#SS 304 pipes

Text

A Guide To Stainless Steel 304 Pipes

Introduction:

Stainless steel 304 is a type of stainless steel that is widely used in the manufacture of pipes, fittings, and other products. It is an alloy of iron, chromium, and nickel, and is known for its excellent corrosion resistance, strength, and durability.

Advantages of Using Stainless Steel 304 Pipes:

Corrosion resistance: Stainless steel 304 has excellent corrosion resistance in a wide range of environments, including exposure to water, chemicals, and high temperatures. This makes it ideal for use in many applications, including plumbing, water treatment, and food processing.

Strength and durability: Stainless steel 304 is known for its high strength and durability, making it resistant to deformation and damage. This makes it suitable for use in applications where the pipes may be subjected to high levels of stress or pressure.

Non-toxic: Stainless steel 304 is non-toxic and does not leach any harmful chemicals into the materials it comes into contact with. This makes it suitable for use in applications where the pipes may come into contact with food or potable water.

Easy to clean: Stainless Steel 304 Pipe has a smooth, non-porous surface that is resistant to bacteria and other contaminants. This makes it easy to clean and maintain, which is important in applications where hygiene is a concern.

Versatility: Stainless steel 304 is a versatile material that can be used in a wide range of applications, including piping, fittings, and other products. It is available in a variety of sizes and shapes, making it easy to find a product that meets the specific needs of your project.:

Stainless Steel 304 Pipes Are Used In a Wide Range of Applications

Plumbing: Stainless steel 304 pipes are often used in plumbing systems due to their corrosion resistance and durability.

Water treatment: Stainless steel 304 pipes are commonly used in water treatment plants due to their corrosion resistance and ability to withstand high temperatures.

Food processing: Stainless steel 304 pipes are often used in food processing plants due to their non-toxic properties and ability to withstand high temperatures.

Chemical processing: Stainless steel 304 pipes are resistant to corrosion and are often used in chemical processing plants.

Marine applications: Stainless steel 304 pipes are used in marine environments due to their corrosion resistance.

Weight:

Stainless Steel Pipe 304 Grade weight will depend on its size and thickness. As a general rule, the weight of a stainless steel 304 pipe can be calculated by multiplying its length by its wall thickness and then multiplying the result by the density of stainless steel, which is about 8 grams per cubic centimeter.

Conclusion:

Overall, Stainless Steel 304 is a popular choice for use in piping and other applications due to its excellent corrosion resistance, strength, and durability. It is widely used in a variety of industries, including plumbing, water treatment, food processing, chemical processing, and marine applications. I hope this information is helpful! Let me know if you have any other questions.

#Stainless Steel Pipe 304 Grade#Stainless Steel Pipe 304#Stainless Steel Pipe#SS 304 pipes#SS 304 pipe

2 notes

·

View notes

Text

#Stainless Steel 304 Pipes Supplier#Stainless Steel 1.4301 Pipe#Stainless Steel 304 Pipe#Stainless Steel 304 Seamless Pipes#SS 304 Pipes#ASME SA312 Stainless Steel TP304 Pipes Supplier#SS 304 pipes

0 notes

Text

Kogyo Steel: Best Manufacturer of SS 304/UNS S30400/DIN 1.4301 Pipes and Tubes in Japan

A renowned Manufacturer of SS 304/UNS S30400/DIN 1.4301 Pipes and Tubes in Japan, Kogyo Steel specializes in creating premium SS 304/UNS S30400/DIN 1.4301 pipes and tubes. Kogyo Steel' SS 304 products are well-known for their remarkable resilience to corrosion and durability, making them perfect for a variety of uses such as food and beverage manufacturing, chemical processing, and architectural endeavors. Every pipe and tube manufactured by Kogyo Steel is guaranteed to fulfill the highest industry standards thanks to the use of sophisticated manufacturing processes and strict quality control systems. Kindly VISIT US

0 notes

Text

SS 304 Flange: Features, Applications, and Price List

The SS 304 flange is a key component in the world of industrial piping, offering outstanding durability, corrosion resistance, and strength. Whether you're managing a large-scale industrial project or a smaller application, SS 304 flanges play a vital role in ensuring secure and leak-proof connections. In this article, we will explore the features, applications, and pricing of SS 304 flanges, along with the latest SS 304 flange price list. At Udhhyog, we provide high-quality SS 304 flanges at competitive prices to meet all your project needs.

