#PTFE Technology

Explore tagged Tumblr posts

Text

#Manufacturing Trends#Industrial Innovation#Industrial Technology#Plastic Manufacturing#Future Manufacturing#PTFE Technology

0 notes

Text

Navigating the Future of Electronics with Rigid-Flex and Taconic PCB Manufacturers

Today’s Printed Circuit Boards (PCBs) are much more flexible and advanced than the first rigid versions. Compact devices with great capabilities and multiple features have earned popularity in the electronics industry, leading to the rise of Rigid-Flex PCBs and Taconic PCBs. The use of these technologies enables unique designs, improves how long the device works, and maintains good electricity flow. Rigid-flex PCB Manufacturers can move and also keep their form, similar to how rigid boards function. They particularly shine in high-speed or RF and microwave applications. Dependable and effective products rely greatly on what electronics do.

Rigid-Flex PCBs: Hybrid Structure with High Functionality

Rigid-Flex PCBs take attributes from both stiff and flexible PCBs and merge them into one board. As a result, rigid and flexible boards no longer need connectors and cables, letting us make assemblies that are lighter and more space-saving. You can find these boards in smartphones, medical devices used on patients, military systems and aerospace devices. They are suited for use in places that require resistance to vibration and bending due to machines. In manufacturing, various layers are made and bonded together using very accurate methods. Therefore, it is only experienced manufacturing companies that can keep products of constant quality and performance.

Key Advantages of Rigid-Flex PCB Manufacturers

Important benefits of using well-known Rigid-flex PCB Manufacturers are their excellent design aid and advanced methodologies. They depend on laser direct imaging for precise work and optical inspection that finds problems in the early stage. Tests using temperature fluctuation and electrical overload guarantee that the product will function in any extreme condition. Manufacturers typically boost efficiency by assisting with design changes that lower the number of components and simplify assembly. In addition, they guarantee that flexible circuit boards meet all IPC standards for quality. Because they are involved in developing products and moving them into mass production, they help make the process more efficient.

Taconic PCBs: High-Frequency Performance Excellence

Taconic PCB Manufacturers are produced from proprietary PTFE-based laminates designed by Taconic with low dielectric loss and thermal stability. These boards are the preferred option for RF, microwave, and high-speed digital designs. They are most prevalent in satellite communications, radar systems, 5G base stations, and aerospace communication modules. Taconic laminates have low signal attenuation and superior dimensional stability. They exhibit moisture resistance as well as heat tolerance, which makes them dependable in extreme working environments. Production using these laminates demands proficiency in drilling, plating, and multilayer bonding because of their special properties.

What to Expect from a Taconic PCB Manufacturers

The best Taconic PCB Manufacturers must possess extensive experience in working with high-frequency laminate material. It involves strict impedance control, surface preparation, and low-loss transmission line engineering. Cleanroom facilities, specially designed PTFE-compatible equipment, and precise lamination procedures are necessary for high-quality output. The producers may perform RF testing and thermal profiling to ensure circuit integrity. They also guide customers on stack-up selection as well as PCB layout according to end-use frequency requirements. By maintaining compliance with IPC and MIL-spec specifications, these companies ensure the critical applications' performance and safety.

Comparing Rigid-Flex and Taconic PCBs

Although both are sophisticated PCBs, Rigid-Flex and Taconic PCBs are for different technical applications. Rigid-Flex is prized for mechanical flexibility, whereas Taconic leads for signal transmission at high speeds. Rigid-Flex boards simplify systems and minimize space utilization in cramped enclosures, while Taconic boards maintain signal purity in communication networks. The components and manufacturing methods are quite different, as are the final-use applications. The two are chosen based on physical space, frequency range, and exposure to the environment. Designers will often talk to both varieties of manufacturers to match their circuit requirements with the appropriate solution.

