#Shaft Slicing Machine

Explore tagged Tumblr posts

Text

generous. toji f.

toji, who after a while of having sex with you decides his new favorite position is missionary.

but it’s not really because it feels the best to him, or because he’s face to face with you even though it’s a pro to the situation.

toji fucks you in missionary because he’s unhealthily obsessed with the fucked out, gawk you always make at him whenever he feeds your cunny slow, long, and deep strokes.

he fucks you so specifically in missionary too, specifically, because if he does it in a certain way for long enough you end up squirting! that’s why he’s got both your legs over his shoulders, your hands grazing up and down his happy trail in a delusional haze, and both his strong arms putting work into making sure you don’t run from him.

“toji—nnhhh”

“stop moving”

his cock slams into you and is pulled back out in a slow machine like manner. toji is running his palms up and down the shin of your soft legs while he bottoms out.

with every stroke you’re yelping when his pelvis comes all the way down and kisses yours, your hands digging all into his nice strong forearms.

it really doesn’t help that he has so much girth when it comes to his cock as well, it feels like he’s splitting you in half when he bottoms out.

every time you guys are in a place where he can take you in missionary, definitely believe it’s the first and only position you’ll do if you don’t ask for anything else, toji says he wouldn’t mind only having sex like that for the rest of his life.

this obsession your boyfriend has with fucking your in missionary eventually leads to a breeding kink. just the thought of fucking such a cute little baby into you in such a rough way turned him on like nothing else.

being able to see your puffy pink lips parted and open while you furrow your eye brows trying to watch his cock slide in and out of you was his little slice of heaven to get through the day—but toji knew it was gonna be a great day if you squirted that morning.

toji who also sloppily rubs his thumb over your clit to get a little extra cream to slip right out of your cunny and slide to the base of his unshaven shaft, just because he likes to see it.

blondieeu xx

#blondieeu#smut#jjk nanami#jujutsu gojo#jujutsu geto#jjk smut#jjk gojo#jujutsu nanami#gojo jjk#fushiguro toji x reader#toji x you#toji smut#jjk toji#toji fushiguro#fushiguro toji#toji x reader#toji zenin#jujutsu toji#jujutsu kaisen toji#toji fluff#fushiguro#jjk fushiguro#fushiguro x reader#jujutsu kaisen fushiguro#itadori x fushiguro#megumi fushiguro#fushiguro toji smut#gojo fluff#gojo smut#gojo x reader

3K notes

·

View notes

Note

Ooooooh love that concept, pls continue :0

Since this au was just in the brainstorming phase and I'm still gathering some ideas and references to this story so bear with me here, anon ^^')

Ehem.

Okay, Imagine that when the heroes thought the galaxy was safe when all the power spheres were secured, when all considered bad guys were gone for good, people were entrusting more to TAPOPS as they will always ensure the safety of each planet. And with all those new generations of heroes are more ready to face the threat than ever.

Nothing will worry them, right?

--- --- ---

Woke up,

Collect the dump,

Mold it into solid cubes using the cube molder tool.

Send it to the big boss at Gogo Ba's Barter Shop,

Get some food, then

Go home.

That's the daily order that he pinned in his brain. Simple for us as trash workers to not do political and complicated things like most Gur'latans to present new game-breaking systems; have no fear of death to survive in the harsh fields of Baraju; ensure billions of living beings to farm supplies and goods in Rimbara; or think revolutionary to manage the logistics and transportations like people of Windara.

No, Gugura is the last nation to end your life and once you move in, there will be no escape. Only higher-ranking citizens were allowed to go in and out of this city. Therefor, why do people visit this nation of scraps? The place barely has eye-catching sights and the only souvenirs for tourists were the bunch of cube-shaped leftovers' irons, woods, and any waste kinds you'll find.

Despite the fact it's a country of all wanted list persons that were mostly thrown by the Cubulus' authorities, Gugura is a fine city for this young teenager to live in. His life was already covered in the present and future. Does that mean he made a bad accusation that made him displaced into this area?

That part was still a mystery to the boy with a single white highlight in the middle of his black messy hair. He never remembered where he was born, his profile, even his name. All he knew, the tag number embedded on his neck was clear enough to remember.

...Or so he thought.

.

'No were to run, _____! Hand over your power watch!'

'Never! Now _____!'

'Wha-?!'

'Teleportation Power!'

'NO!'

'Time Manipulation!'

'____ Hepta Split!'

'You little--!'

.

"#319!"

The sudden high shout erased the boy's dream into reality. "Y-yes sir?"

The cubed helmet soldier pointed the taser gun at the teen's stiffness, "Did I command you to rest?! No sleeping on the job!"

Without protest, #319 hurriedly continued scooping scraps near his feet and throwing them into a mine shaft. It created a whirring sound of gear moving from a cube machine behind him. No need to wait long as it released a perfect solid cube shape from preseed scraps.

The boy peeked at the soldier from his window eye. The man already turned around to inspect the other workers in front of him. It made him at ease for a moment. The boy looked in his pocket and reached out for a small item he found not long ago.

A watch. Just a small, broken ordinary blank watch that he sure it would more useless to bargain for a slice of bread at Bago Go's. He should have put it along with other scraps in the shaft. He was not the kind of collector person unless it was useful and practical for his home. So what was different with this item? He never knew.

But....

That vision interrupts his routine for the fifth time this week. Ever since he found that watch, his peaceful daily work slowly bothered him. He could not sleep normally as that vision--no, nightmares that were done over and over like a broken record. Never once in his life he could shout such a high note while grabbing that old watch in tremor, as if his life depends on it in the next second.

If so, why was he still kept the cursed thing intact?

"....He's now under your supervision."

Hm?

"heh... well I'm in need for someone to replace my spot anyway."

A new replacement?

"You're in luck, Oju Ju! This youngster here is a keen eye for everything you missed, skillful and his snarkiness shows no mercy to command these workers. A perfect discipline for your replacement."

He turned around. A very peculiar shorter soldier who wears round helmet than other common taller and cube helmet ones. A human perhaps? Besides, did the higher ups are now recruiting new generations as well? To this nation? It did not matter to him anyways. Whether young or old, the boy should not underestimate them.

Especially with the new one who he bet from the height was as same as his age.

....

That's all for now!

In short, this is how Gempa and Solar met.

A bit fun fact, Some places like Bago Go's barter station are just a mere name as a legacy to the owners. Some characters are OCs but not too important since...I'm not the oc author. But I still want to interpret the similar traits from their ancestors. Also, I'm still trying to figure out when I use the original ones due to this concept.

Btw I got some inspiration to this au from another headcanon that I found in the same account.

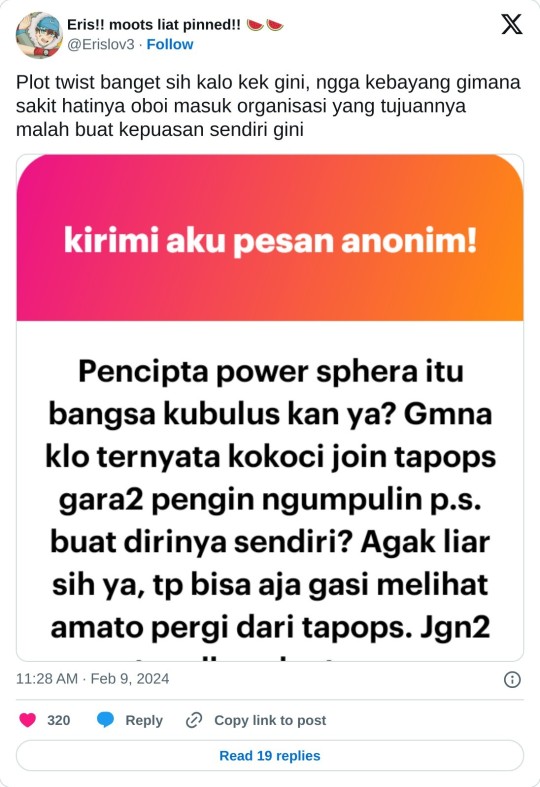

Rough translation:

"What a plot twist indeed if that's the case, can't imagine how painful Oboi felt to join an organization that become spiteful"

Picture translate:

'The Kubulus nation is the creator of the power sphere, right? What if it turns out the purpose of Kokoci's joining TAPOPS is to collect all of them for himself? A bit wild but we can see it from the scene of Amato leaving from TAPOPS, can't we? Perhaps Amato realizes the Organisation's intention is not that pure, hahahah'

Whether it's true or not, it somehow a bit makes sense in a wild way. Oooooooh It would be an interesting twist and more in betrayal than Fang's statement in arc Gur'latan issue 24.