What is SS 304 Flange?

SS 304 flange refers to a flange made from Stainless Steel 304, an austenitic steel known for its excellent corrosion resistance, strength, and versatility. Grade 304 stainless steel is composed of 18% chromium and 8% nickel, making it highly resistant to rust and other forms of corrosion in both mild and harsh environments.

Flanges are used to connect pipes, valves, pumps, and other equipment in piping systems, ensuring a secure seal and facilitating easy assembly, disassembly, and maintenance. The SS 304 flange is one of the most commonly used types of stainless steel flanges in industries like oil and gas, chemical processing, food production, and water treatment.

Key Features of SS 304 Flanges

Corrosion Resistance

The high chromium and nickel content in SS 304 flanges makes them resistant to corrosion from chemicals, moisture, and gases, making them ideal for both indoor and outdoor applications.

Heat Resistance

SS 304 flanges can withstand high temperatures, making them suitable for steam lines, hot water systems, and other high-temperature applications.

Strength and Durability

SS 304 flanges offer excellent mechanical strength, ensuring reliable performance even under high pressure. They are durable, long-lasting, and require minimal maintenance.

Ease of Fabrication

These flanges are easy to weld and machine, allowing for customization based on specific project requirements. Whether you need special dimensions or configurations, SS 304 flanges are highly adaptable.

Versatility

From chemical plants to marine environments, SS 304 flanges are used in a wide range of industries due to their resilience and ability to perform in extreme conditions.

Applications of SS 304 Flanges

SS 304 flanges are used in various industrial sectors, including:

Chemical Processing: With their ability to withstand corrosive chemicals and extreme temperatures, SS 304 flanges are frequently used in chemical plants and processing facilities.

Food and Beverage Industry: The sanitary properties of SS 304 make it a popular choice for food processing and packaging systems.

Oil and Gas Industry: The durability and resistance to corrosion make SS 304 flanges ideal for pipelines in the oil and gas sector.

Water Treatment: In water treatment plants, where corrosion and exposure to water are constant, SS 304 flanges provide reliable, long-lasting performance.

Pharmaceutical Industry: These flanges are suitable for pharmaceutical applications due to their hygienic properties and resistance to contamination.

Factors Influencing SS 304 Flange Prices

When considering the price of SS 304 flanges, several factors can affect the cost. Here's what you should consider:

Material Costs

Fluctuations in the price of stainless steel raw materials, especially nickel and chromium, can impact the price of SS 304 flanges.

Size and Type of Flange

Larger flanges or those with specialized designs (such as weld neck, slip-on, or blind flanges) are typically priced higher due to the additional material and labor required for production.

Surface Treatment and Finishing

Flanges with additional surface treatments, such as polishing or galvanization, may have a higher price, especially if intended for use in corrosive environments.

Manufacturing Precision

SS 304 flanges that undergo precision manufacturing processes, such as forging or CNC machining, are generally priced higher, but they offer superior performance and quality.

Quantity

Bulk purchases usually offer better pricing. At Udhhyog, we provide attractive discounts for bulk orders, making our flanges more affordable for large-scale projects.

Market Demand

Market conditions and demand for stainless steel products can also affect the price of SS 304 flanges.

SS 304 Flange Price List

Here’s a general price overview for common sizes of SS 304 flanges:

1 inch SS 304 flange: ₹300 to ₹650 per piece

2 inch SS 304 flange: ₹400 to ₹850 per piece

3 inch SS 304 flange: ₹600 to ₹1,400 per piece

4 inch SS 304 flange: ₹900 to ₹2,100 per piece

6 inch SS 304 flange: ₹1,600 to ₹3,500 per piece

Please note that these prices are subject to change based on market trends, material costs, and supplier terms. For an accurate and up-to-date SS 304 flange price list, we encourage you to contact Udhhyog directly.

Why Choose Udhhyog for SS 304 Flanges?

At Udhhyog, we are committed to providing high-quality SS 304 flanges at the most competitive prices. Here’s why businesses trust us:

Superior Quality: Our flanges are manufactured using premium-grade SS 304 stainless steel, ensuring maximum durability and performance.

Affordable Prices: We offer some of the most competitive prices in the market, along with bulk purchase discounts.

Customization: We can customize the dimensions and finishes of flanges to meet your project’s specific requirements.

