#Pipe fitting

Explore tagged Tumblr posts

Text

Pipe Fitting Manufacturers India | Find Your Supplier Now

Looking for reliable pipe fitting manufacturers in India? Our comprehensive guide helps you find your supplier now. We feature top-tier companies offering a vast range of high-quality pipe fittings, including steel, stainless steel, and specialized alloys. Whether you need fittings for industrial, commercial, or residential applications, discover trusted manufacturers known for precision engineering, adherence to international standards, and timely delivery. Streamline your procurement process by connecting directly with leading Indian manufacturers dedicated to providing durable and efficient solutions for your piping needs. Start your search today to secure the best pipe fittings for your projects.

0 notes

Text

Pipe fitting, flange, bolt & nut From Xinyue Steel Deliver To South America for Drinking Water Pipeline Construction Specification:API 5L PSL1 X42, ASME B16.9, ASME B16.5

Want to know more? Contact us now! WhatsApp: +8618974849825 [email protected] www.xysteelpipe.com

Xinyue's Vision: Build The World, Serve The Globe! Xinyue's Mission: To promote steel industry, to represent Made-in-China !

#Steel Solutions#XinyueSteel#Steel Industry#Steel Pipe#Steel Project#Global Steel Buyers#Metal Working#Steel Construction#XinYue#Manufacturing#Drinking Water#Pipeline Construction#API 5L PSL1 X42#Pipe fitting#flange#bolt and nut

1 note

·

View note

Text

Trusted Pipe Fittings for Petroleum Needs.

Pearl Pipe Fittings deals exclusively in the design and supply of products for the petroleum industry with a difference. We are one of the largest pipe fittings manufacturers in India, make sure all of our products are built for strength, toughness, and high-duty use. Our reliable fittings ensure that your refineries or pipelines are without hitches. Customers should opt for Pearl Pipe Fittings as they provide maximum performance and are the best in terms of quality. Feel free to contact us today for all your pipe fitting requirements. We are also the best Flange Manufacturer in India and CS Flanges Manufacturers in India

Contact us

Website: https://pearlpipefittings.com

Call us at +91 91723 33437

Product Source: Carbon Steel Pipe Fittings Manufacturers in India and Copper Nickel Flange Manufacturers in India And Pipe Fittings Manufacturers in Bangalore

You may also like: Stainless Steel Flanges Manufacturers in India and Pipe Fittings Manufacturers in Mumbai

0 notes

Text

wild to me that there are people who have no desire to paint their walls in fun ways. and i don't just mean "people who choose sad neutral colors on purpose" i mean: why aren't more homeowners out there scribbling on their walls? it's your property, you can paint and color and draw whatever you want to! when did we as a species stop fingerpainting our homes that was a mistake

#everyone should have a crayon wall. a wall reserved primarily for scribbling on with crayons#we've lost the art of cave painting. and more importantly the SPIRIT of cave painting#*me explaining to my ancestors that i have access to a unimaginable variety of pigments & paints & dyes they could only dream of#but i live in a world where walls are whitewashed and most clothing comes in like. 4 colors. and isn't even tailored to fit *#anyways my biggest homeowner pipe dream is to paint cave art inspired murals in most rooms#and then have one wall specifically reserved for doodling whenever I'm bored. I'll invite friends over for a scribble party#it's honestly so confusing to me that this is not a normal thing for kid's bedrooms especially#we've all heard of young children coloring on walls it's basically instinctive#so if you can afford to why not let your kid have a wall in their bedroom reserved for doodling

3K notes

·

View notes

Text

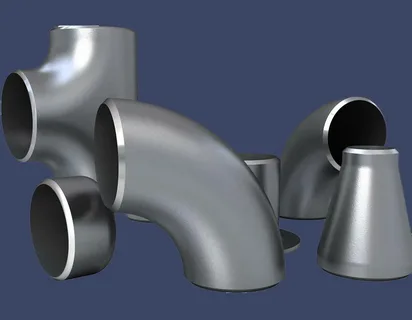

Pipe Fitting is a versatile and essential component used in plumbing and piping systems. It is designed to connect, control, and redirect the flow of fluids or gases within a pipe network.

