#Rotary potentiometer

Explore tagged Tumblr posts

Text

the phrase "steadily increasing volume" suggests to me one of those super-stepdown youtube clickbait gearboxes hooked up to turn a volume knob very verrrrrry slowly clockwise

and then probably break something when it reaches full volume because the torque stepup would just rip through the knob stop

1 note

·

View note

Text

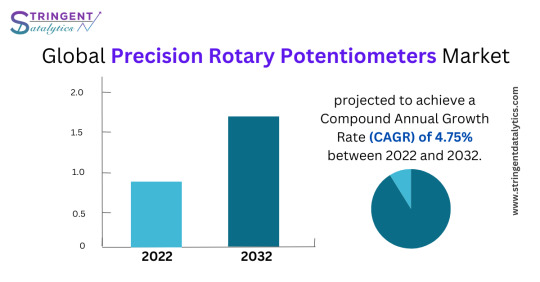

Precision Rotary Potentiometers Market

Precision Rotary Potentiometers Market

0 notes

Text

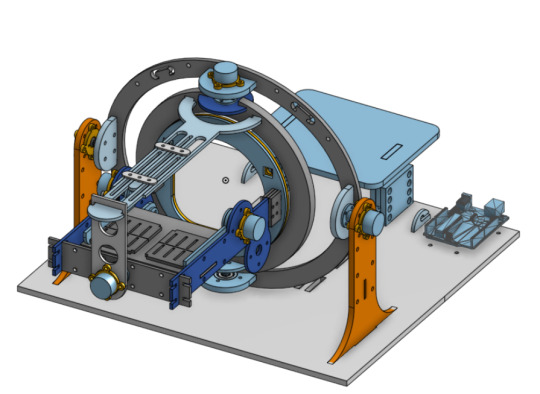

Re-designing my Waldo

I found out they make rotary hall effect sensors (why did no one tell me). These little guys are miracles; they have the exact same effect on the voltage as a traditional potentiometer but with all the advantages of hall-effects. Straight upgrade. And unlike optical encoders, the positioning is absolute, so no calibration needed. The sensors are a slightly different form factor though, and because my first prototype prioritized fewer parts over upgradeability, a tiny little change requires a complete re-design. As you can see, I'm trying to avoid that in the future. This version has far more parts that bolt together rather than weld, particularly where sensors get installed. This was also an opportunity to make some long overdue ergonomic adjustments (the thumb position was atrocious) and add a couple extra sensors for my fingers. If I've done everything right (and I almost never do) this will be easier to repair, lighter, and more expressive.

9 notes

·

View notes

Text

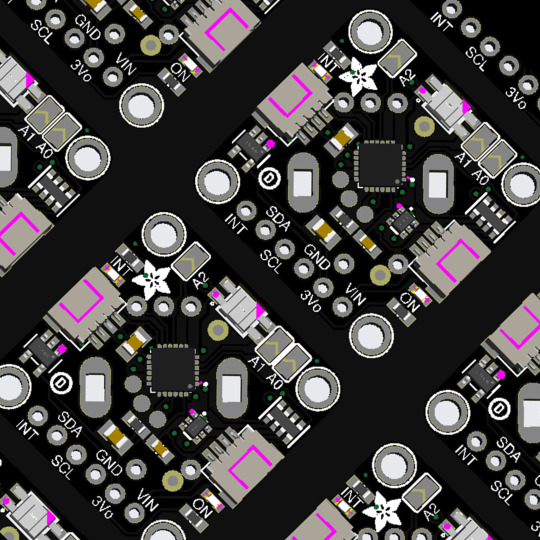

PCB of the day! Adafruit I2C Stemma QT Rotary Encoder Breakout with NeoPixel - STEMMA QT / Qwiic 🔧🔄🎛️

Rotary encoders are soooo much fun! Twist them this way, then twist them that way. Unlike potentiometers, they go all the way around and often have little detents for tactile feedback. But, if you've ever tried to add encoders to your project, you know they're a real challenge to use: timers, interrupts, debouncing…

This Stemma QT breakout makes all that frustration disappear - solder in any 'standard' PEC11-pinout rotary encoder with or without a push switch. The onboard microcontroller is programmed with our seesaw firmware and will track all pulses and pins for you and then save the incremental value for querying over I2C. Plug it in with a Stemma QT cable for instant rotary goodness with any microcontroller from an Arduino UNO up to a Raspberry Pi.

You can use our Arduino library to control and read data with any compatible microcontroller. We also have CircuitPython/Python code for use with computers or single-board Linux boards.

