Steam outlet

Water levels

Combustion and fuel supply

Manual monitoring might have sufficed yesterday, but today there's more at risk. Guessing is not an option when the price of failure includes downtime, damage, or risk. Automation substitutes human response with machine accuracy—step up the PLC controller.

Why Programmable Logic Controllers (PLCs)?

A programmable logic controller isn't just another component of hardware — it's the brain of your boiler system. Designed to handle tough environments (yep, we're referring to rugged PLCs for challenging industrial environments), these digital powerhouses are:

Quick

Respected

Scalable

Flexible

Whether it’s a compact PLC for a tight plant room or a safety PLC for a pharmaceutical facility, Messung’s NX-ERA Xpress range checks all the boxes.

Key Advantages of NX-ERA Xpress PLC-Based Boiler Automation

Enhanced Energy Efficiency

Precision is power. Our smart PLC for energy management systems enables real-time adjustments using PID loops, fine-tuning the air-fuel mix and ensuring optimal combustion. The result?

Lowered fuel consumption

Reduced emissions

Leaner operations

And with an intelligent PLC with Modbus and OPC UA, monitoring energy data becomes effortless.

Enhanced Safety Precautions

Boilers can become a bomb if not taken care of. That’s why PLCs with industrial automation safety standards are non-negotiable. Our UL and DNV-GL certified PLC for automation offers:

Overpressure protection

Dry-run prevention

Automated emergency shutdowns

Safety isn't something that's added, it's built into the firmware.

Increased Reliability and Uptime

PLCs don't get sick. They don't blink. With built-in self-diagnostic features, Messung's NX-ERA Xpress automation directs PLCs to notify you before an issue gets out of hand. That's predictive maintenance in a nutshell.

Real-Time Data Logging and Trend Analysis

Knowledge is power, and our PLCs with OPC UA and Modbus for process control provide you with plenty. They recognise trends, trigger alarms, and share information with your SCADA or cloud dashboards. Say hello to smart decision-making.

Scalability and Flexibility

Need to install a new boiler? Replace a fuel feed system? No worries. Our compact smart PLC for machine automation grows with you without rewiring your whole plant. Modular. Flexible. Future-proof.

Standard PLC-Based Boiler Automation Structure

A robust boiler automation system is a delicate dance of precise components executing in harmony, orchestrated by the PLC at its core. Let's dive into what a typical installation entails:

Sensors and Transmitters: These eyes and ears are continuously tracking key parameters—pressure, temperature, water level, and flow rates. Their real-time data stream is the lifeblood of optimal boiler operation, providing correct signals to the PLC to make smart decisions.

PLCs: At Messung, we use rugged, conformal-coated programmable logic controllers specifically suited for harsh industrial environments. Our NX-ERA Xpress PLCs are complemented with high-level communication protocols like Ethernet/IP and EtherCAT, which provide lightning-fast data exchange and unyielding reliability even in extreme temperatures or vibrations.

HMI and SCADA Systems: Visualisation and control by the operator are enabled by Human-Machine Interfaces (HMI) and Supervisory Control and Data Acquisition (SCADA) systems. They offer operators simple user dashboards to view, set up, and interact as needed—all in real-time.

Actuators: Burners, valves, and pumps—the boiler system's muscles—are powered accurately by automation controllers. They adjust in real-time to PLC instructions to modulate fuel feed, air supply, and steam output.

Communication Protocols: Smooth integration throughout the whole automation environment is based on standards like MODBUS, OPC UA, and CANopen. These protocols enable heterogeneous devices and systems to communicate in a smooth manner, ensuring a harmonised operation.

With Messung, our strength is in integrating expertly crafted specialised controllers—energy management controllers, AHU controllers, and SPM controllers—into a single, scalable platform that optimises control and efficiency.

Industry 4.0 and The Future of Boiler Control

The days when boiler systems operated independently, relying solely on manual inputs and standalone controls, are long gone. Today's boilers are evolving — getting smarter, connected, and predictive than ever before.

With cloud-enabled automation controllers, operators are now able to monitor and control boilers remotely with real-time mobile notifications, ensuring to act fast on any drifts. Our smart PLCs use AI-driven optimisation to constantly refine performance, boosting efficiency and reliability. Messung’s NX-ERA Xpress platform, designed for seamless integration with edge computing, enables remote diagnostics and proactive maintenance, truly bringing boiler automation into the digital world.

Real-World Applications Across Industries

In the vast expanse of industrial automation, the boiler emerges as a pivotal piece of equipment across industries. With each industry, there are certain challenges and needs, whether it is unyielding precision, safety, or efficiency. At Messung Industrial Automation, our advanced PLC control systems are crafted to meet such highly specific needs, allowing industries to do smarter, safer, and more reliably.

Automotive - Steam cleaning sensitive components requires accuracy and toughness. Our rugged PLC for outdoor or high-temperature environments performs where others fail, providing perfect control even in the toughest factory floor environments. It's designed to be tough, just like your production requirements.