0 notes

Text

Revolutionizing Plumbing Projects: The Top Innovations by Pipe Fitting Manufacturers in the USA

Piping Projects is one of the leading Pipe Fitting Manufacturers in USA. Pipe fittings, commonly known as pipe connectors, play an essential role in linking one pipe to another, effectively used to extend their length. The use of standard pipe threads, a prevalent type of screw or thread in pipe fittings, is instrumental in ensuring a secure and tight seal. As a leading Pipe Fitting Supplier in USA, we are dedicated to providing top-notch Pipe Fitting that meets industry standards, contributing to the reliability and efficiency of piping systems across the country.

Intelligent Leak Detection Systems: Preventing Disasters Before They Happen

Pipe Fitting Manufacturers USA The first notable innovation in the plumbing industry is the development of intelligent leak detection systems. These sophisticated systems utilise advanced sensors, artificial intelligence, and real-time monitoring to detect leaks in pipelines, fixtures, and appliances. Here's why they've become a game-changer:

Key Benefits of Smart Leak Detection Systems

Early Leak Detection: These systems can quickly identify minor leaks, enabling prompt repairs and preventing potential water damage disasters.

Remote Monitoring: By connecting to smartphones or computers, these systems allow homeowners to monitor their plumbing systems in real time, ensuring peace of mind, especially when away from home.

Water Conservation: The ability to detect leaks promptly helps conserve water and reduces unnecessary waste, making these systems environmentally friendly.

According to a study published in the Journal of Water Resources Planning and Management, intelligent leak detection systems can reduce water loss by up to 50%.

PEX Piping: Flexibility Redefined

Another groundbreaking innovation transforming plumbing projects is the integration of cross-linked polyethene (PEX) piping. This flexible alternative to traditional rigid copper or PVC pipes has gained popularity due to its numerous advantages:

Advantages of PEX Piping

Flexibility: PEX piping can be easily bent, reducing the need for complicated fittings and connectors. This flexibility simplifies installation and eliminates the risk of leaking joints.

Freeze Resistance: PEX piping is more resistant to freezing than traditional pipes, reducing the chances of bursting pipes during cold winter.

Corrosion Resistance: PEX piping resists corrosion, extending its lifespan and reducing the need for regular maintenance or replacements.

A research study by the International Association of Plumbing and Mechanical Officials (IAPMO) declared that PEX piping has a life expectancy of over 50 years.

Tankless Water Heaters: Efficiency and Endless Hot Water

Tankless water heaters in modern plumbing projects rapidly replace traditional ones with bulky tanks. These compact and energy-efficient devices offer several advantages:

Advantages of Tankless Water Heaters

Energy Efficiency: Tankless water heaters only heat water when needed, eliminating the constant energy consumption of traditional water heaters. This leads to significant energy savings and lower utility bills.

Space Saving: Tankless water heaters are compact and wall-mounted, freeing up valuable space in utility rooms or basements.

Endless Hot Water: Unlike traditional water heaters, tankless systems provide a continuous hot water supply, ensuring you never run out, even during peak usage.

A study by the National Association of Home Builders (NAHB) found that tankless water heaters can be up to 34% more energy-efficient than traditional tank heaters.

Water-Efficient Fixtures: Conserving Water Without Sacrificing Performance

In response to growing concerns about water conservation, pipe fitting manufacturers have introduced a wide range of innovative, water-efficient fixtures. These fixtures offer enhanced performance while minimising water usage:

Examples of Water-Efficient Fixtures

Low-Flow Showerheads: These showerheads reduce water consumption without compromising water pressure or the showering experience.

Dual-flush toilets allow users to choose between low-flush and high-flush options, saving significant amounts of water with each use.

Sensor-Activated Faucets: Sensor-activated faucets automatically turn off when unused, preventing unnecessary water wastage.

According to the Environmental Protection Agency (EPA), water-efficient fixtures can reduce water consumption by up to 30% without sacrificing performance.

Cities Where We Supply Pipe Fitting

Pipe Fitting Manufacturer in Texas

Pipe Fitting Manufacturer in California

Pipe Fitting Manufacturer in Florida

Pipe Fitting Manufacturer in New York

Pipe Fitting Manufacturer in Los Angeles

Conclusion:

Throughout the plumbing industry's history, Pipe Fitting Manufacturers have consistently introduced innovative solutions that have revolutionised plumbing projects. From intelligent leak detection systems to PEX piping, tankless water heaters, and water-efficient fixtures, these advancements have enhanced the field's efficiency, durability, and sustainability. By embracing these innovations, professionals and homeowners can benefit from improved performance, reduced costs, and a positive environmental impact. Is it time to upgrade your plumbing project to the next level?