#adafruit#electronics#pcb#opensource#opensourcehardware#pcboftheday#arduino#raspberrypi#circuitpython#python#linux#rotaryencoder#stemmaqt#neopixel#i2c#breakoutboard#engineering#hardware#microcontroller#diy#technology

35 notes

·

View notes

Text

Digital Display Potentiometer Market: Regional Demand Analysis and Investment Potential

MARKET INSIGHTS

The global Digital Display Potentiometer Market size was valued at US$ 298.7 million in 2024 and is projected to reach US$ 512.4 million by 2032, at a CAGR of 8.12% during the forecast period 2025-2032.

Digital display potentiometers are electronic components that combine traditional potentiometer functionality with digital interfaces for precise resistance adjustment. These devices enable digital control of analog circuits while providing visual feedback through integrated displays. Key variants include linear potentiometers and rotary potentiometers, catering to different application requirements across industries.

Market growth is driven by increasing automation in industrial equipment, rising demand for precision control in automotive electronics, and the expanding consumer electronics sector. The linear potentiometer segment is expected to reach USD 190 million by 2032, growing at 7.2% CAGR, due to its widespread use in industrial measurement systems. Key players like Bourns and ON Semiconductor dominate the market, collectively holding over 35% revenue share in 2024 through continuous product innovation and strategic partnerships.

MARKET DYNAMICS

MARKET DRIVERS

Rising Automation Across Industries Accelerates Digital Potentiometer Adoption

The global surge in industrial automation is significantly propelling the digital display potentiometer market forward. As manufacturing facilities increasingly adopt Industry 4.0 standards, the demand for precise electronic components like digital potentiometers has grown substantially. These devices provide programmable resistance values with digital precision, making them ideal for automated systems requiring consistent calibration. The industrial automation market, valued in the hundreds of billions globally, continues to expand at a steady pace, directly benefiting component manufacturers. Digital potentiometers offer distinct advantages over mechanical variants including higher reliability, better accuracy, and remote adjustment capabilities—features critically important for modern automated environments.

Consumer Electronics Miniaturization Creates Strong Market Demand

The relentless trend toward smaller, more powerful consumer electronics continues to drive innovations in digital potentiometer design. With smartphone manufacturers packing more functionality into increasingly thinner devices and wearable technology gaining mainstream adoption, component manufacturers are under pressure to deliver smaller form factors without compromising performance. Digital potentiometers perfectly meet these requirements through their compact footprint and elimination of moving parts. Recent product launches demonstrate this trend, with several leading manufacturers introducing surface-mount packages under 2mm²—ideal for space-constrained applications. The consumer electronics sector’s projected growth trajectory suggests this demand will persist throughout the forecast period.

Automotive Electronics Expansion Generates Robust Growth Opportunities

Modern vehicles increasingly rely on sophisticated electronic systems, from infotainment to advanced driver assistance systems (ADAS), creating substantial demand for precision electronic components. Digital display potentiometers find extensive application in vehicle lighting controls, instrument clusters, and various sensor calibration circuits. The automotive industry’s current shift toward electric vehicles presents additional opportunities, as these vehicles require more electronic components than their combustion engine counterparts. With electric vehicle production projected to account for significant percentage of all vehicles manufactured within the decade, component suppliers are strategically positioning themselves to meet this growing demand.

MARKET RESTRAINTS

Persistent Semiconductor Shortages Disrupt Market Stability

The digital display potentiometer market continues to face challenges from global semiconductor supply chain disruptions. While the worst of the chip shortage may have passed, the industry remains vulnerable to supply constraints that impact lead times and pricing. Many digital potentiometer manufacturers rely on specialized fabrication processes that compete for capacity with higher-margin semiconductor products. This situation creates an ongoing challenge for maintaining stable production and delivery schedules. Industry analysts note that while capacity expansions are underway, the market may continue experiencing periodic imbalances between supply and demand through the forecast period.

Cost Pressures from Alternative Technologies Constrain Market Expansion

Digital potentiometers face increasing competition from alternative solutions including digital-to-analog converters (DACs) and programmable gain amplifiers in certain applications. While digital pots offer specific advantages in many use cases, their value proposition comes under scrutiny in cost-sensitive applications. Some system designers are opting for integrated solutions that combine multiple functions, potentially reducing demand for discrete digital potentiometer components. Additionally, continued price erosion across the broader semiconductor sector exerts downward pressure on component margins, challenging manufacturers to maintain profitability while investing in next-generation product development.

