#stainless steel forged pipe fittings

Text

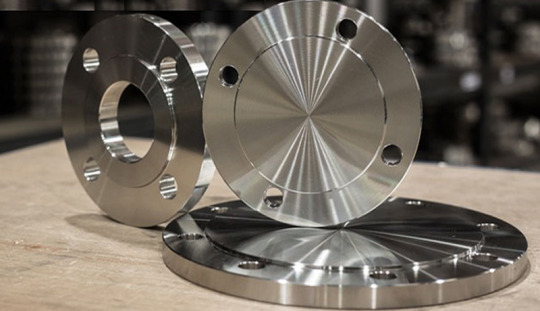

Stainless Steel Flanges in India

Looking for top-quality stainless steel flanges in India. Bu-Lok is one of the best SS flanges manufacturers in Mumbai. Bu-Lok also supplies flanges, fasteners, plates, round bars, and stainless steel forged pipe fittings. Call us at +918888944449.

#stainless steel flanges in India#SS flanges manufacturers in Mumbai#fasteners#round bars#stainless steel forged pipe fittings

0 notes

Text

5 Things about Stainless Steel 316H Forged Fittings manufacturer you will never know!

Stainless steel 316H forged fittings are widely used in a variety of industrial applications due to their exceptional strength, durability, and corrosion resistance properties. These fittings are made by a specialized manufacturer who uses advanced technology and techniques to produce high-quality components.

In this article, we will explore 5 things about stainless steel 316H forged fittings manufacturers that you may never have known before.

Expertise and Experience

SS 316H forged fittings manufacturer has extensive knowledge and experience in the field of metallurgy, engineering, and manufacturing processes. They have the expertise to produce customized fittings that meet specific customer requirements, such as dimensions, shapes, and materials. These manufacturers also have a deep understanding of the properties and characteristics of stainless steel 316H, which enables them to optimize the forging process and produce high-quality components.

High-Quality Standards

This manufacturer follows strict quality control measures to ensure that their products meet the highest industry standards. They use advanced testing and inspection techniques to verify the properties and characteristics of the components, such as hardness, tensile strength, and corrosion resistance. These manufacturers also use high-quality materials and production techniques to ensure that their products are durable and reliable.

Customization Capabilities

They also have the ability to produce customized components based on specific customer requirements. They can create fittings in a variety of shapes and sizes, including elbows, tees, couplings, and reducers. These manufacturers can also produce fittings with specific threads, such as NPT, BSP, or BSPT, and can create specialized components for unique applications.

Advanced Technology and Techniques

They also use advanced technology and techniques to produce high-quality components. They use computer-aided design (CAD) software to create 3D models of the fittings and simulate the forging process to optimize the production process. These manufacturers also use advanced forging equipment, such as hydraulic presses and hammers, to produce high-quality components with precise dimensions and properties.

Compliance with Industry Standards

Stainless steel 316H forged fittings manufacturers comply with various industry standards, such as ASTM, ASME, and ANSI. These manufacturers also adhere to various international standards, such as ISO and EN. Compliance with these standards ensures that the components produced by these manufacturers are safe, reliable, and meet the required specifications.

In conclusion, stainless steel 316H forged fittings manufacturers are experts in the field of metallurgy, engineering, and manufacturing processes. They use advanced technology and techniques to produce high-quality components that meet specific customer requirements. These manufacturers follow strict quality control measures and comply with various industry standards to ensure that their products are safe, reliable, and of high quality.

#Stainless Steel Pipe Fittings#Stainless Steel Forged Fittings#construction#buildings#alloy#steel products#plumbing#Water control system#engineering#civilengineering#SS 316H Pipe Fittings#SS Pipe Fittings#Stainless Steel Pipe Fitting Manufacturer in Mumbai#Stainless Steel Forged Fittings Supplier in India#Stainless Steel Pipe Fittings Price

5 notes

·

View notes

Text

Om Steel is a leading stainless steel manufacturer, specializing in the production of high-quality stainless steel grades such as austenitic, ferritic, and duplex. Our expertise lies in providing customized solutions for diverse applications, offering exceptional corrosion resistance and hygienic properties. With a focus on strength, durability, and precision, we supply stainless steel for industrial sectors including defense, aerospace, oil/gas, and specialty valves. Explore our range of stainless steel products, including sheets, plates, pipes, tubes, round bars, and forged fittings, delivering reliable performance across various industries worldwide.

