#scada software

Explore tagged Tumblr posts

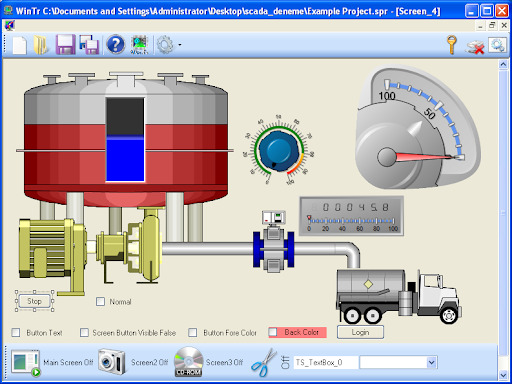

Text

#SCADA#Supervisory Control And Data Acquisition#SCADA software#software#WinTr#industrial#industrial engineering#webcore#old web#techcore#cybercore

7 notes

·

View notes

Text

What is HMI SCADA Software

#automation#trending#tumblr trends#viral#bestdeals#trendingnow#viralpost#rockwell automation#allen bradley#plc#SCADA#software programing#scadatraining#plc scada training#scada software

1 note

·

View note

Text

Key Benefits of Using Siemens SCADA and WinCC in Automation

The ever-increasing demand for real-time monitoring, control, and data-driven decision-making in the industrial world has reached an all-time high. Hence, this is where Siemens SCADA solutions are applied. Siemens SCADA systems try to enhance operational visibility and efficiency by providing robust and scalable automation control in various industries.

Explore the Complete range of Siemens SCADA PC Systems designed for efficient industrial automation.

What is Siemens SCADA?

Siemens SCADA (Supervisory Control and Data Acquisition) is a command center that supervises, controls, and analyzes industrial processes. It provides centralized monitoring and real-time data visualization across distributed automation setups. From small manufacturing plants to large process ones, Siemens SCADA allows for control, less downtime, and increased productivity.

Advanced SIMATIC WinCC platform is the backbone of the SCADA solutions offered by Siemens.

SIMATIC WinCC-The Heart of WinCC SCADA System

SIMATIC WinCC is Siemens’ flagship SCADA platform, applied widely in industrial automation applications. It provides a seamless and flexible environment for engineering and runtime tasks. The integrated suite allows the user to handle operation, monitoring, history data archiving, and advanced analytics.

WinCC SCADA always performs uniformly and intuitively, whether you have a single-machine setup or a network of connected production lines. Other highlights include:

Real-Time Visualization: Allowing for the viewing of critical process data and system state by plant operators in real-time.

Alarm Management: Notifying its users of any deviations or faults from the system on time.

Data Logging & Archiving: Collecting and storing for historical analysis and regulatory compliance.

Remote Access: Authorized personnel can watch and control systems from anywhere.

With its above features, Siemens SCADA Software is widely accepted in industries like automotive, food processing, pharmaceutical, and energy.

Why Choose Siemens SCADA software?

Siemens SCADA software is more than mere monitoring; it is an entire industrial intelligence system that brings together Siemens PLCs, HMIs, and drives under a unified and efficient sun of automation. Its open architecture supports third-party integrations, endowing it with high levels of flexibility to adapt to existing infrastructures.

Some of the advantages include:

Scalability: Works on any kind of project, ranging from the simplest machine-level control to plant-wide operations.

Cybersecurity: Built-in cyber-safety features ensure the protection of the system against unauthorized access and cyber threats.

User-Friendly Interface: An easy operation for engineers and operators.

Industry 4.0 ready: Enables connectivity with IoT platforms, cloud services, and AI-based analytics.

Conclusion

Selecting the correct SCADA system is cardinal in achieving operational excellence. With Siemens SCADA, powered by SIMATIC WinCC, industries unlock real-time insights, process optimizations, and smarter decisions across their entire production facility.

Naksh Technology Solutions LLP takes pride in offering comprehensive customer support and the supply of Siemens SCADA solutions. Naksh Technology is your partner in excellence within the automation space-from consultation and integration to after-sales support.