Anyway, apologies if you find any typos or weird meanings in my word choices.

#boboiboy#boboiboy galaxy#bbb#bbbg#yet if know the reference. I salute you#That's also how I imagine when the first time I know Gugura from movie 2#Now excuse me. I need to learn drawing for this story.#aaaaand learning more of english I guess.#bbbglxs2#boboiboy au#319 au#menjawab anon

4 notes

·

View notes

Text

Concrete Saw Cutting

Concrete Saw Cutting: Power and Precision in Modern Construction

Concrete saw cutting is a cornerstone technique in the construction industry, used to modify, shape, and remove concrete with high accuracy. Whether cutting through roads, walls, or floors, this process makes it possible to access utilities, create openings, or remove damaged sections of concrete without compromising the surrounding structure. From large commercial projects to intricate residential modifications, concrete saw cutting is essential for shaping the built environment with control, safety, and speed.

Understanding Concrete Saw Cutting

Concrete is valued for its strength and durability, but these same properties can make it difficult to modify. Concrete saw cutting solves this challenge by using specialized equipment designed to slice through even the hardest surfaces with minimal disruption. The process involves diamond-tipped blades rotating at high speeds to cut through reinforced concrete, asphalt, masonry, and stone. These blades grind their way through the material, rather than tearing it apart, allowing for clean and controlled results.

Concrete saw cutting is used in both new construction and renovation projects, enabling contractors to install doors, windows, utility systems, and drainage solutions or remove portions of structures that need redesign. It offers a level of precision that demolition tools cannot, making it the preferred method when accuracy matters.

Types of Concrete Saw Cutting Methods

Depending on the project’s size, location, and goals, different saw cutting techniques may be used. Each method is suited for specific applications and provides unique advantages.

1. Flat Saw Cutting (Slab Sawing)

Flat saw cutting, also referred to as slab sawing, is performed on horizontal surfaces such as driveways, sidewalks, bridge decks, floors, and roads. It involves a walk-behind or ride-on machine equipped with a diamond blade that can penetrate several inches into the surface.

This method is commonly used for:

Cutting expansion joints

Removing damaged pavement or flooring

Accessing underground utilities

Leveling uneven concrete

Flat saws offer excellent depth and straightness of cut, making them ideal for large-scale outdoor and indoor work.

2. Wall Saw Cutting

Wall saw cutting is used on vertical or inclined surfaces, such as walls or steep ramps. These saws are usually track-mounted and controlled remotely for maximum accuracy. The blade travels along the track and can make both vertical and horizontal cuts to create precise openings.

Wall saws are essential for:

Installing windows and doors

HVAC and plumbing access

Creating ventilation shafts

Cutting through retaining walls

They can cut through reinforced concrete with ease and often reach depths of over two feet, depending on the blade size and machine power.

3. Hand Saw Cutting

Hand saw cutting is used for smaller, more intricate cuts or in areas where larger machines can’t reach. These handheld saws are highly maneuverable and can be used on floors, walls, ceilings, and corners.

Hand saws are typically used for:

Light demolition

Detail trimming

Tight spaces or confined areas

Cutting around pipes and conduits

While limited in cutting depth, hand saws are excellent for jobs requiring agility and fast turnaround.

4. Wire Saw Cutting

Wire saw cutting is employed in situations where conventional blades cannot reach or where concrete is unusually thick. It involves a wire embedded with diamond segments that moves in a loop to grind through the material.

Wire saw cutting is ideal for:

Cutting large columns and beams

Demolishing thick foundations or bridge sections

Underwater cutting

Projects involving curved or irregular shapes

It’s one of the most versatile concrete cutting methods and can tackle almost any thickness or complexity.

5. Ring and Chainsaw Cutting

Ring saws and chainsaws are specialized handheld tools that offer deep cutting capacity without the bulk of traditional equipment. These tools are particularly useful for making plunge cuts or cutting through thicker sections than a standard handheld saw could manage.

They’re commonly used for:

Emergency access or rescue scenarios

Deep openings in confined spaces

Complex internal cutouts in walls or slabs

Their portability and power make them indispensable on jobs that require both reach and depth.

Equipment and Blade Considerations

Concrete saw cutting tools rely heavily on diamond blades, which are made from industrial diamonds bonded to a metal segment. These blades are capable of grinding through hard aggregates and reinforcement materials without losing their edge quickly.

Depending on the material and method, saws may be:

Electric-powered: Cleaner and quieter, ideal for indoor jobs

Gas-powered: More powerful and suitable for outdoor projects

Hydraulic or pneumatic-powered: Preferred in wet environments or underwater conditions

Blades are chosen based on the type of concrete (reinforced vs. non-reinforced), aggregate hardness, and desired cut quality. Wet cutting is often used to cool the blade and reduce dust, while dry cutting may be used with vacuum systems in controlled environments.

Safety in Concrete Saw Cutting

Concrete saw cutting involves high-speed blades and powerful machines, so safety is paramount. Proper protective equipment must be worn at all times, including:

Eye and face protection

Hearing protection

Dust masks or respirators

High-visibility clothing

Steel-toed boots and gloves

Operators should be trained in machine handling, blade care, and emergency procedures. Job sites must also be inspected for embedded utilities, rebar, and structural stability before any cutting begins. Missteps can lead to costly damage or injury, so pre-planning and risk assessment are essential.

Applications of Concrete Saw Cutting

Concrete saw cutting is utilized across multiple industries and sectors. Some of its most common applications include:

Construction and Renovation: Cutting doors, windows, stairwells, and mechanical openings

Road and Bridge Work: Removing damaged sections, joint sawing, and drainage modifications

Utilities and Infrastructure: Creating access points for electrical, plumbing, and HVAC systems

Demolition and Retrofitting: Controlled removal of slabs, beams, and walls

Industrial Maintenance: Modifying or expanding concrete floors and platforms

Emergency Services: Gaining access through hardened structures during disaster or rescue operations

Its adaptability and effectiveness make concrete saw cutting one of the most frequently used services in the construction lifecycle.

Advances in Saw Cutting Technology

Technological innovation continues to enhance the capabilities of concrete saw cutting. Modern developments include:

Robotic Cutting Systems: Allowing remote-controlled operation for greater safety and precision

Laser-Guided Cutting Tools: Providing pinpoint accuracy for complex or decorative cuts

Electric-Powered Systems: Reducing emissions and noise for indoor and environmentally sensitive areas

Integrated Dust Collection Systems: Improving air quality and compliance with safety regulations

Smart Blades: Equipped with sensors to monitor wear, cutting pressure, and blade temperature

These innovations have helped improve worker safety, cut quality, and overall project timelines.

Conclusion

Concrete saw cutting is more than just a construction service—it's a highly skilled process that blends craftsmanship with technology. Whether working on a commercial buildout, infrastructure upgrade, or residential remodel, this technique allows for clean, accurate, and controlled modifications to some of the toughest materials on the planet.

With the right tools, experienced operators, and a safety-first mindset, concrete saw cutting enables efficient progress on even the most demanding projects. Its versatility across industries and its adaptability to new technology ensure that it remains a vital part of modern construction for decades to come.

1 note

·

View note

Text

Jonard Tools Recreate Safety Standards with High Quality Insulated Tools for Professionals

Jonard Tools introduces its premium range of insulated tools, engineered for maximum safety and performance. Built for electricians, contractors, and technicians, the collection includes insulated screwdrivers, insulated pliers, and advanced tools like the insulated knife. All tools meet IEC and ASTM standards for high voltage protection.

Enhancing Electrical Safety with Jonard’s High Performance Insulated Tools

In an industry where precision meets danger, the importance of having the right equipment can never be overstated. Working with live electrical components demands not only expertise but tools that are engineered for absolute safety. Jonard Tools, a globally recognized name in professional grade hand tools, is making waves with its advanced range of insulated tools. Built for electricians, maintenance professionals, telecom technicians, and field engineers, these tools go beyond the basics delivering protection, performance, and peace of mind in every grip.

Electricians face countless challenges every day, tight spaces, live wires, unpredictable environments. One misstep or faulty tool could mean the difference between safety and serious injury. Jonard Tools addresses these challenges head on with its comprehensive lineup of insulated electrical tools that conform to global safety standards, including IEC 60900 and ASTM F1505.