Technical Limitations in High-Power Applications Restrict Market Growth

Digital potentiometers typically handle relatively low current and voltage levels compared to their mechanical counterparts, which limits their application in certain industrial and power management scenarios. While recent advancements have improved power handling capabilities, many high-current applications still require traditional solutions. This technical constraint represents a significant barrier to broader market penetration, particularly in heavy industrial equipment and power distribution systems. Manufacturers continue to work on advanced materials and designs to overcome these limitations, but progress remains incremental rather than revolutionary.

MARKET OPPORTUNITIES

Internet of Things Expansion Creates New Application Possibilities

The explosive growth of IoT devices presents significant opportunities for digital display potentiometer manufacturers. These components play crucial roles in sensor calibration and signal conditioning across countless IoT applications, from smart home devices to industrial monitoring systems. As IoT deployments continue multiplying across industries, demand for reliable, low-power electronic adjustment solutions will rise correspondingly. Manufacturers that can deliver highly integrated, energy-efficient solutions tailored for IoT applications stand to capture substantial market share in this expanding segment.

Medical Electronics Advancements Open New Market Frontiers

The medical device industry’s ongoing digital transformation creates promising opportunities for precision electronic components. Digital potentiometers find application in various medical equipment including patient monitoring systems, diagnostic devices, and therapeutic equipment. The medical electronics market’s stringent reliability requirements and relatively high component pricing create favorable conditions for manufacturers able to meet these specialized demands. With healthcare expenditure rising globally and medical technology advancing rapidly, this vertical represents a high-growth opportunity for digital potentiometer suppliers.

Emerging Smart Infrastructure Projects Fuel Component Demand

Government initiatives worldwide to develop smart cities and modernize infrastructure are generating demand for advanced electronic components. Digital potentiometers play important roles in smart grid equipment, intelligent lighting systems, and various monitoring and control applications. These large-scale infrastructure projects typically have long implementation timelines but offer stable, multi-year demand for components. Manufacturers that can demonstrate the reliability and longevity required for infrastructure applications stand to benefit from this growing market segment.

MARKET CHALLENGES

Design Complexity Increases Time-to-Market Pressures

As digital display potentiometers incorporate more advanced features and tighter specifications, their design complexity has increased significantly. Many newer models include integrated non-volatile memory, precision voltage references, and sophisticated interfaces—features that add development time and cost. This complexity creates challenges in maintaining competitive product cycles while ensuring robust performance across environmental conditions. The market’s demand for both higher functionality and faster product introductions presents a persistent challenge for engineering teams.

Global Economic Uncertainty Impacts Investment Decisions

The digital display potentiometer market faces headwinds from broader economic conditions that affect capital expenditure across key industries. With manufacturers and OEMs becoming more cautious about inventory levels during periods of economic uncertainty, component suppliers experience greater volatility in order patterns. These fluctuations complicate production planning and capacity investment decisions. While the long-term growth outlook remains positive, navigating near-term economic cycles presents an ongoing challenge for market participants.

Environmental Regulations Require Continuous Compliance Efforts

Increasing environmental regulations regarding materials and manufacturing processes create compliance challenges for digital potentiometer manufacturers. Restrictions on hazardous substances and requirements for energy efficiency continually evolve, requiring regular product redesigns and process adjustments. Meeting these requirements across global markets with varying standards adds complexity to product development and supply chain management. While environmental responsibility represents an industry-wide priority, the associated compliance costs and technical challenges impact profitability and time-to-market for new products.

DIGITAL DISPLAY POTENTIOMETER MARKET TRENDS

Integration of Smart Automation Technologies Driving Market Adoption

The digital display potentiometer market is experiencing significant growth due to advancements in smart automation technologies across various industries. These sensors, which combine mechanical potentiometers with digital displays for precise electrical resistance measurement, are increasingly replacing traditional analogs due to their programmable nature and higher accuracy. With industrial automation investments projected to grow at nearly 10% annually, demand for digital potentiometers as critical components in control systems has surged. Major manufacturers are responding with compact designs featuring enhanced functionalities like touch-based interfaces and wireless connectivity options.

Other Key Trends

Consumer Electronics Miniaturization

As consumer electronics manufacturers push for increasingly compact devices without sacrificing functionality, digital display potentiometers have emerged as ideal solutions for space-constrained applications. Their ability to provide both measurement and visual feedback eliminates the need for separate display components in products like smartphones, wearables, and portable audio equipment. Recent innovations include ultra-thin models measuring under 2mm in thickness, addressing the needs of next-generation foldable devices and IoT sensors.