0 notes

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support

Edwardsville benefits from strong academic institutions like Southern Illinois University Edwardsville (SIUE), which offers programs in engineering, computer science, and industrial technology. These institutions help build a local talent pipeline of engineers and programmers equipped to design and maintain next-generation automation systems.

Additionally, ongoing partnerships between automation companies and local manufacturers ensure that workforce development aligns with real-world needs. On-the-job training and technical certifications are increasingly available to support career growth in automation programming.

Looking Ahead: Smarter Factories on the Horizon

With the rise of Industry 4.0, the future of manufacturing in Edwardsville is smart, connected, and data-driven. Automation programming is a key enabler of this future. Companies are beginning to adopt:

Remote Monitoring and Control

Cloud-Based Data Storage and Analytics

AI-Enhanced Predictive Maintenance

Digital Twin Simulations

These technologies offer unprecedented visibility and flexibility, allowing businesses to operate more efficiently and react quickly to changes in demand or supply chain conditions.

Your Edwardsville Automation Partner: Xtreme Automation LLC

If you're seeking professional automation programming services in Edwardsville, turn to the experts at Xtreme Automation LLC. With deep experience in PLC programming, HMI development, SCADA integration, and smart system upgrades, Xtreme Automation delivers tailored solutions that boost performance and cut downtime. Whether you're building a new line or upgrading legacy systems, their team ensures seamless automation from design to deployment. Learn more at xtremeautomationllc.com.

#Automation Programming Edwardsville IL#PLC Programming Services Illinois#Industrial Automation Edwardsville#HMI Systems Integration#Custom Control Systems Illinois#Manufacturing Automation Solutions#Programmable Logic Controllers#SCADA Systems Edwardsville#Industrial Software Engineering#Automation Services Metro East IL

0 notes

Text

SCADA Development Software: The Backbone of Industrial Automation

If you’re in the industrial automation space, you already know how crucial SCADA (Supervisory Control and Data Acquisition) systems are. They’re the unsung heroes behind manufacturing plants, power grids, water treatment facilities—you name it. But here’s the thing: a SCADA system is only as good as the software powering it. That’s why choosing the right SCADA development software provider is a game-changer.

Why SCADA Development Software Matters

Think of SCADA software as the brain of an industrial operation. It collects real-time data, monitors equipment, and even triggers alerts when something goes wrong. Whether it’s tracking temperature levels in a food processing plant or managing an entire oil refinery, SCADA software gives operators the power to make informed decisions quickly.

But not all SCADA solutions are created equal. A clunky, outdated system can slow down operations and cause unnecessary headaches. That’s why modern SCADA development software focuses on intuitive interfaces, cloud integration, and advanced analytics.

What to Look for in a SCADA Development Software Provider

So, how do you find the right provider? Here are a few things to consider:

Customization – No two industries have the same needs. A good provider will offer flexibility to tailor solutions to your specific requirements.

Scalability – Your business will grow (hopefully!), and your SCADA system should be able to grow with it.

Security – Cybersecurity threats are real. A strong SCADA provider prioritizes data protection.

At the end of the day, investing in a high-quality SCADA development software provider means smoother operations, better efficiency, and fewer surprises. And in the industrial world, that’s worth its weight in gold.

0 notes

Text

customized scada applications

1 note

·

View note

Text

Industrial Alarm Management Application

#industrial reporting solution#industrial reporting software#industrial reports development company#reporting tool for industrial automation#reporting software for industrial automation#Scada reporting software#report generation in Scada#best reporting software#Scada report generation#best reporting tools#industrial automation reporting tool#reporting tool for Scada#web based reporting tools#web based reporting software#automated reporting and data analysis software#Batch Reporting Application#Data Log Reporting Application#MKT Analysis#MKT Analysis reports development#Market Analysis application#Alarm Reporting Application

0 notes

Text

Revolutionize Control: Swastikaas InTouch SCADA Software for Seamless Automation

In today’s rapidly evolving industrial landscape, innovation and efficiency are paramount. Enter Swastikaas InTouch SCADA software — a robust solution crafted to redefine how industries oversee and manage their operations.