Each tool is tested to 10,000 volts and certified for live use up to 1,000 volts AC or 1,500 volts DC. Whether you're repairing a panel, installing outlets, or managing high voltage systems, these tools are designed to ensure your protection without sacrificing productivity.

Engineered for Safety and Built for the Toughest Jobs

What sets Jonard Tools apart is their rigorous manufacturing process and attention to detail. The insulated screwdrivers are made with high grade chrome vanadium steel shafts and molded insulation directly bonded to the blade, eliminating any gaps that could allow voltage leakage.

Each insulated screwdriver set is assembled with an easy to understand design to reduce strain and improve control, even in the most confined workspaces. Perfect machined tips ensure a comfortable fit into fasteners, reducing slippage and rounding. These features make them a favorite among utility companies and industrial technicians worldwide.

For professionals who prefer variety in their toolkits, Jonard offers multiple insulated screwdriver set options flathead, Phillips, and combination tip formats making it easier to handle complex wiring and electronic repairs without switching brands or compromising on safety.

Cut, Strip, and Slice with Confidence

Beyond screwdrivers, Jonard’s line includes heavy duty insulated pliers and a razor sharp insulated knife. These aren’t just hand tools, they are engineered instruments designed to withstand high mechanical stress and extreme working conditions.

The insulated pliers are crafted for perfect gripping, twisting, and cutting. Their slip resistant handles and high leverage pivot points reduce hand tiredness while maximizing force. Available in long nose, combination, and diagonal cutting formats, these pliers are ideal for circuit installation, cable tie, and electrical panel service.

The insulated knife is a standout addition to the lineup. Designed specifically for stripping insulation and cutting cables, the blade is sharp, durable, and built to last. Its insulated handle gives users confidence to perform delicate tasks on live circuits without hesitation.

Tailored Toolkits for Professional Demands

Understanding that every job is different, Jonard Tools offers comprehensive insulated toolkits that bring multiple essentials together in one organized case. Their most popular kit, the 11 piece insulated tool set includes everything from insulated screwdrivers and insulated pliers to precision wire cutters and torque tested grips. This organized set is designed to provide full coverage for electricians who need portability without sacrificing quality.

Each kit comes with custom foam trays, tool labels, and safety guidelines to ensure quick access and proper storage vital in fast paced, high risk environments.

Tested, Trusted, and Certified

What makes Jonard a top choice for professionals isn’t just the quality of its tools, it's the reputation for accuracy, consistency, and compliance. All tools in the insulated range go through extensive quality assurance and testing in controlled environments. This includes insulation resistance, dielectric strength, and cold impact tests to confirm that they perform under stress, in extreme temperatures, and under continuous use.

With rising demand in smart buildings, electric vehicles, data centers, and renewable energy sectors, tools that meet industry standards are no longer optional, they're non negotiable. Jonard’s insulated tools rise to this challenge by offering not just safety but a performance edge.

Designed with Electricians in Mind

Every curve, every grip, every material used in Jonard’s insulated tools is thoughtfully selected with the user in mind. User friendly designs help reduce fatigue during long work sessions, while color coded handles assist in quick identification. Non slip coatings ensure stable handling even in humid or dusty conditions.

This user first approach makes Jonard Tools a staple not just for large companies, but also for independent electricians and field contractors who need reliable tools that perform every single time.

Conclusion: A Safer, Smarter Way to Work

The modern electrical landscape is evolving quickly with more advanced systems, higher voltages, and tighter regulations. In such a high stakes environment, Jonard Tools remains a trusted partner by offering equipment that empowers professionals to work safer, smarter, and more efficiently.

From insulated screwdrivers to high performance insulated pliers and the ultra reliable insulated knife, this product line is not just a toolbox addition, it's a long term safety investment. Ready to upgrade your toolkit with world class protection and performance? Explore the full range of insulated electrical tools at Jonard Tools today.

#Insulated tools#Insulated electrical Tools#insulated screwdrivers#insulated pliers#insulated screwdriver set#insulated knife

1 note

·

View note

Text

Why Are Granulator Blades Important for Efficiency?

Want more efficient grinding? Proper blades reduce downtime and cut costs. Read why choosing the right blades can make a big difference. Get yours today.

Granulator blades play a critical role in the plastic and recycling industries, as well as in manufacturing processes where materials need to be reduced in size. These blades are the heart of granulators—machines that shred plastic waste, rubber, metal, and other materials into smaller, reusable granules or flakes. The efficiency of the entire granulating operation heavily relies on the quality, sharpness, and condition of the granulator blades.

Whether you're in plastic reprocessing, rubber reclamation, or waste management, understanding why granulator blades are important for efficiency can significantly improve output, reduce downtime, and enhance overall profitability.

What Are Granulator Blades?

Granulator blades are industrial cutting tools designed to reduce material size by shearing or slicing. They are typically mounted inside a granulating machine, arranged in a rotary and stationary position. As the rotor blades spin, they come into close contact with the bed knives (stationary blades), cutting the material fed into the chamber.

Made from hardened tool steels or high-speed steel, granulator knives are engineered for durability, wear resistance, and precision. Their sharpness and hardness enable them to process tough materials like plastic, rubber, copper cables, and even certain metals.

The Link Between Blade Quality and Granulating Efficiency

The performance of a granulator is directly linked to the condition and sharpness of its blades. Here are some key reasons why granulator blades are essential for achieving maximum efficiency:

1. Consistent Particle Size Output

A sharp, well-aligned blade ensures the material is cut uniformly, resulting in consistent particle sizes. Consistent granule size is crucial in recycling and manufacturing processes where the material is later melted, molded, or reprocessed. Uneven sizes can lead to quality issues in the final product or cause problems in downstream processes.

2. Reduced Motor Load and Energy Consumption

Dull or damaged blades create unnecessary resistance during the cutting process, causing the motor to work harder. This results in increased power consumption, overheating, and even motor damage over time. Sharp granulator blades reduce friction and cutting force, which means less energy is required for operation and better equipment longevity.

3. Lower Downtime and Maintenance Costs

Frequent breakdowns, clogs, or jamming due to inefficient blades can cause significant downtime. Downtime in any production setup leads to losses in productivity and revenue. With high-quality and well-maintained granulator knives, such interruptions are minimized, leading to smoother operations and fewer maintenance interventions.

4. Improved Throughput and Productivity

Efficient blades cut more material in less time. When blades are sharp and properly aligned, the granulator can process higher volumes without sacrificing quality. This directly translates into increased output and better overall productivity for the plant.

5. Better Safety for Operators

Granulator blades that are in good condition help prevent accidents. Dull or misaligned blades can cause material kickbacks or machine overloads, posing risks to operators. Sharp, well-fitted blades contribute to a safer work environment by ensuring smooth and predictable machine behavior.

Types of Granulator Blades

Different granulating applications require different blade configurations. Common types include:

Rotary Blades: Mounted on a rotating shaft; responsible for slicing the material against stationary blades.

Bed Knives (Fixed Blades): These remain stationary while the rotary blades spin past them.

Fly Knives: Often used in high-speed granulators; they "fly" through the material.

Custom Shaped Blades: Designed for specific materials like films, sheets, or heavy lumps.

Selecting the right type of granulator blade ensures optimum performance and material-specific results.

Materials Used in Granulator Blades

High-performance blades are manufactured using robust materials such as:

D2 Tool Steel: Known for its excellent wear resistance and hardness.

M2 High-Speed Steel: Offers superior toughness and edge retention.

Carbide-Tipped Blades: Used in abrasive applications for extended blade life.

Stainless Steel Blades: Ideal for food-grade or medical-grade applications due to corrosion resistance.

Each material comes with its own advantages, and the right choice depends on the application and type of material being granulated.

Signs Your Granulator Blades Need Replacement or Regrinding

Regular blade inspection is essential for maintaining efficiency. Some warning signs include:

Increase in motor load or energy bills

Irregular particle size or poor cutting performance

Excessive noise or vibration from the machine

Material clogging or buildup in the cutting chamber

Visible dullness or chipping of the blade edges

If any of these signs are evident, it’s time to regrind or replace the blades to restore optimal performance.

Best Practices for Blade Maintenance

To ensure long-lasting efficiency from Granulator Knives, follow these best practices:

Regular Inspection: Schedule routine checks for wear and tear.

Proper Regrinding: Regrind blades using the right angles and equipment to maintain their original specifications.

Correct Installation: Align blades properly to avoid uneven wear.