Strict Quality Control: All our flanges undergo rigorous quality checks to ensure they meet industry standards for performance and safety.

Timely Delivery: Our streamlined supply chain ensures that orders are delivered on time, helping you stay on schedule.

1 note

·

View note

Text

Outstanding Quality Stainless Steel Pipe in India

Pearl Pipe India is a market-leading Stainless Steel Pipe Manufacturer in India and Stainless Steel 202 Pipe Manufacturer in India. Stainless steel pipes are commonly used in industrial settings for the transportation of liquids, gases, and chemicals. Their ability to withstand high temperatures and corrosive environments renders them indispensable in manufacturing processes. We are also the leading Stainless Steel Pipe Manufacturers in Chennai and Stainless Steel Pipe Manufacturers in Bangalore.

Contact us

Phone: +91 91723 33437

Website: https://pearlpipeindia.com

Product Source: SS Pipe Manufacturer in India and Jindal Stainless Steel Pipe Price List PDF

Also visit: Stainless Steel 316 Pipe Manufacturer in India and Stainless Steel 304 Pipe Manufacturer in India

#Stainless Steel 316 Pipe Manufacturer in India#Stainless Steel 304 Pipe Manufacturer in India#Stainless Steel Pipe Manufacturer in India#SS Pipe Manufacturer in India#Stainless Steel Pipe Manufacturer#Jindal Stainless Steel Pipe Price List PDF

0 notes

Text

SPP Alloys: Premier SS Seamless Pipe Manufacturer in India

When it comes to sourcing the best quality of stainless steel seamless pipes, SPP Alloys shines amongst the crowd of various suppliers. Their focus on precision engineering and achieving the pinnacle of quality all thanks to their commitment to excellence. SPP Alloys has set up itself as a trusted name in the industry. Whether you are in need of SS 304 seamless pipes manufacturer, SS321 seamless pipes suppliers, or any other stainless steel seamless pipes, SPP Alloys has the expertise and functionality to meet your requirements.

The Range of Products

SPP Alloys offers an entire sort of stainless steel seamless pipes, catering to diverse commercial and enterprise programs. They specialise in manufacturing SS 304 seamless pipes and SS 321 seamless pipes, known for his or her durability, corrosion resistance, and advanced finish. As a major SS seamless pipe manufacturer in India, SPP Alloys takes satisfaction in turning in products that adhere to worldwide great necessities.

Precision Engineering

At SPP Alloys, precision engineering is in the middle of their manufacturing technique. Each SS seamless pipe undergoes meticulous production strategies to make sure dimensional accuracy, easy surface finish, and impeccable overall performance. The company's modern day facilities and superior equipment enable them to reap consistency properly across their product variety.

Quality Assurance

Quality warranty is paramount at SPP Alloys. As a good SS seamless pipe manufacturer in Mumbai, the company implements stringent exceptional control measures at every degree of manufacturing. From raw material inspection to the very last testing of completed merchandise, SPP Alloys maintains a rigorous first-rate control gadget to uphold the integrity of their chrome steel seamless pipes.

Industry Applications

SPP Alloys' SS seamless pipes locate packages across numerous industries, along with petrochemical, pharmaceutical, food processing, and more. The versatility and reliability of their products cause them be perfect for transporting numerous fluids, gases, and chemical substances in stressful operational environments. Customers can rely on SPP Alloys to deliver SS seamless pipes that meet the specific requirements of their programs.

Customer-Centric Approach

As a purchaser-centric SS seamless pipe producer in India, SPP Alloys prioritizes consumer delight and aims to exceed expectancies with their products and services. The business enterprise's responsive customer service, well timed deliveries, and versatility in catering to custom orders have earned them the belief of customers nationwide.

Conclusion

SPP Alloys emerges as a ideal SS seamless pipe manufacturer in India, providing an intensive range of top-satisfactory stainless-steel seamless pipes. With a focus on precision engineering, adherence to fine requirements, and a purchaser-centric technique, SPP Alloys has solidified its function as a relied on supplier in the industry. Whether it is SS 304 seamless pipes, SS 321 seamless pipes, or custom designed answers, SPP Alloys is dedicated to meeting the diverse desires of its customers with excellence and reliability.

