#Square Terminal Connectors

Explore tagged Tumblr posts

Text

Brass Terminal Manufacturer in Jamnagar India

GK Metals is a leading brass terminal manufacturer in Jamnagar, India. We manufacture, supply and export a wide range of brass electrical terminal, brass terminal block, brass earth terminal, current terminals, PCB terminals, brass earth connectors and more as per customer specifications.

#brass terminals#brass earth terminal#brass terminal manufacturer Jamnagar#brass terminal block#brass electrical terminal#brass earth connectors#brass square connectors#brass RF connectors#connection terminals#screw terminals#brass connectors#current terminals#voltage terminals

0 notes

Note

Crimping is referred to as the action of joining wires in a firm bond. The most common use is to terminate (or "cut") a cable at a desired length in order to "crimp" it to a connector. The one you're most likely familiar with is the square bit of plastic that plugs into your computer from an ethernet cable, though there are countless other examples across the networking and electrical engineering world

thank you queen deltarune.

10 notes

·

View notes

Text

How to Choose the Right Solar Components for High-Rise Installations

As cities grow vertically, solar energy adoption is following suit—making rooftop solar installations on high-rises a booming trend. But unlike ground-level systems, high-rise installations come with unique challenges: high wind loads, limited space, longer cable runs, and enhanced safety protocols.

Whether you’re a solar EPC contractor or a building developer, choosing the right solar components is key to ensuring performance, safety, and durability. Here’s a comprehensive guide to help you make the right choices—powered by insights from Solar 4 All, your one-stop stock partner for all essential solar components.

1. High-Efficiency Solar Panels

High-rise rooftops often have limited surface area. Choosing high-efficiency panels (like mono PERC or half-cut cell technology) ensures you generate more power per square meter. Go for Tier-1 brands with proven performance in urban environments.

Pro Tip: Look for panels with a high wind-load rating and certified durability.

2. Heavy-Duty Mounting Structures

Mounting systems in high-rises must withstand strong wind pressures and potential cyclonic conditions. Opt for corrosion-resistant, galvanized or aluminum structures designed for rooftops with minimum penetration.

Look for: ✅ Wind load-tested structures ✅ Adjustable tilt angles ✅ Anti-rust coatings

3. Fire-Retardant & UV-Resistant Cables

Cable quality can make or break your solar system. In high-rise buildings, longer cable runs increase the risk of energy losses and potential fire hazards. Use high-grade, double-insulated solar DC cables (such as Polycab Solar Cables) that are UV-resistant, weatherproof, and fire-retardant.

4. Reliable DC & AC Protection Devices

Safety comes first—especially when your system is several floors above the ground. Use premium isolators, surge protection devices, MCBs, and fuses to protect your solar installation from surges, overloads, and faults.

Choose brands like Polycab or Solar4All’s curated range that comply with IS/IEC standards.

5. Lightning Arrestors & Earthing Systems

High-rise buildings are more prone to lightning strikes. Equip your setup with properly sized lightning arrestors and multiple earthing pits to safely discharge excess current without damaging the system.

Solar 4 All Tip: Always install both electrical and solar earthing pits, and use copper earthing rods for long-term reliability.

6. Quality Connectors & Junction Boxes

MC4 connectors, string combiner boxes, and junction boxes must be IP65 or higher rated to prevent water ingress. Ensure your junction boxes have proper labeling and quality terminals for safe and easy maintenance.

7. Solar Energy Meters & Monitoring Devices

Accurate monitoring is essential for ROI tracking. Use government-approved solar energy meters and smart monitoring solutions that can track generation, consumption, and feed-in to the grid.

8. Partner with a Trusted Supplier

All the best products mean nothing if sourcing them is a hassle. That’s where Solar 4 All steps in—your one-stop shop for:

Solar Panels

DC/AC Cables

Inverters

Protection Devices

Lightning Arrestors

Meters, Connectors & more!

Final Thoughts

Installing solar systems on high-rises demands precision, planning, and premium components. By choosing the right products and partnering with a reliable supplier like Solar 4 All, you ensure long-term system efficiency, safety, and peace of mind.

✅ Looking for high-quality, ready-stock solar components?

Call us now: +91 74474 01171-76-77 Or visit www.solar4all.in

0 notes

Text

The Advantages of Using Square Brass Plates in Marine and Electrical Applications

Brass is a widely used metal in industrial and commercial applications due to its superior conductivity, corrosion resistance, and durability. Square brass plates, in particular, offer exceptional performance in marine and electrical applications, making them a preferred choice for engineers, manufacturers, and designers.

Why Brass? Understanding Conductivity and Corrosion Resistance

Superior Electrical Conductivity

Brass is an excellent conductor of electricity, making it a reliable choice for electrical terminals, grounding plates, and connectors.

Unlike some metals, brass does not easily degrade or corrode when used in high-voltage and industrial electrical settings.

Exceptional Corrosion Resistance

Marine environments expose metals to harsh conditions, including saltwater, humidity, and temperature fluctuations.