Lubrication and Cleaning: Keep the machine and blade chamber clean and free from debris buildup.

Use OEM Blades: Always use blades recommended by the granulator manufacturer to ensure compatibility and performance.

The Role of Blade Manufacturers in Efficiency

A reliable granulator blade manufacturer can make a significant difference in your production efficiency. Reputable suppliers offer:

Precision-ground blades for clean and accurate cutting

Custom blade designs tailored to your granulator model

Heat-treated and hardened blades for extended life

Technical support for blade alignment and maintenance

Partnering with the right blade supplier ensures your machinery runs smoothly and your operations stay competitive.

Granulator blades are much more than just machine parts—they are key components that directly influence the efficiency, productivity, and safety of your entire operation. Whether you're recycling plastic, shredding cables, or granulating rubber, having sharp, durable, and properly maintained blades ensures optimal results.

Investing in high-quality granulator knives, adopting regular maintenance practices, and choosing the right blade material for your application can lead to reduced downtime, energy savings, and superior product quality.

Visit :- https://www.perfectknives.net/granulator-blades.phpContact : +91 9822050035

0 notes

Text

Counting on Precision: Rotary Contactors in American Manufacturing

In factories across the USA, production lines often combine high-tech automation with tried-and-true mechanical devices. One unassuming component that engineers continue to count on for accuracy is the rotary contactor. It may not flash or beep, but this simple device plays a big role in keeping counts and measurements spot-on – from tallying product units to gauging lengths of material. Let’s explore how a rotary contactor enhances production precision and why it remains a staple in American manufacturing.

Old-School Gadget, Modern-Day Reliability

Rotary contactors have been around for decades, long before today’s digital sensors and IoT-enabled devices. Yet, many U.S. factories still rely on them because of one simple reason: they work, and they work practically anywhere. In an age where high-tech sensors can sometimes glitch due to electrical noise or require complex setup, a rotary contactor offers a refreshingly simple and foolproof solution. It doesn’t need a power supply to do its basic job of counting; a rotating shaft and a magnet or cam inside do all the work to close a switch at just the right moment. This means even if your production floor is dusty, hot, or subject to electrical interference, the contactor keeps on clicking away reliably. American manufacturers have learned that mixing a bit of old-school tech with modern automation can actually boost reliability – the rotary contactor is often that dependable backup that ensures the counts keep coming even when fancier systems hiccup.

Counting Rotations, Lengths, and More

When people hear “rotary contactor,” they often think of simply counting rotations – like how many times a machine arm goes around. And indeed, that’s a core use: for example, counting each revolution of a shaft to know how many cycles a machine has completed. But rotary contactors can do more than just count turns. Pair one with a measuring wheel, and suddenly you have a device that can measure length of material. This is a common trick in industries like textiles, paper, or metal fabrication in the USA: as a sheet or strip of material moves, the wheel turns and the contactor clicks off pulses corresponding to distance. It’s a straightforward way to track how many feet or meters of material have been fed or processed – essentially acting as a basic flat material measuring machine without needing elaborate electronics. Of course, for ultra-precise length measurements or higher resolution, many might opt for advanced encoders. But if one pulse per unit of length is enough, a rotary contactor with a wheel gets the job done with minimal fuss.

Real-World Examples Across the USA

In real-world operations, rotary contactors quietly contribute to accuracy in various ways. Imagine a paper mill in the USA Northeast: as giant rolls of paper are wound, a contactor counts each rotation of the spool. After a set number of turns (translating to a specific length of paper), it signals a cutter to slice the roll at just the right point. Or picture a Midwest packaging plant where a contactor tracks each cycle of a rotary indexing table, ensuring every station (filling, capping, labeling) has completed its task in sync – any missed beat and the contactor would alert operators. Even small workshops benefit: a custom machine builder in the USA might install a rotary contactor on a piece of legacy equipment to give it a simple counting capability without overhauling the entire system. These examples show how from coast to coast, this device adapts to needs both big and small, providing a layer of assurance that “yes, that rotation happened” or “that length of material passed by” when it’s supposed to.

Easy Integration with Modern Systems

Another reason rotary contactors remain relevant is how easily they integrate with modern counting and control systems. The output of a rotary contactor is just an electrical contact closure (basically like a momentary button press), which nearly any counter, PLC, or industrial controller can accept as an input. This means you can connect a rotary contactor to a digital counter display, a programmable logic controller, or even into a PC-based data acquisition system with minimal hassle. It acts as a simple sensor that provides a dependable “tick” each time an event occurs. Many facilities in the USA pair these contactors with electronic counters or PLC programs to trigger actions – for example, stopping a machine after a certain count, or displaying the throughput count on a screen for operators. In essence, the rotary contactor bridges the gap between the mechanical world and the digital world: you get the ruggedness of a mechanical device and the intelligence of modern electronics working together. It’s a relationship that keeps production data flowing smoothly.

Conclusion: In summary, the rotary contactor exemplifies how classic engineering can complement modern manufacturing. Its presence on factory floors across the United States is a testament to its reliability and utility. When precision counts (literally!), having a rotary contactor in the mix can make all the difference in keeping operations smooth and counts accurate. So whether you're troubleshooting an existing line or designing a new system, don't overlook this proven solution. To learn more about rotary contactors and explore a full range of industrial automation tools, you can visit our main website anytime. Sometimes, a little old-school ingenuity is just what your high-tech production line needs to stay on the cutting edge.

0 notes

Text

Spindle Bearing Assembly | PartsFe UK

The spindle bearing assembly is critical to the smooth and efficient operation of commercial catering equipment. The assembly involved in this case is designed for the spindle shaft, which in turn will transfer the rotational force the machine uses for mixed, sliced, etc. The spindle assembly is critical to the precision and durability of kitchen appliances, and therefore to their performance and longevity.

To keep your restaurant running smoothly, it's crucial to invest in Spindle Bearing Assembly that ensure long-lasting performance.

#SpindleBearingAssembly#SpindleBearingAssemblyparts#cateringparts#partsfe#PartsFeUK#partsfebuzz#dishwasherparts#griddleparts

0 notes

Text

Choosing the Right Shredder Machine for Your Industrial Needs

Shredder machines are indispensable components of the waste management and recycling industries, to help businesses and municipalities efficiently deal with volumes of waste. They help in the size reduction of bulky waste into smaller pieces for ease of handling, thereby minimizing landfill entry and aiding sustainable waste processing. Addressing waste management with advanced shredding technologies gives industries the profile space to reduce waste disposal efforts, recycle even better, and minimize pollution.

Types Of Shredder Machines with Their Functions

Shredder machines are present in multiple models and designs to address different waste processing needs. They are classified primarily under the following types:

1. Twin-Shaft Shredder Machine:

It's best for high duty shredding applications. It utilizes two coiling shafts with strong sharp cutting blades tearing apart hard materials such as metals, industrial waste, or heavy plastics.

Application: Disposal of industrial waste; recycling of scrap metals; rubber shredding.

Benefits: It has high-torque and low-speed operation that makes it shredding efficient and with minimum maintenance.

2. Single Shaft Shredder Machine:

An alternative to twin-shaft shredders, single-shaft shredders are fitted with a single rotating shaft and sharp blades that slice the materials into pieces.

Applications: Processing of plastics, wood, textiles, and lightweight industrial waste.

Advantages: Greater output size control, energy-efficient operation, and easy maintenance.

3. PET Bottle Shredder:

The specific types of work which are supposed to be completely done with PET bottles, containers made of plastics, and very lightweight plastics.

Applications: in waste recovery plants, beverage companies, and waste management centers.

Advantages: minimize plastic pollution, increase plastic use efficiency, and yield more finished shredded materials for future use.

Key Features and Applications of Shredder Machine

The shredder machines answer different industrial requirements and employ specialized functions to deal with various waste types. The following are some of its key features and applications:

Heavy-duty Industrial Shredder: Processes a large volume of waste in an efficient manner; suitable for use in manufacturing and recycling activities.

Plastic Bottle Shredder Machine: Are ideal for shredding plastic bottles and containers into reusable pieces.

Tyre Shredder: It is for recycling used tires, thus cutting down on rubber waste, for a sustainable way of disposal.

Plastic Waste Shredder: For the vital destruction of plastic side streams to facilitate downstream recycling processes.

Industrial Waste Shredder: A shredder that is commonly used in factories, building sites, and recycling plants for the purpose of shredding different kinds of waste.