Conclusion

As innovation speeds up in electronics, the need for Rigid-flex PCB Manufacturers and Taconic PCBs keeps increasing. Such technologies facilitate the development of lighter, faster, and more efficient devices across industries. With increasingly sophisticated design challenges, collaborating with an experienced manufacturer is crucial. BS Interconn Hong Kong Co., LIMITED differentiates itself by providing quality-oriented, customer-centric PCB manufacturing services. Whether you're creating a next-generation medical wearable or a state-of-the-art RF device, selecting a reliable Rigid-Flex or Taconic PCB producer guarantees that your product will outperform and outlast the competition.

#Rigid-flex PCB Manufacturers#Taconic PCB Manufacturers#flexible circuit boards#high-frequency PCB#RF PCB solutions#microwave PCBs#PTFE laminates#hybrid PCB design#aerospace PCB#medical device PCBs#5G PCB manufacturer#signal integrity PCB#low dielectric PCB#high-speed PCB#multilayer PCB assembly#IPC compliant PCBs#MIL-spec PCBs#advanced PCB manufacturing#Taconic laminate PCB#Rigid-Flex technology

1 note

·

View note

Text

How Does a Hollow Fiber Membrane Work?

Learn how hollow fiber membranes work, how they filter fluids, their key roles in water treatment, and why they are essential in separation processes. For more information, feel free to reach out to us at +86 130 0635 3124.

0 notes

Text

The Science Behind PTFE Seals: How They Reduce Friction by 90%

Introduction to PTFE’s Friction-Defying Properties Polytetrafluoroethylene (PTFE) has revolutionized sealing technology with its remarkable ability to reduce friction by up to 90% compared to traditional materials. This fluoropolymer, best known by the brand name Teflon®, possesses unique molecular characteristics that make it ideal for applications where low friction and high chemical…

0 notes

Text

#PTFEHose#PTFE#Teflon#PTFEProducts#PTFEApplications#Manufacturing#Engineering#Industrial#Industry#Technology#QualityControl#ISOStandards#Durability#SafetyStandards#Reliability#ChemicalIndustry#AutomotiveIndustry#AerospaceIndustry#PharmaceuticalIndustry#FoodProcessing#Innovation#IndustryNews#ManufacturingExcellence

0 notes

Text

🔧 Enhance Your Projects with Custom PTFE Solutions! 🔧

Looking for high-quality PTFE materials tailored to your specific needs? Our custom machining services provide precision-engineered PTFE components, ensuring optimal performance for your applications.

Explore our offerings and discover how we can elevate your projects.

#ptfe#teflon#custommachining#engineering#manufacturing#industrialsolutions#precisionengineering#materialscience#innovation#technology

0 notes

Text

🎃TALONGAMES Rounded Curved Edges Mouse Skates Compatible with Logitech G PRO X Superlight 2 DEX Wireless Gaming Mouse🎃

🎈[UNRIVALED QUALITY] - Special Teflon feet designed for Logitech G PRO X Superlight 2 DEX Wireless Gaming Mouse, with calibrated thickness for ultimate control and accuracy. [Note: Not compatible with G PRO X Superlight / Superlight 2 Wireless; Mouse not included].

🎆[ENHANCED GAMING EXPERIENCE] - Super-smooth, low-noise glide reduces grip tension, improving accuracy and comfort for extended gaming or work sessions.

🎇[EXCLUSIVE TECHNOLOGY] - Rounded edges offer scratch-free gliding with no break-in period required.

🎃[DURABLE & COMPATIBLE] - Includes 2 sets of 100% virgin PTFE feet with eco-friendly 3M adhesive, providing smooth performance on various mouse pads.

🎎[PRECISE DESIGN] - Custom-sized for optimal fit and thickness, ensuring durability and sensor accuracy.

5 notes

·

View notes

Note

Do you have a favorite plug/socket connector of any kind?

Hmm, favourite, not really, when I need to connect things I'm usually turning to matters of convenience, price and requirement, there's not many alternatives to, say, a u.fl antenna connector. Actually wait no I was talking about this on IRC last night, I do at least kind of have an answer, which are the GES S and 100 series of high voltage, high cycle connectors. Really all the GES high voltage stuff is fun but these are the best.

