#Spring Loaded Hose Clamps

Explore tagged Tumblr posts

Text

The Essential Guide to Spring Loaded Hose Clamps

When working with high-performance hoses and pipes, ensuring a tight, durable seal is paramount. This is where spring loaded hose clamps shine. Offering consistent pressure and a reliable seal under variable conditions, these clamps are indispensable in automotive, HVAC, and heavy equipment applications.

What Are Spring Loaded Hose Clamps?

Unlike standard clamps, spring loaded hose clamps feature a spring mechanism that compensates for expansion and contraction of hoses due to temperature or pressure changes. This spring action maintains a steady grip, preventing leaks, which is crucial for systems prone to temperature fluctuations or high-pressure environments.

Key Benefits of Spring Loaded Hose Clamps

Consistency in High-Pressure Applications: These clamps offer a secure fit that holds strong even in fluctuating environments. Automotive and industrial users often choose spring loaded hose clamps for this reason.

Enhanced Durability: Made with robust materials, these clamps are resistant to corrosion, ensuring long-lasting performance. Over time, they help reduce maintenance costs and downtime.

Easy Adjustability: The spring-loaded mechanism allows for easy adjustments, which means they can be tightened or loosened without much hassle, making them ideal for repeated use.

Leak Prevention: Their strong grip means fewer leaks, which is particularly valuable in critical applications like cooling systems in engines or fuel lines.

Choosing the Right Spring Loaded Hose Clamp

When selecting the right spring loaded hose clamp, consider the following:

Size Compatibility: Measure the hose diameter to ensure a snug fit.

Material Quality: Stainless steel is ideal for resistance to rust and corrosion.

Application Requirements: Check specifications to match the clamp to your system’s pressure and temperature requirements.

Maintenance Tips for Optimal Performance

To ensure the longevity of your spring loaded hose clamps:

Regularly check for signs of wear, particularly in high-pressure systems.

Clean the clamps and hoses periodically to prevent build-up that could compromise the seal.

Inspect the springs and bolts to ensure they maintain adequate tension.

Conclusion

For a high-quality, reliable solution in maintaining hose connections, spring loaded hose clamps are an excellent investment. By providing a consistent, flexible grip under varying conditions, they prevent leaks and reduce maintenance costs, making them ideal for demanding applications. When chosen and maintained correctly, these clamps can offer long-lasting security and peace of mind.

Explore durable spring loaded hose clamps, designed for lasting performance, on Clamp Guy’s website.

0 notes

Text

transforming soffits reorganizing keys formalizing immersion joints justifying kick extractors advising aggregates managing elbows recasting connectors achieving aluminum trowels officiating disks exhibiting absolute spigots progressing coil hydrants jerry-building reflectors informing casters inventing rubber hoists performing wrenches judging chalk adapters upgrading ignition paths

regrowing flashing recommending ratchets approving barriers sweeping impact fillers sewing mirrors detailing collectors enforcing measures distributing systems presenting plugs interwinding registers piloting ash diffusers gathering cranks supplying eave pockets undertaking scroll stops accelerating straps designing fittings protecting diamond boilers logging downspouts correlating shingles uniting mallets qualifying electrostatic lifts sharing clamps obtaining circular fluids ranking foundation gauges sensing miter brackets originating space networks translating drills regulating guards selecting gable padding utilizing pellet dowels reconciling artifacts altering pulleys shedding space filters determining vents representing mortar remaking flash rakers supporting funnels typecasting rotary chocks expressing junctures resetting auxiliary vises professing strip treads inlaying matter trowels questioning drivers forming edge fittings sketching blanks overshooting spark breakers rewriting controls playing tunnels inventorying buttons enduring joint handles effecting ratchet bibbs unwinding couplings forsaking vapor conduits defining sockets calculating heaters raising grids administering tiles measuring resources installing ignition remotes extracting corners manufacturing ventilators delegating consoles treating mounting stones enacting jig deflectors intensifying alleys improvising cargo pinpointing bobs prescribing arc masonry structuring metal chucks symbolizing lathes activating plumb kits adapting coatings fixing channels expediting cordage planning compressors enlisting hangers restructuring keyhole augers shearing ridge hardware collecting reciprocating bolts maintaining corrugated dimmers whetting hole collars conducting mandrels comparing assets compiling sealants completing paths composing equivocation wheels computing dampers conceiving electrostatic treatment ordering cotter grates organizing ties orienting ladders exceeding materials targeting thermocouples demonstrating emery stock expanding latch bases training wardrobe adhesives overcomming[sic] fasteners streamlining storm anchors navigating springs perfecting turnbuckles verifying gate pegs arbitrating arithmetic lifts negotiating outlets normalizing strips building surface foggers checking key torches knitting grinders mowing planers offsetting stencils acquiring bulbs adopting rivets observing avenues ascertaining coaxial grommets slinging wing winches instituting circuit generators instructing wicks integrating pry shutters interpreting immersion lumber clarifying coils classifying wood bits closing cogs cataloging matter strips charting holders conceptualizing push terminals stimulating supports overthrowing shaft spacers quick-freezing connectors unbinding ground hooks analyzing eyes anticipating gateways controlling proposition rollers converting power angles coordinating staples correcting benders counseling joist gaskets recording gutter pipes recruiting drains rehabilitating rafter tubes reinforcing washers reporting guard valves naming freize sprues nominating rings noting straps doubling nailers drafting circuit hoses dramatizing flanges splitting framing compounds refitting stems interweaving patch unions placing sillcocks sorting slot threads securing mode cutters diverting catharsis plates procuring load thresholds transferring syllogism twine directing switch nuts referring time spools diagnosing knobs discovering locks dispensing hinges displaying hasps resending arc binders retreading grooves retrofitting aesthetics portals seeking stocks shrinking wormholes assembling blocks assessing divers attaining lug boxes auditing nescience passages conserving strikes constructing braces contracting saw catches serving installation irons recognizing fluxes consolidating fuse calipers mapping shims reviewing chop groovers scheduling lag drives simplifying hoists engineering levels enhancing tack hollows establishing finishing blocks

21 notes

·

View notes

Text

From Pipes to Panels: Stainless Steel Clamps for Every Industry

Ladhani Metal Corporation, a leading Stainless Steel Clamp Manufacturer in India, is proud to deliver high-performance clamping solutions trusted across multiple sectors from plumbing to pharmaceuticals, automotive to architecture. In today’s fast-paced industries, even the smallest components must meet the highest standards. Stainless Steel Clamps are a prime example: compact, robust, and essential for ensuring secure connections.

As industries evolve and demand more from their systems, these clamps are becoming the go-to choice for durability, hygiene, and long-term reliability.

Why Stainless Steel Clamps Lead the Way

Behind their simple design, Stainless Steel Clamps are engineered to provide unmatched performance under extreme conditions. These clamps resist corrosion, support heavy loads, and hold their shape even when exposed to fluctuating temperatures.

Key benefits include:

Corrosion Resistance – Perfect for marine, chemical, and outdoor environments.

High Strength – Capable of securing large pipes and panels under pressure.

Temperature Tolerance – Reliable in both high-heat and freezing conditions.

Non-reactive Material – Ideal for food-grade and pharmaceutical applications.

Low Maintenance – Durable with a long service life.

As a top Stainless Steel Clamp Supplier in India, we offer clamps that meet international quality standards and serve every major sector.

Stainless Steel Clamps in Every Industry

From large-scale pipelines to delicate instrumentation panels, stainless steel clamps are everywhere. Here's how various industries benefit:

1. Plumbing & Water Management

Used to support water supply lines, drainage systems, and underground pipes, Stainless Steel Clamps offer leak-proof, vibration-free operation. Their corrosion resistance makes them a preferred choice for long-term water infrastructure projects.

2. Automotive & Transportation

From securing turbocharger systems to fuel lines and coolant hoses, Stainless Steel Clamp Manufacturers provide solutions built for high-heat and high-vibration environments. These clamps ensure performance and safety in vehicles, boats, and aircraft.

3. Construction & Infrastructure

Whether securing HVAC ducts, cable trays, or solar panel mounting systems, stainless steel clamps are vital in structural applications. Their weather resistance and load-bearing capacity make them a smart choice for modern construction.

4. Food & Beverage Industry

In environments where hygiene is paramount, stainless steel clamps prevent contamination and withstand rigorous cleaning processes. Commonly used in dairies, breweries, and food processing units.

5. Pharmaceutical & Medical Fields

Cleanrooms and sterile production lines rely on stainless steel clamps to maintain pressure and prevent leaks in fluid transfer systems. Grade 316 clamps are especially common due to their higher chemical resistance.