Types of Industrial Shredders: Several models of industrial shredders are available to deal with shredding specific materials such as paper, rubber, plastic, and metal.

Rubber Shredder: It is specifically designed to shred rubber material for recycling or reuse.

Industrial Twin-Shaft Shredders: They have two shafts to handle large amounts of waste very effectively and durably.

Paper Industries Waste Shredder: Used for shredding any confidential documents or paper wastes to secure the data and contribute toward recycling.

Paper Pulp Shredder: For recycling paper waste, a pulp shredder breaks down the paper waste into smaller fibers for reuse in the manufacturing of paper.

Benefits of Shredder Machines

Environmental Benefits: it reduces waste going to landfills, promotes recycling, and reduces pollution.

Cost Efficiency: Shred waste materials so as to reduce their cost of disposal and improve operational efficiency.

Improved Recycling: Shredded material becomes smaller thus improved in quality and usability of recycled products.

Safety & Compliance: Many industries would have to manage waste responsibly, while shredding has direct linkages to regulatory compliance and waste management standards.

Resource Recovery: Shredding and recycling materials can be reused in manufacturing, and therefore, they will bring down the raw materials required and improve conservation of natural resources.

Conclusion

Shredder machines are essential for waste control in many industries. They reduce the impact of waste on the environment and make recycling processes efficient. No matter whether you need shredding solutions for plastics, metals, paper, or industrial waste, the right shredder machine can greatly help improve operating efficiency. For industrial waste disposal and recycling requirements, EnvCure Technocrat LLP has some of the best shredder machines.

0 notes

Text

Intercom

He presses a child’s foot into Plaster of Paris.

The guaze is too small.

The cast crumbles.

In the ward,

colleagues bumble.

None volunteer assistance.

Lunch is four hours late, so

patience is thin,

productivity is low,

tempers frayed.

There is no vulnerable way

forward.

Patients, rock, mantra-bemoaning,

or patients, thin,

slip away.

Escape can be planned through

an analogue system—

Grey-textured buttons, on

off-white, slatted facias.

An officious female voice

crackles from the hissy ethersphere.

He can hear—

but the words collapse,

gibberish bouncing on Magic Sand.

He asks it to repeat.

To repeat.

repeat.

Unable to focus on its monotoned instruction.

Meaning crumbles

with the lint and gypsum—

shapes barely formed in the qualia,

honing to a footprint.

It sells him tickets.

Tickets to a therapeutic visualisation,

to a somewhere that is peaceful.

A nostalgic landscape—

where every road is wide,

every vehicle hulks, oversized.

Where insurance men assess

every risk—

every sugarized scream,

every slimline-nicotine-curve machine

- The dangers of hard candy.

Of chromium shafts.

Latex bodysuits,

In drops of red,

stretched

upon gleaming,

cylinder head

swooping yellow

Hot Rod wings.

He mutters curt, grumpy responses—

The voice,

stuttering from its robotised script,

Hearing this voice from the past, softens.

Slowly,

Recognition blooms—

It begins to tell him stories.

Stories of a past life,

one he once knew :

Of gardens.

Of gathered loved ones.

Of games played barefoot,

drenched in sun.

Of soft grass and porches.

Of shuttlecocks and cucumber sandwiches.

Fresh, red fruits sliced to brimming jugs

of lust—

Youthful and unrequited.

Hearing her wanting.

Knowing. Placing her voice.

Acknowledging it is

calling to be his.

Even though, as crushed white powder—

the sound of thin skin

A small, crepitate speaker.

—

He pretends.

He simulates obliviousness,

He is oblivious (Not knowing the difference)

He pretends the stress of tardiness

Of his duty.

His replies migrate to a robotised,

preoccupied,

disquieted detachment.

He has tickets now.

Without the requisite confirmation.

Without numbers or peace of mind.

He apologises matter of factly

and releases the button—

knowing he could make it.

If he had left,

before,

Before the conversation started,

Before he had pressed

The grey-button.

——

0 notes

Text

Reaper Attachment for Self Propelled Toolbar: A Complete Guide

When it comes to efficient crop harvesting, modern agricultural technology continually evolves, enhancing productivity and reducing manual labor. One such technological advancement is the reaper attachment for self propelled toolbar like Swaraj Code. This innovative tool is transforming the way farmers approach the harvesting of various crops, offering improved efficiency and effectiveness.

In this guide, we’ll delve into the intricacies of the reaper attachment for self propelled toolbar, exploring its functionality, benefits, installation process, and more.

What is a Reaper Attachment for Self Propelled Toolbar?

A reaper attachment for self propelled toolbar like Swaraj Code is a specialized farm machinery and equipment designed to enhance the harvesting process. It is typically mounted on a self-propelled toolbar, which is a type of agricultural vehicle equipped with a power of hydraulic mechanism. The reaper attachment itself is engineered to cut and gather crops efficiently as the vehicle moves through the field.

The reaper attachment for farming comprises several components, including a cutting blade and conveyor system. The cutting blade is responsible for slicing through the crops, while the conveyor system transports the cut material to the collection area. This system ensures that the harvested crops are collected and organized for further processing.

How Does the Reaper Attachment Work with the Swaraj Code?

The Reaper Attachment is highly compatible with the Swaraj code, known for its robust performance in agricultural tasks. Swaraj code is equipped with a PTO mechanism, which provides the necessary power for operating the reaper attachment (katai machine).

When the Reaper Attachment is mounted on a Swaraj code, the PTO shaft transfers power from the tractor’s engine to the attachment, eliminating problems with RPM. This power drives the cutting blade and conveyor system, allowing the reaper machine for Swaraj code to function seamlessly. As this self propelled toolbar moves forward, the cutting blade slices through the crops, and the conveyor system transports the cut material to the collection area. The efficiency of this process significantly reduces the time and labor required for manual harvesting.

What Crops Can Be Harvested Using the Reaper Attachment for Self Propelled Toolbar?

The reaper attachment for self propelled toolbar is a multi-crop harvesting machine and can handle a wide range of crops. Some of the most common crop-reaping tasks using this attachment include:

Wheat reaping

Paddy reaping

Millet reaping

Bajra reaping

Jowar reaping

Soybean reaping

Corn reaping

Mustard reaping

Gram reaping

Mug reaping

What Are the Benefits of Reaper Attachment for Self Propelled Toolbar?

The reaper attachment for self propelled toolbar offers several benefits that enhance the overall harvesting process:

Increased Efficiency: The Reaper Attachment significantly speeds up the harvesting process compared to manual methods. Its automated cutting system reduces the time required to harvest crops, allowing farmers to complete the task more quickly.

Reduced Labor Costs: By automating the harvesting process, this crop cutting machine minimizes the need for manual labor. This reduction in labor requirements translates to cost savings for farmers.

Consistent Harvesting Quality: The precision of this crop harvesting machine ensures uniform cutting of crops, leading to consistent quality in the harvested material. This consistency is crucial for maintaining the quality of produce and meeting market standards.

Versatility: The attachment’s ability to handle various crops makes it a versatile tool for farmers with diverse agricultural needs. This versatility eliminates the need for multiple specialized harvesting equipment.

Ease of Use: The Reaper Attachment is designed to be user-friendly, with straightforward controls and minimal maintenance requirements. Farmers can quickly adapt to using the attachment, enhancing their overall efficiency in the field.

What is the Installation Process for the Reaper Attachment?

Installing the reaper attachment for self propelled toolbar involves several key steps:

Preparation: Ensure that the self propelled toolbar or tractor is properly prepared for the installation. This includes checking the PTO mechanism and ensuring it is in good working condition.

Making a hydraulic connection:

Step 1: Pump Fitting – First, connect the gear pump to the PTO of the self propelled toolbar.

Step 2: DCV to Pump – Connect the hose pipe from the pump to the pressure plug of the DCV (direction control valves).

Step 3: DCV to Reaper – Connect DCV to Reaper through the hose pipe.

Mounting the Attachment: Align the reaper attachment with the mounting points on the self-propelled toolbar. Secure the attachment using the provided brackets and fasteners.

Connecting the PTO Shaft: Attach the PTO shaft from the self propelled toolbar to the Reaper Attachment through the pump. Ensure that the connection is secure and that the shaft is properly aligned.

Adjustments: Make any necessary adjustments to the attachment’s settings, including the height and angle of the cutting blade. These adjustments ensure optimal performance based on the type of crop being harvested.

Testing: Before starting full-scale harvesting, conduct a test run to ensure that the attachment operates smoothly. Check for any issues with cutting or conveying the crops.

