#QUALITYCONTROL

Text

Update: new info about David Tennant's elusive 1996 short film Quality Control!

I've got a few new updates to add to this post I did a while back about a short film David Tennant did in 1996 called Quality Control. If you haven't yet read my first post about this short film, you can read it at the link I posted above. And then come on back!

Firstly, Quality Control was broadcast many more times than I thought it was! I thought it was only broadcast four times between 1996 and 1998, so imagine my surprise when I did some digging and found it had actually broadcast eleven times between 1996 and 1999. Oops!

But by far the biggest update I have on this short is that recently I've discovered why it was made...and by whom!

But first, the updated broadcast list:

BROADCAST DATES:

1996:

4 Jan 1996 - 1:55pm - Channel 4

10 Jun 1996 - 1:55pm - Channel 4

9 Dec 1996 - 2pm - Channel 4

10 Dec 1996 - 1:30pm - Regional S4C

1997:

18 Jun 1997 - 10:45am - Regional S4C

25 Jun 1997 - 10:45am - Channel 4 & Regional S4C

1998:

8 Feb 1998 - 3:30pm - Channel 4

26 Oct 1998 - 1:30pm - Channel 4

6 Nov 1998 - 1:30pm - Regional S4C

1999:

18 Jun 1999 - 1:30pm - Channel 4

29 Jun 1999 - 1:30p - Regional S4C

Of course now that I've found these, I'm aware there may be other broadcast dates I have yet missed. If so, I didn't find any past 2000. But I reserve the right to be mistaken, ha!

Now here's the bigger update: the why, and the who!

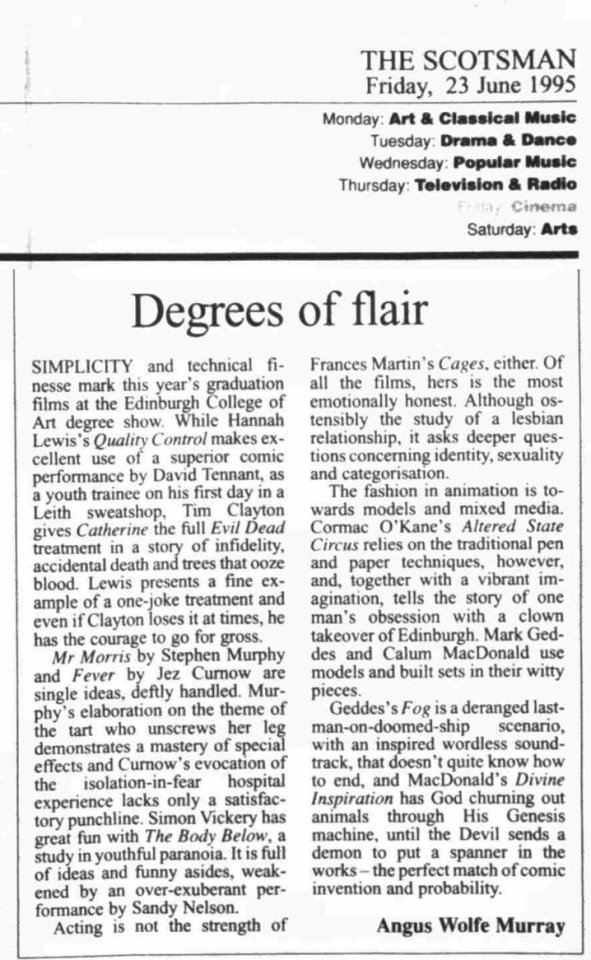

Published 23 June 1995 in The Scotsman, here's the article that broke it wide open for me, and its relevant quote:

"Simplicity and technical finesse marked this year's graduation films at the Edinburgh College of Art degree show. While Hannah Lewis's Quality Control makes excellent use of a superior comic performance by David Tennant as a youth trainee on his first day in a Leith sweatshop…"

WOW, right?

But this new information leads to all sorts of other questions. If this short was initially part of a degree course, how did it make the leap to broadcast? Was it in one of the short film UK production schemes happening at the time which were helping new film creatives launch their ideas: i.e., First Reels, Tartan Shorts, New Found Land?

I'm not sure. At first blush, Quality Control doesn't seem to have been included in a larger broadcast of shorts like Bite and Spaces had been (Bite was shown on the program Don't Look Down on STV, and Spaces was shown on STV as a part of First Reels.) In its broadcast listings, Quality Control is always listed on its own.