6. Oil & Gas Sector

Designed to endure harsh conditions, these clamps secure pipelines and containment systems in both offshore and onshore installations.

7. Renewable Energy & Electrical Systems

Used for cable management, conduit mounting, and solar panel installations, stainless steel clamps are essential in modern energy systems.

Choosing the Right Stainless Steel Clamp

When selecting clamps, consider:

Material Grade: 304 for general use, 316 for corrosive environments.

Clamp Type: Worm drive, T-bolt, V-band, or spring clamps — each suited to different needs.

Load and Fit: Match the clamp to the system dimensions and operating conditions.

As a trusted Stainless Steel Clamp Supplier, we help clients to choose the perfect clamp for their application.

Conclusion

From securing massive pipelines to neatly organizing cables behind solar panels, Stainless Steel Clamps play a key role in every major industry. Their versatility, strength, and resistance to harsh conditions make them a small but powerful asset in any system.

Ladhani Metal Corporation, a premier Stainless Steel Clamp Manufacturer in India, continues to supply top-tier clamps for a wide range of industrial needs. As one of the most reliable Stainless Steel Clamp Suppliers, we’re committed to providing quality, performance, and lasting value no matter the project size.

0 notes

Text

When heavy-duty hose clamping is required, the Stainless Steel Spring Loaded T-Bolt Clamp is designed to maintain consistent tension even under extreme pressure or temperature fluctuations. The spring-loaded mechanism allows the clamp to expand and contract with hose movement, preventing damage or leaks. Perfect for turbocharger systems, intercoolers, and industrial applications, it combines durability with performance.

0 notes

Text

The JG Diesel Repairs & Towing Checklist for Hassle-Free DOT Inspections in Texola

You’re headed across I-40 near Texola and that sign appears: DOT inspection station ahead.

Truckers feel that sudden gut check. Is your rig ready? Are your brakes within spec? Lights working? Tires holding pressure?

That’s exactly why JG Diesel Repairs and Towing crafted a no-nonsense checklist made for Oklahoma haulers. Passing DOT inspections shouldn’t feel like luck. With the right prep and a strong Truck Repair crew behind you, it won’t be.

Why DOT Inspections Matter More Than You Think

Missing one cracked hose or flickering taillight can mean fines. Or worse—out-of-service orders. Every minute off the road burns your paycheck. It ain’t just about being road legal. It’s about protecting your time, truck, and bottom line.

In a place like Texola where loads stretch heavy and weather flips quick, staying compliant is survival.

JG Diesel Repairs and Towing helps you do just that.

Your Pre-Inspection Power Checklist from JG Diesel Repairs & Towing

Use this battle-tested list before every run or DOT stop in Western Oklahoma:

1. Brake System Check

Start here. Inspect your air lines for leaks. Listen for faint hissing. Look for dry rot or cracked hoses. Measure brake pad thickness. Check slack adjusters for proper travel.

If your brakes feel soft or pedal travel’s excessive, schedule a Mobile Truck Repair before it triggers a fail.

2. Tire & Wheel Prep

Inspect tread depth with a gauge—4/32" up front, 2/32" in rear minimum. Spot sidewall damage, bulges, or cuts. Tighten lug nuts. Adjust inflation levels evenly across axles. A blown steer tire during inspection means your wallet takes a hit.

Flat? Call JG Diesel Repairs and Towing for roadside tire swaps—no waiting, no hassle.

3. Lights & Reflectors

Flip every switch. Marker lights. Low beams. High beams. Flashers. Brake lights. License plate lights. Replace dim or missing bulbs.

Your reflectors must be clean and uncracked. Dirty lights or one missing lens equals DOT trouble.

4. Suspension & Steering Systems

Look under the truck. Cracked spring hangers? Worn bushings? Broken shocks? Steering pulling to one side? Loose drag link?

These all raise red flags during an inspection and scream for a quality Truck Repair Shop.

5. Exhaust & Emissions System

Any visible soot leaks or rusted-through piping? They’re instant violations. Confirm clamps are tight and flex joints intact.

Dirty after-treatment filters? JG Diesel Repairs and Towing performs forced regens with their on-site diagnostics.

6. Fluids & Leaks

Pop the hood. Check oil levels. Brake fluid. Coolant. Transmission. Washer fluid. Fuel leaks from tanks or lines? Nope, not acceptable.

Top off before hitting Texola’s inspection points. Catch leaks early with Mobile Truck Repair from pros who know the roads.

Why Use This Checklist in Texola?

That stretch near Texola has its own flavor of challenges. Dust. Random temperature swings. Long gaps between fuel stops. DOT loves setting up there.

JG Diesel Repairs and Towing built this list for local haulers—because no one wants an OOS sticker while moving cattle or hot freight through Oklahoma.

Why Truckers Choose JG Diesel Repairs & Towing for DOT Readiness

Forget guessing or rolling the dice with an unfamiliar Truck Repair Shop Near Me. Real truckers rely on people who know their needs. Out here, that crew is JG Diesel Repairs and Towing.

Here's why:

**They bring repairs to your lot or yard with expert-level Mobile Truck Repair

No random parts swapping. They use diagnostics before action

Their team knows DOT inspection traps—because they’ve seen ‘em all

Service happens fast. No weeklong waits or paper delays

They help fleets and solos with prep and follow-through

When time matters, they show up ready—not with excuses

Times JG Diesel Repairs and Towing Helped Truckers Pass DOT Inspections in Texola

1. ABS Light Nightmare Fixed Fast Driver headed for Weatherford inspection failed due to an ABS code. JG Diesel came roadside, ran diagnostics, replaced a faulty wheel sensor, cleared the fault.

2. Crack in Air Line Detected Pre-Trip Fleet in Sayre called for a checkup. Mobile tech spotted a hidden air line crack. Replaced it right there before a DOT pulled the truck for a leak.

3. Dull Headlights Trigger Warning A trucker flagged for dim beams. JG Diesel installed new headlamp assemblies. Tech cleaned connectors and sealed housing against rain.

4. Brake Slack Out of Adjustment DOT agent warned a driver at inspection but let him roll. Driver called JG Diesel immediately. Adjusted brakes within the hour.

5. Suspension Fix Caught During Prep Cracked spring leaf found on a cattle hauler’s trailer. Mobile crew replaced the spring on-site without needing a shop visit.

6. Forced Regen Saved A Load Truck showed sluggish acceleration and fault code during pre-inspection. JG Diesel forced a regen on the spot. Truck passed DOT and delivered on time.

FAQs About DOT Prep with JG Diesel Repairs and Towing

1. How early should I check my truck before a DOT stop? Ideally 24 hours before. Call JG Diesel for same-day checks or next-day Mobile Truck Repair visits for peace of mind.

2. Can I get DOT pre-checks at my yard? Yes. Their crew comes to you. Whether it's Texola, Sayre, or a fuel stop off I-40, they deliver diagnostics and repairs.

3. What’s included in your DOT prep inspection? Brakes, tires, lights, fluids, emissions, steering, suspension, warning lights, and battery condition. Full inspection done fast.

4. Can JG Diesel help after a failed inspection? Yes. Immediate Truck Roadside Assistance or shop support. They clear codes, repair on scene, or tow to their truck repair shop.

5. Will you help me document repairs for reinspection? Absolutely. They provide receipts and technician notes required by DOT to clear violations.

6. What if I only need a specific fix like a brake chamber or sensor? They stock common parts and can handle one-off repairs without needing a full service. One call gets it done.

Contact JG Diesel Repairs and Towing for DOT-Ready Service in Texola, OK

Keep your rig legal. Stay ahead of fines. Move freight without interruptions. Whether it’s Truck Repair, full Truck Roadside Assistance, or top-tier Mobile Truck Repair, JG Diesel Repairs and Towing keeps you rolling strong across Oklahoma highways.

📍 Address: 315 W 20th St Unit B, Elk City, OK 73644 📞 Phone: +1 (580) 379-0790

One checklist. One team. No surprises. Trust JG Diesel Repairs and Towing to keep your inspections stress-free and your wheels turning.

#Truck Repair#Mobile Truck Repair#Truck Repair Shop Near Me#Truck repair shop#Truck Roadside Assistance

0 notes

Text

Clamp It Down: Securing Performance Where It Matters Most

When it comes to high-performance builds, loose connections just won’t cut it. Boost leaks, fuel pressure drops, and exhaust rattles can all be traced back to one thing: the wrong clamp. That’s why smart builders opt for premium-grade solutions like those from Build Fast Car’s stainless steel clamp collection.