Final Checks: Perform a final inspection to ensure that all components are functioning correctly and that the attachment is securely mounted.

Where Can I Purchase a Reaper Attachment for Self Propelled Toolbar?

If you’re looking to invest in a high-quality reaper attachment for self propelled toolbar like Swaraj code, Krishitek is your best bet. As the leading reaper attachment manufacturer in India, we offer a wide range of reaper attachments suited for various toolbar models and farming needs. Known for our reliability and after-sales support, we ensure you get the best reaper attachment for your farm.

You can explore our product categories online through our website www.krishitek.com. It’s a seamless process where you can compare different models, read reviews, and make an informed decision. We also provide warranties on our products to ensure you feel confident and secure in your purchase.

Conclusion

In summary, the reaper attachment for self propelled toolbar is a powerful crop harvesting machine that make far reaching changes in the harvesting process for a variety of crops. With its compatibility with Swaraj code and versatile crop-handling capabilities, it offers multiple benefits to farmers. Installing and using this attachment is straightforward, making it a valuable addition to any farm.

To explore high-quality reaper attachments, Krishitek offers a range of reliable models that suit diverse farming needs, ensuring productivity and performance in the field.

Reviewed by:

Mr. Rajkumar Bishnoi

Service Manager, Krishitek Industries Pvt. Ltd.

0 notes

Text

Precision and Efficiency with CNC Fiber Laser Cutting Machines in Gujarat

The modern landscape in Gujarat has transformed with the joining of CNC fiber laser cutting machines, furnishing organizations with proficient, exact, and financially savvy producing arrangements. Known for their fast, precision, and capacity to handle mind boggling plans, CNC fiber laser cutting machines are fundamental in enterprises like auto, development, hardware, and metal manufacture. In this blog, we'll dig into the advantages of these cutting-edge machines, investigate their applications, and feature the accepted procedures for choosing the perfect maker in Gujarat.

Understanding CNC Fiber Laser Cutting Technology

The expression "CNC" stands for Computer Numerical Control, where machines work in view of exact advanced commands, disposing of the requirement for physical work. "Fiber laser" alludes to the kind of laser utilized in the machine — fiber optics enhance the laser, making a powerful pillar reasonable for cutting through metals and other hard materials. Not at all like customary techniques, CNC fiber laser cutting offers a no-contact process that limits mileage on machinery and delivers perfect, exact cuts.

This cutting edge innovation is particularly helpful for organizations that depend on repeatable accuracy, rapid, and insignificant material waste. Each cut is custom fitted with negligible safety buffers, decreasing the requirement for revamp and smoothing out creation processes.

Advantages of CNC Fiber Laser Cutting Machines

Improved Accuracy and Precision: CNC fiber laser cutting accomplishes more tight resiliences contrasted with different strategies, making it ideal for complex plans. With a powerful laser shaft, it can handle perplexing cuts with high repeatability, delivering uniform outcomes like clockwork.

Speed and Productivity: These machines fundamentally lessen creation time, cutting through metals rapidly without forfeiting quality. This speed permits organizations to increment yield, comply with more tight time constraints, and lower creation costs by limiting personal time.

Diminished Functional Expenses: The mechanization of CNC fiber laser cutters converts into lower work costs and negligible material waste. Since these machines have negligible consumables and require little upkeep, organizations save money on above costs in the long haul.

Flexible Applications: CNC fiber laser cutting machines can slice through different metals, like stainless steel, aluminum, and mild steel. This adaptability makes them ideal for businesses requiring assorted applications, from vehicle parts to electronic parts.

Further developed Security and Low Support: Laser cutting requires no actual contact, decreasing the gamble of mishaps. The high effectiveness and low support of CNC fiber laser machines likewise add to a more secure and more dependable work area.

Applications Across Enterprises

Gujarat, as a modern center, has seen a flood in the reception of CNC fiber laser cutting machines across different areas:

Auto Industry: Accuracy cut parts, from casings to perplexing specifying, are fundamental in car fabricating. CNC fiber laser cutting guarantees uniformity and strength in parts, fulfilling industry guidelines productively.

Development and Design: Laser-cut metal systems, decorative boards, and underlying parts are popular in the development business. With laser cutting, draftsmen and specialists can rejuvenate complicated plans.

Gadgets Assembling: The hardware business benefits from laser cutting for fragile, high-accuracy parts that require little resiliences and high strength, for example, circuit sheets and nooks.

Aviation and Protection: CNC fiber lasers produce parts that satisfy thorough guidelines expected in aviation and guard. High-accuracy cuts and predictable repeatability are fundamental for security and performance in these fields.

Picking the Right CNC Fiber Laser Cutting Machine Maker in Gujarat

While choosing a CNC fiber laser cutting machine producer in Gujarat, certain elements can assist organizations with settling on an informed decision:

Customization Choices: Various enterprises have interesting necessities. Pick a producer that gives customization choices, including different laser powers, cutting rates, and concentrated highlights.

After-Deals: Areas of strength for backing and preparing programs from a producer can have an immense effect in machine uptime and efficiency. Search for manufacturers with phenomenal after-deals administration to guarantee smooth activity.

Quality Confirmation and Dependability: A respectable producer will offer great machines with powerful development and long haul unwavering quality. Machines ought to meet both public and worldwide standards for quality and security.

Cost-Viability: While putting resources into a great CNC fiber laser cutting machine is significant, taking into account the producer's evaluating choices and funding plans is similarly significant. Look at the drawn out esteem offered by the producer to guarantee a practical venture.

Energy Effectiveness: Energy-proficient machines are harmless to the ecosystem as well as help in decreasing functional expenses. Check assuming the producer offers energy-proficient choices that line up with manageability objectives.

Driving CNC Fiber Laser Cutting Machine Manufacturers in Gujarat

A few manufacturers in Gujarat have left an imprint in the CNC fiber laser cutting industry, offering cutting-edge machines that take special care of different businesses. A few notable manufacturers incorporate [Example Producer Names], known for their quality and development in the field. They offer exhaustive arrangements with strong after-deals support, guaranteeing your business can coordinate their machines with insignificant problem and greatest efficiency.

Future Patterns in CNC Fiber Laser Cutting

As technology propels, CNC fiber laser cutting machines keep on advancing, with upgrades zeroed in on computerization, man-made brainpower joining, and improved software controls. This pattern towards completely computerized and savvy frameworks takes into consideration prescient upkeep, remote observing, and much more noteworthy accuracy. The shift towards eco-friendly assembling is additionally uplifting manufacturers to foster more energy-productive machines that diminish discharges and waste.

Conclusion

CNC fiber laser cutting machines have become an imperative resource for enterprises in Gujarat. With their high accuracy, speed, and flexibility, these machines assist organizations with keeping an upper hand in the present quick moving business sector. Whether you're in the car, development, or hardware area, picking the right CNC fiber laser cutting machine producer in Gujarat can assist you with upgrading creation proficiency, further develop item quality, and lessen costs. Embracing this technology positions your business for progress today as well as prepares for development and advancement later on.

#fiberlasercuttingmachine#fiberlasercuttingmachinemanufacturer#metweld#cncfiberlasercuttingmachine#industrialcncfiberlasercutter#manufacturer#fiberlasercutter

0 notes

Text

Metro-B14 — Slicing Stone Slabs From Blocks

Introduction

In the competitive world of stone cutting, efficiency, precision, and innovation are paramount. Shri Bhagwati Machines Pvt. Ltd., located in Ajmer, India, has established itself as a leader in this field with its state-of-the-art METRO-B14 Multi Cutter Machine. This machine is not just a tool; it represents a significant leap in technology and design that promises to enhance productivity and reduce operational costs for stone manufacturers. In this document, we will delve into the features, benefits, and unique technologies that make the METRO-B14 a must-have for any serious stone cutting operation.

Key Features

· World’s First Successful DUAL RPM SPINDLE Designed for Twin Output Over Single Shaft to Deliver the highest production.

· Unique and fabricated beam, designed without any wheel-carriages to lower the motion friction.

· X axis is working on very Especially Designed “U Shape” Main Box made of thick Cast Iron Material provides excellent compression strength and high vibration damping capacity.

· Machine Bridge Motion by virtue of LINEAR MOTION BEARING SYSTEM gives Highest Positioning Accuracy & Smooth Motion.

· Positioning Accuracy can be controlled up to 0.05 mm.

· No Cutter Marks on Slabs.

· Equivalent water flow on each blades by unique water spray system.