Automotive Sector Innovation Creates Demand

The automotive industry’s shift toward electrification and advanced driver assistance systems (ADAS) has significantly impacted market dynamics. Digital potentiometers are increasingly used in vehicle control modules, battery management systems, and cabin comfort controls due to their durability and precision in harsh environments. With electric vehicle production expected to grow by over 30% annually through 2030, component manufacturers are developing specialized automotive-grade potentiometers meeting stringent vibration and temperature requirements. The convergence of display and control functionality also supports the trend toward centralized vehicle control interfaces.

Wireless Connectivity Integration Reshaping Product Development

Leading manufacturers are incorporating wireless technologies such as Bluetooth and Zigbee into digital display potentiometer solutions, enabling remote monitoring and adjustment applications. These networked systems are particularly valuable in industrial settings where operators need to monitor multiple sensors across large facilities. The integration of Industry 4.0 compatible communication protocols has further accelerated adoption in smart manufacturing environments. Recent product launches feature cloud connectivity options that allow potentiometer adjustments through web-based dashboards, significantly expanding potential applications.

Other Emerging Trends

Healthcare Equipment Modernization

Healthcare’s increasing reliance on precise electronic instrumentation is creating new opportunities in medical device applications. Digital display potentiometers are being incorporated into imaging equipment, patient monitors, and laboratory instruments where their combination of control and visualization enhances operational efficiency. Stringent regulatory requirements are prompting manufacturers to develop specialized medical-grade variants with enhanced sterilization compatibility and electromagnetic shielding.

Material Science Innovations Addressing Temperature Constraints

The push for wider operating temperature ranges is driving material innovations in resistive element production. New nano-composite materials allow digital potentiometers to maintain accuracy across extreme temperature variations from -55°C to 150°C, expanding their use in aerospace and oil/gas applications. These advancements come alongside improvements in mechanical durability, with some models now rated for over 500,000 adjustment cycles while maintaining measurement precision within 1% of full scale.

COMPETITIVE LANDSCAPE

Key Industry Players

Market Leaders Focus on Innovation and Regional Expansion to Gain Competitive Edge

The global digital display potentiometer market exhibits a fragmented competitive landscape, characterized by the presence of established electronics component manufacturers and emerging regional players. Bourns Inc. currently leads the market, holding an estimated 22% revenue share in 2024, owing to its extensive product range and strong distribution network across North America and Asia-Pacific. The company’s recent introduction of high-precision digital potentiometers with I²C interface has further strengthened its position in industrial automation applications.

ON Semiconductor and CURTISS-WRIGHT collectively account for nearly 30% of the market, primarily due to their vertically integrated manufacturing capabilities and contracts with major automotive OEMs. Notably, ON Semiconductor’s 2023 acquisition of GT Advanced Technologies enhanced its silicon carbide production capacity, allowing for more robust potentiometer designs.

Meanwhile, mid-sized players like ETI Systems are gaining traction through specialization – their ruggedized potentiometers for harsh environments have seen 18% year-over-year growth in military and aerospace sectors. Hohner Automaticos continues to dominate the European market with customized solutions, while Electro-Sensors maintains strong relationships with industrial equipment manufacturers through just-in-time delivery systems.

The competitive intensity is expected to increase as Chinese manufacturers enter the space with cost-competitive offerings, prompting established players to accelerate R&D in smart potentiometer technologies. Several companies are now integrating IoT capabilities into their products, with Bourns and ON Semiconductor leading this transition through partnerships with cloud platform providers.

List of Key Digital Display Potentiometer Manufacturers

Bourns, Inc. (U.S.)

ON Semiconductor (U.S.)

CURTISS-WRIGHT (U.S.)

ETI Systems (UK)

Hohner Automaticos (Spain)

Electro-Sensors (U.S.)

Ametek, Inc. (U.S.)

TT Electronics (UK)

Vishay Intertechnology (U.S.)

Segment Analysis:

By Type

Linear Potentiometer Segment Dominates the Market Due to High Precision in Industrial Applications

The market is segmented based on type into:

Linear Potentiometer

Subtypes: Slide Potentiometers, Multi-Turn Linear Pots, and others

Rotary Potentiometer

Subtypes: Single-Turn Rotary Pots, Multi-Turn Rotary Pots, and others

By Application

Industrial Equipment Segment Leads Due to Growing Automation Needs

The market is segmented based on application into:

Household Appliances

Automotive

Industrial Equipment

Communications

Others

By End-User

Manufacturing Sector Accounts for Major Usage Due to Process Control Requirements

The market is segmented based on end-user into:

Electronics Manufacturers

Automotive OEMs

Industrial Machinery Producers

Telecom Equipment Providers

Others

Regional Analysis: Digital Display Potentiometer Market

North America The North American digital display potentiometer market is characterized by advanced technological adoption and strong demand from key industries such as automotive, industrial automation, and communications. The U.S. holds the largest market share in the region, driven by heavy investments in Industry 4.0 and smart manufacturing, projected to exceed $15 billion annually by 2025. Major players like Bourns and ON Semiconductor dominate supply chains, focusing on high-precision, low-noise potentiometers for critical applications. However, competition from Asian manufacturers and pricing pressures remain notable challenges. Despite this, stringent quality standards and the push toward IoT integration continue to fuel demand for premium-grade digital potentiometers.

