#Scrap Grinder Machine

Explore tagged Tumblr posts

Text

Plastic Scrap Grinder Machine Manufacturer, Exporter Plastic Waste Crushing Machine https://www.invoitplast.com/plastic-scrap-grinder-machine/ Each part of this plastic scrap grinder machine is made from superior material, whether it is its body or sharp blades. Plastic Scrap Grinder Machine Manufacturer, Exporter - Plastic Waste Crushing Machine are best suitable for plastic grinding or crushing of Defected and rejected plastic products from Injection Moulding Machine, Blow Moulding Machine, Extrusion lines etc i.e. Chairs, Battery boxes, HDPE Drums, PVC Pipes & Fittings, Barrels, Jerry Cans, Household products, Plastic articles, Toys etc. Invoit Plast Machinery Pvt. Ltd. is also leading exporter of Plastic Scrap Grinder Machine to South #Africa, #Dubai UAE, #Nepal, #Bangladesh and #Qatar. Invoit Plast Machinery Pvt. Ltd. located in Ahmedabad, Gujarat, India., is manufacturer and supplier of Plastic Scrap Grinder Machine and to India specifically Hyderabad, Nasik, Chennai, Baroda, Bangalore and Rajkot.

5 notes

·

View notes

Text

Key Features to Plastic Scrap Grinder Machine Look for When Investing

The demand for sustainable plastic recycling is on the rise as more industries and businesses focus on reducing their environmental impact. One of the most important pieces of equipment in the plastic recycling industry is the plastic scrap grinder machine. These machines play a crucial role in breaking down plastic waste into smaller pieces that can be reused or further processed. But with so many models available, how do you choose the right one? In this blog, we will explore the key features to look for when investing in a plastic scrap grinder machine, while also understanding how it fits into the wider world of plastic recycle machinery.

1. Build Quality and Material

The first thing to check is the build quality of the machine. A plastic scrap grinder machine should be made with high-quality, durable materials, preferably heavy-duty steel. Since these machines are used to grind different types of plastics such as HDPE, LDPE, PET, and more, the machine must withstand continuous usage without breaking down. Machines made of poor-quality material can easily wear out or break, leading to costly repairs and downtime.

2. Motor Power and Grinding Capacity

Another key feature to consider is motor power. The higher the motor power, the more efficiently the machine can grind large volumes of plastic scrap. If your recycling needs are extensive, then choosing a grinder with a powerful motor is essential. This ensures higher productivity and better performance.

Along with motor power, the grinding capacity (usually mentioned in kg/hr or tons/day) is also important. For industrial use, you’ll need a plastic scrap grinder machine with a larger hopper size and higher capacity. For small-scale operations, a medium-capacity machine might be sufficient.

3. Blade Design and Cutting Technology

The blade is the heart of any plastic recycle machinery, especially grinders. Look for machines that come with hardened steel blades that are easy to remove and sharpen. Some machines come with multiple sets of blades for better efficiency and faster grinding. Additionally, check if the blades are adjustable and capable of handling different plastic types and thicknesses.

Innovative cutting technology can improve efficiency, reduce noise, and lower the risk of jamming, all of which contribute to smoother operations.

4. Safety Features

Operating heavy machinery always comes with safety risks. That's why it's vital to choose a plastic scrap grinder machine equipped with solid safety features. Some of the must-have safety features include emergency stop buttons, safety locks, overload protection, and enclosed grinding chambers to avoid accidental contact with blades. A machine with proper safety certifications is always a better investment in the long term.

5. Noise and Vibration Levels

Industrial machines are known to be noisy, but advancements in plastic recycle machinery have led to models that operate with less noise and vibration. Low-noise machines create a better working environment and help prevent long-term hearing damage in workers. Machines with vibration control also tend to have longer lifespans and require less maintenance.

