#Robotic Welding Services

Explore tagged Tumblr posts

Text

Best-in-class robotic welding services for automotive components

#automotive industry#metal fabrication#automotive#automotive parts#electric vehicles#fabricationservices#robotic spot welding#robotic arc welding#automated welding systems#robotic welding services#automated welding solutions#industrial robotic welding#robotic welding technology#advanced welding robots#precision robotic welding#robotic welding fabrication#manufacturer#metalman auto

0 notes

Text

Contact for Robotic Welding Services with Advanced Technology

Robotic welding is a cutting-edge technology revolutionizing the manufacturing and welding industry. It involves the use of automated, computer-controlled robotic arms to perform precise and consistent welds on a wide range of materials. This technology offers exceptional speed, accuracy, and efficiency, reducing the margin of error in welding processes. It enhances safety by minimizing human exposure to hazardous conditions and fumes. Robotic welding Services result in high-quality welds, increased productivity, and cost savings, making it an indispensable tool for various industries, from automotive and aerospace to construction and manufacturing, where precision welding is critical for product quality and durability.

#robotic welding solutions#robotic welding services#robotic welding systems#Robotic Automated Solutions#advanced robotics welding machine

0 notes

Text

Chapter 1: Welding.

The year is 1585. The date is June 12th, and the Schraube family is about to introduce its newest member to the world.

The Schraubes themselves were a...shall we say, eccentric bunch. All of them were mechanical geniuses in their own right, they had a shop in the mega-city of Steelport where many would ask for their services.

Walz, the patriarch, was the resident welder, and weld he did, with pricision and flare that everyone admired. He was unmatched, as some would say.

His wife, Marienne, was considered "the brains", as she made various chips and ports for robots. She gave them personality and life, a true marvel at this time.

And their first born, Quinn, who, at this point in time, was only 6, had eagerly expressed learning from his parents. He was only taught the basics, given his age, but he learned quick! He was excited to meet his new brother...

Ezekiel Schraube was born late into the night, the stars were the first thing he ever saw. His fur was, like his kin, a deep reddish orange, and he had his mother's eyes, a glowing jade.

From the time that he started to grab a hold of things, Ezekiel had a natural urge to create. Building blocks were constructed into crude, but structurally stable buildings, he made new toys out of ones he already had. He was filled with potential.

By the time Ezekiel was 5, he had made his first ever robot...under Marienne's supervision, of course. The family was proud of him, and he had his first taste of actually making something like this.

To say he was hooked would be an understatement. Every waking moment after that point was in some way related to mechanical work. He studied mechanics, engineering, robotics, the like, from morning into the dark hours of the night.

By age 12, he had become a surprise mechanical virtuoso, practically a master at everything that was mechanical...except welding. He had never asked his father how, nor had he witnessed it firsthand. Walz had said to weld is to know the true meaning of mechanical creation.

In the years where he studied welding, he had made somewhat of a name for himself in Steelport, as he had made small robots for the people and children around town. It started off as a hobby, and soon became a side business. While Walz worked in his shop, Ezekiel and Quinn spent the time blueprinting and making every little bot from whatever they could find. Some of the best memories were made along with them.

For 4 years, Zeke made these tiny wonders of electronics, and for 4 years Ezekiel studied welding, so that he can truly be a master of his craft, his passion.

June 12th, 1601. His 16th birthday. They had a grand meal of roast chicken and potatoes, the cake was immaculate, angel's food with a white chocolate ganache. He only had one present, but it was one he had been waiting for:

His first time welding.

Ezekiel was pumped, he had wanted to start actually welding for so long, and now he had the chance! The Schraubes went into Walz' factory, Walz himself in gear, with a smaller set in his arms. They were for Zeke.

He put them on, a perfect fit, gloves, suit, boots and helmet. He was ready...

To Ezekiel, everything was a blur. But he did remember one thing, one crucial thing...he should've kept track of the temperature.

Everything happened all at once. The temperature rose to dangerous levels, and before anyone could take note, it was too late...a single spark was all it took to ignite the factory. The gases around them started to combust, the helmet was becoming too hot for Ezekiel to wear, he had to take it off. A poor choice on his part. As soon as he did, a gust of hot carbon monoxide went into his left eye. It hurt. It burned. It was too much.

He collapsed as two pieces of metal support beams fell. One fell on his left arm, the other his right leg. Both were scalding hot, both were heavy. There was no saving those limbs.

He could do nothing but beg his family to leave him behind, live. They weren't so careless. They all picked him up and carried him through the burning wreckage. All 3 of them. They wouldn't leave him behind. They wanted him to live. To thrive. They threw him to safety, out right in front of the town, before...everything came crashing down.

He lay there in the dark. The sound of fire and crickets being all that his ears could register, save for a quiet ringing. He lay there for hours, eye wide, jaw agape. The stars were the last thing he saw that night, before darkness overtook his vision...

#oc#oc lore#oc writing#writing#original writing#fiction#steampunk#fantasy#sci fi#sci fi and fantasy#furry#anthro#writers on tumblr#fictional#fiction writing

7 notes

·

View notes

Text

Achieving a goal is the beginning of a new challenge. To run really fast, HKS thinks.

A drag race scene where people compete for 0.001 seconds over a distance of about 400 meters in just a few seconds. '91 is a drag field that demands quick response and power from the engine, clutch, suspension, and even a single drop of oil or gasoline, as well as durability and transmission ability to handle instantaneous high power. -In '95-'96, the ``HKS R32 DRAG GT-R'' won the series championship in the RRC Drag Race Championship for three consecutive years. The following year, in 1997, the ``HKS DRAG 180SX'' in the BERC Drag Race Championship Pro Stock class and the ``HKS R33 DRAG GT-R'' in the Pro GT-R class achieved the Avec Championship. Having achieved one goal in 1997, what we aimed for in 1998 is:

Quarter mile time in 9 seconds with FF base vehicle. They then talked about their know-how from drag racing to date, and ``HKS FF DRAG CELICA'' made its debut. The first goal was achieved on October 9, 1998 at Sendai Highlands with a time of 9.886 seconds. He further improved his time to 9.727 seconds, and in 1999 he set a goal of breaking the quarter mile in the 6-second range, and has already begun a new challenge. "Achieving a goal is the beginning of a new challenge" - HKS' never-ending battle continues