Europe Europe’s market thrives on strict regulatory compliance (e.g., RoHS and REACH) and an emphasis on energy-efficient solutions. Germany leads in demand, particularly for industrial equipment and automotive applications, where digital potentiometers are used in sensor calibration and motor control. The region benefits from collaborations between semiconductor firms and automotive OEMs, with companies like ETI Systems and Hohner Automaticos expanding production capacities. However, high manufacturing costs and slow adoption rates in Eastern Europe offset growth to some extent. The European Commission’s Digital Compass 2030 initiative, which prioritizes industrial digitization, is expected to further propel market expansion.

Asia-Pacific With China alone accounting for over 35% of global production volumes, Asia-Pacific remains the fastest-growing region. The surge is attributed to massive electronics manufacturing ecosystems in China, Japan, and South Korea, alongside government-backed semiconductor self-sufficiency programs. India’s market is expanding due to automotive and consumer electronics growth, though it lags in high-end applications. Cost competitiveness drives the preference for mid-range rotary potentiometers, but demand for linear variants is rising in robotics and automation. Challenges include intellectual property concerns and supply chain bottlenecks, yet the region’s export-oriented manufacturing hubs ensure sustained dominance.

South America This region exhibits moderate growth, primarily fueled by Brazil’s automotive and appliance sectors. Local production is limited, leading to heavy reliance on imports from North America and Asia. Economic instability and currency fluctuations deter large-scale investments, though niche applications in renewable energy systems present opportunities. Argentina shows potential in industrial equipment repairs, but infrastructural gaps and low R&D spending hinder progress. Vendors targeting this market prioritize cost-efficient, durable solutions to align with regional budget constraints.

Middle East & Africa The market here is nascent but promising, with growth centered in GCC countries and South Africa. The UAE and Saudi Arabia drive demand through infrastructure modernization projects, particularly in oil & gas and telecommunications. However, lack of local manufacturing forces reliance on global suppliers, increasing lead times and costs. Africa’s adoption is sporadic, hindered by limited technical expertise and underdeveloped electronics sectors. Long-term growth hinges on foreign investments in smart city initiatives, though progress remains uneven.

Report Scope

This market research report provides a comprehensive analysis of the Global Digital Display Potentiometer market, covering the forecast period 2024–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The Global Digital Display Potentiometer market was valued at USD XX million in 2024 and is projected to reach USD XX million by 2032, growing at a CAGR of X%.

Segmentation Analysis: Detailed breakdown by product type (Linear Potentiometer, Rotary Potentiometer), application (Household Appliances, Automotive, Industrial Equipment, Communications, Others), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. The U.S. market size is estimated at USD XX million in 2024, while China is projected to reach USD XX million.

Competitive Landscape: Profiles of leading market participants including Bourns, ETI Systems, CURTISS-WRIGHT, Hohner Automaticos, Electro-Sensors, and ON Semiconductor, covering their product portfolios, market share, and strategic developments.

Technology Trends & Innovation: Assessment of digital potentiometer technologies, integration with IoT systems, and advancements in precision control applications.

Market Drivers & Restraints: Evaluation of factors such as increasing automation demand, growth in consumer electronics, along with challenges like supply chain constraints and pricing pressures.