#Stainless steel manufacturer#Austenitic stainless steel#Duplex stainless steel#Corrosion-resistant steel#Customized stainless steel solutions#Hygienic stainless steel#304 stainless steel#316 stainless steel#430 stainless steel#2205 stainless steel#Stainless steel properties#Industrial stainless steel applications#Stainless steel sheets#Stainless steel plates#Stainless steel pipes#Stainless steel tubes#Stainless steel round bars#Stainless steel forged fittings#Defense & Aerospace stainless steel#Oil/Gas stainless steel

0 notes

Text

Welded SS pipe manufacturers SPP alloys and Metals

SPP Metals and Alloys are the leading welded pipe manufacturer in India. Our connections and supplies are provided all over the world. Welded pipes are our specialty, with multiple options for wide usage. We are trusted with pipings, with our products utilized in several industries. Welded pipes are made by welding two sides together using a metal base. It is the opposite of seamless pipes which are created using a single material.

#pipe seamless#ss pipes#ss tube#pipe stainless steel#flange for pipe#piping manufacturers#forged fittings#carbon steel pipe

0 notes

Link

Triple Nine Piping Solutions Inc. is one of the trusted market leaders in India. We have been engaged in manufacturing & exporting Buttweld fittings in a wide range of materials, grades, shapes, sizes & other specifications. Our buttweld fittings are manufactred in materials like stainless steel, duplex steel, super duplex steel, aluminium alloys and high nickel alloys. We have served our prestigious clients by giving them quality products, timely delivery on a regular basis at the most reasonable prices.

#Stainless Steel 304 Seamless Pipes Nickel 200 Welded Pipes Inocnel ERW Pipes Monel Buttweld fittings Hastelloy Flanges Incoloy Threaded forg#Buttweld fittings#Low price buttwedl fittings#Hihg quality buttweld fittings

0 notes

Text

Forged Valves manufacturers Company in Chin

Your quest for quality fashioned steel valves closes here at "Zhejiang Sailing Steel Industry Co., Ltd." on the grounds that we are an expert maker managing a wide range of valves. We have broad industry experience in assembling various kinds of valves and different subtypes too to take care of assorted business prerequisites.

Broad Range of Forged Valves manufacturers in China

We offer a wide assortment of valves that differ regarding plan and usefulness. Our general classifications are:

• Fashioned Check Valve

• Fashioned Globe Valve

• Fashioned Gate Valve

• Fashioned Y Type Globe Valve

Forged Valves manufacturers in China

"Zhejiang Sailing Steel Industry Co., Ltd." is a provider of fashioned steel valves to numerous enterprises that basically produce paper, sugar, and so on. Our Forged Valves manufacturers in China are likewise utilized in the compound and material enterprises utilizing basic differentiations and alterations to the standard accessible reach.

We offer customization decisions relying upon your utilization. Thus, assuming the kind of valve that you are searching for isn't accessible in our standard reach, our assembling office engages us to specially craft the valve for you. You can choose the material like Forged Valves manufacturers in China, aspect, sort of end, activity explicit, and so forth. Plus, the customization decisions, our valves are:

Profoundly Durable: Valves come in regular contact with various sorts of fluids and are inclined to mileage. This orders organizations to put resources into manufactured steel valves shrewdly. Our valves are strong on the grounds that we utilize quality natural substances and really focus on the treatment of combinations during the assembling system.

Intelligently Priced: "Zhejiang Sailing Steel Industry Co., Ltd." is a mass maker and infers net revenues not by selling individual units but rather a through cluster. This advantages our clients on the grounds that the costs we offer are practically great. Our valves come at appealing costs with no sort of give and take on quality or postpone in conveyance.

