#advanced robotics welding machine

Explore tagged Tumblr posts

Text

Contact for Robotic Welding Services with Advanced Technology

Robotic welding is a cutting-edge technology revolutionizing the manufacturing and welding industry. It involves the use of automated, computer-controlled robotic arms to perform precise and consistent welds on a wide range of materials. This technology offers exceptional speed, accuracy, and efficiency, reducing the margin of error in welding processes. It enhances safety by minimizing human exposure to hazardous conditions and fumes. Robotic welding Services result in high-quality welds, increased productivity, and cost savings, making it an indispensable tool for various industries, from automotive and aerospace to construction and manufacturing, where precision welding is critical for product quality and durability.

#robotic welding solutions#robotic welding services#robotic welding systems#Robotic Automated Solutions#advanced robotics welding machine

0 notes

Text

Discover how artificial intelligence and robotics are transforming welding—from early robotic arms to modern AI‑powered cobots, smart sensors, real‑time monitoring, adaptive control, and IoT‑enabled systems. Learn how intelligent welding robots elevate quality, efficiency, flexibility, and safety, while skilled professionals gain new opportunities through advanced training. This article explores key advances—arc welding bots, cobots, spool‑welding, sensor fusion, and machine‑learning‑driven path planning—that are reshaping the future of metal fabrication.

#robotic welding program#AI welding robotics#intelligent cobots in welding#sensor‑driven welding automation#machine learning welding robots#robotic arc welding#smart welding sensors#welding industry automation#IoT in welding#welding technology advancements#welding robot training

0 notes

Text

Top Custom Welding Automation Machine Manufacturers in India

Weldarc India is a leading name among welding automation machine manufacturers in India, specializing in custom-made welding solutions to meet the unique needs of various industries. With a commitment to innovation and quality, Weldarc India designs and manufactures state-of-the-art welding machines that enhance precision, efficiency, and productivity. From robotic welding systems to advanced CNC solutions, each machine is engineered to deliver exceptional performance in demanding environments. Trust Weldarc India for state-of-the-art automation that drives your business forward with reliable, custom-crafted welding machines designed to excel in any application.

#welding automation machine manufacturers#custom welding machines#welding machine manufacturers in India#robotic welding systems#CNC welding machines#custom-made welding solutions#welding technology India#Weldarc India#industrial welding machines#advanced welding automation

0 notes

Text

Custom Robotic Welding Machine Manufacturers in India

Weldarc India is at the forefront of innovation as one of the leading robotic welding machine manufacturers in India. We specialize in manufacturing custom-made welding machines that meet the unique needs of various industries. Our state-of-the-art robotic solutions ensure precision, efficiency, and reliability, significantly increasing production capacity. With a commitment to quality and advanced technology, Weldarc India offers state-of-the-art welding machines tailored to meet specific requirements, helping businesses achieve unmatched excellence. Trust Weldarc India for custom robotic welding solutions that boost productivity and growth in the competitive manufacturing landscape.

#Robotic Welding Machine Manufacturers India#Custom Welding Machines#Welding Machine Manufacturers#Robotic Welding Solutions#Advanced Welding Technology#Precision Welding Machines#Industrial Welding Equipment#Welding Automation India#Custom Made Welding Machines#Indian Welding Machine Manufacturers

0 notes

Text

With robots, software, and automation, welding isn’t what it used to be

At its most basic, welding’s job in fabricating is to join two pieces of metal. It seems simple but things get complicated pretty quickly in welding. It takes a trainee a while to find the right speed, the right feed, accuracy in the weld line, amount of fill if that’s part of the job—there are probably 20 things to manage during a weld.

The ability to weld is a highly sought-after skill, and people who can do it well are well-paid. The demographics of welders, however, shows that many of them are getting to retirement age, and not enough young welders are emerging to take their place. As with many things in metal fabricating—really, in general manufacturing—automation is invoked as the answer to short supplies of qualified people.

Trumpf’s automatic weld path

Machine tool giant Trumpf released a product that takes care of itself, mostly. It is a robotic welding system uses sensors to program its own weld path. The robot uses the company’s new smart seam-tracking technology, which was developed with Fraunhofer Institute for Manufacturing Engineering and Automation IPA. The sensor automatically calculated the weld path for each part. The sensor is located in the welding torch head.

Instead of programming a new weld spot into the software for each change of direction, the user places the robot in the start position, and the technology takes care of the rest. The robot’s sensor determines the weld path automatically. Software calculates the weld spots and creates the program. It all takes a matter of seconds.

This capability will be in all new Trumpf TruArc Weld 1000 products, and can be retrofit into existing robot welders of the same model.

Laser welding advancements

Another titan of machine tools, AMADA, has offered a laser welding robot for a number of years. They offer the Fiber Laser Welder 3000 ENSIS, a complete welding system designed to use minimal heat on the weld zone to improve productivity and weld quality.

It boasts a rotating lense, which means the laser beam is not aligned with a particular point along the target path. The beam circles in a small area as the system does its work. The rotating lens improves filler feeding and aluminum welding. Larger and uneven gap sizes can be bridged in a clean, even weld. The amount of heat input into the material while welding optimizes and improves edge definition.

The unit also comes with a Variable Beam Control unit. It automatically adjusts the beam’s properties to process a wide range of thicknesses. The unit’s power is 3 kW, all generated by a single laser module. This reduces power consumption and negates the need for a combiner for several modules. Any deviations from the actual weld path can be adjusted accurately by utilizing the Teaching Assist System (TAS) on the system’s control. Using a CCD camera, new target points are selected to instantly teach the welding robot the correct target path.

Here come the robots, to a welding shop near you.