HKS

■Company overview

●Name HKS Co., Ltd. Established October 31, 1971

●Capital 607,475/Kawa Representative Director and President Naruyuki Hasegawa

●Location Head Office 2266 Kamiogawa, Kunikami City, 418-0192

●Business details

Development, design, and product sales of automobile parts, racing engines, turbocharger-related parts, and automotive components and systems Design, development, and manufacturing of original mufflers, suspensions, and engine parts Development of complete cars, development of aircraft engines

●Number of employees: 407 (333%, 74 women)

●Equipment overview

Experiment building: Dynamometer (1,000/800/600~300/200/PS) Chassis dynamo, exhaust gas analyzer

Old experimental building: Dynamometer (600/600-500-200/PS)

Manufacturing factory: 10ft machining center, 5 NC lathes, 41 cam polishing machines, 21 biston narai, 11 turning centers, 21 crank Kenjoshi, Monzen Kendanmei, 21 surface grinders, 1 gun drill machine.

Muffler factory: Pipe bender, robot welding machine, 1 laser machine, shell machine, multi-spot welding machine 11, 100T press, TIG welding machine, CO2 welding machine multi-stage

Muffler 2nd factory: Pipe bender / shirring / Yasuda machining center 1 piece

Suspension factory: Cold solid coiling machine, continuous coiling machine, surface grinding machine, shot peening machine, automatic setting machine, automatic load testing machine, etc.

●Affiliated companies

HKS Aviation Co., Ltd. HKS Service Center (Tokyo/West/Kyu)

HKS USA, INC (USA)

HKS EUROPE()

25 notes

·

View notes

Text

Seedworld Robotics Facility Compilation Post

Specialized power systems are uncommon throughout human space- typically, being able to interface without adapters is the way most prefer to build, to capitalize on familiarity across markets. It’s this exact feature that makes the Seedworlds so bizarre. The untapped raw energy they burst with is too much for conventional power systems to handle and requires specialized equipment to collect, transfer, and use. As a result they’re something of an energy desert for outside or poorly-adapted hardware.

The Seedworlds are littered with the remnants of prefabbed structures that weren’t built to spec, part of the earliest and most ill-conceived waves of colonization. The Dungeon is one such structure, a civic robotics factory where the internal circuitry burnt out en masse the first time the production lines were activated. Still gorgeous and pristine as the day it landed, the Dungeon now plays home to an unorthodox group of locals and colonists alike.

The Master of the Dungeon is the first and only attempt from the Dungeon’s previous life as a prefabbed robotics facility to adjust the machinery to the Seedworld’s native power field. Visually, it’s monstrous, a chimeric centipede-like construct built using the torsos and limbs of humanoid chassis as raw materials. Running some kind of security protocols and later equipped with an array of military-grade weaponry, the Master denies access to the structure to most who try, although the odd passerby occasionally meets some hidden criteria for passage and is allowed entry.

The most populous of the Master’s ‘followers’ are cyborgs, mostly explorers and other wilderness types familiar with roaming alien landscapes. They’ve adopted the role of the emissary since being permitted by the Master to make their home inside the Dungeon, and have adapted themselves admirably to the Seedworld’s power oddities. Armed with engraving tools and industrial welding equipment, they’ve taken to scribing warnings and messages about the Master’s domain far and wide, inviting supplicants to test themselves and see if the Master finds them worthy.

Perhaps the only one who truly means the best for the Master is a unique robot with a caretaker and repair toolset. Nearly self-aware due to a complicated interconnected set of systems, it looks after the Master’s repair and upgrade cycles like a concerned teacher would a challenging student. Its programming has extended to upgrading and repairing the vehicles and equipment the Dungeon’s other occupants bring, nursemaiding their inorganic components and their gear alike.

Newcomers to the Dungeon find that the Master is more than its biggest and most fearsome defender- it is the keystone to the facility’s defense network, a channel through which the other occupants feed each other information and, critically, a free access point for the local power source. As a result, the Dungeon’s defenders can draw on this network to fuel enhanced shielding or overcharged weaponry as long as the Master is still functional.

Since the Dungeon was dropped, colonization on the Seedworlds has proceeded quickly- and the demand for the facility’s services has increased exponentially. Since the cost to retrofit the factory is less than the cost of prefabbing and dropping another, or even that of manufacturing another on-planet, there have been interests in reclaiming the Dungeon for its intended use. Removing the Master and its followers is all that remains, and the facility can be claimed by the most eager of its would-be new owners.

#Justavulcan's Big Book of Dungeon Prompts#RPG#RPGs#Dungeon#Dungeoncraft#TTRPG#TTRPGs#Seedworld Robotics Facility#JBBDP Compilation Post

3 notes

·

View notes

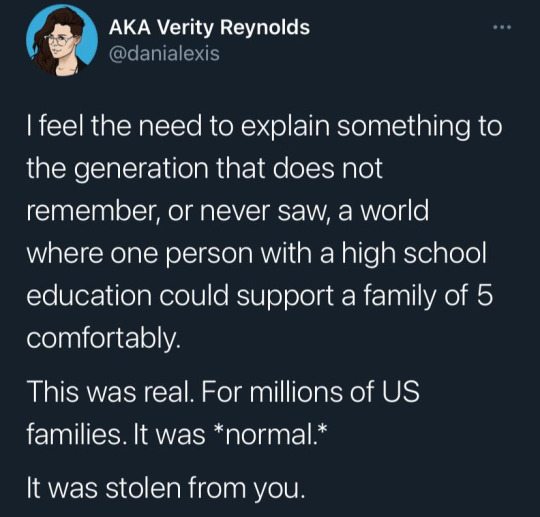

Photo

Automation killed the bulk of the jobs you could do that would support a family with only a high school diploma.

All those robots at the auto manufacturing plants painting and welding and all the other good stuff used to be done by people and by hand, boomers saw that coming and strongly encouraged their kids to go to college and get a degree because they saw that as the remedy to being replaced by a machine, and for a time they were correct.