Square brass plates, especially marine-grade brass sheets, resist corrosion, preventing rust and material degradation over time.

Their ability to withstand harsh environments makes them ideal for boat fittings, marine hardware, and offshore structures.

Real-World Applications of Square Brass Plates

1. Marine Applications

Boat Hull Protection – Square brass plates act as protective components against corrosion in ships and boats.

Marine Fittings & Fasteners – Used in manufacturing hinges, brackets, and connectors that need resistance to seawater exposure.

Propeller Shafts & Bearings – Brass plates help reinforce mechanical parts that operate under high stress in marine environments.

2. Electrical Applications

Grounding Plates – Essential for electrical safety and stability in power distribution systems.

Bus Bars & Connectors – Their conductivity ensures efficient power transmission in industrial and commercial setups.

Transformer & Circuit Components – Brass plates are frequently used in high-voltage applications for their low electrical resistance and high durability.

FAQs: Square Brass Plates for Marine and Electrical Use

Q1: Why should I choose brass over other metals for marine applications? A: Brass is corrosion-resistant, durable, and has excellent machinability, making it ideal for marine-grade applications.

Q2: Can square brass plates be customized for specific electrical projects? A: Yes! Many suppliers, including Accromet, offer custom-cut brass plates tailored to industry requirements.

Q3: How does brass compare to copper in electrical conductivity? A: While copper is more conductive, brass offers better durability, cost-effectiveness, and resistance to environmental wear, making it a preferred choice in certain electrical applications.

Q4: Where can I buy high-quality square brass plates for industrial use? A: Accromet specializes in corrosion-resistant brass plates, offering premium-quality materials for marine and electrical applications.

Order Premium Square Brass Plates from Accromet

Looking for reliable, high-quality brass plates for your next project? Accromet provides precision-cut, marine-grade brass sheets and brass plates for electrical work tailored to your specifications. Contact us today for a custom quote or to learn more about our extensive range of brass products!

0 notes

Text

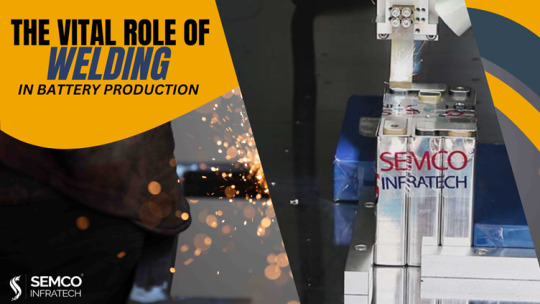

Joining Forces: The Vital Role of Welding in Battery Production

Whether dealing with square or cylindrical batteries, welding stands as a cornerstone of the manufacturing process. In the intricate dance of lithium-ion battery production, welding techniques are primarily employed in the middle and later stages, where precision and reliability are paramount.

Let's explore some key welding processes that contribute to the creation of safe and efficient batteries:

1. Safeguarding with Explosion-Proof Valve Welding (Safety Vent Welding)

The explosion-proof valve, often called a pressure relief valve, is a critical safety feature. It's a thin-walled component located on the battery's top cover. In the event of excessive internal pressure, this valve is designed to rupture, releasing gas and preventing a catastrophic battery burst.

This valve boasts a clever design, typically involving laser welding two precisely shaped aluminium sheets together. The laser welding process must be meticulously controlled to ensure a reliable seal and consistent rupture pressure. If the weld is too weak or too strong, it can significantly compromise battery safety. Therefore, this process demands extremely precise control over the heat applied.

2. Connecting the Power: Terminal Welding

The battery cover features positive and negative terminals, which serve as the pathways for electrical current. Electrons flow from the active materials within the battery, through foils, tabs, and terminal extensions, ultimately reaching the vehicle's electrical components.

Terminal connections are categorized as internal and external. Internal connections involve welding the battery cell tab to the cover's terminal. External connections involve welding the battery terminal to connecting pieces, forming series or parallel circuits within a battery module.

Typically, the positive terminal is made of aluminium, while the negative terminal is made of copper. A common construction involves riveting followed by full welding. To meet the required tensile strength and conductivity, fibre lasers or composite welding lasers, known for their excellent beam quality and uniform energy distribution, are preferred. These lasers help achieve stable welds in both aluminum-aluminum and copper-copper structures, minimizing spatter and maximizing production yield.

3. Bridging the Gap: Tab Extension Welding

Adapters and flexible connectors are essential components that link the battery cover and the battery cell. These components must withstand high currents, maintain structural integrity, and minimize spatter. Therefore, the welding process must create a sufficiently wide weld while preventing any particles from falling onto the battery cell, which could cause a short circuit. Copper, being a highly reflective material, requires a higher energy density for successful welding.

4. Sealing the Shell: Shell Sealing Welding (Can Sealing Welding)

Power battery shells are typically made of aluminium alloy, with some made of pure aluminium. Stainless steel, particularly 304 stainless steels, is also used due to its excellent laser weldability.