The Evolution of Automation

Gone are the days of manual control and isolated systems. Modern industries demand real-time insights, streamlined operations, and adaptable solutions. Developed by Wonderware, Swastikaas In Touch SCADA software leads this evolution, empowering businesses to boost productivity while minimizing downtime and costs.

What is Swastikaas InTouch SCADA Software?

Swastikaas InTouch SCADA (Supervisory Control and Data Acquisition) software acts as the nerve center of industrial operations. It seamlessly integrates data acquisition, visualization, control, and analysis into a unified platform. This enables operators to monitor processes, make informed decisions, and swiftly adapt to changing conditions — critical for maintaining competitiveness in today’s dynamic market.

Key Features and Benefits

1. Real-time Monitoring and Control: Swastikaas InTouch provides a live view of operations across facilities, allowing operators to swiftly identify anomalies and take corrective actions.

2. Scalability and Flexibility: Whether managing a small facility or a global enterprise, Swastikaas InTouch scales effortlessly to meet diverse needs. Its modular design and customizable features ensure it evolves alongside your business requirements.

3. Advanced Visualization: With rich graphics and intuitive interfaces, Swastikaas InTouch simplifies complex data interpretation, empowering operators at all levels to act decisively on critical insights.

4. Operational Efficiency: By automating routine tasks and optimizing workflows, Swastikaas InTouch reduces operational costs and enhances overall efficiency, enabling businesses to allocate resources strategically.

5. Seamless Integration: Swastikaas InTouch SCADA seamlessly integrates with existing systems and third-party applications, ensuring minimal disruption during implementation and maximizing return on investment.

Real-world Applications

Case Study 1: Energy Sector Swastikaas InTouch SCADA software has revolutionized how energy companies manage distribution networks. Real-time data visualization and predictive analytics enable proactive maintenance, minimizing downtime and optimizing energy delivery.

Case Study 2: Manufacturing In the manufacturing sector, Swastikaas InTouch optimizes production processes by providing actionable insights into equipment performance and operational bottlenecks. This has led to substantial improvements in throughput and quality control.

Future Outlook

As industries embrace digital transformation, the role of SCADA software like Swastikaas InTouch becomes increasingly pivotal. Advances in AI and machine learning promise to further enhance its capabilities, unlocking new opportunities in predictive maintenance, anomaly detection, and autonomous operations.

Conclusion

Swastikaas InTouch SCADA software transcends being merely a tool; it catalyzes innovation and efficiency in industrial automation. By harnessing its capabilities, businesses can achieve operational excellence, drive growth, and maintain competitiveness in an interconnected world.

Whether optimizing existing processes or embarking on a digital transformation journey, Swastikaas InTouch SCADA software is poised to revolutionize how you control and automate operations.

Embrace the future of automation with Swastikaas InTouch SCADA — where control seamlessly meets innovation.

0 notes

Text

Explore why tracking equipment downtime is crucial and how to effectively implement it to minimize disruptions and enhance productivity.

0 notes

Text

What is the SCADA control system

#automation#trending#tumblr trends#viral#bestdeals#trendingnow#viralpost#allen bradley#rockwell automation#SCADA#scada software#programming#scada systems

1 note

·

View note

Text

SCADA software assists?

SCADA software can be used to assist the production. Supervisory control and data acquisition. Temperature, pressure, energy, counts, levels, engines, statistics, etc.

SCADA software download

Tools for automation, also in industry.

0 notes

Text

Why Siemens SCADA Software is the Future of Process Control

These monitoring and control functions, in combination with apt optimization of the industrial processes, are fundamental for operational efficiency and competitive edge in the current scenario marked by Industry 4.0. That is where Siemens SCADA enters the picture: a very strong and scalable solution, addressing these needs, within the Siemens SCADA paradigm. All systems relating to industrial automation can utilize Siemens SCADA. It will enable industries with visualization of data in real time, better decision-making, and dependable system control.