These are the family of single-pole high voltage connectors that use a long, long, LONG PTFE socket to provide safe isolation for the spicy end of an equally long PTFE sheathed plug, so that when you turn on a 50+kV source on the one side you can trust that you haven't just electrified the panel you plugged into by forming an arc. They look like this:

I saw a video of these on Twitter or Fedi once and I unfortunately cannot find it because they're great, when you pull them out they leave a vacuum behind so as the tip clears it makes a loud *pop* noise. These are effectively an electrical connector on the end of a sufficiently long stick that the enormous potential you're creating between the tip and the panel can't arc back up and bite you in the ass.

The various models are rated for up to 100kV of potential, the small ones can do 30A and the big ones can do 80A. They're also rated 100k mating cycles, so you can use them when you're working with, say, high voltage machinery that might need to be disconnected and serviced regularly.

Consider that, at 80A and 100kV, you're moving 8 megawatts, which is somewhere between 5-15 % of the output of your average nuclear reactor.

They make multi-pole ones rated for more ordinary 5-12kV loads, which are much more convenient if you only have to deal with moderately high voltage connections.

9 notes

·

View notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] From the manufacturer About us Prestige - A kitchen appliance brand. It is caters to the various needs of home makers in the country. It has varied product portfolio ranging from pressure cookers, non-stick cookware, gas stoves, induction cooktops, mixer grinders to varied other electrical appliances and kitchen tools. The company has been at the forefront of innovation and has been one of the fastest growing company in the kitchen appliance space. Prestige Omega Granite Aluminium Kitchen Set Prestige omega deluxe granite 5-layered non-stick cookware series is made using German technology and it lasts three times longer than ordinary non-stick cookware. It’s special spatter-coated surface looks new for longer and is also metal-spoon friendly. Omega deluxe granite can be used on both gas and induction cook-tops. Set of 4: • Omni Tawa 280 mm • Fry Pan 240 mm • Kadai with Glass Lid 240 mm • Milk Pan with Glass Lid 160 mm Greblon C3+Non-Stick Coating Prestige omega deluxe granite series comes with 5 layer coating. • Top coat - The highly efficient PTFE coating gives special granite finish to the cookware making it more attractive • Reinforced spatter coat (2 layers) – Spatter coat helps in making the cookware look new for longer. This coat ensures that the cookware is metal spoon friendly and convenient to use • Intermediate coat - This coat helps in even heating and also in retaining non-stick properties and making it durable • Base coat - This coating works like adhesive between non-stick coating and substrate. It offers excellent abrasion resistance to the coating This 5 layer non-stick coating lasts 3 times longer than ordinary non-stick cookware, thus making us healthier and assures stain free interior. Outer body is made from one of the best quality aluminium, it comes with black colour powder coating with granite finish which looks attractive and enhances the appearance of the kitchen. The outer coating helps in easy cleaning of the cookware

Powerful 750 Watts Motor Grind all types of food with ease with the powerful 750 Watts motor. Sturdy Handles Handle the jar with ease with the ergonomically designed sturdy handles. Versatile Jars Versatile jars designed to perfection with superior quality stainless steel. Product 1: Material: Non-stick Aluminium; Size: Tawa Dia (280 Mm), Fry Pan Dia (240 Mm), Kadai (240 Mm), Milk Pan (160 Mm); Base type: Induction Base; Base thickness (in mm): 2.8; Included components: 4 Kitchen Set With Milk Pan; Colour: Black Product 1: Warranty: 2 Years; Included in warranty: Manufacturing defects will be covered in the warranty. Remaining things have been mentioned in the user manual; Not included in warranty: Mentioned in the manual Product 1: Durable Granite finish Product 1: Superior Non stick surface Product 2: Warranty: 2 year warranty provided by the manufacturer from date of purchase Product 2: 3 Stainless Steel Jar - (1.5 Litre Wet Jar with blade, 1 Litre Dry Jar with blade and 300 ML Chutney Jar with Blade) and 1 Transparent Juicer Jar with blade Product 2: Powerful 750 Watt motor Product 2: Appealing design [ad_2]

2 notes

·

View notes

Text

Top Non-Metallic Wear Rings and Bearing Isolator Suppliers in India: Why Mascot Dynamics Leads the Way

In today's industrial landscape, the performance and longevity of machinery depend heavily on high-quality sealing and wear-resistant components. Two such crucial elements are non-metallic wear rings and bearing isolators. These components help ensure equipment reliability, reduce maintenance costs, and improve operational efficiency. Among the leading names providing these solutions in India is Mascot Dynamics.