Continuous laser welding of thin-shell lithium-ion batteries significantly boosts efficiency while enhancing appearance and sealing. To achieve even faster welding speeds and a more uniform appearance, many manufacturers are adopting composite welding and annular spot welding, moving away from slower single-fiber welding. In mass production, welding speeds have reached impressive levels, while ensuring weld stability.

5. Securing the Seal: Sealing Nail Welding

Sealing nails, or injection hole caps, come in various forms, often round caps. The welding process must ensure a robust seal capable of withstanding high pressure, free from pinholes, cracks, or explosion points.

As the final step in battery core welding, the yield of sealing pin welding is particularly important. Residual electrolyte can lead to defects like explosion points and pinholes. Minimizing heat input is crucial for suppressing these defects. Laser welding significantly enhances stability and consistency, leading to improved yields.

6. Building Modules and Packs: Module and PACK Welding (Busbar Welding)

A battery module is essentially a combination of lithium-ion cells connected in series and parallel, equipped with individual cell monitoring and management devices. The module's structural design dictates its performance and safety. It must support, secure, and protect the cells while meeting overcurrent requirements, ensuring current uniformity, controlling cell temperature, and providing a means to cut off power in case of severe abnormalities.

Because laser welding copper and aluminium together can create brittle compounds, it is generally used for copper to copper and aluminium to aluminium, in addition to ultrasonic welding. Because copper and aluminium have high laser reflectivity and conduct heat quickly, the connecting piece tends to be thick, requiring higher power lasers.

In Conclusion:

Welding is not merely a joining process in battery production; it's a critical determinant of safety, performance, and longevity. Each welding stage, from the delicate safety vent to the robust module assembly, demands precision and control. The adoption of advanced laser technologies and meticulous process management are essential for achieving high-quality, reliable welds. As battery technology continues to evolve, so too will the welding techniques that underpin its advancement, ensuring safer and more efficient energy storage solutions.

#laser welding#laser welding machine#laser welding machine in India#laser welding equipment#fiber laser welding machine

0 notes

Text

The Essential Guide to Fiber Optic Connectors

Fiber optic connectors are an integral part of modern communication systems, enabling high-speed data transmission across vast distances. These connectors join optical fibers, ensuring efficient signal transfer while maintaining the integrity of the light signal. Let’s delve into the basics of fiber optic connectors, their types, and their applications.

What Are Fiber Optic Connectors?

Fiber optic connectors are devices used to terminate the ends of optical fibers and allow for quick and easy connection and disconnection. Unlike traditional copper connectors, fiber optic connectors are designed to transmit light signals with minimal loss. Their precision engineering ensures alignment of the optical fibers—a critical factor for efficient data transfer.

Key Components of Fiber Optic Connectors

Fiber optic connectors generally consist of three primary components:

Ferrule: A thin cylindrical structure, typically made of ceramic, metal, or plastic, that holds the fiber in place.

Connector Body: Houses the ferrule and provides the necessary alignment.

Coupling Mechanism: Ensures the connector stays securely attached to another connector or device, such as a transceiver.

Types of Fiber Optic Connectors

Numerous types of fiber optic connectors cater to different applications. Here are some of the most commonly used:

SC (Subscriber Connector): Known for its square-shaped design and push-pull mechanism, SC connectors are widely used in data centers and network applications.

LC (Lucent Connector): Smaller than SC connectors, LC connectors are ideal for high-density applications due to their compact size.

ST (Straight Tip): Featuring a bayonet-style coupling mechanism, ST connectors are commonly used in legacy networks.

FC (Ferrule Connector): With a threaded coupling mechanism, FC connectors are preferred for high-vibration environments.

MTP/MPO (Multi-Fiber Push-On/Pull-Off): These connectors are designed for high-performance multi-fiber applications, such as data centers and large-scale installations.

Applications of Fiber Optic Connectors

Fiber optic connectors are indispensable in various industries, including:

Telecommunications: High-speed internet and voice communication.

Data Centers: Interconnecting servers and storage devices.

Medical Devices: Precision instruments like endoscopes.

Military and Aerospace: Secure and reliable communication in challenging environments.

Importance of Choosing the Right Connector

Selecting the appropriate fiber optic connector is critical for optimizing performance. Factors such as insertion loss, return loss, and durability should guide your choice. Additionally, proper maintenance, including cleaning and inspection, ensures long-term reliability and efficiency.

Conclusion

Fiber optic connectors are the unsung heroes of modern connectivity, enabling seamless communication and data transfer. As technology continues to evolve, these connectors will remain vital in shaping the future of communication networks. Whether you’re upgrading a network or implementing a new system, understanding the various types and applications of fiber optic connectors is essential for success.

0 notes

Text

CFOFC Communications (Shenzhen) Co., Ltd is a high-tech company specializing in the manufacturing and supply of fiber optic communication products. With over 10 years of industry experience, our R&D and production teams excel in providing OEM and ODM services. Our 10,000-square-meter factory, equipped with 20 production lines, is ISO 9001, RoHS, and Reach certified, holding 6 patents. We offer a wide range of products, including indoor and outdoor fiber cables, high-density MPO/MTP patch cords, FTTH and FTTA solutions, fast connectors, adapters, closures, terminal boxes, media converters, and more.

