#Quick turn PCB fabrication

Explore tagged Tumblr posts

Text

Trusted PCB Manufacturing Companies in India

Pcbcircuit is well-known fast-growing Pcb manufacturer in india. We are committed to excellence, sustainability, and customer satisfaction”. We strive to provide our customers with the highest quality and most reliable PCBs that can withstand rigorous applications.

#pcb fabrication#low-cost pcb manufacturer#flex pcb manufacturer#pcb manufacturer in haryana#quick turn pcb fabrication

2 notes

·

View notes

Text

Helpful Analysis of the Latest Printed Circuit Board Design Software

Navigating the ever-evolving landscape of PCB technology demands the right tools, especially when working with prototype circuit board projects that require precision and efficiency. Quick turn PCB fabrication plays a vital role in accelerating innovation and cutting down lead time, making modern design tools indispensable for engineers and developers.

Enhancing Accuracy Through Structured PCB Design

To streamline complex circuits and ensure optimal performance, structured design methods offer better control and consistency. These strategies are essential for professionals working on intricate PCB layout design or utilizing advanced printed circuit board design software to meet tight development cycles. From seamless design integration to real-time collaboration, today’s software solutions empower engineers to move from concept to final board faster. Bay Area Circuits supports innovation with services like high-quality prototype production and rapid assembly. Visit their website and explore their services.

For more reading, Visit here - https://67d7ed103fe91.site123.me/blog/helpful-analysis-of-the-latest-printed-circuit-board-design-software

#Quick turn PCB fabrication#prototype circuit board#PCB layout design#printed circuit board design software

0 notes

Text

PCB Assembly Precision and Performance For Every Project

A PCB assembly company in Hyderabad specializes in manufacturing and assembling printed circuit boards (PCBs) for various industries such as electronics, automotive, and telecommunications. These companies offer services including PCB design, prototyping, component sourcing, assembly, and testing, serving both small-scale and large-volume production needs.

#top 10 pcb manufacturer#pcb fabrication#quick turn pcb fabrication#pcb stencil#pcbcircuit#low-cost pcb manufacturer

0 notes

Text

Top PCB Manufacturer in India

PCBcircuit is a leading PCB manufacturer in India, offering high-quality printed circuit boards tailored to diverse industries. With advanced technology, precision engineering, and reliable customer support, we ensure efficient and cost-effective PCB solutions to power your innovations. Trust PCBcircuit for quality and excellence in PCB manufacturing.

#flex pcb manufacturer#prototype pcb manufacturing#pcb manufacturer#custom pcb manufacturing#low-cost pcb manufacturer#pcb fabrication#quick turn pcb fabrication#high-quality pcb manufacturing#multilayer pcb manufacturer

0 notes

Text

Best Pcb Manufacturer Company in Bombay

Looking for the best PCB manufacturer in Bombay? Pcbcircuit is your go-to choice, offering high-quality, reliable, and cost-effective PCB solutions. With state-of-the-art technology and a dedicated team of experts, We ensures precision, durability, and prompt delivery for all your electronic needs. Trust Pcbcircuit for unparalleled service and top-notch products in the industry.

#prototype pcb manufacturing#quick turn PCB fabrication#Best pcb stencil maker in hyderabad#Two layer pcb stencil#Pcb stencil#Pcb manufacturer in delhi#pcbcircuit

0 notes

Text

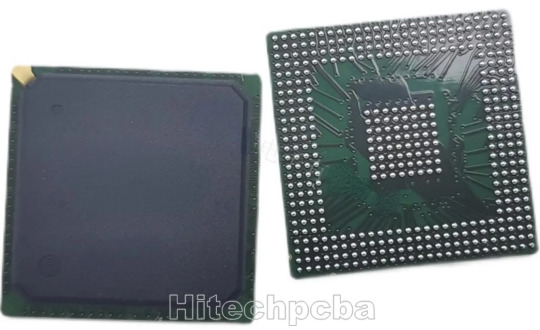

BGA PCB Assembly

What’s BGA PCB?

BGA PCB is Printed Circuit Boards with Ball Grid Array. We use various sophisticated techniques for making BGA PCBs. Such PCBs have a small size, low cost, and high packaging density. Hence, they are reliable for high-performance applications.