The description the article gives on the short is also very interesting. The article says David played a youth trainee on his first day in a Leith sweatshop. But reviews and blurbs of the short's plot in newspapers say he was a job trainee who becomes a quality controller/inspector at a skateboard factory. It seems to me that a sweatshop and a skateboard factory are two very different places, but are they? Was that changed somehow between its showing at the College of Art degree show, or was it just the article writer's bad description?

Blurbs about Quality Control from various newspapers

And just who is Hannah Lewis, its creator? Well my money's on producer Hannah Lewis, who's worked with Morag McKinnon and Colin McLaren. They all met at the Edinburgh College of Art, and had made three shorts together by 1999 (one of which, 'Home', won a BAFTA!) But if she is the right Hannah Lewis, Quality Control isn't listed anywhere on her IMDb. So while I can't be sure she's the short's creator, the time is right, and the place is right. A lot of the dots sure do line up!

Now we know why it was done - and who did it - can we find it? Is it archived somewhere? I haven't found it so far if it is - at least it's not archived at the Moving Image Archive in Glasgow, or at the British Film Institute. But I've yet to check to see if the Edinburgh College of Art may have it.

As far as all the other questions this raises - like how did David get involved with the project (since he was living in London at the time) and if he knew someone who knew someone who...ya know? Pfffft. Your guess is as good as mine! It's one more "I dunno" to add to the pile.

In conclusion, we may be as close as we've ever been to finding out more about David's elusive 1996 short, Quality Control.

I'll keep on searching!

23 notes

·

View notes

Text

Kanban in action! Visualize your workflow, identify bottlenecks, and improve continuously. 🔍💡

Visit http://vabro.com and try for free!!!!

#Vabro#Agile#Kanban#Lean#ProjectManagement#Kaizen#LeanManufacturing#ContinuousImprovement#TaiichiOhno#ProcessImprovement#QualityControl

2 notes

·

View notes

Text

Ultimate Guide to PCB Testing Methods: Ensuring Quality and Reliability in Your Circuits

In the electronics sector, Printed Circuit Boards (PCBs) are the life-lines of virtually all gadgets that are in use in the modern society. From humble home appliances to gigantic industrial equipment, PCBs are the skeletal framework of hardware organization and connection of circuit elements. It is vital to guarantee the quality and dependability of these fundamental parts – thus enters PCB testing methods. It is our hope that this extensive hand will help identify the most suitable test strategies for PCB testing, why these techniques matter, and how to maximize your circuits’ functionality.

Introduction

Firstly, an increase in the capability of different electronic devices leads to higher necessary requirements to the PCBs used in their production. Performing tests on the PCBs is an essential step in the manufacturing process done to confirm that a given board performs as a unit to the expected levels. This guide aims at explaining various techniques of PCB testing with a view of having a better understanding on how to achieve quality and reliability on the circuits.

Why PCB Testing is Crucial

PCB Testing When it comes to the potential defects on PCBs, there are shorts, opens, and some component placements. They can cause device failure, decline in performance level, and sometimes also pose safety issues. Through high-quality testing regimes, it becomes easier to address problems before they reach the customer, and thus manufacturers will have reliable and efficient products. Key reasons for PCB testing include:

Detecting Manufacturing Defects: Solder bridges, missing and placed in wrong position components, all can be detected in the initial stages easily.

Ensuring Functionality: Ensuring that the PCB does what is wanted and needed when it is in use, and under several conditions.

Quality Assurance: Ensuring that the business meets industry standards, and what clients require of them.

Cost Efficiency: Decreasing the likelihood of rework and recall by identifying possible defects before they get to the customer.

Types of PCB Testing Methods

These are the types of PCB Testing Methods:

Visual Inspection

Technique one as also referred to as the VI or visual inspection is the simplest and basic type of testing done on PCBs. The technique entails inspecting the board with naked eyes for some of the common faults including solder bridges, missing parts, and misalignment issues.

Automated Optical Inspection (AOI)

AOI employs cameras and software algorithms to check PCBs for defects and performs the inspections singly. This method of inspection is far more efficient than the manual inspection and simultaneously versatile enough to identify numerous problems.

X-ray Inspection

Some functions which include examination of features of BPCs that could not be easily inspected include solder joints under components through x-ray inspection. It is especially effective in inspecting defects in BGA (Ball Grid Array) and other various packages as well.