1 note

·

View note

Text

Brass Rods Manufacturers in India

Predominant complete nature of Brass Rods are accessible by us in different complete alternatives including round, square, level and additionally rectangular and hex shapes. These metal poles are created as institutionalized items and discover use in industry segments including gadgets, autos, designing, electrical, clean fittings and building equipment. Further, we can likewise offer these quality metal poles in various sizes and breadth alternatives at moderate costs. We Chhajed Steel & Alloys Pvt Ltd. best Manufacturers, Exporters & Stockist of Brass Rods in India.

Brass Rods Manufacturers, Brass Rods Suppliers, Brass Rods Exporters, Brass Rods Importers. Brass Rods Manufacturers in India, Brass Rods Suppliers in India, Brass Rods Exporters in India, Brass Rods Importers in India.

Brass rods are cylindrical metal bars made primarily of copper and zinc alloy, renowned for their durability, malleability, and corrosion resistance. These rods find widespread applications in various industries, including construction, plumbing, electrical engineering, and decorative arts. Due to their excellent conductivity, brass rods are commonly used in electrical components, such as connectors and terminals. Their resistance to corrosion makes them ideal for plumbing fittings, where they ensure longevity and reliability in water and gas pipelines.

Additionally, brass rods are valued in artistic and decorative applications due to their attractive gold-like appearance and ease of shaping. They are often used in ornamental hardware, musical instruments, and intricate sculptures. In construction, these rods are employed for their strength and malleability, allowing for versatile applications in structural components. The alloy's antimicrobial properties further enhance its suitability for healthcare equipment and fixtures.

Manufacturers produce brass rods in various sizes and shapes to cater to diverse industry needs. This versatile material's ability to withstand harsh environmental conditions, along with its aesthetic appeal and functional properties, makes brass rods an indispensable choice in numerous sectors, ensuring enduring quality and performance in a wide range of applications.

0 notes

Text

Fiber Optic Adapter - SC Female to SC Female

A Fiber Optic Adapter (also known as a coupler or connector adapter) is a passive device used to connect two optical fibers with the same or compatible connectors. In this case, an SC Female to SC Female adapter would be designed to connect two SC-terminated fiber optic cables together.

Here's a breakdown of the components:

SC Connector: The SC (Subscriber Connector) is a common type of fiber optic connector with a square-shaped snap-in coupling mechanism. It is widely used in data communication and telecommunication networks. The connector has a push-pull design that ensures a secure connection.

Female Connector: The "Female" designation indicates that the connector has a socket or receptor to accept a male connector. In the case of an SC Female connector, it means that the adapter has an SC port with a socket to accept the male end of an SC-terminated fiber optic cable.

SC Female to SC Female Adapter: This adapter is designed to connect two SC-terminated fiber optic cables that have male SC connectors at their ends. Each side of the adapter has an SC Female port (socket) where the SC connectors from the cables can be inserted. This creates a continuous optical connection between the two cables, allowing light signals to pass from one fiber to another.

These adapters are useful in scenarios where you need to extend the length of a fiber optic cable or connect two cables with SC connectors that are too short to reach each other directly. Fiber optic adapters are commonly used in networking, data centers, telecommunications, and other applications where high-speed and reliable data transmission is crucial.

When choosing a fiber optic adapter, it's important to ensure compatibility between the connector types and the mode of the fiber (single-mode or multi-mode) being used. Additionally, make sure to handle and install fiber optic components with care to avoid damage to the delicate optical fibers and connectors.

#Fiber Optic Adapter#Buy Fiber Optic Cable Adapter Coupler#Fiber Optic Adapter SC to LC Singlemode Simplex#SC Male to LC Female UPC Fiber Optical#Fiber Optic Adapters#Fiber Adapters#Fiber Optic Connector Adapters