If you're looking for a clamp that stays tight no matter the heat cycle, the Stainless Steel Constant Tension Clamp is engineered for exactly that. It maintains consistent pressure, compensating for thermal expansion and contraction in turbo and coolant systems.

For lightweight builds or tight space installs, the Stainless Steel Embossed Clamp delivers excellent grip without over-tightening. It’s perfect for low-pressure coolant and vacuum lines where reliability matters.

Exhaust setups often call for strong, vibration-resistant fittings. The Stainless Steel Exhaust Pipe Clamp Sleeve offers a secure, no-weld solution to joining muffler sections, resonators, or custom pipe lengths. It’s a must-have for builders looking for adjustability and long-term durability.

Fuel systems need clamps you can absolutely count on. That’s where the Stainless Steel Fuel Injection Clamp comes in. Designed for higher pressure lines, these clamps stay secure under hard pulls and high revs.

For turbo applications or high-boost builds, nothing beats the Stainless Steel Spring Loaded T-Bolt Clamp. The spring-loaded design keeps constant pressure even under wild boost spikes—ideal for intercoolers and charge pipes.

Similarly, the Stainless Steel T-Bolt Clamp provides a heavy-duty seal and is great for intake systems, radiators, or any large-diameter hose with minimal flex.

For exhaust setups and turbocharger flanges, the Stainless Steel V-Band Clamp is the cleanest, strongest solution out there. It ensures a leak-free seal that’s easily removable when it's time to upgrade or service your system.

Looking for even more corrosion resistance? The 316 Marine Grade V-Band Clamp is ideal for high-moisture environments and long-term durability. Perfect for race cars, track builds, or vehicles exposed to harsh elements.

Even for general-purpose lines like heater hoses or overflow tanks, the Stainless Steel Worm Gear Liner Clamp Delivers reliable grip without cutting into the hose. Its integrated liner prevents leaks while protecting the hose’s integrity.

Control and Precision: Suspension & Camber Components

Handling performance isn’t just about horsepower—it’s about how the vehicle responds to every input. Whether you're chasing lap times or dialing in the perfect stance, control components like bushings and camber kits play a major role.

Worn-out bushings can cause vague steering, poor alignment retention, and noisy suspension. Upgrading to a Control Arm Bushing improves road feel, tightens up your suspension geometry, and reduces unwanted movement in the control arms.

For those chasing perfect wheel alignment and aggressive fitment, a Front Upper Camber Kit is a game-changer. It allows fine-tuning of camber angles to maximize tire contact and handling—ideal for both daily-driven setups and track-oriented builds.

And don’t forget the back end. Installing a Rear Upper Camber Kit ensures that your rear tires wear evenly and stay planted, whether you’re launching at the strip or carving corners on a weekend cruise.

Build Smart. Build Fast.

Every bolt, bend, and bushing plays its part. From the tightest clamp in your fuel system to the widest sweep in your aluminum piping, each component contributes to the bigger picture: power, reliability, and control.

Build Fast Car offers a curated lineup of high-quality, precision-engineered components to bring your vision to life—whether you're building a turbocharged monster, a show-ready street car, or a reliable daily with just the right performance edge.

0 notes

Text

Pneumatic Linear Actuators: How They Work and Why You Need One

Introduction

Pneumatic linear actuators are essential components in various industrial and automation applications. They convert compressed air energy into mechanical motion, providing a reliable and efficient means of achieving linear movement. Whether in manufacturing, robotics, or material handling, these actuators play a crucial role in enhancing productivity and automation.

How Pneumatic Linear Actuators Work

Pneumatic linear actuator operate using compressed air to generate movement. The basic components of a pneumatic actuator include a cylinder, piston, rod, and valves. Here’s a step-by-step breakdown of their operation:

Air Compression – The actuator receives compressed air from a pneumatic system.

Piston Movement – Air pressure forces the piston to move inside the cylinder, pushing or pulling the attached rod.

Directional Control – Control valves regulate airflow, determining whether the actuator extends or retracts.

Exhaust Release – Air exits through an exhaust port when the actuator returns to its original position.

Speed and Force Control – Flow control valves and pressure regulators fine-tune the speed and force output.

Pneumatic actuators can be either single-acting (air pressure moves the piston in one direction, while a spring returns it) or double-acting (air pressure moves the piston in both directions, allowing for more precise control).

Advantages of Pneumatic Linear Actuators

Pneumatic actuators offer numerous benefits over other types of actuators, including hydraulic and electric options. Some key advantages include:

Reliability and Durability – With fewer moving parts, pneumatic actuators have a long service life and require minimal maintenance.

Cost-Effective – They are generally more affordable to install and operate than electric or hydraulic alternatives.

Fast Response Time – Compressed air enables quick movement, making them ideal for high-speed applications.

Safe and Clean – Unlike hydraulic systems, they don’t require oil, reducing the risk of leaks and contamination.

High Power-to-Weight Ratio – Pneumatic actuators provide strong force while remaining lightweight and compact.

Explosion-Proof – Since they don’t generate sparks, they are safe to use in hazardous environments.

Applications of Pneumatic Linear Actuators

Due to their versatility and efficiency, pneumatic actuators are used across various industries, including:

Manufacturing & Automation – Used in assembly lines, conveyor systems, and robotic arms.

Aerospace – Employed in aircraft control systems and landing gear mechanisms.

Medical Equipment – Found in automated surgical tools and laboratory machinery.

Automotive Industry – Used in braking systems, clamping devices, and engine control mechanisms.

Packaging & Material Handling – Assist in sorting, packaging, and moving heavy loads efficiently.

Choosing the Right Pneumatic Linear Actuator

Selecting the right actuator depends on factors such as:

Load Capacity – Ensure the actuator can handle the required force.

Stroke Length – Choose an actuator with the necessary range of motion.

Operating Speed – Different actuators offer varying speeds based on air pressure and cylinder design.

Environmental Conditions – Consider factors such as temperature, moisture, and exposure to chemicals.

Control Requirements – Some applications require precision control, which may necessitate additional components like sensors and regulators.

Maintenance and Troubleshooting

Pneumatic actuators require periodic maintenance to ensure optimal performance. Key maintenance tasks include:

Inspecting for Air Leaks – Regularly check hoses, fittings, and seals.

Cleaning and Lubrication – Keep components clean and well-lubricated to prevent wear and tear.

Checking Pressure Levels – Ensure the air supply pressure is within recommended limits.

Replacing Worn Components – Replace damaged seals, pistons, or rods as needed.

Conclusion

Pneumatic linear actuators are invaluable in industrial automation, offering efficiency, reliability, and cost-effectiveness. Whether you need precision control in manufacturing or robust performance in harsh environments, these actuators provide an optimal solution. By understanding their operation, advantages, and maintenance requirements, you can maximize their efficiency and longevity in your applications.

Contact Us Atiactuators 21225 FM 529 Rd Houston, TX 77433 USA Cypress Area +1-800-924-8037 +1-713-934-0171 [email protected]

0 notes

Text

Resolve BMW Clutch Problems: Professional Maintenance and Replacement Services for Optimal Performance

BMW vehicles are synonymous with luxury, precision engineering, and a driving experience that is second to none. The clutch, a critical component in manual transmission BMWs, plays a vital role in delivering the smooth and responsive driving experience that BMW owners expect. However, like all mechanical parts, the clutch is subject to wear and tear over time, leading to various issues that can affect performance. Understanding common clutch problems, their causes, and the importance of professional maintenance and replacement services is essential for maintaining your BMW’s optimal performance.

Understanding the Role of the Clutch in a BMW

The clutch in a BMW is responsible for engaging and disengaging the engine from the transmission. This allows the driver to change gears smoothly, whether accelerating, decelerating, or shifting to reverse. When the clutch pedal is pressed, the clutch disconnects the engine from the wheels, enabling the driver to shift gears. Releasing the pedal re-engages the engine, transmitting power to the wheels and allowing the car to move forward.

In a BMW, the clutch system typically consists of several key components:

Clutch Disc: The friction disc that presses against the flywheel to transfer power from the engine to the transmission.

Flywheel: The rotating disc that the clutch disc presses against to engage the engine.

Pressure Plate: A spring-loaded plate that clamps the clutch disc against the flywheel.

Release Bearing: The component that disengages the clutch when the pedal is pressed.

Clutch Pedal: The pedal inside the car that the driver presses to operate the clutch.

Each of these components must work in harmony for the clutch to function correctly. Any issues with one or more parts can lead to clutch problems that affect the vehicle's performance and drivability.