Complicatedly Designed: Design is a significant piece of a valve. The plan empowers smoother working and furthermore helps with the kind of activity like programmed or manual. Choosing standard assortments is planned to remember the major modern applications. Notwithstanding, we offer total customization administrations also.

Globally Certified: All our items and we as an association are ISO guaranteed. ISO has turned into a typical certificate and consequently, we have procured a couple of additional particular confirmations to encourage our clients. Our produced steel valves are agreeable with different plans, testing, F to F, and ANSI guidelines.

Resource URL: https://sailingsteelchina.blogspot.com/2022/08/forged-valves-manufacturers-company-in.html

#Forged Flanges manufacturers china#Forged Valves manufacturers china#Seamless stainless steel pipe supplier china#Investment Casting Valves manufacturers china#dairy valves and fittings

0 notes

Photo

Back in a former life, I had an addiction that I loved beyond sanity. Here’s the story of it.

2002 2003 2004 2005 2006 2007 2008 2009 pt1 2009 pt2 2009 Redux

This is the final spec list for my glorious, insane Brutal Truth.

Nissan Skyline BCNR33 GT-R (Type 2) manufactured in April 1996. JDM non V-Spec vehicle retailed through Osaka Nissan Prince in May/June 1996. Imported to the

UK in June 1997. Remained in original JDM spec without speedometer conversion until August 2002. Only the steering wheel & white dial sets were fitted in Japan.

Nismo RB26N1 bare engine: [N1 water pump (improved flow & less cavitation)/Reinforced cylinder block head bolt boss/Increased sump capacity (6L 20w60)/1.2mm oil restrictor]

N1 head with 0.5mm overbore (2598cc)

Cryogenically hardened N1 crankshaft

Wossner forged & cryogenically hardened pistons

Abbey Motorsport reinforced & cryogenically hardened con-rods

ACL Race Series conrod & crankshaft bearings

Tomei sump baffle kit

Tomei high flow (larger drive gears) oil pump

HKS 1.2mm metal head gasket

Tomei Procam Spec 2 cam kit (270 degree inlet & outlet with 10.25mm lift)

HKS V-Cam System Step 1 Type B (variable 248-278 degree inlet; replaces Procam inlet camshaft)

HKS vernier cam pulleys

HKS kevlar reinforced timing belt

Trust metal intake & throttle gaskets

HKS front pipe & decat gaskets

GReddy Iridium 08 Racing sparkplugs

Mocal 19-row oil cooler & Abbey Motorsport remote oil filter assembly

Abbey Motorsport catch tank & washer reservoir with SFS breather hoses

Abbey Motorsport Pro Alloy large radiator

Tomei fuel pump, fuel regulator & 600cc injectors

A’PEXi Power Intake induction kit

A’PEXi GT Spec intercooler (237x610x136mm) & hard pipe kit

HKS GT-SS turbos

HKS twin AFM delete kit

Tomei turbo elbows

HKS downpipes

HKS Silent Hi-Power exhaust

Abbey Motorsport 80mm decat pipe

Mine’s VX-ROM

HKS F-Con V Pro

HKS EVC 6 boost controller (1.6 bar)

AEM wideband lambda sensor

Splitfire DI Super Direct Ignition System

HKS Circle Earth kit

HKS GD Max twin-plate clutch (with lightened flywheel)

Abbey Motorsport rebuilt transfer box

Abbey Motorsport rebuilt gearbox with cryogenically hardened gear set, modified Nissan synchromesh upgrade and OS Giken strengthening plate

Abbey Motorsport rebuilt rear diff

Nismo gearbox mounts

Nismo Solid Shift gear stick (10% short shift)

Omex Shift Light Sequential

Sunsei SE-135 solar panel trickle charger mounted on a custom aluminium riser between the rear parcel shelf speaker enclosures.

Team Dynamics Equinox alloys 19x9.5, ET+15 in silver with polished stainless steel rim.

