#Stainless Steel Welding

Text

Stainless steel welding is a specialized service offered by experienced fabricators and welders. It involves joining stainless steel components using various welding techniques like TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), or stick welding.

0 notes

Text

Revolutionizing Pipe Spool Fabrication with Nikit Engineers: The Future of Welding Automation and Robotic Solutions

In the dynamic landscape of industrial fabrication, the quest for efficiency, precision, and cost-effectiveness has led to significant advancements. Among these, pipe spool fabrication stands out as a vital process in industries ranging from oil and gas to pharmaceuticals and beyond. At the forefront of this evolution is Nikit Engineers Welding Automation and Robotic Solutions, pioneering innovative approaches to enhance the pipe spool fabrication process in India.

Key Takeaways about Pipe Spool Fabrication:

Off-Site Precision: Pipe spool fabrication entails the assembly of pre-cut pipe sections and fittings in a controlled off-site environment. This controlled setting allows for meticulous attention to detail, ensuring precise measurements and welds.

Reduced Construction Time: By fabricating pipe spools off-site, construction time at the installation site is significantly reduced. This streamlined process minimizes downtime, accelerating project completion timelines.

Enhanced Quality Control: Fabricating pipe spools in dedicated facilities enables easier quality management. Rigorous inspection protocols can be implemented, ensuring compliance with industry standards and specifications.

Mitigated Production Delays: Fabrication in specialized facilities mitigates the risk of production delays caused by adverse weather conditions or site-specific challenges. This resilience to external factors enhances project reliability and on-time delivery.

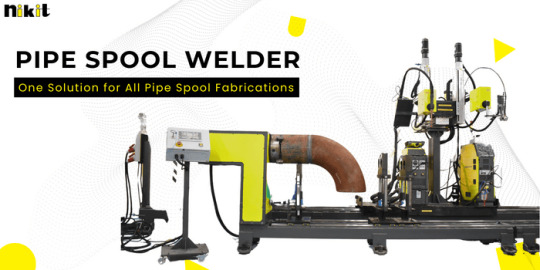

What Is Pipe Spool Fabrication?

Pipe spool fabrication involves the prefabrication of interconnected pipe sections, valves, and fittings into modular units known as spools. These spools are then transported to the installation site for final assembly, significantly simplifying on-site construction.

Pipe Spooling Application

The versatility of pipe spooling extends across various industrial sectors, including:

Oil and Gas: Pipeline networks for transportation and distribution.

Chemical Processing: Complex piping systems for chemical production.

Power Generation: Steam and water piping for thermal and nuclear power plants.

Pharmaceutical: Hygienic piping for pharmaceutical manufacturing facilities.

HVAC: Heating, ventilation, and air conditioning systems in commercial and industrial buildings.

Why Are Pipe Spools Prefabricated?

The prefabrication of pipe spools offers several advantages:

Precision Engineering: Off-site fabrication ensures consistent quality and adherence to design specifications.

Cost Efficiency: Reduced labor and material costs associated with on-site assembly.

Enhanced Safety: Controlled environments minimize the risk of accidents and injuries.

Flexibility: Modular spools allow for easy customization and adaptation to project requirements.

Cost Savings in Pre-Fabrication, Inspection, and Testing

Nikit Engineers leverages cutting-edge welding automation and robotic solutions to optimize the pipe spool fabrication process. By integrating advanced technologies, they deliver unparalleled efficiency, accuracy, and cost savings throughout the fabrication journey. From automated welding systems to robotic inspection and testing, Nikit Engineers ensures that every spool meets the highest standards of quality and performance.

Contact Nikit Engineers for Your Next Industrial Pipe Spool Fabrication Project

With a proven track record of excellence and innovation, Nikit Engineers is your trusted partner for all your industrial pipe fabrication needs. Whether you’re embarking on a new construction project or seeking to optimize existing processes, our team of experts is ready to deliver tailor-made solutions that exceed your expectations.