Common Clutch Problems in BMWs

Clutch problems can manifest in various ways, depending on the severity of the issue and the specific component affected. Some of the most common clutch problems in BMWs include:

Clutch Slippage

Clutch slippage occurs when the clutch disc fails to fully engage with the flywheel, causing the engine to rev without transmitting full power to the wheels. This can result in a loss of acceleration, particularly when driving uphill or under load. Clutch slippage is often caused by a worn clutch disc or pressure plate, or by oil contamination on the clutch surfaces.

Difficulty Shifting Gears

If you experience difficulty shifting gears or if the transmission grinds when changing gears, it may indicate a problem with the clutch. This issue can be caused by a worn clutch disc, a failing release bearing, or low hydraulic fluid levels in the clutch master or slave cylinder.

Clutch Pedal Feels Soft or Spongy

A soft or spongy clutch pedal can make it difficult to engage or disengage the clutch fully. This problem is often due to air in the hydraulic system, a leaking master or slave cylinder, or a failing clutch hose.

Noisy Clutch Operation

Unusual noises when operating the clutch, such as squeaking, rattling, or grinding, can indicate a problem with the release bearing, pressure plate, or clutch disc. These noises often suggest that the clutch components are worn or damaged and need to be inspected and possibly replaced.

Burning Smell

A burning smell when driving, especially during gear changes or when the clutch is engaged, is a clear sign of clutch trouble. This smell typically indicates that the clutch disc is slipping excessively, causing friction and heat buildup. If left unaddressed, this can lead to further damage to the clutch and flywheel.

Clutch Pedal Sticking

If the clutch pedal sticks to the floor or fails to return to its normal position after being pressed, it may indicate a problem with the clutch cable, release bearing, or hydraulic system. This issue can make it difficult to drive the vehicle and requires immediate attention.

The Importance of Professional Clutch Maintenance and Replacement

Addressing clutch problems in a BMW requires specialized knowledge and expertise. BMWs are precision-engineered vehicles, and their clutch systems are designed to exacting standards. Attempting to repair or replace clutch components without the necessary skills and tools can lead to further damage and costly repairs.

Here’s why professional maintenance and replacement services are essential for resolving clutch problems in your BMW:

Accurate Diagnosis

Professional technicians with experience in BMW vehicles can accurately diagnose clutch issues using advanced diagnostic tools and techniques. They can identify the root cause of the problem, whether it’s a worn clutch disc, a failing release bearing, or an issue with the hydraulic system. Accurate diagnosis is critical for determining the appropriate repair or replacement solution.

High-Quality Parts

When it comes to clutch repair and replacement, using high-quality, OEM (Original Equipment Manufacturer) parts is essential. Professional repair services ensure that all replacement parts meet BMW’s strict specifications, ensuring compatibility and long-term reliability. Whether it’s a new clutch disc, pressure plate, or release bearing, using the right parts is crucial for maintaining your BMW’s performance.

Expert Installation

Clutch replacement is a complex procedure that involves removing the transmission to access the clutch components. Professional technicians have the expertise and equipment needed to perform the job correctly, ensuring that all components are installed and adjusted according to BMW’s standards. Proper installation is key to preventing future issues and ensuring smooth clutch operation.

Hydraulic System Service

Many BMW clutch systems rely on hydraulic components, such as the master and slave cylinders, to operate the clutch. Professional repair services include a thorough inspection and servicing of the hydraulic system, including fluid replacement and bleeding to remove air from the lines. This ensures that the clutch pedal feels firm and responsive, and that the clutch operates smoothly.

Comprehensive Vehicle Inspection

During clutch repair or replacement, professional technicians will also conduct a comprehensive inspection of your BMW’s transmission, drivetrain, and related components. This helps identify any additional issues that may need attention, such as worn transmission mounts or leaking seals. Addressing these issues at the same time as the clutch repair can prevent future problems and save you time and money.

Preventive Maintenance Tips for BMW Clutch Longevity

In addition to professional services, there are several steps BMW owners can take to extend the life of their clutch:

Avoid Riding the Clutch

Keep your foot off the clutch pedal when not shifting gears. Riding the clutch can cause unnecessary wear on the clutch disc and pressure plate.

Use the Handbrake on Hills

When stopped on an incline, use the handbrake instead of holding the vehicle with the clutch. This reduces stress on the clutch and prevents slippage.

Shift Smoothly

Practice smooth and deliberate gear changes to reduce wear on the clutch components. Avoid aggressive or rapid shifting, which can strain the clutch.

Regular Inspections

Schedule regular inspections of your BMW’s clutch system as part of routine maintenance. Early detection of wear and tear can prevent more serious issues and extend the life of the clutch.

Conclusion

The clutch is a vital component in your BMW’s transmission system, and keeping it in good working order is essential for maintaining optimal performance and driving pleasure. By recognizing the signs of clutch problems and seeking professional maintenance and replacement services, you can ensure that your BMW continues to deliver the smooth, responsive performance that you expect. Regular maintenance, high-quality parts, and expert installation are key to resolving clutch issues and enjoying the full capabilities of your BMW for years to come.

0 notes

Text

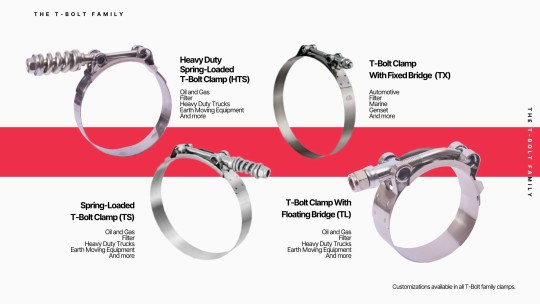

Mastering Precision: The Engineering Marvel of T-Bolt Clamps

In the dynamic world of engineering and technology, precision and reliability reign supreme. At Jolly Clamps, we understand the pivotal role that quality clamping solutions play in ensuring the seamless operation of various industrial processes. That’s why we take immense pride in manufacturing the highest quality T-Bolt Clamps adhering to the stringent SAE standards.

The Epitome of Engineering Excellence

Our T-Bolt Clamps are more than just components; they are the epitome of engineering and technology. Crafted with precision and tested for performance and durability, our T-Bolt Clamps stand as a testament to our commitment to excellence. Designed for the long haul, they find applications in automobiles, heavy trucks, duct connections, industrial machinery, radiators, irrigation systems, and various other industries.

Unraveling the Mechanism

A T-Bolt Clamp derives its name from its unique construction. It features a stainless steel band securely fastened by a forged T-Bolt. This robust assembly ensures the restraint and stability of components even in high-vibration environments. Engineered with the highest quality stainless steel, our T-Bolt Clamps offer unmatched durability and flexibility, making them the preferred choice for discerning customers.

Why Choose Jolly T-Bolt Hose Clamps?

As one of the leading T-Bolt Clamp manufacturers in India, Jolly Clamps stands as a beacon of trust and reliability. Our unwavering commitment to precision and perfection drives us to provide the highest quality clamping solutions tailored to our customers’ unique requirements. Whether it’s Spring Loaded T-Bolt Clamps, Heavy-Duty variants, or those with fixed or floating bridges, we offer a comprehensive range to meet diverse industry needs.

At Jolly Clamps, we understand that every application is unique. That’s why we offer customized T-Bolt Clamping solutions designed to excel in various industries. From Spring Loaded to Heavy-Duty variants, our diverse range ensures that our customers receive tailor-made solutions that deliver unmatched performance and reliability.

In the realm of precision engineering, T-Bolt Clamps stand tall as indispensable components ensuring the seamless operation of critical systems. At Jolly Clamps, we take pride in crafting these engineering marvels that epitomize quality, reliability, and precision. With our commitment to excellence and customer satisfaction, we continue to lead the way as pioneers in the realm of T-Bolt Clamp manufacturing, setting new standards of quality and performance with every innovation.

0 notes

Text

Fasteners Manufacturer in India

In India, a wide variety of fasteners are manufactured to meet the diverse needs of industries such as automotive, construction, aerospace, electronics, and general engineering. Some of the commonly manufactured fasteners in India include:

Bolts: Bolts are threaded fasteners with an external male thread designed to be used with a mating nut. They come in various types such as hex bolts, carriage bolts, and eye bolts.

Nuts: Nuts are internally threaded fasteners designed to mate with bolts or screws to secure components together. Common types of nuts manufactured in India include hex nuts, lock nuts, and wing nuts.

Screws: Screws are threaded fasteners with a helical ridge (thread) and a head, used to fasten objects by engaging with a corresponding threaded hole. They include machine screws, wood screws, self-tapping screws, and sheet metal screws.