Falken FK452 265/30/19 Y-rated tyres

Cusco brake master cylinder brace

Cusco rear steering delete kit

Cusco front & rear upper suspension links

AST Sport Line 1 full suspension kit with UK spring setup

Nismo stainless steel braided brake hoses

StopTech 355mm rotor 4 pot caliper front brake kit

StopTech 355mm rotor 2 pot caliper rear brake kit with Abbey Motorsport modified pad retainers

Ferodo DS2500 brake pads front & rear

Bomex AD-390 front splitter

Nismo R34 smoked front indicators in custom aluminium mounting plates finished in crackle black

Nissan Xenon headlamp units

Border Racing Aero Fenders (vented front wings) with silver GT emblems from a R32 Skyline

Nismo smoked side repeaters

Top Mix one-off FRP twin blade rear spoiler on custom aluminium mounting plates

Entire exterior resprayed in BMW black (code 086) base and lacquer

Nissan Motorsport International carbon fibre B-pillar plates

PIAA carbon effect silicon wipers, front pair with spoilers, rear without

Nismo white face dial sets (dashboard & centre console) in carbon fibre panels

AEM AFR gauge mount replaces the lighter socket

HKS EVC display mounted on custom carbon fibre plate replacing the ashtray

Lighter socket relocated to the fog light switch panel

Nissan Momo steering wheel (with airbag)

Dressycar Nismo harness pads

Redline Automotive leather gearstick & handbrake gaiters

Abbey Motorsport carbon fibre door sill trims

Carbon fibre boot sill trim

Inlet plenum and sundry induction pipework finished in powder grey

Trust clear cam pulley cover

HKS Kansai Service carbon fibre spark plug cover

Right hand cam cover finished in crackle black

Nismo radiator & washer reservoir caps

HKS Kansai Service front strut brace finished in high gloss black

GReddy aluminium slam panel finished in crackle black

Tein bonnet dampers with black sleeves

Custom made one-off Cobra Misano Lux front seats: [Alcantara (colour code 9189) outers/Alcantara (colour code 9182) centre panels/One-piece carbon fibre backs/Sidewinder bases on custom subframes adapted by Abbey Motorsport/Cobra logo in silver thread on the headpads/GT-R logo beneath the grommets on seat backs]

JVC KD-AVX2 multi-media DVD/CD receiver with built-in 3.5” widescreen monitor

2x JL Audio Evolution VR600-CXi 6” speakers (front)

2x JL Audio Evolution TR650-CXi 6.5” speakers (rear)

Multiple and interlaced Thatcham rated security systems.

500 bhp. 520 ft/lb.

Ludicrously, hilariously, unbelievably fast.

Hope you enjoyed this little trip down memory lane with me. Cheers! JM.

(Photo by N. Liassides.)

#r33#bcnr33#skyline#gt-r#nissan skyline#Abbey Motorsport#HKS#Bomex#Tomei#A'PEXi#GReddy#Nismo#RB26N1#Mocal#Team Dynamics

12 notes

·

View notes

Text

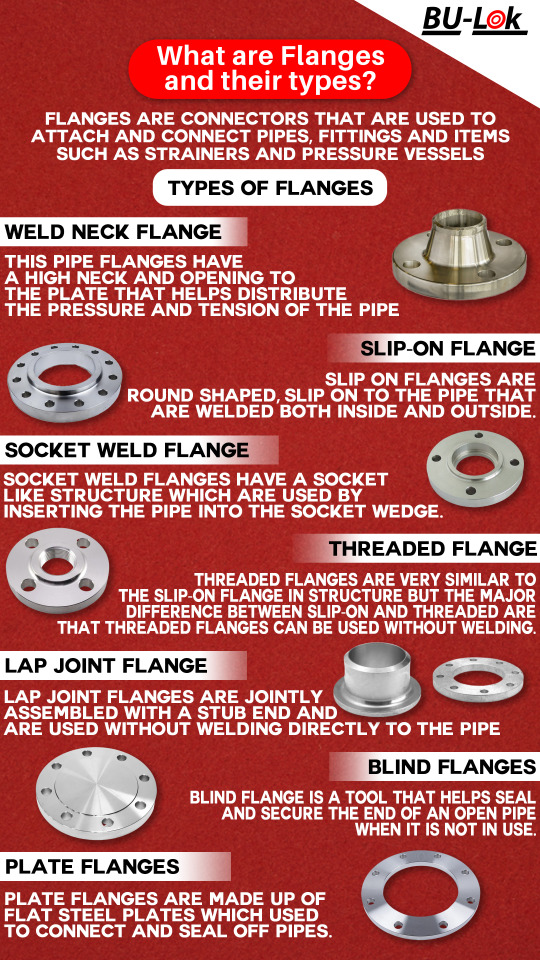

Types Of Flange & Flange Manufacturer in India

WHAT ARE FLANGES AND HOW DO THEY WORK?