In-Circuit Testing (ICT)

ICT entails applying different voltage across the PCB to checks on the electrical characteristics of the needy part and connections. The use of this method is highly recommended for the identification of functional problems and verification of the circuit’s goodness.

Functional Testing (FCT)

Functional testing evaluates the effectiveness of the PCB pointing to the fact that it can be tested when placed in use. This method enables the certification of that the PCB works as expected under actual environment.

Flying Probe Testing

In flying probe testing, the probes are moved around to test the electrical properties of the created PCB. Lower to medium volume production runs can be made easily by using this technique; hence it is advantageous in this regard.

Boundary Scan Testing

Boundary scan testing also called as JTAG testing extends test circuitry into all the components for testing the connections between them. Although, this method is very efficient for identifying connection problems and faults.

Burn-In Testing

Burn-in testing puts the PCB in a state of operational stress for a long time to capture early-life failures. This aspect makes the method reliable for the long term since it is likely to identify problems that may occur when the equipment is in use for a long time.

Detailed Analysis of Each Testing Method works

These are the detailed analysis of each testing method works:

Visual Inspection

Pros:

Simple and low-cost

Determined to be a system for the reporting of noticeable defects as soon as they are observed.

Cons:

Time-consuming for complex boards

Limited to visible defects

Automated Optical Inspection (AOI)

Pros:

Fast and accurate

Is capable of detecting various kinds of defects.

Non-destructive

Cons:

High initial setup cost

May need to have better settings optimized for specific boards.

X-ray Inspection

Pros:

Examines hidden features

Ideal for complex packages

Cons:

Expensive equipment

Requires skilled operators

In-Circuit Testing (ICT)

Pros:

Thorough electrical testing

High fault coverage

Cons:

Requires custom fixtures

Not for all the boards or servers that you wish to build.

Functional Testing (FCT)

Pros:

Ensures real-world performance

Detects system-level issues

Cons:

Time-consuming

The mathematical test object can involve complex arrangements of test configurations.

Flying Probe Testing

Pros:

Flexible and adaptable

Cost-effective for small batches

Cons:

Slower than ICT for big volumes

Applicable only when the board is specially designed

Boundary Scan Testing

Pros:

Interconnections have high fault coverage.

Said; No need to have physical access to the test points

Cons:

Requires boundary scan-enabled components

Complex setup

Burn-In Testing

Pros:

Identifies early-life failures

Ensures long-term reliability

Cons:

Time-consuming and costly

Perhaps stressful to the board

Choosing the Right Testing Method

The choice of the appropriate method of PCB testing can be influenced by several factors such as the level of complexity of the PCB and the numbers of boards to be tested as well as the actual costs of the testing process and other features. Consider the following when choosing a testing method:

Board Complexity: Great board densities or component placement can be a determinant as to whether one needs AOI or X-ray inspection.

Production Volume: Applications that are characterized by high volumes can be easily facilitated by ICT while the low to medium volume applications may require flying probe testing.

Budget: Both manual inspection and AOI are favorable for various production volumes, while X-ray and ICT are more expensive at the beginning.

Specific Requirements: There are two types of the test, namely Functional Test and Burn-In Test that should be made so as to attain the long term reliability in applications that are critical.

Best Practices for PCB Testing

Using the best techniques in testing PCBs increases the quality and reliability of the circuits that you are working on. Here are some key practices to follow:

Early Testing: It is recommended to carry out the tests when the product is still in its design and manufacturing phase so that problems can be noted earlier before they reach a very catastrophic level.

Automate Where Possible: Use method such as automation to reduce the time and improve on the quality of the testing.

Regular Calibration: It is necessary to check if all the testing equipment used for calibration are accurate.

Comprehensive Coverage: This way, you will be able to ensure that there are no defects that are not tested as the best testing approach combines all types of testing methods.

Document Everything: Ensure that you keep records of the tests performed, the results obtained, as well as any measures taken to correct the breaches.

Common Challenges and How to Overcome Them

These are the common challenges and how to overcome them:

False Positives/Negatives

Automated testing methods maybe good some times, they give you the results that are either positive or negative and this will lead to unnecessary rework or more alarming leaving critical defects unfound. In order to avoid this, make sure that testing algorithms and testing equipment are updated and fine-tuned from time to time.

Component Access

Some of the testing techniques involve handling parts of the circuit and with high density board this can be very difficult. Some of the ways in which testbench implementation can be avoided are as follows Boundary scan testing and X-ray inspection.