#With robots#software#and automation#welding’s job#fabricating#Trumpf’s automatic weld#Laser welding advancements#Teaching Assist System (TAS)#CCD camera#machine tools#Software calculates#aluminum welding

0 notes

Text

Perhaps so the universe has a way to make it up to us for everything else going on, there is currently an explosion in really neat laser-based tools. You can get a laser welder, or a laser CNC machine, or a laser engraver, or... a laser level. I swear I can almost afford that last one. They want like fifteen dollars for it at the Princess Auto. Sheesh. It's like they expect their core customer to be employed now.

Although lasers are probably centuries old, according to a drinking-machine summary of a wikipedia article I glanced at while trying to kill time in line at the parole office, it's only recently that humanity has figured out how to make them more affordable for the common, workaday asshole. What's the secret to this incredible advancement in inexpensive optical technology? Have a factory in China build them.

As a result of all this trans-national becheapening, the local "maker space" has acquired for themselves a thousand-watt laser welder. Any moron off the street can use it to stitch two pieces of metal together in a way that would make professional welders poop with envy. Which is perfect, if you're a moron off the street and your $89 Princess Auto "Li'l Don't Look Directly At The Spark Junior Welder's Kit" doesn't quite have the zoot to put those spring perches on a rusty, oily Ford 8.8 you got out of that big F150 crash on the side of the highway last winter.

Like you would expect, it (the welder, not the axle) cost about as much as a good used car used to cost, before used cars cost $20,000. Still, that's peanuts if you have several hundred members who are willing to pay to use it to make Star Wars pirate memorabilia and combat robots. I, however, am not willing to pay. In fact, I have to be forced to spend money on just about anything. So I decided to see if I could just walk in there, use the laser welder to do my daily welding, and then bounce without opening my wallet.

Friends: it worked great. After a couple minutes of pushing buttons and adjusting various screens that I wouldn't bothered to have read fully even if they weren't written in Chinese, I was able to fart on a pair of narrowed spring perches that were ideal for my Viscount.

Now, you might think it's suspicious that I was able to roll a 175-pound chunk of cast iron through the middle of a warehouse full of nerds without anyone asking me for my ID, but it's all thanks to another fancy new consumer of inexpensive lasers: the smoke alarm on the ceiling. I set that sucker off with a brick to the "test" button, before walking right in the front door while dressed as a firefighter. Sometimes, rock beats laser.

110 notes

·

View notes

Text

Imagine the Ice Emperor's robotic nature, but from the perspective of the people of the Never-Realm, who have zero context for a being like him. They don't have robotics or particularly advanced technology, though they at least have magic to expand their imagination with, and are aware that (some of) the Blizzard Samurai are made of ice.

But still, machinery on the level of Zane must be totally foreign to them. Alien, even, and it technically is if we go by the strict definition of the term. People rightfully assume the Ice Emperor is made of, well, ice; But they aren't aware that he's metal. He has metal organs and bones unlike any creature they have ever seen before. He doesn't breathe; He doesn't eat, doesn't drink, doesn't even bleed. When he is 'asleep' it is like being in the presence of a lifeless statue, that is to say there is no presence, just impersonal cold; One looking for the Ice Emperor might even assume they've only found a statue in his likeness.

Imagine if during those sixty years, someone came close, really close, to defeating the Ice Emperor before the ninja arrived; But they failed and died because they could not have anticipated his nature as a machine. They tear apart the Ice Emperor, his head is rolling at their feet... And his eyes blink anyway. He's still alive. He bleeds not blood but sparks of lightning.

He puts himself back together like a puppet. He creaks and groans and emits strange noises. He does not 'live' in the sense that the Never-Realm understands; He is an uncanny mimicry, not quite moving the same, even more unimaginable beneath the already terrifying exterior. The Ice Emperor doesn't heal naturally, he must weld and fuse his body back into place. Imagine if the evil sorcerer plaguing your lands was finally taken down, only for him to have a second phase where it's revealed he's a Terminator. And when you consider that he's from the future, the comparison to the Terminator is even more apt.

His former Titanium Ninja moniker suggests he's made of the stuff. Had the Ice Emperor not awoken, had Akita gone through with stabbing him with her knife... Would it have just broken against the 'skin' beneath the armor? Would she have not found skin underneath the armor, not realizing the Ice Emperor is armor all the way through? If Akita had made a cut, would it have been enough to actually affect the Ice Emperor in a meaningful way, for a slashed neck is not as much to a machine as it is to one of flesh and blood?

There's just a lot of potential when it comes to exploring the Ice Emperor from an eldritch horror angle, an alien that even Vex is lowkey afraid of, because obviously he came from somewhere, someone made him; What is that world like? It'd be like meeting the Iron Giant and realizing he was built originally as a weapon. What if the rest of that world comes for us, wondering where their scout went?

134 notes

·

View notes

Text

(PREVIEW) Identity Within︱Chapter 7 - Something Tried and True

If Peter concentrated any harder on rebuilding his web cartridges, he was sure that he’d give himself a juvenile stroke — not that Tony would’ve noticed, too busy across the workshop with welding goggles covering his eyes and sparks of molten metal igniting the room with bright flashes of heat.

The two were so caught up in their individual tasks that for once, the music playing overhead could barely be heard. Tony’s protective gear blocked out the sounds on his end, with earmuffs snugly fit over his head — whereas Peter’s intense focus kept his attention strictly on the machine in front of him; his hands carefully removing a freshly molded web cartridge that he not-so-carefully tossed into the tray on the opposite side of the table.

He was so focused on creating the next cartridge that he almost failed to pay any mind as DUM-E came wheeling by, carefully picking up the tray with an advance grip of his pincher claw and taking it across the workshop.

Peter was just about to push down on the hydraulic press mold — far more advanced than the dinky old model he had back home, and for good reason — when he saw the robot come to a stop near Tony’s work station.

“Wait, wait, wait — no, no, no, no! Not over there, DUM-E — not over there!” Peter rushed out in a panic, his one hand waving frantically in DUM-E’s direction. “If that heat gets too close to the cartridges before they mold, they'll explode!”