· Stainless steel cutter guard with spray technology.

· Equipped with servo motors for fast to & fro travelling and accurate movement.

· Powerful for hard density granite material.

METRO-B14 Multi Cutter Machine

· Shri Bhagwati Machine Pvt. Ltd. is the visionary behind the DRSH (DUAL RPM SINGLE HOUSING) technology. With a focus on innovation and excellence, we have redefined the cutting machine landscape. Metro B-14 is 6th generation masterpieces of Multi-Blade Granite Block Cutters are nothing short of technological marvels. Designed and crafted by Shri Bhagwati Machine Pvt. Ltd., they bring a new dimension to stone cutting.

· Their magical capabilities enable them to deliver top-tier production levels while keeping power costs minimal and cycle times shorter than ever before. The secret behind these remarkable products lies in their revolutionary DRSH (DUAL RPM SINGLE HOUSING) technology.

· DRSH, or Dual RPM Single Housing, is a groundbreaking concept that defies conventional wisdom. This technology allows the machine to achieve unprecedented levels of production and tool longevity while consuming significantly less power. These machines aren’t just about cutting-edge technology; they’re also incredibly user-friendly. The programmed interface is designed with the user in mind, ensuring ease of operation. The use of “RITTAL” enclosure and switch gears from SIEMENS/SCHNEIDER guarantees the latest safety features, making them robust enough to withstand electrical fluctuations.

Technical Specifications

Axis Motion

Speed & Power

Features

Cables

Industry Impact

The METRO-B14 has already made a significant impact in the stone cutting industry. Numerous clients have reported increased productivity and efficiency after integrating this machine into their operations. Here are some testimonials from satisfied customers:

· Client A: “Since we started using the METRO-B14, our production has doubled. The precision and speed are unmatched!

· Client B: “The energy savings alone have made this machine a worthwhile investment. We highly recommend it to anyone in the stone cutting business.”

Unmatched Cutting Speed

The METRO-B14 is engineered for speed without sacrificing quality. Its ability to cut multiple blocks simultaneously reduces cycle times, enabling businesses to meet tight deadlines and increase throughput.

Durability and Reliability

Constructed with high-quality materials, the METRO-B14 is built to withstand the rigors of daily use in demanding environments. Key aspects of its durability include:

· Reinforced Structure: The machine’s robust design ensures stability during operation, reducing the risk of misalignment.

· Quality Bearings: The use of LM bearings minimizes friction, leading to longer service life and reduced maintenance costs.

Feedback from Operators

Operators have praised the METRO-B14 for its ease of use and reliability. Many have highlighted the machine’s user-friendly interface, stating that they were able to operate it effectively with minimal training.

Conclusion

The METRO-B14 Multi Cutter Machine from Shri Bhagwati Machines Pvt. Ltd. is a testament to innovation in the stone cutting industry. With its advanced technologies, user-friendly design, and robust performance, it is the ideal solution for businesses looking to enhance their cutting operations. By investing in the METRO-B14, companies can achieve higher productivity, lower operational costs, and superior quality in their stone products.

Click Here for detailed product video

0 notes

Text

Machine learning enables viability of vertical-axis wind turbines

03.04.24 - EPFL researchers have used a genetic learning algorithm to identify optimal pitch profiles for the blades of vertical-axis wind turbines, which despite their high energy potential, have until now been vulnerable to strong gusts of wind. If you imagine an industrial wind turbine, you likely picture the windmill design, technically known as a horizontal-axis wind turbine (HAWT). But the very first wind turbines, which were developed in the Middle East around the 8th century for grinding grain, were vertical-axis wind turbines (VAWT), meaning they spun perpendicular to the wind, rather than parallel. Due to their slower rotation speed, VAWTs are less noisy than HAWTs and achieve greater wind energy density, meaning they need less space for the same output both on- and off-shore. The blades are also more wildlife-friendly: because they rotate laterally, rather than slicing down from above, they are easier for birds to avoid. With these advantages, why are VAWTs largely absent from today’s wind energy market? As Sébastien Le Fouest, a researcher in the School of Engineering Unsteady Flow Diagnostics Lab (UNFOLD) explains, it comes down to an engineering problem – air flow control – that he believes can be solved with a combination of sensor technology and machine learning. In a paper recently published in Nature Communications, Le Fouest and UNFOLD head Karen Mulleners describe two optimal pitch profiles for VAWT blades, which achieve a 200% increase in turbine efficiency and a 77% reduction in structure-threatening vibrations. “Our study represents, to the best of our knowledge, the first experimental application of a genetic learning algorithm to determine the best pitch for a VAWT blade,” Le Fouest says. Sébastien Le Fouest and an experimental VAWT blade © Alain Herzog CC BY SA Turning an Achilles’ heel into an advantage Le Fouest explains that while Europe’s installed wind energy capacity is growing by 19 gigawatts per year, this figure needs to be closer to 30 GW to meet the UN’s 2050 objectives for carbon emissions. “The barriers to achieving this are not financial, but social and legislative – there is very low public acceptance of wind turbines because of their size and noisiness,” he says. Despite their advantages in this regard, VAWTs suffer from a serious drawback: they only function well with moderate, continuous air flow. The vertical axis of rotation means that the blades are constantly changing orientation with respect to the wind. A strong gust increases the angle between air flow and blade, forming a vortex in a phenomenon called dynamic stall. These vortices create transient structural loads that the blades cannot withstand. EPFL's experimental VAWT blade © UNFOLD EPFL CC BY SA To tackle this lack of resistance to gusts, the researchers mounted sensors onto an actuating blade shaft to measure the air forces acting on it. By pitching the blade back and forth at different angles, speeds, and amplitudes, they generated series of ‘pitch profiles’. Then, they used a computer to run a genetic algorithm, which performed over 3500 experimental iterations. Like an evolutionary process, the algorithm selected for the most efficient and robust pitch profiles, and recombined their traits to generate new and improved ‘offspring’. This approach allowed the researchers not only to identify two pitch profile series that contribute to significantly enhanced turbine efficiency and robustness, but also to turn the biggest weakness of VAWTs into a strength. “Dynamic stall – the same phenomenon that destroys wind turbines – at a smaller scale can actually propel the blade forward. Here, we really use dynamic stall to our advantage by redirecting the blade pitch forward to produce power,” Le Fouest explains. “Most wind turbines angle the force generated by the blades upwards, which does not help the rotation. Changing that angle not only forms a smaller vortex – it simultaneously… http://actu.epfl.ch/news/machine-learning-enables-viability-of-vertical-a-2 (Source of the original content)

1 note

·

View note

Text

The 4 Most Common Types of Precision CNC Machining

CNC machining is a catch-all term for a wide range of machining applications. The term “CNC” stands for Computer Numerical Controlled and refers to the machine’s programmable feature, which allows the machine to perform many functions with little human intervention. CNC machining is the process of creating a component with a CNC-controlled machine. A lot of CNC Manufacturers in India excel in providing you with these machines. The term refers to a group of subtractive manufacturing processes that involve removing material from a stock workpiece or bar to create a finished component part.

The 4 most common types of Precision CNC Machining are as follows:

CNC Lathes and Turning Machine:

During machining, CNC lathes and turning machines rotate materials. These machines use linear cutting tools to remove material around the revolving bar stock’s circle until the required diameter is reached. Internal and external components such as drilled holes and threads can be produced by a CNC lathe or a CNC turning machine. Screws, bolts, shafts, and poppets are examples of CNC machined components. Precision Components manufacturers may assist you with a CNC lathe and turning machine. A CNC lathe or a CNC turning machine can produce internal and external components such as drilled holes and threads.

2. CNC Milling Machines:

CNC milling machines are distinguished by their ability to rotate cutting tools while remaining stationary with the material workpiece/block. They can make a variety of shapes, such as face-milled features (shallow, flat surfaces and cavities in the workpiece) and peripheral-milled features (deep cavities such as slots and threads). CNC milling machine components are typically square or rectangular in shape and have a variety of features.

3. CNC Laser Machines:

CNC laser machines use a pointed router with a highly focused laser beam to cut, slice, or engrave materials precisely. The laser heats the material, causing it to melt or vaporize and leaving a cut in it. The material is typically in sheet form, and the laser beam moves back and forth across the material to create a precise cut. CNC laser engravers are frequently used to mark machined components. It can be difficult, for example, to machine a logo and company name into a CNC-turned or CNC-milled component.