High Costs

Some form of testing such as X-ray and ICT testing is often very costly. The effectiveness must come with reasonable prices; try to combine some of the mentioned approaches to cover all the aspects without spending too much money.

Future Trends in PCB Testing

About the future, it can be stated that its trends will be in fact linked to the tendencies in technologies and expectations towards ever higher quality and quantity of tested PCBs. Key trends to watch include:

AI and Machine Learning: Using of intelligence algorithms and machine learning in testing algorithms to enhance the efficiency and the minimization of false negative or false positives.

IoT and Smart Manufacturing: Higher testing flexibility and opportunities for the continuous test process supervision.

Advanced Imaging Techniques: The need for better techniques that would enhance the detection of defects within a printed circuit.

Environmental Stress Testing: More focus in the testing of PCBs under different environmental pressures in order to improve on its longevity.

Conclusion

Quality and reliability of packaged circuits have to be maintained to contribute positively in any electronic equipment. This paper seeks to explain the common testing techniques for PCB so that PCB manufacturers are able to test and see if they are free from defects and if they are functional. This ultimate guide will give you a full insight on the available options in PCB testing that will enable you make the best decision that will give you perfect circuits.

The aim is to help you understand how to attain the best quality of PCBs, what methods are worth following, and what trends drive future improvements, thus contributing to the quality of the final electronic products and, consequently, consumer satisfaction.

#PCBTesting#Electronics#CircuitBoard#QualityControl#Engineering#Technology#Manufacturing#IndustrialDesign#Tech#Innovation

2 notes

·

View notes

Text

SELECTIVE SOLDER 🔬🔥🔧

Selectively soldering components to printed circuit board (PCBs), while avoiding heat-sensitive parts - ensuring that only the desired areas are soldered, minimizing potential damage to the components and making high quality finished boards!

#adafruit#electronics#selective#solder#selectivesolder#pcb#opensource#opensourcehardware#manufacturing#factory#electronicsproduction#qualitycontrol#heatsensitive#componentprotection#circuitboards#innovation#precisionengineering#techmanufacturing

14 notes

·

View notes

Text

#SurfaceMetrology#PrecisionMeasurement#MetrologyTechnology#ManufacturingAdvancements#QualityControl#Industry4.0#TechnologyInnovation#RoughnessMeasurement#ContourMeasurement#ManufacturingIndustry#Automation#DigitalMeasurement#IndustryTrends#QualityAssurance#MetrologyStandards#EfficiencyImprovement#ManufacturingQuality#FutureTechnology#SurfaceProfiling#SmartManufacturing

2 notes

·

View notes

Link

Are you in search of high-quality sterile surgical gloves? Look no further than Guilin HBM Health Protections, Inc. As the top surgical gloves factory in China, we are dedicated to providing our customers with the best products possible. Each of our gloves goes through a rigorous inspection process, ensuring that they are 100% air inflated and inspected seven times before delivery. We take pride in delivering high-quality and safety medical gloves to our customers. Our annual production capacity is 800,000,000 pairs, making us the leading surgical gloves factory in China. We specialize in producing 100% blow-checked surgical gloves with a high AQL of 0.65. Our gloves are sterilized in-house using E-Beam sterilization, ensuring the highest level of safety and quality. We are proud to have received several certifications, including CE, EN455, ISO13485, FDA 510K, SATRA, PPE, and CCPIT certifications. Our clients include well-known organizations such as Medline, UNICEF, UN Migration, and UNOPS. At Guilin HBM Health Protections, Inc., our team is composed of over 2,000 dedicated professionals who are committed to providing our clients with the best service possible. We take pride in our work and are dedicated to making sure our customers receive the best products and services. So why wait? Visit our website at surgicalgloves.com to learn more about our products and services. And if you have any questions or would like to place an order, our team is here to help. #SterileSurgicalGloves#SurgicalGlovesFactory#MedicalGloves#EBeamSterilization, #QualityControl

2 notes

·

View notes

Text

#VBK Architects & Engineers#For More Information Contact:6362695891#Email-ID:[email protected]#Architects#Engineers#QualityControl#QualityControlPodcast#engineering#architecture#EngineeringManagementInstitute#projectmeetings#mentorship#qualitycontrolonprojects#teamcommunication