Despite the commotion that suddenly erupted, Tony never looked up from his own project. The intense sparks of metal continued to reflect against his goggles as DUM-E slowly retreated away from the dangerous heat, taking the tray with him until he found a safe spot to discard it.

It clanked and clattered as he dropped it down onto a cluttered bench.

“Yeah, yeah — right over there, that’s perfect, that’s great.” Peter’s bulky, heavy-duty work gloves kept his thumbs-up from fully forming, but he tried nonetheless. “Thanks, DUM-E, you’re the best.”

Tony never looked up from his welding as he said, “Stop complimenting him, he’ll think he’s doing a good job.”

Peter spun around on his stool until he faced Tony — nearly spinning all the way around had he not scraped his sneakers against the floor to prevent a complete three-sixty turn.

“He is doing a good job!” Peter defended, his smile reaching ear-to-ear while his arm extended straight out like a stick. “He’s only caused like, one fire so far.”

The sizzling heat of Tony’s welding torch came to an abrupt stop, with the sparks that flew off the scorching metal eventually dissipating in the air like embers.

“Him?” Tony asked, the hand not holding his welding torch lifting the safety goggles over his head — exposing his eyes in full. “Or you?”

Peter wished he could blame the heat of Tony’s welding for the embarrassed blush that dotted his cheeks. Unfortunately, it was hard to say whether the look on Mr. Stark’s face, one-hundred percent ‘not buying it’, was the cause of his humiliation — or the fire extinguisher that laid used and now trashed across the workshop, with bits of foam still dripping down the sides.

In his defense, he wasn’t expecting an entire tray of his web cartridges to explode from a few nearby flames of Mr. Stark’s welding torch. And in double his defense, he wasn’t expecting DUM-E to have a full blown panic attack when struggling to find the fire extinguisher that Peter misplaced the last time they were in the workshop together.

From the look on Tony’s face, Peter figured neither defense was going to win his case.

“I just gotta get a stronger casing on these things,” Peter mumbled, more to himself than anyone else. The bulky safety glove that covered his hand massaged half-heartedly at the nape of his neck. “The aluminum shelling of the cartridge is way better than the original design, but the melting point of six hundred degrees is still too low.”

DUM-E’s whine of discontent towards the situation almost sounded like he agreed with Peter — who felt lowkey bad for startling the robot with a very unexpected fire that, to Peter’s surprise, seemed to barely phase Mr. Stark.

“What are you trying to do,” Tony started to ask, yanking off his safety goggles and earmuffs with one quick motion and tossing them onto the table with ease. “Jump into fires?”

Peter gave a dramatic shrug, one that brought both his shoulders all the way up to his ears.

“Maybe,” he murmured, insecurely turning back to the machine in front of him. His fingers fiddled on the handle of the press mold without any real intention of continuing his work. “Wouldn’t be the first time I wound up in a burning building.”

The sigh that escaped his chest was unintentional, and halted mid-exhale. Peter clamped his mouth shut and clenched his jaw with frustration, shaking away the lingering thoughts of self-doubt that had so rudely managed to creep into his head lately.

Seriously — who would’ve thought the pressures of being brought back from the dead would top the stresses of maintaining his GPA in high-school. He sure didn’t.

Though music still played overhead and throughout the workshop, and was far louder now that Tony’s welding had taken a pause, Peter had a gut feeling that sigh still managed to be heard — even with his best attempts to stifle it.

A dead giveaway was the lingering stare that burned a hole in his back. It felt hotter than if Tony’s eyes were actual welding torches blowing fire right against his t-shirt, with the large print text of ‘Think like a proton and stay positive’ catching the overhead ceiling lights.

Right along with ‘that’ look Peter was all too familiar with.

“Just…gotta make sure I’m prepared. For the next time,” Peter muttered, not daring to give ‘that’ look any acknowledgment as he ripped off both his gloves with the desperate need to fidget his hands. The heat that spread across his cheeks — this time for a reason other than one impromptu use of a fire extinguisher — kept him from turning to face that stare head-on.

That was, until, Mr. Stark finally spoke up.

“You’re distracted.”

Peter spun in his stool so rapidly, he didn’t stop until the entire three-sixty ride gradually circled him back to Tony’s direction

“Of course I’m distracted!” Peter practically shouted, tossing both his arms wildly in the air. “There’s a spaceship outside!”

Tony gave a sharp, concise nod before turning right back to his work. “And there it is.”

Peter either elected not to hear his exasperation, or was way too excited to pay it any attention.

“You gotta let me meet them, Mr. Stark — c’mon!” Peter all but exclaimed, to the point where his voice cracked in pitch and he couldn’t even be bothered to care.

Tony didn’t even look at Peter as he wagged the welding torch his way.

“That homework finished yet?” he asked, deadpanned and serious — so deadpanned and serious that at first, Peter swore on his young life the man was joking.

It took a solid five seconds to realize he wasn’t.

“What!?” Peter, once again, was too worked up too notice the crack in his voice. His arms flew down from the ceiling until a rigid hand pointed right at Tony. “You said if I spent two hours working on my paper then you would compromise and let me spend two hours working on my cartridges—”

Tony nodded. “Yes, I know, I never said that I didn’t say that—”

“You just said that!” Peter hastily interrupted.

Tony made a face, one that words failed to describe. “I just said that I never said that, I didn’t say—”

Peter kept his hand pointed at Tony. “You totally said that, Mr. Stark—!”

It was Tony’s turn to spin around on his stool, the look that followed so hot it put his welding torch to shame.

Peter elected to keep his mouth shut after that.

Reluctantly.

And with much struggle.

