#Stainless steel forged fittings

Text

5 Things about Stainless Steel 316H Forged Fittings manufacturer you will never know!

Stainless steel 316H forged fittings are widely used in a variety of industrial applications due to their exceptional strength, durability, and corrosion resistance properties. These fittings are made by a specialized manufacturer who uses advanced technology and techniques to produce high-quality components.

In this article, we will explore 5 things about stainless steel 316H forged fittings manufacturers that you may never have known before.

Expertise and Experience

SS 316H forged fittings manufacturer has extensive knowledge and experience in the field of metallurgy, engineering, and manufacturing processes. They have the expertise to produce customized fittings that meet specific customer requirements, such as dimensions, shapes, and materials. These manufacturers also have a deep understanding of the properties and characteristics of stainless steel 316H, which enables them to optimize the forging process and produce high-quality components.

High-Quality Standards

This manufacturer follows strict quality control measures to ensure that their products meet the highest industry standards. They use advanced testing and inspection techniques to verify the properties and characteristics of the components, such as hardness, tensile strength, and corrosion resistance. These manufacturers also use high-quality materials and production techniques to ensure that their products are durable and reliable.

Customization Capabilities

They also have the ability to produce customized components based on specific customer requirements. They can create fittings in a variety of shapes and sizes, including elbows, tees, couplings, and reducers. These manufacturers can also produce fittings with specific threads, such as NPT, BSP, or BSPT, and can create specialized components for unique applications.

Advanced Technology and Techniques

They also use advanced technology and techniques to produce high-quality components. They use computer-aided design (CAD) software to create 3D models of the fittings and simulate the forging process to optimize the production process. These manufacturers also use advanced forging equipment, such as hydraulic presses and hammers, to produce high-quality components with precise dimensions and properties.

Compliance with Industry Standards

Stainless steel 316H forged fittings manufacturers comply with various industry standards, such as ASTM, ASME, and ANSI. These manufacturers also adhere to various international standards, such as ISO and EN. Compliance with these standards ensures that the components produced by these manufacturers are safe, reliable, and meet the required specifications.

In conclusion, stainless steel 316H forged fittings manufacturers are experts in the field of metallurgy, engineering, and manufacturing processes. They use advanced technology and techniques to produce high-quality components that meet specific customer requirements. These manufacturers follow strict quality control measures and comply with various industry standards to ensure that their products are safe, reliable, and of high quality.

#Stainless Steel Pipe Fittings#Stainless Steel Forged Fittings#construction#buildings#alloy#steel products#plumbing#Water control system#engineering#civilengineering#SS 316H Pipe Fittings#SS Pipe Fittings#Stainless Steel Pipe Fitting Manufacturer in Mumbai#Stainless Steel Forged Fittings Supplier in India#Stainless Steel Pipe Fittings Price

5 notes

·

View notes

Text

Om Steel is a leading stainless steel manufacturer, specializing in the production of high-quality stainless steel grades such as austenitic, ferritic, and duplex. Our expertise lies in providing customized solutions for diverse applications, offering exceptional corrosion resistance and hygienic properties. With a focus on strength, durability, and precision, we supply stainless steel for industrial sectors including defense, aerospace, oil/gas, and specialty valves. Explore our range of stainless steel products, including sheets, plates, pipes, tubes, round bars, and forged fittings, delivering reliable performance across various industries worldwide.

#Stainless steel manufacturer#Austenitic stainless steel#Duplex stainless steel#Corrosion-resistant steel#Customized stainless steel solutions#Hygienic stainless steel#304 stainless steel#316 stainless steel#430 stainless steel#2205 stainless steel#Stainless steel properties#Industrial stainless steel applications#Stainless steel sheets#Stainless steel plates#Stainless steel pipes#Stainless steel tubes#Stainless steel round bars#Stainless steel forged fittings#Defense & Aerospace stainless steel#Oil/Gas stainless steel

0 notes

Text

Stainless Steel Forged Fittings Manufacturer

0 notes

Text

Stainless Steel Pipe/Tube Fittings Supplier in Oman | Bhagya laxmi industrial

Stainless steel pipe and tube fittings are important components in a big type of industries, from petrochemical and oil and gasoline to manufacturing and food processing. As industries in Oman preserve to amplify, the demand for extremely good stainless-steel fittings has expanded considerably. Bhagyalaxmi Industrial stands proud as a relied on Stainless Steel 304 Forged Fittings Manufacturer and Stainless Steel 304L Forged Fittings Supplier, offering pinnacle elegance products tailor-made to satisfy the precise dreams of those industries.

Importance of Stainless Steel Pipe/Tube Fittings in Oman

In Oman, industries together with oil and gas, petrochemicals, and creation are vital humans to the economic system. These sectors depend closely on long lasting and reliable substances to make certain seamless operations. Stainless metal pipe and tube fittings provide first rate corrosion resistance, durability, and versatility, making them pleasant for those worrying packages.