Experience the future of pipe spool fabrication with Nikit Engineers Welding Automation and Robotic Solutions. Contact us today to discuss your project requirements and discover how we can transform your vision into reality.

Experience the Future with Nikit Engineers: Free Weld Trial Services

Embark on the journey of enhanced efficiency and precision with Nikit Engineers. To showcase the transformative power of our automation solutions, we are proud to offer Free Weld Trial Services. Experience firsthand how our profile welding automation systems can elevate your welding processes.

Book Free Weld Trial Services

At Nikit Engineers, we believe that the future of welding lies in automation. Our commitment to excellence, precision, and efficiency sets us apart as leaders in the field. Elevate your profile welding processes with Nikit Engineers Welding Automation and Robotic Solutions – where innovation meets craftsmanship.

Contact us today to schedule your Free Weld Trial Services and unlock the potential of automation in profile welding.

Nikit Engineers’ Robotic Welding Automation Solutions proudly declare that all our products are #MADEININDIA

Check out our other industrial ventures www.thewelder.in and www.civilautomation.com

Don’t forget to subscribe to our YouTube Channel for the latest videos and updates – www.youtube.com/@Nikitengineers

#robotics solutions#welding automation#orbital welding#circular welding#linear welding#Profile Wedling#Stainless Steel Welding

0 notes

Text

Phased Array Ultrasonic Testing services in India

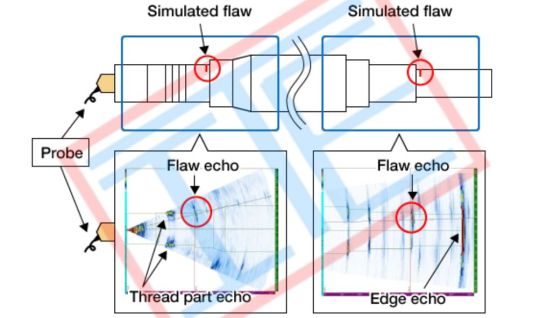

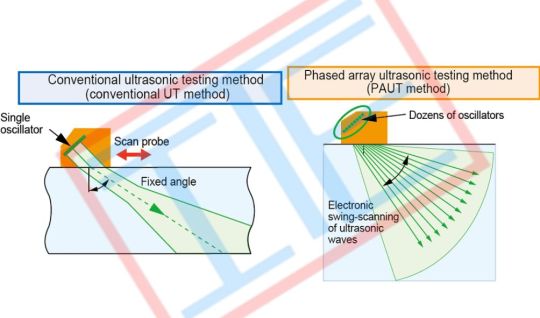

Phased Array Ultrasonic Testing (PAUT) services in India have gained significant popularity in recent years. PAUT is a non-destructive testing technique that uses ultrasonic waves to inspect materials for defects or flaws. It offers several advantages over traditional methods, making it a preferred choice for material testing in various industries.

PAUT inspection involves the use of an array of ultrasonic transducers that can be electronically controlled to emit and receive ultrasonic waves at different angles. This allows for the creation of a detailed and accurate image of the material being tested. The ability to control the angle and focus of the ultrasonic waves makes PAUT testing highly versatile and effective in detecting both surface and subsurface defects.

One of the major benefits of PAUT testing is its speed and efficiency. With traditional ultrasonic testing methods, multiple scans are required to cover the entire area being inspected. However, with PAUT, multiple beams can be emitted simultaneously, covering a larger area in a single scan. This not only reduces the inspection time but also increases productivity and cost-effectiveness.

Another advantage of PAUT inspection is its ability to provide real-time imaging. The data collected from the ultrasonic waves can be displayed as a visual image, allowing for immediate analysis and interpretation. This real-time imaging feature enables faster decision-making and reduces the need for additional testing or re-inspection.

PAUT testing is widely used in various industries such as aerospace, oil and gas, power generation, manufacturing, and infrastructure. In the aerospace industry, PAUT is used for inspecting critical components such as aircraft wings, turbine blades, and engine parts. In the oil and gas industry, it is used for inspecting pipelines, storage tanks, and pressure vessels. In power generation, PAUT is used for inspecting boilers, turbines, and heat exchangers.