Learn more about, Siemens SCADA (SIMATIC WinCC): A Complete Industrial Automation Guide

What is Siemens SCADA?

Siemens SCADA is a comprehensive suite of software solutions performing the monitoring and control functions at various levels for industrial systems. Processes and building management are supervised in a centralized way for all key activities. The most well-known of products is SIMATIC WinCC, which serves as a global powerhouse SCADA platform for visualization and control of industrial processes.

Siemens SCADA ensures smooth, efficient, and safe operations across a manufacturing plant, power station, or water treatment facility.

Primary Features of SIMATIC WinCC

SIMATIC WinCC remains a central part of the Siemens SCADA. With a scalable, flexible approach for both simple applications and complex distributed systems, some key features include:

Real-time Monitor: WinCC SCADA gives operational support for continuous monitoring and controlling processes in real time, therefore creating quick responsiveness and downtime reduction.

Scalability: The system from smaller standalone applications to complex multi-user client-server architectures grows with your operational needs.

Open Connectivity: Integration with a multitude of PLCs, databases, and third-party systems.

User-Friendly Interface: Helps an operator to quickly navigate, analyze and respond to alarms or changes in system behavior through an intuitive interface.

Comprehensive Data Logging: Logging of all processed data, alarms, and user actions for further analysis and compliance requirements.

Applications of Siemens SCADA Software

Siemens SCADA Software finds its applications in diverse industries owing to its flexibility and robustness. Some of the common applications are:

Manufacturing & Automation: Delivers superior insight into production lines with the purpose of improving efficiency and product quality.

Energy & Utilities: For power distribution management, renewable energy monitoring, and utility control centers.

Water & Wastewater: Provides real-time status reports and predictive maintenance to ensure optimum performance of water treatment facilities.

Infrastructure Management: Manages newly developed smart buildings and campuses in HVAC, lighting, and security systems.

Advantage of adopting WinCC SCADA

Adopting WinCC SCADA opens:

Increased visibility and transparency across operations

Increased uptime of the system and much maintenance cost saving

Safety through intelligent alarm systems

Industry compliance through an audit trail of the processes

Partner with the Experts – Naksh Technology Solutions LLP

Partnering with the right automation expert to implement Siemens SCADA Software makes the difference. On top of being a trusted dealer and solutions provider for Siemens automation products, Naksh Technology Solutions LLP brings deep industry knowledge and a customer-centric approach. We help operationalize clients by designing, deploying, and supporting adaptive SCADA systems tailored for operational goals.

Whether the journey has just started or someone's thinking of upgrading an existing setup, Naksh Technology is the one place one would go to find a reliable Siemens SCADA solution partner.

0 notes

Text

Unlocking Operational Efficiency: Aveva SCADA Software

Aveva SCADA software, a flagship product of Aveva Group plc, empowers industries to monitor, control, and optimize their operations efficiently. With its intuitive user interface and advanced features, Aveva SCADA enables real-time data visualization, analysis, and decision-making.

0 notes

Text

What are the types of industrial automation?

Industrial automation is critical to increasing production, efficiency, and safety in a variety of sectors. With technological improvements, many forms of industrial automation have evolved to meet specific demands and procedures. In this article, we will look at some of the most common forms of industrial automation and discuss their uses and advantages.

Fixed Automation :

Programmable Automation :

Robotic Automation :

Process Automation :

Information Technology (IT) Automation :

Fixed automation, often known as hard automation, is the employment of specialized equipment and machinery designed to regularly perform a certain activity or group of duties. It is suited for high-volume production lines with consistent processes. Automotive production, electronics assembly, and food processing are among businesses that use fixed automation. Benefits include faster manufacturing, more accuracy, and lower labor costs.