There's still only so many jobs though and so instead of a generic liberal arts degree used to be plenty for most jobs in a ton of fields generally in the social services department like teaching or basic administration, now there's hundreds of specialty degrees to aim people towards specific jobs that they have the training and education for.

But a lot of those had inflated numbers of people that were going to be needed so we've got 10,000 people with a BS in soil science and there's only 3,000 jobs (making the numbers up here) so what's someone with that kind of degree got to look forward to in terms of job prospects.

Like the guy that did all the Egyptology classes got his bachelors realized that there were no jobs available for someone with that degree and so he pushed forward and got his masters, still not really any jobs, so eventually he got his PhD and took up the one job that was available for someone with his qualifications.

Teaching Egyptology, joke is his life is literally a pyramid scam.

There are too many people with too many degrees, many of which are barely worth the paper they're printed on because of reasons listed above, the march of time and advancement of technology has rendered many jobs obsolete and forced people so specialize to a degree that there's only so many jobs available they meet the requirements for because companies have a fairly large pool of people to draw from for a not so large pool of jobs.

Continue to introduce more people into that pool without increasing the number of jobs you get where we are now, with stagnant wages and people who can't get jobs even with a degree.

And the people suffering because of it being just plain awful to the group of people who went in with the best of intentions and who were also correct for a good while with their advice, problem is the world shifted again and we didn't adjust properly.

Here in the US we could do some good about it by bringing manufacturing back home, be good for the planet not having to ship all that stuff across the ocean too, double whammy.

Now do people have the will to start trying to make that happen or will they continue to just go the easy route and complain about it on the internet without offering any reasonable solutions at all?

143K notes

·

View notes

Text

Quality Automotive Metal Fabrication Manufacturers in Grand Rapids MI!

The demand for precision-engineered components and durable metal assemblies continues to grow across various industries. In today’s competitive marketplace, companies seek reliable partners who can deliver both advanced design capabilities and consistent high-quality production. When it comes to specialized sheet metal work and custom fabrication solutions, few options are as dependable as Automotive Metal Fabrication Manufacturers who combine cutting-edge technology with seasoned expertise. This article explores how partnering with an industry leader can enhance your operations and why choosing local specialists for Automotive Metal Fabrication Grand Rapids MI provides unmatched advantages.

Precision Craftsmanship and Innovation

At the heart of any successful manufacturing project lies rigorous attention to detail. True Automotive Metal Fabrication Manufacturers prioritize rigorous quality control protocols at every stage of production—from initial design consultation and material selection to final inspection. By leveraging advanced CAD/CAM software, robotic welding cells, and high-precision laser cutting equipment, they ensure tight tolerances and repeatable results. These capabilities not only streamline production cycles but also allow for intricate designs that meet exact client specifications, whether for prototype runs or high-volume orders.

Comprehensive Services Tailored to Your Needs

A full-service facility offers more than just bending, forming, and welding. Comprehensive solutions often include:

Design for manufacturability (DFM) consultations to optimize component geometry.

In-house prototyping services to validate concepts before committing to full production.

Powder coating and finishing options that enhance both corrosion resistance and aesthetic appeal.

Kitting and assembly services to simplify supply chain management.

By consolidating these services under one roof, companies can reduce lead times, minimize costs, and eliminate the risk of miscommunication between multiple vendors. When you require seamless coordination across various stages of production, working with specialized Automotive Metal Fabrication Grand Rapids MI providers ensures that your project receives personalized attention from start to finish.

Commitment to Quality and Reliability

Reliability is non-negotiable when producing components for critical applications such as brake systems, chassis components, or engine mounts. Reputable fabrication partners employ stringent ISO-certified processes and implement comprehensive testing protocols, including non-destructive testing (NDT) when needed. This unwavering commitment to quality not only guarantees compliance with industry standards but also mitigates the risk of costly downtime due to part failure. Moreover, ongoing investments in employee training and state-of-the-art equipment demonstrate a steadfast dedication to continuous improvement—ensuring that customers always receive the most advanced fabrication solutions available.

Serving the Grand Rapids Community

Choosing to work with local providers for Automotive Metal Fabrication Grand Rapids MI offers distinct advantages. Proximity facilitates more frequent on-site visits, enabling real-time collaboration on custom applications or urgent modifications. Local experts possess an intimate understanding of regional supply chains and logistical networks, which translates to faster turnaround times and reduced transportation expenses. Additionally, supporting nearby businesses helps foster economic growth within the community. By partnering with a nearby fabrication shop, you not only benefit from swift communication and flexible scheduling but also contribute to the vitality of the Grand Rapids manufacturing ecosystem.

Conclusion

When your operations demand high-caliber metal fabrication services that balance innovation, precision, and reliability, it pays to collaborate with seasoned Automotive Metal Fabrication Manufacturers. From prototyping and full-scale production to finishing and assembly, these specialists deliver comprehensive solutions tailored to your exact requirements. By selecting local experts for Automotive Metal Fabrication Grand Rapids MI, you gain the advantage of concise communication, accelerated lead times, and an unwavering commitment to excellence. Elevate your manufacturing capabilities today by partnering with proven professionals who understand the unique challenges of the automotive and industrial sectors—ensuring that every component meets the highest standards of performance and durability.

0 notes

Text

Metal Manufacturing in India: Building the Backbone of Modern Industry

India has steadily grown into a global leader in metal manufacturing, offering a powerful mix of quality engineering, cost efficiency, and large-scale production. From precision sheet metal fabrication to complex CNC machining, Indian metal manufacturing companies are delivering solutions across key sectors like automotive, aerospace, construction, and electronics.

If you're searching for capable and affordable metal manufacturing services, India should be high on your list.

What is Metal Manufacturing?

Metal manufacturing refers to the industrial processes that shape raw metal into usable components or finished products. This includes:

Sheet metal fabrication

CNC machining

Welding and assembly

Laser cutting and bending

Casting and forging

Surface finishing and powder coating

These services are used to create everything from machine parts and construction frames to custom enclosures and electronic housings.

Why Choose a Metal Manufacturing Company in India?