India has witnessed a significant growth in the demand for PAUT services due to its numerous advantages and applications. Several testing service providers in India offer PAUT inspection services to cater to the growing needs of industries. These service providers use advanced PAUT equipment and employ trained technicians who are proficient in operating and interpreting the results from PAUT systems.

When selecting a PAUT testing service provider in India, it is important to consider factors such as experience, expertise, and certifications. The service provider should have a proven track record in performing PAUT inspections and should be equipped with state-of-the-art equipment. Additionally, they should have a team of qualified technicians who are trained in conducting PAUT inspections and interpreting the results accurately.

In conclusion, PAUT inspection services in India have gained immense popularity due to their speed, efficiency, and accuracy. The ability to detect both surface and subsurface defects makes PAUT an ideal choice for material testing in various industries. With the growing demand for reliable non-destructive testing methods, PAUT is expected to continue being widely used in India's industrial sectors.

If you are looking for testing service in Delhi/NCR, India worldwide. Look no further now, contact us : +91-9810059715, +91-9953489999 . Our Address is F 22-23, Site C, Surajpur Industrial Area, UPSIDC, Greater Noida, 201306.

#paut inspection#paut testing#non destructive testing#ultrasonic testing equipment#material testing#stainless steel welding#steel welding

0 notes

Text

1 note

·

View note

Text

At Advance Tube Engineering, our material capabilities include bending aluminum, stainless steel, and mild steel, in addition to square tube bending services to customer specification. In addition to bending, we also offer beading, flaring, swaging, and other services.

We are capable of meeting your tube bending needs with a variety of applications including: beading, flaring and welding.

2 notes

·

View notes

Text

Leading Distributor of Pipes for Solar System Works - tubetrading

Discover the future of energy with Tube Trading, your go-to source for top-quality pipes for solar system works in Vadodara. We are your trusted partner in harnessing the power of the sun. Our wide range of pipes and expert guidance will ensure your solar projects shine bright. Find the perfect pipes for your solar projects, from the most reliable brands. Our knowledgeable team is here to guide you in choosing the right solutions. We deliver pipes that meet the highest industry standards. With Tube Trading, you get more than pipes; you get innovation, quality, and sustainability.

Join us in creating a cleaner, greener planet through solar energy.

#Pipes for solar system works distributors in Vadodara#Pipes for solar system works#Stainless steel pipes#spiral welded pipes#IBR pipes#ERW pipes#Steel industry#Gujarat#Vadodara#tubetrading#Jindal pipes#business

6 notes

·

View notes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL

Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

interview at welding job on tuesday :3c

#emord rambles#not fr#i'm used to strike start tig on carbon steel but they do pulse welding on stainless steel so that's gonna be... an adjustment#the interview includes a welding test and im like. gimme a barebones explanation and i'll get it#if it's anything like the other tig stuff i'll be fine at it immediately but oh lord unfamiliarity under pressure is insane

6 notes

·

View notes

Text

Metal Fabrications Types

Casting

Casting is the process of pouring hot metal into a mould or die, allowing it to cool, harden, and take the desired shape. The mass manufacture of parts using the same mould repeatedly to produce similar goods is suitable for the metal fabrication process. There are numerous casting variations. Die-casting is the process of forcing liquid metal into a die rather than a mould, where the pressure retains the metal in place as it cures. The fast applications that this approach provides are its main selling point. Pouring molten metal into a mould is a permanent mould casting technique.

Cutting

Cutting a workpiece to divide it into smaller portions is a relatively typical method of metal production. While sawing is still the most common way to cut, more recent techniques include laser, waterjet, power scissors, and plasma arc cutting. Cutting might be the first step of a more involved fabrication process, or it might be the sole one.