Product: Pipe Fitting Manufacturer in USA

Website: pipingprojects.us

#Pipe Fitting Manufacturers in USA#Pipe Fitting Supplier in USA#Pipe Fitting Manufacturers#Pipe Fitting Supplier#Pipe Fitting

0 notes

Text

Forged Fittings Bushing Manufacturer in India

Petromet Flange INC is an emerging Forged Fittings Bushing Manufacturer In India. A forged fitting bushing is a pipe fitting used in a piping system to minimize the size of a threaded connection.

It is frequently utilized in situations where smaller pipes must be linked to bigger ones. Forged fittings Bushing Manufacturers create it via forging, which results in better mechanical qualities and increased strength.

Carbon steel, stainless steel, and various alloys are among the materials utilized. They are long-lasting and dependable in high-pressure applications, making them ideal for sectors such as oil and gas, petrochemical, chemical, and power production.

For More Details On The Company Visit:

Website: Petromet Flange INC

We Also Are Flange Manufacturers and 45 degree elbow manufacturer in India.

#Forged Fittings#Pipe Fitting#Forged Fittings Bushing Manufacturer#Petromet Flange INC#45 degree elbow#Manufacturing#Construction

0 notes

Text

The Future of Pipe Fitting: Trends and Emerging Technologies

The world of pipe fitting, a cornerstone of plumbing, industrial processes, and infrastructure development, is evolving at an astonishing pace. With advances in materials, design, and technologies, the future of pipe fittings holds exciting possibilities that promise to enhance efficiency, sustainability, and reliability in various applications. In this article, we'll explore the emerging trends and technologies that are set to transform the pipe fitting industry.

1. Smart Pipe Fittings:

One of the most exciting developments in the world of pipe fittings is the integration of smart technologies. These intelligent pipe fittings, embedded with sensors and communication capabilities, can provide real-time data on pressure, temperature, flow rates, and even detect leaks or failures. This data empowers operators to make informed decisions, optimize maintenance, and enhance system performance. In the era of Industry 4.0, smart pipe fittings are set to revolutionize industrial processes and infrastructure management.

2. 3D Printing and Customization:

Additive manufacturing, or 3D printing, is making waves in the pipe fitting industry. This technology allows for the rapid production of highly customized fittings, tailored to specific applications. Engineers can now design intricate, precisely fitting components that were once deemed impossible, opening up new opportunities in complex plumbing and industrial systems.

3. Sustainable Materials:

With an increasing emphasis on sustainability, pipe fitting materials are undergoing a transformation. We're seeing the rise of eco-friendly materials such as recycled plastics, biodegradable compounds, and low-impact metals. These sustainable materials not only reduce the environmental footprint of pipe fitting production but also offer improved corrosion resistance and longer lifespans.

4. Nano-Coatings and Anti-Corrosion Technologies:

Corrosion is a common challenge in pipe fitting systems, leading to leaks and inefficiency. Emerging nanotechnology coatings and anti-corrosion treatments are becoming more prevalent. These coatings create an ultra-thin, highly protective layer that resists corrosion, extending the lifespan of pipe fittings and reducing maintenance costs.

5. Augmented Reality (AR) in Maintenance:

The application of AR in maintenance and repair tasks is simplifying the inspection and upkeep of pipe fittings. Technicians equipped with AR devices can access real-time information, schematics, and step-by-step repair instructions, improving the speed and accuracy of maintenance tasks.

6. Improved Joining Techniques:

Traditionally, welding and threading were the primary methods for joining pipes and fittings. However, emerging technologies like press-fit and adhesive-based joining techniques are gaining popularity. These methods are faster, cleaner, and require fewer resources, making installations more efficient.

7. Health Monitoring Systems:

For applications where water quality is paramount, health monitoring systems integrated into pipe fittings are becoming a game-changer. These systems can detect contaminants, water quality issues, or even bacterial presence in real-time, ensuring that water remains safe for consumption.

8. Lightweight and High-Strength Materials:

In industries where weight and strength are critical factors, advancements in lightweight, high-strength materials like composites are reshaping pipe fitting design. These materials reduce installation and maintenance costs while improving structural integrity.