Stainless metal pipe and tube fittings are used to connect, manage, and alternate the course of piping structures. The fittings are to be had in numerous sorts, which encompass elbows, tees, reducers, couplings, and extra, to ensure compatibility with unique piping necessities. For industries that require precision, protection, and sturdiness, selecting the proper fittings is important.

Types of Stainless Steel Pipe/Tube Fittings

When it comes to stainless steel fittings, there are various options available, each designed for unique applications. Some of the most common fittings embody:

Elbows: Used to exchange the route of the piping device, to be had in forty five°, 90°, and one hundred 80° angles.

Tees: Used to attach 3 pipes, making an allowance for the branching of a piping gadget.

Reducers: Used to connect pipes of numerous sizes, bearing in mind a easy transition in diameter.

Couplings: Used to attach pipes together, making sure a leak-evidence joint.

Caps: Used to shut the surrender of a pipe, stopping the glide of liquid or gas.

These fittings are artificial in special grades of stainless-steel, together with 304 and 304L. The choice of the proper grade is predicated upon at the specific necessities of the utility, which includes resistance to corrosion, temperature dealing with, and mechanical strength.

Benefits of Stainless Steel 304 and 304L Forged Fittings

1. Corrosion Resistance:

One of the number one motives for using stainless steel fittings, in particular grades 304 and 304L, is their superior resistance to corrosion. In harsh environments similar to the ones determined in Oman’s oil and fuel vicinity, wherein publicity to corrosive materials is common, the ones fittings ensure extended-lasting standard performance without compromising safety.

2. Durability:

Stainless metal is renowned for its electricity and capability to face up to excessive pressure and temperature. The mechanical homes of 304 and 304L stainless-steel cause them to suitable for each high-stress and immoderate-temperature environments, making sure that the fittings hold their integrity beneath difficult conditions.

3. Ease of Fabrication and Maintenance:

Stainless metal 304 and 304L are without troubles fabricated, welded, and installation, making them tremendous for custom designed programs. The ease of cleansing and preservation is an added benefit, specifically in industries like food processing and prescribed drugs, in which hygiene is a scenario.

4. Cost-Effectiveness:

While chrome steel fittings could likely have a better initial rate in assessment to different materials, their sturdiness, low protection, and minimum want for opportunity cause them to a charge-powerful solution in the end. For industries in Oman, in which minimizing downtime is vital, making an funding in amazing chrome steel fittings is a smart choice.

Why Choose Bhagyalaxmi Industrial as Your Stainless Steel Fittings Supplier in Oman?

1. Comprehensive Product Range:

Bhagyalaxmi Industrial gives a numerous type of stainless steel pipe and tube fittings, along with elbows, tees, reducers, couplings, caps, and additional. The products are to be had in numerous sizes, specs, and custom configurations to meet the correct requirements of customers in special industries.

2. Quality Assurance:

Quality is at the middle of Bhagyalaxmi Industrial's operations. The enterprise commercial enterprise agency adheres to worldwide satisfactory necessities and employs strict best control measures at each diploma of manufacturing. The chrome steel 304 and 304L sturdy fittings are synthetic the use of top notch raw materials, ensuring reliability and sturdiness.

3. Customization and Flexibility:

Recognizing that every business enterprise has specific desires, they give customization options for its stainless steel fittings. Whether it’s custom dimensions, unique finishes, or specific certifications, the enterprise is prepared to deliver products tailor-made to customers' requirements.

4. Expertise and Experience:

With years of experience in production and supplying stainless-steel product, they possess the technical records needed to supply solutions that meet the first-rate enterprise standards. The enterprise’s deep information of marketplace needs in Oman lets in it to provide fittings that offer first-rate common overall performance in neighborhood conditions.

5. Competitive Pricing and Timely Delivery:

In addition to imparting top class products, Bhagyalaxmi Industrial ensures that its fittings are price range pleasant. The business employer’s inexperienced supply chain and strategic partnerships permit it to deliver product at once, making sure that clients get preserve of their orders without useless delays.

Applications of Stainless Steel Pipe/Tube Fittings in Oman

The industries in Oman that benefit from chrome steel pipe and tube fittings embody:

1. Oil and Gas Industry:

The oil and gasoline region in Oman is one among the largest clients of chrome steel fittings. The harsh and corrosive environments on this company name for substances that may resist excessive conditions. Stainless metallic 304 and 304L fittings are used extensively in pipelines, refineries, and offshore drilling systems.

2. Petrochemical and Chemical Processing:

In chemical processing flora, the go with the float of competitive chemicals calls for substances that provide high corrosion resistance. Stainless metal fittings provide the important sturdiness and resistance, making them a in fact perfect preference for the ones applications.

3. Construction and Infrastructure:

Stainless metal fittings are carried out in severa creation obligations, inclusive of water distribution systems, fireside protection structures, and HVAC structures. Their energy, corrosion resistance, and aesthetic attraction make them suitable for every useful and ornamental programs in manufacturing.