0 notes

Photo

Senseair K30 CO2 meter Hi, I’ve installed a Senseair K30 CO2 meter to an ESP32 and i’d like to share this with you. Big thanks to martgras and znerk13 for showing the way (Add Senseair K30 CO2 sensor · Issue #1587 · esphome/feature-requests · GitHub). Starting off with the most important question first: why choose the expensive Senseair K30 sensor, and not something else? The choice is based on this scientific publication, which shows the K30 to be a very good sensor. Tomomi Yasuda et al, Comparison of the Characteristics of Small Commercial NDIR CO2 Sensor Models and Development of a Portable CO2 Measurement Device, Sensors 2012, 12, 3641-3655 The result is backup-up by this peer-reviewed paper: Cory R. Martin et al, Evaluation and environmental correction of ambient CO2 measurements from a low-cost NDIR sensor, Atmos. Meas. Tech., 10, 2383–2395, 2017. The result is also backup-up by this non-peer-reviewed paper, which also shows the K30 to be a good sensor: Mengna Li et al, Design of a Calibration System for Miniature Carbon Dioxide Sensors, FLOMEKO 2019, Lisbon, Portugal Okay, based on these results, i choose the Senseair K30. The K30 uses automatic baseline calibration (ABC) to auto-calibrate every 7.5 days. It assumes that lowest measurement in this period is the baseline value of 400 ppm. This mechanism works fine unless somebody is at home all the time (the baseline of 400 would never be reached in those 7.5 days). If the baseline is never reached, it is also possible to disable the ABC-mechanism, but i have not investigated this. Hardware: Power Supply: Mean Well RS-15-5 ESP32: ESP32 WROOM Devkit CO2 sensor: Sensair K30 Bi-directional Logic Level Shifter 3.3v <-> 5v The sensor is very flexible, it can be connected analog and digital via I2C and UART (modbus). I choose UART based on the previous work of martgras and znerk13. Dupont pin headers are soldered onto the Senseair K30 UART terminal. In he picture below, from left to right: ground, 5v, RX, TX From here, the RX and TX go to the Logic Level Shifter → ESP32 TX (GPIO1, orange cable) and RX (GPIO3, yellow cable). As always, RX from the sensor goes to TX of the ESP and TX from the sensor goes to RX of the ESP. Screw the ESP into a project box and fixate the logic level shifter inside. Use a cable gland to fixate cabling in the project box. Now, screw the Senseair K30 outside of the project box, on top of the lid. Make sure to only use two screws, not more. Reason: Senseair advices this to prevent strain on the pcb. Also make sure that both screws are isolated from each other and isolated from main ground (for example by using plastic screws). Connect the wires and screw the top on the project box. CO2 sensors are sensitive to temperature, therefore the ESP32 is inside the box and the sensor is outside of the box attached via spacers. This is also the reason why the power supply is in another location. Building the power supply: this is pretty standard stuff. Crimp ring (or fork-style) connectors to the cables and screw the cables to the power supply. The power supply is placed into a ventilated project box (you can drill holes for this). Make sure to use cable glands to secure the 230v cables, otherwise you are creating a very dangerous situation. Use thick cabling to go from the power supply to the esp32/K30 combination to prevent voltage drop. I’ve used 0.75mm squared cables. You can calculate the required wire thickness using this website: Voltage Drop Calculator Inside the esp32 project box, i’ve placed Wago 221 to divide the cables further into shorter smaller cables to which i crimped dupont connectors (for the ESP32 and the K30) and ferrules (for the Wago 221). End-result of the device. Again, please be aware to place the power supply away from the K30 sensor to prevent warm-up and drifting CO2 measurements. I’ve placed the device inside the ventilation shaft that is extracting air from my living room to the outside. ESPHome is installed onto the ESP32. See the config below. esphome: name: living-room-co2-meter friendly_name: Living Room CO2 Meter comment: ESP32ESP-32S Wroom Devkit v1 + Senseair K30 esp32: board: esp32dev framework: type: arduino # Enable logging logger: baud_rate: 0 # Enable Home Assistant API api: encryption: key: "xxx" ota: password: "yyy" wifi: ssid: !secret wifi_ssid password: !secret wifi_password # Enable fallback hotspot (captive portal) in case wifi connection fails ap: ssid: "Living-Room-Co2-Meter" password: "zzz" captive_portal: uart: id: mod_uart tx_pin: 1 rx_pin: 3 baud_rate: 9600 stop_bits: 1 parity: none modbus: send_wait_time: 200ms uart_id: mod_uart id: mod_bus modbus_controller: - id: sensek30 ## the Modbus device addr address: 0xFE modbus_id: mod_bus command_throttle: 500ms setup_priority: -10 update_interval: 30s sensor: - platform: modbus_controller modbus_controller_id: sensek30 id: status_raw name: "CO2 Status Raw" internal: True address: 0 register_type: "read" value_type: U_WORD accuracy_decimals: 0 - platform: modbus_controller modbus_controller_id: sensek30 id: co2 name: "CO2 Level" address: 3 unit_of_measurement: "ppm" register_type: "read" value_type: U_WORD accuracy_decimals: 0 text_sensor: - platform: template name: "CO2 Status" lambda: |- if (id(status_raw).state == 0) { return {"Ok"}; } if (id(status_raw).state == 1){ return {"Error"}; } else { return "Unknown Code: " + to_string(id(status_raw).state); } The end-result is looking very good. 1 post - 1 participant Read full topic https://community.home-assistant.io/t/senseair-k30-co2-meter/593808

0 notes

Note

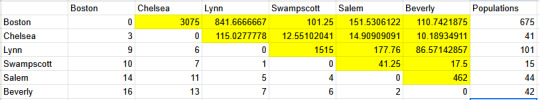

Essay time!

So the main tool that I use to evaluate service priority is an inverse square or gravity model. To calculate, you take the product of the populations and divide them by the distance squared. We'll take the Lowell Commuter rail as our example because it would be the terminus that would extend to Nashua, Manchester, and maybe Concord.