Programmable Automation: The use of programmable logic controllers (PLCs) and computer numerical control (CNC) equipment to automate various industrial processes is referred to as programmable automation. PLCs are programmable electronic devices that control machinery and processes, whereas CNC machines do machining, cutting, and milling. Programmable automation provides flexibility by permitting changes in production settings and output customization. It is used in sectors such as manufacturing, aircraft, and robotics.

The automation:The Automation of industrial processes, particularly those requiring continuous or batch production, is the subject of process automation. It entails integrating numerous systems, sensors, and software in order to monitor and control complicated operations. Oil and gas, chemical manufacture, electricity generation, and water treatment are among the businesses that use process automation. Improved process control, increased productivity, decreased waste, and consistent product quality are all advantages.

IT Automation: IT automation is concerned with automating and simplifying administrative and management operations inside an organization. It entails utilizing software and technologies to automate operations like data management, system monitoring, network configuration, and security management. IT automation allows for more productivity, fewer human mistakes, and greater scalability. It is used in a variety of sectors to ensure smooth operations and efficient resource utilization.

Conclusion:

Industrial automation has transformed the way businesses work, increasing productivity, efficiency, and safety. Industries may discover the best solutions for their unique needs by studying the many forms of industrial automation. Whether it's fixed automation for high-volume manufacturing or robotic automation for precision assembly jobs, each provides distinct benefits that contribute to simplified operations and increased profitability. Adopting industrial automation paves the way for a more sophisticated and sustainable future in a variety of industries.

One might learn more about the automation Industry by joining an automation training institute. DIAC in Noida is one of the best institutes for automation in Delhi NCR. The Dynamic Institute of Automation & Control is such an institute that offers hands-on training in real-world industry circumstances. DIAC offers a variety of courses in automation, including PLC SCADA, HMI, Robotics, Drive and Motion, AutoCAD, etc. The institute provides you with the skills and information you need for a successful career in industrial automation through industry experienced teachers, interactive learning, industry-relevant projects, and lifetime 100% placement assistance.

#industrial automation training#eplan training#eplan course#plc training#plc scada training#automation training#iiot training#plc scada training in noida#plc networking#scada training#plc scada training in delhi#industrial#automation training institute#eplan software training#plc programming training#plc programming courses#PLC SCADA TRAINING#PLC courses#best automation training institute in noida

1 note

·

View note

Text

A Comprehensive Guide to Power Systems Protection for Engineers

Introduction:

Power systems protection is a critical aspect of electrical engineering that focuses on safeguarding electrical equipment, personnel, and the power grid from faults, failures, and abnormal operating conditions. This comprehensive guide aims to provide engineers with valuable insights into key principles, techniques, and best practices in power systems protection.

1. Understanding System Operation and Fault Types:

Before delving into protection strategies, it is essential to have a solid understanding of how power systems operates and the various types of faults that can occur. This includes studying system components, such as generators, transformers, transmission lines, circuit breakers, relays, and protective devices. Familiarity with fault types like short circuits, open circuits, ground faults, and transient overvoltages is crucial as a foundation.

2. Principles of Protection Coordination:

Effective power systems protection requires proper coordination among protective devices. Engineers must understand the concept of selectivity to ensure that only the device closest to a fault operates, minimizing disruption to the rest of the system. Proper coordination involves selecting appropriate current settings, time delays, and coordination curves for relays and circuit breakers.

3. Relay Device Fundamentals:

Relays are an integral part of power systems protection, serving as the first line of defense against electrical faults. Engineers should have a thorough knowledge of different relay types, including overcurrent relays, differential relays, distance relays, and directional relays. Understanding their operating principles, features, and limitations aids in choosing the most suitable relays for specific applications.

4. Protective Device Coordination:

Coordinating protective devices within a system is critical to maintaining stability and preventing cascading failures during faults. Engineers must carefully analyze and design protection schemes that consider factors such as fault impedance, fault currents, relay response characteristics, and coordination margins. Advanced techniques like time grading and impedance grading can be employed to achieve optimal coordination.