6. Maintenance and Spare Parts Availability

Before buying, consider how easy it is to clean and maintain the machine. Regular maintenance is essential to keep your automatic pulverizer machine running efficiently. Check if the manufacturer provides detailed maintenance manuals, service support, and readily available spare parts. A machine that is easy to clean and maintain will save time, reduce downtime, and extend the machine’s overall lifespan.

7. Energy Efficiency

With increasing electricity costs, energy efficiency is becoming a major concern for businesses. Look for plastic recycle machinery that consumes less power without compromising on performance. Some modern machines come with smart control systems that optimize energy use based on load and capacity. Investing in an energy-efficient model can lead to significant savings in the long run.

8. Compatibility with Pulverizer Machines

If you are using or planning to use an LLDPE pulverizer machine or an automatic pulverizer machine, it’s crucial that your grinder machine is compatible with them. The output from the grinder should match the input requirements of the pulverizer. Seamless integration ensures a smooth flow of materials between machines, boosting productivity and reducing manual intervention.

Some grinders come with adjustable output sizes, allowing better control over the size of shredded plastic. This is particularly useful when feeding material into an LLDPE pulverizer machine, which requires consistent granule sizes for uniform pulverizing.

9. Automation and Smart Features

The future of plastic recycle machinery lies in automation. Machines with smart sensors, automatic shut-off systems, load balancing, and real-time monitoring reduce human effort and improve efficiency. An automatic pulverizer machine or a grinder with automated features can drastically enhance your recycling operations and minimize errors.

Look for features like auto-reverse (to prevent jamming), touch-screen panels, and remote diagnostics that add convenience and improve operational control.

10. Brand Reputation and Customer Support

Last but not least, always buy from a trusted manufacturer with a good market reputation. Check customer reviews, case studies, and after-sales support. A well-known brand often ensures better quality, warranty coverage, and long-term support, which is vital when dealing with industrial plastic recycle machinery.

Conclusion

Investing in a reliable plastic scrap grinder machine is an important decision for any plastic recycling business. By focusing on key features like motor power, build quality, safety, blade design, and automation, you can ensure long-term value and efficiency. Also, don’t forget to ensure compatibility with related equipment like an LLDPE pulverizer machine or an automatic pulverizer machine, so you can build a seamless and powerful recycling setup.

#Plastic Recycle Machinery#Plastic Scrap Grinder Machine#LLDPE Pulverizer Machine#Automatic Pulverizer Machine

0 notes

Text

Comprehensive Guide to Plastic Scrap Grinder Machine Prices in India

Plastic grinder machines are crucial in the recycling industry, playing a significant role in processing plastic waste into reusable material. Understanding the pricing of these machines in India is essential for businesses looking to invest in efficient recycling solutions. This article delves into the factors influencing the price of plastic scrap grinder machine and provides an overview of what you can expect when purchasing one in India.

Factors Influencing Plastic Grinder Machine Prices

Several factors influence the price of plastic grinder machines in India:

Machine Capacity: The capacity of the grinder, measured in kilograms per hour (kg/h), significantly affects the price. Higher capacity machines that can process more plastic waste will generally be more expensive.

Blade Quality and Type: The quality and type of blades used in the grinder impact the machine's price. Machines with high-quality, durable blades will cost more but offer better performance and longevity.

Motor Power: The power of the motor, usually measured in horsepower (HP), affects the machine's efficiency and price. More powerful motors can handle tougher materials and larger volumes, thus increasing the cost.

Build Quality: The materials used in the construction of the machine, such as high-grade steel, affect durability and price. Machines built with robust materials will last longer and withstand heavy use, justifying a higher price.

Features and Automation: Advanced features such as automated operation, adjustable settings, safety mechanisms, and ease of maintenance can add to the machine's cost. These features enhance usability and efficiency, making the investment worthwhile.

Brand and Manufacturer: Established brands with a reputation for quality and reliability, like Mechnocraft, often charge a premium for their products. Investing in a reputable brand ensures better customer support and product performance.