What’s BGA PCB Assembly?

Ball Grid Array (BGA) assembly technology is a surface mount packaging technology applied to integrated circuits, which is often used to permanently fix devices such as microprocessors. BGA assembly can accommodate more pins than other packages such as Dual in-line packages or Quad Flat Packages, and the entire bottom surface of the device can be used as pins , instead of only peripherals available, and also have a shorter average wire length than peripheral-limited package types for better high-speed performance.

Our BGA assembly services cover a wide range, including BGA prototype development, BGA PCB assembly, BGA component removal, BGA replacement, BGA rework and reballing, BGA PCB assembly inspection, and so on. Leveraging our full-coverage services, we can help customers streamline the supply network and accelerate product development time.

Benefits of BGA PCB Assembly

Efficient Use of Space – BGA PCB layout allows us to efficiently use the available space, so we can mount more components and manufacture lighter devices.

Better Thermal Performance – For BGA, the heat generated by the components is transferred directly through the ball. In addition, the large contact area improves heat dissipation, which prevents overheating of components and ensures long life.

Higher Electrical Conductivity – The path between the die and the circuit board is short, which results in better electrical conductivity. Moreover, there is no through-hole on the board, the whole circuit board is covered with solder balls and other components, so vacant spaces are reduced.

Easy to Assemble And Manage – Compared to other PCB assembly techniques, BGA is easier to assemble and manage as the solder balls are used directly to solder the package to the board.

Less Damage to Leads – We use solid solder balls for manufacturing BGA leads. Hence, there is a lesser risk that they will get damaged during the operation.

In a word, BGA PCB assembly, have these advantages, high density, better electrical conductivity, lower thermal resistance, easy to assembly & manage are some of the advantages of BGA PCB.

Stringent BGA PCB Assembly Testing Process

To achieve the highest quality standards for BGA assembly, we use a variety of inspection methods throughout the process including optical inspection, mechanical inspection, and X-ray inspection. Among them, the inspection of BGA solder joints must use X-rays. X-rays can pass through the components to inspect the solder joints below them, so as to check the solder joint position, solder joint radius, and solder joint thickness.

Inspection of BGA PCB

We mostly use X-ray inspection for analyzing the features of BGA PCBs. This technique is known as XRD in the industry and relies on X-rays for unveiling the hidden features of this PCB. This kind of inspection reveals.

* Solder Joint Position

* Solder Joint Radius

* Change in Circular shape

* Solder Joint Thickness

The Hitechpcba advantage lies in a whole range of aspects, beginning from the fact that we have the proven technology available at our disposal. With over 15 years of experience in a wide range of PCB Fabrication and Assembly techniques, what we also have is trained manpower and importantly, robust industry experience and best practices that you can benefit from.

Our unstinting devotion to quality and customer satisfaction means that once you partner with us, you can rest assured that you will get nothing but the best. The customer-oriented approach also shows up in your commitment to delivery times. With quick turnaround times, you can reap the benefit of quick time-to-market, which, in turn, can be a major source of competitive advantage.

Whether your requirement is BGA PCB design, BGA PCB, BGA PCB layout, BGA PCB Assembly or BGA rework, you can rest assured that you will get superior quality and performance, that will in turn, positively impact the performance of your final product.

With our efficient network of component suppliers and the many economies of scale that we enjoy, that you will get optimal costs, is a given.

Please feel free to contact us ([email protected]) if you have any other special request on the BGA pcb assembly.

3 notes

·

View notes

Text

Accelerate Innovation with Custom Rigid-Flex PCB Solutions from XPCB Ltd

Our quick-turn manufacturing capabilities are particularly valuable for industries where speed and precision are vital. With our advanced fabrication technologies, we can produce complex rigid-flex PCBs quickly—without sacrificing durability or electrical performance.

0 notes

Text

Understanding PCB Fabrication Companies: The Backbone of Modern Electronics

Printed Circuit Boards (PCBs) are the unsung heroes behind every electronic device we use today. From smartphones and smartwatches to industrial machines and aerospace systems, PCBs make electronic functionality possible. But before any device reaches your hands, it all begins at a PCB fabrication company—the specialized manufacturers responsible for creating the physical board that powers modern technology.