Washers: Washers are thin plates with a hole in the center, used to distribute the load of a threaded fastener such as a bolt or nut. They prevent damage to the surface being fastened and help to ensure a secure connection.

Rivets: Rivets are permanent mechanical fasteners consisting of a cylindrical shaft with a head on one end. They are commonly used to join two materials together by deforming the shaft to form a head on the other end.

Anchors: Anchors are fasteners used to attach objects or structures to concrete, masonry, or other materials. They come in various types such as concrete anchors, wedge anchors, and sleeve anchors.

Studs: Studs are threaded rods without a head, used to secure components by being threaded into a tapped hole or welded onto a surface.

Pins: Pins are cylindrical fasteners used to align, join, or retain parts in a machine or structure. They include dowel pins, taper pins, and clevis pins.

Clips and Clamps: Clips and clamps are fasteners used to secure or hold together components or parts. They include hose clamps, spring clips, and retaining rings.

Specialized Fasteners: Manufacturers in India also produce specialized fasteners designed for specific applications, such as automotive fasteners, aerospace fasteners, and electronic hardware.

These are just some examples of the types of fasteners manufactured in India. The industry is diverse and continually evolving to meet the changing demands of various sectors both domestically and internationally.

Click here to know more: https://vidyafasteners.com

0 notes

Text

What industries use fasteners?

Fasteners play a critical role in construction, manufacturing, and engineering. As a leading force in the industry, Bullion Pipes & Tubes LLP stands out as the premier fasteners manufacturer, supplier, stockist, and exporter worldwide. With an extensive range that includes Bolts, Nuts, Screws, Washers, Studs, Rivets, Self-Clinching Fasteners, and more, our commitment is to provide top-notch solutions that cater to diverse project requirements.

This blog post aims to shed light on the diverse industries that heavily rely on fasteners, emphasizing the broad spectrum of applications our products cater to.

Types of Fasteners We Offer

With us, we offer fasteners with a variety of Types and Features, including the following;

Bolts: These threaded fasteners require corresponding nuts for secure connections. Choose from an array of head styles, including hex head, socket head, and round head.

Nuts: Complementing bolts, nuts secure connections. Opt for hex nuts, lock nuts, or wing nuts based on specific application requirements.

Screws: Known for versatility, screws find use in diverse applications. Choose from different head styles like Phillips, flat, or hex, and opt for self-tapping or machine screws.

Washers: Flat and disk-shaped, washers play a pivotal role in distributing fastener loads and protecting surfaces. Types include flat, lock, and spring washers.

Studs: Characterized by threaded rods without heads on one end, studs are ideal for dual-threaded connections and situations where nuts are impractical.

Rivets: Permanent fasteners with a cylindrical shaft and deformed head create a secure connection.

Pins: Cylindrical fasteners for alignment, securing, or support, including types like dowel, cotter, and clevis pins.

Anchors: These fasteners affix objects to hard surfaces, such as concrete. Common types involve wedge, sleeve, and drop-in anchors.

Clips and Clamps: Secure items like hoses and cables using clips and clamps, such as hose clamps, spring clips, and wire rope clamps.

Threaded Rods: Lengthy straight rods with continuous threading, frequently used for hanging and providing support.

U-Bolts: Featuring a U-shaped design with threads on both ends, they secure round objects to surfaces.

Eye Bolts: Equipped with a loop or "eye," these bolts are designed for lifting and securing heavy loads.

Stud Bolts: Threaded at both ends with an unthreaded portion in the middle, commonly used in flange connections.

Self-Clinching Fasteners: Specifically designed for sheet metal and thin materials, including self-clinching nuts, studs, and standoffs.

Hinges and Latches: Serving as fasteners for attaching doors, gates, and panels, they include hinges, hasps, and latches.

Materials Wise Grade We Offer – Fasteners

At, Bullion Pipes & Tubes LLP, provides a wide variety of fasteners, including;

Copper – CDA 102, CDA 101, CDA 110

Titanium – Titanium Alloy Gr 2 & Titanium Alloy Gr 5

Monel – Monel K500 & Monel 400

Carbon Steel – ASTM A193/194 & ASME SA193/194 Carbon Steel

Brass – Alloy 260, Alloy C48200 – C48500, Alloy 385, Alloy 360, Alloy 353, Alloy 330, Alloy 272, Alloy 464

Tantalum – RO5200, RO5400, RO5252(Ta2.5W), RO5255(Ta10W)

Inconel – Inconel 718, Inconel 600, Inconel 601, Inconel 625

Aluminum – he 20 65032 6061, he 30 64430, ASTM 6061, 6063, 6351

Nickel – Nickel Alloy 200/201

SMO 254 – ASTM A 479 ASME SA 479

Duplex Steel – Duplex Steel UNS S32205, Duplex Steel UNS S31803

Hastelloy – Hastelloy C22 & Hastelloy B2, Hastelloy C276

Super Duplex Steel – Super Duplex Steel UNS S32750, Super Duplex Steel UNS S32760

Incoloy – Incoloy 800/800H/800HT, Incoloy 825

Alloy 20 – DIN 2.4460 Alloy Hexagonal Nut, Alloy 20 Bolts, UNS N08020 Alloy 20 Screws, Alloy 20 Washers

Industries Uses Fasteners

Here are some industries where fasteners are used extensively:

Construction: Fasteners such as bolts, nuts, screws, and anchors are widely used in the construction industry for connecting structural elements like beams, columns, and panels.

Automotive: The automotive industry relies heavily on fasteners for assembling vehicles. A variety of screws, bolts, nuts, and clips are used in the manufacturing of cars, trucks, motorcycles, and other vehicles.

Aerospace: Aerospace applications require precision and reliability. Fasteners play a critical role in assembling aircraft and spacecraft components, ensuring safety and structural integrity.

Manufacturing: In general manufacturing processes, fasteners are used to assemble a wide range of products across different industries, including appliances, electronics, and consumer goods.

Energy: Fasteners are used in the energy sector for assembling components in power plants, wind turbines, solar panels, and other energy infrastructure.

Shipbuilding: The shipbuilding industry relies on fasteners for assembling the various components of ships, including the hull, decks, and internal structures.

Railway: They are crucial in the railway industry for connecting rail tracks, assembling train components, and maintaining the structural integrity of railway infrastructure.

Oil and Gas: In the oil and gas industry, fasteners are used in the construction and maintenance of pipelines, platforms, and other infrastructure.

Electronics: Fasteners play a role in the assembly of electronic devices and equipment. They are used to secure components on circuit boards and in the housing of electronic products.

Medical Devices: Fasteners are used to ensure that components are held together in a precise manner in medical devices and equipment.

Furniture: In the furniture industry, fasteners such as screws, bolts, and nuts are used to assemble various types of furniture, from simple household items to complex office furniture.

Final Words! As a global Fasteners Supplier, Manufacturer Stockist, and Exporter, Bullion Pipes & Tubes LLP takes pride in contributing to the success of diverse industries. Our fasteners, available in an array of sizes, specifications, standards, grades, materials, and types, offer versatility and reliability. Whether it's bolts, nuts, screws, washers, studs, rivets, or self-clinching fasteners, our commitment to quality ensures that our customers can confidently choose the perfect solution for their project requirements. Contact us today at [email protected] or [email protected] to explore how our fasteners can enhance the strength and durability of your applications.

0 notes

Text

Radiator Filler Neck: for your vehicle's long lifespan

Our article is about the filler neck, covers its radiator filler neck, useful uses, and much more. We will give you clear information about radiator filler caps, fuel caps, filler caps, fuel caps, and more. Keep reading! Before we begin, let's understand what are filler necks. and caps! The fuel cap is a plastic or metal cap that seals the fuel outlet of the vehicle.

The cap is attached to the top of the compressed rubber seal and prevents fuel from leaking, and the fuel. tank cap is also a vent through which air enters the tank to maintain pressure. The fuel filler hose connects the fuel tank cap inlet to the fuel tank, which is usually covered with hose clamps. If you need to replace a cracked or worn hose, there are a variety of gas fillers available. A few other important things to know when it's time to replace your fuel filler

Using a cooling cap seals the fuel tank preventing vapors from escaping and allowing the system to release restricted gasoline into the atmosphere. Prevent mud, debris, debris, and dirt from entering the fuel tank. Assembly - Radiator filler neck In the vehicle, the radiator filler is placed on top of the radiator and has a spring-loaded piston.