Why Non-Metallic Wear Rings Matter

Non-metallic wear rings are used in hydraulic cylinders to guide the piston and rod, prevent metal-to-metal contact, and absorb side loads. These rings significantly reduce friction and wear, making them vital for smooth and efficient operation in demanding environments such as steel plants, oil & gas units, and chemical processing industries.

As one of the top non-metallic wear rings dealers in India, Mascot Dynamics offers products made from high-performance materials like PTFE, PEEK, and composite polymers. These materials ensure excellent durability, chemical resistance, and thermal stability.

Bearing Isolators for Enhanced Equipment Life

Another crucial component in modern rotating equipment is the bearing isolator. These non-contact, non-wearing devices prevent the ingress of contaminants and the egress of lubricants, thus extending bearing life and reducing equipment downtime.

Mascot Dynamics is a trusted bearing isolators supplier in India, specializing in Inpro bearing isolators and Inpro Air Mizer products. These solutions are widely used in high-tech industries such as pharmaceuticals, food processing, and petrochemicals.

Industry-Leading Brands and Technologies

By partnering with globally renowned brands like Inpro, Mascot Dynamics brings innovative technology to the Indian market. Their offering of Inpro Air Mizer distributors and bearing isolator dealers for industrial plants ensures clients receive tailored solutions for their specific operational challenges.

Pan-India Presence and Expert Support

With a presence in all major cities and a state-of-the-art service center near Mumbai, Mascot Dynamics provides unmatched support and timely delivery across India. Their team of trained engineers ensures clients receive not just products but complete application engineering and after-sales service.

Conclusion

When it comes to non-metallic wear rings suppliers and bearing isolator distributors in India, Mascot Dynamics stands out with its premium product offerings, deep technical expertise, and commitment to customer success. For industries looking to boost equipment efficiency and extend asset life, partnering with Mascot Dynamics is a smart and strategic choice.

0 notes

Text

Plastic Tubes: Engineering Simplicity in a Complex World

Plastic tubes are simple in form yet remarkably diverse in function, serving as essential components across industries such as medical technology, construction, packaging, electronics, and consumer goods. They are flexible, durable, lightweight, and cost-effective—qualities that have made them indispensable in both industrial and everyday applications. This article explores their manufacturing process, functionality, advantages, and the challenges they present in terms of sustainability.Get more news about plastic tube,you can vist our website!

Composition and Manufacturing Plastic tubes are commonly made from a wide array of polymers, including polyethylene (PE), polyvinyl chloride (PVC), polypropylene (PP), and polytetrafluoroethylene (PTFE), among others. The choice of material depends on the application. For instance, medical-grade tubing requires high chemical resistance and biocompatibility, often achieved using PTFE or silicone-based compounds.

Manufacturing methods include extrusion—where molten plastic is shaped by being forced through a die to form a continuous tube—and injection molding, which is more typical for rigid or specially shaped tubes. Additives like UV stabilizers, colorants, and plasticizers can be included to enhance performance under specific conditions.

Everyday Applications Plastic tubes are present in nearly every part of modern life. In households, they serve as dispensers for toothpaste, ointments, and cosmetics. In gardening and plumbing, flexible tubes are used to carry water, chemicals, or air. Food and beverage industries rely on sanitary-grade plastic tubing to handle liquids safely.

In the medical sector, plastic tubes take on highly specialized roles—used in intravenous therapy, catheterization, respiratory devices, and surgical instruments. The lightweight and sterilizable nature of plastics makes them ideal for such sensitive uses.

Industrial and Technological Use In industries such as automotive manufacturing, construction, and electronics, plastic tubes function as conduits for wiring, fluid transmission, insulation, or structural elements. Cable management, fuel lines, and HVAC systems all depend on the reliable performance of engineered tubing.