In this article, we’ll explore what PCB fabrication companies do, why they’re essential, and how to choose the right one for your project.

What Does a PCB Fabrication Company Do?

A PCB fabrication company is dedicated to producing the physical printed circuit boards used in electronic devices. These companies focus solely on manufacturing the board structure—copper layers, insulating substrates, vias, and surface finishes—before any electronic components are mounted.

Key steps in PCB fabrication include:

Design file analysis and preparation

Copper pattern etching

Drilling holes and vias

Applying solder mask and silkscreen

Surface finishing (ENIG, HASL, etc.)

Electrical testing for continuity and shorts

These processes require high-end machinery, cleanroom environments, and precise engineering expertise to ensure every board meets the required performance standards.

Importance of PCB Fabrication in Electronics Manufacturing

PCB fabrication is a critical phase in electronics manufacturing. Without a reliable board, even the most advanced components can’t function properly. A well-fabricated PCB ensures durability, performance, and compliance across various applications.

Here's why PCB fabrication companies are so important:

Enable compact and lightweight designs

Support multilayer and high-density circuits

Ensure electrical reliability and heat management

Allow mass customization and quick prototyping

Comply with strict industry standards (IPC, ISO, RoHS)

Services Offered by PCB Fabrication Companies

While core PCB manufacturing is the primary service, leading fabrication companies also offer value-added solutions to simplify the product development lifecycle.

Typical services include:

Prototype to mass production

Multilayer PCB fabrication (up to 40+ layers)

Rigid, flexible, and rigid-flex PCB production

High-frequency and HDI PCB capabilities

Lead-free and RoHS-compliant fabrication

Design for Manufacturability (DFM) support

Impedance control and surface finish customization

These services help customers streamline their design-to-production process and improve time-to-market.

Industries That Rely on PCB Fabricators

PCB fabrication companies cater to a wide range of industries, each with unique technical requirements:

Consumer Electronics – Smartphones, tablets, wearables

Automotive – Engine control units, ADAS, EV batteries

Medical Devices – Diagnostic tools, monitoring equipment

Telecom – Routers, 5G infrastructure, network devices

Aerospace & Defense – Navigation, radar, satellite systems

Industrial Automation – PLCs, controllers, IoT systems

Whether it’s high-frequency performance or thermal durability, different sectors demand tailored fabrication capabilities.

How to Select the Right PCB Fabrication Company

Choosing the right PCB fabrication company in India is critical to product quality, lead time, and cost. Here’s what to look for:

Certifications – ISO 9001, IPC-6012, RoHS, IATF 16949

Technology Capabilities – Multilayer, HDI, flexible PCBs

Quality Assurance – Electrical testing, AOI, X-ray inspection

Engineering Support – DFM analysis, CAD-to-CAM processing

Lead Time – Quick-turn prototyping and on-time delivery

Cost Efficiency – Transparent pricing and scalable production

Customer Reviews – Testimonials and case studies

Partnering with the right company ensures your boards are reliable, cost-effective, and delivered on time.

Leading PCB Fabrication Companies

Here are some reputable names in the global and Indian PCB manufacturing landscape:

Global Leaders

TTM Technologies (USA)

Unimicron Technology (Taiwan)

AT&S (Austria)

Zhen Ding Tech (China)

Top PCB Fabrication Companies in India

AT&S India (Nanjangud)

CIPSA-TEC India Pvt. Ltd. (Bangalore)

Shogini Technoarts (Pune)

Meena Circuits Pvt. Ltd. (Gujarat)

Genus Electrotech Ltd. (Gandhinagar)

These companies are known for their advanced manufacturing capabilities, global delivery networks, and strict quality controls.

Growth of PCB Fabrication in India

India is rapidly becoming a global hub for electronics manufacturing, and PCB fabrication companies in India are rising to meet demand.

Key growth drivers include:

Make in India and Digital India initiatives

PLI (Production Linked Incentive) scheme

Growing demand from EVs, smartphones, and IoT sectors

Investment in semiconductor and ESDM ecosystems

With increasing local and global investment, Indian PCB manufacturers are scaling operations and adopting advanced technologies like automation and AI in fabrication processes.