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

8 notes

·

View notes

Text

Specification and Uses of Forged Fittings

Top Quality Forged Fittings Manufacturers in India

Regent Steel Inc is the leading Forged Fittings Manufacturers in India. Our products, which are made in accordance with international standards, are extensively used by the petrochemical, chemical, oil and gas, and other industries. We are the top Molybdenum Rod Manufacturers and Carbon Steel Flanges Manufacturers in India.

Forged Fittings Specification

Material: Stainless steel, carbon steel, alloy steel, etc.

Size Range: 1/8" to 4" or larger

Pressure Ratings: 3000#, 6000#, 9000# or custom

Types: Elbows, tees, couplings, unions, crosses, caps, plugs, reducers, etc.

Design Standards: ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, etc.

Applications of Forged Fittings

Water Treatment Plants

Fertilizers Industry

Marine & Industrial

Oil and Gas Industry

Aircraft Industry

India’s leading Flanges Manufacturer

Regent Steel Inc is a top Forged Fittings Manufacturers in India.We appreciate how crucial having trustworthy and durable flanges are for your piping systems, thus we are committed to offering flanges that adhere to the highest standards of quality and performance. We are the top Flange Manufacturer in Pune and Flange Manufacturer in Kolkata.

Contact us:

Website: forgefittings.com

Mail: [email protected]

Product source: Forged Fittings Manufacturers in India and Carbon Steel Flanges Manufacturers in India.

You may also like: Flanges Manufacturers in India

#Forged Fittings Manufacturers in India#Forged Fittings Manufacturers#Carbon Steel Flanges Manufacturers#Carbon Steel Flanges Manufacturers in India#Flanges Manufacturers in India#Molybdenum Rod Manufacturers

3 notes

·

View notes

Text

Detailed Information about Steel Fittings

Pipe fittings involve rerouting the water supply via tees, elbows, and other pipe components. Reducing tees, reducers, and similar pipe fittings are used to modify pipe sizes. In addition to the countless variations of coupling, there are

ASME B16.9 bend

Schedule 40 ASME B16.9 bend Producer Steel Tubing Curves It is usual to have the pipe's diameter, wall thickness, and pressure contained within its program. The ASME B16.9 standard, for instance, applies to pipe and fitting diameters between 1/2 inch and 48 inches.

Steel Hollow Section

Tubular sections made from steel that have had their interiors hollowed down are called hollow steel. In addition to "structural steel tubes" and "Hollow Structural Sections," these terms can also be used interchangeably (HSS). steel hollow section suppliers are often used as beams in welded frames and columns because of their many advantages in building and mechanical applications.

Pipe Clamps

Pipe clamps, also known as pipe clips or saddle clamps, are standard, straightforward fixtures used in various do-it-yourself and professional installation scenarios. pipe clamps suppliers are channel support systems frequently used in HVAC, plumbing, and electrical installations.

Forged Fittings

Pipe fittings constructed from forged carbon steel, stainless steel, or high nickel alloys are known as "forged steel fittings." That's why Forged Fittings suppliers in uaeproductsso helpful to have a method of making sturdy fittings that forges steel.

Branch Fittings

Pipes that cross each other can be joined with branch fittings. T-fittings and 45- and 60-degree wyes are the two most common types of pipe produced by Branch Fittings suppliers. Considering the necessary sweep when choosing a branch suited for a specific sector is essential.

Heat Exchanger Tubes

One common type of tube produced by Heat exchanger tubes suppliers in UAE is the shell-and-tube type. It is the standard heat exchanger used in oil refineries and other large-scale chemical processes because it can withstand greater pressure.