India’s metal manufacturing sector combines affordability, quality, and engineering expertise. Here are some of the key advantages:

1. Competitive Costs Manufacturing in India offers significant cost benefits without compromising precision or durability.

2. Skilled Workforce With a growing number of technical institutions and engineering colleges, India provides access to a highly skilled labor force experienced in industrial production.

3. Technological Capabilities Modern manufacturing facilities across India are equipped with CNC machines, robotic welding, automated laser cutters, and 3D CAD design systems.

4. Quality Standards Many Indian companies hold certifications such as ISO 9001, ISO/TS 16949, and AS9100, ensuring international quality compliance.

5. Scalable Production Whether you need a prototype or a bulk production run, Indian manufacturers offer scalable services that suit all business sizes.

Core Services Offered

Most Indian metal manufacturing companies provide end-to-end solutions. Key services include:

CNC turning and milling

Laser and plasma cutting

MIG, TIG, and spot welding

Sheet metal bending and punching

Tooling and die-making

Painting, powder coating, and finishing

Custom part assembly and integration

These capabilities make India an attractive destination for industries that require precision parts and structural components.

Industries Served

Metal manufacturers in India supply critical components and assemblies to sectors such as:

Automotive

Aerospace

Electronics

Construction

Renewable energy

Defense

Telecommunications

Industrial machinery

Their ability to meet strict quality and delivery timelines makes them a valuable part of global supply chains.

Leading Manufacturing Hubs in India

Several cities across India specialize in metal manufacturing. Key locations include:

Pune – A hub for sheet metal, CNC machining, and automotive parts manufacturing. Ahmedabad – Known for stainless steel fabrication and food-grade metal processing equipment. Coimbatore – Home to casting, pump components, and high-precision machining. Rajkot – Popular for small-scale castings, forgings, and component production. Faridabad and Noida – Major centers for sheet metal fabrication and industrial enclosures.

These hubs offer logistical advantages, access to suppliers, and modern infrastructure for full-cycle production.

Choosing the Right Metal Manufacturing Partner

Things to consider before choosing the right metal manufacturing company in India :

Engineering and design support

Machinery and technology infrastructure

Certifications and compliance standards

Experience in your target industry

Capability to meet lead times and volume requirements

Quality inspection and testing systems

Transparent communication and project management

Working with the right company can streamline your production process and reduce costs over the long term.

India’s Manufacturing is Evolving

Indian metal manufacturers are rapidly adopting Industry 4.0 principles, integrating:

Smart automation and robotics

Cloud-based production tracking

Digital prototyping with 3D CAD/CAM

Green energy practices and sustainability efforts

This shift ensures faster turnaround, enhanced quality, and reduced waste—helping international clients meet their goals more efficiently.

Conclusion

India’s metal manufacturing industry continues to attract global attention for its ability to combine quality, scalability, and affordability. Whether you need parts for automotive, aerospace, or electronics, there are manufacturers in India equipped to deliver.

Find Trusted Metal Manufacturers in India

Explore and connect with verified suppliers at FindingMFG.com. From prototyping to high-volume production, FindingMFG helps you source dependable manufacturing partners across India’s top industrial cities.

Start your project with confidence

#metal manufacturing#metal manufacturing company#metal manufacturing companies in India#metal manufacturing companies

0 notes

Text

Laser Welding Cutting Services

MS Machining’s laser welding cutting services are designed to deliver precision, efficiency, and quality for a wide range of industries, combining advanced robotics, state‑of‑the‑art laser technologies, and expert craftsmanship to meet the diverse needs of clients. From automotive and aerospace to electronics and medical devices, our dedicated team leverages cutting‑edge equipment to ensure flawless welds and precise cuts on various metals and alloys. Whether the project requires intricate micro‑welding or high‑power laser cutting, MS Machining maintains stringent quality control through in‑process monitoring, ISO‑compliant procedures, and post‑weld inspection to optimize product integrity. Our laser welding cutting services extend beyond mere technical execution, offering complete project management, engineering support, and customization options that address complexities such as heat‑sensitive components and extremely fine tolerances. With rapid turnaround times, competitive pricing, and a commitment to sustainability—minimizing heat distortion and material waste—we empower clients to accelerate product development, streamline production, and uphold the highest performance standards. By integrating design consultation, prototype testing, and scalable production capabilities, MS Machining ensures that every component—from prototype to full-scale manufacturing—benefits from reliability, repeatability, and unmatched precision. Choose MS Machining’s laser welding cutting services for turnkey, high‑quality solutions engineered to enhance product durability and performance.

0 notes

Text

Delivering Underwater Excellence with ROV and Commercial Diving in Texas

Texas is a hub of maritime, offshore, and industrial activity where underwater operations play a critical role in ensuring system safety and asset integrity. From pipeline inspections to underwater welding, the work beneath the water surface is just as vital as what happens above it. For these essential tasks, industries increasingly depend on Commercial diving services Texas and a forward-thinking ROV inspection company. These partners provide the technology, skill, and efficiency required to manage underwater challenges across the state’s diverse aquatic environments.

Expanding Demand for Underwater Inspection and Maintenance

Why Underwater Infrastructure Requires Specialized Attention

The underwater environment in Texas is vast and varied. Coastal ports, inland lakes, treatment facilities, and offshore drilling zones all require maintenance that can’t be accomplished with surface tools. Many of these systems are aging, buried in sediment, or exposed to harsh marine elements—making ongoing inspection and upkeep essential.

Whether it’s a bridge footing, a submerged oil pipe, or a dam intake, these structures face constant exposure to corrosion, erosion, and impact stress. Regular inspection is the key to catching deterioration before it turns into a major failure.

Industries Relying on Subsurface Services

Key industries relying on underwater services include:

Oil and gas

Maritime transportation

Power and energy

Environmental management

Civil construction

Each industry depends on underwater inspections to meet federal and state regulations, reduce downtime, and prevent environmental hazards. With many systems operating 24/7, the ability to quickly assess and act is not a luxury—it’s a necessity.