#fanfiction#fanfic#mcu fanfic#spider-man fanfic#avengers fanfic#marvel fanfic#iron dad#irondad#iron dad fanfic#peter parker#tony stark#spider-man#iron man#mcu#marvel#avengers found family#avengers family#found family fanfiction#found family#found family fanfic#whump

17 notes

·

View notes

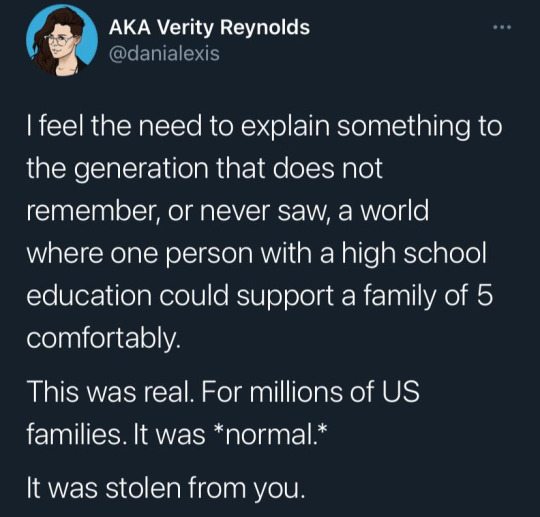

Photo

Automation killed the bulk of the jobs you could do that would support a family with only a high school diploma.

All those robots at the auto manufacturing plants painting and welding and all the other good stuff used to be done by people and by hand, boomers saw that coming and strongly encouraged their kids to go to college and get a degree because they saw that as the remedy to being replaced by a machine, and for a time they were correct.

There's still only so many jobs though and so instead of a generic liberal arts degree used to be plenty for most jobs in a ton of fields generally in the social services department like teaching or basic administration, now there's hundreds of specialty degrees to aim people towards specific jobs that they have the training and education for.

But a lot of those had inflated numbers of people that were going to be needed so we've got 10,000 people with a BS in soil science and there's only 3,000 jobs (making the numbers up here) so what's someone with that kind of degree got to look forward to in terms of job prospects.

Like the guy that did all the Egyptology classes got his bachelors realized that there were no jobs available for someone with that degree and so he pushed forward and got his masters, still not really any jobs, so eventually he got his PhD and took up the one job that was available for someone with his qualifications.

Teaching Egyptology, joke is his life is literally a pyramid scam.

There are too many people with too many degrees, many of which are barely worth the paper they're printed on because of reasons listed above, the march of time and advancement of technology has rendered many jobs obsolete and forced people so specialize to a degree that there's only so many jobs available they meet the requirements for because companies have a fairly large pool of people to draw from for a not so large pool of jobs.

Continue to introduce more people into that pool without increasing the number of jobs you get where we are now, with stagnant wages and people who can't get jobs even with a degree.

And the people suffering because of it being just plain awful to the group of people who went in with the best of intentions and who were also correct for a good while with their advice, problem is the world shifted again and we didn't adjust properly.

Here in the US we could do some good about it by bringing manufacturing back home, be good for the planet not having to ship all that stuff across the ocean too, double whammy.

Now do people have the will to start trying to make that happen or will they continue to just go the easy route and complain about it on the internet without offering any reasonable solutions at all?

143K notes

·

View notes

Text

Machine Tending Robots Market Analysis and Forecast

Machine tending robots are specialized industrial systems designed to automate the loading, unloading, and overall management of machine operations within manufacturing environments. Equipped with advanced sensors and control systems, these robots execute repetitive tasks highly, enhancing productivity, improving workplace safety, and reducing labor costs. Their integration across various industrial sectors supports streamlined production processes and optimizes operational efficiency.

The machine tending robots industry was valued at $9,873.9 million in 2024 and is projected to reach $25,598.1 million by 2034, growing at a CAGR of 9.99% during the forecast period.

Industrial Impact

By automating monotonous, dangerous, or highly precise operations, machine tending robots have completely changed the production scene. Faster production cycles, less human error, and consistent product quality have resulted from their use. Furthermore, by reducing human exposure to potentially hazardous jobs, these devices have improved workplace safety.

Beyond automation, these robots promote innovation, assist company scalability, and reallocate workers to more strategic positions, all of which result in cost savings. They are positioned as important facilitators in the creation of smart industrial environments because to their alignment with the objectives of digital transformation.

The growing need for effective production solutions, continuous developments in artificial intelligence and sensor integration, and the general trend toward intelligent and adaptable automation technologies all contribute to the market's expansion.

Market Segmentation

1. By Application

CNC Machine Tending

Injection Molding

Grinding and Polishing

Welding

Packaging and Sorting

2. By End-Use IndustryAutomotive

Electronics and Semiconductors

Metal and Machinery

Plastics and Packaging

Consumer Goods and Food Processing

3. By Robot Type

Articulated Robots

Cartesian Robots

SCARA Robots

Delta Robots

4. By Region

North America

Europe

Asia-Pacific

Rest-of-the-World

Recent Developments

In May 2024, ABB rolled out a novel machine tending cell that streamlines automation while alleviating labor shortages. The system employs advanced robotics to boost operational efficiency and minimize manual intervention in manufacturing processes.

In March 2025, Vention launched its innovative click-and-customize robotic work cells for both machine tending and welding applications. This solution is designed for rapid deployment, effectively addressing manufacturing labor challenges through enhanced automation.

In August 2024, Hurco revealed a strategic partnership with Kawasaki Robotics to offer comprehensive, industrial-grade robotic machine tending solutions. The collaboration is focused on optimizing manufacturing automation and mitigating the impact of workforce shortages.

Market Opportunity

Under-automated industries and small to mid-sized businesses (SMEs) have significant prospects. Automation is being used more and more in industries like consumer packaging, textiles, food processing, and pharmaceuticals to improve traceability, adhere to hygienic regulations, and fight growing labor costs.

The entry barriers for SMEs have been reduced by the availability of affordable, pre-configured robotic systems, which enable them to integrate automation with little capital input and customisation. This change is paving the way for robot integrators and manufacturers to enter new markets and achieve sustained growth.