#ss 304 seamless pipe#ss 321 seamless pipe#ss seamless pipe manufacturer in india#ss seamless pipe manufacturer in mumbai

0 notes

Text

Premium Stainless Steel 304 Seamless Pipe Manufacturer in India

One of the biggest Stainless Steel 304 Seamless Pipe Manufacturer in India is Shree Impex Alloys. We have been offering our clients a large assortment of 304 stainless steel seamless pipes. A range of standards, sizes, thicknesses, and custom lengths are available for SS 304 Seamless Pipes. We never cut corners when it comes to quality and provide premium SS 304 Seamless Pipes to customers worldwide as one of the top Stainless Steel 304 Seamless Pipe Suppliers in India.

As one of the leading ss 304 seamless pipe suppliers in Mumbai, Shree Impex Alloys has a sizable stock of these pipes in sizes that are common for the industry. Austenitic grades 304, 304L, 316, 316L, and 316L in diameters ranging from 6NB to 1200NB make up the majority of our stock.

Our exceptional quality stainless steel 304 seamless pipe has earned Shree Impex Alloys respect across the world as a Stainless Steel 304 Seamless Pipe Supplier in India. We are achieving new heights in the production of some of the best 304 stainless steel seamless pipe thanks to our internal capabilities.We provide stainless steel pipes in a variety of cities, including Stainless Steel Pipe Manufacturer in Kolkata, ss pipe supplier in pune and ss pipe suppliers in bangalore

#Stainless Steel 304 Seamless Pipe Manufacturer in India#Stainless Steel 304 Seamless Pipe Supplier in India#ss 304 seamless pipe suppliers in mumbai#ss pipe supplier in pune

0 notes

Text

Stainless Steel 304 buttweld fittings - Nissan Steel offers a comprehensive range of buttweld fittings made from high-quality grades of stainless steel 304, 304L, and 304H.

#Stainless Steel 304 Pipe Fittings#304 Stainless Steel Buttweld Fittings#SS 304L Butt weld Pipe Fittings#UNS S30400 Buttweld Fittings

0 notes

Text

Recyclability and Environmental Impact SS 304 -

In today's world, where environmental consciousness is paramount, the utilization of materials across different industries has garnered considerable focus. Among the stainless steel options available, Stainless Steel 304 stands out as an exceptionally versatile grade, possessing outstanding properties and a wide array of applications. Shree Venktesh Wires and Steels Pvt Limited, a leading Stainless Steel 304 products distributor and supplier in India take pride in being a trusted Stainless Steel 304 Stockist. Our commitment lies in delivering top-notch solutions that cater to the diverse project requirements of our esteemed customers. Whether you are seeking Stainless Steel 304 sheets, plates, coils, or other related products, we offer superior quality at competitive SS 304 prices, ensuring satisfaction at every step. Explore the various grades of stainless steel, including the renowned Stainless Steel SS304, and discover the unparalleled benefits they bring to your projects.

In this blog post, we will explore the recyclability and environmental impact of Stainless Steel 304, highlighting its sustainable characteristics and why it is an excellent choice for various applications.

Understanding Stainless Steel 304

Before we delve into the recyclability and environmental impact of Stainless Steel 304, let's first understand its composition and properties. Stainless Steel 304 is an austenitic grade that contains 18% chromium and 8% nickel, making it highly corrosion-resistant and durable. It offers excellent strength and versatility, making it suitable for a wide range of applications in industries such as construction, architecture, automotive, and more.

The Recyclability of Stainless Steel 304

Stainless Steel 304 is renowned for its exceptional recyclability. Unlike many other materials, stainless steel can be recycled repeatedly without losing its properties or performance. Here are some key points regarding its recyclability:

Infinite Recyclability: Stainless Steel 304 can be recycled indefinitely, making it a truly sustainable choice. It can be collected, melted down, and transformed into new products without any degradation in quality.

Energy Efficiency: Recycling stainless steel requires significantly less energy compared to the production of primary stainless steel. This energy-saving aspect further enhances its environmental benefits.

Reduction of Waste: By choosing Stainless Steel 304, you contribute to reducing waste generation. The ability to recycle stainless steel reduces the need for mining new raw materials and decreases the amount of waste sent to landfills.

Environmental Impact of Stainless Steel 304

Stainless Steel 304's environmental impact is considerably lower compared to other materials. Here's why:

Reduced Carbon Footprint: Stainless Steel 304 production emits relatively low levels of carbon dioxide (CO2) compared to other metals. Its production process consumes less energy and emits fewer greenhouse gases, making it an eco-friendly choice.