4. Food and Beverage Industry:

Hygiene and cleanliness are important in the food and beverage company. Stainless metal fittings, especially those made from 304 and 304L grades, are desired due to their smooth-to-easy surfaces and resistance to infection. They are substantially utilized in piping systems, processing system, and garage tanks.

5. Water Treatment and Desalination Plants:

Oman’s developing call for for easy water has brought approximately the growth of desalination and water remedy flowers. Stainless metal fittings play a crucial feature in these facilities, providing dependable and corrosion-resistant connections that make sure the non-forestall and strong float of water.

The Role of Stainless Steel 304 Forged Fittings in Critical Applications

Stainless metal 304 solid fittings are especially designed for excessive-pressure applications in which strength and durability are paramount. In Oman, industries that address excessive-temperature and immoderate-pressure environments, collectively with energy generation and oil and fuel, rely on those fittings to keep tool integrity and prevent leaks.

The forging approach utilized in production those fittings complements their mechanical houses, making them suitable for demanding applications. The 304L model, with its low carbon content material material, is in particular powerful in preventing carbide precipitation in the route of welding, reducing the chance of intergranular corrosion.

How Stainless Steel 304L Forged Fittings Meet Industry Standards

Stainless steel 304L Forged Fittings Supplier robust fittings meet diverse global requirements, such as ASTM, ASME, and ANSI. These requirements make sure that the fittings meet the required specs for dimensions, mechanical homes, and usual usual performance. Industries in Oman that prioritize outstanding and compliance with worldwide necessities can rely on these fittings for his or her essential operations.

Key Features of Stainless Steel 304L Forged Fittings:

Low Carbon Content: Reduces the threat of carbide precipitation, making them appropriate for welding packages.

High Corrosion Resistance: Suitable to be used in environments with publicity to chlorides, acids, and one of a kind corrosive marketers.

Good Mechanical Properties: Ensures energy, sturdiness, and reliability in immoderate-strain and excessive-temperature packages.

Versatile Applications: Used in a massive type of industries, which incorporates oil and gas, petrochemical, and meals processing.

Conclusion

Oman’s business place requires dependable and high-standard overall performance materials to make sure smooth and green operations. Stainless steel pipe and tube fittings, in particular the ones made from grades 304 and 304L, provide the essential corrosion resistance, energy, and flexibility wanted for critical programs. As a leading Stainless Steel 304 Forged Fittings Manufacturer and Stainless Steel 304L Forged Fittings Supplier, they are devoted to turning in products that meet the very pleasant necessities of great and performance.

Whether you are inside the oil and gasoline company, creation, or chemical processing, Bhagyalaxmi Industrial is your move-to supply for stainless-steel fittings in Oman. Their vast product variety, customization options, and willpower to awesome reason them to the right accomplice on your enterprise goals. For extra records or to vicinity an order, contact them in recent times and revel in the distinction that excellent and expertise ought to make on your operations.

0 notes

Text

Incoloy Alloy 800/800HT/825 Forged Fittings

Introduction

In the world of industrial manufacturing and engineering, materials that can withstand extreme environments are crucial. Incoloy alloys, particularly Incoloy 800, 800HT, and 825, are known for their exceptional performance in high-temperature and corrosive environments. These alloys are widely used in various industries, including chemical processing, power generation, and oil and gas. Forged fittings made from these alloys are essential components in these industries due to their superior mechanical properties and resistance to oxidation and carburization. Ranflex Metals, a leading manufacturer in the field, specializes in producing high-quality Incoloy Alloy 800/800HT/825 forged fittings, ensuring reliability and durability in critical applications.

Understanding Incoloy Alloys

Incoloy 800

Incoloy 800 is an iron-nickel-chromium alloy with excellent resistance to oxidation and carburization at high temperatures. It maintains its structural integrity and strength even when exposed to extreme temperatures, making it ideal for applications such as furnace components, heat exchangers, and petrochemical processing equipment. Its composition typically includes 30-35% nickel, 19-23% chromium, and trace amounts of aluminum and titanium, which enhance its stability and resistance to scaling.

Incoloy 800HT

An enhanced version of Incoloy 800, Incoloy 800HT contains higher levels of carbon, aluminum, and titanium, providing improved creep and stress rupture properties. This makes Incoloy 800HT particularly suitable for applications requiring prolonged exposure to high temperatures. Industries that benefit from this alloy include nuclear power plants, where it is used in steam generators and heat exchangers, and petrochemical processing, where it finds applications in high-temperature reaction vessels and catalytic support grids.

Incoloy 825

Incoloy 825 is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. This unique composition offers outstanding resistance to both reducing and oxidizing acids, as well as to stress-corrosion cracking. It is extensively used in environments where sulfuric and phosphoric acids are present. Typical applications of Incoloy 825 include chemical processing, pollution control equipment, and oil and gas well piping.