3 notes

·

View notes

Photo

Captain quality control eyeing my newest pewter inlays in this nice little 18th century brass pipe tomahawk. For a tutorial on how poured pewter inlays are made check out the blog post by Iron John! https://www.irontreeforge.com/post/poured-pewter-inlays-tutorial #artofweapons #howto #pipetomahawk #pewter #pewtercasting #pouredinlays #pewterinlays #cattomahawk #shopcat #weaponscat #qualitycontrol https://www.instagram.com/p/CpJtS1FMYKw/?igshid=NGJjMDIxMWI=

#artofweapons#howto#pipetomahawk#pewter#pewtercasting#pouredinlays#pewterinlays#cattomahawk#shopcat#weaponscat#qualitycontrol

4 notes

·

View notes

Photo

Super Sonic ~ ~ ~ New manics red corduroy hats by @referenceco > > > > Available in store n webshop • Delivery services available • South Jersey area only • Dm for more info #basketball #baseball #nba #mlb #paint #weinthepaint #ballup #seattlemariners #supersonic #snapback #corduroy #luxury #clean #qualitycontrol #reference #hatsofinstagram #heatwave #supercold #westcoast #westcoastfashion (at Seattle, Washingtion) https://www.instagram.com/p/Cj-9ntJr4Le/?igshid=NGJjMDIxMWI=

#basketball#baseball#nba#mlb#paint#weinthepaint#ballup#seattlemariners#supersonic#snapback#corduroy#luxury#clean#qualitycontrol#reference#hatsofinstagram#heatwave#supercold#westcoast#westcoastfashion

3 notes

·

View notes

Text

💡Application of telecentric lens in auto parts inspection.

#machinevision#visioninspection#imageprocessing#imaging#computervision#production#industrialautomation#processautomation#qualityassurance#innovation#packing#packexpo#inspection#qualitycontrol#qualityinspection

2 notes

·

View notes

Text

David Tennant's Obscure Short Films: 1996's Quality Control

I'm back for a short(er) little David Tennant in Obscure Performances post today. Let's have a teeny-tiny chat about another rarity of David's, shall we? - a short film he did in 1996 called Quality Control. And when I say this is a rarity, believe me….it's a rarity.