Conservation of Natural Resources: By utilizing recycled stainless steel, you help conserve valuable natural resources. Stainless Steel 304's recyclability reduces the demand for virgin raw materials, minimizing the need for mining and extraction activities.

Waste Reduction: Stainless Steel 304's long lifespan and recyclability contribute to waste reduction. By opting for this material, you promote a circular economy where resources are used efficiently and waste is minimized.

Shree Venktesh Wires and Steels Pvt Limited - Your Trusted Stainless Steel 304 Supplier, Stockist, Trader, Dealer, and exporter in India

At Shree Venktesh Wires and Steels Pvt Limited, we understand the importance of sustainable solutions. As the leading Stainless Steel 304 Products stockist, supplier, distributor, trader, and dealer in India. we offer an extensive range of sizes, specifications, and standards to cater to your specific project requirements. Our Stainless Steel 304 products are sourced from Jindal Stainless Steel Limited, a trusted manufacturer known for their superior quality.

We proudly serve various cities in India, including Greater Noida, Himachal Pradesh, Ludhiana, Panipat, Lucknow, Aurangabad, Alwar, Agra, Punjab, Jaipur, Faridabad, Gwalior, Lucknow, and Sonipat. With our commitment to sustainability and customer satisfaction, we aim to be your go-to supplier for Stainless Steel 304 Plates and Sheets.

Specifications of Stainless Steel 304

Standards: ASTM A240 / ASME SA240

Width: 1000mm, 1250mm, 1500mm, 2000mm,

Thickness: 4mm-100mm

Length: 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Surface Finish: 2B (Cold Rolled), N1(Hot Rolled) No.4/pvc, and Ba finish

Hardness: Soft, Hard, Half Hard, Quarter Hard, Spring Hard, etc.

Form: Coils, Foils, Rolls, Plain Coil, Shim Coil, strips, Flats, Blank (Circle), Ring (Flange), etc.

Application of Stainless Steel 304

Stainless Steel 304 is a widely used and versatile stainless steel alloy that offers excellent corrosion resistance, durability, and ease of fabrication. Here are some of the key applications of Stainless Steel 304:

Architecture and Construction

Food Processing and Equipment

Medical and Pharmaceutical Applications

Automotive Industry

Chemical and Petrochemical Industry

Aerospace and Aviation

Oil and Gas Industry

Marine Applications

Other Application

Final Thoughts!..

Stainless Steel 304 Products provided by SV Stainless Steel offer not only excellent mechanical properties and aesthetic appeal but also contribute to sustainable and environmentally friendly practices. With its recyclability, energy efficiency, and durability, Stainless Steel 304 emerges as a top choice for architects, engineers, manufacturers, and individuals seeking reliable and sustainable materials. Choose Stainless Steel 304 for your projects, and join us in promoting a greener and more sustainable future.

#304 stainless steel sheet metal price#SS 304L Industrial Sheets Supplier#jindal steel pipe 304 price#Stainless Steel 304 Plates supplier

0 notes

Text

1 note

·

View note

Text

Everything You Need To Know About Stainless Steel 304 Pipe

stainless steel pipe grade 304 price list Introduction:

Stainless steel pipe grade 304 is a commonly used material in the construction and engineering industries. It is made from an alloy of iron, chromium, and nickel, and is known for its high corrosion resistance and strength. It is often used in the production of pipes, tubes, and other items that require durability and resistance to harsh environments.

There Are Several Advantages to Using Stainless Steel Pipe Grade 304:

Corrosion resistance: The high chromium and nickel content of grade 304 stainless steel makes it resistant to corrosion and rust, even in highly acidic or salty environments.

Strength and durability: Stainless steel grade 304 is known for its high strength and durability, making it suitable for use in a wide range of applications.

Easy to clean: The smooth surface of grade 304 stainless steel makes it easy to clean and maintain, which is important in hygienic environments such as food processing plants.

Non-toxic: Stainless steel grade 304 is non-toxic and does not leach harmful chemicals into the environment, making it suitable for use in the production of food and medical products.

Stainless Steel Pipe Grade 304 has a Wide Range of Applications

Construction: Stainless steel grade 304 is often used in the construction of buildings, bridges, and other structures due to its strength and corrosion resistance.