Steel Angle

In most cases, hot-rolled carbon steel or high-strength low-alloy steel is used to create steel angle, also known as angle iron or Steel Angle supplier’sbar. It has an L-shaped section with two legs that can be the same length or different lengths, and the angle would be 90 degrees.

Sanitary Fittings

Cleanable tubing connections, known as Sanitary Fittings, are fitted in process piping systems to provide a germ-free environment. Sanitary Fittings suppliers in UAE like regular fittings, are used to regulate the flow of fluid by connecting different sections of piping systems.

Welding Electrode

Electrical arc welding requires electrodes and lengths of wire linked to a welding machine. A high amount of heat is generated by the arc created when current flows through this wire to melt and fuse metal for welding electrode suppliers in uae.

Fasteners

A mechanical tool or element, a Fasteners suppliers in UAE, firmly binds multiple items together. The pins can take apart or reassemble the parts without any problems. But they can also serve as fixed connections.

Conclusion

Tube fittings connect tubing segments to one another or to other tubes, pipes, hoses, or other components in various configurations, including in-line, offset, multi-port, and mounting. The straight components of a system are joined together by fittings, which are couplings and joints made from specialised materials.

2 notes

·

View notes

Text

Forged Pipe Fittings

Looking for top-quality stainless steel flanges in India. Bu-Lok is one of the best Forged Pipe Fittings suppliers in Mumbai. Bu-Lok also supplies flanges, fasteners, plates, round bars, and stainless steel forged pipe fittings.

#forged fitting manufacturer in Mumbai#stainless steel flanges in India#Forged Pipe Fittings#fasteners#plates

0 notes

Text

Why should you use steel in crucial projects?

Steel, a metal with a wide range of possible applications, is available in many different "grades," or qualities, defined by the specific proportions of its constituent elements. In both domestic and commercial settings, mild steel seems to be the most cost-effective option. The versatility of mild steel makes it the most often used kind of steel. It's strong, durable, and weldable, plus it's magnetic.

Metal rusts easily, but it may be kept from doing so by coating it with anything that will keep the surface from being directly affected by the elements, such as paint, grease, or oil. The industrial and everyday uses of mild steel are almost endless, from mild steel plates to car and motorbike frames to huge pipes. Whenever a large amount of metal is required, mild steel is the material of choice. Alloy steel flanges manufacturers in India are always willing to provide a hand.

Carbon steel.

Carbon steel, in this context, refers to steel that does not include any additional alloying elements. Depending on how much carbon is in them, we have ultra-high, high, medium, and low carbon steels. Weld neck flanges manufacturers in India has reasonable prices. To make steel strips or flat-rolled sheets for use in manufacturing vessels, automobiles, and a wide range of other products and constructions, all four variants are put to use. There are many different kinds of industrial uses for carbon steel pipe fittings. You can easily find a good astm a105 flange manufacturer.

Grade 316L Stainless Steel, Certified by the American Institute of Steel Analysis

The anti-corrosive properties of stainless steel make it an attractive material for a wide range of applications where a high standard of cleanliness and security is required. Cookware made of stainless steel, among other materials, is consequently a common fixture in modern home kitchens. Slip on flanges manufacturers in India are indeed fantastic. V-belt power transmission necessitates its usage, and this material is fashioned into sheaves to store the belts. Ingredients like nickel, chromium, and molybdenum are just a few of the many that go into making stainless steel. Stainless steel flanges manufacturers in India has been doing a great work for quite some time.

Austenitic, ferritic, martensitic, and duplex steel are the four most common kinds of stainless steel on the market. The features that make each type useful are different, as are the ways in which it is put to use. That's why you'll find them in everything from household goods to architectural facades to industrial pipes and containers to paper and pulp production, and much more besides. Stainless steel 304 flanges manufacturers in India can be contacted easily.

There seems to be a bright future for the manufacturing of steel, as the number of companies engaged in this industry continues to rise. As usual, you can count on assistance from stainless steel forged fittings manufacturer.