Stakeholder Analysis: Strategic insights for component manufacturers, OEMs, system integrators, and investors regarding market opportunities and competitive positioning.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/laser-diode-cover-glass-market-valued.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/q-switches-for-industrial-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ntc-smd-thermistor-market-emerging_19.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lightning-rod-for-building-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cpe-chip-market-analysis-cagr-of-121.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/line-array-detector-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/tape-heaters-market-industry-size-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wavelength-division-multiplexing-module.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/electronic-spacer-market-report.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/5g-iot-chip-market-technology-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/polarization-beam-combiner-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/amorphous-selenium-detector-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/output-mode-cleaners-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digitally-controlled-attenuators-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/thin-double-sided-fpc-market-key.html

0 notes

Text

The Precima 400001 Caldaro SFCP22EG-7114 Potentiometer is a high-quality rotary sensor designed for accurate position detection in industrial automation systems. Ideal for applications requiring precise control and feedback, this potentiometer offers reliable performance and long service life. With its durable construction, it can withstand harsh environments, making it perfect for use in mobile machinery, robotics, and factory automation. The compact design allows easy integration into tight spaces. Choose the SFCP22EG-7114 potentiometer from Auto2mation for dependable performance and smooth operation in demanding applications. Improve your automation accuracy and efficiency with this trusted potentiometer solution.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Precima#Potentiometer#Variable Resistor

0 notes

Text

0 notes

Text

Draw Wire Potentiometer - Enhance Precision in Motion Sensing

Discover how draw wire potentiometers enhance precision in motion sensing with their high accuracy, versatility, and robust design for various industrial applications.

0 notes

Text

0 notes

Text

Essential Guide: How to Drive a Servo Motor Like a Pro

Servo motors have become vital across various industries, from robotics and CNC machinery to automation. Their precision and control make them ideal for applications requiring specific movement or positioning. For those new to the world of servo motors or anyone seeking to sharpen their skills, understanding how to drive a servo motor effectively is key to harnessing its full potential. This guide will walk you through everything you need to know to drive a servo motor like a pro, covering basics, technical tips, and best practices.

What Is a Servo Motor?

A servo motor is a specialized rotary actuator designed for precise control of angular or linear position, velocity, and acceleration. Unlike traditional motors, which typically run at a constant speed, servo motors respond to specific instructions to move to set positions with a high degree of accuracy. They are commonly used in robotics, conveyor systems, camera focus mechanisms, and beyond.

Key Components of a Servo Motor System

To operate a servo motor effectively, it's essential to understand its components:

Motor – The main driver of motion, either DC or AC, that generates rotational movement.

Controller – Sends specific signals to the motor to reach a target position or speed.

Feedback Device – Typically an encoder or potentiometer, providing feedback on the motor's position to ensure accuracy.

Drive Circuit – Interfaces the controller with the motor, enabling controlled power and precise motion.

Step 1: Choose the Right Servo Motor for Your Application

Choosing the right motor type depends on your application's power, speed, and control requirements. Generally, servo motors fall into two main categories:

DC Servo Motors – Better suited for applications requiring lower power and precise control.

AC Servo Motors – More powerful and suitable for higher-speed applications, often used in industrial automation.

Consider the torque, speed, and voltage ratings as you assess which servo motor fits your needs.

Step 2: Understand Control Signals

Servo motors require control signals to determine movement. There are three main types:

Pulse Width Modulation (PWM) – Common in hobbyist and small-scale applications, it involves sending pulses to control motor position.

Analog Signals – Often used in industrial settings, where a specific voltage range controls motor speed or position.

Digital Signals – A more advanced option that communicates precise instructions for accurate control in complex systems.

Step 3: Master the Basics of Servo Motor Controllers

To drive a servo motor effectively, you’ll need a servo controller, the brain behind the operation. It’s responsible for interpreting the commands and converting them into movements. There are two primary control modes:

Position Control – This mode commands the servo to move to a specified position and is highly accurate.

Speed Control – Here, the controller maintains a steady speed, ideal for applications like conveyor belts.

Selecting the right controller based on your application can make all the difference in achieving optimal performance.

Step 4: Set Up Your Servo Drive

The servo drive is an essential component, bridging the motor and controller. Here’s a basic setup guide:

Power Supply – Connect a power source that matches the servo motor’s voltage and current requirements.

Signal Wires – Connect the control signals from your controller to the servo motor input.

Feedback Mechanism – Ensure the encoder or potentiometer is connected to relay accurate positioning data.

Check Connections – Verify all wiring and connections are correct, ensuring stable performance and avoiding overheating or short circuits.

Step 5: Programming Your Servo Motor

Servo motors can be controlled manually or programmed via a microcontroller or PLC (Programmable Logic Controller) for automation. Start by writing basic commands to rotate the motor to specific angles, then proceed to more complex programs for movement sequences. Popular platforms like Arduino and Raspberry Pi are ideal for beginner programmers.

Step 6: Fine-Tuning Performance

To drive a servo motor like a pro, fine-tuning is necessary. Here are some techniques:

PID Tuning – PID (Proportional-Integral-Derivative) controllers are commonly used to fine-tune servo motors, helping achieve smoother and more precise control.