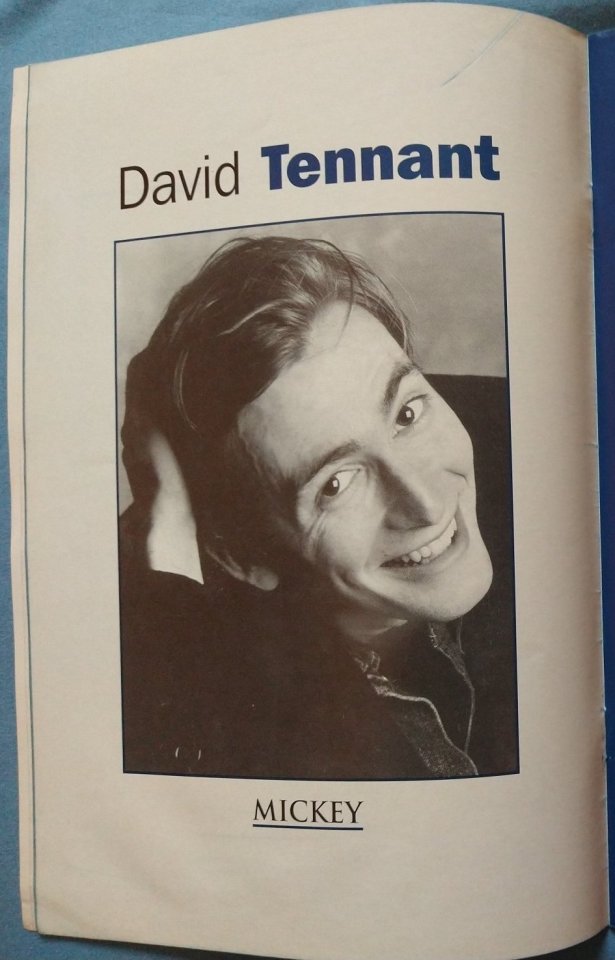

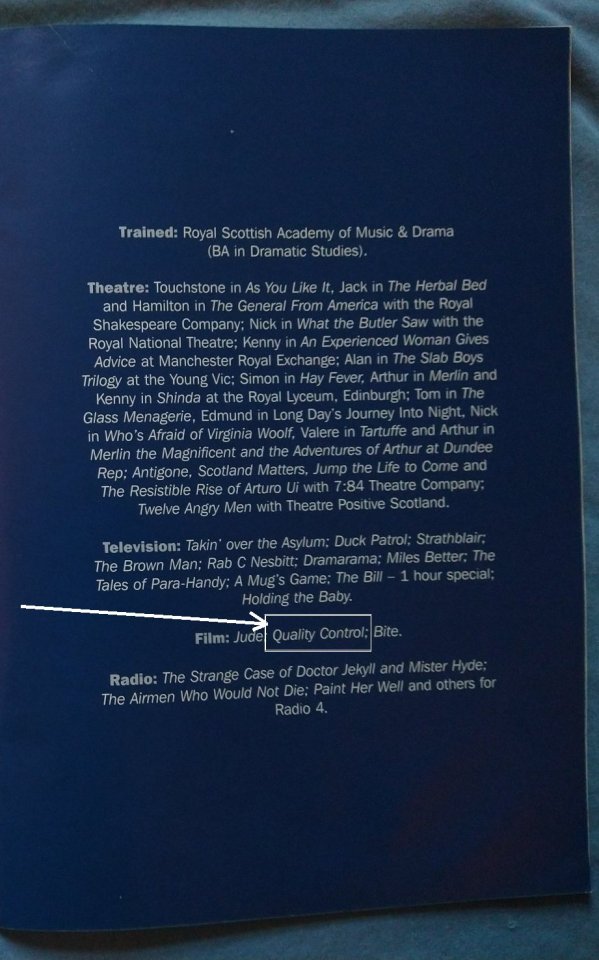

I've at least been able to confirm David acted in this short film, for he mentions it as a film credit in two places: the 1996 programme for The Herbal Bed, and the 1997 programme for Hurly Burly - as evidenced by this cast listing of his from my Hurly Burly programme:

Quality Control has very little to no presence on the Internet, and there are only a few mentions of its existence. The first one I've been able to track which attributed the short to David was from a "David Tennant Fact Of The Day" post from May 2012.

The second mention is from the British Film Institute (BFI). If you study this notation, you'll notice another interesting detail: unlike many other works, the BFI does NOT hold any film or video materials relating to Quality Control. So they don't have a copy!

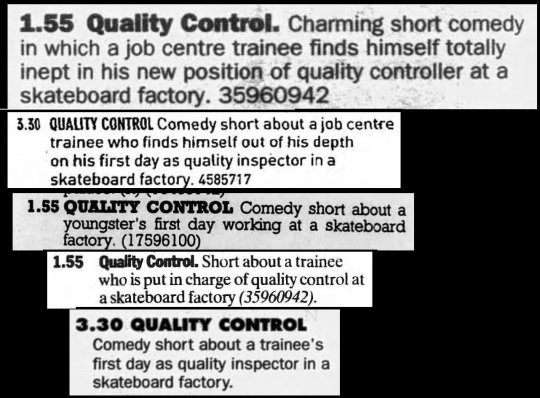

The BFI describes the film as a "comedy in which a job centre trainee finds himself totally inept in his new position of quality controller at a skateboard factory." But I hoped I might find a few other clues from another contemporary source: newspapers. So that's where I went!

All of the descriptions said Quality Control was a 20-minute short comedy - but I also learned it was the trainee's first day on the job, too. One can also assume (and I certainly do) David plays the role of the trainee. Here are some various listings I found:

What's very interesting, though, is something the BFI doesn't list: Quality Control was also re-broadcast two years later in 1998! The 'Fact of The Day' I mentioned earlier clued me into that detail, and that tidbit was invaluable in my search for mentions of the short. Why? Because this one's a real tough one to search. David's never mentioned in any printed synopsis, and seriously…just try to do a search using only the words, "Quality Control." It's an utter nightmare!

But knowing what I knew, I was able to add to the information the 'Fact Of The Day' had provided. Quality Control originally aired at 1:55p on 10 Jun 1996 on BBC Channel 4. In 1998, Channel 4 aired it two more times: on 8 Feb 1998 at 3:30p, and at 1:30p on 26 Oct 1998. It was also repeated regionally on S4C at 1:30p on 6 Nov 1998.

Its repetition in 1998 has intrigued me. It implies the BBC kept a copy of the short from 1996 to its re-air dates in 1998. The BFI listing for the short says it doesn't have a copy in its archives, but unless the BBC has subsequently erased it, a copy of that short might still exist. Somewhere. I'd love to find it, as it's one of the few things David did during that time I haven't seen. So we have no screenshots. But we know he did it. And who knows if the BBC has it in their archive.