✅ Conclusion

PCB fabrication companies form the backbone of the electronics industry. Their ability to produce high-quality, precision-engineered circuit boards directly impacts the performance, safety, and reliability of electronic products.

Whether you’re developing a consumer gadget or an aerospace control system, partnering with the right PCB fabrication company is vital. Look for proven expertise, robust infrastructure, and strong customer support.

0 notes

Text

The Importance of Precision PCB Prototyping Tools and Router Bits for LPKF and T-Tech Systems

In the fast-paced world of electronics design, rapid prototyping is crucial for turning ideas into functional products. Whether you’re developing consumer electronics, medical devices, or aerospace systems, having the right tools for PCB prototyping can significantly impact turnaround times and product quality. This is where specialized PCB prototyping tools for LPKF T Tech systems and precision PCB router bits come into play.

Why PCB Prototyping Matters

Before full-scale production, electronic engineers rely on prototyping to test circuits, validate designs, and troubleshoot issues. Quick in-house PCB fabrication allows designers to make rapid iterations without the long lead times of outsourced manufacturing.

Machines from brands like LPKF and T-Tech are industry standards for PCB prototyping. They provide desktop-sized milling and routing systems capable of producing high-quality PCBs within hours. However, the quality of the output heavily depends on using the right tools—specifically, reliable router bits, drills, and engraving tools designed for precision PCB work.

Essential PCB Prototyping Tools for LPKF and T-Tech

Prototyping PCBs isn’t just about having a milling machine—it’s also about using the correct accessories that match the unique requirements of circuit board materials. The most common PCB prototyping tools for LPKF T Tech systems include:

Micro Drill Bits: For creating accurate vias and component holes as small as 0.005 inches.

PCB Router Bits: For cutting board outlines, internal slots, and mechanical features with precision.

End Mills: Used for milling traces, removing copper, and cutting isolation paths between signal lines.

V-Engraving Bits: Ideal for fine trace isolation where ultra-narrow gaps are needed.

Surface Planing Bits: To ensure perfectly flat surfaces on copper clad substrates before milling.

These tools are typically designed with a 1/8” (3.175mm) shank to fit standard collets on LPKF, T-Tech, MITS, and AccurateCNC systems.

The Role of PCB Router Bits in Prototyping

When it comes to shaping circuit boards, PCB router bits are indispensable. They are specifically engineered to handle materials like FR-4, polyimide, or PTFE-based laminates without causing delamination, burning, or excessive burrs.

High-quality router bits feature:

Optimized Flute Geometry: For smooth chip evacuation and reduced tool wear.

Diamond Cut or Chipbreaker Styles: Depending on whether the priority is ultra-smooth edges (diamond cut) or faster chip removal (chipbreaker).

Durable Carbide Construction: To withstand the abrasive nature of fiberglass-reinforced PCB laminates.

Upcut or Downcut Designs: Upcut bits remove chips from the surface, while downcut bits push chips downwards, providing cleaner top edges, especially useful when cutting thin substrates.

How the Right Tools Enhance Prototyping Efficiency

Choosing the right PCB prototyping tools for LPKF T Tech offers several benefits:

Faster Turnaround: High-precision drills and router bits reduce errors and rework.

Improved Edge Quality: Reduces the need for post-processing such as sanding or deburring.

Accurate Hole Placement: Essential for multilayer designs where vias must align perfectly.

Material Compatibility: Whether using FR-4, Rogers, or flexible substrates, the right bit ensures clean cuts without damage.

Longer Tool Life: High-quality carbide tools maintain sharpness, reducing downtime for tool changes.

Applications Across Industries

From startup makers to large R&D departments, companies rely on PCB prototyping tools for LPKF T Tech to develop:

IoT devices

Medical diagnostic equipment

Wearable electronics

Automotive control systems

Aerospace navigation units

The combination of precise router bits and reliable CNC systems allows designers to go from schematic to working board in a matter of hours instead of weeks.

Conclusion

For any electronics engineer or manufacturer involved in circuit design, investing in high-quality PCB prototyping tools for LPKF T Tech and durable PCB router bits isn’t just a convenience—it’s a necessity. The right tools ensure that prototypes are reliable, precise, and production-ready.