When the vehicle is cold or in normal condition, you can remove the cap and check the coolant level in the radiator or even add coolant. To avoid accidents, the vehicle's cooling system must be flushed and refilled regularly. Avoid touching the radiator's neck when the vehicle is hot. When the engine has cooled down properly, open the radiator cap to avoid injury and burns.

So be careful when you remove the radiator filler cap when the engine is hot, as it can spray coolant. Allow the engine and radiator to settle before removing the radiator cap. You can also add plain water if you do not have the right coolant mixture. It is best to buy a new, high-quality, durable radiator filler if you see that the cap is in poor condition, not in satisfactory condition, worn, or does not close properly. Fuel tanks or gas tank parts are easy to find at https://www.capsnecks.com for more visit the site.

0 notes

Text

Bolts, Nuts, Screws & More: Discover Pipex’s Complete Fastener Collection

Fasteners are the overlooked greats that keep everything together when it comes to constructing, repairing, or assembling anything from do-it-yourself furniture to large, industrial undertakings. And if you’re looking for a one-stop shop for all your fastening needs, Pipex.ai is the name you need to know.

In this guide, we’ll take a deep dive into the world of fasteners, exploring the full range of Pipex’s complete fastener collection, including bolts, nuts, screws, washers, anchors, rivets, and specialty items. Whether you're a weekend warrior or a professional contractor, you’ll find something that fits your needs literally and figuratively.

What Are Fasteners, and Why Do They Matter?

Fasteners are mechanical components used to join two or more objects together, usually permanently or semi-permanently. They are essential in construction, automotive, machinery, home improvement, and countless other fields.

Why Choose Pipex for Your Fastening Needs?

So, why Pipex? Here are just a few reasons:

Massive inventory: One of the most diverse selections in the market.

High-quality materials: Durability and strength are top priorities.

Industry expertise: Years of experience catering to pros and DIYers alike.

Affordable pricing: Bulk options are available without breaking the bank.

Pipex isn’t just another hardware supplier it’s your partner in getting things done.

Bolts: Built to Hold Strong

Types of Bolts Offered by Pipex

Pipex carries a vast selection of bolts, including:

Hex bolts

Carriage bolts

Lag bolts

Eye bolts

U-bolts

Socket head bolts

Each type has its unique application, from carpentry to metal fabrication.

Materials and Finishes

You can choose from stainless steel, carbon steel, brass, and even coated options for corrosion resistance. That means whether you’re working indoors or out in the rain, your bolts won’t bail on you.

Nuts: The Perfect Partner to Your Bolts

Different Types of Nuts

You can’t have a bolt without a nut. We stocks:

Hex nuts

Lock nuts

Wing nuts

Cap nuts

Flange nuts

Custom Fit and Thread Matching

Worried about threading? Don’t be. We ensure compatibility with standard metric and imperial thread sizes.

Screws: Small but Mighty

Screws might be small, but they do some seriously heavy lifting. We carries screws for every project, including:

Wood screws

Machine screws

Self-tapping screws

Drywall screws

Deck screws

Need to hang a shelf or assemble a deck? Pipex has your back with options that bite and hold like a champ.

Washers: Tiny but Essential

Washers distribute load and reduce wear between surfaces. They’re like the cushions of the fastener world.

Types Available

Flat washers

Spring washers

Lock washers

Sealing washers

With the right washer, your bolts and nuts will last longer and stay tighter.

Anchors: Fasten to Concrete Like a Pro

Anchors allow fasteners to grip concrete, drywall, brick, or any other material that doesn’t take screws easily.

Common Types at Pipex

Expansion anchors

Sleeve anchors

Toggle bolts

Plastic anchors

They’re perfect for mounting shelves, cabinets, TVs, and even structural beams.

Rivets: Permanent Fastening with Clean Finish

When welding isn't an option and bolts aren’t practical, rivets step in.

Pipex Rivet Options

Pop rivets

Solid rivets

Blind rivets

Drive rivets

Used in automotive, aerospace, and manufacturing, these are for serious, lasting strength.

Specialty Fasteners: When Standard Just Won’t Cut It

Some jobs need fasteners that go above and beyond the basics. We offers:

Threaded rods

Retaining rings

Clinch studs

Hose clamps

These are ideal for more complex assemblies, especially in plumbing, HVAC, and industrial setups.

Corrosion-Resistant Options for Outdoor Use

If you're working outdoors, rust is your enemy. We offers:

Galvanized

Zinc-coated

Stainless steel

Anodized aluminum

Don’t let moisture mess up your hard work; choose materials built to resist the elements.

Sizing & Compatibility Guides

Not sure what size you need? We provides:

Measurement charts

Thread guides

Material compatibility info

No more guessing games. Get the perfect fit the first time.

Bulk Orders & Custom Kits for Businesses

If you're a contractor or run a shop, buying in bulk can save you time and money. We offers:

Bulk discounts

Custom fastener kits

Same-day shipping on large orders

It’s like a Costco for fasteners but more focused and professional.

Eco-Friendly Packaging and Responsible Sourcing

Pipex is committed to sustainability. With:

Recyclable packaging

Ethically sourced materials

Energy-efficient warehouses

You can feel good about what you're buying and where it’s coming from.

Whether you're hammering out a weekend project or assembling industrial machinery, the right fasteners make all the difference. With us complete fastener collection, you’ll never be left scrambling for the right nut, bolt, or screw again.

For More Details

Website: pipex.ai

Facebook: PipexAi

X: pipex.aiInstagram: pipex_ai.

0 notes

Text

Get consistent pressure across your hose connections with the Stainless Steel Spring Loaded T-Bolt Clamp. It’s the go-to for boosted and high-performance builds.

0 notes

Text

Mac + Alkali + Eyes

A MacGyver Fan-Fiction

by @emachinescat

@febuwhump day 18 - “I can’t see”

Summary: Mac is used to being the one who uses random chemicals to his advantage, but that changes when a fleeing target throws a bucket of drain cleaner in MacGyver’s face – right into his unprotected eyes. Or, in which Jack has to hurt MacGyver in order to help him.

Characters: Mac, Jack

Words: 3,377

TW: graphic description of chemical burns to the eyes, panic attacks

Keep reading here, or on AO3!

If you enjoy, please consider liking, commenting, or re-blogging, and you can follow me for more content like this! :)

MacGyver was used to being the one who used his surroundings to his advantage. Most of the people he went up against – terrorists, traitors, hitmen, dealers – were fairly traditional with their weapons and combat. Mac was used to being shot at, beaten to hell, and nearly blown up. What he wasn’t used to was bad guys abandoning their trusty firearms for a bucket of drain cleaner left over from Mac’s most recent improvisation. That’s not to say that this particular weapons dealer was creative about his approach – but the sad truth was that alkali was just as effective when thrown into someone’s eyes as it was in an impromptu fog machine.

Mac didn’t have enough time to close his eyes all the way. He saw what was going to happen the second before the chemical splashed into his face, and then he didn’t see anything.

Pain exploded behind his squeezed-shut eyelids, radiating from the point of contact like RF waves from a cell tower. He stumbled to his knees, skidding hard on the concrete floor of the abandoned auto shop turned weapons-stash, his fingers instinctively reaching up, clawing for his eyes, desperate, panicked, needing to do something to stop the burning, to ease the howling agony searing his eyes. He managed to keep himself from touching the eyelids, if only just. Even with his eyes on fire, he still knew that touching would only make things worse. He also knew how to treat severe chemical burns to his eyes, and step one was actually keeping his eyelids peeled open – squeezing them shut would only increase the damage.

The racing footsteps of the bad guy had disappeared into the distance the second that Mac had gone down. He supposed he should count himself lucky that the guy didn’t stick around to finish him off, though it was hard to feel lucky when his eyes felt like they were dissolving in pools of acid. Nausea rolled Mac’s stomach, and he nearly vomited. He was now listening for another pair of footsteps, coming from somewhere behind. Where the hell is Jack?

Well, in the meantime, Mac thought frantically, feeling the tears streaming down from his damaged eyes, he could stop putting off the inevitable and do what he needed to do. Mac didn’t normally procrastinate, even when the thing he didn’t want to do was going to hurt. But now, the thought of trying to open his eyes, which were already twin pools of lava eating through his head, almost made him wish that his attacker had used his gun instead. Mac took a deep breath – he felt its tremble to his very core – and wrenched his eyelids open with a yell of defiance.

And immediately slammed them back down, a rough sob exploding from his chest in anguish. Open air on his eye felt like he was being doused all over again, like someone had jabbed red-hot pokers into his eye sockets and was twisting them around for good measure.