But you know, maybe someone's got it recorded somewhere on an old Betamax tape.

34 notes

·

View notes

Text

Ensuring Excellence in High-Pressure Gas Cylinder Quality

Ensuring Excellence in High-Pressure Gas Cylinder Quality

Inspection | Quality Inspection | ThirdEye AI

Gas Cylinder Quality Control | ThirdEye AI | Quality Inspection

Visit Here- https://third-eye.ai/

#quality#gas#control#cylinder#qualitycontrol#thirdeyeai#thirdeye#qualityinspection#inspection#AI#artificialintelligence#Visioninspection#technicalshorts#manufacturing industries#manufacturing business#manufacturing fallout 4#manufacturing videos#manufacturing business ideas in india#manufacturing intellect#manufacturing consent noam chomsky and the media#manufacturing consent audiobook

0 notes

Text

#AIVisionInspection#AI#ArtificialIntelligence#VisionInspection#QualityControl#MachineVision#Automation#Industry40#DataAnalytics#SmartManufacturing#ManufacturingInnovation#ComputerVision#InspectionTechnology#AIApplications#DigitalTransformation#QualityAssurance#TechTrends#PredictiveMaintenance#VisualInspection#InspectionSolutions

0 notes

Text

What is QMS Software for Medical Devices?

Quality Management Software (QMS) has become an essential tool in industries that require rigorous quality control, particularly in the medical device and pharmaceutical manufacturing sectors. As these industries operate in highly regulated environments, ensuring compliance with global standards is paramount. QMS software offers a digital solution that streamlines the management of quality processes, helping companies maintain consistent product quality, adhere to regulations, and reduce the risk of non-compliance.

In this article, we will explore the role of QMS software for medical devices, its features and benefits, and how it compares to QMS software for pharmaceutical manufacturing. Whether you're looking to implement a new system or upgrade an existing one, this guide will give you a comprehensive understanding of QMS software.

Why QMS Software is Crucial for Medical Device Manufacturers

Medical devices are directly linked to patient safety, so manufacturers must adhere to stringent quality control measures. Mistakes or non-compliance can lead to costly recalls, legal issues, or even patient harm. This is where QMS software for medical devices comes into play. It helps medical device companies establish, monitor, and maintain a standardized approach to quality management.

Ensuring Compliance

One of the primary reasons medical device manufacturers turn to QMS software is to ensure compliance with global regulatory standards, such as ISO 13485, FDA 21 CFR Part 820, and the EU Medical Device Regulation (MDR). QMS software automates and organizes compliance tasks, enabling manufacturers to track, document, and report on all quality processes.

Risk Management and Control

QMS software for medical devices incorporates risk management tools to identify, evaluate, and control risks throughout the product lifecycle. This includes the ability to perform Failure Mode and Effects Analysis (FMEA), track risk mitigation efforts, and ensure that quality-related risks are well-documented.

Streamlined Documentation and Records

Medical device manufacturers must maintain extensive documentation to support the safety and efficacy of their products. QMS software helps automate document control, ensuring that records are up-to-date, easy to access, and securely stored. With version control and audit trails, companies can easily manage document approvals, updates, and reviews, reducing the risk of errors.

Key Features of QMS Software for Medical Devices

Document Management System

Medical device companies must handle vast amounts of documentation, including design controls, risk management plans, and production data. A good QMS software provides a comprehensive document management system that ensures the right people have access to the right documents at the right time. It also provides real-time collaboration and centralized storage, enabling easy retrieval and audits.

Corrective and Preventive Actions (CAPA)

The Corrective and Preventive Action process is a core component of quality management in any regulated industry. QMS software automates CAPA processes, from identifying non-conformities to implementing corrective actions. It helps medical device companies track issues, analyze root causes, and take the necessary preventive steps to avoid future problems.

Supplier Quality Management

Ensuring the quality of materials and components provided by suppliers is crucial for medical device manufacturers. QMS software integrates supplier quality management tools that allow businesses to evaluate, approve, and monitor supplier performance. This feature also helps maintain supplier documentation and ensures that suppliers comply with regulatory requirements.

Audit Management

Regular internal and external audits are essential to maintain compliance with regulatory bodies. QMS software for medical devices simplifies audit management by automating the scheduling, execution, and documentation of audits. The system tracks findings, generates audit reports, and monitors corrective actions, ensuring continuous improvement.