4. CNC Plasma Cutting Machine:

CNC plasma cutters are also used to slice materials. They do it, however, with a computer-controlled high-powered plasma torch. Plasma torches operate similarly to hand-held gas welding torches but reach temperatures of 50,000°F. To form a cut, the plasma torch melts through the material. Precision CNC machining is used in the manufacturing industry to create CNC-machined components. Depending on the environment, material, lead time, volume, budget, and features, there is usually an optimal way to provide the desired output.

Supreme Metal Works is considered amongst the best steel components manufacturers. We are recognized as one of the renowned CNC Turned Component Manufacturers in Mumbai, India. Our diverse services include tube fitting which also happens to be our primary expertise. Quality and Customer satisfaction are what we assure you at Supreme Metal Works.

You can reach us on suprememetal.in

#cnc machined components manufacturer#manufacturers of tube fittings in india#ferrule fittings manufacturer in india#cnc machined components manufacturer in india

0 notes

Text

EN24 ALLOY STEEL

EN24 ALLOY STEEL :

EN24 is an excessive strength metallic alloy that is additionally known as 4340. It is furnished, tempered, and hardened. It is popular and extensively used due to its tremendous strength in numerous additives, which includes bolts, gears, and studs. Other grades can be surfaced-hardened to create parts with stepped forward water resistance through nitriding or induction.

Chemical composition of EN24:Element Carbon Silicon Manganese Phosphorus Sulphur Chromium Molybdenum Nickle Content (%) 0.36-0.44 0.10-0.35 0.45-0.70 0.035 Max 0.040 Max 1.00-1.40 0.20-0.35 1.30-1.70

EN24 Physical Properties:

Physical PropertiesMetricUS/ImperialDensity7.80 g/cc0.282 lb/in³

Hardness-248 to 302HRC

Forging Properties of EN24:

Preheat carefully, then raise temperature to 1000-1100°C for forging. Do now not forge the steel beneath 850-1100°C. After forging cool slowly preferably in a furnace.

Forms of EN19 Steel Pipes:

Outer Diameter(OD)-Upto 550mm

Inner Diameter(ID)-upto 400mm

Length-Upto 6000mm length

Forms of EN24 alloy Flat bar steel:

EN24 Flat

EN24T flat sections can be produced via go slicing from massive cast machined billet.

Flat bar/Rolled flat bar-thickness upto 50mm width upto 455mm

Forged flat bar-thickness upto 305mm and width upto 455mm

Forms of EN24 alloy steel Round bar:

EN24 Round Bar

EN24 is produced in a massive variety of round bar sizes starting at 6.35mm up to about 1 metre in diameter.

Rolled round bar – diameter 16mm to 250mm

Heavy forged round – diameter 200mm to 450mm

Heavy machined round – diameter 260mm to 620mm

Forms of En24 alloy steel plates:

Width upto 2000mm

Length upto 6300mm

Thickness upto 120mm

EN24 applications:

When used for programs in its heat treated circumstance EN24 combines excessive tensile strength with shock resistance. It is simple to work and may be forged or stamped with out trouble. EN24 is machinable inside the annealed circumstance or when hardened and tempered.

• Power transmission gears and other gears requiring maximum hardness.

• Bolts, screwed components, stub axles, swivel fingers required very tough.

• Structural additives with top high tensile wishes.

• Cranks, axles, propellor and gearbox shafts requiring good high tensile residences.

• Connecting rods, unique cranks and different elements required to be stiff and but preserve a excessive degree of toughness.

• Plastics and rubber moulding industry parts for moulds, hob preserving earrings, stop pins.

TYPES OF OTHER GRADES AVAILABLE :

C45, EN8, EN9, EN19, EN24, EN31,EN36C, EN41B, EN47, EN353, IS2062, 42Crmo4, HCHCR, OHNS, D2, D3, H-11, H-13,M2, M35, M42, M48,1.2714, SKD-11, P20, P20+S, P20+Ni, P20+Ni+HH, SAE 4140, SAE4340, SAE 8620, 16MNCR5, 20MNCR5, C35, C40, C50, C60, CK45, 40C8, 45C8, 55C8, C55MN75, SAE 52100, S40C,S355J2G3.

CITIES IN WHICH WE ARE DEALING:

Uttar Pradesh:

Kanpur,Lucknow,Ghaziabad,Agra,Meerut,Varanasi,Prayagraj,Bareilly,Aligarh,Moradabad,Saharanpur,Gorakhpur,Noida, greater Noida, udham nagar,Firozabad,Jhansi,Muzaffarnagar,Mathura,Ayodhya,Rampur,Shahjahanpur,FarrukhabadFategarh,Budaun,Maunath,Bhanjan,Hapur,Etawah,Mirzapur,Vindhyachal,Bulandshahr,Sambhal,Amroha,Hardoi,Fatehpur,Raebareli,Orai,Sitapur,Bahraich,Modinagar,Unnao,Jaunpur,Lakhimpur,Hathras,Banda,Pilibhit,Barabanki,Khurja,Gonda,Mainpuri,Lalitpur,Etah,Deoria,Badaun,Ghazipur,Sultanpur,Azamgarh,Bijnor,Sahaswan,Basti,Chandausi,Akbarpur,Ballia,Tanda,Shikohabad,Shamli,Awagarh,Kasganj.

Rajasthan:

Jaipur, Jodhpur, Kota ,Bikaner ,Bhiwadi ,Ajmer ,Udaipur ,Bhilwara ,Alwar ,Bharatpur,bharan ,Sri Ganganagar ,Sikar ,Pali ,Tonk ,Kishangarh ,Beawar ,Hanumangarh ,Dhaulpur ,Gangapur City, Sawai Madhopur ,Churu ,Jhunjhunu ,Baran ,Chittaurgarh ,Makrana ,Nagaur ,Banswara ,Dungarpur, pratapgarh

Haryana:

Faridabad (New Township) ,Gurgaon , Panipat, Yamunanagar, Rohtak, Hisar, Karnal, Sonipat, Panchkula (Urban Estate), Ambala Sadar, Bhiwani, Ambala, Sirsa, Bahadurgarh, Jind, Thanesar, Kaithal, Rewari, Palwal, Hansi, Narnaul, Fatehabad, Gohana, Tohana, Narwana.

For more details:

Phone no-8076217931

Office Address:

Alloy Carbon Steel

693 Saini Vihar, Mundka, Delhi 110041

Email [email protected]

Website Link-http://alloycarbonsteel.com/

0 notes

Text

20231021 10TH ANNIV. TOUR [KOCHI]

■ DJ: 村田タケル

Tramhaus / The Goat

bar italia / Nurse!

Yard Act / 100% Endurance

Jockstrap / Glasgow

Cate Le Bon / Crab Day

feeble little horse / Tin Man

Tanukichan / Like You

bar italia / Harpee

King Krule / Seaforth

Drug Store Romeos / What's On Your Mind

bar italia / Clark

■ DJ: okaken

Gabriels / Offering

Geese / 3D Country

Viagra Boys / Punk Rock Loser

Spoon / Devil & Mister Jones

Alan Palpmo / Nudista Mundial '89 (feat. Mac DeMarco)

Gareth Donkin / Falling For You

Yard Act / Payday

Alien Tango / B.F.F.

The Strokes / Brooklyn Bridge to Chorus

Choir Boy / Sweet Candy

Passion Pit / Eyes As Candles

Water From Your Eyes / Out There

Girl Ray / Everybody's Saying That

Bell & Sebastian / The Party Line

Romy / She's On My Mind

■ DJ: 遠藤孝行

Troye Sivan / Rush

The Orielles / Old Stuff, New Glass

Talking Heads / Don't Worry About the Government

Mock Media / Modern Visions

The Lounge Society / Burn The Heather

Courting / Flex

Pixies / Here Comes Your Man

Primal Scream / Gentle Tuesday

Viagrea Boys / Girls & Boys

O. / Slice

Battles / My Machines (Featuring Gary Numan)

Nirvana / Very Ape

Fountaines D.C. / Jackie Down The Line

shame / Born in Luton

The Garden / :(

PIGBAG / Papa's Got a Brand New Pigbag

XTC / Living Through Another Cuba

Spoon / You Got Yr. Cherry Bomb

■ DJ: タイラダイスケ

Shame 69 / If The Kids Are United

Lizzy Mercier Descloux / Fire

Wet Leg / Ur Mum

Liquid Liquid / Optimo

Nirvana / Drain You

Wednesday / Chosen to Deserve

DYGL / Wanderlust