Additionally, in laboratories and chemical processing plants, tubing made from chemically inert plastics is crucial to transport corrosive or temperature-sensitive substances safely.

Advantages and Challenges The primary advantages of plastic tubes lie in their adaptability, corrosion resistance, and low production cost. They outperform metal counterparts in weight and chemical tolerance, making them ideal for complex or mobile systems. However, their environmental impact remains a pressing concern.

Many plastic tubes are not readily recyclable due to their composite materials or contamination after use, especially in medical and industrial contexts. Single-use plastic tubes generate considerable waste, contributing to pollution and landfill buildup.

Toward a Sustainable Future Efforts to make plastic tubing more eco-friendly are underway. Bioplastics derived from renewable resources, such as PLA (polylactic acid), are gaining attention, though they currently have limitations in durability and heat resistance. Advances in mechanical and chemical recycling technologies also promise a more circular lifecycle for plastic tubing materials.

Manufacturers are increasingly exploring ways to design products for disassembly, reuse, or safe degradation. In parallel, regulatory frameworks in various regions are pushing industries to reduce dependency on virgin plastics and increase transparency in material sourcing.

0 notes

Text

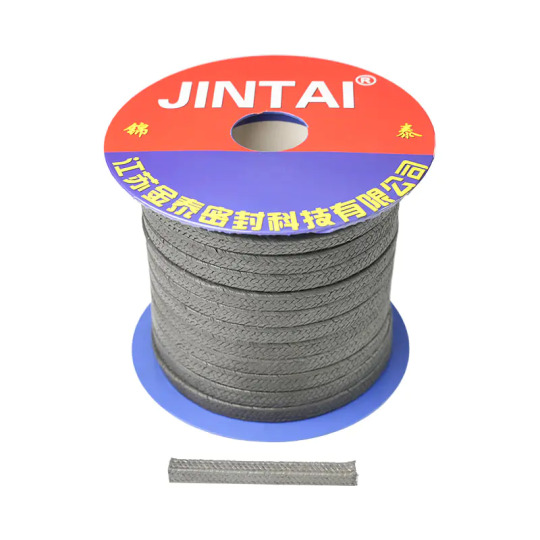

Mechanical/Water Pump PTFE Seal Packing Ramie Fiber Gland Packing

0 notes

Text

Innovative Coatings for Alloy Steel Chains: Boosting Rust Protection & Performance

Alloy steel chains play a crucial role in heavy lifting, rigging, construction, mining, and transport industries. However, even the strongest chains can suffer from wear and corrosion, especially when exposed to moisture, chemicals, or extreme environments. This is where coating technology steps in. Innovative coatings are helping alloy steel chains last longer, resist rust, and perform better in tough conditions.

Why Coatings Matter in Alloy Steel Chains

Alloy steel chains are built for strength, but they are still vulnerable to:

Rust and corrosion from water, chemicals, or salty air.

Surface wear from friction and heavy loads.

Environmental stress like extreme heat or cold.

Without proper protection, these factors can weaken chains, reduce their load-bearing capacity, and shorten their service life. Coatings act as a barrier to these elements, enhancing both safety and lifespan.

Common Coating Challenges in Industrial Use

Before diving into innovations, it's important to understand the limitations of traditional coatings:

Zinc plating offers some rust resistance but may wear off quickly.

Painted coatings can chip or peel under mechanical stress.

Basic galvanization helps with corrosion but doesn’t always handle abrasion well.

Industries need coatings that are not only rust-resistant but also durable, flexible, and environmentally safe.

1. Hot-Dip Galvanizing (HDG): A Classic with Upgrades

Hot-dip galvanizing remains a popular choice for alloy steel chains. Chains are dipped in molten zinc, forming a protective layer.

Benefits:

Excellent corrosion resistance

Self-healing properties on small scratches

Cost-effective for outdoor and marine use

Innovations: Modern HDG includes additives that improve adhesion, surface finish, and longevity in acidic or high-salt conditions.