Another method of cutting metal that employs a die is die cutting. In rotary die cutting, the material is cut using a rotating cylindrical die that is fed via a press. On thicker metal materials, flatbed die cutting is employed. When the die stamps down on the metal, it cuts out shapes.

Drawing

Tensile power is used in drawing to draw metal bending into and through a tapered die. The metal is thinned by the die's stretching action. Drawing is typically done at normal temperature and is known as "cold drawing," however the metal workpiece can be heated to lessen the effort needed.

When the finished result has a depth that is equal to or more than its radius, the procedure is referred to as deep drawing. It is typically used in conjunction with sheet metal fabrication to create hollow cylinder- or box-shaped vessels from sheets of metal.

Folding

Metal is bent at an angle during this metal engineering manufacturing process. The most typical method is using a brake press, which pinches the metal to make wrinkles in it. Holding the workpiece between a punch and a die, the punch applies pressure, causing the workpiece to crease. Typically, this method is used to form sheet metal. In addition to employing a folding machine, also known as a folder, or hammering the workpiece until it bends, folding can also be accomplished manually. The device features a flat platform where flat sheet metal is placed, a clamping bar to secure the workpiece, and a front panel that raises upward to bend the metal that is extended over it.

#bending services sydney#custom metal fabrication#sydney public art fabrication#metal engineering#welding services#linished stainless steel#steel fabrication

3 notes

·

View notes

Text

Enhancing Industrial Efficiency: Welding Components on Nikit Engineers’ Mini Profile Welder

n the realm of industrial automation, precision and efficiency are paramount. Nikit Engineers Welding Automation and Robotics Solutions India have been at the forefront of revolutionizing industrial processes with their cutting-edge technologies. Among their impressive array of offerings, the Mini Profile Welder stands out as a versatile solution for welding various industrial components with utmost precision. Let’s delve into the diverse components welded on this remarkable machine and explore how they contribute to enhancing industrial efficiency.

Stellite Welding

Stellite, known for its exceptional wear resistance and durability, is a vital component in many industrial applications, particularly in high-temperature and corrosive environments. Welding Stellite requires precision and expertise to ensure a strong bond without compromising its properties. The Mini Profile Welder, equipped with advanced welding capabilities, ensures seamless welding of Stellite components, guaranteeing optimal performance and longevity in industrial settings.

youtube

Bellow with Flange

Bellow assemblies find widespread use in various industries for their ability to absorb thermal expansion, vibration, and misalignment. Welding bellows with flanges demands meticulous attention to detail to maintain structural integrity and sealing effectiveness. With its precise control and customizable welding parameters, the Mini Profile Welder ensures flawless welding of bellows with flanges, meeting the stringent quality standards required in industrial applications.

youtube

Spin Tube

Spin tubes play a crucial role in diverse industrial machinery, facilitating smooth rotational motion and power transmission. Welding spin tubes demands high precision to achieve uniformity and strength along the weld joints. The Mini Profile Welder’s advanced welding technology, coupled with its automated processes, enables consistent and reliable welding of spin tubes, contributing to the seamless operation of industrial equipment.

youtube

Copper Busbar

Copper busbars are essential components in electrical power distribution systems, requiring robust welding techniques to ensure efficient current flow and conductivity. Welding copper demands specialized expertise due to its high thermal conductivity and susceptibility to oxidation. The Mini Profile Welder’s advanced welding capabilities, including precise heat control and shielding gas management, facilitate accurate and reliable welding of copper busbars, ensuring optimal electrical performance in industrial applications.

youtube

Castor Wheel Brackets

Castor wheel brackets play a critical role in facilitating mobility and maneuverability in various industrial setups. Welding these brackets demands structural integrity and stability to withstand dynamic loads and harsh operating conditions. The Mini Profile Welder’s precision welding technology ensures strong and durable welds on castor wheel brackets, providing reliable support for equipment mobility in industrial environments.