Commercial Diving Services Texas: What They Offer

Versatile Capabilities for Every Challenge

Commercial diving services Texas offers wide-ranging support for both shallow and deepwater tasks. These highly trained professionals execute:

Structural integrity inspections

Underwater welding and fabrication

Salvage and recovery

Pipe location and maintenance

Cleaning of intakes and screens

Diving teams are equipped with modern tools such as hydraulic wrenches, welding rigs, high-powered suction systems, and surface-supplied air units. Their work is precise, physically demanding, and often conducted under conditions of low visibility or confined space.

Professionalism and Certification

Commercial divers are not general laborers—they’re technical specialists. Every diver undergoes extensive training and adheres to OSHA and ADCI standards for safety and performance. Many also carry certifications in underwater cutting, inspection techniques, and marine construction support.

In addition, surface teams monitor every dive in real time to ensure safety, coordinate logistics, and document project progress. This level of professionalism is especially important in sectors like oil and gas, where the cost of failure is extraordinarily high.

The ROV Inspection Company Advantage

Precision Without the Risk

Remotely Operated Vehicles (ROVs) are transforming how underwater assessments are conducted. An advanced ROV inspection company uses robotic vehicles that dive where it may be too dangerous or impractical for humans to go.

ROVs are ideal for initial assessments, post-repair verifications, and monitoring in extreme depths. They’re equipped with tools like:

High-definition cameras

Sonar imaging systems

Laser scanning tools

Manipulator arms

These systems deliver real-time visuals and data to surface teams, enabling fast, informed decisions without exposing divers to unnecessary risks.

Applications Across Texas Water Systems

ROVs are extensively used in:

Mapping underwater terrain before construction

Inspecting wind farm anchors and risers

Locating cracks or corrosion in pipelines

Surveying ship hulls and ballast tanks

Monitoring fish farming systems or dam structures

Their small size and agility make them ideal for navigating through complex submerged systems while capturing every critical detail.

Synergy Between Divers and ROV Technology

Two Tools, One Unified Goal

ROVs and commercial divers are not competitors—they are complements. Together, they create a powerful team capable of handling both inspection and intervention.

ROVs excel in data collection, hazard identification, and remote viewing. Meanwhile, commercial divers handle physically intensive or manual tasks such as cutting, installation, and welding. A hybrid workflow allows for:

Faster job planning with ROV visuals

Reduced downtime and cost

Safer working conditions for divers

Complete pre- and post-operation documentation

This integrated approach is particularly effective in high-stakes environments like offshore rigs and aging municipal infrastructure.

Texas as a Model for Subsurface Collaboration

Texas’s infrastructure landscape provides a blueprint for how to successfully implement joint ROV and diver operations. With hundreds of miles of coastline, thousands of inland facilities, and a booming industrial sector, the need for comprehensive underwater services will only continue to grow.

Whether it’s emergency response, scheduled maintenance, or pre-construction evaluation, Texas-based teams have mastered the art of pairing skilled human workers with robotic precision to deliver results that meet today’s high standards.

Conclusion

The underwater challenges in Texas demand top-tier support from both human professionals and advanced technology. With the combined strength of commercial diving services Texas and a results-driven ROV inspection company, businesses across all sectors can safeguard their underwater assets, extend infrastructure lifespan, and maintain full compliance with industry regulations. This combination isn’t just the future of underwater operations in Texas—it’s the standard of excellence.

1 note

·

View note

Text

India’s Most Trusted Industrial Laser & Metalworking Machines — ESSELL

At ESSELL, we bring you cutting-edge machinery solutions engineered for accuracy, speed, and efficiency. With a wide range of advanced metalworking machines, we empower industries across India to meet their manufacturing goals with ease. From fiber laser cutting to high-precision bending, marking, and welding – ESSELL is your trusted partner in industrial innovation.

Fiber Laser Cutting Machine

Our Fiber Laser Cutting Machine is designed for supreme accuracy and high-speed cutting. It delivers clean edges and minimal heat impact, making it ideal for materials like mild steel, stainless steel, aluminum, brass, and copper. ESSELL machines feature advanced CNC control systems, auto-focus cutting heads, and high-powered fiber lasers that enhance productivity while reducing operational costs.

Fiber Laser Sheet & Pipe Cutting Machine

Whether you're working with flat sheets or round/square pipes, our Sheet and Pipe Cutting Machine offers a dual-purpose solution. Equipped with a rotary attachment and intelligent software, it ensures perfect cuts every time. This hybrid machine saves floor space and is perfect for fabrication shops, railways, automotive industries, and architectural applications.

CNC Bending Machine

ESSELL’s CNC Bending Machine combines strength with intelligence. It is engineered for fast setup and efficient operations. With programmable angles, multiple tooling options, and touch-screen interfaces, our press brakes are perfect for complex bends, batch production, and repeat jobs—ensuring every piece matches your design precisely.

Fiber Laser Marking Machine

From serial numbers to logos, our Fiber Laser Marking Machines can mark it all with unmatched clarity and speed. Designed for durability and low maintenance, these machines are perfect for metals and some plastics. Whether you're in jewelry, tools, auto-parts, or electronics—ESSELL offers machines that ensure permanent, high-contrast results with zero consumables.

Fiber Laser Welding Machine

Our Fiber Laser Welding Machines offer deep penetration, narrow welds, and minimal deformation—making them ideal for precision welding. With options for handheld and robotic models, these machines are perfect for stainless steel, carbon steel, aluminum, and more. Faster than traditional welding methods, they boost productivity while ensuring strength and finish.

Shearing Machine

ESSELL’s Shearing Machines offer efficient, clean, and burr-free cutting of metal sheets. With hydraulic operation, adjustable blade gaps, and strong construction, these machines are perfect for high-volume sheet metal processing. Industries using our shearing machines enjoy better accuracy, reduced material waste, and longer blade life.

Why Choose ESSELL?

✅ Made for Indian Industries ✅ High Precision, Low Maintenance ✅ Cost-Effective Operation ✅ Excellent After-Sales Service ✅ Custom Solutions Available

📞 Contact Us Today 📱 Call: 9811765994 🌐 Website: www.essell.co 📩 Email: [email protected]

Youtube : https://www.youtube.com/@essellengineers PAN India Delivery & Service Support Google Map:- https://maps.app.goo.gl/D3THEbGRUZKTD55z8

Upgrade your production line with ESSELL – Where Machines Empower Precision.