Pop. Lowell: 115k

Pop. Boston: 675k

Distance: 22 Miles*

Gravity Score: 160

We'll use this as our baseline. The units here are gibberish (people^2/sqmi) but we can proportionally compare these numbers to get an approximation of the relative demand. Now, lets add Nashua and Manchester.

Pop. Nashua: 91k

Pop. Boston: 675k

Distance: 34 miles

Gravity Score: 53

Pop. Manchester: 115k

Distance to Boston: 50 miles

Gravity Score: 31 Miles

Now, when we're proportionally comparing these numbers, you can think of them as ratios of estimated trips. For each 160 trips to Lowell, you might reasonably expect 53 to Nashua and 31 to Manchester. That said, we would be potentially looking at a 55% (88/160) increase in riders compared to Lowell.

55% is a lot, but we do have to factor in increased costs. Certain costs are per mile. These per mile costs would increase by 127% (28 new track miles / 22 current track miles) Other costs are fixed or variable in different ways, and I don't have great tools to evaluate them. What I can say is that if this were to be a practical reality, the federal government could also be called on to help as it would be an interstate transportation project to offset some of those costs as well.

But, just with what we have here, lets compare with each other terminal stop on the network.

Needham: 216

Worcester: 86

Providence: 76

Stoughton: 71

Haverhill: 57

Franklin: 38

Scituate: 37

Plymouth: 35

Fall River: 31

New Bedford: 27

Fitchbug/Wachusett: 14**

Rockport & Newburyport: 5&11 ***

The direct comparison here shows in large part why such a service would be consistent with other commuter rail lines. Many of the gravity scores here are lower than what would be expected of a Nashua Connector, and several of these service areas are comparable lengths as well. New Bedford, Worcester, Providence, and Fitchburg all make journeys of close to 50 miles in under two hours on their schedules, matching the distance to Manchester.

There is another thing that the combination of Nashua and Manchester highlights which also is clear in the abnormally low scores for Rockport and Newburyport. On each line, population centers will have mutually reinforcing gravity scores. Beverly, Salem, Swampscott, Lynn and Chelsea all generate trips to Boston but also generate trips to each other, giving the following table.

Now, some of these numbers look a little absurd. How is the 1515 lynn-swampscott score to be read in context? Well, Lynn center and Swampscott center are only a mile away from each other because swampscott is a continuous suburb of Lynn. Therefore, the economic interaction between these two populations is expected to be exponentially higher because of their proximity. A statistically significant number of someones in swampscott aren’t going into boston on a weeknight dinner, but they are going to lynn. When they travel from one to the other, they do it in cars, buses, bikes, and on foot, because the distance is short enough to make all those transit modes viable. Trains realistically make up the smallest part of that 1515 because other modes are more convenient. We don’t need to try to change this. Even setting reductions in driver miles as a goal, buses will solve the problem better than the commuter rail could as a static piece of heavy rail infrastructure. It doesn’t have the dynamic range buses do. The 1515 represents an estimated proportion of economic interactivity that drives and can be used to measure transit demand. So does Rockport’s 5. Even if everyone in rockport leaves rockport on the commuter rail to boston every day, that’s still only 7k people compared to lynn’s 101k and those people are commuting much farther, incentivizing switching to a job with a shorter commute. Nobody likes their 90min commute.

Now, even if we can’t count 100% of those gravity scores as demand for more trains (because more convenient mode shares outweigh trains in practice over small distances), the train still benefits from high trip demand between cities that aren’t the terminus, and many of these city pairs are in fact excellent train connections. Salem-Lynn and Beverly-Lynn score comparably to Boston-Salem and Boston-Beverly, and are in a distance range where walking, biking and buses are less practical, so the train reasonably serves many more people. It’s entirely reasonable to assume that these network effects will also boost ridership for a manchester lowell connection.

When we look at the manchester and Nashua numbers, we get this chart:

These numbers aren’t as high as the north shore, which is to be expected based on the distances, but they’re reasonable compared to the rest of the network shown below.**** The main exception here is Concord. The only score that Concord has above 10 is with Manchester, and it would be the terminus of the line. It’s 20 extra miles of track, almost as long as he initial segment to lowell in the first place. Why would we extend it all that way?

Well, Concord is the capital of New Hampshire. Capital cities drive business traffic in excess of their populations because certain business can only be done there. The gravity model only takes in population and distance, so it can’t reliably assess a variable like that. I like it because it’s fast to calculate and easily comprehensible, but the gravity model is not the best or most sophisticated tool for assessing transit demand. Additionally, if Massachusetts wants to connect population centers in New Hampshire to MA, they would most likely ask New Hamshire to help, and a railroad connecting the capital to its most populous cities would be a project that would mostly benefit New Hampshire. Having them pay for it would be more than reasonable. Then, the actual terminus of the line would be decided by representatives of the actual riders rather than someone in boston. To be clear, I think either terminating in manchester or concord would be reasonable with clear advantages and disadvantages, it just seems like the sort of thing that should be decided democratically by NH itself.

*Geographical distance is substantially shorter than the actual by-car routes, so error in gravity scores should skew actual figures down.