The Role of Forged Fittings

Forged fittings are critical components in piping systems, providing secure and leak-proof connections. The forging process involves shaping metal using compressive forces, resulting in a product with a dense and uniform grain structure. This enhances the mechanical properties of the fittings, making them stronger and more reliable than cast or machined fittings.

Ranflex Metals: Excellence in Forged Fittings

At Ranflex Metals, we pride ourselves on producing top-quality Incoloy Alloy 800/800HT/825 forged fittings. Our state-of-the-art manufacturing facility and stringent quality control measures ensure that each fitting meets the highest standards of performance and durability.

Our Product Range

Elbows: Available in various angles, our Incoloy elbows provide smooth directional flow in piping systems, reducing turbulence and pressure drop.

Tees: Our tees are designed to distribute fluid flow evenly, ensuring efficient operation of your piping network.

Reducers: Used to connect pipes of different diameters, our reducers ensure a seamless and secure transition.

Couplings: Our couplings provide a reliable connection between two pipes, ensuring leak-proof performance.

Quality Assurance

Ranflex Metals is committed to delivering products that meet or exceed customer expectations. Our Incoloy forged fittings undergo rigorous testing, including:

Chemical Analysis: Ensuring the precise composition of the alloy.

Mechanical Testing: Verifying tensile strength, hardness, and impact resistance.

Non-Destructive Testing: Detecting any surface or internal defects to ensure the integrity of the fittings.

Conclusion

Incoloy Alloy 800, 800HT, and 825 forged fittings are indispensable in industries where high-temperature and corrosion-resistant materials are required. Ranflex Metals stands out as a trusted supplier, providing high-quality forged fittings that meet the demanding requirements of various applications. Our commitment to excellence and customer satisfaction makes us a preferred choice for Incoloy forged fittings. When it comes to ensuring the reliability and durability of your piping systems, trust Ranflex Metals to deliver the best.

#Incoloy Forged Fittings#Incoloy Alloy 800/800HT/825 Forged Fittings#ASTM B564 Incoloy Alloy UNS N08800/11/25 Forged Fittings#825 Incoloy Alloy reducer#800 Incoloy elbow#800 stainless steel tee#601 Incoloy Alloy cross#825 Incoloy Alloy stub closes#825 Incoloy Alloy channel twist#800 Incoloy Alloy short range elbow Suppliers India

0 notes

Text

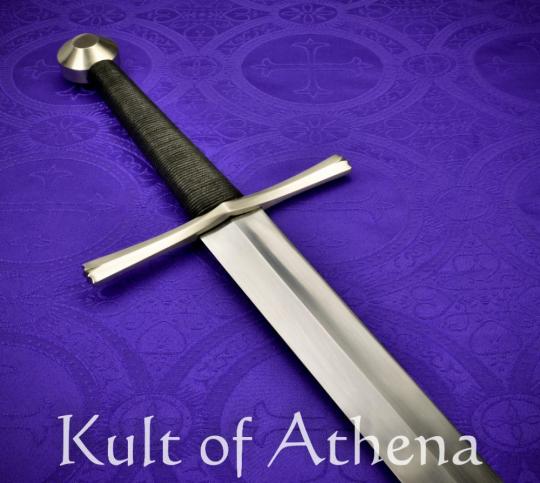

Forged Pipe Fittings

Looking for top-quality stainless steel flanges in India. Bu-Lok is one of the best Forged Pipe Fittings suppliers in Mumbai. Bu-Lok also supplies flanges, fasteners, plates, round bars, and stainless steel forged pipe fittings.

#forged fitting manufacturer in Mumbai#stainless steel flanges in India#Forged Pipe Fittings#fasteners#plates

0 notes

Text

Stainless Steel 316L Forged Fittings Exporters in India

Technolloy Inc. is the maker and stockiest of the wide degrees of the SS 316/316L/316Ti Forged Fittings. We are similarly the provider of the normal thought of the shaped fittings open from one side of the world to the other. The created fittings are also open in various nuances like surface zenith, end finish, viewpoints, shapes, sizes, and length.

The manufactured fittings are open in various sorts which are utilized in present day applications. In any case, a piece of the shaped fittings which are open are elbows, couplings, equivalent, and others. the manufactured fittings are the kind of line fittings which are made with following the making system.

SS 316L is the low carbon mix grade of the 316 blends tempered steel which is besides containing the things in chromium and nickel. Notwithstanding, this is the explanation that the compound is having phenomenal use block limit with the presence of carbon and the increases of molybdenum.

The SS 316/316L/316Ti Forged Fittings is having different attributes with the presence of the alloying parts. A piece of the properties which are there in the manufactured fittings are sensational adaptability, strength, steady quality in the raised temperature, extraordinary solidness, high flexibility, and fantastic weldability. This is the explanation that made fittings are utilized in two or three undertakings. A piece of the associations which are utilizing such planned fittings are drugs, petrochemical, oil and gas, pound and paper, rail lines and several others.