Price Range of Plastic Grinder Machines in India

Based on the above factors, plastic grinder machines in India can vary widely in price. Here’s a rough breakdown of the pricing:

Small Capacity Machines: These are suitable for small-scale operations and can process up to 50 kg/h. Prices typically range from ₹1,00,000 to ₹2,50,000.

Medium Capacity Machines: Ideal for medium-sized businesses, these machines can process between 50 to 200 kg/h. Prices generally range from ₹2,50,000 to ₹5,00,000.

Large Capacity Machines: Designed for large-scale operations, these machines can process over 200 kg/h. Prices start from ₹5,00,000 and can go up to ₹10,00,000 or more, depending on the specific features and capabilities.

Where to Buy Plastic Grinder Machines in India

India has several manufacturers and suppliers of plastic grinder machines. When looking to purchase, consider the following:

Local Manufacturers: Companies like Mechnocraft offer a range of high-quality plastic grinder machines with excellent customer support and after-sales service.

Online Marketplaces: Platforms like IndiaMART, TradeIndia, and Amazon India offer a variety of options from different manufacturers, providing a convenient way to compare prices and features.

Trade Shows and Expos: Attending industry trade shows and expos can provide insights into the latest models and technologies, allowing for informed purchasing decisions.

Conclusion

Investing in a plastic grinder machine is a crucial decision for businesses in the recycling industry. Understanding the factors that influence the price and knowing the typical price ranges can help you make an informed choice. For high-quality machines with reliable performance, consider contacting reputable manufacturers like Mechnocraft. Their expertise and range of products can provide the perfect solution tailored to your needs.

0 notes

Text

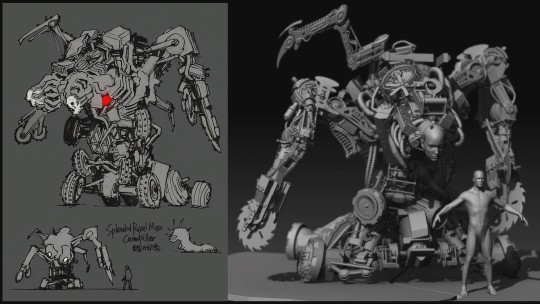

KARL HEISENBERG CONCEPT ART

● Karl Heisenberg

↳ Heisenberg's main concept is based on Frankenstein. We wanted to create a cool gray-haired character who was a little rough around the edges. He smokes his favorite Cuban cigars.

↳ An early draft of Heisenberg's family. The biggest difference was that Heisenberg was going to be a twin and his mother was a subject for brain experiment.

● Mutated Heisenberg

↳ We went for a look that was the opposite of his human form, a giant mechanical monster. The design based on the idea that he uses scrap left scattered around the factory. He owns weapons from tanks and planes, and has mountains of scrap for his mass-produced experiments.

● Mutated Heisenberg in Detail

↳ The original design was based on the splendid royale moth caterpillar. We wanted him to look like he moved on treads and be faster than any other boss monster.

↳ Heisenberg's father was going to be the leader of the village, and the boss fight with the mechanical mutation was originally going to be with him.

↳ Concept art of a day in the life of Heisenberg. Night after night his modified henchmen dig up corpses from the graveyard to be used in his metal army.

● Soldat Eins

↳ We called these enemies "Drillman" for a long time during development because one arm was replaced with a drill. The idea for these enemies is they have a reactor inside their chests with the parasite inside that acts like an internal combustion engine. The goggles are units that Heisenberg uses to control them.

↳ Designs for various Soldat reactors, but the final design was a grotesque mechanical heart.

● Soldat Panzer

↳ We consciously created the enemies in the factory to be different so they didin't just terrify players but also created a strong sense of anticipation. The design was based on Western medieval armor and helmets.