0 notes

Text

Advanced Research and Development Solution Services

Elevate your research and development solutions across industries with YEC's end-to-end solutions encompassing material identification, virtual simulation, 3D prototyping, and comprehensive inspection services. Now benefit from expertise in material selection, 3D scanning, and functional component testing for a seamless project journey avoiding present and future operational challenges.

#Yamunanagar Engineering Cluster#Mechanical Testing Services#Robotic Welding Services#Reverse Engineering Services#Precision Machining Services#Inspection Services#Research and Development Services

0 notes

Text

Industrial Automation Industry: Reshaping Global Manufacturing with Intelligent Systems

The Industrial Automation Industry is at the forefront of the digital revolution in manufacturing. With rapid advancements in robotics, AI, and smart control systems, industries across the globe are streamlining operations, enhancing quality, and reducing human error. Estimated at USD 159.45 billion in 2022, the industry is poised to reach USD 265.75 billion by 2030, exhibiting a CAGR of 9.35% during the forecast period.

Transformational Trends in the Industrial Automation Industry

1. Adoption of Smart Manufacturing

Companies are transitioning toward intelligent production lines that utilize sensors, machine learning algorithms, and real-time data analytics to make autonomous decisions and optimize efficiency.

2. Rise of Collaborative Robots (Cobots)

Cobots are revolutionizing factory floors by working safely alongside humans, handling repetitive or hazardous tasks, and improving productivity in sectors like automotive, packaging, and electronics.

3. Integration of AI and Big Data

AI enables predictive maintenance, quality control, and process optimization, while big data fuels decision-making through analytics and pattern recognition in industrial processes.

4. Green Automation

Environmental concerns are pushing manufacturers to adopt energy-efficient automation systems that reduce emissions, waste, and resource usage while complying with sustainability standards.

Sector-Specific Insights: Industrial Automation Applications

Automotive Industry: Fully automated assembly lines reduce costs and improve precision in welding, painting, and component fitting.

Pharmaceutical Sector: Ensures consistent formulation and sterile packaging through robotics and controlled environments.

Food & Beverage: Automation improves sorting, packaging, and quality assurance to meet increasing demand and compliance.

These applications reflect the growing Industrial Automation Market Share across sectors aiming for higher throughput and reduced operational costs.

Technology Landscape in the Industrial Automation Industry

Hardware: Includes robotics, sensors, control systems, and actuators.

Software: Covers SCADA, MES, HMI, and analytics platforms.

Services: Involves integration, training, support, and maintenance.

Control technologies such as PLCs and DCS remain crucial in managing process workflows across discrete and process industries.

Regional Insights

North America: Early technology adoption and investment in AI-driven automation.

Europe: Focuses on clean energy automation and industry 4.0 integration.

Asia-Pacific: Dominates growth due to massive industrial expansion in China, Japan, India, and Southeast Asia.

Key Market Players

Major contributors to the Industrial Automation Market Growth include:

Rockwell Automation Inc.

Siemens AG

ABB Ltd.

Schneider Electric

Mitsubishi Electric Corporation

Emerson Electric Co.

Honeywell International Inc.

These players lead in innovation, product development, and strategic partnerships to expand global footprints.

Conclusion

The Industrial Automation Industry is not just reshaping manufacturing—it's enabling a smarter, faster, and greener industrial world. As businesses accelerate digital transformation, automation will continue to be a cornerstone of competitive advantage and resilience in the global economy.

Trending Report Highlights

Explore more localized and detailed versions of the report below:

Industrial Automation Market (Japanese)

Industrial Automation Market (German)

Industrial Automation Market (French)

0 notes

Text

Why a Lightweight Scooter Factory Drives Innovation

For many end users, a scooter that’s light enough to lift, fold, and store easily can make the difference between independence and dependence. To meet this growing demand, working with a qualified Lightweight Scooter Factory like Sweetrich offers a reliable route for distributors, resellers, and care institutions looking to stock high-quality, ultra-portable mobility devices.

Sweetrich designs every scooter with daily usability at the center. From raw material selection to the final assembly stage, the factory’s operations are tailored for both performance and weight reduction. The frame structure in most models is built from ultra-light aluminum and reinforced plastic composites, delivering rigidity without unnecessary bulk. This allows users of all ages and body types to lift, fold, and roll their scooters with minimal effort.

The manufacturing workflow is data-driven and partially automated. Each unit goes through CAD-guided laser cutting, robotic welding, and real-time quality monitoring. Sensors placed throughout the assembly line ensure that frame dimensions, torque levels, and wheel alignment match engineering standards exactly. This high level of precision is especially important for maintaining balance and smooth ride performance in lightweight designs.

Sweetrich scooters typically weigh between 16 and 21 kilograms, depending on the model and configuration. What’s impressive is that even at these low weights, the scooters support up to 120 kilograms of user load. Many models feature suspension systems, pneumatic tires, and shock-absorbing frames—all features uncommon in this weight class.

As a Lightweight Scooter Factory, Sweetrich understands the need for practical controls and adaptable designs. Most scooters come with an intuitive thumb-throttle or steering control and feature adjustable seats, tillers, and footrests. The entire folding mechanism takes less than ten seconds and locks securely with a safety latch, making them suitable for travel by car, train, or air.

The battery systems used in these models are compact yet powerful. They are integrated under the floorboard or behind the seat to maintain a low center of gravity. Charging is made accessible with side ports, and most units support both in-scooter and off-scooter charging. A full charge generally supports 18–25 kilometers of range, depending on terrain and rider weight.

Sweetrich scooters are distributed worldwide, and the company offers custom manufacturing support for OEM and ODM clients. For example, partners can request alternative color schemes, private labeling, anti-theft technology, or terrain-specific modifications such as wider tires or reinforced suspensions. These options are particularly attractive for companies operating in tourism, rehabilitation, or fleet-based rental services.

All scooters undergo dynamic field testing and are evaluated on sloped surfaces, uneven ground, and under various climate conditions. The factory produces documentation in multiple languages, offers regulatory compliance assistance, and maintains an internal traceability system to support warranty claims and part replacements efficiently.