By leveraging precision router bits and specialized tooling, engineers can streamline their development cycles, reduce costs, and accelerate time to market. Whether you’re producing a single prototype or iterating multiple design revisions, quality tooling is the foundation of successful PCB fabrication.

0 notes

Text

Common Printed Circuit Boards in New Energy Vehicles

As new energy vehicles handle high voltage and current, various PCB types are utilized to conduct and control electricity safely across functions:

Multi-layer PCBs 6-12+ layer boards employ complex internal circuitry to precisely transmit signals and power between electronic modules. More layers enable more robust connectivity.

Thick Copper PCBs Ultra-thick 2oz, 3oz and even 4oz copper reliably channels currents up to 400A+, applied for motor control and power conversion requiring stable high ampacity traces.

HDI PCBs High-density interconnect technology with microscopic vias and dense circuitry allows integrating more functionality and components in confined control units, saving space and weight.

Large-area PCBs Sprawling PCBs powering functions like body electronics and chassis controls enable more consolidated layouts and simplified connectivity.

At Hitech Circuits, we are a premier PCB manufacturer providing one-stop PCB fabrication and assembly services to meet the diverse needs across multiple industries. With years of experience and cutting-edge capabilities, we deliver high-quality, quick-turn PCB solutions tailored to each application’s unique requirements.

Our Core Expertise:

Wide range of PCB technologies: HDI, rigid-flex, RF/microwave, thermal boards, and more Advanced manufacturing processes: high-density interconnect, buried/blind vias and more Fast prototype to production cycle times Strong engineering support from quote to delivery High-reliability PCBs for demanding applications

Whether you need prototypes for new product development or high-volume PCB production, Hitech Circuits is your trusted partner.

1 note

·

View note

Text

Flexible PCB Manufacturer - Custom Solutions for Innovative Electronics

We specialize in designing and manufacturing high-quality flexible pcb manufacture (PCBs) tailored to meet the demands of diverse industries. Our expertise in flexible circuit technology enables us to produce durable, reliable, and compact PCBs for applications ranging from consumer electronics to medical devices, automotive, and more. With precision engineering, fast turnaround times, and advanced manufacturing processes, we provide customized solutions that drive innovation in your electronic products.

#best pcb manufacturer#flex pcb manufacturer#multilayer pcb manufacturer#pcb manufacturer in haryana#low-cost pcb manufacturer#pcb manufacturer#pcb manufacturer in delhi#quick turn pcb fabrication#pcb manufacturer in maharashtra#pcb manufacturer near me

0 notes

Text

Reliable PCB Solutions: Fast Prototyping & Quick Turn Fabrication

Bringing electronic designs to life requires precision and speed, and quick-turn PCB fabrication plays a key role in making that happen. Whether you need a single board or a full production run, having a reliable manufacturing partner ensures high-quality results with faster turnaround times. Advanced fabrication techniques streamline the process, making it easier to meet project deadlines without compromising on performance.

For product development, a well-crafted prototype circuit board is crucial to testing functionality before full-scale production. With accurate prototyping, engineers can refine designs, identify potential issues, and optimize performance. Working with a trusted manufacturer simplifies the process, providing efficiency from concept to completion.Beyond fabrication, professional PCB assembly services take your boards from bare circuits to fully functional components. From precise component placement to thorough quality checks, expert assembly ensures reliability in every board. Get the best solutions for your PCB needs—start your order today!

#pcb manufacturing company#quick turn pcb fabrication#pcb prototype service#full turn key pcb#pcb prototype manufacturer

0 notes

Text

India's Best Custom PCB Manufacturer - Pcbcircuit

We specialize in delivering high-quality, precision-engineered PCBs tailored to your exact specifications. From concept to final product, our team ensures top-notch reliability and innovation at every stage. Trust us to power up your electronics with industry-leading PCB solutions! Best PCB manufacturers are known for their experience, customer support, and ability to scale production based on project requirements.