Automotive: Stainless steel grade 304 is used in the production of exhaust systems and other automotive parts.

Food and beverage: Stainless steel grade 304 is used in the production of food processing equipment, brewing and distillation equipment, and other items that come into contact with food and drink.

Medical: Stainless steel grade 304 is used in the production of medical instruments and equipment due to its corrosion resistance and non-toxic properties.

Conclusion:

In conclusion, stainless steel pipe grade 304 is a versatile and widely-used material in the construction and engineering industries due to its corrosion resistance, strength, and durability. Its non-toxic properties make it suitable for use in the production of food and medical products. While it is more expensive than some other types of steel, its long lifespan and low maintenance costs make it a cost-effective choice in many applications.you can visit thepipingmart for Stainless Steel Pipe Grade 304 Price List.

#stainless steel pipe grade 304 price list#stainless steel pipe grade 304#SS 304 Pipe Price List#SS 304 Pipe Price#SS 304 Pipe

0 notes

Photo

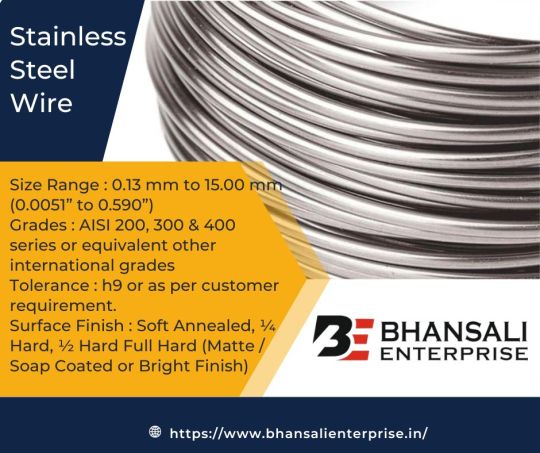

"Manufacturer of Stainless Steel In India."

The highly state-of-the-art infrastructure facility at Bhansali Enterprise undergoes regular update, for reasons of attaining a repudiated and dynamic position in the industry and to maintain high production capacity so that we can cater large quantity demands in limited time. Laced with all the machines and equipment needed, we have been able to develop the offered products as per the modern market developments. In order to attain streamlined and hassle free management of the firm’s operations, the facility has been parted into several functional units. Its superior strength, optimum performance, and longer service life are owed to the best grade raw materials and latest machines used, in line with the norms and guidelines defined by the industry. Apart from this, the offered collection is provided in the market at the most economical price possible. To cater the diverse demands of our clients, we are offering these products in various configurations.

#stainless steel round bar#stainless steel wire#stainless steel wire manufacturers in india#ss 316 chemical composition#stainless steel 316l#stainless steel 304#manufacturer of stainless steel in india#uns s32750#stainless steel 201 cu wire manufactures in mumbai#wire manufacturers#stainless steel round bar manufacturer in india#titanium grade 5#forging of steel#titanium pipes#duplex 2205 stainless steel

0 notes

Text

Main characteristics of stainless steel

weldability

Stainless steel sculpture

Product use of different welding performance requirements are also different. A kind of tableware generally does not require welding performance, even including some pot enterprises. But the vast majority of products need good welding performance of raw materials, such as second class tableware, thermos cup, steel pipe, water heater, water dispenser and so on.

Corrosion resistance

The vast majority of stainless steel products for corrosion resistant performance is good, like a, 2 kinds of tableware, kitchen utensils and appliances, water heaters, water dispensers, etc., some foreign businessmen on corrosion resistance of products also do experiment: in NACL aqueous solution heated to boiling, after a period of time out solution, wash and drying, weight loss, to determine the degree of corrosion (note: When polishing the product, due to the content of Fe in emery cloth or sandpaper, it will lead to rust spots on the surface of the test.

Polishing performance

In today's society, stainless steel products are generally polished in the production of this process, only a few products such as water heater, water dispenser tank do not need polishing. Therefore, the polishing performance of raw materials is very good. The main factors affecting the polishing performance are as follows:

① Surface defects of raw materials. Such as scratches, pitting, pickling and so on.

② Raw material problems. The hardness is too low, it is not easy to shine when polishing (BQ is not good), and the hardness is too low, the surface is easy to appear orange peel phenomenon when deep stretching, thus affecting the BQ. The BQ with high hardness is relatively good.