Frequency Response Tuning – Adjusting frequency parameters can prevent oscillations and improve stability.

Gain Adjustment – Increasing or decreasing gain settings affects responsiveness and precision.

Step 7: Troubleshoot Common Servo Motor Issues

When driving a servo motor, issues may arise. Here’s how to troubleshoot:

Inconsistent Positioning – Verify the feedback device is correctly calibrated and connected.

Overheating – Check that the motor isn’t overloaded and that the drive circuit isn’t providing excessive current.

Unexpected Stopping – Inspect connections, power supply, and control signal integrity.

Noise and Vibration – Adjust gain settings or consider a damper if high-frequency noise affects performance.

Step 8: Regular Maintenance

Regular maintenance ensures optimal servo motor performance and extends lifespan. Here are some maintenance tips:

Check Wiring and Connections – Loose connections can cause erratic movements.

Lubricate Bearings – Especially in industrial environments, to prevent wear and tear.

Inspect Feedback Devices – Clean encoders or potentiometers for accurate data.

Why Learn to Drive a Servo Motor Like a Pro?

Mastering servo motor operation enhances productivity, precision, and cost efficiency. Industries benefit from improved control and accuracy in applications ranging from robotics to medical devices, where precise movement can make a crucial difference.

Conclusion

Driving a servo motor may seem complex initially, but with this guide and hands-on practice, you'll be able to control it confidently. Whether you’re aiming for exact positioning or consistent speed, mastering servo motors will open up opportunities for innovation and efficiency.

0 notes

Text

What Are Rotary Potentiometers?

A rotary potentiometer is an adjustable resistor consisting of a rotating shaft and a resistive material. The resistive material is typically arranged in a circular or spiral pattern, and a sliding contact moves along the resistive material via the rotating shaft to adjust the resistance value.

Get more details: What Are Rotary Potentiometers?

#electronics#integrated circuits#semiconductor#components#electronic#module#electronic devices#chips#manufacturing

0 notes

Text

0 notes

Text

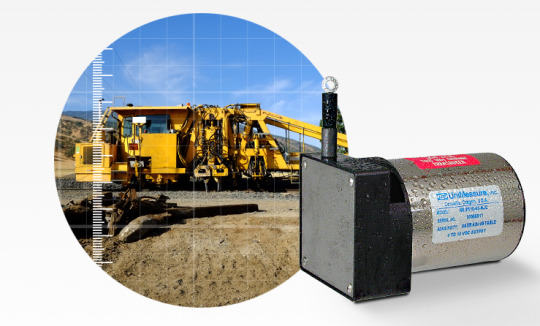

UniMeasure Inc

UniMeasure Inc

UniMeasure, Inc. has been manufacturing position and velocity sensors in Corvallis, Oregon since 1987. The company has steadily grown over the years to become a leader in the linear and rotary transducer industry with a focus on customer service, innovative design, and high-quality products. The Corvallis facility is ISO 9001:2015 certified with many raw materials and vendor services sourced in the local area. With a core group of long-standing employees, UniMeasure is dedicated to manufacturing position sensors in the USA and providing high-quality solutions while further enhancing customer experience.

UNIMEASURE LINEAR POSITION TRANSDUCERS

String Potentiometer

Often referred to as string pot, yo-yo pot, draw wire transducer, cable extension transducer, cable actuated transducer, UniMeasure extending wire rope linear position transducers have proven to be an attractive approach for a multitude of applications in many different industries. With relatively non-critical alignment requirements, compact size, and ease of installation wire rope actuated transducers are the linear position measurement system of choice in applications as diverse as bone densitometers in the medical industry, crash testing in the automobile industry, pump jacks in the crude oil extraction industry and irrigation and flood control in the water management industry. With a wide variety of electrical outputs, UniMeasure linear displacement measuring and position sensor products provide an extremely cost effective method for linear position feedback.

UNIMEASURE ROTARY POSITION TRANSDUCERS

Position Sensor

UniMeasure rotary position transducers provide an analog output signal that is directly proportional to the angle of rotation of the shaft of the device. With a voltage or 4 to 20 mA analog electrical output, UniMeasure rotary position transducers are also known as angle sensors, analog rotary shaft encoders and analog multiturn analog shaft encoders and absolute angle encoders. These position sensor devices are commonly used in applications where an absolute output signal is a must. Typical use occurs in closed loop process control and in testing applications where oscillatory rotary motion occurs. UniMeasure absolute analog rotary position transducers have proven to be an extremely cost effective alternative for measuring rotational positioning.