#top 10 pcb manufacturer#pcb fabrication#quick turn pcb fabrication#pcb stencil#pcbcircuit#low-cost pcb manufacturer

0 notes

Text

Choosing The High-quality PCB Manufacturing in India

Pcbcircuit is a High-quality PCB manufacturing service in India. We offer precision-engineered printed circuit boards tailored to meet diverse industry needs. Ensure reliability, durability, and efficiency in your electronic projects by choosing our high-quality PCBs, designed to exceed global standards. Perfect for innovation-driven businesses.

#custom pcb manufacturing#pcb manufacturer#flex pcb manufacturer#low-cost pcb manufacturer#quick turn pcb fabrication#high-quality pcb manufacturing#pcb fabrication#prototype pcb manufacturing#multilayer pcb manufacturer

0 notes

Text

What Are PCB Prototypes and How Do They Accelerate Your Electronic Designs?

In the fast-paced world of gadgets, turning an thought into a completely utilitarian item requires exactness, speed, and unwavering quality. One of the most pivotal steps in this improvement travel is making a PCB prototype. A PCB prototype is basically a preparatory adaptation of a printed circuit board utilized to test and approve the plan some time recently mass generation. It permits architects and engineers to distinguish mistakes, assess execution, and make vital alterations early in the advancement process.

A Circuit Board Prototype is ordinarily fabricated in little amounts and can run from a basic single-layer board to a more complex multi-layer plan. The essential reason of a proto PCB is to simulate the last item as closely as conceivable, empowering exhaustive testing of the circuit's usefulness, format, and plan astuteness. With a prototype in hand, engineers can physically connected with the plan, making it much less demanding to identify imperfections or wasteful aspects that might not be apparent in a advanced simulation.

One of the key focal points of utilizing a PCB Prototype is its capacity to quicken the electronic plan prepare. In conventional workflows, moving specifically from plan to generation can lead to exorbitant botches, particularly if the board has plan imperfections or component misplacements. Be that as it may, prototyping bridges that hole by advertising a low-risk stage for experimentation and refinement. Architects can test numerous arrangements, attempt out distinctive components, and make iterative improvements—all sometime recently committing to full-scale manufacturing.

Moreover, utilizing a circuit board prototype decreases the time and fetched related with item improvement. It permits for fast investigating, empowering engineers to settle issues early when changes are less costly and simpler to actualize. This not as it were speeds up the advancement cycle but moreover guarantees higher item quality and execution. In competitive markets where time-to-market is basic, this can make a critical contrast in a product's success.

Another advantage of a Proto PCB is made strides communication and collaboration among groups. A physical prototype serves as a substantial reference point for talks between originators, engineers, and partners. It improves clarity, makes a difference adjust desires, and encourages superior decision-making all through the plan process.

Thanks to headways in PCB manufacturing innovation, making a PCB prototype is quicker and more available than ever. Numerous producers presently offer quick-turn administrations that provide high-quality prototypes in fair a few days. This speed permits groups to repeat rapidly, refine their plans, and bring items to advertise faster.

In conclusion, PCB prototypes are an basic apparatus in advanced electronic plan. They offer a commonsense and proficient way to approve, test, and refine your thoughts, eventually decreasing advancement costs and quickening time-to-market. Whether you're a start-up working on an inventive item or an built up company creating the another huge thing, leveraging circuit board prototypes and proto PCBs can allow your plan handle the dexterity and accuracy it needs to succeed.

0 notes

Text

Top 15 PCB Board Manufacturers in USA

When it comes to building reliable electronics, choosing the right PCB board manufacturer in USA is critical. Whether you’re a startup, engineer, OEM, or tech company, having a dependable partner for printed circuit board fabrication and assembly ensures faster production, fewer errors, and better results.

In this blog, we list the Top 15 PCB board manufacturers in the USA known for high-quality PCB fabrication, assembly, and fast delivery. These companies are widely searched and trusted across various industries — from medical to aerospace, IoT, automotive, and industrial applications.

1. PCB Power

PCB Power is one of the most trusted names among PCB board manufacturers USA. With over two decades of industry experience, PCB Power offers quick-turn PCB fabrication, full turnkey assembly, and components sourcing — all under one roof.

As a USA-based PCB company, they focus on delivering high-quality single, double, and multilayer PCBs with fast turnaround and competitive pricing. Whether you’re building prototypes or mass production, PCB Power’s online ordering system makes it easy to get instant quotes, track orders, and communicate with real engineers.