**The abnormally low Gravity score here is partially explained by a large financial contribution from Wachusett mountain resort, which funded an extension of the line to connect to its bus shuttles

***This abnormally low gravity score is because service is extended to Rockport and Newburyport from Salem and the rest of the populous North Shore. Salem alone has a score of 151.

****I’m going to clean up the data because I grabbed numbers fairly sloppily and publish my spreadsheets with consistent population and distance measurements when I get the chance. These are extremely rough numbers with a spur of the moment methodology but the point that they make is worth investigating further. Once I have more consistent numbers I’ll update the numbers in the original post as well.

Why do none of the commuter rail lines extend into New Hampshire? There are two that almost get there but stop short. Don't you care about the people trying to flee the hellhole that is the granite state?

Hey Anon you made me eat my words so hard on this one that I switched to desktop so I could type more

95 notes

·

View notes

Text

Top 10 Uses for Square Brass Plates in Industrial and Artistic Applications

Introduction Square brass plates are highly sought after in a variety of industries due to their unique combination of strength, durability, and aesthetic appeal. Whether you're a manufacturer, designer, or DIY enthusiast, brass plates from Accromet in Monroe, NC, provide the perfect solution for numerous applications. In this post, we’ll explore the top 10 uses for square brass plates and answer some frequently asked questions to help you make the most of this versatile material.

Primary Keyword: Square brass plates Monroe NC

1. Decorative Panels and Trim Square brass plates are a favorite in interior design, often used for decorative panels, trim, and furniture accents. Their natural shine and resistance to tarnishing make them a long-lasting choice for high-end aesthetics.

2. Electrical Components Brass’s excellent conductivity and resistance to corrosion make square plates an essential material for electrical terminals, connectors, and other components.

3. Architectural Features In architecture, brass plates are used for custom features such as plaques, signage, and ornamental designs. Their durability ensures these elements withstand the test of time.

4. Industrial Machinery Brass plates are commonly utilized in industrial settings for components like bearings, gears, and bushings due to their low friction and high strength.

5. Jewelry Making Jewelry designers favor brass for its gold-like appearance and workability. Square plates can be cut and shaped into custom designs, adding elegance to handmade pieces.

6. Marine Applications In marine environments, brass plates are used for fittings and decorative elements due to their excellent resistance to saltwater corrosion.

7. Heat Exchangers Brass’s thermal conductivity and resistance to heat make it an ideal material for components in heat exchangers and radiators.

8. Sculptures and Artwork Artists use square brass plates as a medium for sculptures, engravings, and mixed-media projects, taking advantage of their malleability and visual appeal.

9. Musical Instruments Brass is an integral material in musical instruments, and plates are used for components like reeds, valves, and decorative inlays.

10. Restoration Projects Brass plates are perfect for restoring antique furniture, hardware, and architectural elements, maintaining the integrity and authenticity of historical pieces.

FAQs About Square Brass Plates

Q: Why should I choose square brass plates from Accromet in Monroe, NC? A: Accromet provides high-quality brass plates with consistent dimensions and finishes. Their local availability in Monroe, NC, ensures quick delivery and reliable customer support.

Q: Are brass plates suitable for outdoor use? A: Yes, brass is resistant to corrosion and tarnishing, making it a great choice for outdoor applications.

Q: Can I customize the size of the brass plates? A: Absolutely. Accromet offers customization options to meet the specific requirements of your project.

Q: How do I maintain the shine of brass plates? A: Regular cleaning with a brass polish and a soft cloth can help maintain the shine and prevent tarnishing.

Q: Are brass plates eco-friendly? A: Yes, brass is recyclable and has a long lifespan, making it an environmentally friendly material choice.

Conclusion Square brass plates are incredibly versatile, finding applications in industries ranging from manufacturing to fine arts. Accromet in Monroe, NC, is your trusted source for high-quality brass plates that meet the demands of your projects. Whether you need them for industrial machinery or a creative masterpiece, brass plates offer unmatched durability and style.

Ready to get started? Contact Accromet today to explore our range of square brass plates!

0 notes

Link

#Test Terminal Block#Power Blocks#Brass Sliding Blocks#DIN Rail Terminal Blocks#Universal Terminal Blocks#Electrical Terminal Connectors#Square Terminal Connectors#PCB Terminal Connectors#italy

0 notes

Text

Introducing Wrap030-ATX

New Boards Day!

They're here!

This is a project that has been a long time coming, and something I have wanted to do for a long time.

This is the largest, most complex PCB I have ever designed — a 9.6x9.6 inch (244x244mm) square, 4-layer, complete motherboard for my MC68030 homebrew computer project.

It is designed to support the Motorola MC68030 CPU, MC68882 FPU, two 72-pin SIMM sockets, 512kB ROM, two serial ports, one parallel port, PS/2 keyboard, 4-bpp VGA video, IDE hard drive, and three ISA expansion slots. A complete system all in a microATX form factor.