2. Epoxy-Based Powder Coating: Durable and Protective

Epoxy powder coating involves applying a dry powder to the chain, which is then baked to create a hard, protective film.

Benefits:

Strong resistance to chemicals and water

Smooth, hard finish that reduces friction

Available in color coding for load identification

Innovations: New formulas include UV-blocking properties and flexible layers that resist cracking under repeated stress.

3. Ceramic Coatings: Ultra-Hard Protection

Ceramic-based coatings are a newer innovation designed to provide top-tier protection in high-wear environments.

Benefits:

Extreme hardness and abrasion resistance

High heat tolerance (ideal for mining or smelting operations)

Chemical and corrosion resistance

Use Case: Ceramic coatings are often used in mining and offshore drilling where chain exposure to harsh grit or chemicals is common.

4. PTFE (Teflon) Coatings: Low Friction & High Protection

PTFE or Teflon coatings are known for their slick, non-stick surface and chemical resistance.

Benefits:

Low friction for smooth chain movement

Resistant to oil, grease, solvents, and weather

Lightweight coating that doesn't add bulk

Applications: Ideal for environments where chains are exposed to grease, moisture, or continuous motion like conveyor systems.

5. Nano-Coatings: The Future of Chain Protection

Nano-coatings use microscopic particles to create a thin but highly protective layer over metal surfaces.

Benefits:

Invisible protection with zero added weight

Water-repellent and self-cleaning properties

Long-lasting barrier without flaking or peeling

Trends: Nanotechnology is being used in military and aerospace sectors and is now entering industrial lifting and rigging.

6. Duplex Coatings: Combining Two Layers for Superior Results

Duplex coatings combine galvanization with a topcoat (like powder coating or epoxy), offering dual protection.

Benefits:

Enhanced corrosion resistance

Better adhesion and impact protection

Longer maintenance intervals

Common Combo: Hot-dip galvanizing + powder coating is a popular duplex choice in coastal and marine applications.

Environmental & Regulatory Considerations

With increasing environmental regulations, coatings must also be:

Non-toxic and free of heavy metals

VOC-compliant (volatile organic compounds)

Safe for human handling in manufacturing and field use

Eco-friendly coatings are gaining popularity, with water-based and bio-polymer solutions now under development.

How to Choose the Right Coating for Your Chain

When selecting a coating, consider:

Operating environment: Is it wet, hot, salty, or chemical-heavy?

Chain use frequency: Daily, seasonal, or occasional use?

Load requirements: Will coatings affect weight tolerances or flexibility?

Maintenance schedule: Do you need longer intervals between inspections?

Consulting your chain supplier or coating expert can help match the right protection to your workload.

Innovative coatings are revolutionizing how alloy steel chains perform under pressure. Whether you're lifting cargo in coastal zones, mining underground, or moving loads in high-heat environments, the right coating can significantly extend chain life and improve safety. From epoxy to ceramic, PTFE to nano layers, these advancements not only protect your investment but also reduce downtime and risk. Investing in coated alloy chains is a smart move for any operation demanding strength, reliability, and resilience.

0 notes

Text

Gazebo Tensile Structure Manufacturers: Combining Elegance with Engineering

Gazebos have developed into much more than just classic wooden shelters as outdoor living and recreational areas become more and more popular in public, business, and residential settings. Tensile gazebos are the new norm for outdoor cover and design these days. These constructions are efficient and aesthetically pleasing because to their sleek lines, sturdy materials, and modern appeal. The need for skilled Gazebo Tensile Structure Manufacturers who can provide quality, durability, and customisation in every project has increased as a result of the development in architectural innovation. As weather-protected havens that improve the environment, these contemporary buildings are perfect for gardens, terraces, resorts, parks, cafés, and outdoor event venues.

Why Are Tensile Gazebos Different? Tensile gazebo constructions may take on flowing, organic forms that are impossible with standard construction because they are made with a mix of metal frame systems and tensioned fabric membranes. The end product is a structure that is simple yet eye-catching, robust but lightweight, and open yet protected. PTFE, PVC-coated polyester, and HDPE shade cloth are examples of materials that are designed to endure severe weather conditions including wind, rain, and UV rays while retaining their structural integrity and aesthetic appeal for many years.