Key Features:

US-based production for fast and reliable delivery

ISO-certified processes for superior quality

Advanced manufacturing for high-density, multilayer PCBs

Turnkey assembly and BOM handling

Expert support for startups, engineers, and OEMs

If you’re looking for a complete PCB manufacturing solution in the USA, PCB Power should be your first stop.

2. Advanced Circuits

Advanced Circuits is one of the largest and oldest PCB manufacturers in the United States. Known for high-quality prototypes and low-to-medium volume production, they serve industries like aerospace, defense, and telecom.

They offer same-day and next-day shipping options and have their own in-house manufacturing for consistent quality.

3. Sierra Circuits

Sierra Circuits is a full-service PCB company specializing in quick-turn fabrication and assembly. They’re well-known for their high-performance HDI PCBs, rigid-flex boards, and support for complex designs. Sierra Circuits is ideal for companies looking for technical precision and tight tolerances.

4. Sunstone Circuits

Sunstone Circuits has built a reputation for delivering reliable prototype PCBs and small-batch orders. Their online design tools and instant quote system are ideal for hobbyists, startups, and small engineering teams. Their US-based manufacturing ensures high quality and fast shipping.

5. Bay Area Circuits

Located in California, Bay Area Circuits serves the Silicon Valley tech community with rapid prototyping, fabrication, and assembly services. They are experts in small-run production and serve various industries including medical, aerospace, and communications.

6. Rush PCB Inc.

Rush PCB Inc. offers full turnkey PCB services, including design, manufacturing, and assembly. They specialize in multilayer, flex, and rigid-flex PCBs with quick-turn options. Their experienced team supports everything from prototypes to volume production.

7. Custom Circuit Boards

Based in Arizona, Custom Circuit Boards provides high-quality PCBs for engineers and hardware startups. They focus on fast production and specialize in multilayer boards, thick copper PCBs, and RF designs.

8. Imagineering Inc.

Imagineering Inc. offers both PCB fabrication and assembly with ISO 9001 and AS9100 certifications. They serve demanding industries like medical and aerospace and are known for excellent quality and fast lead times.

9. Epec Engineered Technologies

Epec is a full-service provider offering custom PCB manufacturing, flexible circuits, and battery packs. With decades of experience, they provide engineered solutions for complex applications and tight deadlines.

10. APCT Inc.

APCT is known for high-speed, high-density interconnect PCBs. They support quick-turn and production-scale manufacturing. Their specialties include aerospace and defense-grade boards with rigorous quality requirements.

11. OnBoard Circuits

OnBoard Circuits offers affordable PCB prototyping, fabrication, and assembly with domestic and offshore capabilities. They are known for great customer support and fast delivery for small to medium volume orders.

12. Millennium Circuits Limited (MCL)

MCL provides reliable PCBs including rigid, flex, and rigid-flex boards. They serve industries like telecom, industrial, and medical, offering fast turnaround times and excellent pricing.

13. TechnoTronix

TechnoTronix offers advanced PCB manufacturing and assembly solutions with a strong focus on precision and fast lead times. They work with both small businesses and large enterprises, offering everything from basic to complex PCB designs.

14. RedBoard Circuits

RedBoard Circuits provides quality PCBs with a focus on customer service and quick delivery. They offer a wide range of PCB types including FR4, aluminum, and Rogers materials.

15. ALLPCB USA

ALLPCB USA offers cost-effective PCB solutions with a quick-turn focus. They provide both prototype and production runs and serve customers looking for affordable yet reliable circuit boards.

Choose the Best PCB Manufacturer for Your Needs

Selecting the right PCB board manufacturer in USA can be the difference between a successful project and costly delays. Whether you need fast prototyping, volume production, or full turnkey PCB assembly, each of these top 15 manufacturers brings something unique to the table.

However, if you’re looking for a complete solution with fast delivery, reliable quality, and competitive pricing — PCB Power is a clear leader. With US-based manufacturing, expert support, and a user-friendly online ordering platform, PCB Power makes your PCB journey seamless from design to delivery.

0 notes