CONTACT US

UniMeasure Inc https://unimeasure.com/ ADDRESS: 4175 SW Research Way Corvallis, OR 97333 PHONE: (541) 757-3158

Facebook

1 note

·

View note

Text

A pop hero: the Yamaha DX-7

If there is one instrument that managed to give a particular sound to the pop music of the 80’s, it is the Yamaha DX-7. Launched in 1983, the Yamaha DX-7 marked the golden age of digital synthesizers: unlike analog synthesizers, they were cheap, easier to program and move, had a battery of varied tones, and the technology allowed sounds to be stored in memory. In addition, its format was innovative: it replaced rotary potentiometers with pushbuttons, a two-line display, and a data slider to change its many parameters. These features allowed musicians to do a better job, good presets for composing, and endless possibilities for playing. Because of this it became so popular and catapulted the sound of the 80’s like no other instrument. One of the first songs where the Yamaha DX-7 became popular was Billy Idol’s Eyes Without Face; then, from Depeche Mode in their incredible People are People, through the absolute hit of Pet Shop Boys Domino Dancing, to one of Charly Garcia’s masterpieces, Piano Bar, no artist resisted the charms of this unique synthesizer, pop hero, the machine of unforgettable and eternal hits. Now when we think and feel how much we love the music of the 80’s, no doubt we have to thank the Yamaha DX-7.

Raul Silva

0 notes

Text

Vulcan Hart 00-857398-00001 Controller Kit | PartsFe

Dimensions

Length: 14 In

Width: 12 In

Height: 7 In

Weight: 2.1 lbs

Product Notes

Kit Contains 857112-1 Controller, 857388-1 Probe,

857389-1 Potentiometer,

857390-1 Plate, 857397-1 Harness, 854693-1 Rotary Seal,

854762-1 Locking Nut

854763-1 Oring, Washers And Instructions.

Vulcan Braising Pan Ve30, Ve40, Vg30, Vg40

0 notes

Text

Global Position Transducers Market growth, trend, opportunity and forecast 2023-2030

Position Transducers Market

The Position Transducers Market is expected to grow from USD 1.70 Billion in 2022 to USD 2.60 Billion by 2030, at a CAGR of 5.30% during the forecast period.

Get the sample report: https://www.reliablebusinessinsights.com/global-position-transducers-market-r1297260

Position Transducers Market Size

Position transducers are devices used to measure linear or rotary positions of objects accurately. The global position transducers market research report categorizes the market based on type, including draw wire linear position transducers, incremental encoder, absolute position encoders, inductive proximity sensors, LVDT transducer, linear potentiometer, magnetostrictive transducer, and non-contact or laser linear position sensors. The report also segments the market by application, including metal processing industries, geotechnics, rubber and plastic injection presses, earth-moving and agricultural machines, blowing machines, renewable energies, machines in the automotive sector, pneumatic and hydraulic sensors, and the food industry, and by region, including North America, Asia Pacific, Middle East, Africa, Australia, and Europe. Leading market players include TE Connectivity, Honeywell, Gerfan, Rota Engineering, Novotechnik, Allergo Microsystems, Panasonic, and Qualcomm Technologies. Regulatory and legal factors specific to market conditions are also analyzed in the report.

Position Transducers Market Key Players

TE Connectivity

Honeywell

Gerfan

Rota Engineering

Novotechnik

Position Transducers Market Segment Analysis

One of the latest trends in the Position Transducers market is the integration of sensors with advanced technologies such as IoT and AI. The sensors are designed to capture position, acceleration, and temperature data, which is then analyzed using advanced data analytics tools to provide valuable insights to manufacturers and service providers. Moreover, the miniaturization of Position Transducers is also a major trend in the market, enabling its installation in small and confined spaces.

In conclusion, the Position Transducers market presents various growth opportunities with its wide target market and increasing demand for automation and motion control systems. However, challenges such as high costs and regular maintenance and calibration requirements need to be addressed to ensure a sustainable revenue growth path. By integrating advanced technologies, manufacturers can enhance their product offerings, which could lead to increased market adoption and revenue growth.

This report covers impact on COVID-19 and Russia-Ukraine wars in detail.

KEY PRODUCT APPLICATION COVERED

Metal Processing Industries

Geotechnics

Rubber and Plastic Injection Presses

Earth-Moving and Agricultural Machines

Blowing Machines

KEY PRODUCT TYPES COVERED

Draw Wire Linear Position Transducers

Incremental Encoder

Absolute Position Encoders

Inductive Proximity Sensors

Contact Info:

Krishna Sharma

US:- +1 507 500 7209Email:- [email protected]

0 notes