youtube

Bellow Nut Assembly

Bellow nut assemblies are integral components in mechanical systems, providing adjustable support and sealing capabilities. Welding bellow nut assemblies requires precision to maintain dimensional accuracy and thread integrity. With its advanced welding features and customizable parameters, the Mini Profile Welder enables seamless welding of bellow nut assemblies, ensuring optimal functionality and performance in industrial applications.

youtube

In conclusion, the Mini Profile Welder by Nikit Engineers Welding Automation and Robotics Solutions India offers a comprehensive solution for welding a diverse range of industrial components with precision and efficiency. By seamlessly welding components such as Stellite, bellows, spin tubes, copper busbars, castor wheel brackets, and bellow nut assemblies, this innovative machine enhances industrial productivity and reliability, setting new standards in welding automation technology. With its advanced features and robust performance, the Mini Profile Welder continues to revolutionize industrial welding processes, driving progress and innovation across various sectors.

Why Choose Nikit Engineers for Mini Profile Welding Automation?

Tailored Solutions: At Nikit Engineers, we understand that every welding project is unique. Our automation solutions are customized to suit the specific needs and intricacies of profile welding applications. From simple profiles to complex geometries, our systems adapt to the nuances of each project.

Expertise that Matters: Backed by years of experience, our team of engineers is well-versed in the intricacies of profile welding. We provide comprehensive support from the initial consultation to the implementation phase, ensuring a seamless transition to automated welding processes.

Robust Training Programs: Transitioning to automation can be daunting, but not with Nikit Engineers. We offer robust training programs to empower your workforce with the skills needed to operate and maintain our automated welding systems. Our goal is to make the adoption of automation a smooth and positive experience for your team.

Experience the Future with Nikit Engineers: Free Weld Trial Services

Embark on the journey of enhanced efficiency and precision with Nikit Engineers. To showcase the transformative power of our automation solutions, we are proud to offer Free Weld Trial Services. Experience firsthand how our profile welding automation systems can elevate your welding processes.

Book Free Weld Trial Services

At Nikit Engineers, we believe that the future of welding lies in automation. Our commitment to excellence, precision, and efficiency sets us apart as leaders in the field. Elevate your profile welding processes with Nikit Engineers Welding Automation and Robotic Solutions – where innovation meets craftsmanship.

Contact us today to schedule your Free Weld Trial Services and unlock the potential of automation in profile welding.

Nikit Engineers’ Robotic Welding Automation Solutions proudly declare that all our products are #MADEININDIA

Check out our other industrial ventures www.thewelder.in and www.civilautomation.com

Don’t forget to subscribe to our YouTube Channel for the latest videos and updates – www.youtube.com/@Nikitengineers

#robotics solutions#welding automation#orbital welding#circular welding#Stainless Steel Welding#Profile Wedling#Youtube

0 notes

Text

LOCAL GREATEST DIPSHIT SPOTTED

#everyone i know has seen a cybertruck by now EXCEPT for me EXCEPT. for now#it was so ugly why did it look like that#looked like somebody had just welded sheets of stainless steel together#phox.txt

0 notes

Text

Bright Annealed Tubes vs. Other Stainless Steel Tubes: Which Is Right for You?

When it comes to selecting stainless steel tubes, understanding the differences between bright annealed tubes and other options is crucial. Each type offers unique characteristics that cater to specific applications and requirements.

Bright Annealed Tubes: Shining Through Excellence

Definition and Characteristics: Bright annealed tubes undergo a specialized heat treatment process known as bright annealing. This process involves heating the tubes in a controlled atmosphere to prevent oxidation, resulting in a smooth, reflective surface finish. The bright annealing process enhances the tubes' corrosion resistance, improves their mechanical properties, and gives them an aesthetically pleasing appearance.

Key Advantages:

Superior Corrosion Resistance: Ideal for environments where resistance to corrosion is paramount, such as chemical processing plants and marine applications.

Enhanced Aesthetic Appeal: The bright, polished finish makes these tubes suitable for architectural and decorative uses.