This builds on my previous work with the 68030, based heavily on my wire-wrap project and the boards that followed. It's a project over four years in the making. I have made a few improvements on the old design, like 16550-compatible serial ports and an updated memory map to support much more RAM in a contiguous space.

Keeping with my existing system designs, I've combined most of the logic into a set of CPLDs. This makes things like PCB layout and logic debugging so much easier. Most of the remaining discrete logic on the board is 74'245 bus transceivers for driving memory and the ISA slots.

I've kept the name "wrap030" in honor of the project's origin as a wire-wrapped prototype, despite the move to proper PCBs. It's just what I've been calling the project in my own head (and design files) all this time, so at this point no other name would feel right.

I of course wasted no time starting to assemble one, but I did stop myself from getting too carried away with the soldering iron. I want to be methodical and test each section before moving on to the next.

I have already found one major error in my board layout — the footprint for the VGA connector is backwards. I may need to bodge together some kind of adapter.

So far I've confirmed the minimalist AT power supply section works with no major shorts on power supply rails, and the reset circuit is working as expected. Next step is to try a free run test with the CPU to ensure the system clock and CPU are working. Once that is confirmed working, I can start loading logic for accessing ROM. My goal is to have it at least running BASIC on a serial terminal by VCFSW in June.

I've forked my existing wrap030 repository on GitHub for this new Wrap030-ATX, since it does make some breaking changes that will require updates to logic and programs. New repo is here:

#homebrew computing#mc68030#motorola#motorola 68k#motorola 68030#vintage computing#jlcpcb#vcf southwest#wrap030-atx

32 notes

·

View notes

Photo

I have been busy! These are two new Tritium designs. Unlike normal glow in the dark Tritium doesn’t need to by charged by an existing light source. It’s a gas, slightly radioactive (not dangerously so) and glows continuously for 12 to 15 years. It’s used in high end watches, gun sights - anything that requires constant illumination. But it’s very, very expensive and is sold in a range of small glass tubes. For the safety of the tube I install them in a second glass or crystal vial.

The green stick is small 12mm x 2mm. It’s sealed in the square crystal vial hung on semicircle silver tone connector with pointed terminals. Two flat struts are used to attach the chain.

The orange/pink stick is larger 24mm x 2mm sealed within a second glass vial test tube. I created a hanging bracket for the vial. The vial is topped with a 5 finned post. There is a brass ring on the test tube that holds the vial at a midpoint and can be removed. The vial itself can be worn without the bracket by clipping two clasps to the holes on the top cap that will be included.

#tritium#tritium jewelry#tritium vial#steampunk#Steam Punk#steampunk jewelry#Glow in the dark#green glow#orange glow#necklace#Pendant#crystal#handmade#science#science jewelry#OOAK#Etsy shop#Etsy seller#etsyseller#etsy#Mad Scientist#glass vial#Radioactive#jewellery#jewelry#brass jewelry

132 notes

·

View notes

Text

Parc Clematis Condo - Prices, Reviews & Property

Occupants will get a free vehicle organization for the underlying 15 months, to a MRT station nearby.And finally, there is a completed extent of 88 workplaces. Something for everyone, whether or not for entertainment or loosening up, or for fitness.As Singapore's unique, and one of its parc clematis balance units crucial regional focus focuses, Tampines has been shown into a certain business centre.It continues to prosper and create as a point of convergence of business development in the eastern locale. Further, under URA's Master Plan, Tampines remains on course for augmentation and improvements.This will see the progression of significantly more workplaces to address the issues of Tampines occupants, and by chance those of Parc Central Residences too.

In all honesty, Tampines is presently one of the most acclaimed dwelling spaces, given its circumstance between the CBD and Changi Airport. It is pretty autonomous too. There are different adequate estimated malls with burger joints and supermarkets, network library, business environments, sports and swimming structures, retail park, schools, and clear passage by methods for roads or the MRT.Tampines is some different option from a point of convergence of business, or a private area. It is generally given educational establishments up to tertiary level, and overall schools also.

For instance, the United World College of South East Asia (East Campus) across Tampines Avenue 5, and Temasek Polytechnic around 15 minutes walk around the road.For step by step necessities, there is a line of neighborhood shops close by, at block 872C, a few minutes walk around the essential path of Parc Central EC. It covers an incredibly wide extent of things.

From a bistro that closes down at 11pm, to a 24-hour Sheng Siong store, a composing material shop, a DIY look for nuclear family items, a confectionary, a laundromat, optician, boutique, and dental and clinical clinics.There are similarly a couple of nature parks in the brief district inside walking distance. The amusement place connector running past the site prompts Bedok Reservoir Park, with Tampines Quarry Park across Tampines Avenue 10.

The Parc Central pioneer loft suite will benefit by its proximity to Changi Airport as well. Extremely isolated from the solace for those getting flights. The air terminal terminals are a goal in themselves, with their enormous number of eating and retail decisions, not the least of these being JEWEL.The Parc Central Residence EC site is a medium estimated, longish bundle of land. It runs in excess of 260,000 square feet, with expected created zone of around 750,000 square feet.

1 note

·

View note