5. Fault Analysis and System Modeling:

Performing fault analysis and system modeling helps engineers gain insights into power flow, fault currents, voltage profiles, and system stability. Engineers must be proficient in using software tools like ETAP, PSCAD, and DSA Tools to accurately simulate fault scenarios and assess the performance of protection schemes. Detailed knowledge of system modeling techniques enables engineers to make informed decisions regarding relay settings and coordination.

6. Communication-Based Protection:

With the increasing complexity of modern power systems, communication-based protection plays a crucial role in maintaining reliability. Knowledge of communication protocols such as IEC 61850, GOOSE (Generic Object-Oriented Substation Event), and SCADA (Supervisory Control and Data Acquisition) systems is essential for engineers to design and implement advanced protection solutions that utilize real-time data exchange between substations and control centers.

7. Integration of Automation and Control Systems:

Incorporating automation and control systems into power systems protection enhances operational efficiency and reduces response time during faults. Engineers need to understand concepts like remote terminal units (RTUs), programmable logic controllers (PLCs), and human-machine interfaces (HMIs). Familiarity with protocols like Modbus, DNP3 (Distributed Network Protocol), and OPC (OLE for Process Control) enables seamless integration of protection systems with wider control infrastructure.

8. Commissioning, Testing, and Maintenance:

Implementing effective protection strategies requires thorough commissioning, testing, and maintenance procedures. Engineers should be well-versed in practices like primary injection testing, secondary injection testing, relay calibration, fault simulation, and periodic inspections. Adhering to manufacturer guidelines, industry standards, and safety protocols ensures equipment reliability and optimal performance.

9. Access to Resources and Industry Awareness:

Staying connected with organizations like the IEEE (Institute of Electrical and Electronics Engineers) and IET (Institution of Engineering and Technology) is crucial for access to valuable resources. Engineers should actively seek research papers, technical articles, conferences, and networking opportunities. Staying informed about relay technology advancements from prominent manufacturers aids in adopting the latest protection techniques.

10. Software Applications for Enhanced Protection:

Utilizing software applications is vital in power systems protection. Advanced tools like ETAP, PSCAD, and DSA Tools aid in relay coordination analysis, fault simulation, and system modeling. Acquiring proficiency in these common industry software packages enables engineers to design and optimize protection schemes effectively.

11. Compliance with Local National Codes:

Adhering to local national codes and regulations is paramount in power systems protection. Understanding and implementing specific electrical codes and standards relevant to the country of operation is crucial. Compliance ensures safe and reliable system design, installation, and operation aligned with legal requirements and best practices.

Conclusion:

By encompassing the principles, techniques, and best practices discussed in this guide, engineers pursuing careers in power systems protection can develop a strong foundation. Continuous learning, staying updated on industry advancements, and compliance with local national codes will ensure engineers can design, implement, and maintain robust and reliable protection schemes for the power grid and its critical assets.

The Author Biography: Qusi Alqarqaz

Qusi Alqarqaz is an experienced professional in power system protection, specializing in sharing knowledge and guiding young engineers. With a career spanning utility and oil and gas industries in Texas, New Mexico, and Qatar, he has amassed extensive industry experience.

Collaborating with leading manufacturers such as SEL, ABB, Siemens, Schneider, among others, Qusi has gained proficiency in a range of protective relays. He actively pursues continuing education, completing professional development courses with software providers including ETAP and Milsoft, enabling him to utilize advanced tools for power system analysis and protection design.

Qusi's dedication to staying up-to-date with industry advancements led him to pursue additional training. He completed professional development courses at Wisconsin University, equipping him with specialized knowledge crucial for working with high-voltage power systems. He also studied power generation extensively at Strathclyde University in the UK.

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals. Through his posts, he aims to offer guidance and mentorship for young engineers in power system protection. His practical advice and personal experiences will empower the next generation of experts in this field.

Contact the Author:

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals.

Qusi Alqarqaz

9 notes

·

View notes