● Soldat Jet

↳ We were really attached to the name "Jet Drill" during development. They use jets on their backs and their heads look like fighter planes. The design is similar to the horseshoe crab. We designed the front and back with different amounts of detail so the back would be particularly shocking.

● Sturm

↳ The propeller on his head is made from three chainsaw blades. He chopped his own arms off when they got in the way of the spinning blades. There was one plan to have the Sturm be Heisenberg's real father. And during development he was called "Propeller Man."

● Bridge Ruins

↳ Concept art for the bridge to Heisenberg's factory. It was initially going to be just to the side of the path leading to the Altar ruins.

● Sturm Attacks

↳ Sturm chasing Ethan down a narrow corridor, destroying everything in his way.

● Giant Cavern

↳ The concept art for Heisenberg kicking Ethan down into the hole and the giant cavern under the factory.

● Casting Machine

↳ A casting machine which uses molds to create objects made out of cast iron. This concept for a puzzle was around since early development as a way to create a key.

● Foundry

↳ This room was once only used for casting iron but Heisenberg ended up utilizing it for his experiments. This room links to the hidden engine room.

● Engine Room

↳ An engine room powered by giant pistons.

↳ Concept art for Heisenberg's factory where Ethan is chased by the Soldat series. If the reactors in their chests are destroyed then the parasite inside will attempt to escape.

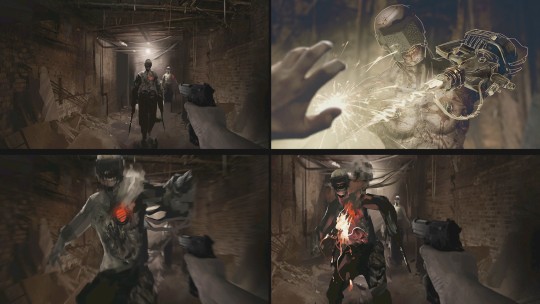

● Grinder Shaft Fight

↳ A fight inside the grinder shaft. These were early designs for the Soldat Jet. We originally imagined a space where they could freely fly about.

● Heisenberg's Key

↳ We went with a design that had a powerful looking horse just like the one on Heisenberg's crest.

● Start of the Battle With Heisenberg

↳ Concept art for the flow of events leading up to the battle with Heisenberg. We pictured Ethan falling into the pit around dusk and returning from it to a dark stormy night sky. The general layout of events didin't change much from early development.

● Mutated Heisenberg-Fight 1

↳ Concept art for the boss fight with Heisenberg. Even early on in development this battle was going to commence with a self-propelled artillery. The only difference is that in the final version, Heisenberg is not defeated using falling transmission towers.

● Mutated Heisenberg-Fight 2

↳ We figured that Heisenberg's yard would be full of scrap and vehicles, which he uses during the fight.

↳ Boss fight with mutated Heisenberg where he turns into his final form.

#resident evil 8#resident evil 8 village#resident evil village#re8#re8 village#re village#Lord Heisenberg#Karl Heisenberg#Heisenberg

151 notes

·

View notes

Note

What kind of bitties would be ok with someone who likes to scrap? I'm talking them having a workshop and everything. The place will probably be perpetually a little dirty and a bit of a mess, me and my dad clean our area pretty often, but yknow.

They would also have to be okay with loud notices. Despite what shows might tell you, most scrappers down need loud machines for most work, but it is still good to plan ahead of time. Things like sawzalls and grinders aren't used often, but they make a bunch of noise.

I'm asking because I'm thinking about writing a short(ish) story on a character who scraps, but ends up adopting bitties as well.

*Thankfully most of the lamia bitties that would enjoy scrapping (I'm assuming you mean more scrapbooking and crafts and not recycling scrap metal) wouldn't mind the noise. There are a few lamia bitties that would definitely NOT like the noise though.