The SS 316/316L/316Ti Forged Fittings is besides going through several materials testing to guarantee the clients that they are given the phenomenal thought of the framed fittings.

Stainless Steel 316/316L/316Ti Forged Fittings Manufacturers in Mumbai, Stainless Steel 316/316L/316Ti Forged Fittings Suppliers in Mumbai, Stainless Steel 316/316L/316Ti Forged Fittings Stockists in Mumbai, Stainless Steel 316/316L/316Ti Forged Fittings Exporters in Mumbai

0 notes

Text

Welded SS pipe manufacturers SPP alloys and Metals

SPP Metals and Alloys are the leading welded pipe manufacturer in India. Our connections and supplies are provided all over the world. Welded pipes are our specialty, with multiple options for wide usage. We are trusted with pipings, with our products utilized in several industries. Welded pipes are made by welding two sides together using a metal base. It is the opposite of seamless pipes which are created using a single material.

#pipe seamless#ss pipes#ss tube#pipe stainless steel#flange for pipe#piping manufacturers#forged fittings#carbon steel pipe

0 notes

Text

Forged Fittings - Grades, Types, Range, Form| Stainless and Carbon Steel

Metal Forge India is one of the leading manufacturers of high quality forged fittings in all major grades including ASTM A182, A105, A105N, A350 LF2, A182 F5. We produce forged pipe fittings for end-users and stockists all over the world. We can also offer forged pipe fittings in Low Temp ASTM/ASME SA350 LF2 and Stainless Steel ASTM/ASME SA182 F304/L & F316/L. We manufacture and supply ANSI forged pipe fittings in all materials and pressures.

#Forged Fittings Manufacturer in India#Forged Fittings Supplier in India#Forged Fittings Supplier#Stainless and Carbon Steel Manufacturer in India#Stainless and Carbon Steel Supplier in India

0 notes

Text

⠀⠀𓋜 warnings : fem! reader. ōral [m receiving]. choking. spit. praising. tongue piercing. hair pulling. dacryphila. [.5k]

⠀⠀ " baby you’re the baddest , nobody else matters girl. "

streetracer getō . . . that loves when your precious plump lips are wrapped firmly around the girth of his dick. the elevating tingle of your stainless steel tongue piercing raking alongside his veined base , his tip prodding your delicate uvula with each stroke you glided against him.

⠀⠀⠀⠀⠀oh how he adored watching your teary-eyed expression contort with every buck he shoved down your throat. the black-induced liquid that tainted your beloved face , an impression he loved dearly. your acrylic covered fingers wrapped the end of his dick that couldn’t fit into your mouth , gripping and twisting his skin which earned you a few grunted moans from your boyfriend.

⠀⠀⠀⠀⠀" you’re such a damn tease , love. " rasp and hoarse , his tone lingered your senses like an intoxicating pheromone.

⠀⠀⠀⠀⠀thick , sleek , and calloused fingers made their way to the top of your head , a stern grasp tangling within your thick curls whilst he shushed your pathetic cries. deepening his length into your mouth was music to his ears as gags vibrated the sides of his dick. the girth far too wide to fit any deeper. all you could cough up was saliva that coaxed his base , your fingers kneading it into your strokes along his end.

⠀⠀⠀⠀⠀hazed eyes tried so desperately to keep contact with Suguru , though with how drunk you were from the sheer amount of booze you both shared prior to jumping into the back seat of his 2003 Nissan Fairlady 350z , that was almost impossible. His whispers of raw accolade did absolutely nothing to soothe the burning fuel that boiled within your abdomen , hums and whimpers dripping from your tongue while your lower half squirmed like a mouse.

⠀⠀⠀⠀⠀" f— fuck , y/n , just like that , baby~ " his words only worsened your state , head maneuvering at a more frequent pace with squelches and slurps filling all silence within his vehicle.

⠀⠀⠀⠀⠀one arm rested atop the head cushions in the backseat of his car , the other containing a solid hold against your head. his own tossed back as he allowed the alcohol to likewise consume his system , the euphoric feeling of your warm mouth practically swallowing his dick whole all the more enthralling.

⠀⠀⠀⠀⠀the only thing keeping him from truly getting lost in the burning pleasure was your piercing dragging his walls , his urges to fuck your face settling as he struggled to contain himself from doing so. the thought was just too overwhelming , hips thrusting his entire length into your throat every other minute.

⠀⠀⠀⠀⠀the popping sound that erupted from your lips each time you pulled his dick from your mouth was deafening , saliva dripping from your corners and lubricating his delicate tip. thumb pads found their way to his slit , rubbing your mixed liquids through it and earning a stomach churning moan from the man himself. teeth pulled the fat of your lip into your mouth as you continued to tease his climax , one hand fondling his tip whilst the other worked twists against his base.

⠀⠀⠀⠀⠀" keep .. f— fuckin' .. doin' that … 'nd i'll make ya .. regret it. " his broken threats were merely muffled out by the sounds of his own groans , a devious grin forging your expression.