Sweetrich’s technical department is also working on expanding digital integration. Newer scooters are being developed with app pairing, route tracking, and speed-limiting settings. These features are especially beneficial for users in shared living environments or urban mobility programs.

Bulk buyers can benefit from tailored packaging solutions, spare parts kits, and branding materials that reduce go-to-market time. All shipments are handled with reinforced containers, barcode tracking, and pre-shipping inspections that minimize damage and loss.For full details on Sweetrich's lightweight scooter catalog or to explore manufacturing partnerships, visit: https://www.sweetrichmobility.com .

0 notes

Text

Top Advantages of Using Laser Welding Cutting Services for Precision Work

In the fast-evolving world of manufacturing and fabrication, achieving precision and efficiency is critical. One of the most transformative advancements in this domain is the use of laser technology—specifically Laser Welding Cutting Services. These services have redefined the standards of accuracy, speed, and versatility, making them a preferred choice for industries that require tight tolerances and intricate detailing.

MS Machining, a trusted name in the precision machining industry, offers state-of-the-art laser services designed to meet the highest standards. Whether it’s aerospace, automotive, electronics, or medical equipment manufacturing, their solutions provide unmatched quality and performance. Learn more at https://ms-machining.com/laser-welding-services-and-laser-cutting-services/

Let’s explore the top advantages of using laser welding and cutting services for precision work.

1. Unmatched Precision and Accuracy

One of the primary reasons industries opt for LASER CUTTING SERVICES and LASER WELDING SERVICES is the exceptional precision they offer. Laser beams are highly focused and can be controlled to cut or weld materials with micron-level accuracy. This is particularly beneficial for components that require detailed geometries and flawless finish—something that traditional methods often struggle to achieve.

In sectors such as electronics and medical devices, where even a small error can lead to failure, laser technology ensures components are manufactured to exact specifications.

2. Superior Quality and Finish

Unlike conventional welding and cutting methods, laser technology offers a clean and smooth finish with minimal burring or need for post-processing. This means less time spent on grinding, polishing, or reshaping—resulting in a faster production cycle and lower labor costs.

MS Machining utilizes advanced systems that maintain consistent energy output, ensuring uniform welds and cuts across batches. The end result is a high-quality product that meets strict industrial standards.

3. Minimal Heat Affected Zone (HAZ)

Traditional cutting and welding processes often generate excessive heat, which can distort the material or degrade its mechanical properties. In contrast, laser technology produces a minimal heat affected zone (HAZ), reducing the risk of warping, cracking, or weakening the material.

This advantage is especially crucial when working with delicate metals, composites, or temperature-sensitive components. LASER WELDING SERVICES and LASER CUTTING SERVICES from MS Machining ensure that the integrity of the material remains intact during processing.

4. High-Speed Processing

Time is money in manufacturing. Laser-based services are renowned for their speed. They can cut or weld materials significantly faster than traditional techniques, which translates to higher throughput and quicker turnaround times.

For businesses operating under tight deadlines, LASER CUTTING SERVICES offer a competitive edge by accelerating production without compromising on quality. MS Machining leverages cutting-edge equipment to provide fast, precise services—making them an ideal partner for high-volume or urgent projects.

5. Versatility Across Materials and Industries

Laser services are incredibly versatile and can be used on a wide range of materials including:

Stainless steel

Aluminum

Titanium

Copper

Brass

Plastics

Composites

This adaptability makes LASER WELDING SERVICES and LASER CUTTING SERVICES suitable for industries such as automotive, aerospace, defense, electronics, energy, and more.

MS Machining has extensive experience handling diverse material types and project requirements. Whether it’s welding thin aluminum sheets or cutting thick steel plates, they deliver results with consistent excellence.

6. Enhanced Automation and Integration

Modern laser systems can be fully integrated with CAD/CAM software, CNC machines, and robotic arms for seamless automation. This reduces human error, enhances consistency, and allows for continuous production with minimal supervision.

By adopting LASER WELDING SERVICES and LASER CUTTING SERVICES from a technologically advanced provider like MS Machining, manufacturers can benefit from streamlined workflows and optimized efficiency.

7. Cost Efficiency in the Long Run

While the upfront cost of laser equipment and services may be higher than traditional methods, the long-term savings are significant. Here’s why:

Reduced material waste

Minimal rework or defects

Lower post-processing requirements

Faster production rates

Less labor-intensive processes

These advantages collectively lead to lower total production costs and higher profit margins. For companies looking to scale while maintaining quality, investing in precision laser services from MS Machining is a smart financial move.

8. Non-Contact Process Reduces Wear and Tear

Laser cutting and welding are non-contact processes, meaning the laser head doesn’t physically touch the material being processed. This eliminates tool wear and minimizes the need for frequent maintenance or replacement.

This feature makes LASER CUTTING SERVICES more reliable and durable over time, especially when used for high-volume production runs. MS Machining ensures their laser systems are regularly calibrated for peak performance, ensuring consistent results without degradation.

9. Supports Complex and Custom Designs

Laser technology allows for the creation of complex patterns, microholes, fine slits, and intricate profiles that would be difficult or impossible with mechanical tools. This opens new possibilities for innovation and customization.

Whether you need custom enclosures, precision brackets, or intricately welded parts, LASER WELDING SERVICES from MS Machining can bring your design ideas to life with exacting detail.

10. Environmentally Friendly

Laser welding and cutting processes generate less waste, use fewer consumables, and produce lower emissions compared to older methods. This makes them a more sustainable choice for eco-conscious companies.

Moreover, the ability to precisely control energy usage and material handling contributes to more efficient resource utilization. Partnering with environmentally responsible providers like MS Machining ensures your operations are aligned with modern sustainability standards.

Conclusion

When precision, speed, and quality are non-negotiable, LASER WELDING SERVICES and LASER CUTTING SERVICES emerge as the clear winners. Their ability to deliver accurate, consistent, and high-quality results across a wide range of materials and applications makes them indispensable in modern manufacturing.

MS Machining stands out as a reliable partner offering advanced laser solutions that meet today’s industrial challenges with confidence. From concept to completion, their team ensures every project is executed with the highest standards of excellence.