Yay for scrapping: Papython, Krait, FireRing, Pygmy, Chain, Mamba

Boo for loud noises: Krait, Honey Bo, Coral

Mostly indifferent to both scrapping and noise: Corny, King

*Cornies and Kings wouldn't mind helping you scrap, especially if the Corny can make puns while doing it, but it isn't their thing. Corals will want to swipe your materials, but the noise of power tools might be overwhelming for them as well as Kraits and Honey Bos.

*I hope my late answer didn't interfere with you writing your story!

#vexy answers#valiantsuitcaseskellington#lamia bittybones#bittybones#lamia bitty imagines#lamia bittybones and scrapping

19 notes

·

View notes

Text

Modification

I want to share a little project I've been working on this past week. It may seem like nothing, but it was a lot of work and a big pain until I got it done.

Back when my spouse and I moved into our current house, I immediately recognized a dearth of counter space in the kitchen. We resolved this by purchasing a buffet table from Ikea. The table in question was a "Norden" model, which they have since discontinued. Simple enough table, a bit over a meter long and maybe a third that in depth, two drawers and two additional shelves. Great for holding kitchen appliances on top and storage below.

The first thing I did was add locking casters to the bottom so I could move it around easily. That's been a big bonus, as it makes cleaning much easier. I also put some hooks on the ends to hang my cast iron pans.

The problem arose I guess about three years ago when I upgraded to a commercial-grade espresso machine. The Gaggia was okay, but the Expobar is in a completely different class. And that's GREAT for good coffee. For a tabletop that's made of laminated particle board? Not so much.

Now, I had been aware of this problem for a while. I'd tried to ameliorate it by putting a silicone baking mat on top of that side of the table; that slowed down the deterioration, but did not stop it. It was also a daily annoyance, as the espresso machine moved a bit when I torqued the portafilter in place and it would get bunched up. About once a week I would have to lift the espresso machine and move things back.

This came to a head two weeks ago when I took the espresso machine in for some repairs and had to face that the tabletop was ruined. My initial thought was to get a replacement top from Ikea and then put maybe a piece of stone countertop in where the espresso machine sits.

This ran into two problems. First, as I mentioned before, this particular item is discontinued. Ikea will honor the warranty, and the Ikea rep tried pretty hard to make that work, but the reality is I got it too long ago and whatever abuse it's undergone is my problem; they don't sell the parts for it anymore.

Second, stone countertops are EXPENSIVE. While I just want what might be considered scrap, it was still going to be a lot of money, and I was not able to find a source.

Eventually I want to replace the entire thing with something I build myself, and I have some ideas for that. However, right now I have neither the time nor skill to make that happen. I was going to have to replace the top myself.

Since I didn't want to pay for stone, I opted for metal. I ordered a 4'x2' sheet of metal from McMaster and proceeded to prep the top. I sanded down the areas which were bubbling up and roughed up the rest of the surface.

Then, once the metal arrived I used my angle grinder to cut it to width and round the sharp corners. I had this notion that I might bend it over the top and maybe nail it down, or see if I could knurl the edges. However, while I think that was maybe possible, to do it well would have called for tools I don't have and skills I generally lack. The steel was 0.03" thick rolled mild steel. While that's not exactly a knife's edge, and you can touch it without cutting yourself, it's not exactly safe. And although I got much better with the angle grinder in the process (I had a grinder and hardly ever used it), the cut edges were a but uneven. So, I ordered some rubber edging.

In the meantime, I put the metal on the buffet table and prepared it.

I opted for a matte finish, since I would need better buffing tools than I have to get a mirror finish, and matte is easier to maintain than brushed. Since it's mild steel - which rusts easily - I sealed it with a spray lacquer.

Today, the rubber edging finally arrived. This is the same stuff you have on the edges of your car door. I glued it in place, except for one small section which is removable so I can easily clean detritus like coffee grounds off the table top. I also added two receivers to hold the feet of the espresso machine so it doesn't move when I put in the portafilter.

And, behold!

The result looks almost nothing like the original buffet table from Ikea. Someday I'll make something better, but whatever I make will be strongly informed by this, which has been heavily modified to fit my use case.