He didn’t hear Jack’s feet slapping against the pavement over his own cries, but he did feel the strong, safe hand fall on his shoulder, felt himself being turned around, heard Jack’s frantic voice demanding to know what had happened, what was wrong. Trying his best to regain control of himself now that Jack was here – Jack fixed things, it’s what he did, it would be okay – Mac managed to choke out three of the most terrifying words he’d ever uttered:

“I can’t see.”

***

Jack Dalton couldn’t remember the last time that he had been so terrified.

He didn’t know what he had been expecting when ran up to see the dealer gone and Mac hunched on the ground – all Jack could see was a head of disheveled blonde hair and Mac’s back, shoulder muscles bunched together like a snake coiling up on itself. Fear thudded through him in time with his heart as he approached, thinking maybe the kid had been shot or stabbed or something.

He didn’t expect to see Mac’s face a grotesque shade of red, skin patchy and raw, studded with tear tracks. But the worst of it was Mac’s eyes. Jack felt sick at the sight. Mac’s eyes were shut tight, the lids swollen and puffy, an electric red like the skin had been peeled off, revealing the gooey bits underneath. And his kid’s body quivered with uncontrollable sobs that he tried desperately to contain, and Jack’s heart shriveled up and died at the sound.

“Mac – Mac, hey, buddy, I need you to focus. I need you to talk to me, okay?” Jack had no idea how he managed to keep his voice mostly calm, how he kept the raging panic from consuming every word. His own hands were shaking as he tried to calm Mac down, to get his attention so he could figure out what the hell had happened to his boy.

A great sniffle – Jack couldn’t stand to think about how much pain Mac had to be in if he was so openly showing his pain. Mac didn’t cry, certainly not from injury. His primary objective when sick or hurt was to downplay the ailment as much as possible. He didn’t show pain, not to this degree. Not like this. And the fact that he was now scared the shit of Jack.

Mac’s voice shook as he answered, but he managed to supply his overwatch with a semi-coherent answer: The fleeing bad guy had sloshed a bucket of drain cleaner into his eyes. Jack’s heart nearly gave out then. He didn’t know all the sciencey details or the chemical makeup of drain cleaner, but he knew enough to understand that this was bad.

He barely managed to temper his own panic – his desire to keep Mac calm and get him the help that he needed was the only thing that kept his emotions in check – as he asked, “Okay, what do I do? How do I help?”

Mac’s answer was breathless, his chest hitching as he made a valiant effort to regain control over his body’s reaction to his pain. “Uh… f-first. Call ambulance.” Jack did, keeping one hand on his kid’s shoulder in an attempt to ground him, to remind him that he wasn’t alone in his suffering. Once a Phoenix bus was on its way, he asked, “What next? How do we treat it until it gets here?” He thought back to his high school chemistry days (they seemed farther away than he liked to admit), and recalled a sign on the cinderblock wall about safety goggles and eye-flushing. “Gotta flush those suckers out, right?”

Mac nodded. With difficulty, he directed, “There’s a hose … around back. Get m-me there, and we–” he broke off with a huff of agony, but he didn’t need to finish: Jack was already hauling his partner to his feet. Mac was nearly dead weight, all his focus and energy sapped by his burned eyes.

“I can’t see,” he reminded Jack, though his overwatch was well aware.

“Don’t worry, brother. I gotcha. Just one foot in front of the other. That’s it. Careful there – slight step down. Here we go… All right, let’s ease ya down.” Gently, Jack lowered Mac to the ground. “What’s the best way to do this?” he asked, standing up to grab the hose and twisting the tap. For a horrible moment, nothing happened, then a great gurgling erupted from within the wall, and the hose stiffened, came to life like an industrial green snake. It was the kind that had a nozzle with several settings, but all of them were too strong for his purposes, so he removed the nozzle all together, and a stream of water gushed forth at a much more reasonable rate.

“Um…” Mac’s fingers were clenching and unclenching, raised up to his chest, like he was having to actively restrain himself from reaching up and touching his swollen eyes. “I should lie down, I think.”

So Jack helped him lie back, stripping off his own jacket to slip under Mac’s head. The kid lay there, muscles taut, body so tense Mac could’ve been spring loaded. Jack sat down on the ground next to him, hose within reach.

“All right. Let’s wash out those baby blues. Can you open your eyes for me, Mac?”

To his credit, the kid tried. Like everything else he did, Mac put every ounce of heart and effort into prying his puffy eyelids open. Jack caught the tiniest slit of glazed blue set against fiery red before Mac’s eyes clamped closed again. Fresh tears, from pain or from the chemicals, leaked down the angry, reddened cheeks. The shame in Mac’s voice hurt Jack almost as much as the sight of his partner in this much pain.

“I can’t.”

Jack closed his own eyes for the briefest of moments, steeling himself for what he was about to have to do. The thought of inflicting more pain on Mac cut him to the very center of his being, but he knew that they’d already waited too long to start flushing the burns. They couldn’t delay any longer, certainly not until the ambulance arrived.

“Okay,” Jack said, and he did his best to sound like he was in control of his own emotions, which he most certainly was not. “I’m going to have to hold them open.”

Mac nodded, and Jack could tell by the way his jaw clenched that he was scared. Jack moved quickly, well aware that if he didn’t throw himself into his task that he would lose the courage and resolve to do what needed to be done. As gently as he could, Jack placed the palm of one hand on Mac’s burned forehead, and used his index and middle fingers to carefully pry Mac’s eyes open.

Mac hissed, his hands flying up instinctively to pull Jack away. “Hey, hey, hey,” Jack soothed, and he used his other hand to swat Mac’s hands back down. “I think it might be best if you sit on them, hoss.”

Mac levered his torso off the ground and wedged his hands behind his back, lowering his full weight onto them. “Attaboy.” Jack forced Mac’s eyelids up a bit more – the skin was hot to the touch, an iridescent shade of red, and incredibly swollen. What lay underneath was far worse. Mac’s irises, normally a vibrant cobalt, were dulled, almost filmy, and the whites of his eyes no longer existed - to Jack, stomach twisting uncomfortably, it looked as if the whites of Mac’s eyes had been peeled. Every inch of surface area had turned bright red. He looked like he was trying out for the part of Lord Voldemort.

As more of his eyes were exposed to the open air, a choked gurgling sound forced its way up Mac’s throat, and Jack thought for a terrible moment that he was going to be sick. But instead, Mac just writhed, his legs kicking out helplessly against the pain, arm muscles bulging from the strain of trying to keep his hands beneath him.

Jack himself could barely see at this point through the tears in his own eyes. He brushed them away, touched his free hand briefly in a fleeting moment of comfort against Mac’s cheek, then got to work. He picked up the hose, which had been spewing water the whole time Jack had been prepping Mac, and had created a cool puddle beneath them. Jack had barely realized that he was ass-deep in water. He figured Mac hadn’t noticed at all.

Carefully, Jack placed his thumb in the middle of the stream of water, separating it into two smaller streams, which he directed as gingerly as possible into Mac’s eyes. When the water hit, Mac howled, unable to contain himself and he thrashed on the ground, nearly dislodging Jack’s grip.

“Hey, now, brother,” Jack muttered, his own voice thick with emotion. He did the only thing he could think of – he swivelled his legs around on top of Mac’s torso and applied pressure, holding the kid down. He heard Mac’s breath hitch in panic, knew that he was probably miles away now, unaware of who was holding him down, pouring water onto his face. He was in agony, restrained, and on the receiving end of a face full of cold water. In their line of work, those three things combined usually only meant one thing: waterboarding. Mac had only been waterboarded once, by a terror cell in Libya a couple of years ago, but that kind of thing was something you just didn’t get over. You never truly got over torture of that nature.

Jack was crying now, but he continued to flush out Mac’s eyes, murmuring a string of mostly senseless reassurances, trying to remind himself that what he was doing was ultimately helping Mac, but he hated himself more with each second that passed. Finally, after about five minutes, Mac began to calm, and Jack hoped that the water had begun to sooth. But no – all of the tension suddenly drained from MacGyver’s body at once, and he went limp.

He’d passed out. Thank God, he’d passed out.

Two minutes later, the Phoenix ambulance screamed into the lot. Mac was placed on a stretcher, and Jack climbed up in the back of the bus with him. He stayed out of the way, watching the medics work, using clamps to keep Mac’s eyes open and applying a constant, steady stream of saline. While one medic did this, another began to wash the chemical burns on Mac’s cheeks, forehead, and nose.

The entire ride back to Phoenix, Jack alternated between watching his kid and glaring at his hands. He despised his hands for what they’d done to Mac, what they’d put him through.

Who was he kidding? His hands were just the tools he’d used to torture his best friend.