Conclusion: A Bright and Innovative Future

The future of pipe fitting is undeniably bright, driven by technological innovations, sustainable practices, and a growing emphasis on efficiency and reliability. Smart pipe fittings, 3D printing, sustainable materials, anti-corrosion technologies, AR-based maintenance, improved joining techniques, health monitoring systems, and advanced materials are reshaping the industry.

As these trends and technologies continue to evolve, we can anticipate safer, more efficient, and environmentally responsible pipe fitting systems that will underpin the development of modern infrastructure and industrial processes. The pipe fitting industry is not just keeping pace with change; it's actively driving innovation toward a future that promises enhanced functionality, sustainability, and reliability.

0 notes

Text

The Top 8 Uses of a Pipe Flange

Pipe flanges are essential components used in various industries for connecting pipes, valves, pumps, and other equipment. Here are the top eight uses of a pipe flange.

Pipe Connection

The primary use of a pipe flange is to connect pipes together. Flanges provide a secure and leak-proof connection, allowing for easy assembly and disassembly of pipes when required.

Valve Connections

Flanges are commonly used to connect valves to pipelines. The flange connection allows for easy installation and removal of valves for maintenance or replacement purposes.

Pump Connections

Pipe flanges are used to connect pumps to the piping system. The flange connection provides a secure attachment, allowing for an efficient flow of fluids and easy removal of pumps for maintenance or repair.

Pressure Vessel Connections

Flanges are utilized to connect pressure vessels, such as tanks and reactors, to the piping system. The flange connection ensures a tight seal and allows for the safe transfer of fluids or gases under high pressure.

Expansion Joints

The pipe fitting is incorporated in expansion joints, which are used to accommodate thermal expansion, vibrations, and movement in piping systems. Flanges on either end of the expansion joint enable easy installation and provide a flexible connection.

Pipe Racks and Supports

Flanges are used in pipe rack structures to support and anchor the piping system. They provide a stable connection point for the pipes, ensuring proper alignment and support.

Instrumentation and Measurement Devices

Flanges are used to connect instrumentation and measurement devices, such as flow meters, pressure gauges, and temperature sensors, to the piping system. The flange connection allows for accurate measurement and monitoring of fluids or gases.

Blind Flanges and Spectacle Blinds

Blind flanges are used to close the end of a pipeline when it is not in use or during maintenance. Spectacle blinds, which consist of two metal discs with a solid section and a full opening section, are used for flow isolation or diversion purposes.

Conclusion

Pipe flanges have a wide range of uses in various industries, including connecting pipes, valves, pumps, and pressure vessels. They provide secure connections, enable easy installation and maintenance, and play a crucial role in the functionality and integrity of piping systems.

1 note

·

View note

Text

anybody think abt the turning point between old aika and present aika. anybody think abt the point where she just started forgetting to dye her hair and the roots are beginning to show. anybody think abt the first time she wishes for a lead pipe. anybody think abt ‘the others back home’

anyway I was thinking abt isat again and some suspiciously magical-girl-colored markers appeared and then I blacked out

#I’m saving the rest of the midnight ramblings for the tags#but uhhhh yeah memory of sadness event but aika edition!#I am once again unable to stop the isat and idwtbamg fixations from fucking around in my head#uhhhhh also! bc aika design is partially inspired by jirachi#and I suck ass at coming up with designs off the top of my head#the other magical girls are also based off mythical pokemon that fit the colors I had and also I think would be cool thematically#shaymin manaphy victini diancie from left to right#also yes in my mind this is the first time she beat in eclipse’s shins with a lead pipe#I don’t know where my digital drawing tablet went so all yall get is pencil and crayola lol#isat spoilers#<- kind of reference of a spoilery event?#in stars and time#i don’t want to be a magical girl#pretty pretty please i don't want to be a magical girl#aika idwtbamg#idwtbamg#my art

336 notes

·

View notes

Text

Best in Class: Discover India’s Leading Pipe Fittings Supplier

In this regard, Pearl Pipe Fittings is happy to be in the list of the leading pipe fittings manufacturers in India. We offer high-quality and technologically advanced pipe fittings and flanges in carbon steel to different sectors. Get value for your money when you purchase our high quality and reliable products. We are also the best Flange Manufacturer in India and CS Flanges Manufacturers in India