14 notes

·

View notes

Text

Exporter of LDPE Film Scrap Washing Line in Kuwait

R Mech Machines LLP is an Exporter of LDPE Film Scrap Washing Line in Kuwait. R Mech Machines LLP was established in 2008 in Ahmedabad, Gujarat, India. Our offerings encompass Plastic Scrap Turbo Washing Machines, Plastic Scrap Grinder Machines, Plastic Scrap Shredder Machines, Blade Sharpening Machines, Screw Press Squeezer Machines, Friction Washer Machines etc. Overview: We designed the LDPE washing system to clean contaminated film or thin materials. We design the grinding machine to create standardized particle sizes that are easy to wash and dry for film or thin materials. The high-speed turning of the rotor produces centrifugal force, which we utilize to remove dirt and sand from the washer. We use floating materials such as LDPE/HDPE/PP film/labels on the top and sink materials like PVC/PET/PC on the bottom. Both have separate discharge points to collect different materials based on density. Horizontal dryers and thermal drying systems control the moisture content of the finished product. At a moisture level of less than 5%, the material is appropriate for high-quality pelletizing. Features: Steel body structure User friendly Longer running life Smooth finish R Mech Machines LLP is an Exporter of LDPE Film Scrap Washing Line in Kuwait and places like Kuwait City, Mahboula, Ahmadi, Salmiya, Jabriya, Hawally, Zour, Sabah Al Salem, Al Farwaniyah. If you have any questions or need more information, feel free to reach out to us. Read the full article

#Ahmadi#Ahmedabad#AlFarwaniyah#BladeSharpeningMachines#cleancontaminatedfilm.dryingsystems#createstandardized#Exporter#ExporterofLDPEFilmScrapWashingLine#ExporterofLDPEFilmScrapWashingLineinKuwait#FrictionWasherMachines#Gujarat#Hawally#high-qualitypelletizing#high-speedturning#Horizontaldryers#India#Jabriya#Kuwait#KuwaitCity#LDPEFilmScrapWashingLine#LDPEFilmScrapWashingLineinKuwait#Longerrunninglife#Mahboula#Manufacturer#PlasticScrapGrinderMachines#PlasticScrapShredderMachines#PlasticScrapTurboWashingMachines#SabahAlSalem#Salmiya#ScrewPressSqueezerMachines

2 notes

·

View notes

Text

Answers to Common Plastic Granulator FAQs

Plastic granulators are widely utilized in plastics processing but also involve some common areas of concern. Here are answers to frequent questions about granulators:

How are granulators different from shredders or grinders?

Granulators use sharp rotating blades to cut plastics into uniform chips or particles. Shredders tear and grind plastics into uneven shapes.

What safety risks are involved?

Rotating blades pose injury hazards if not properly guarded. Other risks are dust explosions and noise. Proper precautions are essential.

What throughput can I expect?

Throughput depends on material, particle size, rotor speed and more. Typical rates range from 200 lb/hr for small units to over 2000 lb/hr for large granulators.

How much power do they require?

Common motors range from 5HP to over 100HP. Harder plastics need more power. Hydraulic drives offer variable speed control.

What maintenance is required?

Key tasks include blade sharpening or replacement, belt tightening, lubrication, cleaning out material buildup and inspection of screens and bearings.

What are common problems and troubleshooting tips?

Issues like irregular particle size, overheating, vibration, jamming or speed fluctuations generally point to worn blades, blocked screens, buildup or improper settings.

What safety features are recommended?

Lockable hoppers, emergency stops, machine guards, dust collection and noise reduction measures should be used.

With proper selection, operation and maintenance, plastic granulators can reliably and efficiently process plastic scrap for recycling or reuse in production.

2 notes

·

View notes

Note

valiantsuitcaseskelli...

Hello!

I would like to know which bitties would be best for people who do scrapping?