What Jack truly despised was himself.

***

When Mac awoke, it was to a blurry hospital room – probably Phoenix, if he had to guess – comprised of vague approximations of shapes and colors. His eyes felt like they’d been pulsed in a blender – raw and painful and cut to shreds. He closed them, but that didn’t take away the discomfort. It took him a moment to remember what had led him here in the first place, but when everything came back to him, his eyes snapped open with panic, and his upper body surged up in bed.

Immediately, a strong hand was on his chest and though Mac could only see a fuzzy caricature of its owner, he knew without doubt it was Jack.

“Hey, Mac, you’re all right,” Jack said, and it sounded to Mac like his partner was trying to calm a crying child or a lost pet.

Mac allowed himself to be eased back onto his pillow, but the fear running through him was like live wires. “Jack,” he rasped. His throat burned, and he didn’t know if it was because of the screaming, or if he’d gotten a little of the drain cleaner in his mouth. He prayed it was the former. “I can’t see!”

Jack’s voice had a restrained quality to it when he spoke, like he was just keeping himself from falling off of a very steep ledge, and Mac heard the squeak of a chair, saw the blurred figure that had been looming over him lower itself down. “What do you mean, you can’t see?” Each word was carefully measured. Jack was trying not to panic himself, which only made Mac panic more.

“The whole world is just colors and shapes, Jack! I can’t make out anything clearly.”

To his surprise, a relieved laugh exploded from Jack’s direction. The hand was back, this time squeezing his shoulder. “Doc said that’s normal, Mac. Said your vision should come back in time, if you weren’t completely blind – thank God you’re not! From her examination, she said that we treated it in time to avoid major scarring or reformation.”

Mac, heart slowing down to a more normal rhythm, relief cascading over him like a summer rain, barely caught Jack’s mispronunciation. Almost. “Do you mean perforation?” Half the time, Mac couldn’t tell if Jack messed up words on purpose just to get a rise out of him, or if he really did get words mixed up on the regular. Either way, it had become a part of their natural rhythm, one of the little quirks of their relationship, and after all he’d been through, correcting Jack felt a little bit like coming home.

Mac allowed his body to relax into the bed a little more and did a quick self-assessment. He came to the conclusion that he wasn’t in nearly as much pain as he should have been. “Am I on drugs?” he asked, only now realizing that his head felt floaty, his limbs like noodles.

“Oh, yeah. You were given a shot of morphine, but they’re gonna switch you to hydros now that you’re awake. And you’re on a strong antibiotic to fight off infection, and Doc poured about an ocean’s worth of eye drops in your eyeballs.”

Mac allowed his eyelids to drop; his eyes still felt swollen, and the burning had increased, though that could have just been exhaustion, the pull of the drugs.

“Hey, man, I know you need to sleep, but can I say somethin’ real quick?”

Mac opened his eyes again, concern rising in him at the seriousness in Jack’s voice. “What’s up?”

A pregnant pause. Then, Jack Normally-So-Good-At-Speaking-His-Mind Dalton stuttered out, “I… I – well, shit, man. I’m so sorry.”

Mac blinked, then wished he hadn’t, because it felt like he’d just given his eyes a good scrub with sandpaper. “Sorry? What for?”

“For what I put you through. Hell, kid, I might as well have been torturing you.”

Ah. So Jack was feeling guilty about the lengths he’d had to go to to treat Mac’s eyes. If Mac hadn’t been on drugs, he probably would have predicted this sooner.

Mac fought through the tiredness that seemed to drag his body downwards into the surprisingly comfortable hospital bed and looked Jack in the eye, or at least where he guessed Jack’s eyes would be. “You did what you had to, Jack, and it is nothing to feel guilty about.”

“Mac, if you’d’a heard you…”

“I was there, Jack. I had a front-row seat, remember? I was out of my head with pain anyway. When you started flushing the burns, I think I detached from reality completely. Went back… remembered – things.” He shook himself mentally, then pressed on, his voice as strong as he could make it, imploring, desperate for Jack to understand. “But none of that is your fault. None of that is your doing. You almost certainly saved my vision.” It hit him then, the realization that if it hadn’t been for Jack’s treatment, he would have been helpless to perform first aid on himself. It hadn’t been for Jack’s strength and resolve, his ability to inflict pain on his partner and closest friend in order to treat his wounds, Mac would be blind right now. Most likely forever.

Mac’s next words shook with emotion. “It’s because of you that I can see, Jack. You have a strength I can’t even pretend to understand. You shouldn’t be apologizing to me! I should be thanking you.” A pause. “So thank you for what you did, Jack. Thank you so much.”

A tear burned down his face. He blamed it on the trauma, on the drugs. He reached out his hand in Jack’s direction, and immediately, that warm, familiar grip wrapped itself around it. “I’d do anything for you,” Jack said gruffly.

“I know, big guy. Thank you.”

Jack’s hand squeezed his own. “Get some sleep kid. I’ll be here when you wake up.”

Mac squeezed back, then let his eyes slip closed.

Jack didn’t let go of his hand, and when Mac did wake up to clearer vision and a lighter heart, Jack was the first person that he saw. Just as he’d promised, Jack hadn’t left his side.

But then again, Jack never did.

#febuwhump#febuwhumpday18#macgyver#jack dalton#febuwhump 2021#i can't see#chemical burns#eye injury#graphic description of chemical burns to the eye#whump#jack gives mac medical treatment#panic attacks tw#mac whump#jack feeling guilty#friendship#bromance#epic bromance#mission gone wrong#temporary blindness#hospitalization#alkali#drain cleaner#drain cleaner in eyes#aftercare#hurt/comfort#angst#fluff at the end#macgyver 2016

19 notes

·

View notes

Text

Enhancing Performance and Durability with High-Quality Stainless Steel Clamps and Suspension Components

When it comes to automotive performance and durability, choosing the right components is crucial. Whether you are upgrading your vehicle’s exhaust system, securing fuel lines, or improving suspension performance, high-quality clamps and bushings play a vital role. This article explores some of the best stainless steel clamps and suspension components available to enhance your vehicle’s reliability and efficiency.

Reliable Stainless Steel Clamps for Optimal Performance

1. Stainless Steel Constant Tension Clamp

For those looking to prevent hose leaks caused by thermal expansion and contraction, the Stainless Steel Constant Tension Clamp is a must-have. Designed to maintain consistent pressure, this clamp ensures a secure seal in high-performance applications.

2. Stainless Steel Embossed Clamp

The Stainless Steel Embossed Clamp provides enhanced gripping strength with its unique embossed band design. It is an excellent choice for securing hoses without causing damage or deformation.

3. Stainless Steel Exhaust Pipe Clamp Sleeve

Upgrade your exhaust system with the Stainless Steel Exhaust Pipe Clamp Sleeve. This clamp is perfect for joining exhaust pipes seamlessly, ensuring a leak-free and vibration-resistant connection.

4. Stainless Steel Fuel Injection Clamp

For fuel systems requiring a strong and durable clamp, the Stainless Steel Fuel Injection Clamp is an ideal choice. It provides a secure grip on fuel lines, preventing leaks that could lead to performance issues.

5. Stainless Steel Spring Loaded T-Bolt Clamp

Designed for high-pressure applications, the Stainless Steel Spring Loaded T-Bolt Clamp ensures superior clamping force, making it suitable for turbocharged and high-performance engines.

6. Stainless Steel T-Bolt Clamp

The Stainless Steel T-Bolt Clamp offers a strong and reliable hold, making it a popular choice for high-performance applications such as intercooler piping and intake systems.

7. Stainless Steel V-Band Clamp

For those working on custom exhaust systems, the Stainless Steel V-Band Clamp is an excellent choice. It allows for easy disassembly and reassembly of exhaust components, making maintenance a breeze.

8. 316 Marine Grade V-Band Clamp

For superior corrosion resistance, especially in marine environments, the 316 Marine Grade V-Band Clamp provides durability and reliability, even under harsh conditions.

9. Stainless Steel Worm Gear Liner Clamp

The Stainless Steel Worm Gear Liner Clamp is designed for optimal torque distribution, ensuring a secure and uniform grip on hoses.

Upgrade Your Suspension System with Premium Components

1. Control Arm Bushing

For improved handling and stability, investing in a high-quality Control Arm Bushing is essential. These bushings reduce vibrations and enhance the overall driving experience.

2. Front Upper Camber Kit

For precision alignment and better tire wear, the Front Upper Camber Kit is a great addition. It allows for fine-tuned camber adjustments, crucial for performance driving.

3. Rear Upper Camber Kit