The tube inside the fitting is so strong that it will burst before the fitting shows any signs of leaking or movement. However, the thickness of the tube's walls does place certain restrictions on this. Astm a105 forged fittings have been proven excellent.

2 notes

·

View notes

Text

Unveiling the Excellence of Zecor 310M (UNS S38815) Stainless Steel Pipe Fittings: A Global Perspective

Introduction:

In the realm of stainless steel manufacturing, one name shines brightly for its remarkable attributes and wide-ranging applications: Zecor 310M. This high-performance alloy, designated as UNS S38815, has garnered widespread acclaim for its exceptional corrosion resistance, high strength, and adaptability to diverse environments. In this article, we explore the significance of Zecor 310M stainless steel pipe fittings on a global scale, delving into its unique properties, manufacturing process, and applications across different countries.

Zecor 310M: Defining Excellence in Stainless Steel:

Zecor 310M is a high-alloy austenitic stainless steel renowned for its superior corrosion resistance and mechanical properties. With a composition rich in chromium, nickel, molybdenum, and nitrogen, this alloy offers unmatched durability and reliability, even in highly corrosive environments such as chemical processing plants, offshore platforms, and marine applications. Its designation as UNS S38815 signifies compliance with international standards, ensuring consistency and reliability in performance across various applications.

Steel Manufacturing: The Art of Precision and Quality:

The production of Zecor 310M involves advanced steel manufacturing techniques aimed at achieving precise composition and microstructure. Through processes such as vacuum induction melting, hot rolling, and heat treatment, steel manufacturers meticulously control the alloy's properties to meet the stringent requirements of critical applications. The result is a material that combines exceptional corrosion resistance with superior mechanical strength, making it an ideal choice for demanding environments where reliability is paramount.

Zecor 310M Across Different Countries:

1. United States: In the United States, Zecor 310M stainless steel pipe fittings find extensive use in industries such as oil and gas, petrochemical, and power generation, where corrosion resistance and high-temperature stability are essential for uninterrupted operation.

2. United Kingdom: In the UK, Zecor 310M fittings are favored in marine engineering applications due to their ability to withstand harsh seawater environments and corrosive marine atmospheres.

3. Germany: German industries leverage the superior weldability and formability of Zecor 310M fittings for fabricating complex piping systems in chemical processing plants and pharmaceutical facilities.

4. China: With its rapidly growing industrial sector, China relies on Zecor 310M stainless steel fittings to ensure the reliability and efficiency of its infrastructure projects, including water treatment plants, refineries, and power stations.

Features:

- Corrosion Resistance: Zecor 310M's high chromium and molybdenum content impart exceptional corrosion resistance, making it suitable for a wide range of corrosive environments.

- High Strength: The alloy's robust mechanical properties ensure reliable performance under high-pressure and high-temperature conditions, minimizing the risk of system failures.

- Global Compliance: Zecor 310M complies with international standards such as ASTM, ASME, and EN, ensuring consistency and reliability in performance across different countries and industries.

- Custom Fabrication: The alloy's excellent weldability and formability allow for the fabrication of custom-designed pipe fittings tailored to specific project requirements, enhancing overall system performance and longevity.

Conclusion:

In conclusion, Zecor 310M (UNS S38815) stainless steel pipe fittings exemplify the pinnacle of excellence in stainless steel manufacturing, offering unparalleled corrosion resistance, high strength, and adaptability across diverse applications and industries worldwide. As countries continue to invest in infrastructure development and industrial expansion, the demand for high-performance materials like Zecor 310M remains steadfast, driving innovation and progress in the global stainless steel market.

#steel manufacturing#success#marketing#steel flange#butt weld pipe fittings#forged fittings#flanges#pipe fittings#steel manufacturer#forged steel fittings#stainless steel pipe fittings manufacturer#stainless steel pipe fittings#Zecor 310M#UNS S38815

0 notes

Text

Carbon Steel Flanges VS Stainless Steel Flanges

Generally speaking, a flange is a forged or cast ring of steel that is used to connect or join sections of pipe. It also includes flanges that are integral to pressure vessels, pumps, or any other element that utilizes flanges. Bolts connect flanges together and threaded or welded them to the piping system. There are a variety of types of flanges available, including stainless steel flanges (SS flanges), alloy steel flanges, carbon steel flanges, slip-on flanges, blind flanges, weld neck flanges, threaded flanges, lap joints, and orifice flanges. This article discusses stainless steel vs carbon steel.