Download Our Sample Report Now!

Learn more about Robotics and Automation Vertical. Click Here!

Conclusion

The market for machine tending robots is expanding at a revolutionary rate due to the growing demand for automation, improved accuracy, and increased operational efficiency. Machine tending robots are becoming an essential part of contemporary production processes as firms look to maximize productivity and lessen their reliance on human labor.

Key application areas include CNC machine tending are anticipated to dominate, and the market will expand more quickly due to the increasing usage of robots across a variety of sectors. Unrealized potential in SMEs and historically less mechanized industries offers a calculated path to future expansion.

In addition to changing industrial automation today, machine tending robots are laying the groundwork for tomorrow's smart factories.

#Machine Tending Robots Market#Machine Tending Robots Industry#Machine Tending Robots Report#automation

0 notes

Text

Sheet Metal Fabrication Companies in Bangalore: Powering India's Manufacturing Backbone

Bangalore, widely celebrated as India's Silicon Valley, is known for its thriving technology ecosystem. But beyond the digital realm, the city also boasts a highly developed manufacturing sector. Among the key players in this industrial landscape are sheet metal fabrication companies in Bangalore, which provide vital services to sectors like aerospace, automotive, electronics, telecommunications, and construction.

These companies form the structural backbone of numerous industries, delivering components that are as essential as they are precisely engineered. This blog explores the world of sheet metal fabrication in Bangalore — the processes involved, the advantages the city offers, and the increasing demand for reliable, innovative, and cost-effective fabrication services.

What Is Sheet Metal Fabrication?

Sheet metal fabrication refers to the process of transforming flat sheets of metal into finished products or structural components. This involves a series of techniques such as cutting, bending, welding, forming, and assembling. The materials used often include stainless steel, aluminum, mild steel, and galvanized iron, depending on the application.

Fabrication shops typically use tools like CNC laser cutters, hydraulic press brakes, turret punches, and automated welding machines to ensure high precision and repeatability. The growing complexity of product designs across industries has elevated the need for experienced sheet metal works in Bangalore, capable of meeting tight tolerances and fast delivery schedules.

Types of Services Offered

The services provided by fabrication companies in Bangalore vary from one company to another, but most established providers offer a comprehensive range of fabrication solutions. These include:

1. Custom Sheet Metal Components

Many businesses require tailor-made metal parts to fit their specific applications. Fabrication companies deliver on this by working closely with clients to produce components based on custom blueprints or CAD files.

2. Enclosure Fabrication

From electrical cabinets and server enclosures to telecom housings and battery boxes, enclosures form a significant part of sheet metal output. These require not just structural accuracy but also aesthetic and functional precision.

3. Laser Cutting and CNC Punching

High-precision laser cutting and CNC punching allow manufacturers to create intricate designs with minimal material waste and maximum repeatability.

4. Bending and Forming

Press brakes and bending machines are used to shape sheet metal into the desired geometry. Proper bending ensures structural integrity and a high-quality finish.

5. Welding and Assembly

Post-cutting and forming, components are welded and assembled using MIG, TIG, or spot welding techniques, depending on the materials and the end-use.

6. Surface Finishing

Powder coating, anodizing, plating, and painting enhance both the appearance and corrosion resistance of fabricated components.

Why Bangalore is a Fabrication Hub

There are several reasons why sheet metal fabrication companies in Bangalore are in such high demand, not only within India but also globally:

1. Proximity to Key Industries

Bangalore is home to industries like aerospace, defense, electronics, medical equipment, and renewable energy. These sectors require precision sheet metal components, making the city a natural hub for fabrication services.

2. Skilled Workforce

The city attracts a large talent pool of engineers, machinists, and fabricators who are well-versed in the latest tools and techniques. This enables sheet metal works in Bangalore to handle even the most complex projects with efficiency.

3. Advanced Infrastructure

Many fabrication units are equipped with state-of-the-art machinery such as fiber laser cutters, CNC press brakes, and robotic welding arms. These facilities are capable of delivering high-quality products at scale.

4. Cost-Effectiveness

Compared to international markets, Bangalore offers competitive pricing without compromising on quality. This makes the city an attractive option for both domestic clients and international firms outsourcing their fabrication needs.

5. Robust Supply Chain

With its well-established network of raw material suppliers, logistics providers, and auxiliary services, Bangalore ensures smooth production and timely delivery — a key factor in today's fast-paced markets.

Applications Across Industries

The versatility of sheet metal makes it applicable across a wide range of industries. Here are some areas where fabrication companies in Bangalore play a critical role:

Aerospace & Defense: Manufacturing of brackets, panels, airframe parts, and ground support equipment.

Electronics: Enclosures, racks, and frames for computers, servers, and communication devices.

Construction: HVAC ducts, roofing systems, support frames, and facades.

Automotive: Battery enclosures, engine parts, and structural frames.

Renewable Energy: Mounting structures for solar panels, inverter boxes, and electrical cabinets.

With this broad range of applications, it’s clear that sheet metal works in Bangalore are pivotal to the growth and sustainability of multiple core sectors.

Choosing the Right Fabrication Partner

Selecting the right fabrication company is critical to ensuring the success of any manufacturing or construction project. Here are some key factors to consider:

- Technical Capability

Look for companies equipped with the latest machinery and technology, including CNC machines, 3D modeling, and automated systems.

- Quality Standards

Check if the company adheres to national or international quality standards such as ISO 9001. Consistency and precision are non-negotiable in high-stakes industries.

- Experience

Experience in serving your specific industry often translates into better problem-solving and understanding of compliance requirements.

- Customization & Flexibility

The ability to handle unique, low-volume orders alongside mass production is a sign of a well-rounded fabrication service provider.

- Lead Time

Timely delivery is crucial. A strong local supply chain and responsive customer support often determine project success.