⠀⠀⠀⠀⠀silence was your response as you lowered your head once more , oh so slowly dragging your tongue up the bottom of his base and through the slit of his tip. spinal chills spiraled Suguru’s back , a knuckled fist brought to his teeth all the while you continued to prologue his eager release.

⠀⠀⠀⠀⠀if not for his itching climax , he’d have you bent over the middle console with himself buried ball deep inside you. the more you taunted him , the closer his release inched up. not a damn thing helped , especially not when you puckered your lips around his tip and sucked his pre-cum from it , your tongue dancing across his slit yet again. eyes rolled and heads tossed at the ecstatic endurance he faced , hips subconsciously bucking his dick into your mouth yet again. though , this time he quickly took advantage of your vulnerability and placed his hand against the back of your head.

⠀⠀⠀⠀⠀the moment you felt his rough palm against your scalp , you knew you’d fucked up. and he made sure you stared right into his piercing gaze as he vigorously abused every inch and crevice of your mouth. hands pathetically clawed at his inner thighs , eyes continuously rolling white with saliva dripping onto the leather fabric of his seats.

⠀⠀⠀⠀⠀" look at me , damn it. " his grip only tightened at his harsh words , your eyes barely able to make contact with his own with how rough his movements were.

⠀⠀⠀⠀⠀every time he collided his abdomen with your nose , his fat girth widened the stretch of your mouth whilst his tip kissed the back of your throat.

⠀⠀⠀⠀⠀" where’s that snarky grin at now .. hm? " he likewise taunted , bottom lip pulled between his bared teeth as he could feel himself becoming sloppy with his thrusts.

⠀⠀⠀⠀⠀alas , one final plow and his white seed painted your gums like a fresh bedroom , overbearing your throat as you struggled to swallow it all. however , all he did was slowly thrust himself further , forcing his juices down your insides. limbs dropped to your side , exasperated eyes far too lazy to open wide.

⠀⠀⠀⠀⠀Suguru knew he’d have to get his car detailed after this , though it’d have to wait because he also had an obligation to make you feel good now , after all he’s put you through.

⠀⠀⠀ " hope nobody catch us , kinda hope they catch us. "

SINCERELY , YOURS TRULY Ξ ©SXPLICT, 2024

#━━━━━⠀⠀©⠀ 𝐒𝐈𝐍𝐂𝐄𝐑𝐄𝐋𝐘 ⸝⠀𝐋𝐘𝐒𝐈'²⁴#jjk#jujutsu kaisen#jujutsu kaisen x reader#jjk smut#jjk x reader#geto suguru#geto x reader#jujustsu kaisen x reader#jjk geto#jjk x you#jujutsu suguru#jujutsu geto#geto x you#geto smut#getou suguru x reader#geto x y/n#jjk suguru#suguru geto smut#jujutsu kaisen suguru#getou suguru x you#getou suguru x y/n#anime smut#female reader

276 notes

·

View notes

Text

The SR-71, along with her sisters A-12 MD -21 and YF -12, was built at the Lockheed Skunk Works plant in Burbank, California, in the early 1960s. Kelly Johnson, designer of the Blackbirds and his prestigious crew of engineers set out to design and build perhaps the most remarkable aircraft in aviation history. Working with Titanium, a metal that had desirable characteristics for the high heat environment of Mach Three flight, proved in itself to be a daunting challenge. The metal had never been forged in large quantities and the quality had to meet strict controls for consistency. In addition, the US had to import the metal indiscreetly from the largest source in the world; the USSR. The landing gear on the SR-71 is the largest single piece of forged Titanium. Other segments of forged Titanium was made oversize and then milled to exact tolerances for stringers, fuselage and wing construction. At the end of construction almost 90% of the Blackbirds material consisted of Titanium.

~First time stealth was applied to an air frame~

Stainless steel was used for hydraulic and fuel lines. From the ground up the Blackbirds were designed to withstand the 900+ degree temperatures on the surface skin at Mach three or better. There were expansion joints in almost all fittings as the aircraft grew several inches from the high heat generated. To make the aircraft stealthy, plastic composite panels shaped like a triangle were inserted on the outer perimeter of the wing surfaces. There were alternating titanium and composite plastic wedges designed to break up the incoming radar signals. Rudders were canted inward for the same reason. The paint consisted of minute iron ferrite balls and the cost per quart of Blackbird paint was nearly $400. Needless to say, the entire aircraft was not regularly repainted but rather spot painted as needed. Exotic alloy metals such as Hasteloy X and ceramics were used in the construction of the Pratt & Whitney J-58 engines. Temperatures in the afterburner sections reached 3200 degrees Fahrenheit.

Leland Haynes is my source of some of the facts.