Pharmaceuticals - When ultra-clean steam generation is critical with sterility, compromise is not an option. Our programmable logic controller for industrial HVAC (AHU) gives you reproducible, contamination-free conditions, enabling you to meet rigorous regulatory requirements while providing the reliability that pharma plants count on every day.

Food and Beverage - From sterilisation to packaging, product integrity remains paramount. Our PLC controller with UL and DNV-GL certifications protects safety without compromising taste, providing hassle-free automation that promotes food safety regulations and business excellence.

Power Plants - Safety isn't an option in megawatts and turbines. Our safety PLC for mission-critical manufacturing applications ensures fault detection in real time and failsafe shutdowns — because when the power is on, you can't be offline

Textiles - Continuous steam for dyeing and drying processes? Our intelligent controller logic is elegantly woven into your process, giving you smooth, uninterrupted control that keeps your colours vibrant and production consistent. Visualise it as expertly stitched into your process.

From the factory floor to key processing facilities, our NX-ERA Xpress PLC solutions are designed to flex and thrive, turning boiler automation into a force of precision and safety in every industry.

Why Messung? A Legacy of Innovation

With over 4 decades in the automation game, we at Messung are more than a provider—we’re a partner. Our PLC control systems, built with compact, rugged, conformal-coated PLCs, power some of the most demanding boiler rooms in the country.

We offer:

Custom automation solutions

Certified automation controllers

Local service and global experience

So whether you’re integrating a new PLC for servo motion and SPM controllers or upgrading an old system to meet modern industrial automation safety standards, Messung’s NX-ERA Xpress is your go-to expert.

Conclusion

Boiler automation is no longer a luxury—it's a cold, hard necessity in today's fast-paced industrial world. At the heart of this revolution are programmable logic controllers (PLCs) — the unsung, rugged workhorses powering precision, safety, and efficiency in boiler control.

These innovative controllers don't just automate processes; they provide unparalleled reliability, energy efficiency, and strict compliance with industrial automation safety standards, all while offering seamless integration with smart factory systems.

At Messung, we provide you with something greater than a PLC control system; we provide you with peace of mind through UL and DNV-GL certification, state-of-the-art technology, and solutions specifically designed to meet your specific boiler issues. Our space-saving, durable, and smart NX-ERA Xpress PLCs for harsh industrial conditions ensure your boiler runs at optimal performance with utmost safety.

Ready to turn your boiler room into a smart, efficient powerhouse? Let us help build tomorrow's industrial future.

FAQs

How does NX-ERA Xpress improve boiler safety?

A safety PLC like NX-ERA Xpress monitors parameters in real-time and automatically shuts down systems when the limits are exceeded. This eliminates human delay and complies with industrial automation safety standards.

What is the best PLC communication protocol for boiler applications?

MODBUS, OPC UA, Ethernet/IP, and EtherCAT are all highly used. They all offer different integration advantages depending on your configuration.

Can a small PLC control sophisticated boiler operations?

Indeed! Messung's NX-ERA Xpress smart PLC for machine automation delivers big system power in a small package.

What certifications should I be searching for in a PLC?

Seek UL and DNV-GL certified PLCs for compliance, dependability, and worldwide acceptability.

In what ways does boiler automation save energy?

With automated PID loop control, real-time data acquisition, and intelligent fuel-air control, automation produces maximum output with minimum input.

0 notes

Text

Fountain Show Programming: How It Works and Why It Matters

From iconic landmarks like the Bellagio in Las Vegas to public plazas and shopping centers worldwide, water fountain shows captivate audiences with their stunning blend of music, movement, and light. At the heart of these spectacles lies a sophisticated process known as fountain show programming—the creative and technical foundation that brings water to life.

In this blog, we’ll break down how fountain show programming works and explore why it’s essential for crafting visually compelling, emotionally resonant experiences.

What Is Fountain Show Programming?

Fountain show programming is the process of designing, choreographing, and controlling a fountain’s behavior—specifically, its water jets, lighting, and special effects—in sync with music and timing cues. It combines software, hardware, and artistic vision to create captivating performances that can last just a few seconds or several minutes.

Professional fountain shows don’t just happen—they’re carefully mapped and orchestrated using advanced technology and creative storytelling.

How Fountain Show Programming Works

1. Design and Planning

Every show begins with a creative vision. Designers choose the theme, music, and tone of the performance. This is followed by the layout and selection of components such as:

Water jets (straight, arcing, mist, rotating)

Lighting systems (LED, lasers, color effects)

Soundtracks or live audio

Special effects (fire, fog, projection)

These elements are then mapped into a storyboard or digital model of the fountain area.

2. Music Synchronization

Music is the emotional backbone of many fountain shows. Software analyzes audio tracks to identify beats, rhythms, and transitions. Designers then sync the movements of water jets and lights to specific musical cues, creating a dance-like choreography.

3. Programming and Simulation

Specialized fountain show programming software is used to write the show’s “script.” Each second is mapped with precise instructions for water height, jet timing, color changes, and light effects. Programs are often tested in virtual simulators before being applied to the actual fountain system.

4. Integration with Control Systems