The Future of Sheet Metal Fabrication in Bangalore

The demand for fabricated components is only expected to grow as industries like electric vehicles, space technology, and sustainable infrastructure continue to scale. Automation, smart manufacturing, and Industry 4.0 practices are being rapidly adopted by sheet metal fabrication companies in Bangalore, pushing the boundaries of speed, precision, and cost-efficiency.

Moreover, with the government’s push for “Make in India” and the development of industrial corridors across the state, Bangalore is well-positioned to remain a leader in advanced manufacturing.

Conclusion

Sheet metal fabrication is no longer just a support function—it is a critical enabler of innovation across multiple sectors. Fabrication companies in Bangalore are meeting this demand head-on with a unique combination of skilled labor, technological adoption, and a deep understanding of industrial requirements.Whether you're in aerospace, electronics, or construction, working with the right sheet metal works in Bangalore can make all the difference in product quality, timeline, and overall project success.

#fabrication companies in bangalore#heavy fabrication companies in bangalore#sheet metal fabricators in bangalore#sheet metal works in bangalore

0 notes

Text

How Technology Is Transforming EPC Engineering Construction in Saudi Arabia

Technology is rapidly reshaping the landscape of EPC engineering construction in Saudi Arabia. From digital project management to advanced automation and AI-driven design, the EPC sector is undergoing a transformation that boosts efficiency, reduces costs, and accelerates timelines. As Saudi Arabia pushes forward with Vision 2030 and its ambitious giga-projects, technology plays a pivotal role in redefining how engineering, procurement, and construction companies operate.

1. Digital Tools and Smart Project Management

One of the most significant advancements is the adoption of Building Information Modeling (BIM). BIM enables EPC companies to create highly detailed 3D models of infrastructure before construction begins. This allows for better collaboration between design and execution teams, reduces errors, and shortens project timelines. Cloud-based platforms and AI-powered project management tools also allow real-time data analysis, helping EPC teams identify bottlenecks and make proactive decisions.

Moreover, AI and machine learning are now widely used to predict project outcomes, optimize schedules, and manage risks. These tools are transforming how EPC companies in Saudi Arabia handle large-scale projects with greater accuracy and efficiency.

2. Robotics and Automation on Construction Sites

Automation is transforming the way construction is carried out on-site. Robotics are being used for tasks like welding, bricklaying, and concrete pouring, significantly reducing human error and improving safety standards. IoT (Internet of Things) sensors embedded in equipment and materials provide real-time data about usage, quality, and performance. This technological integration ensures proactive maintenance and prevents costly downtime.

Furthermore, drones are being deployed for site surveys, inspections, and progress monitoring—offering real-time aerial views and enhancing on-site transparency.

3. Smarter Logistics and Supply Chain Efficiency

Advanced technology is also streamlining logistic services in Saudi Arabia, a crucial aspect of large EPC projects. Real-time GPS tracking, automated warehousing, and digital inventory systems help EPC firms manage complex supply chains efficiently. These systems ensure timely delivery of materials and optimal resource allocation, reducing delays and improving overall project performance.

Saudi Arabia’s investment in transport and infrastructure also supports this evolution, making the region a strategic hub for smart logistics in EPC execution.

Conclusion

Technology is no longer a luxury—it's a necessity for modern EPC engineering construction in Saudi Arabia. From smart design tools to robotic automation and efficient logistics, digital innovations are driving faster, safer, and more cost-effective project delivery.

If you’re seeking a reliable EPC company in Saudi Arabia, TALKE offers a comprehensive range of services, including engineering, procurement, construction, and logistic services in Saudi Arabia. With a strong focus on innovation and operational excellence, TALKE ensures your project meets the highest standards from start to finish.

#epc engineering construction saudi arabia#epc company in saudi arabia#logistic services saudi arabia

0 notes

Text

Tube Sheet Drilling: Precision Engineering for Heat Exchanger Efficiency

Introduction to Tube Sheet Drilling

Tube sheet drilling is a highly specialized machining process used to create accurate and aligned holes in tube sheets—critical components in heat exchangers, boilers, pressure vessels, and condenser systems. These precision-drilled holes allow for the insertion and secure mounting of heat exchange tubes, ensuring optimal thermal transfer efficiency and mechanical stability.

With increasing demands in petrochemical, oil & gas, power generation, and chemical industries, high-precision tube sheet drilling has become more essential than ever for leak-proof, high-pressure, and high-temperature applications.

What is a Tube Sheet?

A tube sheet is a thick metal plate, typically made from carbon steel, stainless steel, copper alloys, or nickel-based alloys, that holds tubes in position within a heat exchanger or similar device. These plates are drilled with hundreds or even thousands of holes, each of which must be precisely located and dimensioned to ensure proper tube alignment and flow dynamics.

Tube sheets may be:

Flat or flanged

Cladded or solid

Fixed or floating

The integrity of tube sheet drilling directly influences the operational efficiency and lifespan of the entire equipment.

Key Features of Tube Sheet Drilling

1. Ultra-Precision Hole Placement

Hole pitch accuracy within ±0.02 mm

Accurate alignment for seamless tube-to-sheet welding or expansion

Support for complex configurations like square, triangular, or staggered pitch patterns

2. Custom Hole Diameters

Hole diameters typically range from 10 mm to 50 mm

Precision tools for countersinking, reaming, and chamfering as per design requirements

3. CNC and Multi-Spindle Drilling Options

CNC drilling offers repeatability, speed, and automation

Multi-spindle heads reduce cycle time by drilling multiple holes simultaneously

Option to program tool paths, feed rates, and depths

4. Compatibility with Multiple Materials

High-speed steel and carbide-tipped drill bits for superior performance

Capability to drill cladded tube sheets (e.g., stainless steel + carbon steel)

Coolant-fed tools and optimized cutting conditions to handle exotic alloys

Applications of Tube Sheet Drilling

1. Heat Exchangers

Critical for U-tube heat exchangers, shell & tube designs, and double-pipe configurations