How QMS Software Supports Compliance in the Medical Device Industry

For medical device companies, regulatory compliance is non-negotiable. QMS software plays a vital role in ensuring that organizations meet industry standards while reducing the administrative burden on quality teams.

ISO 13485 Compliance

ISO 13485 is the international standard for quality management systems in the medical device industry. QMS software is designed to help companies align their processes with ISO 13485 requirements. The software provides tools to manage design controls, risk assessments, and production processes, ensuring that all activities are documented and compliant with the standard.

FDA 21 CFR Part 820 Compliance

In the United States, medical device companies must comply with FDA 21 CFR Part 820, which sets the quality system regulations for medical device manufacturing. QMS software helps manage the necessary records, such as device history files, device master records, and quality audits, ensuring that companies are always ready for an FDA inspection.

The Differences Between QMS Software for Medical Devices and QMS Software for Pharmaceutical Manufacturing

While both industries require strict quality control, there are distinct differences in how QMS software is applied in medical device and pharmaceutical manufacturing environments.

Regulatory Focus

Medical device companies focus primarily on ISO 13485, FDA 21 CFR Part 820, and the EU MDR. Pharmaceutical manufacturers, on the other hand, must adhere to different sets of regulations, such as Good Manufacturing Practices (GMP), FDA 21 CFR Part 211, and the ICH guidelines. QMS software for pharmaceutical manufacturing often includes specific features to address these regulations.

Product Complexity

Medical devices can range from simple tools like scalpels to complex devices like pacemakers. QMS software for medical devices is designed to manage a diverse range of product designs, including design controls, risk management, and traceability. In pharmaceutical manufacturing, the focus is more on managing production batches, formulation control, and tracking product stability.

CAPA Processes

Both industries rely heavily on CAPA processes, but the types of corrective actions differ. For medical devices, the CAPA process may involve re-designing a product, updating software, or re-training employees. In pharmaceutical manufacturing, CAPA often focuses on process improvements, changes in raw materials, or adjustments to production parameters.

Benefits of Implementing QMS Software for Medical Devices

Improved Product Quality

By providing a structured approach to quality management, QMS software improves overall product quality. It helps companies detect potential issues early, allowing for swift corrective actions before products reach the market.

Increased Efficiency

Automation is one of the biggest advantages of QMS software. By automating tasks such as document management, CAPA, and audits, companies can reduce the time spent on manual processes, freeing up resources for other critical activities.

Reduced Risk of Non-Compliance

QMS software ensures that all quality processes are well-documented and up to date with the latest regulations. This reduces the risk of non-compliance, costly fines, or product recalls, which can have devastating effects on a company’s reputation and bottom line.

Enhanced Collaboration

In a global market, medical device manufacturers often work with teams across different locations. QMS software provides a centralized platform that enables real-time collaboration and ensures that everyone is working with the most current information.

Conclusion

QMS software is a crucial component for medical device manufacturers aiming to meet regulatory requirements, improve product quality, and ensure patient safety. By streamlining processes such as CAPA, document management, and supplier quality, QMS software provides a comprehensive solution that supports compliance and operational efficiency.

For companies looking to implement QMS software for pharmaceutical manufacturing, many of the same principles apply, though the specific regulatory focus and product complexities may differ. Both industries can greatly benefit from adopting a QMS software that aligns with their unique needs.

If you're a medical device manufacturer looking to improve your quality management system, investing in QMS software is a smart choice that can help you stay ahead in a competitive, highly regulated industry.

#quality management system#qualityassurance#biotechnology#qms#amplelogic#qualitycontrol#biotech#pharmaceutical industry#quality

0 notes

Text

Quick Tips on Electrogalvanizing.

https://www.noblemetalcoating.com/

#Electrogalvanizing#MetalCoating#CorrosionProtection#Electroplating#MetalFinishing#GalvanizingTips#SurfacePreparation#CoatingThickness#ChemicalBalance#Passivation#PlatingProcess#MetalCare#IndustrialCoating#QualityControl#MetalProtection#GalvanizedMetal#PlatingTips#DurableCoatings#ElectroplatingTips#MetalMaintenance

0 notes

Text

Hematology Analyzer 17 kg

Zimed Hematology Analyzer offers 3-part WBC differentiation and processes 60 samples/ hr. It analyzes 20 parameters with only 15μL whole blood. Features include an 8" LCD display, 16000 result storage, and precise results using Coulter Principle. Compact at 440×350×440 mm.

1 note

·

View note