Improved Mechanical Properties: Increased strength and durability compared to untreated stainless steel tubes.

Other Stainless Steel Tubes: A Comparative Analysis

Cold Drawn Tubes:

Definition and Characteristics: Cold drawn tubes are manufactured by pulling the stainless steel through a die to achieve the desired dimensions. This process results in a smooth surface finish and tight dimensional tolerances. However, cold drawn tubes may not offer the same level of corrosion resistance and aesthetic appeal as bright annealed tubes.

Key Considerations:

Mechanical Properties: Cold drawn tubes offer excellent dimensional accuracy and surface finish, making them suitable for precision applications.

Applications: Commonly used in industries where tight tolerances and high mechanical strength are required, such as automotive and hydraulic systems.

Welded Tubes:

Definition and Characteristics: Welded stainless steel tubes are formed by welding strips of steel together. While this method is cost-effective and suitable for large-scale production, welded tubes may have visible weld seams and reduced corrosion resistance compared to seamless bright annealed tubes.

Key Considerations:

Cost Efficiency: Welded tubes are often more economical than seamless options.

Appearance and Integrity: Welded tubes may have visible weld lines, which can affect their appearance and structural integrity.

Which Is Right for You?

Choosing the Right Tube for Your Application:

If Corrosion Resistance and Aesthetic Appeal Are Key: Bright annealed tubes are the clear choice, offering superior resistance to corrosion and a polished finish that enhances visual appeal.

For Precision and Mechanical Strength: Cold drawn tubes excel, providing tight tolerances and high mechanical properties suitable for demanding applications.

Cost-Effective Solutions: Welded tubes offer affordability and are suitable for applications where appearance is less critical.

Conclusion

In conclusion, the decision between bright annealed tubes and other stainless steel tube options depends on your specific application requirements. Whether you prioritize corrosion resistance, aesthetic appeal, mechanical strength, or cost efficiency, Krystal Global Engineering Limited can provide expert guidance and high-quality solutions tailored to meet your needs.

Contact Us Today: For more information on selecting the right stainless steel tubes for your project, contact Krystal Global Engineering Limited. With our expertise and commitment to quality, we ensure you get the optimal solution that meets your specifications and exceeds your expectations.

0 notes

Text

Hydraulic Tubes Manufacturer | Skiving and Roller Burnished SRB, Honed Tube Manufacturers in India | Hydraulic Cylinder Tube Suppliers

Kongu Enginears: Your trusted source for Hydraulic Cylinder Tubes - Skiving and Roller Burnished SRB Tubes / Honed Tubes in India. As premier SRB, Honed Tube Manufacturers and Suppliers, we deliver precision-engineered solutions for your hydraulic cylinder tubes and sub assembly needs.

#Cold Drawn Seamless Tubes#SRB / Honed Hydraulic Cylinder Tubes & Sub#Assemblies#Stainless Steel Welded Tubes#Automotive & Non Automotive#Automotive Heavy Vehicle & Farm Equipment Parts#Submersible Pump Parts#Textile Machinery tubes & Parts#Transformer - Radiator Butterfly Valves

0 notes

Text

What are the benefits of MS Pipe angle and MS Pipe beam?

MS angle, also known as mild steel angle, is a type of L-shaped cross-section that has several applications in the building industry. MS angles, also known as metal angles, are typically used to create right angles with two equal sides with the same width and length. Equal angles are those in which each side is the same length, and unequal angles are those in which one or more of the sides is longer than the other.

While Tube Trading Co. is just one of many MS angle manufacturers in India, it is widely recognized as a leading supplier of MS Pipe angle in Vadodara. MS angles are easy to weld, drill, as well as cut to a desirable size, making them versatile for a wide range of applications. They also have exceptional mechanical qualities.

Applications of MS Angle:

Angles made of mild steel (MS) are produced using two materials, either high-strength low alloy steel or hot-rolled carbon steel, which gives them a great deal of stability for use in a variety of structural applications as well as other general fabrication and maintenance activities. It finds widespread applicability across a variety of engineering fields, including commercial, industrial, and domestic settings.