Precise drilling ensures efficient thermal conductivity and mechanical locking

2. Boilers and Pressure Vessels

Supports high-pressure operations

Helps in achieving zero-leakage expansion joints

3. Oil Refineries and Chemical Plants

Used in corrosive environments where precision and metallurgy are key

Hole alignment ensures uninterrupted flow of process fluids

4. Power Generation and Nuclear Plants

Used in superheaters, economizers, and condenser systems

Requires radiographic inspection compliance for nuclear-grade tube sheets

Tube Sheet Drilling Process: Step-by-Step

1. Design and Layout Preparation

3D CAD models or 2D technical drawings created for hole mapping

Pitch, margin, and hole count are finalized

2. Material Preparation

Tube sheets undergo annealing, cleaning, and marking

Plate thickness checked (often ranges from 20 mm to 200 mm)

3. CNC Drilling Operation

CNC-controlled drill head moves in X-Y coordinates

Drilling depth, diameter, and tolerance pre-set for each hole

Coolant system active to prevent heat build-up and tool wear

4. Finishing

Chamfering or reaming if needed

Deburring for smooth hole edges

Non-destructive testing (NDT) to check hole accuracy and spacing

Advanced Technologies in Tube Sheet Drilling

1. Deep Hole Drilling Machines

Capable of handling thick tube sheets over 150 mm

Specialized gun drilling or BTA (Boring & Trepanning Association) methods used

2. Laser Drilling (For Special Alloys)

Non-contact, heat-concentrated drilling

Used where traditional tooling may not work (e.g., titanium, Inconel)

3. Robotic Drilling Systems

Fully automated arms integrated with CAD/CAM

Ideal for custom tube sheets or small production batches

Quality Control and Inspection

1. Dimensional Inspection

Coordinate Measuring Machines (CMM) used for verifying hole positions

Ensures compliance with ASME, TEMA, and ISO standards

2. Surface Integrity Checks

Inspection for burrs, cracks, or work hardening

Use of penetrant testing (PT) and ultrasonic testing (UT)

3. Fit-Up Verification

Tube insertion test to validate hole alignment and tightness

Simulates real working conditions under thermal and hydraulic stress

Choosing the Right Tube Sheet Drilling Partner

When selecting a supplier for tube sheet drilling, consider the following:

Experience in large-diameter tube sheets

Capability for high-volume or prototype jobs

Access to modern CNC drilling machines

Compliance with international QA/QC standards

In-house NDT and post-drilling inspection systems

Conclusion

Tube sheet drilling is more than just a machining task—it is an engineering-critical operation that demands micron-level accuracy, repeatability, and material adaptability. As industries continue to evolve towards energy efficiency and system reliability, precision-drilled tube sheets form the backbone of high-performance heat exchange systems. Investing in advanced tube sheet drilling solutions means investing in long-term operational safety, energy conservation, and system longevity.

1 note

·

View note

Text

Transforming Manufacturing with Advanced Automation and Conveyor Solutions in Malaysia

In today’s highly competitive manufacturing landscape, efficiency, precision, and reliability are paramount. Companies seeking to enhance their production lines must adopt innovative solutions that streamline operations while maintaining high quality standards. Malaysia’s manufacturing sector is rapidly evolving, embracing cutting-edge technology to stay ahead. At the forefront of this transformation are providers offering comprehensive automation robotic systems, conveyor solutions, and electrical control systems tailored to diverse industrial needs.

Revolutionizing Production with SMT PCB Machines & Conveyor Systems

Surface Mount Technology (SMT) PCB machines are vital for modern electronics manufacturing. These machines facilitate the placement of electronic components onto circuit boards with remarkable speed and accuracy. Integrating SMT PCB machines with reliable conveyor systems ensures a seamless flow of materials through the assembly process. SMT PCB Machine & Conveyor Efficient conveyor systems not only assist in transporting PCBs between different stages but also reduce manual handling, minimizing errors and increasing throughput.

A key aspect of implementing SMT PCB machines effectively is pairing them with high-quality conveyor solutions. Conveyor systems specialized for electronics manufacturing are designed to accommodate delicate components while maintaining precise positioning. This integration results in a streamlined production line capable of handling high-volume output with consistency.

Leading the Market as a Belt Conveyor Supplier in Penang

In Penang, a bustling industrial hub, companies are increasingly turning to trusted belt conveyor suppliers to meet their logistical needs. Belt conveyors are versatile and cost-effective, suitable for transporting a wide range of materials across manufacturing facilities. As a prominent belt conveyor supplier penang local providers deliver tailored solutions that fit specific factory layouts and operational demands.

These conveyor systems are engineered for durability and efficiency, ensuring minimal downtime and maintenance. Whether used for conveying raw materials, finished goods, or intermediate products, belt conveyors optimize material handling processes, thereby enhancing overall productivity. Partnering with a reputable supplier guarantees access to customized designs, quality components, and reliable after-sales support.

Embracing the Future with Automation Robotic Systems & Solutions

Automation robotic system & solution have become indispensable in modern factories aiming for smart manufacturing. Robots equipped with advanced sensors and AI capabilities perform tasks ranging from assembly and welding to packaging and quality inspection. Implementing robotic automation not only accelerates production but also improves precision and reduces labor costs.

These robotic systems are often integrated into broader factory automation strategies, allowing for synchronized operations across different production stages. Smart robotic solutions can adapt to various tasks, making them invaluable in facilities that require flexibility and high throughput. As industries move towards Industry 4.0, automation robotic systems are essential for achieving intelligent, responsive manufacturing environments.

Enhancing Efficiency with Factory Automation & Electrical Control Systems

Central to modern manufacturing is the deployment of factory automation and electrical control systems. These systems coordinate machinery, conveyor belts, robotic arms, and other equipment, enabling smooth, coordinated operations. factory automation & electrical control system Electrical control systems serve as the brain of the factory, managing real-time data, controlling processes, and ensuring safety protocols are maintained.