0 notes

Text

Sheet Metal Fabrication Companies in Bangalore: Powering India's Manufacturing Backbone

Bangalore, widely celebrated as India's Silicon Valley, is known for its thriving technology ecosystem. But beyond the digital realm, the city also boasts a highly developed manufacturing sector. Among the key players in this industrial landscape are sheet metal fabrication companies in Bangalore, which provide vital services to sectors like aerospace, automotive, electronics, telecommunications, and construction.

These companies form the structural backbone of numerous industries, delivering components that are as essential as they are precisely engineered. This blog explores the world of sheet metal fabrication in Bangalore — the processes involved, the advantages the city offers, and the increasing demand for reliable, innovative, and cost-effective fabrication services.

What Is Sheet Metal Fabrication?

Sheet metal fabrication refers to the process of transforming flat sheets of metal into finished products or structural components. This involves a series of techniques such as cutting, bending, welding, forming, and assembling. The materials used often include stainless steel, aluminum, mild steel, and galvanized iron, depending on the application.

Fabrication shops typically use tools like CNC laser cutters, hydraulic press brakes, turret punches, and automated welding machines to ensure high precision and repeatability. The growing complexity of product designs across industries has elevated the need for experienced sheet metal works in Bangalore, capable of meeting tight tolerances and fast delivery schedules.

Types of Services Offered

The services provided by fabrication companies in Bangalore vary from one company to another, but most established providers offer a comprehensive range of fabrication solutions. These include:

1. Custom Sheet Metal Components

Many businesses require tailor-made metal parts to fit their specific applications. Fabrication companies deliver on this by working closely with clients to produce components based on custom blueprints or CAD files.

2. Enclosure Fabrication

From electrical cabinets and server enclosures to telecom housings and battery boxes, enclosures form a significant part of sheet metal output. These require not just structural accuracy but also aesthetic and functional precision.

3. Laser Cutting and CNC Punching

High-precision laser cutting and CNC punching allow manufacturers to create intricate designs with minimal material waste and maximum repeatability.

4. Bending and Forming

Press brakes and bending machines are used to shape sheet metal into the desired geometry. Proper bending ensures structural integrity and a high-quality finish.

5. Welding and Assembly

Post-cutting and forming, components are welded and assembled using MIG, TIG, or spot welding techniques, depending on the materials and the end-use.

6. Surface Finishing

Powder coating, anodizing, plating, and painting enhance both the appearance and corrosion resistance of fabricated components.

Why Bangalore is a Fabrication Hub

There are several reasons why sheet metal fabrication companies in Bangalore are in such high demand, not only within India but also globally:

1. Proximity to Key Industries

Bangalore is home to industries like aerospace, defense, electronics, medical equipment, and renewable energy. These sectors require precision sheet metal components, making the city a natural hub for fabrication services.

2. Skilled Workforce

The city attracts a large talent pool of engineers, machinists, and fabricators who are well-versed in the latest tools and techniques. This enables sheet metal works in Bangalore to handle even the most complex projects with efficiency.

3. Advanced Infrastructure

Many fabrication units are equipped with state-of-the-art machinery such as fiber laser cutters, CNC press brakes, and robotic welding arms. These facilities are capable of delivering high-quality products at scale.

4. Cost-Effectiveness

Compared to international markets, Bangalore offers competitive pricing without compromising on quality. This makes the city an attractive option for both domestic clients and international firms outsourcing their fabrication needs.

5. Robust Supply Chain

With its well-established network of raw material suppliers, logistics providers, and auxiliary services, Bangalore ensures smooth production and timely delivery — a key factor in today's fast-paced markets.

Applications Across Industries

The versatility of sheet metal makes it applicable across a wide range of industries. Here are some areas where fabrication companies in Bangalore play a critical role:

Aerospace & Defense: Manufacturing of brackets, panels, airframe parts, and ground support equipment.

Electronics: Enclosures, racks, and frames for computers, servers, and communication devices.

Construction: HVAC ducts, roofing systems, support frames, and facades.

Automotive: Battery enclosures, engine parts, and structural frames.

Renewable Energy: Mounting structures for solar panels, inverter boxes, and electrical cabinets.

With this broad range of applications, it’s clear that sheet metal works in Bangalore are pivotal to the growth and sustainability of multiple core sectors.

Choosing the Right Fabrication Partner

Selecting the right fabrication company is critical to ensuring the success of any manufacturing or construction project. Here are some key factors to consider:

- Technical Capability

Look for companies equipped with the latest machinery and technology, including CNC machines, 3D modeling, and automated systems.

- Quality Standards

Check if the company adheres to national or international quality standards such as ISO 9001. Consistency and precision are non-negotiable in high-stakes industries.

- Experience

Experience in serving your specific industry often translates into better problem-solving and understanding of compliance requirements.

- Customization & Flexibility

The ability to handle unique, low-volume orders alongside mass production is a sign of a well-rounded fabrication service provider.

- Lead Time

Timely delivery is crucial. A strong local supply chain and responsive customer support often determine project success.

The Future of Sheet Metal Fabrication in Bangalore

The demand for fabricated components is only expected to grow as industries like electric vehicles, space technology, and sustainable infrastructure continue to scale. Automation, smart manufacturing, and Industry 4.0 practices are being rapidly adopted by sheet metal fabrication companies in Bangalore, pushing the boundaries of speed, precision, and cost-efficiency.

Moreover, with the government’s push for “Make in India” and the development of industrial corridors across the state, Bangalore is well-positioned to remain a leader in advanced manufacturing.

Conclusion

Sheet metal fabrication is no longer just a support function—it is a critical enabler of innovation across multiple sectors. Fabrication companies in Bangalore are meeting this demand head-on with a unique combination of skilled labor, technological adoption, and a deep understanding of industrial requirements.Whether you're in aerospace, electronics, or construction, working with the right sheet metal works in Bangalore can make all the difference in product quality, timeline, and overall project success.

#fabrication companies in bangalore#heavy fabrication companies in bangalore#sheet metal fabricators in bangalore#sheet metal works in bangalore

0 notes