Contact us

Website: https://pearlpipefittings.com

Call us at +91 91723 33437

Product Source: Carbon Steel Pipe Fittings Manufacturers in India and Copper Nickel Flange Manufacturer in India You may also like: Stainless Steel Flanges Manufacturer in India and SS Pipe Fittings Manufacturers in India

0 notes

Text

literally me w my she/they swagger

#nothing says she/they energy than detective fit smoking a fat pipe#i literally screamed when i saw these cosmetics…#tf2#team fortress 2#tf2 pyro#pyro tf2#my art

3K notes

·

View notes

Text

stream https://www.youtube.com/watch?v=ncLoEunRqCc

:)

#k*rupt didn't ever do anythign to me to deserve being linked in a drawing that has neloth cheeks bro#my art#skyrim#talvas fathryon#neloth#based and referenced off a scene from fr*sh (1994) good movie btw#in my mind that drawing was gonna convey something miserable but idk it can be any Mood it seems. pick one#but as the artist i say talvas is at his wits end from getting 800 year old pipe#but art is for the Masses!#i figured that i'm sad partially to always drawing things that never convey happiness so i drew the ponies to go with it#taking 498 pictures of skyrim rooms for research (nelvas post-pipe) that;s Disgusting to say#HURL#nobody in this barren country or island has doors to their rooms and it's making me crayz#it fits with neloth i think cus he dgaf but i'm still caught up on that college dorm arrangement#round and doorless#..........MESS.

177 notes

·

View notes

Text

the Nice Dog Agency

#rain code#master detective archives#mdarc#abcd art#yuma kokohead#halara nightmare#desuhiko thunderbolt#fubuki clockford#vivia twilight#yakou furio#yuma is a little teacup chihuahua fueled by anxiety and fear#halara is an athletic italian greyhound or whippet#desuhiko is some kinda terrier#fubuki… ok so hear me out. i looked up ‘dumbest dog breeds’#and apparently the afghan hound has a bad reputation for being Not Very Smart (hard to train)#but that’s because they have such a very specific skill set (sighthound)#which totally fits her.#vivia and yakou are both just random doggy shapes#and not specific breeds. but feel free to pipe up if you feel like there’s a specific breed you think they resemble

212 notes

·

View notes

Text

The Ultimate Guide to Choosing the Right Pipe Fitting Manufacturer

Piping Projects is one of the leading Pipe Fitting Manufacturers in USA. Pipe fittings, commonly known as pipe connectors, play an essential role in linking one pipe to another, effectively used to extend their length. The use of standard pipe threads, a prevalent type of screw or thread in pipe fittings, is instrumental in ensuring a secure and tight seal. As a leading Pipe Fitting Supplier in USA, we are dedicated to providing top-notch Pipe Fitting that meets industry standards, contributing to the reliability and efficiency of piping systems across the country.

We are committed to supplying high-quality Pipe Fitting Manufacturers USA. We take pride in offering a diverse range of products to meet the specific needs of our customers. Our inventory includes various materials, sizes, and configurations, allowing versatile applications across various industries. Whether you require fittings for plumbing, industrial, or commercial purposes, our comprehensive range ensures that you find the right Pipe Fittings for your project. With a focus on customer satisfaction and a dedication to excellence, we strive to be your reliable Pipe Fitting Supplier in other countries.

What is Pipe Fittings?

Steel pipe fittings are accessories that are used to connect steel pipes. They are used to change the direction of the flow of fluids or gases, to regulate the flow rate, or to close off a pipe. Steel pipe fittings are made of steel and are available in various shapes and sizes, such as elbows, tees, reducers, couplings, and flanges. They are used in various industries, including oil and gas, chemical, and construction.

Types of Pipe Fittings

Pipe Fitting Manufacturers are components that help in changing the direction of the flow, altering the size of the pipe, connecting different components, and stopping the flow. There are various types of pipe fittings available for piping work, including:

Adapters: Connects two pipes of different types.

Bushing: Reduces the size of a pipe fitting.

Caps & Plugs: Stops the flow of fluid.

Coupling: Connects two pipes together.

Crosses: Connects four pipes together.

Elbows: Changes the direction of the pipe.

Flange: Connects pipes to other equipment.