What are carbon steel flanges?

A flange connects two ends of a pipe or ends a pipe. Various materials are available for them. Flanges made from carbon steel are one such type. This material provides excellent durability, corrosion resistance, and finishing properties. There are several types of them. It is common to use Carbon Steel Blind Flanges to terminate pipes. The raw materials used in the manufacture of these flanges are of high quality. Between 0.25 and 0.60 percent of their carbon content is carbon. In addition to being highly ductile, the product is also excellently fabricated due to its high carbon and manganese content.

What are Stainless steel flanges?

In residential, commercial, and industrial piping systems, stainless steel flanges and fittings are used. Stainless steel is widely used for the transportation of gases or liquids, chemical processing, maritime applications, sanitary applications, and areas requiring corrosion resistance because of its strength, corrosion resistance, and ability to withstand high temperatures, pressures, and flows.

To determine the right stainless steel grade and flange type for your application, refer to the appropriate standards or contact us. To determine the right stainless steel grade and flange type for your application, refer to the appropriate standards or contact us.

Carbon Steel vs Stainless Steel

Stainless steel has a higher melting point and a lower carbon content than iron-carbon alloys. In appearance and properties, carbon steel is similar to stainless steel, but it contains a higher percentage of carbon.

A common application of engineering and construction materials like carbon steel is in large-scale industrial processes like telecommunications, transportation, chemical processing, and petroleum extraction and refining.

The process used in making Stainless Steel 304 Flanges is essentially two steps consisting mostly of iron and carbon. There are many types of steel that can be called stainless steel 304 flanges. Corrosion resistance can be achieved by adding nickel and chromium to stainless steel.

Flanges in detail:

Pipe Flanges are most often manufactured from forgings produced in grades A-105. There are two grades of A-350 material: LF2 for applications requiring lower temperatures and F42-F70 for applications requiring high yields. It is widely accepted that pipeline service is carried out with high-yield materials due to their increased strength.

Besides having a greater amount of chrome and molybdenum than carbon steel flanges, alloy steel flanges are able to withstand temperatures and pressures that are higher than those of carbon steel flanges. In contrast to conventional carbon steel flanges, they have a higher Chromium content, which makes them more corrosion resistant.

Flanges are commonly manufactured from stainless steel containing Nickel, Chromium, and Molybdenum. Flanges are commonly manufactured from stainless steel containing Nickel, Chromium, and Molybdenum. Forgings classes can be serviced with trace elements during melting. Aside from this, the 300 Series is not magnetic, whereas the 400 Series is magnetic, as well as has weakened corrosion resistance.

Read More About This Article On Our Website For More information: https://thesteelexporter.com/carbon-steel-flanges-vs-stainless-steel-flanges/

#design#architecture#interiordesign#steel#art#garden#gardendesign#rust#gardening#sculpture#metal#welding

2 notes

·

View notes

Text

Neminox Steel & Engineering Co. provides the widest range of Industrial metal products like pipes, tubes, weld, flanges, rods, forges & fittings in various materials such as Stainless steel, Alloy, Carbon & High Nickel, Inconel, Monel, Hastelloy etc of certified quality.

2 notes

·

View notes

Link

Triple Nine Piping Solutions Inc. is one of the trusted market leaders in India. We have been engaged in manufacturing & exporting ferrous and nonferrous products in a wide range of materials, grades, shapes, sizes & other specifications. Our products include pipes & tubes, pipe fittings, flanges, bars & rods, sheets & plates, fasteners in materials stainless steel, duplex steel, super duplex steel, aluminium alloys and high nickel alloys. We have served our prestigious clients by giving them quality products, timely delivery on a regular basis at the most reasonable prices.

1 note

·

View note