~ Linda Sheffield Miller

212 notes

·

View notes

Text

Ronin Katana – Hand and a Half Bastard Sword #15

This late Medieval bastard sword from Ronin Katana has a tempered and sharp blade forged from 1075 high carbon steel with hollow ground blade geometry. The stiff blade will cut and thrust with authority and decisiveness. The guard and pommel are crafted from stainless steel and the grip is wood which is tightly bound in leather. The blade is mounted into the hilt with a peen over the pommel for a tough and lasting construction. The sword is paired with a wood-core scabbard which is overlaid in faux leather and fitted with stainless steel chape and locket. A simple sword belt and frog of faux leather is included.

Please Note: The sword scabbard with its buckles is arranged for wearing on the right hip for a left hand draw.

#Kult of Athena#KultOfAthena#New Item Wednesday#Hand and a Half Bastard Sword 15#Ronin Katana#sword#swords#weapon#weapons#blade#blades#Bastard Swords#Medieval Swords#Medieval Weapons#Longswords#Long Swords#European Swords#European Weapons#Hand and a Half Swords#Battle Ready#1075 high carbon steel

12 notes

·

View notes

Text

Emcor Engineering: Your Trusted Partner for High-Quality Metal Products

Established in 2019-2020, Emcor Engineering has quickly become a highly acclaimed manufacturer, supplier, and stockist of ferrous and non-ferrous metal products, including high nickel alloys. We offer an extensive range of products such as pipes, tubes, flanges, buttwelded pipe fittings, forged fittings, tube fittings, sheets, plates, coils, bars, fasteners, shims, slitting coils, screws, washers, elbows, reducers, and tees.

Our relentless efforts to deliver premium quality products have earned us an unparalleled position in the industry. We import, export, supply, and trade a wide array of materials, including stainless steel, high nickel alloys, duplex and super duplex, titanium, and cupro nickel in all grades. Emcor Engineering is also a specialist in 400 series sheets and coils and is one of the leading foundry grade scrap suppliers in India. Trust us to meet your needs with exceptional quality and service.

#metal products manufacturers#SS Pipe manufacturers in India#SS Pipe Fittings manufacturers in India#SS Forged Fitting manufacturers in India#SS Flange manufacturers in India#Blind Flange manufacturers in India

3 notes

·

View notes

Text

Stainless Steel 304/304L/304H Forged Fittings Suppliers | Bhagya laxmi Industrial

Discover high-quality Stainless Steel 304/304L/304H Forged Fittings from our reputable supplier. Our extensive range includes Stainless Steel 304, 304L, and 304H options, ensuring durability and resistance to corrosion. These fittings are precision-engineered for optimal performance and have been rigorously tested to meet industry standards. With our knowledgeable team and efficient supply chain, we provide reliable and prompt delivery of your required fittings. Trust in our expertise and choose the best stainless steel forged fittings for your industrial applications.

0 notes

Note

teasing

Some allusions to plot points of level 92 MSQ.

Koana x V'anille Tia

“I cannot thank you enough for the hospitality you have all shown me. I was content to let my nameday pass without fuss,” Koana said, giving a small bow to V’anille and his parents, V’tenpe and V’lamuhi, the family hosting a small dinner at the Last Stand.

“You have been a good friend to Anille. When he told us you were unable to return to your family for your special day, we insisted he let us treat you to dinner. While the Vulture clan has spread through Eorzea, tradition is still important to our people. Even before the Calamity, we were constantly moving, unable to find a foothold in any one location. The nomadic life was harsh, and many perished. That is why our elders made it a point to celebrate life, and why we continue to find a means to party and be together long after we’ve found places to settle down and raise families,” V’tenpe said, taking his wife’s hand to give a little squeeze.

V’anille smiled at his parents before turning to Koana who had turned his attention to his lap. He leaned a little, seeing the other claw at his thighs a moment before relaxing them and looking up to smile. “Then I am more than honored for this kindness. From the bottom of my heart, thank you.”

V’lamhui smiled. “The evening is not over yet. V’anille says that you are quite taken with Sharlayan, though has neglected to say where you hail from.”

“It is of little importance,” Koana said, shaking his head as he waved off the inquiry.

“Well then, for when you depart for your home my husband and I picked up a few things to remind you of your stay,” V’lamhui said, letting go of her husband's hand to reach down and pick up a small basket to hand over.

Koana looked down, finding the basket to be lined with a quilt patterned with the Sharlayan emblem, as well a set of matching mugs, a journal, and boilmaster to match. “Thank you,” he said, eyes softening.

“I…had something made for you as well,” V’anille said, sliding a palm sized box over to Koana.

“This is all too much, really,” Koana said, cracking open the box to find a wrist chronometer fitted on a stainless steel band forged by the goldsmiths of Ul’dah while the clockwork was commissioned from Ishgard’s machinist guild. The face had been painstakingly painted with a view of Sharlyan from the sea, V’anille having spent many nights doing so using a magnifying glass and his finest tipped brushes. Of course, this was largely unnoticed as Koana’s ears and tail rose. “This is truly a marvel of Sharlyan perfection. Flawlessly crrrafted-”

“Um…” V’anille started.