They would most likely need to be okay with a dirty space, as work areas are seemingly perpetually dirty in some way, even when me and my dad clean our place pretty often, there's still some kind of mess, usually residues like dust or screws about.

They would also need to be ok with loud noises, as even though sawzalls and grinders aren't used often, they are very loud machines and are good to take into account

I'm asking because I plan on making a short(ish) story about someone who scraps and also ends up with some bitties.

P.S. I am asking other bitty shops the same question, so don't feel bad if yours doesn't get in the story. I am able to send you the story either way if you so with.

Oh I would definitely say my Rice and BossMouse pair- however loud noises can be painful-

I could make a hard of hearing pair though this might cause conflict or trouble for your character-

not only that but a double hard of hearing pair would be extremely rare and almost a one in a trillion chance to happen due to how my pairing system for my BossMouses and Rice work- (the weakest go with the strongest) perhaps… a rescue pair-? yes yes-! Most likely a fighting ring pair- they will be extremely jumpy- and because if the noise constantly they will had damaged ears-

this is a common Injured and disability from a Pit fighter BM and Rice!

both love scraping and gems and making jewelry! Their quick on their feet, very sensitive to different things like vibrations and smells, they make and Shape their own jewelry by breaking and bending scrap and gems of different kinds! They shape form and melt metals with innovation and a very smart! Creating their own little machines and weapons using scrap and such things! ^^ and they don’t mind mess at all! In fact they thrive in it by making secret stashes and nests in ones messy piles!

(I would love a link to see the story!)

#bittybones#my asks#Valiantsuit-ask!#Rice Bitty#BM Bitty#BossMouse Bitty#Ask#Bitty ask#Bitty pairing#Bitty adoption

4 notes

·

View notes

Text

https://baobikhangloi.com.vn/mang-phu-nong-nghiep-duc-lo-san

Perforated agricultural film products Between the conventional coating and the perforated film, users often choose the non-perforated type because they are significantly cheaper. Pre-perforated coatings are more expensive not because the cost of the perforating equipment is too high, but because this perforation will slow down the overall system productivity considerably. However, in our opinion, the high price of these products is completely worth the performance they bring. If you've ever used mulch for your growing work, you'll understand that punching holes for seeds or seedlings is a tedious and time-consuming task. Before the advent of perforated mulch, farmers around the world thought of many ways that this perforation could be done faster and easier.

On the smallest and simplest scale, they use knives, scissors or any other sharp object to make a cross in the membrane, then fold the excess plastic underneath to create holes shaped like square. This manual folding of 4 pieces of plastic takes a lot of time, the strength of the film is also weakened and it is easy to tear at the location of the cuts.

More advanced cutting tools for making circular holes in the coating have also been invented. Old milk cans are drilled with 2 small holes and inserted electrical wires to make handles, then hot coals are inserted. When the can of milk is hot enough, the farmer carries it away and places it on top of the mulch already spread in the garden, in the places where they want to drill holes. The plastic at this location will melt into the shape of the bottom of the box, and another farmer can go behind to collect the excess plastic. Plants or seeds can also be transplanted at this time.

In the same way as above, there are places where it is very popular to use wire mesh frames in old car air filters, especially those of light trucks and pickup trucks. The sharp edges on the mesh combined with the temperature of the coal inside will cut through the plastic film more easily. Instead of coal, one can also use kerosene or scrap plastic, or whatever as long as they are capable of burning for a long time.