Implementing sophisticated factory automation enhances operational control, reduces human error, and enables predictive maintenance. Electrical control systems, designed with advanced PLCs and SCADA systems, provide visibility into production metrics and facilitate swift adjustments. This integration results in increased productivity, improved product quality, and lower operational costs.

The Path to a Smarter Factory

Adopting these advanced solutions—ranging from SMT PCB machines and conveyor systems to robotic automation and electrical controls—is essential for factories aiming to stay competitive. The synergy of these technologies creates a smart manufacturing environment where processes are optimized, waste is minimized, and quality is consistently maintained.

Partnering with experienced providers who understand local industrial requirements ensures the successful implementation of these systems. Whether upgrading existing facilities or designing new production lines, customized solutions tailored to specific operational needs can significantly boost efficiency and profitability.

0 notes

Text

Agriculture Equipment Manufacturing Company: Premier Solutions Today!

Boosting Farm Efficiency with Premium Equipment

In today’s fast-paced agricultural landscape, farmers need machinery that keeps pace with demanding workloads. Partnering with a specialized agriculture equipment manufacturing company ensures access to durable, reliable, and innovative solutions. From robust tillage implements to high-capacity harvesters, the right machinery can transform planting cycles, reduce downtime, and ultimately increase yields. By relying on experts who understand farm challenges, producers can focus on core operations while enjoying peace of mind that their equipment will perform when it matters most.

Commitment to Quality and Innovation

Choosing an experienced provider often translates to receiving machines built with meticulous attention to detail. Leading agricultural machinery fabrication manufacturers invest heavily in research and development, staying at the forefront of metalwork techniques, component integration, and automation. Whether it’s precision-engineered frames that resist corrosion or electronic control modules that optimize fuel consumption, thoughtful design delivers tangible benefits. Farmers gain machinery that not only meets industry standards but also introduces forward-thinking features—giving them a competitive edge in a market where efficiency and sustainability are paramount.

Customized Solutions for Every Farm

No two farms are identical, and a one-size-fits-all approach rarely suffices. That’s why many producers turn to a trusted agriculture equipment manufacturing company capable of tailoring solutions to specific crop types, acreage, and soil conditions. Whether the need is for customized attachments, adjustable frame heights, or reinforced gearboxes to handle rocky terrain, bespoke fabrication solves critical pain points. Collaborative engineering sessions allow farmers to communicate precise requirements—ensuring that final products integrate seamlessly into existing workflows, fit within budget constraints, and deliver a rapid return on investment.

Excellence in Fabrication and Assembly

Fabrication is both an art and a science. Top-tier agricultural machinery fabrication manufacturers maintain rigorous quality-control measures at every production stage. Skilled welders, machinists, and assemblers work in synchrony to produce equipment that adheres to tight tolerances. From laser cutting of high-strength steel plates to robotic welding for consistently uniform joints, advanced processes reduce waste and minimize the risk of field breakdowns. Assembling complex hydraulic systems and testing performance under real-world loads further ensures that each piece of machinery operates flawlessly from day one.

Why Investing in Proven Manufacturing Pays Off

Cutting corners on equipment may yield short-term savings, but long-term costs often skyrocket due to frequent repairs, energy inefficiencies, and unpredictable downtimes. By partnering with a reputable agricultural machinery fabrication manufacturers partner, farmers receive not only durable products but also comprehensive support services. Preventive maintenance plans, quick-response repair teams, and readily available spare parts reduce unplanned stoppages. Moreover, well-engineered machines often retain higher resale values—providing an additional financial incentive when equipment cycles reach the end of their service life.

Conclusion: Equip Your Farm for the Future

Embracing innovation in agriculture starts with selecting machinery that embodies quality, reliability, and adaptability. An experienced agriculture equipment manufacturing company offers more than just metal and motors—it delivers solutions designed to streamline operations, reduce costs, and boost overall productivity. Backed by proven expertise and state-of-the-art fabrication practices, farms can confidently navigate evolving market demands, deliver bountiful harvests, and secure long-term success.

0 notes

Text

ABB Servo Motors: Precision, Power, and Performance

ABB is a global leader in automation and electrification, known for its advanced servo motor technology. Built for precision, durability, and efficiency, ABB Servo Motors are ideal for high-performance industrial and marine applications.

Key Features

Exceptional Precision Delivers accurate speed and position control—ideal for robotics, CNC machines, and automation lines.

High Efficiency Optimized for low energy consumption without compromising output power.

Durable Design Built to withstand harsh industrial environments, including extreme temperatures, dust, and humidity.

Compact and Versatile Space-saving form factor allows seamless integration into complex systems.

Flexible Connectivity Compatible with a wide range of automation platforms and control systems.

Applications

Robotics Enables smooth, precise movements for tasks like assembly, welding, and pick-and-place operations.

CNC Machines Provides accurate tool control for superior surface finishes and product quality.

Automated Assembly Lines Powers conveyor systems, robotic arms, and production equipment with high reliability.

Packaging & Labeling Ensures speed and accuracy for filling, sealing, and labeling processes.

Textile Machinery Maintains consistent motion in weaving, knitting, and fabric processing.

Printing Systems Delivers fine control of print heads and rollers for high-quality results.

Benefits

Increased Productivity Fast response and precision help accelerate production cycles.

Improved Product Quality Accurate control minimizes defects and ensures consistency.

Energy Efficiency Designed to reduce power usage and support sustainable operations.

Long-Term Reliability Engineered for long service life with minimal maintenance.

Conclusion

ABB Servo Motors are trusted by industries worldwide for their performance and reliability. Whether you're upgrading existing systems or building new solutions, these motors provide the speed, precision, and efficiency to meet today’s automation demands.

Explore our full range at ramautomations.com or contact us to find the right solution for your operation.

1 note

·

View note