MS Angle is highly recyclable, and as a result, it is regarded as an economically viable material for the production of a wide variety of tiny and big components in virtually every industry. MS angles have a very broad range of applications since they may be utilized in a variety of contexts to perform a variety of functions to meet your needs.

The construction of bridges, buildings, as well as other types of structures, farm equipment and machinery, precipitators, transmission lines and towers, transportation corners and frames, border frames, as well as a variety of other applications are just some of the common industries that make use of MS angle.

Tube Trading Co. is one of the most reliable sources for all of your requirements if you are looking for a trusted distributor of MS Pipe angle in Vadodara, and if so, you should consider using their services.

Advantages of MS Angles:

In light of what has been discussed thus far, it should come as no surprise that the malleability and high degree of versatility inherent to MS angles confer a plethora of advantages.

The pipe angles made from Mild Steel are also available in a variety of grades, dimensions, as well as surface treatments. It has a lower carbon percentage, which makes it simpler to deal with because it can be easily drilled, cut, and welded to suit a vast range of applications, especially construction because of its tenacity. Additionally, it has a lower carbon content, which makes it more environmentally friendly. MS angles have a superb surface finish, and they are available in mild to high steel, all of which contribute to their popularity as a material for the construction of dependable building frames and structures. It is also quite versatile in nature, and as a result, it is regarded as a "green material" for the fabrication of all construction-related components because of this quality.

Therefore, regardless of the kind of building work you could be doing, you should think about using MS angle because it has such a vast array of different mechanical qualities. When it comes to acquiring items made of mild steel, it is usually suggested to purchase from reputable manufacturers and suppliers.

MS Beams:

Mild steel, often known as MS, is a common and flexible building material that may be found in the construction of large structures like skyscrapers and residential buildings alike. The Mild Steel used in construction is designed to withstand significant weight. MS Pipe beam in Vadodara is available in a variety of dimensions, and its application is determined by the needs of the construction. In order to protect a structure from being damaged by severe weather, it is common practice to make use of MS beams while constructing roof structures and the frames of homes. The ability of MS pipes and beams to be bent and shaped is an important factor in the construction industry's reliance on the usefulness of these materials.

Features of Mild Steel pipes:

● High tensile strength

● Made of a low % of Carbon

● Easily welded

● Budget-friendly

● Long-life

Primary Applications of MS Pipe Beams:

● General engineering purposes

● Mechanical purposes

● Structural purposes

● Water treatment plants

● Chemical processing plants

Advantages of MS Beams:

● Recyclable:

In contrast to the majority of other materials used in construction, structural mild steel may be recycled. This contributes significantly to the reduction of waste produced by construction.

● Durable:

Mild Steel beams and other structural components made of Mild steel are known to have a higher tensile strength that can withstand heavy weight, which contributes to their remarkable durability. It is more resistant to fracture under pressure than a mass of stone or wood of the same volume would be under the same conditions. One of the benefits that make structural mild steel structures ideal for the building of big skyscrapers and bridges is the fact that they can withstand wear and tear for a long time.

● Rust and Corrosion resistance:

The life expectancy of construction materials such as wood is poor because of the increased likelihood that they would rot sooner. Because of the chemical structure of mild steel beams, these components are resistant to rust and corrosion, which are two factors that could otherwise reduce the structure's longevity. Because of this benefit, the life expectancy of structures that are created using mild steel beams supplied by Tube Trading Co. - an excellent supplier and distributor of MS Pipe beam in Vadodara is higher when compared to other construction materials.

#MS Pipe angle in Vadodara#MS Pipe beam in Vadodara#Businss#Industry#MS angle#MS pipe#MS steel#seamless pipe#GI pipe#stainless steel pipe#spiral welded pipe#IBR pipe#ERW pipe#pipes for fire fighting work

7 notes

·

View notes