③ For deeply stretched products, small black spots and RIDGING will appear on the surface of the area with great deformation, which will affect the BQ property.

Heat resistant performance

Heat resistance refers to the high temperature stainless steel can still maintain its excellent physical and mechanical properties.

Influence of carbon: Carbon is an element that strongly forms and stabilizes austenite and enlarges austenite zone in austenitic stainless steel. The ability of carbon to form austenite is about 30 times that of nickel. Carbon is an interstitial element, and the strength of austenitic stainless steel can be significantly improved by solution strengthening. Carbon can also improve the stress and corrosion resistance of austenitic stainless steel in high concentration chloride, such as 42%MgCl2 boiling solution.

But, in the austenitic stainless steel, carbon is often seen as the harmful elements, this is mainly due to the corrosion of stainless steel used in some conditions, such as welding or heating by 450 ~ 850 ℃), carbon steel with chromium in forming high chromium Cr23C6 type carbon compounds which can lead to local chromium depletion, make steel corrosion resistance especially resistant to intergranular corrosion performance degradation. So. Since the 60 s of the development of new cr-ni austenitic stainless steel is mostly carbon content less than 0.03% or 0.02% of the ultra-low carbon type, you can know as the carbon content is reduced, the steel intergranular corrosion sensitivity is reduced, when carbon content less than 0.02% is one of the most obvious effect, some experiments also pointed out that the carbon will also increase the chromium austenitic stainless steel corrosion tendency. Due to the harmful effect of carbon, not only in the process of austenitic stainless steel smelting should be controlled as low as possible carbon content, but also in the subsequent hot, cold processing and heat treatment process to prevent stainless steel surface carburization, to avoid chromium carbide precipitation.

When the number of chromium atoms in the steel is not less than 12.5%, the electrode potential of the steel can be changed from negative to positive. Prevent electrochemical corrosion.

#stainless#304 stainless steel prices#stainless steel 304#ss 304 scrap#stainless steel sheet 304#stainless steel 316#304 ss pipe

1 note

·

View note

Text

Best-Quality Stainless Steel Pipe in India

Pearl Pipe India is a market-leading Stainless Steel Pipe Manufacturer in India and Stainless Steel 202 Pipe Manufacturer in India. Stainless steel pipes are commonly used in industrial settings for the transportation of liquids, gases, and chemicals. Their ability to withstand high temperatures and corrosive environments renders them indispensable in manufacturing processes. We are also the leading Stainless Steel Pipe Manufacturers in Chennai and Stainless Steel Pipe Manufacturers in Bangalore.

Contact us

Phone: +91 91723 33437

Website: https://pearlpipeindia.com

Product Source: SS Pipe Manufacturer in India and Jindal Stainless Steel Pipe Price List PDF

Also visit: Stainless Steel 316 Pipe Manufacturer in India and Stainless Steel 304 Pipe Manufacturer in India

#Stainless Steel 316 Pipe Manufacturer in India#Stainless Steel 304 Pipe Manufacturer in India#Stainless Steel Pipe Manufacturer in India#SS Pipe Manufacturer in India#Stainless Steel Pipe Manufacturer#Jindal Stainless Steel Pipe Price List PDF

0 notes

Text

#jindal stainless steel pipe#jindal stainless steel 304 pipe#ss 202 pipe#jindal 304 pipe#stainless steel 304 pipe supplier

0 notes

Text

.SSP Metal and Alloys is the leading manufacturers of Flanges, Fittings, Fasteners and Stainless Steel Product etc.

SSP Metal and Alloys is the largest manufacturers and Suppliersof the best qualitysuppliers of Industrial Raw Material Like 400 Series Sheet/Plate/Coils, Weided 409 Tubes , Frorged Fitting, Buttweld Fittings,Sheet & Plate, Wire Mesh, Pipes, Tubes, Pipe Fittings, Flanges, Welding Rod, Fasteners, and Process Equipment in UAE, Oman, Saudi Arabia. Yemen, south Africa, Namibia, Nigeria, Sudan, Turkey etc. We understand how critical it is for materials to reach our customers based on the timeline they’re expecting.

#sheet metal fabrication sheet manufacturing sheet metal parts manufacturer industrial sheet metal fabrication ss 304 seamless pipe#tube butt weld

0 notes