Nipple: A short stub of pipe, usually male-threaded.

Saddle Tees: Used to tap into a pipe.

Tees: Connects three pipes together.

Unions: Connects two pipes together and allows for easy disassembly.

Wyes: Connects a branch pipe to the main pipe.

Pipe fittings are made from various materials, including brass, copper, PVC, and stainless steel. The most commonly used standard pipe fittings are either forged or wrought. Only seamless pipes are used to produce wrought fittings. Large-diameter welded fittings are manufactured from the plate. Pipe fittings are available in different types of end connections.

Materials Used in Pipe Fitting

Pipe fitting involves using various materials to create a reliable and efficient piping system. The choice of materials depends on factors such as the type of fluid being transported, the pressure and temperature requirements, and the specific application. Here are some commonly used materials in pipe fitting:

Steel:

Carbon Steel: Widely used for industrial applications due to its strength and durability. It is suitable for high-pressure and high-temperature systems.

Stainless Steel: Known for its corrosion resistance, making it ideal for applications where resistance to rust and corrosion is crucial, such as in the food and chemical industries.

Copper:

Copper Tubing: Commonly used in residential plumbing due to its malleability, corrosion resistance, and ability to handle both hot and cold water. Copper is often chosen for its aesthetic appeal and ease of installation.

PVC (Polyvinyl Chloride):

Rigid PVC: Lightweight, cost-effective, and corrosion-resistant, PVC is commonly used in residential plumbing for transporting water.

CPVC (Chlorinated Polyvinyl Chloride): Similar to PVC but designed to handle higher temperatures, CPVC is suitable for hot and cold water applications.

PEX (Cross-linked Polyethylene):

Flexible PEX Tubing: Known for its flexibility and ease of installation, PEX is commonly used in residential plumbing. It is resistant to scale buildup and freeze damage.

Cast Iron:

Cast Iron Pipes: Used for drainage systems and sewer lines due to their durability and resistance to corrosion. Cast iron is well-suited for underground applications.

Brass:

Brass Fittings: Brass is often used for fittings due to its corrosion resistance and ability to withstand high temperatures. It is commonly employed in plumbing and gas distribution systems.

Aluminium:

Aluminium Tubing: Lightweight and corrosion-resistant, aluminium is used in specific industrial applications. It is often chosen for its malleability and ability to resist rust.

HDPE (High-Density Polyethylene):

HDPE Pipes: Known for their durability, chemical resistance, and flexibility, HDPE pipes are used in various applications, including water supply and irrigation.

Galvanised Steel:

Galvanized Pipes: Regular steel pipes coated with a layer of zinc for corrosion resistance. They are often used in outdoor applications or where the pipes may be exposed to corrosive elements.

Nickel Alloy:

Nickel-Copper Alloys: Known for their corrosion resistance in harsh environments, nickel alloys are used in chemical and petrochemical industries where corrosion is a significant concern.

Cities We Supply Pipe Fittings

Pipe Fitting Manufacturer in Texas

Pipe Fitting Manufacturer in California

Pipe Fitting Manufacturer in Florida

Pipe Fitting Manufacturer in New York

Pipe Fitting Manufacturer in Los Angeles

Installation of Pipe Fittings

The installation of a steel pipe fitting involves the following steps:

Cut the pipe: Cut the steel pipe to the desired length using a pipe cutter or hacksaw.

Thread the pipe: Use a threading tool of diameter to match the pipe to thread the pipe.

Apply sealant: Apply Teflon tape or pipe thread compound to the threads of the pipe fitting.

Hand tighten: Hand tighten the pipe and coupling or fitting.

Tighten with a wrench: Using a pipe wrench, tighten one and a half more turns on one pipe and one fitting.

Conclusion:

Mastering the art of pipe fitting is an essential skill for anyone involved in construction, plumbing, or industrial processes. By understanding the basics, employing proper techniques, and following best practices, professionals can ensure the reliability and longevity of pipe systems. Whether you're a seasoned plumber or a DIY enthusiast, investing time in learning and honing your pipe fitting skills will pay off in the form of efficient and leak-free plumbing systems.

#Pipe Fitting Manufacturers in USA#Pipe Fitting Supplier in USA#Pipe Fitting Manufacturers#Pipe Fitting Supplier#Pipe Fitting

0 notes