These structures are particularly attractive because of their adaptability. Tensile gazebos may be tailored in size, shape, and colour to fit any situation, whether you're searching for a romantic canopy for your garden or a large covered sitting area for a business site. Prominent manufacturers of Gazebo Tensile Structures know how to create places that seem spacious and airy while offering efficient shelter by designing these systems for both performance and aesthetics.

Why Pick Tensile India for Structures for Gazebos? Tensile India is one of the leading manufacturers of Gazebo Tensile Structures in the nation and is one of the most well-known brands in the tensile architecture industry. Tensile India has successfully supplied tensile gazebos across a variety of industries because to its years of industry expertise, sophisticated design skills, and staff of knowledgeable engineers and fabricators. They are a reliable option for tensile gazebo installations that are both long-lasting and fashionable because of their meticulous attention to detail, use of premium materials, and dedication to client pleasure.

Tensile India provides comprehensive solutions that include everything from design and conception to manufacturing and on-site installation, for anything from little backyard gazebos to massive public shade structures. Their design team makes sure every gazebo is both aesthetically pleasing and structurally robust by using CAD technology and 3D visualisation. To guarantee a flawless fit and long-lasting performance, each structure is tailored to the client's requirements and the particular site circumstances.

Gazebo Tensile Structure Applications Tensile gazebos may be used for a variety of purposes because to their adaptability. They serve as tranquil havens or eating areas in residential settings, bringing appeal and functionality to roofs, courtyards, and gardens. Tensile gazebos are often utilised in the hospitality industry by cafés, restaurants, and resorts to provide hospitable outdoor dining spaces that shield patrons from the rain and sun. These buildings are beneficial to public parks and recreational areas because they provide visually appealing children's play areas, performance stages, and shaded seats.

Tensile gazebos are also used in malls, health clubs, educational institutions, and event spaces for either temporary or permanent structures that combine functionality and style. Tensile membranes and corrosion-resistant frames are a great option for businesses wishing to invest in sturdy outdoor infrastructure because of their minimal maintenance requirements, which guarantee long-term value.

Eco-Friendly and Chic Outdoor Solutions As people's understanding of sustainable design grows, tensile gazebos provide a number of environmental advantages. In comparison to conventional techniques, the buildings themselves need less resources for construction, the materials are recyclable, and their light-reflective surfaces aid in lowering heat absorption. Customers may improve outdoor comfort without sacrificing sustainability or cost by erecting tensile gazebo structures.

Tensile India is a progressive choice for customers that value environmental responsibility since they include eco-friendly methods into their design and production operations. Their gazebo solutions are made with the future in mind, creating long-lasting, eco-friendly areas that are not just functional for today's demands.

Join Forces with India's Top Tensile Gazebo Specialists Tensile India is the place to go if you want the ideal fusion of long-term durability, technical prowess, and innovative design. Being one of the most reputable manufacturers of Gazebo Tensile Structures in India, they provide highly effective structures that are completely customised to meet your unique outdoor requirements. Their crew is prepared to provide outcomes that go above and above, whether you're improving a landscape or creating a striking structure.

Visit https://tensileindia.co.in/gazebo-tensile-structure-manufacturers/ to learn more about their full line of gazebo tensile solutions and to take the next step in converting your open spaces with strength, style, and elegance.

1 note

·

View note

Text

PTFE Plastic in New Energy Applications: A Material Powering the Future

As the world transitions toward sustainable energy solutions, polytetrafluoroethylene (PTFE) is emerging as a critical material enabling technological breakthroughs. This remarkable fluoropolymer’s unique properties make it indispensable across solar, wind, battery, and hydrogen energy systems. Why PTFE is Ideal for New Energy Technologies PTFE (commonly known by the brand name Teflon®)…

#Battery Technology#Fluoropolymers#Fuel Cells#Hydrogen Energy#Polymer Materials#PTFE#Renewable Energy#Sustainable Energy

0 notes

Text

0 notes