Some people also use old PVC pipes, using a grinder to cut the pipe edges into a serrated shape to create a hole punching mold. When we forcefully press the water pipe into the covered ground, we will also get round holes like other methods. However, in hard areas, the plastic saw teeth will easily wear or break. Currently, metal punching tools with a similar design have also been sold a lot on e-commerce platforms. There are even variations that use electricity from the battery to heat. However, no matter how creative these tools are, they are still manual, still consuming a lot of labor to perform on large agricultural lands. To cater for farming on such a scale, automatic agricultural film punching machines have been built. They are integrated right on the film production line, to produce pre-perforated agricultural films. Machined perforated agricultural film will have holes with uniform size and spacing according to pre-set parameters. These distances will be calculated to leave the most reasonable space for the growth of the plant's roots. Currently, our Khang Loi company has invested in machinery system to produce perforated agricultural films, perforated on both transparent films and 2-layer films with one black side and one side. grey. Although our large format plastic films or agricultural mulch can reach up to 8 meters wide, our mulch punching machine currently only works on films up to a maximum size of 8 feet. 3 meters. We will give you the option of 1 to 4 rows of holes. Each hole is 8cm in diameter and the distance between holes is customizable. Our perforated agricultural film products use virgin resin as the main material, blended with special additive formulations to increase UV resistance and durability. Flexibility is also an advantage worth mentioning. This property makes our products resistant to the tension that occurs during installation, and is compatible with all mechanical punching operations, seeding operations, seedling without worrying about damage. membrane will be torn. If you have a need or need more advice on the product, please contact us at 0902.732.168, or leave us a message in the contact section. Thank you very much!

2 notes

·

View notes

Text

Plastic Scrap Grinder Machine

Believe Machinery is leading plastic scrap grinder machine manufacturer in India, our offer plastic scrap grinder machine are respected and approved for its dimensional precision, durability and high strength & quality, these offered machines are highly acknowledged. furthermore, these are manufactured and developed with the utilization of supreme quality basic material and progressive tools and machinery. Our offer pvc pulverizer machine, lldpe pulverizer machine, automatic pulverizer machine, wpc pulverizer machine, spc flooring pulverizer machine high demanded in market for their production quality.

1 note

·

View note

Text

Vingettes of Helotage in Antarctica I

A helot guides waste buckets into a macerator at a recycling plant, pulling them off the line and over the gnashing teeth. It must be quick because the momentum of each can easily drag it along. It has been 10 hours on a shift that will stretch to sixteen. It is delerious and grips too tightly to a bucket that drags it over the railing. Almost before it is aware it falls in to the grinder, nerves searing with the pain of broken limbs being tugged into metal teeth

It screams and begs for help while it is slowly dragged into the teeth feet first. Other slaves rush to figure out how to shut off the machine while viscera mixed with scrap iron is deposited in chunks on the floor. One of them manages to shut down the machine but half of its torso is gone and it dies shortly thereafter from blood loss. They then have to painstakingly go through the scrap and separate out the chunks of bone and meat before it goes into the smelter to ensure it has the right composition.

1 note

·

View note

Text

Plastic Waste Extruder Machine

Discover sustainable solutions with HIKON INDIA's Plastic Waste Extruder Machine. As a leading name in the plastic recycling industry, we're dedicated to transforming waste into valuable resources. Our cutting-edge technology and precision engineering ensure efficient and reliable performance, reducing environmental impact while maximizing productivity. With our state-of-the-art manufacturing facilities, we deliver innovative solutions to tackle plastic waste effectively. Whether it's plastic scrap grinders, shredder machines, or PET recycling plants, our products are engineered for excellence. Join us in creating a greener future with HIKON INDIA's Plastic Waste Extruder Machine – turning waste into opportunity.

#plastic waste recycling machine#plastic recycling india#plastic recycling machine#waste plastic washing plant#plastic scrap crusher

0 notes

Text

0 notes

Text

Our Plastic Scrap Grinder Machine is widely appreciated by the clients for its features like Size, operation and maintenance, high speed grinding and production, Strength level and performance.

0 notes

Text

Plastic Scrap Shredder and Grinder Machine in Tamil Nadu

#plasticrecyclingmachine #hdperecycling #plasticrecycling #wasteplasticrecycling #wovensacksrecycling #mlpscraprecycling #Ahmedabad #Gujarat #india

0 notes