“Tracking the passing of time through mechanical means. Only Sharlyan ingenuity could capture time in something so small,” Koana continued, fixing the watch about his wrist.

V’anille sighed then smiled. “Oh yes, it is indeed a modern marvel.”

Koana fiddled with the dials, mesmerized a moment before looking up to his friend. “Anille, I do not think I could accept such an extravagant gift. This must have cost you a small fortune. I would have been just as happy with an hourglass with the sands of the Sharlayan shore. I do not think I could ever repay this kindness you’ve afforded me.”

“Oh no. It really wasn’t all that much,” V’anille said, cheeks red from hearing his clan title dropped. His parents looked at one another, then laughed softly between themselves as their son “Listen, I know that Sharlyan seems to have left such an impression on you, but you should know-”

“V’anille, you could not possibly undersell the majesty of this creation.”

“Koana! The only Sharlyan thing about it is the face I painted upon it. Chronometers are commonplace in Eorezea, and perhaps most of the territories we regularly trade with. I worked with other artists and engineers on the mainland to have it made for you.”

Koana’s ears immediately fell flat, his face darkening with embarrassment as he looked at the gift then up at V’tenpe as the man rolled up his sleeve to show off his simpler piece. “I see,” he said, pushing his glasses up the bridge of his nose.

“I am happy to hear we’ve left such an impression on you,” V’lamhui said before standing. “Many of our neighbors do not hold us in such high regard despite friendly enough ties,” she hummed before looking at her son. “I hope that you might find yourself at home here in our city.”

Koana shook his head. “That I could. I have responsibilities that I will have to see to in my homeland, but I am forever touched by the innovation and collective efforts of Sharlyan. My memories and connections here will carry me home and color how I work to make my country a better place to live for all. That we might come together as you have for a better future.”

V’anille lowered his head, starting to fumble with the napkin in his lap as he thought of the other leaving. His father standing and letting out a yawn, he looked up and watched as he took his mother’s hand. “I think we will leave you two to finish out the night together. If you wish for more spirits or dessert, have Rickon add it to the family tab,” he said, before giving Koana a rough pat on the shoulder, making the younger man nearly topple over and lose his glasses.

“Th-thank you. Goodnight,” Koana breathed out as he resituated himself, once more pushing his glasses back into place.

“Goodnight,” V’anille echoed, watching his parents walk away together.

A moment of silence passed between the two as they nursed their drinks. Koana eventually clearing his throat scooted his chair a bit closer to V’anille’s. “I am sorry if my praise got away from me. It truly is a fine gift, no matter who crafted it. The face too, it was very thoughtful. Is it your work? I’m afraid the details are so small I cannot discern your familiar brush strokes, but I note that it is in the pastels you use.”

“Yes, I did. If you were to become homesick, or…whatever the reverse of it is, you can look upon your wrist to see our city,” he said, hand gently sliding up Koana’s arm to turn the face towards them. “And then the outer wheel you can set to move in tandem with the hour hand so that you can always know what time it is here if you know the local discrepancy between the two.”

“That is a brilliant touch, Anille…”

V’anille flushed as Koana leaned over to kiss the edge of his ear, causing him to turn his head toward him and be kissed softly upon the lips. “I have truly loved every bit of Sharlayan,” he Koana whispered, pulling away.

V’anille's heart raced as he crushed the napkin in his palm. “If you wanted to stay, you would have a home here.”

Koana sighed. “Alas, I cannot. I will return to my homeland with the knowledge I've gained from my stay here,” he said before finishing his drink, eyes returning to the timepiece. “I will write though. And should I see myself at the end of what I must do, I will call upon you to visit me across the salt. Perhaps then I will have more room within myself to be what you deserve.”

“The…salt…?,” V’anille repeated.

Koana turned, “I mean to say the sea. Upon my departure all will be made clearer. I promise that. Come, I've spoiled the festive mood. Why do we not see if Rickon will let us take a bottle of Sharlayan sherry back to my apartment and talk about happier things? I do not want to end such a wonderful night on a sour note.”

Standing, Koana held his hand out for V’anille to take. Together, they stopped for their spirits then made their way toward Koana’s apartments and onto pleasanter time together.

#final fantasy xiv#ffxiv#final fantasy 14#ff14#ffxiv oc#ff xiv#ffxiv miqo'te#y'zel tia#V'anille Tia#Koana#koana ffxiv#ffxiv koana#wol x koana#dawntrail#dawntrail spoilers

4 notes

·

View notes

Text

Stainless Steel Flanges in India

Looking for top-quality stainless steel flanges in India. Bu-Lok is one of the best SS flanges manufacturers in Mumbai. Bu-Lok also supplies flanges, fasteners, plates, round bars, and stainless steel forged pipe fittings. Call us at +918888944449.

#stainless steel flanges in India#SS flanges manufacturers in Mumbai#fasteners#round bars#stainless steel forged pipe fittings

0 notes